Diy belt 3d printer

Is It Possible To Build Your Own Belt 3D Printer? « Fabbaloo

By Kerry Stevenson on February 14th, 2022 in news, printer

Tags: artillery, belt, conversion, homemade, video

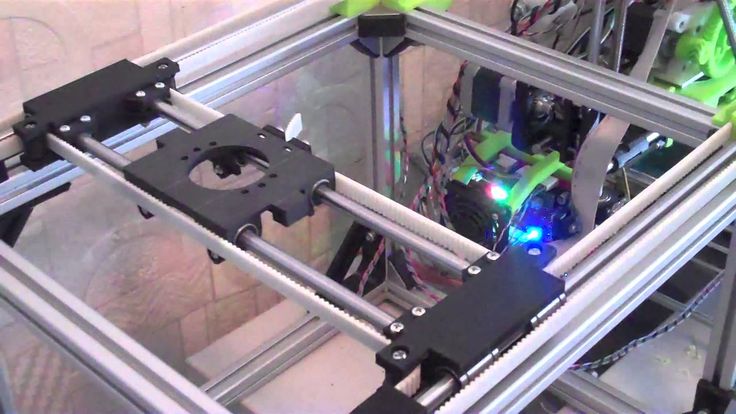

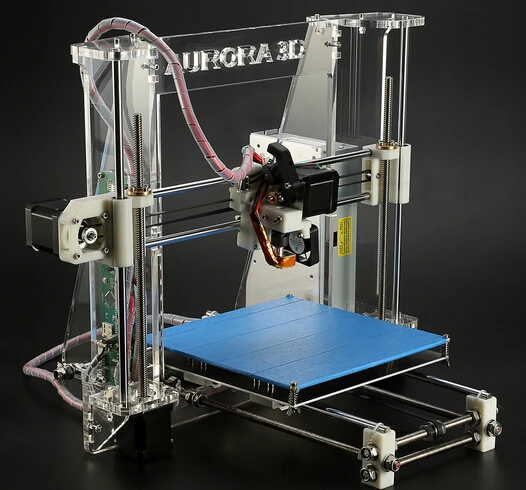

Using a belt 3D printer conversion [Source: Swaleh Owais / YouTube]Belt 3D printers are becoming more popular, but they can be expensive. Can you build one instead?

That was the question facing Swaleh Owais, a Canadian engineer and 3D printing enthusiast.

Belt 3D printers are becoming highly desirable because of their ability to 1) 3D print very long objects, far larger than the printer itself, and 2) print a continuous stream of objects in unattended mode.

There are a number of belt 3D printer options on the market today, with the lowest cost model being offered by Creality, the CR-30, at around US$1000. That’s quite a bit more than commonly available basic desktop 3D printers, which can run US$200-500.

An alternative might be to find an open source design for a belt 3D printer and get to it. However, while such plans exist they involve many parts to be bought and printed, and comprehensive assembly activities. It’s entirely possible to build one in this way, but the effort and expertise required are beyond many people’s skill levels.

Owais had another idea: why not take an inexpensive 3D printer and convert it into a belt 3D printer with some (relatively) straightforward modifications? Is this actually possible?

