Cfam 3d printer

CEAD officially launches industrial-scale continuous fiber CFAM Prime 3D printer

Some 3D printing stories take place over extended periods, such as the month-long 3D printing of a bridge. Other times, research and development can take even longer. In those cases, we try to keep readers apprised of major developments as they occur.

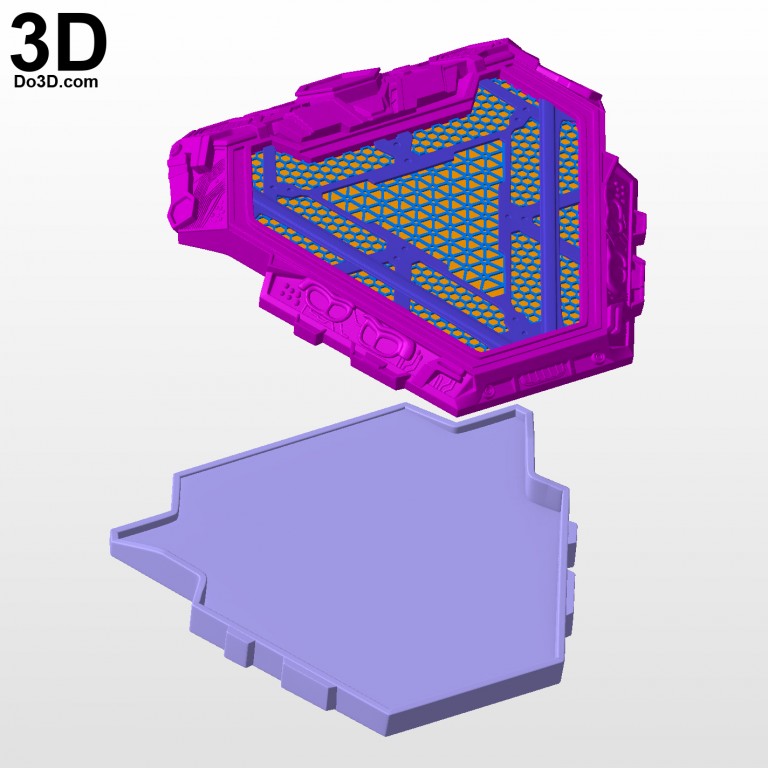

Today, we bring updates on the CEAD large-scale CFAM Prime 3D printer designed for shipbuilding, infrastructure work, and industrial projects. CFAM stands for Continuous Fiber Additive Manufacturing and involves infusing continuous strands of carbon fiber or glass into 3D printed thermoplastics.After settling into their new Delft location and printing various materials for a couple months, CEAD hosted an event to officially launch and show off the capabilities of the CFAM Prime. They 3D printed parts with their continuous fiber and with short fibers so attendees could feel the mechanical properties differences between them. There was also a live demonstration of a CFAM Prime adding a console to a cabin that had been 3D printed earlier.

Dutch company CEAD developed the technology because they wanted to produce parts with the complex geometries enabled by 3D printing but with the industrial strength of composite moulds. There are many fiber-reinforced plastics available for 3D printing, but they all use short fibers, which increase the strength of parts incrementally but not to the standard of industrial applications. By pushing a continuous strand of fiber with the plastic extrusion, parts become incredibly rigid.

The CFAM Prime 3D prints are strong enough even for CEAD’s first two customers, Royal Roos, a marine engineering company, and Poly Products, a specialist in fiber-reinforced plastics and construction. Royal Roos is already using a CFAM Prime to 3D print ship models for motion and resistance testing in basins. “Fast and accurate 3D printing of large and strong (ship) parts was so far not possible. With this new 3D printer this will work. We are, for example, investigating how to use this technology to produce gangways. 3D printing is not only fast, but you can also calculate the cost price in advance. Moreover, it is possible to recycle materials," remarked Fulko Roos, founder of Royal Roos.Poly Products will be receiving their CFAM Prime around the middle of 2019, with plans to 3D trim lines for cargo ships. “At Poly Products we manufacture fibre-reinforced plastic products,” stated Jan Schrama, founder of Poly Products. “With this 3D printer we can work faster, at lower costs and we have less manual labour. This makes it easier to make one-off products and showing customers a prototype, without making a mould.”

