Dremel 3d printer projects

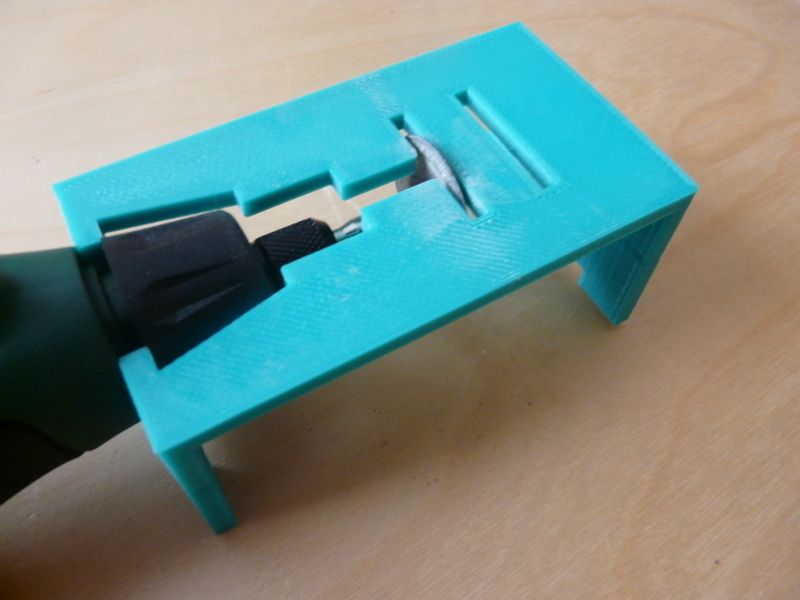

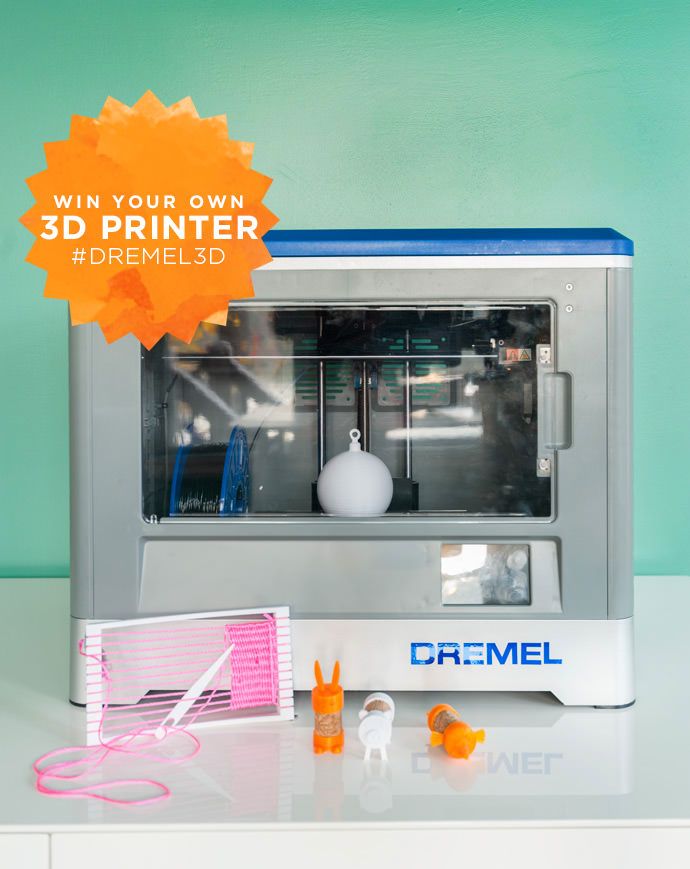

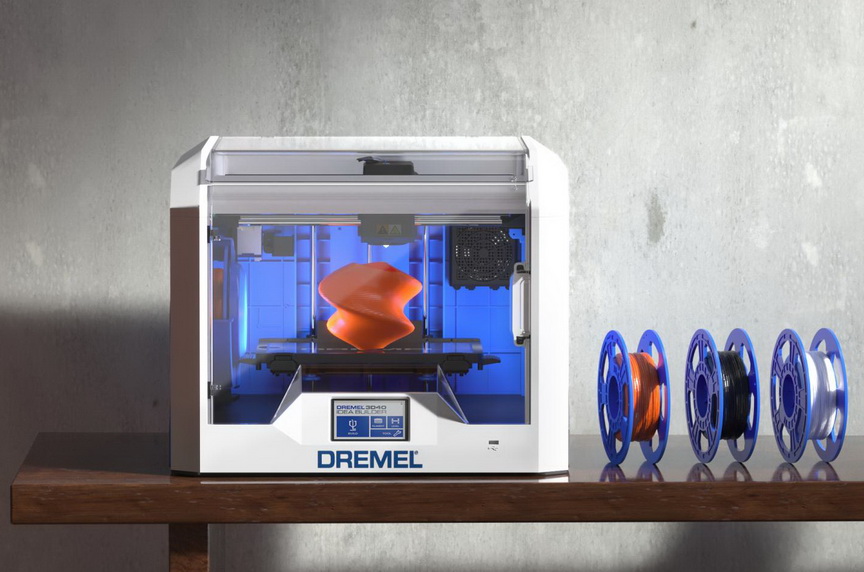

Dremel's First 3D Printer - Idea Builder 3D20

We at Makerspaces.com are huge fans of all types of 3D printing technology and believe that 3d printers can add a new dimension of learning and creativity to maker projects. We’ve tested a few great 3d printers recently and its exciting to see where the industry has come from in just a short amount of time. There are some great 3D and color label solutions and printers on the market so you’ll be spoilt for choice.

Just recently, we were lucky enough to check out Dremel’s first 3d printer called the Idea Builder (3D20) and in fact it’s also their first additive maker tool. The company is very well known for their hand-held rotary tools which are by design a subtractive piece of equipment.

The Idea Builder was first released to the public in 2014 and it’s a single-extruder printer that weighs around 19 pounds. This current model features a fully enclosed work space which is helpful for stabilizing temperature during printing. This printer doesn’t include a heated build plate so you wont be able to print in ABS. This generally isn’t a problem especially in educational settings where printing with PLA is more than sufficient.

The company states that the Idea Builder has a print resolution of 100 microns in a build volume of 230mm x 150mm x 140mm (9″ x 5.9″ x 5.5″). Listed below are additional features and specs of the 3D20.

Product Features:

- Full-color touchscreen control panel

- Removable build platform

- 100 micron print resolution

- Pre-installed extruder for plug and play operation

- Fully enclosed workspace

