Blue tape for 3d printer

Blue Tape for 3D Printing: The Complete Guide [2021]

3D Printing has rapidly grown in popularity and accessibility. What used to only be possible in advanced laboratories is now possible in the comfort of the home!

Whatever your purpose for 3D printing, whether professionally or just for fun, there are many components that play into the quality of the final product. One of the most important is bed adhesion.

Here is the ultimate guide to 3D printing with blue painters tape.

3D Printing Bed AdhesionWhat is 3D printing bed adhesion?Bed adhesion in 3D printing is how well the printed plastic parts are able to stick to the build plate. Good bed adhesion means that the plastic will not be easily removed or nudged, while poor bed adhesion means that it might move around during the printing process.

Essentially, as the filament hardens on the build plate, bed adhesion is what keeps everything in place. If the plastic pieces become top-heavy or get bumped, adhesion to the build plate is what keeps everything in place.

Bed adhesion is an important part of the 3D printing process. Luckily, there are special products designed to create the perfect amount of bed adhesion. Here are the reasons why bed adhesion is so crucial in 3D printing.

Not enough adhesion

If the 3D printed parts are loose enough to move around during the printing process, it can ruin the entire build. 3D printing requires exact measurements, so any sort of movement can misalign the entire build.

Too much adhesion

Alternatively, if the build plate has too much adhesion, it can be difficult to remove the plastic components. Any particularly thin pieces can potentially become damaged by the greater force required to remove them from the adhesion.

What kind of adhesives are used for 3D printing?Options for 3D Printing Bed Adhesion

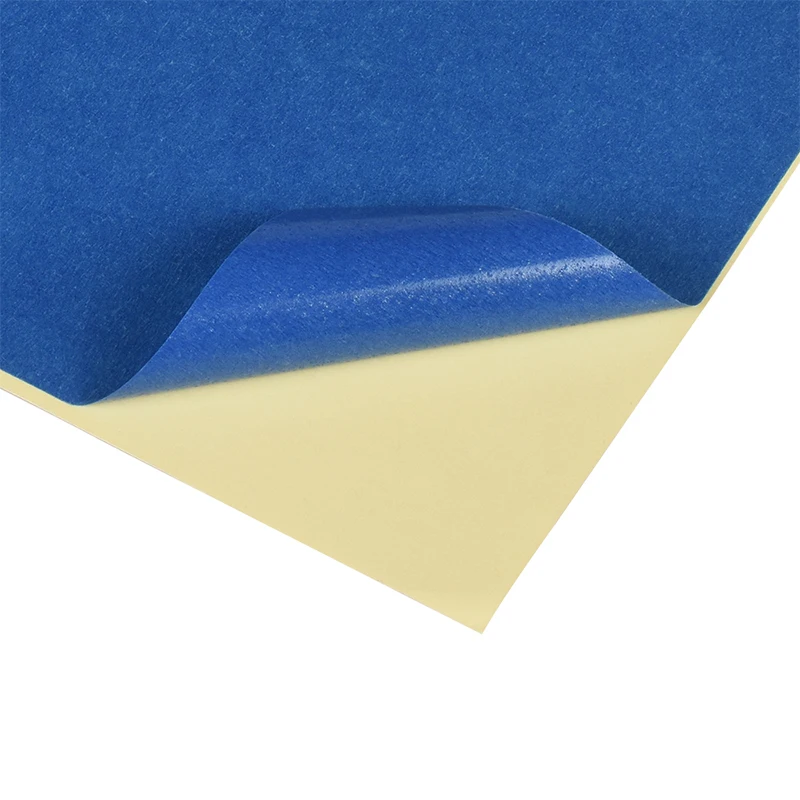

PEI Sheets

PEI sheets, or Polyetherimide sheets, are adhesive plastic sheets designed to withstand the cycles of heat in 3D printing. On one side, they adhere to the build plate, and on the other they allow you to build your 3D prints.

On one side, they adhere to the build plate, and on the other they allow you to build your 3D prints.

While are supposed to be reusable for up to a month, the soft plastic can be dented and damaged very easily. A build plate that isn’t perfectly level can ruin a print. Investing in a PEI sheet can be risky because if it is damaged during an early print, the sheet can become unusable.

Adhesive Spray

Another option for bed adhesion is adhesive sprays. You simply spray the adhesive onto the plate and start printing. This route is easy and allows you to maintain a level bed. Plus, cleaning up is simple too, as most sprays are soluble in water.

Even though this is certainly a convenient method of getting your prints to stick, it is not the most effective. Getting an even stickiness to the bed with a spray can be difficult, and often it can be hard to get the bed to be sticky enough.

Glue

Using a glue stick is a way to keep your prints in place during 3D printing. Special glue designed for 3D printing is available at a relatively low cost. All you have to do is rub the glue stick where you are going to be printing, and the printer will take care of the rest.