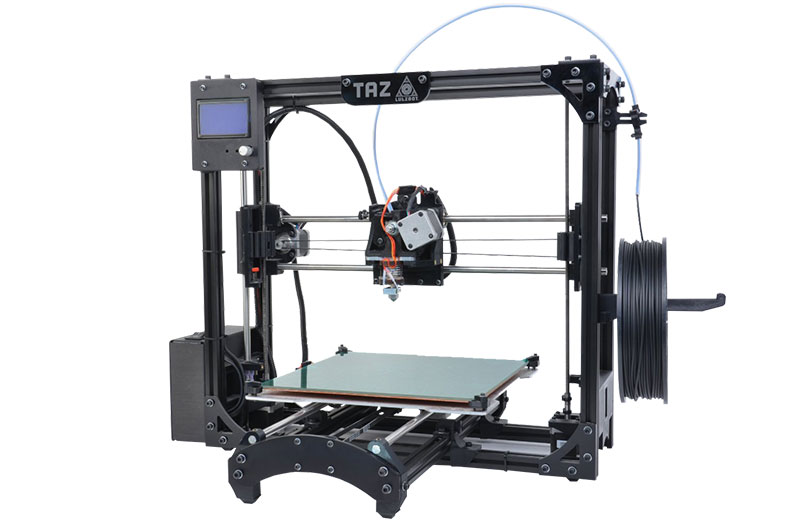

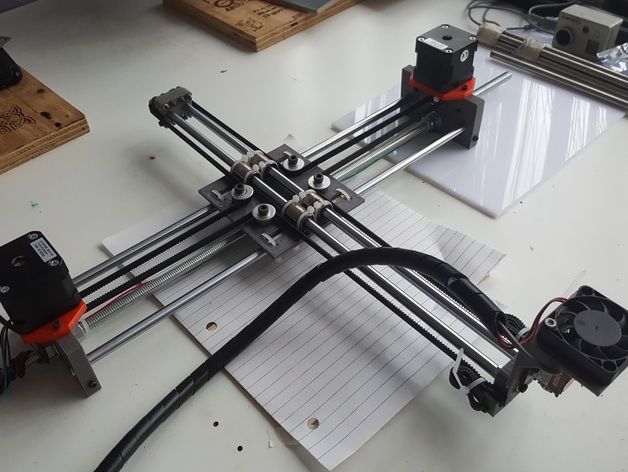

Building a belt 3D printer conversion [Source: Swaleh Owais / YouTube]Indeed it is. Owais documented his journey in a recently published video where he transformed a stock Artillery Hornet desktop FFF 3D printer into a belt 3D printer. This device costs a very low US$179, far lower than the cost of a belt 3D printer.

The process involved 3D printing a number of parts, presumably done before taking apart the machine and rebuilding it. These would provide mounts for the belt that would travel over top of the heated print surface, tip the extruder 45 degrees, and rearrange other features to accommodate belt 3D printing.

The new belt 3D printer required flashing its firmware to a new version produced by Owais, which basically respecified the maximum Z-axis limit. The machine also requires use of a software slicing tool that understands belt 3D printers. He recommends using the custom BlackBelt Cura, which I’ve also used.

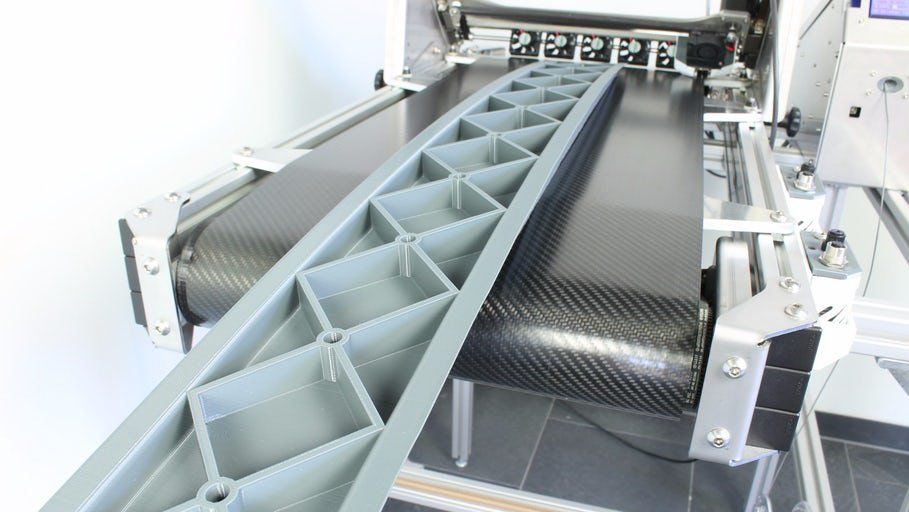

Perhaps the most interesting aspect of this build is the nature of the belt itself. The belt is a critical component that must be not only flexible, but it must also be durable, adhesive to the print material, and withstand heat.

In my long-ago experience with the ancient MakerBot CupCake automated build platform, the belt was the point of failure: after several prints the belt material would bulge, fouling the leveling and causing me to abandon the hardware completely.

A huge print made on a belt 3D printer conversion [Source: Swaleh Owais / YouTube]Here Owais undertook a detailed study of different materials for the belt, but ended up with a solution that in retrospect seems obvious: buy a purpose-built 3D printer belt. His supplier was none other than PowerBelt, the makers of the upcoming TinyBelt 3D printer. This belt material hits all the necessary specifications, and enabled Owais to produce a working belt 3D printer for a rock bottom price.