- Pre-loaded models for 3d printing

- Active cooling fan

- UL certified

- 1 year limited warranty

Product Specs:

- Extruder: Single extrusion

- Extruder temperature: Up to 230°C /397°F

- Operating Interface: 3.5” full color IPS touch screen

- Maximum Build Volume: 9” x 5.

9” x 5.5” / 230 mm x 150 mm x 140 mm

9” x 5.5” / 230 mm x 150 mm x 140 mm - Layer Thickness: 4 mil | 0.004 inches 100 microns | 0.10 mm

- SD Card: Up to 32GB in size /3D20 will not work with SD cards larger than 32GB

- Internal Storage: 4GB

- 19 pounds 8 oz (8.845 kg)

- Height: 15.7 inches (400 mm)

- Width: 19.1 inches (485 mm)

- Depth: 13.2 inches (335 mm)

- Uses 1.75mm PLA filament

Box Contents

• One spool of PLA filament

• A power cable

• A USB cable

• A spool lock

• A project removal tool

• A cleaning tool

• A leveling sheet

After a quick unboxing of the unit, the detailed user instructions had us printing in about 20 minutes.

Included with the Idea Builder

The Idea Builder comes with a nice collection of 3d models that are pre-installed and ready to print. We choose to print out the tree frog and the dinosaur.

After a few hours of printing multiple 3d files, we can say that this is a solid 3d printer with exceptional print quality. The only negative that we could find is the fact that prints sometimes don’t stick the first time. After trial and error we found that using painters tape and keeping the build tray perfectly level were essential in getting the prints to adhere.

The only negative that we could find is the fact that prints sometimes don’t stick the first time. After trial and error we found that using painters tape and keeping the build tray perfectly level were essential in getting the prints to adhere.