Special glue designed for 3D printing is available at a relatively low cost. All you have to do is rub the glue stick where you are going to be printing, and the printer will take care of the rest.

However, like PEI sheets, they can create an unlevel bed. If too much glue builds up in one spot, the print can become crooked. Also, clean up can be kind of a pain because the glue will stick to the plate and the print.

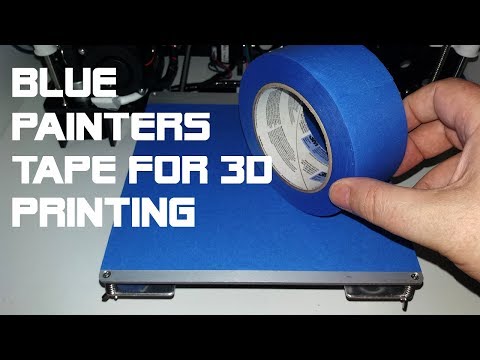

Blue Painter’s Tape

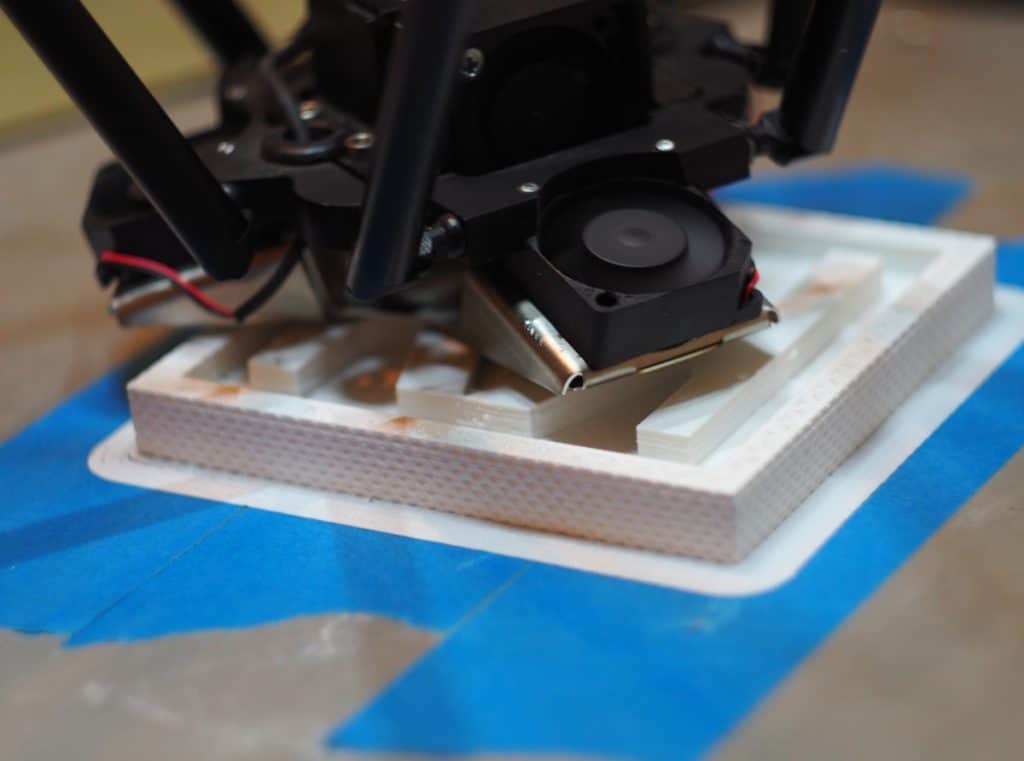

Specialized blue painter’s tape is a great option for creating bed adhesion. The porous nature of the blue tape allows PLA nylon, and other filaments to stick directly to the back of the tape. Painter’s tape is also heat resistant so it can withstand heated beds and the heat of the filament.

While it does take some set up, the price of the supplies and the quality of the printed parts are unmatched.

How to Use Blue Tape for 3D PrintingClean the Surface

Before you start applying the tape, you should clean your printing bed of all residue. This lets the tape stick and helps to keep your plate level.

This lets the tape stick and helps to keep your plate level.

