Open closed 3d print

Free STL file Open-CloseD sign・3D print design to download・Cults

Crocus, Forget-me-not, flowers

Free

Vickers machinegun

Free

Magic Faucet with flowing water

Free

Clerget 9B rotary aero engine

Free

Escher Fish #20

Free

Eyeballs and eyebrows for JamesRX's Olaf

Free

Peugeot 206cc 2005 Key unlock button

Free

Ellipse-Heart

Free

Best 3D printer files of the Art category

Low Poly Figure v2

€4.70

Spooky Flexi Gecko Skeleton (magnet version included)

€2. 81

Iceland

Free

Minion Kevin Rabbit (Easy print no support)

€1.25

Flexi JellyFish

€0.92

Deer God Mask Simple + Wooden Version

€9.40

Smartphone and Apple Watch charging stand

€4.71

WiCat

Free

Best sellers of the category Art

CUTE FLEXI PRINT-IN-PLACE CROCODILE

€2.77

Cute Flexi Print-in-Place T-Rex Dinosaur

€2.77

Thing

€7 -50% €3. 50

50

Cute Flexi Print-in-Place Sloth

€2.77

Bearded Dragon Articulated Toy, Print-In-Place Body, Snap-Fit Head, Cute Flexi

€3.27

Flexi Print-in-Place Astronaut

€2.77

Biting dragon

€3

Adorable Articulated Axolotl, Print-In-Place Body, Snap-Fit Head, Cute Flexi

€3.27

The Annoying Gift Box

€2.82

Baby Crystalwing Dragon, Cinderwing3D, Articulating Flexi Wiggle Pet, Print in Place, Fantasy

€3.76

Flexi Print-in-Place Skeleton Hand

€1.87

Flexi PRINT-IN-PLACE Hand

€1.83

Cute Flexi Print-in-Place Elf

€1. 83

83

Rose Dragon, Valentine's Day, Articulating Flexi Wiggle Pet, Print in Place, Fantasy

€3.82

CHRISTMAS TREE WITH LEGS

€2.89

Flexi Print-in-Place Triceratops

€2.77

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

▷ closed open sign 3d models 【 STLFinder 】

Open / Closed (Nope) Sign

thingiverse

OPEN / NOPE SIGN An open / closed sign with attitude.

Open/Closed Sign

thingiverse

Open and Closed sign with gears. ...I haven't printed it yet, I'll update when I do!

Open/Closed Sign

myminifactory

A useful object that we also have in our workshop :) It's an open/closed sign (in Greek) with a custom made font.

Open/Closed sign

youmagine

A collaboration with our friends at http://synergastirion.tumblr.com/ who designed the beautiful font for our custom made open/closed sign for our shops. (The sign is in greek for those wondering)Print the 3 files and glue them together to create...

Open/Closed Sign

thingiverse

A collaboration with our friends at http://synergastirion.tumblr.com/ who designed the beautiful font for our custom made open/closed sign for our shops. (The sign is in greek for those wondering) Print the 3 files and glue them together to create...

Cage Open/Closed Sign

thingiverse

. .. a simple sign that I could put on the outside of their room to let us know if they are in their cage or not. The outer panel should slide across the Open and Closed signage. ...

***Untested print***

Probably need supports for the overhangs

.. a simple sign that I could put on the outside of their room to let us know if they are in their cage or not. The outer panel should slide across the Open and Closed signage. ...

***Untested print***

Probably need supports for the overhangs

Open Closed Entrance Sign

thingiverse

A sign I made for my partner business.

Open/Closed Sign

thingiverse

Inspired by Ikeda Yosuke's open/close sign design which relies on gravity and relatively frictionless joints, I decided to design one using planetary gears to drive the movement of the letters. An animation of the transition can be seen here:. ..

..

Open / Closed Sign

prusaprinters

Inspired by Ikeda Yosuke's open/close sign design which relies on gravity and relatively frictionless joints, I decided to design one using planetary gears to drive the movement of the letters. An animation of the transition can be seen here: <a...

OPEN/CLOSED Shop sign

cults3d

... status of it with a cool 3d print. ... The print stands up by itself, the weight is divided by the two sides, and it's pretty cool to see it standing up, since the main sign is connected to the base with a very thin piece, but it holds up very well.

OPEN / CLOSED DOOR STORE SIGN

thingiverse

Hello , this thing is a simple door store sign for open / closed time. ...

Print in your favorite colour ( also for avoid client's shocks with glass doors...) ;)

Just for glass door add a suction hook and you are done !

...

Print in your favorite colour ( also for avoid client's shocks with glass doors...) ;)

Just for glass door add a suction hook and you are done !

Laser cut open n closed sign

thingiverse

Open n closed is sign I made for a request and task has been completed...Material used 3mm acrylic with 3 face plates.....Blank one in the middle and the other 2 on each side like a sandwitch... ... Thank Sheeraz

Open-Closed Sign - Vintage Open-Closed Sign - Red and Black Sign Low-poly 3D model

cgtrader

Antique tin styled open-closed reversible sign, with metal handle. Detailed with scratches, paint wear and dust. Fully tested in all formats included. Polygons: 1320 Vertices: 688 File formats: FBX OBJ Textures: PBR textures, 2048 x 2048,...