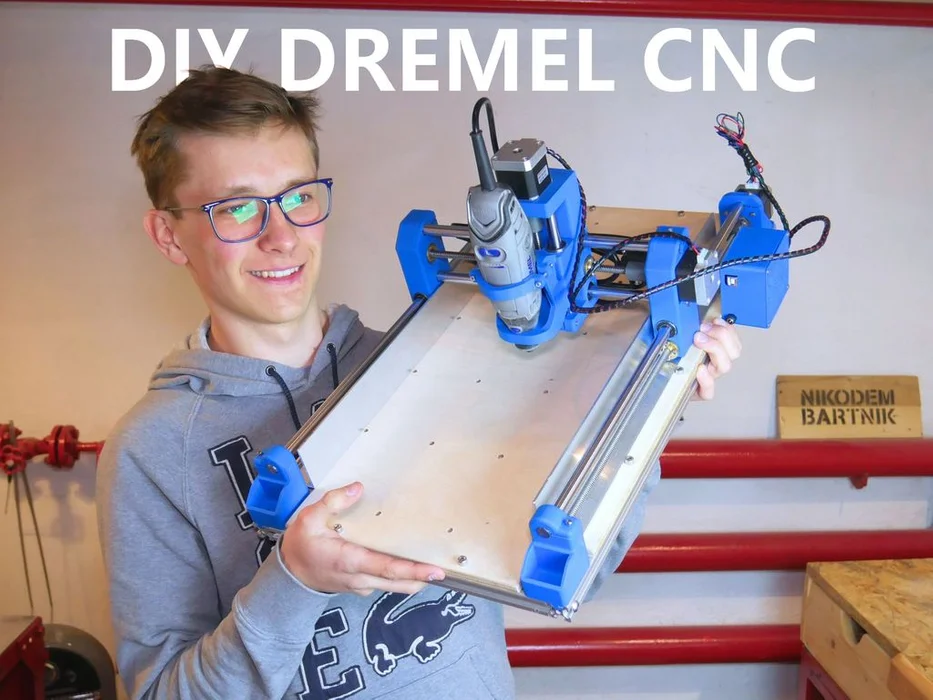

VIDEO – Dremel & 3D Printing

Learn how to start and run a makerspace

Follow us on Twitter and learn how to bring maker education into the classroom or library. Get makerspace ideas, find STEM projects, learn about 3D printing, get info on project based learning (PBL) and much more from the top maker educators in the world.

Follow @Makerspaces_com

Makerspaces.com

Makerspaces.com was built to help schools and libraries start and run their own makerspaces. We truly believe that adding a makerspace to a school or library can help students acquire the skills needed for the 21st century.