His supplier was none other than PowerBelt, the makers of the upcoming TinyBelt 3D printer. This belt material hits all the necessary specifications, and enabled Owais to produce a working belt 3D printer for a rock bottom price.

Well, the price plus some effort to put it all together.

If you’re interested in trying this approach to obtaining a belt 3D printer, you’ll certainly want to watch this video and use the approach Owais has pioneered.

Via YouTube

Twitter Kerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

So far, it seems to be working!

View all of Kerry Stevenson's posts.

White Knight 3D Printer - 3D Distributed

White Knight 3D Printer - 3D DistributedHome

Midwest RepRap Festival: The Best DIY 3D Printer Event

White Knight 3D Printer

white knight 3d printer midwest reprapCarl from NAK3DDesigns

Have you ever needed to print an object but you were limited to the size of your 3d printer print area? If only…. you could print with an unlimited range….. an unlimited Z……..

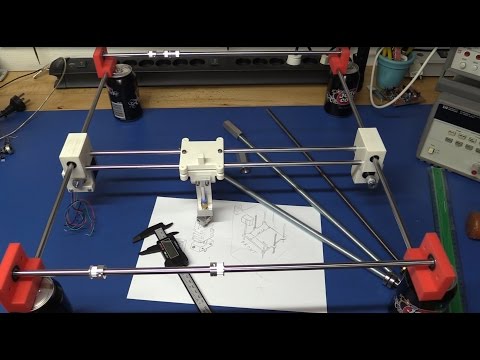

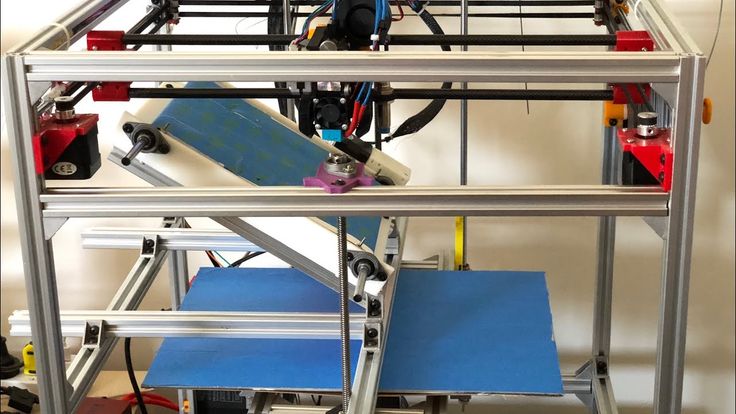

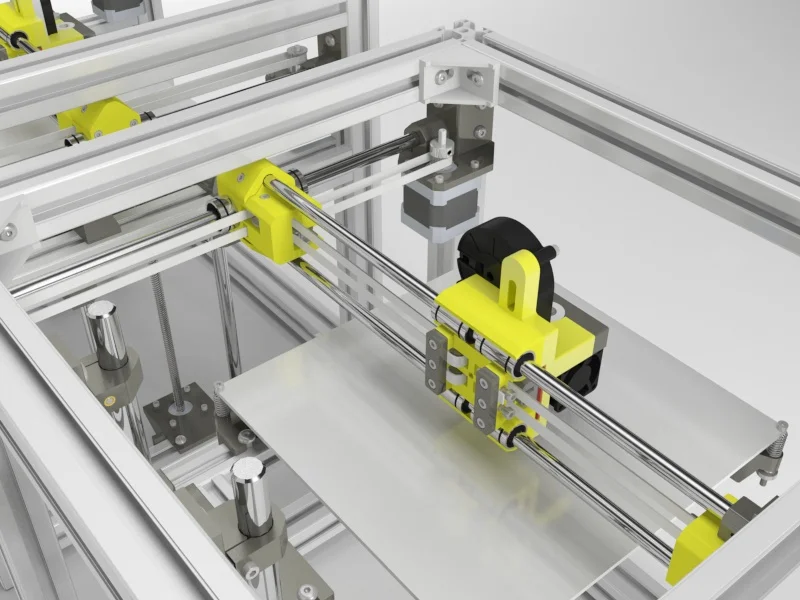

White Knight Belt 3D PrinterOut of all of the awesome 3d printers at Midwest Reprap Festival…. I have to say that the White Knight belt 3d printer was the most impressive build. A well thought out design by Carl from NAK3DDesigns has changed the game for belt printers. If your not up to par with the concept of belt 3d printers here’s the details.