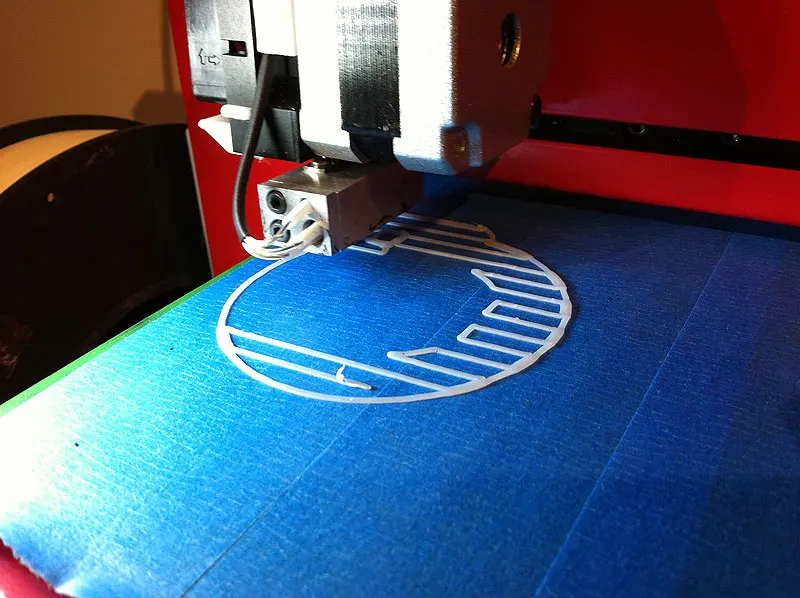

Taping a 3D Printer Bed

While it will take a few minutes to properly tape your build plate, the prep work is not too difficult and can quickly be mastered.

With the adhesive side down, lay the tape down side by side. You want to be as precise as possible with this step so that there are no gaps that could let the filament through, but you also do not want any overlap of the tape which would cause the surface to be uneven.

Tape Diagonally

A key tip for taping a build plate is to lay the pieces of tape diagonally. When laying out the pieces side by side, start from one corner at a forty-five degree angle and work your way over.

This is helpful because it keeps the tape from warping with the print. If the straight edges of the print line up with the straight edges of the tape, the tape can lift off the plate as the filament cools.

Remove Bubbles with a Scraper

As you lay the pieces of tape down, be sure that there are no bubbles underneath the tape. To ensure this, run a scraper over every piece as you place it.

To ensure this, run a scraper over every piece as you place it.

You want to be gentle so that you do not damage or tear the tape, but you must be firm enough to remove any imperfections. If there is a piece of tape that becomes unusable, tear it off and try again; it is better to waste one piece of tape than an entire print!

Trim the Tape

When sizing up the strip of tape, pull it so it is longer than the width of the plate. Then when placing it, be sure to leave plenty of slack on either side of the plate. With a sharp razor, carefully slice the ends of the tape so it is flush with the sides of the plate.

If you don’t have a razor, it is also an option to wrap the excess tape underneath the bottom of the plate. However, this can affect the leveling of the build plate.

Avoid Touching the Top of the Tape

During this whole process of taping your build plate, try to touch the top of the tape as little as possible. The oils in your fingers can affect the porousness of the tape.

The oils in your fingers can affect the porousness of the tape.

If you are trying to print onto tape that you have been touching a lot, the oils from your hands may keep your parts from adhering to the tape. It is not so impactful that you need to wear gloves to place the tape, but just keep your contact to the tape at a minimum.

Preparing the Surface of the Tape

Once you have your blue painter’s tape on the build plate, there are various ways you can prepare the surface of your tape. Depending on what kind of adhesion you are looking for, you can use different methods for your own work.

You want to find the best balance between adhesion and clean removals that you can. If it has too much grip, the parts will not be easily removed. This could rip the tape or damage the parts. Too little adhesion will keep the printed parts from staying in place.

Unprepped Blue Tape

Leaving the blue tape untreated is a viable way to get adhesion. The porous nature of the tape allows the filament to attach itself, keeping your printed parts in place.

This method of adhesion should give you extremely clean removals. However, for prints that are top-heavy or unbalanced, you may need more adhesion to keep them steady and attached.

Scuffed Blue Tape

A simple trick you can use to add more adhesion to your blue tape is to scuff up the surface. Just take a dry sponge and rub-down the spot that you want to add adhesion to. By doing this, you increase the porousness of the tape, allowing the filament to stick to it even more.

This increases the adhesion of the tape, but it still allows for very clean removal of printed parts. The downside is, it will limit the lifespan of your tape. If you continue scuffing the same spot print after print, the tape will become worn down more quickly and will stop giving you quality results.

Glue on Blue Tape

Another option to greatly increase adhesion is combining blue tape with other methods of adhesion. Spraying hairspray or adhesive spray on top of the tape can give it more grab, and adding glue to the tape can increase it even more!

However, adding too much adhesive can cause problems. If you have a print with a large surface area stuck to the tape, it can be very challenging to remove it cleanly from the build plate.

If you have a print with a large surface area stuck to the tape, it can be very challenging to remove it cleanly from the build plate.

Additionally, while you can clean glue and spray off of the build plate, you cannot clean it off of tape. Using alcohol to clean glue off of the tape ruins porousness, making it unusable for future prints.

When to Add More Adhesion to the Build Plate

The typical rule of thumb is the more surface area that is in contact with the plate, the greater the adhesion will be. This is a good rule to take into account when dealing with bed adhesion. Blue painter’s tape will already provide great adhesion even without any added prep work.

Large-Based Parts

If your printed part has a wide base that will be making a lot of contact with the build plate, it could be unwise to add more adhesion. It could become difficult to remove the part even without added adhesion.