Detailed with scratches, paint wear and dust. Fully tested in all formats included. Polygons: 1320 Vertices: 688 File formats: FBX OBJ Textures: PBR textures, 2048 x 2048,...

Open-CloseD sign

thingiverse

Still W-I-P. Sharing because comments on the original asked for some of these improvements, and because several things changed from Quintox303's design: Added the D Pins/holes to locate the letters accurately. Two-part base for printing on smaller...

Door Open/Closed Sign

thingiverse

I made this for my wife's office. She works in a cubical and people are always stopping by and interupting her work. She may not have a door but now people can know when her 'door' is closed and when she is free to chat!

This object was made in...

She may not have a door but now people can know when her 'door' is closed and when she is free to chat!

This object was made in...

Open-CloseD sign

prusaprinters

<p>Still W-I-P. Sharing because comments on the original asked for some of these improvements, and because several things changed from Quintox303's design:</p> <ol> <li>Added the D</li> <li>Pins/holes to locate the letters accurately.</li>...

Open-CloseD sign

cults3d

Still W-I-P. Sharing because comments on the original asked for some of these improvements, and because several things changed from Quintox303's design: 1. Added the D 2. Pins/holes to locate the letters accurately. 3. Two-part base for printing on...

Added the D 2. Pins/holes to locate the letters accurately. 3. Two-part base for printing on...

flanged parts on modified open/closed sign cog wheel

thingiverse

I used the cog wheel from bmscott (Modified Open/Closed Sign Parts (easier), but still broke it off, so decided to make compatible plugs which fit in the holes of the wheel. This way, you can just use the printed wheel. Break off again? no problem,...

Open Closed

cults3d

C'est ouvert? ...Ou bien c'est fermé? Le loquet rouge coulisse entre open ou closed au choix.

Open / Closed sign geared - REMIX

thingiverse

You will need some glue and silicone lubricant. There ist only one part that needs support (joiner new).

...

There are 3 options for the left gear:

- just the gear

- the gear plus a crank to glue on (like i did)

- the gear with crank as one...

There ist only one part that needs support (joiner new).

...

There are 3 options for the left gear:

- just the gear

- the gear plus a crank to glue on (like i did)

- the gear with crank as one...

Open Sign

prusaprinters

Open sign

Open Sign

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=40705 Instructions Using the following options: font_one_size = 60 manual_length = 100 Font = write/orbitron.dxf hole_radius = 0 icon = 5 font_two_size = 30 emboss_style = 0 manual_width = 100...

Closed sign

thingiverse

Closed sign

Modified Open/Closed Sign Parts (easier)

thingiverse

I've added cutouts to the flanged parts so they are a tiny bit flexible, which makes them far easier to assemble without breaking. ... I've also attached the extender to the right-side gear, eliminating the need to glue it on (at the cost of a small...

Cupola open & closed

thingiverse

2 kinds of simple cupolas. ... one is open, the other closed. ... The picture shows the cupola on top of my glass dome.

Door Open / Closed Latches

thingiverse

... screws with the longer black ones that came with your printer. The Open Latch used the original screws. Print Settings Printer: QIDI TECH 1 Dual Extruder Rafts: No Supports: Yes Infill: 100% Notes: Rafts are only needed on the Open Latch portion.

Milk Carton (Open & Closed)

prusaprinters

Easily scalable milk carton that can be used as a prop or decoration. Two files:Milk carton openedMilk carton closed No support needed. ...Please post your makes!</p>

Two files:Milk carton openedMilk carton closed No support needed. ...Please post your makes!</p>

Tunable "Open/Closed" Headphones

pinshape

Closed Earcups: Print earcups large open-end down, print the back plate logo side down. Arms: The print settings should allow for a small 0.2mm gap in the middle of the arm structure, which is for the "flex". You will also need to fill the bolt-slots...

Tunable "Open/Closed" Headphones

thingiverse

Closed Earcups: Print earcups large open-end down, print the back plate logo side down. Arms: The print settings should allow for a small 0. 2mm gap in the middle of the arm structure, which is for the "flex". You will also need to fill the...

2mm gap in the middle of the arm structure, which is for the "flex". You will also need to fill the...