Teacher Review of Dremel 3D Printer

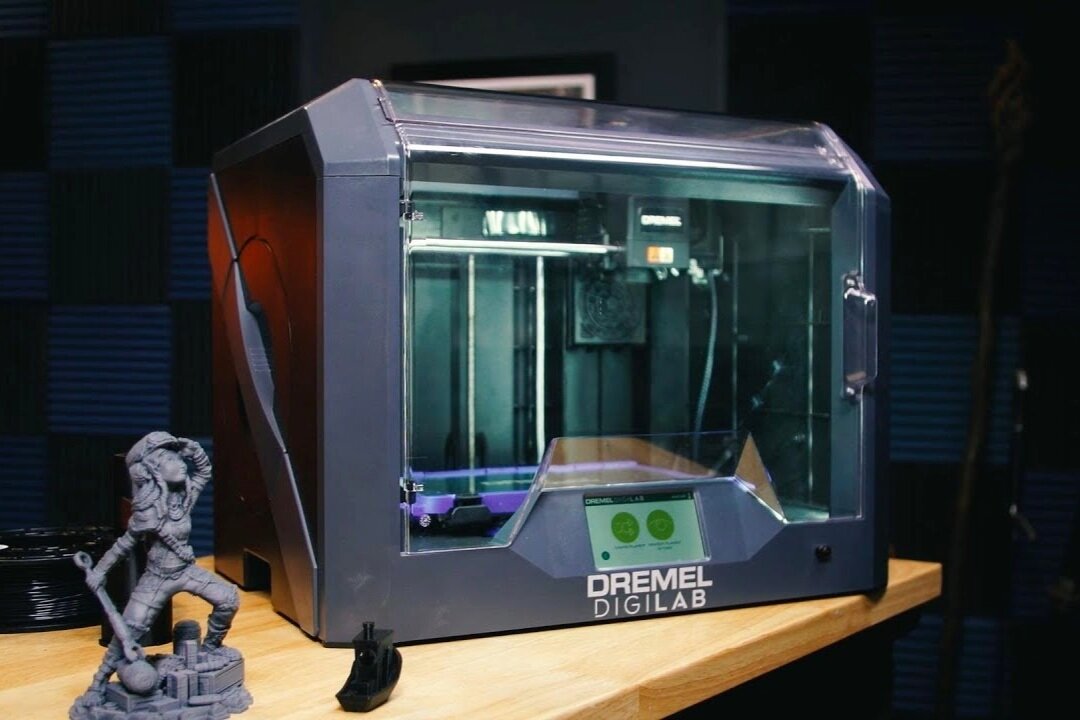

Dremel DigiLab 3D45 is tailored for the education environment, winning the acclaimed All3DP ‘Best 3D Printer for Schools’ title. CREATE Education recently asked Ambassador, Caroline Keep, to review the Dremel DigiLab 3D45. As a physics teacher at Penketh High School, Director of Spark Penketh, the first school Makerspace in the UK and co-founder of Liverpool Makefest, a festival to promote STEAM and maker-education for young people, Caroline was more the perfect candidate to put the printer through its paces.

Dremel DigiLab 3D45 … I didn’t expect to love you but I do …

Unpacking Dremel DigiLab 3D45 in lockdown …

When I was asked to review the Dremel DigiLab 3D45, I wondered whether they knew that it was me that they had asked to review it. Quite often, I’m quite critical of any technology that is pitched to schools. It’s got to be brilliant, it’s got to last, it’s got to be durable, and I’ve got to think it’s absolutely something for me to put my approval on it.

So at the beginning of lockdown when this giant box arrived I wondered whether it would stand up. It was a welcome tool to arrive for our students and me as a teacher. In unpacking, it became clear that this was not your average 3D printer. Just a glance at the Dremel itself will show that is a very different kind of printer then we are used to having. I have been working with 3D printers for some extensive time in extracurricular learning and making.

I was surprised at the absolute durability of the Dremel. So here are a few bits and pieces, on the Dremel DigiLab 3D45 why I would say, it the best 3D printer on the market right now, especially for schools.

Enclosed Printing

Quick clean bed…yes thanks 😊

Number one, the doors. Everybody’s had that moment when you took a 3D printer and said to all your students don’t stick your hands in it, don’t go anywhere near the nozzle on our 3D printer and pointed out it is truly hot!! It is a continuous worry for those of us who print with children regularly. Now the Dremel itself makes a massive difference in this as it has TWO doors. A door at the front and there is a door on top of the printer. They make the whole process of printing just a little bit easier. Not only does it maintain the heat within the actual print itself, but it also gives a professional feel for the whole printer. Having that lovely experience of being able to look down into the printer and see what’s printing from a totally different angle is just lovely. Later models added a camera.

Now the Dremel itself makes a massive difference in this as it has TWO doors. A door at the front and there is a door on top of the printer. They make the whole process of printing just a little bit easier. Not only does it maintain the heat within the actual print itself, but it also gives a professional feel for the whole printer. Having that lovely experience of being able to look down into the printer and see what’s printing from a totally different angle is just lovely. Later models added a camera.

Changing filament and the auto-adjusting bed

Changing filament on the Dremel is just an absolute dream!! A section on the side of the Dremel where the filament and is stored is a nice touch. This just makes it so much nicer and easier. They’ve made all the filament’s RFID tagged so the minute that you load the Dremel itself tells you what material you put into it. Once you’ve fed it through and down into the nozzle, the Dremel just automatically does all those awkward jobs you normally find in 3D printing for you. How thankful was I for that? Adjusting height or levelling beds, no problem. Dremel does this for me! This was transformational in my 3D printing. I love it! No more messing around with a small card trying desperately to make sure you’ve got the bed level, just nice clean bed back on press build to start and you’re away.

How thankful was I for that? Adjusting height or levelling beds, no problem. Dremel does this for me! This was transformational in my 3D printing. I love it! No more messing around with a small card trying desperately to make sure you’ve got the bed level, just nice clean bed back on press build to start and you’re away.