Small-Based Parts

On the other hand, printed pieces that have small legs or slim bases will not attach as firmly to the tape. These pieces may need additional adhesion to keep it in place.

These pieces may need additional adhesion to keep it in place.

The best way to remove a 3D printed part from a taped bed is simply to wrench it loose with your hand. Do this carefully though, because applying too much force could snap your part.

You want to use this method if you can because it will preserve the quality of your tape, letting you use it again for future prints. However, if the adhesive of the tape is too strong, use these tricks to remove your printed parts safely.

Pry with a Putty Knife

After trying to wiggle the printed part free with your hand, the next course of action should be to use a putty knife to pry the piece off of the plate. If you can, slide the knife under a corner and work around the part, gently prying the piece free.

Remove the Tape

If that does not work, then the next step will be to remove the tape from the build plate. You can use your knife to make tears in the tape so you can remove it all.

Spray Isopropyl Alcohol

It is possible that the tape will tear up everywhere except for underneath the part. In this instance, you will want to spray or rub a solution made up of alcohol and water around the base of the piece. Wait a few seconds and the printed part and the tape underneath should remove easily.

Adjust the Height of the Nozzle

If your printed pieces are so hard to remove that you need to resort to removing the tape and spraying alcohol after every print, you may just need to adjust the height of the nozzle. The filament might be taking too long to cool between leaving the nozzle and contacting the plate, so it is seeping too deeply into the pores of the tape.

Start by raising the distance between the nozzle and the build plate by .1mm for your next print. Then continue raising it by this increment until you find that your parts are easy to remove but still have enough adhesion to the bed to get the job done.

When to Remove Blue Tape from a 3D Printer Bed

If you treat your blue tape carefully, you can get several weeks of use (up to 20 prints) out of a single taping. The more care you take with placing and maintaining your tape, the longer it will work for you.

The more care you take with placing and maintaining your tape, the longer it will work for you.

If you need to apply alcohol, tear up the tape, or the filament stops sticking to it, you will have to apply a fresh layer of tape to the build plate.

How to Remove Blue Tape from a 3D Printer Bed

Once you decide that it is the proper time to remove the tape, the process is as simple as unsticking it from the plate. If you have trouble getting it off in spots where parts were built, spray some alcohol and wait ten seconds. It should come off cleanly after that.

Once you have removed all of the tape, you should clean the build plate with alcohol so that there is no adhesive residue left behind. Once you have a clean build plate, you are ready to retape it to begin your next print!

Common QuestionsDoes blue painter's tape work on heated beds?

Because blue painter’s tape is heat resistant, it is able to withstand the heat generated by a heated 3D printing bed. Quality painters tape will not come loose from the bed or become misshapen from the heat.

Quality painters tape will not come loose from the bed or become misshapen from the heat.

PLA and PETG are the best filaments for sticking to blue tape. They seep into the tape, allowing for grip to take place with no extra adhesives applied. ABS will stick to blue tape if you add some sort of extra adhesive.

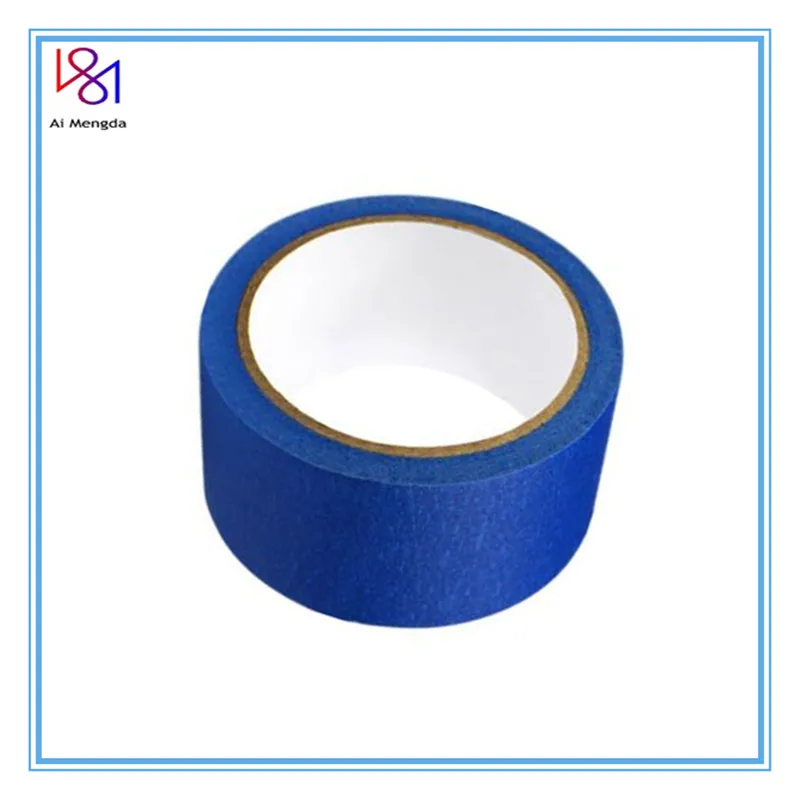

Can masking tape be used for 3D printing?While masking tape can be used for 3D printing, it is not nearly as effective. Even though a roll of masking tape is similarly priced to blue tape, the rolls are typically slimmer so it takes more tape to cover the build plate.