Open Sign - Neon

sketchfab

Open Sign - Neon

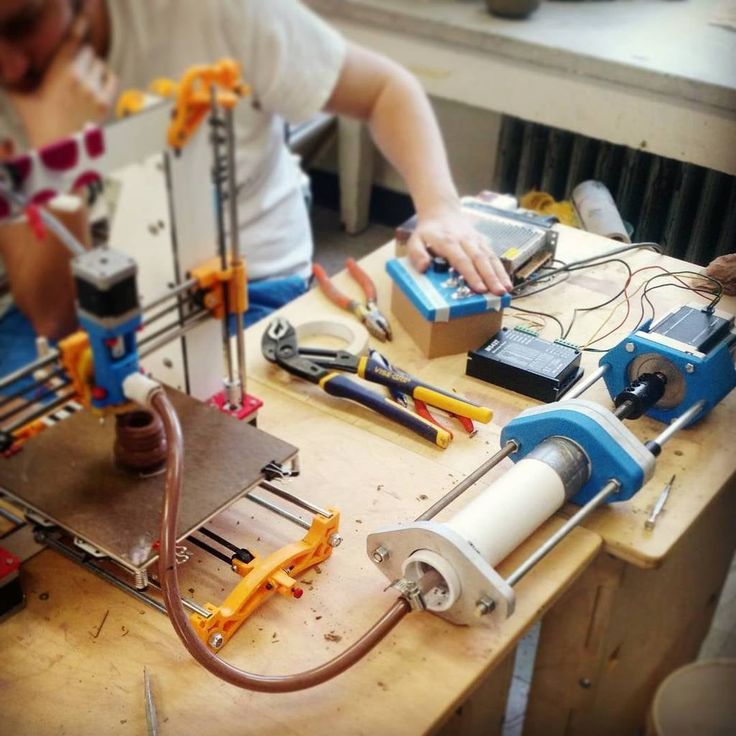

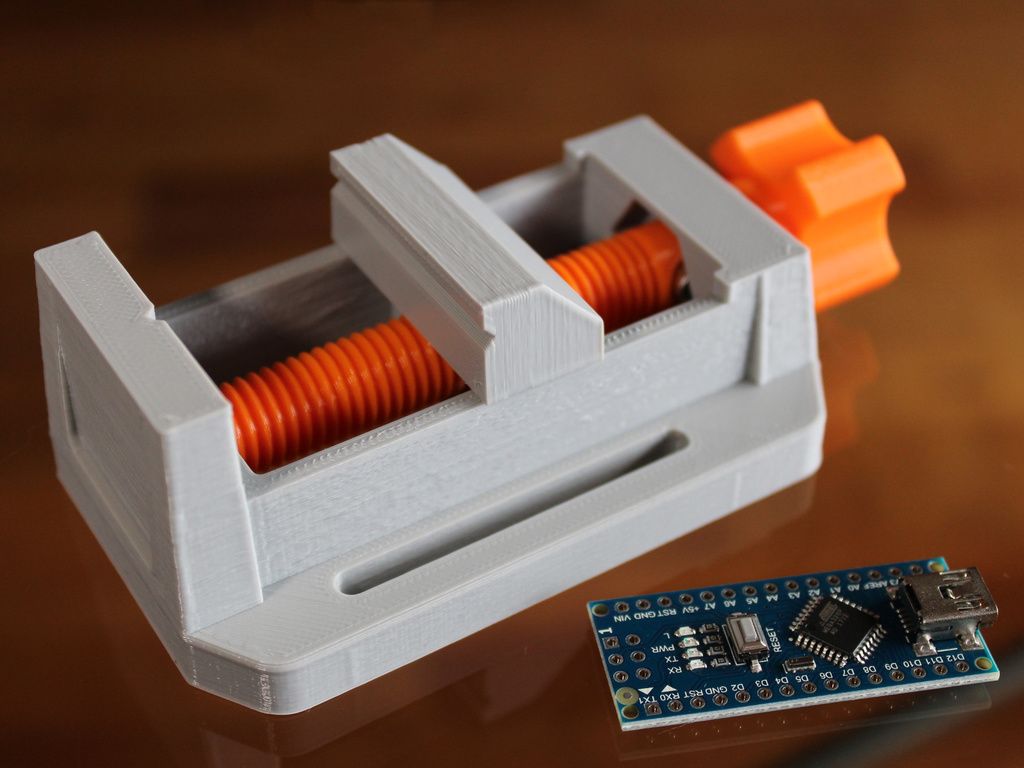

3D printed mesh fabric

Prologue

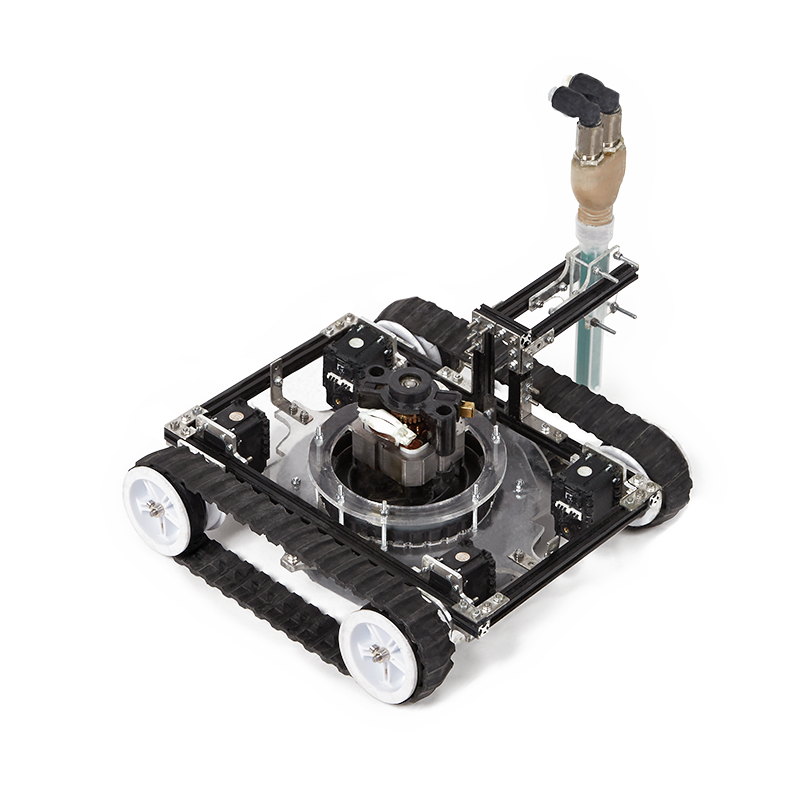

Hello everyone! I am developing "smart sequins" - electromechanical color-reproducing devices for designer clothes. Our team is passionate about the idea of creating clothes and accessories that can change their color at the request of the owner or depending on environmental conditions.