3D printing is not only fast, but you can also calculate the cost price in advance. Moreover, it is possible to recycle materials," remarked Fulko Roos, founder of Royal Roos.Poly Products will be receiving their CFAM Prime around the middle of 2019, with plans to 3D trim lines for cargo ships. “At Poly Products we manufacture fibre-reinforced plastic products,” stated Jan Schrama, founder of Poly Products. “With this 3D printer we can work faster, at lower costs and we have less manual labour. This makes it easier to make one-off products and showing customers a prototype, without making a mould.”

Besides making super sturdy parts, the CFAM Prime can make very large parts as well, with a build volume of 2m x 4m x 1.5m; that makes it the largest 3D printer commercially available in Europe. Here are some of its other impressive specs:

Smart heating/cooling system uses thermal cameras and adjusts in real time

Siemens CNC system base

Can process ABS, PP, PET, and high-temp materials like PEEK and more

Output of 15kg/hour

Able to run for 24 hours without operator presence

There will be only six CFAM Prime 3D printers produced in the first series, so if you'd like one of these nearly $1 million machines, place your orders soon.

Compare

Remove all

Compare up to 10 products

CEAD's new large-format Continuous Fiber 3D printer

0Shares

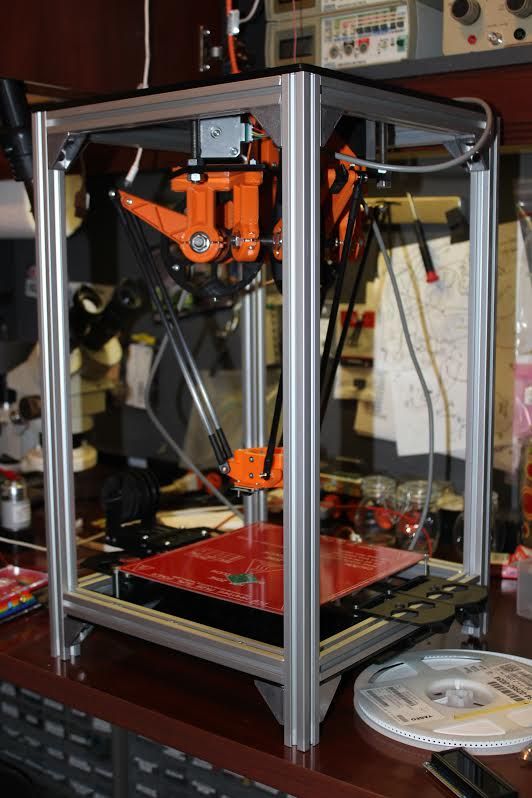

The Netherlands based company CEAD is developing a large-format Continuous Fiber Additive Manufacturing (CFAM) machine for industrial applications, including construction and shipbuilding.