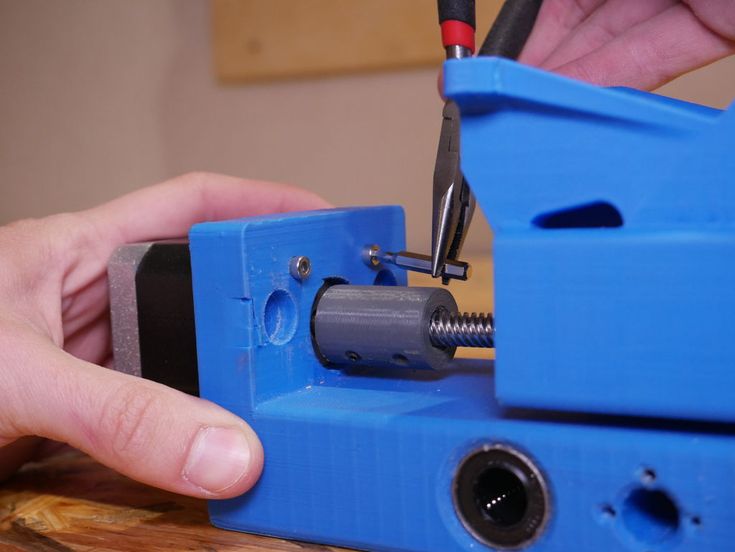

Cleaning the bed, we’ve all had that moment where we have spent ages and ages, with one of those wallpaper spatulas trying to get the glue off the bed of a 3D printer. Well no more my friends, this bed just lifts off with the easy click of 2 black buttons. You can then just go take it an area in your classroom or office and just give it a quick clean in a sink. Next, you have dried it and put it back on.

No more levelling nightmares

Noisy Printing

One of the nicest things about the Dremel DigiLab has been the noise reduction. The amount of noise can be important, especially if you’re in a noisy classroom. We don’t really want a 3D printer out in the background clunking away. Dremel made it nice for when I was using it in the office, whilst we were in lockdown. I used the 3D printers to print endless amounts of coronavirus door spaces, along with any safety materials for our school (a suggestion that I hope all are doing already ) the noise that this 3D printer gave off when running through door spaces in my small office was near minimal.

Dremel made it nice for when I was using it in the office, whilst we were in lockdown. I used the 3D printers to print endless amounts of coronavirus door spaces, along with any safety materials for our school (a suggestion that I hope all are doing already ) the noise that this 3D printer gave off when running through door spaces in my small office was near minimal.

Fine Printing

During the latter months of lockdown, I took to giving the Dremel a real whirl, whilst 3D printing myself some fashionable items including the top that I am just about to finish. 3D printed chain mail just to push the Dremel to its extremes. The Dremel just did not disappoint. I find it managing some of the very very fine-tuned prints well and I am just about to finish my 3D printed top ready for Christmas. So those virtual staff parties will look very modern.

Material just got really fun to play with!!

The Dremel 3D45 just did not disappoint and given its cost, I’d probably say the best 3D printing investment you can make. The use of access, the way that they built it to put all of the parts that are normally sticking out your 3D printer into one single hub, the doors and their automatic levelling all of this equals a stellar 3D printer and one of which truly gets my approval.

The use of access, the way that they built it to put all of the parts that are normally sticking out your 3D printer into one single hub, the doors and their automatic levelling all of this equals a stellar 3D printer and one of which truly gets my approval.

So hats off Dremel keep it up!

For more information about the Dremel DigiLab Range please see the product page

Dremel DigiLab Range

Welcome, visitor. Files are available to download with this content. Please sign up to Download. Sign up or Login

Dremel Offers DigiLab 3D45 Desktop FDM 3D Printer

News

The American company Dremel brings to the market a new 3D printer using the layer-by-layer deposition of a polymer rod (FFF / FDM) technology. The novelty is focused on application in the educational sphere and combines ease of use and high reliability with operational safety.

The Idea Builder, a rebranded Dreamer 3D printer developed by the Chinese company Zhejiang Flashforge 3D Technology, has been released in the United States under license since 2015. The new device, announced last summer and designated Dremel DigiLab 3D45, is designed with maximum user safety in mind and is designed primarily for use in the educational field.

The new device, announced last summer and designated Dremel DigiLab 3D45, is designed with maximum user safety in mind and is designed primarily for use in the educational field.