- Belt

- Unlimited Z-Axis

- Large Build Area

- Continuous 3D Printing

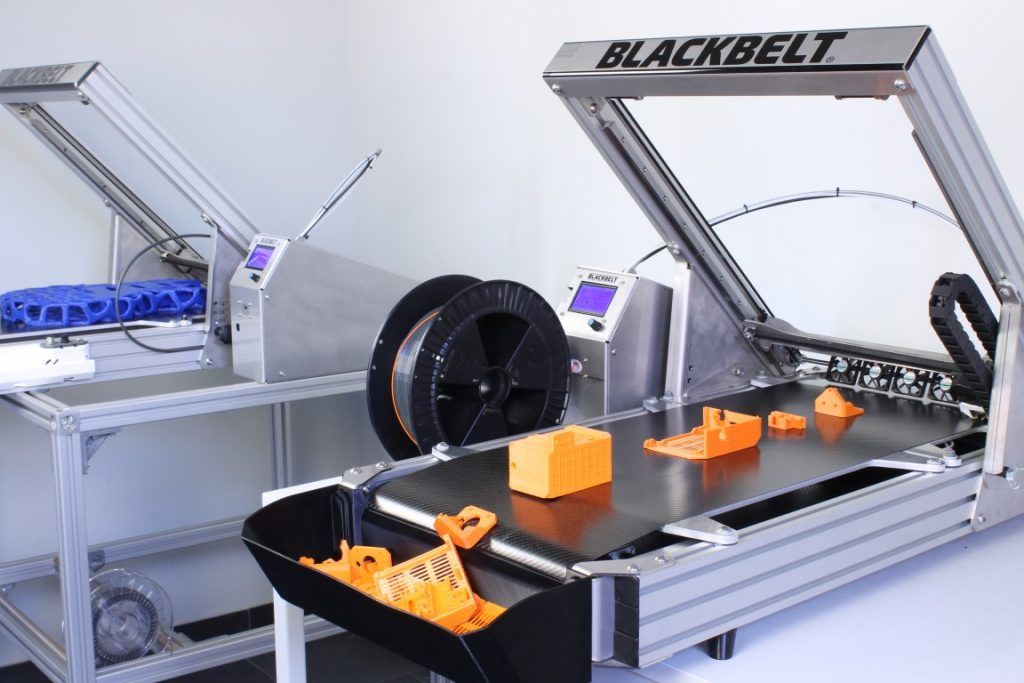

Belt 3d printers first showed up to the 3d printing scene when the Black Belt 3d printer was launched. The Black Belt printer is a closed source belt printer that sales for $13,600. The benefits and possibilities of a belt 3d printer are long prints and printing horizontal overhangs without support. In addition the belt printer has the mechanical advantage for production 3d printing. As long as there is filament feed to the printer the machine can print for as long as you want. The ideal production printer that isn’t restricted to part removal.

The Black Belt printer is a closed source belt printer that sales for $13,600. The benefits and possibilities of a belt 3d printer are long prints and printing horizontal overhangs without support. In addition the belt printer has the mechanical advantage for production 3d printing. As long as there is filament feed to the printer the machine can print for as long as you want. The ideal production printer that isn’t restricted to part removal.

Carl developed the White Knight 3d printer out of necessity. He needed to print long parts but at the Black Belt price range of $13,600 this was out of reach. In addition to the high price tag of the Black Belt printer the next problem is the under developed closed source platform and small x and y-axis travel distance That’s when Carl developed the White Knight 3d printer. The White Knight 3d printer has a 400mm x 430mm print area compared to the Black Belts’s 340mm x 340mm. With the complete Build of Materials the White Knight can be built for under $2000.

You can find the published design open source on Thingiverse and Github. Check out Carl’s Thingiverse post where he states “This is my design for a 400mm x 430mm x Infinity belt printer. The main design works around a CoreXY D-bot design. I’ve integrated the use of Linear rails and have designed the mount for the E3D V6 or Mosquito hotends(but mosquito fits without any modifications to the hotend.” In addition the large belt printer is using:

- Duet Wifi 3d printer electronics

- E3D 5 to 1 geared down stepper motor

- Mosquito Hotend by Slice Engineering

- Bondtech Extruder

- Buildtak printing surface (belt)

“Currently the only slicer that I am aware that works with belt printers and can handle the 45degree angle is Cura Blackbelt.”