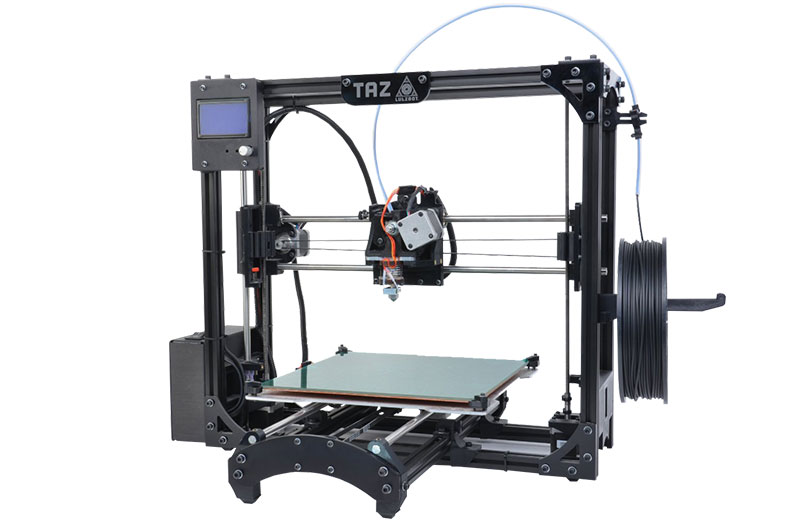

CEAD is developing a large-format 3D printer for industrial applications. Photo via CEAD.Continuous fiber 3D printing

CEAD has not revealed the specifications of their CFAM process, as they are still in the process of securing patents, however other solutions for working with carbon fiber are already on the market. It will be interesting to learn how the CEAD process compares.

Continuous fiber 3D printing has been commercially available since 2015, with the release of the MarkForged Mark One. Continuous Fiber Fabrication (CFF) is a process developed and coined by Markforged, a Massachusetts-based producer of 3D printers.

CFF uses two print nozzles to produce parts with continuous strands of composite materials, such as carbon fiber, fiberglass or kevlar. The first nozzle follows a conventional printing process, extruding the outer shell of a part in layers. The second nozzle deposits a continuous strand of material on every layer that MarkForged CEO, Greg Mark, says produces components “five times stronger and twenty times stiffer” than regular 3D printed parts. Currently, MarkForged do not offer 3D printers with build sizes as large as CEAD’s CFAM machine. Read more about CFF in a 3D Printing Industry interview with Mark.

Testing and production

In January CEAD revealed some key specifications of the 3D printer, including an impressive max build size of 4x2x1.5m and a deposition rate of 15kg of material an hour. The printer is compatible with many different thermoplastics, including ABS, PET, PP and PEEK.

Since then, CEAD has successfully tested the impregnation and extrusion of continuous glass and carbon fiber materials in the printing process. During the test the CFAM machine ran for 24 hours without operator interference. CFAM samples were subjected to several interlaminar shear strength (ILSS) tests showing parts conforming to several ISO standards.

During the test the CFAM machine ran for 24 hours without operator interference. CFAM samples were subjected to several interlaminar shear strength (ILSS) tests showing parts conforming to several ISO standards.

CEAD have moved production to a larger 1000 square meter facility, located near Delft, Netherlands. The location will be used to produce the first full-scale CFAM machine.

The company say the CFAM 3D printer will be available this year.

CEAD Group’s CFAM machine. Image via CEADBe the first to read about the latest 3D printers and 3D printing technologies. Subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Vote in the 2018 3D Printing Industry Awards, before it closes.

Post a job, or kick-start a career in 3D printing. The 3D Printing Industry Jobs board is live.

Featured image shows CEAD’s logo. Photo via CEAD.

Photo via CEAD.

Tags CEAD Mark One markforged

Eric Lai

Eric is a writer at 3D Printing Industry. From Ireland, he has an MA in Philosophy and English Literature from the University of Edinburgh. He views things through a philosophical lens and is interested in 3D printing's potential to radically alter the manufacturing landscape, and the cultural and societal changes that will follow.

CARIMA DENTAL 3D PRINTER

Delivery

In Moscow and Moscow Region within 3 days. To other regions by courier service at the expense of the recipient.

Payment

DEAR CLIENTS!

Due to the general economic situation and exchange rate instability , all prices on the website have the status "on request" .

We ask you to clarify the cost and availability of the ordered equipment from our managers by phone or on-line consultant. nine0011 Please note that price is valid for one day!

nine0011 Please note that price is valid for one day!

You can fix the price by making an advance payment for the selected product.

THANK YOU FOR YOUR UNDERSTANDING!

Cashless payment.

Cash in the office, st. Elektrodnaya, house 10.

Manufacturer

Carima

product code

CARIMA DENTAL 3D PRINTER

Art. No.