The Dremel DigiLab 3D45 3D Printer is equipped with a closed camera and an onboard camera for remote monitoring of the printing process in real time. Carbon filters protect users from microparticles and volatile compounds. Particular emphasis is placed on ease of use (the notorious "3D printing out of the box") and reliability. The on-board interface consists of a 4.5-inch touch screen, USB, Wi-Fi and Ethernet connections, and an internal memory of 8 GB.

The size of the construction area reaches 255x152x170 mm with a layer thickness of 50 to 300 microns. Printing is carried out by a single extruder with an all-metal hot end and direct-feed filament. The diameter of the standard nozzle is 0.4 mm. The extruder is heated up to 280°C, and the stage - up to 100°C. The company offers a choice of three consumables with a diameter of 1.75 mm - biodegradable polylactide (PLA), a "sustainable" version of ABS plastic and nylon for advanced users. The 3D printer automatically recognizes the filament used and changes the operating settings accordingly. nine0003

The company offers a choice of three consumables with a diameter of 1.75 mm - biodegradable polylactide (PLA), a "sustainable" version of ABS plastic and nylon for advanced users. The 3D printer automatically recognizes the filament used and changes the operating settings accordingly. nine0003

“3D printers are becoming important educational tools as the global economy adjusts to the changes from the next industrial revolution. The Dremel DigiLab provides the opportunity and necessary tools to teach children the skills that will be in demand in the professions of the future. The DigiLab 3D45 is the first 3D printer ideally suited for the school environment, combining ease of use and reliability with the ability to deliver advanced designs at a price point that is affordable for educational institutions,” said Dremel President John Kavanagh. nine0003

The Dremel DigiLab 3D45 3D printer is priced at $1,799 in the manufacturer's online store. The device is currently available in the US and UK, but should soon be available in other countries. Standard kit consists of 3D printer, eco-ABS black filament spool, black nylon spool, USB cable, USB stick, Cura-based slicer, 3DPrinterOS-based Dremel Print Cloud software license, scraper and glue stick . Additional information is available on the Dremel website. nine0003

The device is currently available in the US and UK, but should soon be available in other countries. Standard kit consists of 3D printer, eco-ABS black filament spool, black nylon spool, USB cable, USB stick, Cura-based slicer, 3DPrinterOS-based Dremel Print Cloud software license, scraper and glue stick . Additional information is available on the Dremel website. nine0003

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected]

Subscribe author

Subscribe

Don't want

2

Dremel 3D Idea Builder Overview

What is 3D printing? ready for consumers? Dremel, the brand that is synonymous with rotary tools, is great for this with their 3D Idea Builder for 999 dollars. 3D Idea Builder is aimed at consumers and creatives with its simple 3D assembly processes, simplified setup, and easy-to-use software. It also offers Linux, Mac and Windows compatibility. But is it worth $1,000?

It also offers Linux, Mac and Windows compatibility. But is it worth $1,000?

I have never used a 3D printer before

The Dremel printer caters to beginners just like me. But someone should have warned me about the dangers of 3D printing. It is similar to a drug in its addiction, especially if you are always preparing a DIY project. I've spent days looking for STL files (3D printable models) on sites like Yeggi and Shapeways and found amazingly useful 3D models. There are parts that are not even manufactured and that can only be printed on a 3D printer. For example, I found a DC plug that fits my personal computer. The 3D model was not designed for my computer, but by chance it fit almost perfectly. nine0003

This is not limited to repairing old computers. 3D printing offers real value. If you could print replacement parts instead of buying new products, you could recoup some of the cost of the printer within a few years (check out 9 Cool Things You Can 3D Print). And if you're just making household goods. , you can even sell them. There's also the convenience factor: if users can copy hard-to-find parts, they can avoid a trip to the store. nine0003

And if you're just making household goods. , you can even sell them. There's also the convenience factor: if users can copy hard-to-find parts, they can avoid a trip to the store. nine0003

Specifications and design

- One reel prints about 5 large prints, 16 medium prints and 36-45 small prints.