All files are available on Carl’s GitHub..

https://github.com/NAK3DDesigns/White-Knight (make sure to follow him on twitter)

Carl states “I uploaded the files to GitHub for future ease of collaboration and in hopes as a community we can make this printer perfect. ”

”

Although the White Knight uses aluminum extrusions and other hardware, Carl plans to redesign the printer to be completely 3d printed to bring down the price for the average user.

Carl plans to release a smaller version with a 230mm x230mm x infinite called the Squire at #ERRF2019 and later add on the E3D Tool Changer once released. In addition Carl plans to implement a Palette by Mosaic Manufacturing to run multi material extrusion.

Loose belts are a common problem for users and cause a variety of issues. It may or may not be obvious that your 3d printer is experiencing issues. Belt tensioning defects can occur.

While a Duet 3 won’t be replacing the Duet 2 anytime soon, it’s a much more professional electronics board that adds a range of options and functionality to your machine build. Although the Duet 3 may be overkill for most users, these options are not for everyone you do get much more out of Duet

Is CoreXY better?

What is the best 3d printer to start with? We review the newest coreXY 3d printers of 2020.

Midwest Reprap Festival 2019 was wven more than the year before. There were so many more people attending and exhibiting. The venue was packed to seams with the coolest 3d printer builds you ever seen.

#MRRF2019 was fantastic and in this video we take a look at all the awesome CoreXY 3d printers that were at the show. There were many different set ups including the E3D Toolchanger to Railcore 3D Printers.

Prusa XL Update Prusa XL Review – 3D Printing Nerd 3/21/21 Unfortunately the picture above isn’t the new Prusa XL. It’s a clip from Joel Telling’s 3D Printing Nerd Youtube

CoreXY Belt Routing One of the most important parts for corexy movement is belt routing. Here’s a guide to the mechanics of corexy belt routing pulley layout in order to

CoreXY Kinematics Explained? The corexy kinematics mechanical arrangement includes a unique motor movement where the X or Y motor move together or opposite of each other to move the carriage

We first discovered RailCore Labs and their beautiful corexy design at MRRF 2019. The Railcore 3d printer was designed by designed by Tony Akens and J. Steve White when discussing an idea of a core xy printer with linear rails on the x,y and z-axis on Reprap IRC.

The Railcore 3d printer was designed by designed by Tony Akens and J. Steve White when discussing an idea of a core xy printer with linear rails on the x,y and z-axis on Reprap IRC.

Modular

Scalable

Linear Rails

Balanced Carriage Pull

Enclosure

BOM utilizes most available parts

All Metal Parts or 3D Printed

Z-Axis: Independent Driven or Shared Belt Routing

The WorkHorse is a large scale machine platform for 3d printing.

What Size Stepper Motor Should You Use? While the size of a stepper motor is just the footprint it’s the winding that determines torque. There are Nema 17’s with as

Like this:

Like Loading...

%d bloggers like this:

How the belt tension of the Ender-3 (Pro/V2) 3D printer affects print quality. How to properly tighten them.

In this article, we're going to look at some pretty important and useful information about the straps on Ender 3 (Pro/V2) 3D printers and how tight they should be.

We will also look at the results of 3D printing in three ways: one with loose belts, one with tight belts, and one with optimal belt tension.

This will give you a visual and understanding of the importance of keeping the printer belts tight and the impact they can have on your print quality. Looking ahead, let's say that in one of these cases, printing a part turned out to be an impossible task. nine0003

Of course, we will also tell you how to properly tension the belts, as well as where to find convenient tensioners for Ender 3 and Ender 3 Pro (Ender 3 V2 already comes with tensioners) to make the whole process easier.

How tight should the straps be on the Ender 3?

Only trial and error will help determine the correct belt tension.

First check the belt to make sure it is tight and not slipping off the pulleys. You should feel some resistance as you squeeze the top and bottom of the belt. nine0003

You must pull the belts as tight as possible to prevent slack, otherwise your belt will slip and the printer will skip.

After tensioning the belts, be sure to carry out a test. To do this, print some simple model, a small test cube is best for this. If you still see ripples, layering, or some other negative effect on the surface, it might be worth checking the tension again.

If your belt is too tight, it can cause you to skip steps, overheat the engine and prematurely wear out the mechanics. An overtightened belt will cause unusual deformations on your part. nine0003

Also note that belts that are too tight are subject to faster wear and in some cases may even break.

Some signs that you need to check the belts on your 3D printer:

- Loud sounds coming from the printer.