Additionally, masking tape does not remove cleanly like painters tape does, meaning you will have to work a lot harder to clean your build plate once you are done with a layer of masking tape.

Is investing in blue tape to improve bed adhesion worth it?YES! Blue painter’s tape is an extremely cheap way to get bed adhesion for your 3D prints. With other products, you need to worry about potentially damaging your bed adhesives, but a build plate can be covered with blue tape for less than a dollar.

With other products, you need to worry about potentially damaging your bed adhesives, but a build plate can be covered with blue tape for less than a dollar.

Blue tape is cheap, resilient, and simple to use. If you need a simple solution to your bed adhesion problems, blue tape could be the answer you are looking for.

Shop Blue Painter's Tape

The Complete Guide to 3D Printing on Blue Tape

The Complete Guide to 3D Printing on Blue Tape

Created on Thursday, September 28, 2017.

Filed under Physical Objects, 3D Printing.

All the things I’ve worked out about how to use blue tape for 3D printing.

Blue tape is magical

Blue tape is (probably) the most popular 3D printing surface for some really good reasons:

- It’s inexpensive. It costs about 50 cents to cover my platform, and I can keep using that layer until it wears down completely after 10–20 prints.

- You can find it in your local hardware store, so you don’t need to wait for stuff to come in the mail.

- It has very good adhesion for PLA and PETG. I haven’t personally tried ABS yet, but RepRappers say it sticks.

- It can be used on an unheated bed (PLA and PETG only).

- You can damage it without feeling bad. Can’t say that about BuildTak!

- It leaves a pleasant and clean surface on the bottom layer – if you’ve tuned your settings right.

A lot of people have moved on from blue tape to other surfaces like PEI or glass, and indeed many printers now come with a PEI build surface so that newbs can skip all of that and just start printing. But I really like blue tape and I want to help you like it too. This document contains all the things I’ve worked out about how to use blue tape, from what to buy, to how to lay it down, to how to print on it and get it just right.

What is ‘blue tape’?