In this article I want to talk about how we used 3D printing in our project, share our experience and tools. nine0008

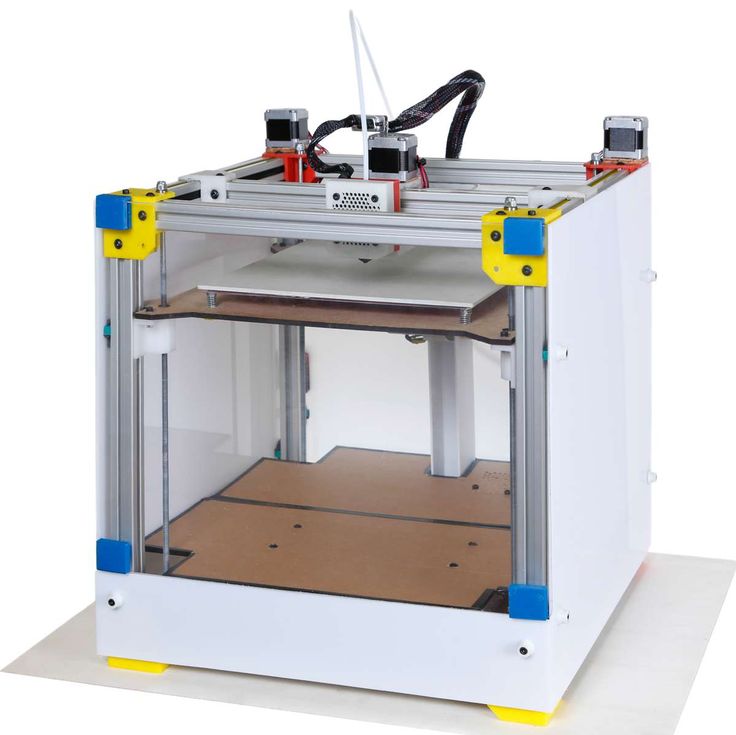

3D printing on fabric

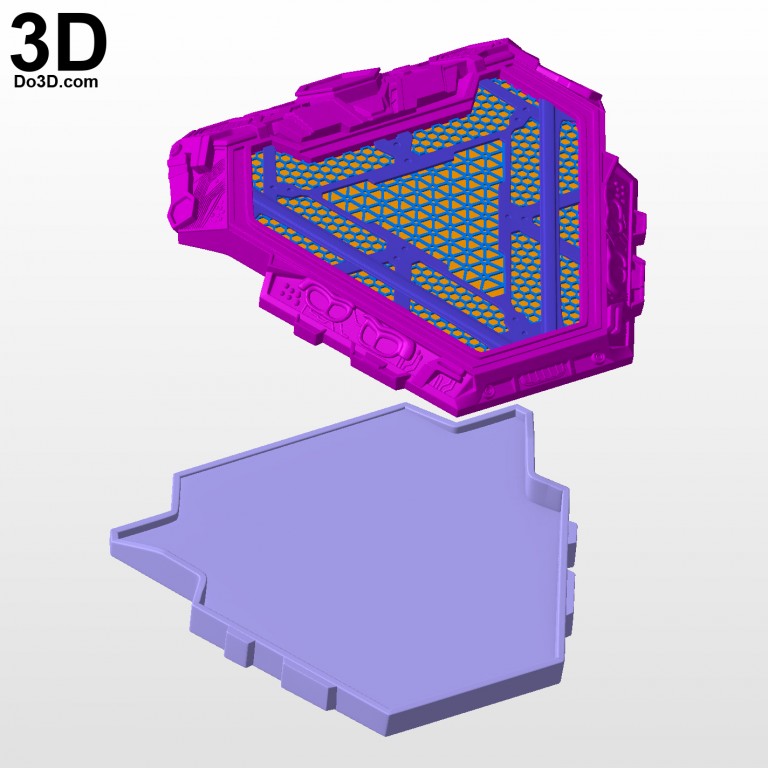

One of the tasks that I had to solve was to figure out how to make an elastic fabric out of plastic sequins, which in its properties would resemble textile materials. At the same time, it is necessary to provide for the possibility of easily creating electrical connections between the sequins.