Description

CARIMA DENTAL 3D PRINTER

Make your imagination a reality with the world's best 3D printing technology

Carima is the forerunner of the CK industry that made photolithography machines and was founded in 2000 by Lee Byung-guk with the idea of "wear + imagine" for 3D printing. printer.

Carima is the oldest and specialized 3D printing manufacturer in Korea with 23 patents and 63 pending patents. In addition, Carima has won many technical awards such as the Prime Minister's Award. nine0003

nine0003

Benefits

- No. 1 Korea IMD DLP Dental 3D Printer by CARIMA designed for dentists and dental technicians

- Open type printer (compatible with various resins designed for LCD/DLP printing)

- Fast printing, high accuracy, stability

- Optimal stage size for simultaneous printing of maxillary and mandibular models

- Designed for dental clinics and dental laboratories

Specifications

| Application | Models, templates, caps, blanks for casting and pressing ceramics |

| Printable area | 124x70x140 |

| Pixel size (X/Y) | 65µm nine0087 |

| Layer thickness | 25, 50, 100, 150µm |

| Projector power | 365, 385, 405 nm UV LED |

| Projector resolution | FHD 1920x1980 |

| Compatible file formats nine0087 | stl, obj, amf, slc, ply, svg |

| Printer size | 391x405x589 mm |

| Printer weight | 18. |

| Food | DC 24V 5A with adapter |

Similar products

Robotic 3D printing machine with pellets CFAM Prime at the manufacturer's price with delivery - "TopStanok"

- Description

- Specifications Har-ki

Description

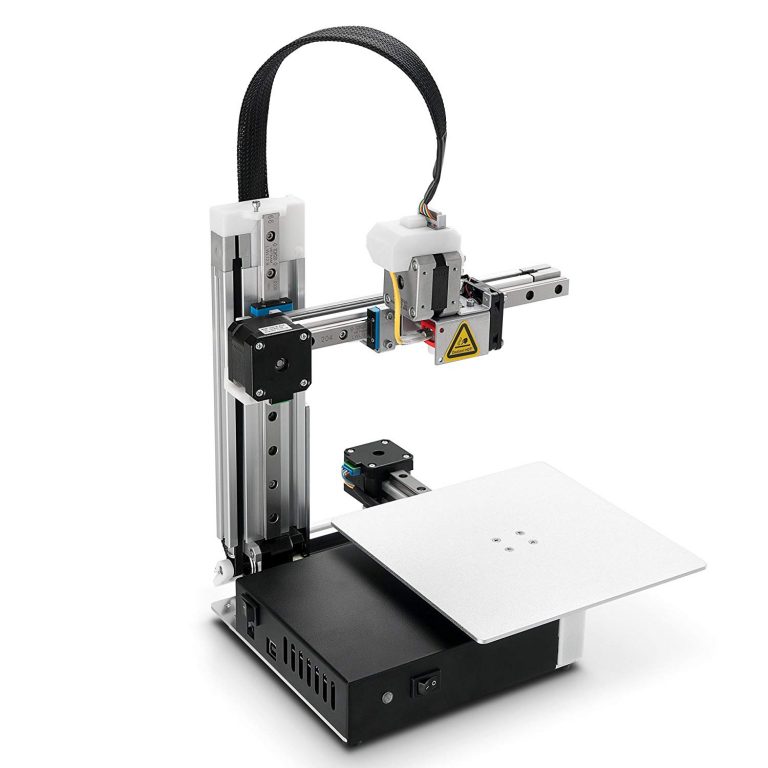

CFAM Prime is specially designed for series production. The machine is focused on speed and reliability of printing. Ideal for efficient production of very large parts or multiple parts in one production run. Supplied entirely turnkey. nine0003

The large print area also increases speed. With this printer, you can print not only large objects, but also several medium ones in one cycle. What standard professional and especially desktop printers spend dozens of hours on, CFAM Prime is able to print in a few hours.

5 kg

5 kg