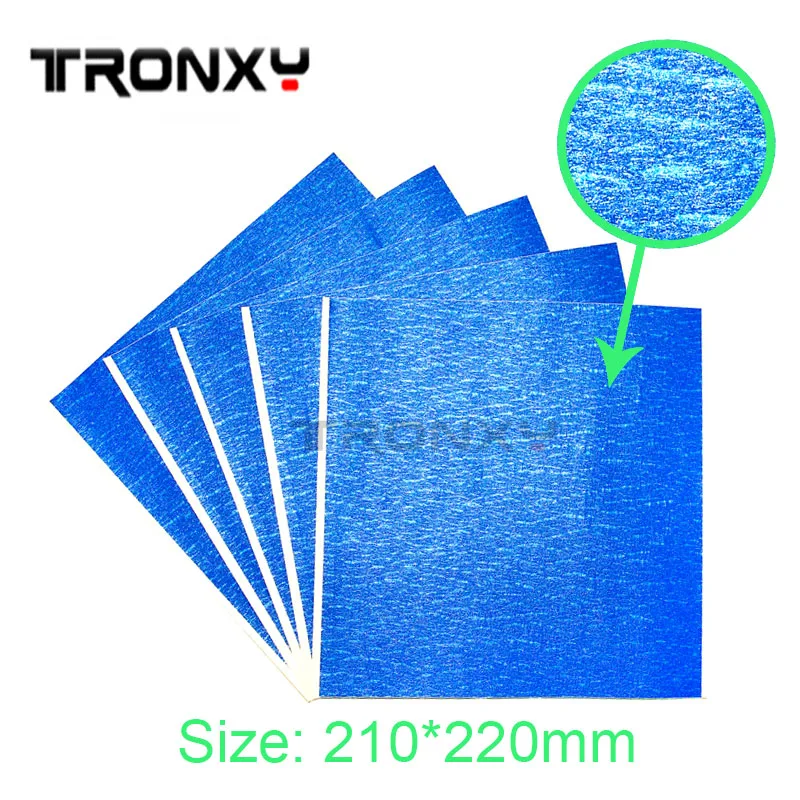

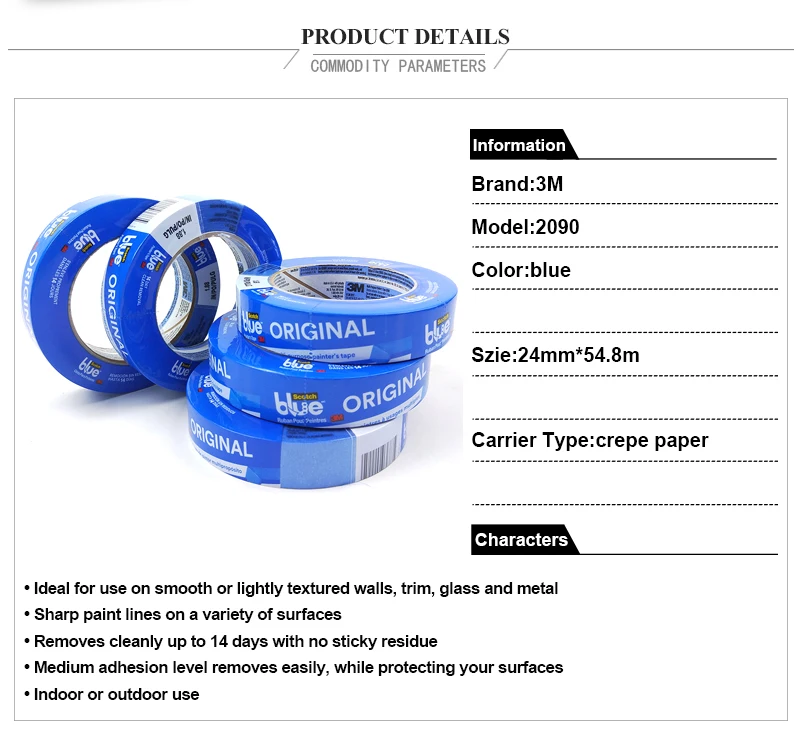

‘Blue tape’ is 3M Scotch-brand #2090 Original Multi-Surface painter’s tape, as wide as you can find it. I use the 49 mm width. You can buy very large sheets of blue tape that are large enough to cover your whole bed at once, but I don’t know who manufactures that and I’ve never worked with it.

I use the 49 mm width. You can buy very large sheets of blue tape that are large enough to cover your whole bed at once, but I don’t know who manufactures that and I’ve never worked with it.

Blue tape is not 3M Scotch-brand #2097 Exterior. I could not get anything to stick firmly to this tape even after wiping it with alcohol, wiping it with acetone, or rubbing it with sandpaper. It will stick for the first layer, but then curl up almost instantly as soon as the next layer hits it. The brand name is also printed on the backing of this tape, and it gets transferred to the bottom layer of the print even if you’ve scrubbed off as much of the ink as you can using acetone.

Finally, other people report success with different 3M tapes like green tape (#2055), but I have not tried these. People report that green tape sticks to the bed more strongly than blue tape does, but both blue and green tape are labelled ‘medium adhesion’ by 3M, so I sort of doubt it.

Finally, 3M does create a heat-resistant version of green tape, but I have not had any issues at all using normal #2090 blue tape on a heated bed.

Applying blue tape to the bed

- Remove any old surface treatments from the bed with rubbing alcohol or acetone and a lint-free cloth. Allow it to air-dry for a few seconds. Don’t skip this step. The tape needs to adhere well.

- Begin laying tape strips diagonally on the bed, starting from a corner and working across. Do not touch the clean bed with your fingers.

- Smooth each strip down with a clean plastic scraper.

-

- Do not allow the strips to overlap; all adhesive tapes are coated with a release agent to prevent the roll from sticking to itself, so strips that overlap will not stick together properly. Remember: a gap is better than overlap!

- You should leave the release agent on the tape if you can – but if you need extra bed adhesion, you can wipe it off with some rubbing alcohol or acetone and a lint-free cloth.

Why should I lay my tape out diagonally?

3D-printed parts tend to have a lot of straight edges. If those edges are close to the edge of a strip of tape, then the part will peel the tape up as it warps. You can position your object so that it spans multiple strips of tape, or you can rotate all of your parts by 45° when you slice them, or you can lay the tape diagonally and not think about it anymore. The difference is significant on an unheated bed.

If those edges are close to the edge of a strip of tape, then the part will peel the tape up as it warps. You can position your object so that it spans multiple strips of tape, or you can rotate all of your parts by 45° when you slice them, or you can lay the tape diagonally and not think about it anymore. The difference is significant on an unheated bed.

The table below shows how corner-curling is influenced by the direction that the tape is laid down. This was done on an unheated bed, so the curling is huge compared to the numbers I show later in this article. The test object was a 30×30×5 mm box with rounded corners. ‘Corner shrinkage’ is how much the corners of a box have shrunk compared to the center of the box. ‘Corner gap’ is how far the corners have risen off the bed, and it was measured by clamping the box to a flat plate and using a feeler gauge to measure the gap between the plate and the corner.

| Tape direction | Corner shrinkage (mm) | Corner gap (mm) |

|---|---|---|

| Diagonal | 0. 14 14 | 0.17 |

| Horizontal | 0.28 | 0.31 |

Printing on blue tape

The first layer

The most important things for blue tape are nozzle distance (AKA first layer height) and first layer temperature. The easiest way to tune nozzle distance is to start too close to the bed and work your way back. For example, for a 0.20 mm layer height you might start with a 0.10 mm nozzle distance and rise by 0.02 mm until you find a nice height.