There are quite a few articles and materials on making clothes on a 3D printer. Many different methods have already been invented, from creating hinges right in the printing process to printing with elastic plastics. nine0008

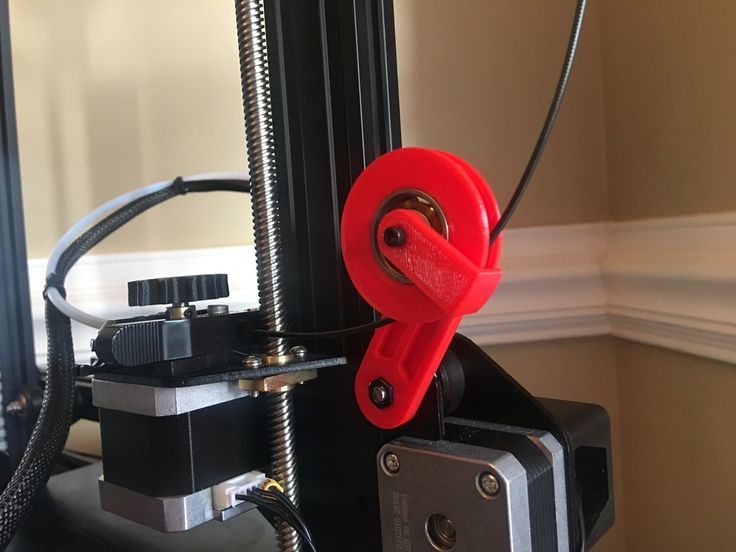

While looking for a solution, I came across this video. From it, I first learned about the method of printing on mesh fabric using a conventional FDM 3D printer.

The author himself claims that he spied the idea here: Shorey Designs.

The essence of the method is very simple. We create a 3D model of a fragment of the future canvas, then arrange a lot of fragments so that we get a whole canvas. We start the slicer and prepare the G-code. Before sending it to the printer, you need to insert a pause and raise the extruder before printing a certain layer. The printer will stop during operation. At this point, we cover the printed layers with a mesh cloth. We continue to print. Due to the presence of large holes in the fabric, the layers of plastic will interlock with each other, as in conventional printing, and the mesh fabric will be firmly integrated into the parts. nine0008

We continue to print. Due to the presence of large holes in the fabric, the layers of plastic will interlock with each other, as in conventional printing, and the mesh fabric will be firmly integrated into the parts. nine0008