- Your belt appears to be loose when you look at it.

- Parts are rippled and/or deformed

- Your printer stops for no apparent reason.

Inspecting the printer will allow you to locate the problem. Similar effects can be caused by other reasons, however, do not forget to check the degree of tension of the belts.

Difference in print quality between loose and tight straps.

We have loosened the belts enough to show you the quality of the 3D printer with the X and Y belts loosened.

3D printed results.

Cube 1: The belts are too loose, the efficiency of the transmission chain is reduced, as a result the entire cube has shifted to the left. nine0003

This phenomenon is quite common when 3D printing with a loose X-axis belt, but it can be easily diagnosed and corrected because you can clearly see what is happening.

For Cube 2, we tightened the straps, but not tight enough. Layers and waves are clearly visible on the model.

Cube 3 printed with optimally tensioned straps. The print quality has improved a lot, there are no visible waves, layer lines are also less visible.

With cubes 2 and 3, you can clearly see how belt tension affects 3D print quality. nine0003

Loosely tensioned belts can also cause your prints to show more visible layer lines, detracting from the appearance of your model.

This problem can be caused not only by weak belts, but also by uneven extrusion. However, in this situation, most people do not think that the reason is in the belts and forget to check the degree of their tension.

Another example of the difference in 3D printing quality between weak and tight belts.

Can the belts on the Ender 3 be too tight? nine0011

For best 3D printing quality, 3D printer belts should be pulled as tight as possible without stretching or breaking.

Under-tensioned belts create a stepped effect on your part, and in the worst case completely distort its geometry.

However, it is worth noting that you can damage the straps when overtightening. So while you should do your best to tighten them as tight as possible, do so carefully.

In the next section, we'll show you how to adjust the tension on both belts on the Ender 3 using the provided tools, which is quite simple but won't allow you to tighten them as much as you could with the special belt tensioners.

How to adjust belt tension on Ender 3 (Pro).

The Y-axis belt is often tensioned at the factory by the manufacturer and is usually well adjusted. We had to loosen it on purpose to show you the print quality on loose belts. nine0003

You install the X-axis belt yourself, so something can go wrong here.

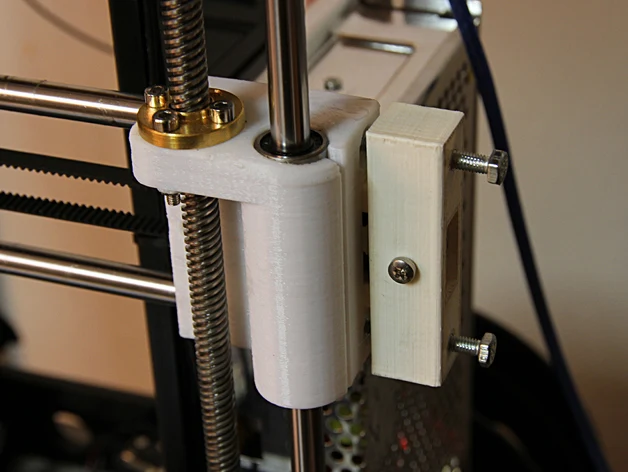

How to adjust the X-Axis Belt on the Ender 3.

You only need one tool for this, the second largest hex wrench that comes with the printer.

Loosen the two screws on the idler on the far right side of the X-axis.

Use a larger hex wrench and insert it between the tensioner and the X-axis guide.0002 You can now use it as a lever to apply force to the tensioner and hold it as far as possible to keep the belt tight.

Tighten the strap and, holding it with one hand, tighten the screws again.

How to adjust the Y-Axis strap on the Ender 3.

The Y-Axis strap is a little trickier to tighten because there are more screws holding the entire bracket in place, and if you're doing it by hand, you'll need to put in some effort to tighten it tight enough. nine0003

nine0003

However, you will need the same hex key as before.

Loosen all four screws on both sides of the bracket using the included hex wrench.

Pull the tensioner to tension the belt.

Tighten the four screws while holding the belt so that it does not loosen.