- SD card supports up to 32 GB (meaning it's FAT32)

- 4 GB internal memory (external SD card included)

- Resistive touchscreen

- Single extruder

- Two active cooling fans

- Ports: USB 2.0 port, USB B port

- System: Cortex M4 Processor

- Layer thickness: 100 µm (0.004 in)

- Dimensions: 400mm x 485mm x 335mm

- Assembly resolution (minimum layer thickness): 100 µm

- Collecting tray dimensions: 230mm x 150mm x 140mm

- Weight: 8.945 kg

Dremel uses the proven Fused Deposition (FDM) 3D printing process. Unlike new methods, FDM costs much less and requires less labor on the part of the user. This makes it an ideal product for both beginners and the education industry. nine0003

This makes it an ideal product for both beginners and the education industry. nine0003

The Dremel 3D Idea Builder comes with a proprietary PLA spool. Very little assembly is required and there are minimal loose parts. Inside the box, there is a USB 2.0 cable, a power plug, a wedge, and two covers for the build tray. The build tray needs to be removed in order to install the PLA coil. After that, you apply the ribbon to the build platform. I found that the mounting platform tape comes firmly glued to the extruded PLA plastic. I've tried painter's tape and found that it's much easier to knock it out of newly printed models. nine0003

Set up and setup

Installation only takes about 15 minutes, depending on how long it takes to watch the Dremel video. Before you start, I recommend watching the video. There are a few things that a user might get hung up on for the first time.

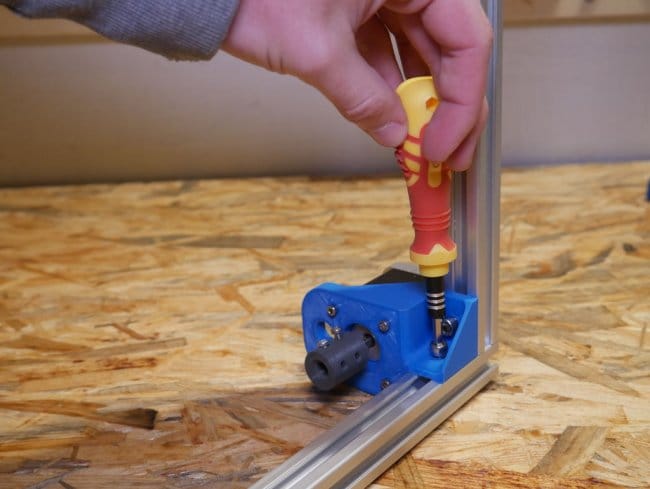

The setup and adjustment process is as follows:

- Remove the build platform;

- Place the spool of thread in the spool holder and lock in place; nine0054

- Pass the filament through the guide tube and into the extruder;

- Place the assembly tape over the platform;

- Insert assembly try;

- Connect 3D Idea Builder;

- Optional (and highly recommended), install the Dremel software;

What sets the Idea Builder apart from the competition is its ability to store 3D printable models on its internal memory (4GB SD card), so users don't need to connect via USB to start printing. nine0003

nine0003

3D printing

Dremel software is at the heart of the Idea Builder. The 3D software can load most 3D model files, including STL and a few other formats. But it will convert it to Dremel's own file format before printing. Users can choose between printed designs stored on the included 4GB SD card or can download designs online.

Unfortunately, the printer itself only reads Dremel's proprietary format, so unless the printer connects to a computer with the Dremel software installed, you won't be able to print downloaded models directly from the device. This is somewhat of a limiting factor as it requires users to either install software or convert each STL (or other) file format to Dremel's own format. nine0003

Proprietary

Idea Builder filament works best with Dremel's proprietary PLA filament, but will not print ABS due to the lack of a heated printer bed. Dremel PLA is available in colors ranging from silver to translucent. It costs about $30 - compared to other threads, it's about $6-8 more. While it's not a huge difference, it's worth mentioning. I don't think using a proprietary filament is a deal breaker as it has been reported online that the Dremel recommends only its use (we expect it to improve print jobs). There were many online accounts of a non-proprietary thread that worked without problems.

It costs about $30 - compared to other threads, it's about $6-8 more. While it's not a huge difference, it's worth mentioning. I don't think using a proprietary filament is a deal breaker as it has been reported online that the Dremel recommends only its use (we expect it to improve print jobs). There were many online accounts of a non-proprietary thread that worked without problems.