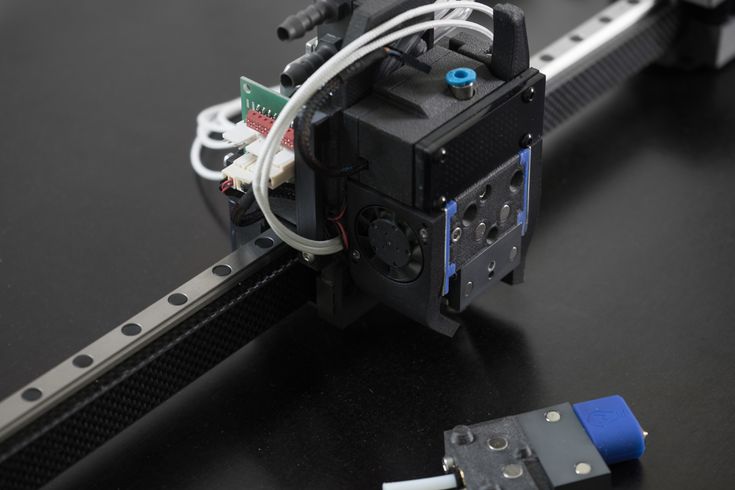

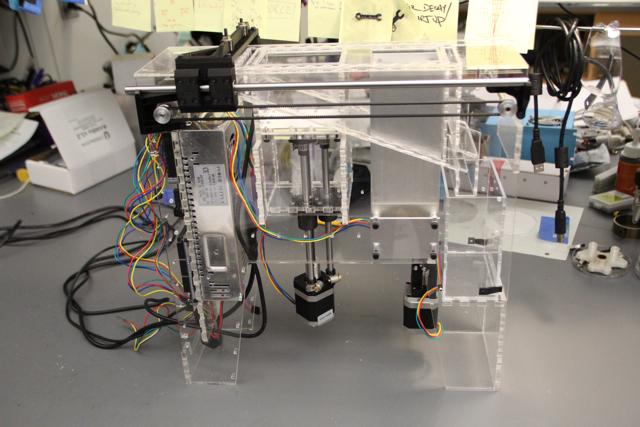

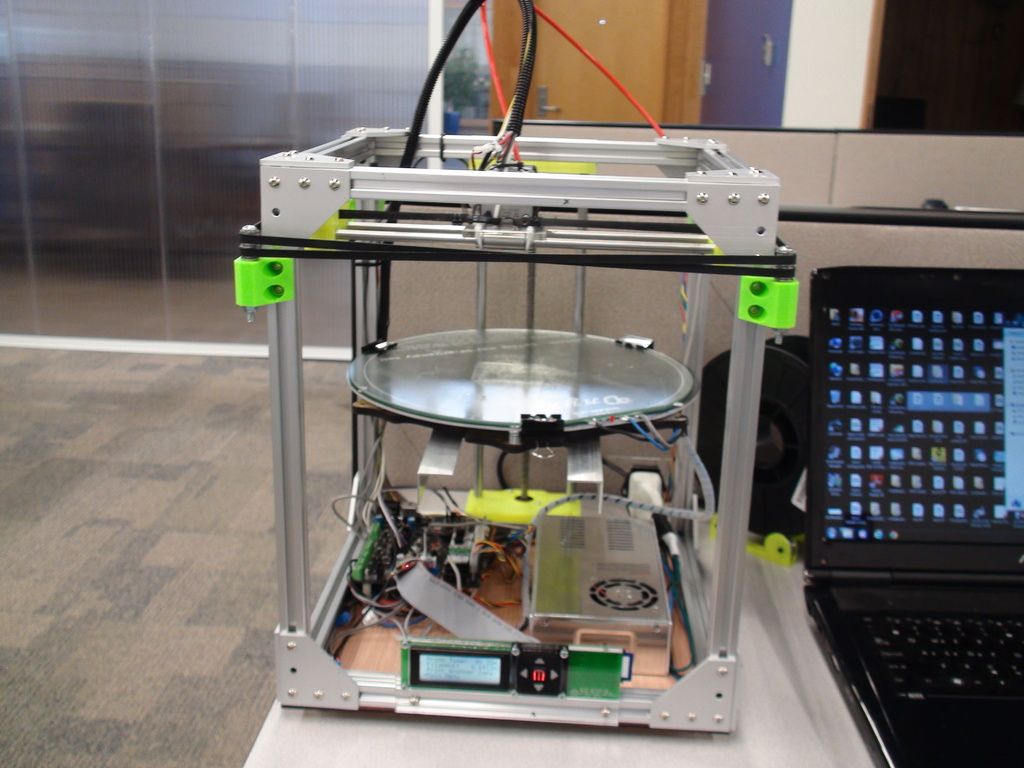

Modifying G-code

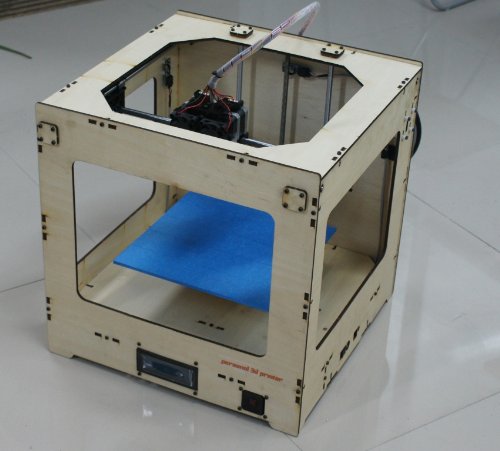

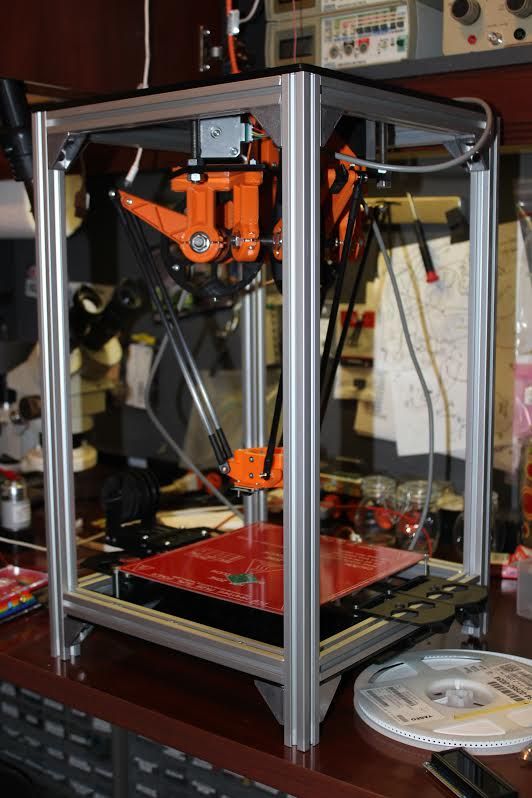

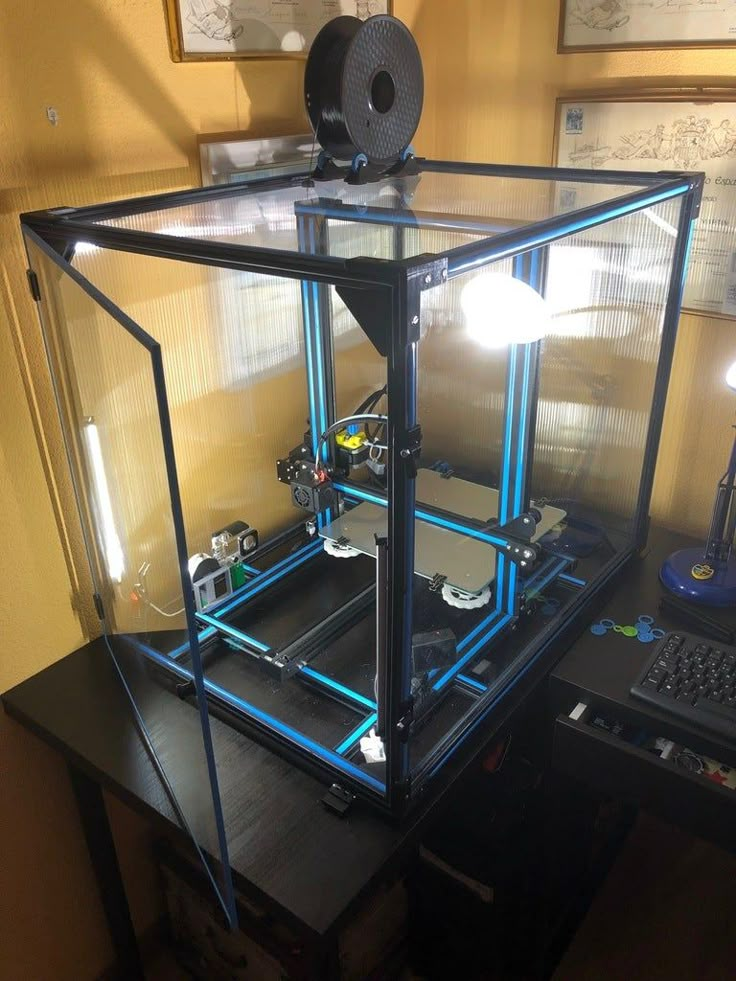

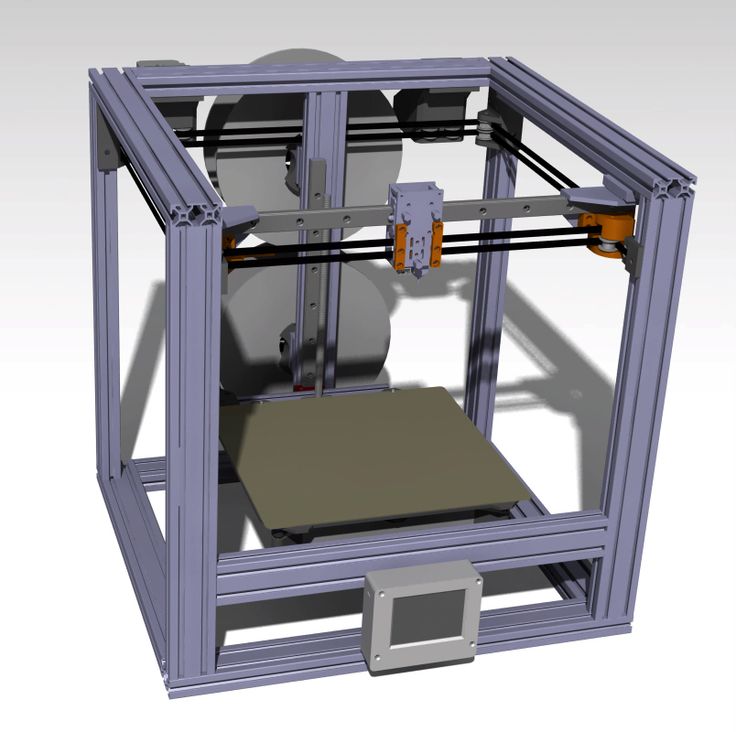

I use Cura version 3.2.1 as a slicer. 3D printer - homemade H-bot controlled by a board based on ATmega2560 (RAMPS 1.4) with Marlin firmware.

To pause the printer, there is an M25 command. Command for lifting in Z by 20mm: G0 Z20. It is noteworthy that the M25 must go before the ascent, otherwise the next command is processed first. Why this happens is a mystery to me, apparently somehow connected with the processing of commands by the printer. nine0008

Add commands to G-code:

Operation automation

Manually searching for the required line in the G-code file and inserting commands is not the most modern solution, I thought and wrote a simple program that allows you to open and view toolpaths.

For the convenience of viewing the layers, the “explode” command is provided, which allows you to visually increase the distance between the layers of the model. After pressing the "insert pause" button, the distance between the marked layer (red) and the previous one increases. This means that the print will be interrupted precisely between these layers. nine0008

To understand where one layer ends and the next begins, I used the comments that Cura kindly provides in its output files. The keyword ";LAYER:X" allows you to accurately find the boundaries of layers in a text file.

Pressing the "write file" button allows you to save the modified G-code in the specified location.

Save the file to the SD card and bring it to the printer.

It's funny that only while preparing this article, I came across a video that tells how you can do the same using standard Cura tools ... But the process is already running, it's too late to slow down! nine0052 Here, starting at 7:30, it is described in detail how to do it.

Well ... hurry up - learn how to parse G-code!

Trying to print

Formation of the first layers. We print on glass. Heated table. Table temperature 60⁰С, printing temperature 220⁰С. The print material is PLA plastic. Layer height 0.2mm.