After adjusting the tension of the belts, make sure that the carriage moves smoothly along the X and Y axes from one end to the other, and the belt does not rub against the guides. nine0003

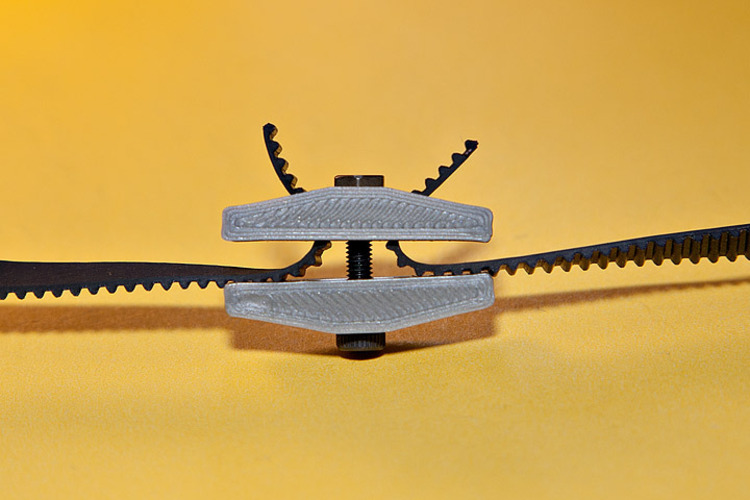

Installation of adjustable belt tensioners.

Adjusting the tension of the belts on the Ender 3 or Pro is a little trickier because, unlike the Ender 3 V2, earlier Ender 3s don't come pre-installed with adjustable belt tensioners.

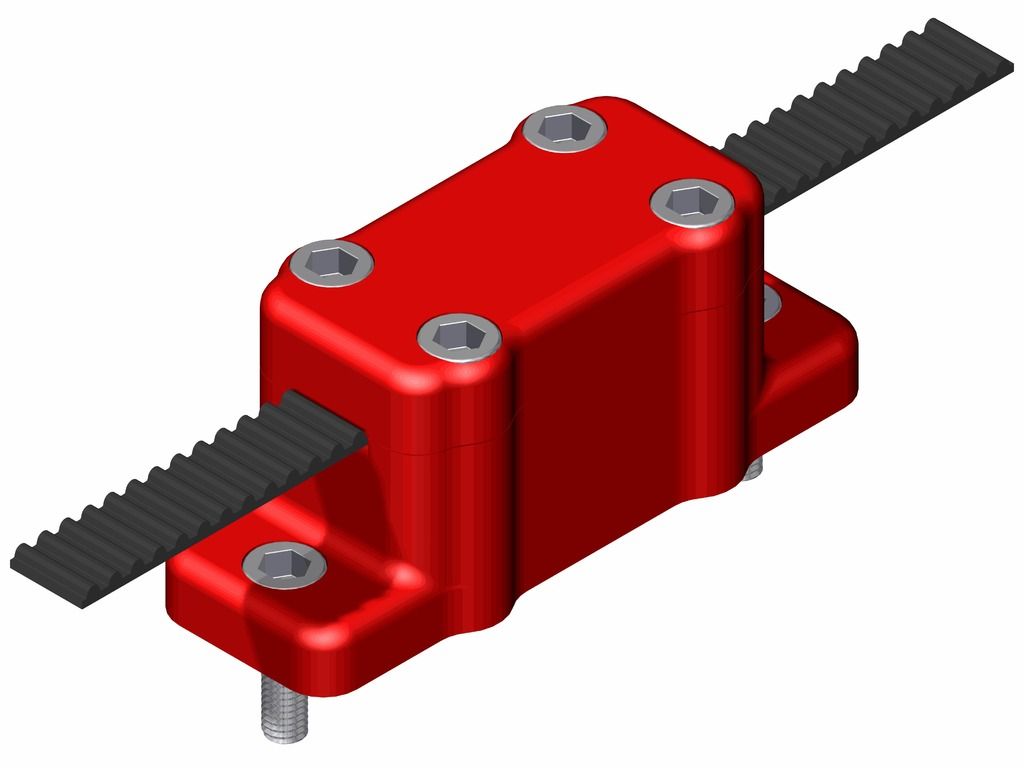

Instead, Creality uses fixed belt pulleys that are at the ends of the X and Y axes and cannot be moved easily.