Firmware and Software Upgrade

Dremel also includes upgradeable firmware. The update process is incredibly simple:

In short, installing the Dremel 3D printing software and connecting it to the printer automatically updates the firmware. nine0003

Using the Dremel 3D Printer

The Dremel User Interface includes two main options: Build and Tools . In the Tools section, users can choose between Filament , Level , Home , Operating Mode , Setting , Preheat and About the program" . Luckily, most users won't need either of these options, making printing much easier for beginners. The most relevant of the configuration options is preheat, which reduces the time spent waiting for a 3D print to start. But even preheating is an unnecessary step. nine0003

Luckily, most users won't need either of these options, making printing much easier for beginners. The most relevant of the configuration options is preheat, which reduces the time spent waiting for a 3D print to start. But even preheating is an unnecessary step. nine0003

Of the two printing options available (printing from internal memory or via USB cable), I chose to install the Dremel 3D printing software and print via USB cable. Since connecting via a USB cable automatically updates the firmware on the 3D printer, I highly recommend a direct connection between the printer and the PC.

After installing the Dremel software, users simply open the 3D model and the Dremel software should launch automatically. From there, users simply select the build button to start printing. If users have not initiated a preheat cycle, it takes less than 5 minutes to start printing. nine0003

What I didn't like about the Dremel

3D printer The biggest problem with the Dremel 3D printer is that it doesn't read STL files, which is the industry standard for 3D models. Instead, it reads G3DREM's own proprietary files. It is possible to convert G3DREM files to STL, but this is an extra step that consumes an unnecessary amount of time. However, Simplify 3D, the leading third-party commercial printing software, supports Idea Builder. nine0003

Instead, it reads G3DREM's own proprietary files. It is possible to convert G3DREM files to STL, but this is an extra step that consumes an unnecessary amount of time. However, Simplify 3D, the leading third-party commercial printing software, supports Idea Builder. nine0003

The second biggest problem is that the Idea Builder software doesn't seem to automatically generate support for printing bridges and overhang models. We have contacted Dremel Customer Support for confirmation and are awaiting a response.

This is not actually a printer error, but mine. The model in question probably won't print on a $1,000 printer. As for the bridges, the Dremel looks pretty good. For example (in the picture below) there is a really well done bridge on the right:

There are some useful ready-made projects: if Dremel wants to really engage users in the home and home products segment, they need to include ready-made models for practical, useful things. I'm talking spacers, screws, washers, and other components that might require a trip to the hardware store. It's worth noting that Dremel provides a large library of really useful 3D designs - it's just that the models included in the 4GB SD card aren't very useful. If Dremel included amazing 3D models, I would be more likely to choose their printer over competing products. nine0003

I'm talking spacers, screws, washers, and other components that might require a trip to the hardware store. It's worth noting that Dremel provides a large library of really useful 3D designs - it's just that the models included in the 4GB SD card aren't very useful. If Dremel included amazing 3D models, I would be more likely to choose their printer over competing products. nine0003

Software error : The Dremel software also suffers from bugs. For example, using the Dremel desktop client after printing causes the USB to disconnect from my desktop. I could not determine the cause of the problem, but for this I need to turn off the printer and turn it on again. I'm sure Dremel will release a software update soon.

Resistive touch screen . Choosing a resistive touch screen in the Idea Builder is both worrying and confusing. This is because resistive screens rely on pressure to register touches rather than conduction. Unlike a smartphone's capacitive touchscreen, a resistive panel breaks down slowly over time. The more the touch screen is used, the faster it breaks down. Although the resistive panel can last for years of heavy use, if it fails, it loses touch sensitivity in the areas that users touch the most. Choosing a resistive screen may just be a cost-cutting solution. nine0003

The more the touch screen is used, the faster it breaks down. Although the resistive panel can last for years of heavy use, if it fails, it loses touch sensitivity in the areas that users touch the most. Choosing a resistive screen may just be a cost-cutting solution. nine0003

Should I buy a Dremel 3D Idea Builder?

I was under the impression that the 3D Idea Builder should cost about $100-$200 less. While it offers a simple plug and play setup process, solid software, and good all-round specs, it's not perfect. For $400 more, you can get a CEL Robox dual extruder that prints at 20 micron layer thickness with any filaments (ABS, PLA, etc.). If your target price is is less than $1000, Idea Builder competes with the very similar Craftbot and FlashForge Creator. In the $1,000 category, the Dremel 3D Builder comes out on top in terms of expandable internal memory and ease of setup - though it doesn't offer dual extruders or a heated bed. And if you're printing smaller models, you can try the M3D Micro, which retails for $350.