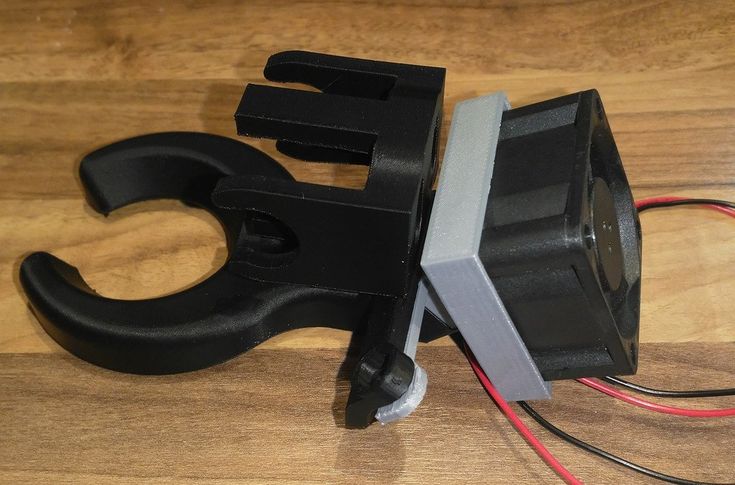

During the pause, place a piece of fabric and fix with magnets. Since the table is aluminum (paramagnetic), we put the magnets on the top and bottom sides of the table. Fixation is made in 4 places, in the corners of the part. This is quite enough. The main thing is not to place them too close to the print area, otherwise the magnets will stick to the print head. nine0008

After 40 minutes, this is the structure. The thickness of each 6 carbon element is 1mm. The gap between the elements is 2mm.

In this experiment, tulle was used as the backing fabric. It is a lightweight mesh fabric of medium stiffness, woven from polyester threads.

Experiments have also been made with mosquito net printing. In the hardware store, there were two types of them: fabric and fiberglass. Fabric mesh is softer than tulle, but has greater mechanical tensile strength, as well as less elasticity. The fiberglass mesh is harder than tulle, its mechanical strength is the highest of all participants in the experiment. nine0008

Hexagonal sequin printing on fiberglass mosquito net. The gap between the elements is 1mm. The matrix is very hard. Clearance is clearly not enough.

Round sequin printing on fiberglass mosquito net. The gap between the circles is 2mm. It has a lot of flexibility, but there is too much unfilled space between the sequins.

After several test prints, the fabric mesh was chosen. She formed the basis of the matrix of smart sequins. The resulting matrix can bend in all directions. nine0008

The video demonstrates the operation of the program, the printing process and the final result.

Conclusion

The method of printing on mesh fabric proved to be very good. This is an ideal solution for our task, because the fabric substrate allows us to weave conductive threads into it, which are used to provide electrical connection between the individual sequins of the matrix. Moreover, the formation of a “pattern” of conductors can be carried out at the preparatory stage. And the 3D printing itself is later. nine0008

The strength of the resulting structure depends mainly on the strength of the substrate material. But the flexibility will also depend on the distance between the sequins, as well as their shape.

The developed program still needs to be improved. For example, you can finish the retract before lifting, allow the user to adjust the height of the extruder.

Link to the source code for the processing environment.

And also a link to the release with the .exe file of the program.

By the way, we recently launched our "smart sequins" on the crowdfunding platform. For those who want to get to know our work better, I will leave a link. nine0008

Blender 3D for 3D printers

Correct position! But some problems can still be covered by polygonal modeling.

Gathered here the answers to the four most common and non-obvious problems.

Dimensions

When I tried to order 3D printing from a company for the first time about seven years ago, it was like this:

— Igor! You sent an empty file! nine0110 - No! Here's a screenshot, well!

One meter in the Blender is equal to one millimeter in the slicer, nothing has changed in these seven years.

Designing in meters is wonderfully inconvenient, so when exporting to STL / OBJ, set the Scale value to 1000:

Closed geometry The ability to create open geometry is both a scourge and a bonus of polygonal modeling.

In the modern world, slicers (not all) have learned to work with this, but there may be surprises: want a hole? get a blank wall! nine0008

If you don't like surprises, you should use Blender's geometry analyzer.

In the mesh edit mode, select the vertex selection, and click Select → Select All By Trail → Non Manifold

To eliminate such trash as on the right ball, there is a Merge By Distance tool. Lives in Mesh → Clean Up → Merge By Distance.

In other cases, it is necessary either to give the wall thickness by extruding, or to close up the hole, or is this geometry really necessary? nine0008

Now for the good news: in Blender 2.8 the 3D printing addon is built right into Blender, hooray! Geometry analysis just got easier. You just need to turn it on, and in the edit mode in the N-panel everything will be (and even the preliminary volume of the model!).

Flying geometry

As unclosed, only flying. So the slicer can still try to shove it into the G-code!

So the slicer can still try to shove it into the G-code!

The annoyance is that if the volume of the walls was made by a modifier, these mesh pieces can no longer be found with the Non Manifold tool. nine0008

Select any polygon on the target mesh, and use the Ctrl+L hotkey: it will add all physically connected polygons to the selection. After that, invert the selection with the Ctrl+I hotkey and delete everything you don't need.

Normals

Roughly speaking, the polygon has a "face". When the polygon enters the slicer, the slicer looks at where the polygon has a “face”, tries to fill the wrong side with plastic, and at the same time checks for overhangs.

Accordingly, a cube with normals inside will be perceived clumsily. In fairness, in modern slicers this is no longer so important. nine0008

The solution is super-simple: turn on the display of normals:

Turn in the right direction: select the polygon with the normal turned inside out and press Alt+N.