The first layer on blue tape follows all the usual rules:

- The lines should be laid perfectly beside each other, making full contact with the neighbouring lines.

- The line should be pressed down, but not completely flattened. If you observe the edge of the line becoming wavy as it is extruded, you are too close.

- When you run your finger parallel to the lines, the surface should be smooth. Any roughness means that you are too close.

Troubleshooting adhesion on blue tape

If you know that your nozzle distance is correct but you’re still having trouble with adhesion, try these:

- Are you sure your nozzle distance is correct? Use a feeler gauge to measure and set it properly.

- Disable the cooling fan for the first layer.

- Print the first layer at +10 °C nozzle temperature.

- Print the first layer at +10 °C bed temperature.

- Print the first layer more slowly.

- Finally, try scrubbing the release agent off the tape.

Things you should

not need to do for adhesion- You shouldn’t need to sand blue tape.

- You shouldn’t need to put glue or hairspray on blue tape.

- You shouldn’t need to grind the plastic into the blue tape with a low nozzle.

Avoid doing any of these things. Not only do they mask the actual cause of your adhesion problems and create dimensional inaccuracy, but they also make the bottom surfaces of your prints dirty by leaving a layer of glue or by embedding tape fibres in the bottom layer.

What bed temperature should I use with blue tape?

That really depends on your material, but a good rule of thumb is your first layer should be at the glass transition temperature, and then you should print the rest about 10-20 °C colder than that. A hotter first layer gives the plastic more time to spread into the blue tape and adhere to itself.

A marked advantage of using blue tape is that it’s difficult to over-adhere the plastic, so you can print hotter. When I was printing on PEI I had to use a lower bed temperature or else the plastic would stick tight, and it became very hard to remove the print without damaging the PEI. But with blue tape I can crank the bed temperature up and reduce my warping without making the prints harder to handle.

The table below shows how the corner gap (the gap between a flat plate and the corner of the test print, as previously explained) is affected by the bed temperature. In all of these cases, the part popped off the bed with an easy twist of a spudger. When I tried to do this test on PEI, I did not feel comfortable raising the bed temperature above 50 °C because the print was difficult to remove safely. In that case, corner gap was 0.06 mm on average.

When I tried to do this test on PEI, I did not feel comfortable raising the bed temperature above 50 °C because the print was difficult to remove safely. In that case, corner gap was 0.06 mm on average.

| Bed Temperature (°C) | Corner gap (mm) |

|---|---|

| 40 | 0.10 |

| 50 | 0.14 |

| 60 | 0.08 |

| 70 | 0.04 |

How do I remove parts from blue tape?

Grab your spudger or spatula and work it under the corner of a print, and then give it a twist. If you need to rip the blue tape to remove the print (particularly if you’re using an unheated bed), then you should increase the nozzle distance next time.

I have found that it is easier to remove prints from a heated bed than an unheated one, even when the bed is at room temperature during print removal. My hypothesis is that at the end of a heated-bed print, the plastic pulls away from the tape more uniformly as it cools.

What kind of surface finish does blue tape give?

The bottom face comes out matte or semi-gloss depending on how new the tape is. The layer lines are almost always visible, and the texture of the tape itself is faintly imposed. No blue tape should be stuck on the print – if it is, either you have done one of the things-to-avoid that I listed above, or the tape is worn and needs to be replaced.

I personally love this finish. It’s visually pleasing, similar to many semi-gloss manufactured plastics. Compared to the shiny smoothness of something printed on glass, the bottom face of a blue tape print doesn’t grab your attention by being different from the other faces. The texture is pleasingly tactile like a super-smooth Kraft paper, and it fades into the background when you put other elements on top of it, like buttons and switches on an electronics enclosure.

How often should I replace blue tape?

Blue tape is very durable, so the short answer is that you should replace it when you feel that your current layer won’t be good enough for your print. I’ve used the same layer for two weeks and had it look like new, and I’ve printed tens of identical test objects in exactly the same position and worn it down to fibres, and it still grabbed the plastic. I’ve ripped slivers of tape up, and then just stuck those slivers back down and printed over them. But whenever I had a big flat object that I didn’t want to warp, or if I wanted a very good surface finish on the bottom face, I always replaced the tape.

I’ve used the same layer for two weeks and had it look like new, and I’ve printed tens of identical test objects in exactly the same position and worn it down to fibres, and it still grabbed the plastic. I’ve ripped slivers of tape up, and then just stuck those slivers back down and printed over them. But whenever I had a big flat object that I didn’t want to warp, or if I wanted a very good surface finish on the bottom face, I always replaced the tape.

That's all there is, there isn't any more.

© Desi Quintans, 2002 – 2022.