Fortunately, the Ender 3 development community, Creality and others have developed adjustable belt tensioners that allow you to change the belt tension on the axle by simply turning a knob. In this section, we'll look at how to upgrade your Ender 3 or Pro with an adjustable belt tensioner. nine0003

In this section, we'll look at how to upgrade your Ender 3 or Pro with an adjustable belt tensioner. nine0003

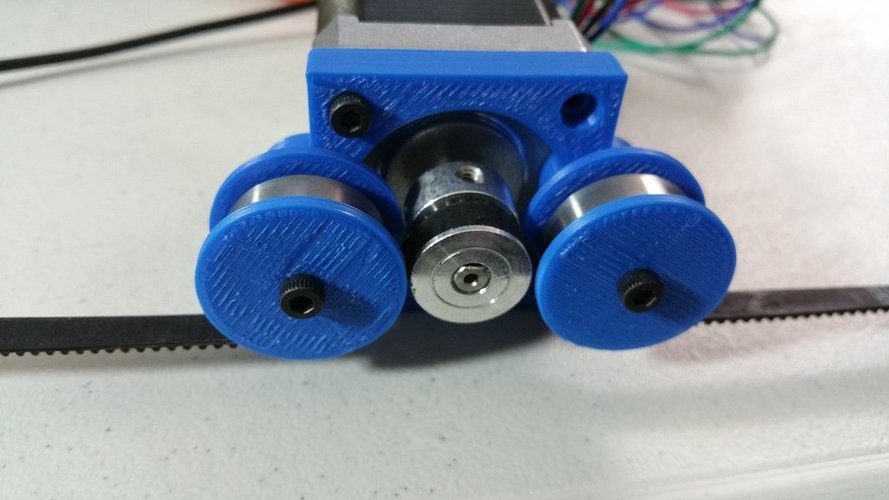

Belt tensioners are an efficient way to adjust belt tension without having to manually move the pulley on the axle.

Ender 3 and Ender 3 Pro are very similar and the X-axis belt tensioner will work on both printers. However, since the Pro version has 40x40 Y-rails, while the original Ender 3 uses 20x40 rails, the Y-axis tensioner for the two printers is different.

Ender 3 Y-Axis Tensioner

Ender 3 Pro 9 Y-Axis Tensioner0003

X-Axis Tensioner for Ender 3 and Ender 3 Pro

It is important to note that in order to 3D print belt tensioners for Ender 3 or Pro, you must use print settings that will produce a strong and durable part. The belt tension will depend on the structural integrity and strength of the belt tensioner, so give it due consideration as you don't want it to break in the middle of the process.

Ring belt for 3D printer - GT2

UAH 25 – UAH 205

Closed belt - ring.

It is actively used in the construction of 3D printers, when the torque is not transmitted directly from the motor shaft, but through a belt.

This approach saves space and reduces vibration.

Belt standard: GT2

Category: 3D printer mechanics Article: 02-096 Tags: GT2 ring belt tensioner belt drive belt

- Description nine0153 Details

- Reviews (0)

Description

Ring belt for 3D printer

In the presence of GT2 belts of the following sizes:

Option 1: Length-15.8 cm (158-2GT)

9000 Option 2: length-20: 20 .32 cm (B100 MXL)

Option 3: Length - 48.768 cm (192MXL)

Option 4: Length - 35 cm (350-2GT-6)

Option 5: Length-122 cm (1220-2GT)

Option 6: Length-135 cm (1350-2GT)

Option 7: length-97. 6 cm (976- 2GT-6)

6 cm (976- 2GT-6)

Option 8: Length - 154 cm (1540-2GT-6)

Option 1:

| Model

| 158-2GT |

| Teeth | 79 |

| Step | 2.0mm |

| Height | 6mm |

| Length | 158mm |

| Material | Rubber |

| Color | Black |

Option 2:

| B100MXL |

| 192 |

| 2.032mm | nine0221

| 6.4mm |

| 203.2mm |

| Rubber |

| Black |

Option 3:

| 192MXL |

| 192 |

2. 032mm 032mm |

| 6.4mm |

| 390.144mm |

| Rubber |

| Black |

Option 4:

| 350-2GT-6 |

| 175 |

| 2.mm |

| 6mm |

| 350mm |

| Rubber |

| Black |

Option 5:

| Model | 1220-2GT |

| Teeth | 610 |

| Pitch | 2mm |

| Height | 6mm |

| Length | 1220mm |

| Material | Rubber |

| Color | Black |

Option 6:

| 1350-2GT |

| 675 |

| 2mm |

| 6mm |

| 1350mm |

| Rubber |

| Black |

Option 7:

| 976-2GT |

| 488 |

| 2mm |

| 6mm |

| 976mm |

| Rubber |

| Black |

Only registered customers who bought this item can post reviews.