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

What do you use to keep your blue ribbon from rising?

adhesion build plate monoprice-maker-select masking-tape

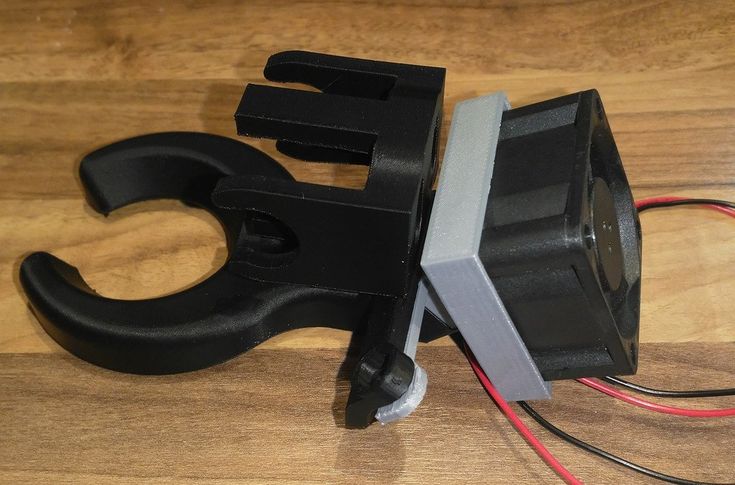

I'm having a few issues with the blue tape I'm trying for the first time.

Ribbon appears to warp, bubble, and peel off the aluminum plate when it is heated and cooled and during printing. I've put a few clips on it, but I'm not sure if that's the standard.

The print also seems to come off the ribbon itself (lower left corner). I applied some magic glue to it. Perhaps I shouldn't have done this. nine0003

I feel like this print won't do it...

I'm printing with Monoprice Select V2, AmazonBasics ABS with a 100°C bed and extruder temperature of 250°C, with a seed bed speed of 15mm/s and print speed of 60mm/s sliced with Ultimaker Cura.

@kane, 👍3

6 answers

▲ 2

My dad uses the print stick on the table before printing and the table keeps the print stick at the right temperature for it to stick. nine0003

, @ Bin-Yamin Ali

▲ 4

Your printer has a built-in tac clone surface. The blue tape doesn't stick well to this: you'll get better results by printing directly onto a Build-Tac clone.

The blue tape doesn't stick well to this: you'll get better results by printing directly onto a Build-Tac clone.

Masking tape I use only on flat surfaces: it works well directly on glass, aluminum or unheated fiberglass, but it is absolutely necessary to take into account its thickness when leveling. nine0003

, @ Trish

▲ 4

The tape would probably adhere better to the aluminum table than the cloned BuildTak sheet you have, as it would have more surface area to mount.

What I have found to work best is printing on a bare aluminum table with a PVA based spray, this could be hairspray or a specific 3D printer like 3DLAC or just a glue stick. I threw the ribbon away after the first day (for the reasons you mentioned) and only print on aluminum or glass with no problems, sometimes it sticks too well and the table has to cool to room temperature before I can remove the print. This has been described as an answer to the question: Should hairspray be used on a metal desktop 3D printer? . nine0003

This has been described as an answer to the question: Should hairspray be used on a metal desktop 3D printer? . nine0003

Removing a BuildTak clone sheet can be quite laborious if a very sticky adhesive is used (it took me a long time and a lot of solvents to remove the slime/adhesive from a PEI sheet I used once), better try printing on a BuildTak sheet, maybe use PVA-based spray (for hair) or glue stick.

In addition, ABS is more difficult to print than PLA or PETG. ABS printing is difficult due to the relative large shrinkage on cooling of the filament. Therefore, it requires careful heat management (no cooling of parts, traction, fencing, etc.). This thread needs a good surface to build on and requires edges, mouse ears, glue spray or glue to get the first layer to stick and not curl. Tape at 100°C will become soft and lose its ability to stick. Kapton's tape could have worked better. nine0003

, @ 0scar

▲ 0

The absolute best way to solve the sticking problem is with an overture assembly surface. I couldn't get anything to stick. Got a free build sheet when I bought a filament from them. What's the difference, now everything sticks, just cleaned with alcohol between uses.

I couldn't get anything to stick. Got a free build sheet when I bought a filament from them. What's the difference, now everything sticks, just cleaned with alcohol between uses.

, @ Joe Wesley

▲ 1

Old thread, but I have a direct answer to the specific question asked. This is a technique that I haven't seen documented elsewhere and works pretty well for me. nine0003

- Clean the glass plate with an isopropyl alcohol swab - allow to air dry completely.

- Apply blue tape (the two most famous, well-known brands work best) to the glass plate, ensuring there are no overlaps - small gaps are fine.

- Place the plate on the heated table with the tape down.

- Turn on the tabletop temperature to 50 °C for about 3 minutes.

- Remove the sheet quickly and roll the entire surface of the tape tightly with a wallpaper seam roller while the adhesive tape is still warm.

Learn more