3D printer with hepa filter

Why you won’t find a HEPA filter hanging on the back of our enclosures – Printed Solid

First we should talk about 3D printer enclosure designs and why you may want one. Enclosures serve three main purposes. 1) It helps keep heat in and prevent drafts over your build volume. 2) It keeps pets and hands away from hot ends and beds and pinch points. 3) It can help control VOC’s (volatile organic compounds)

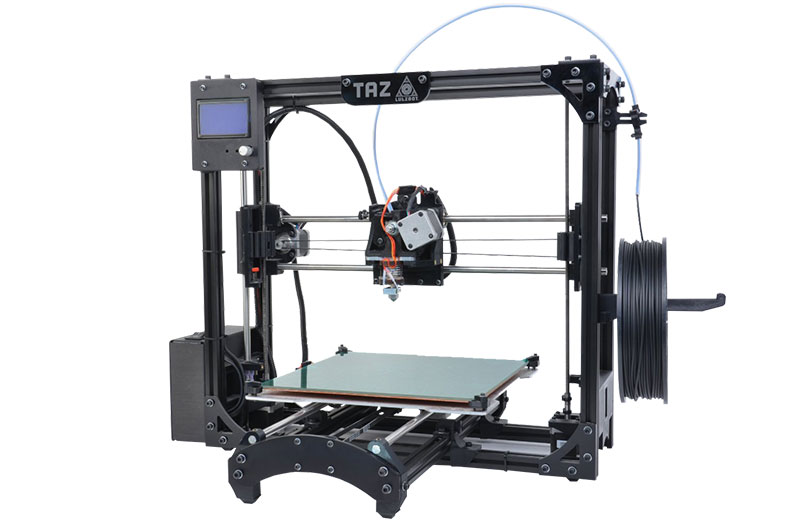

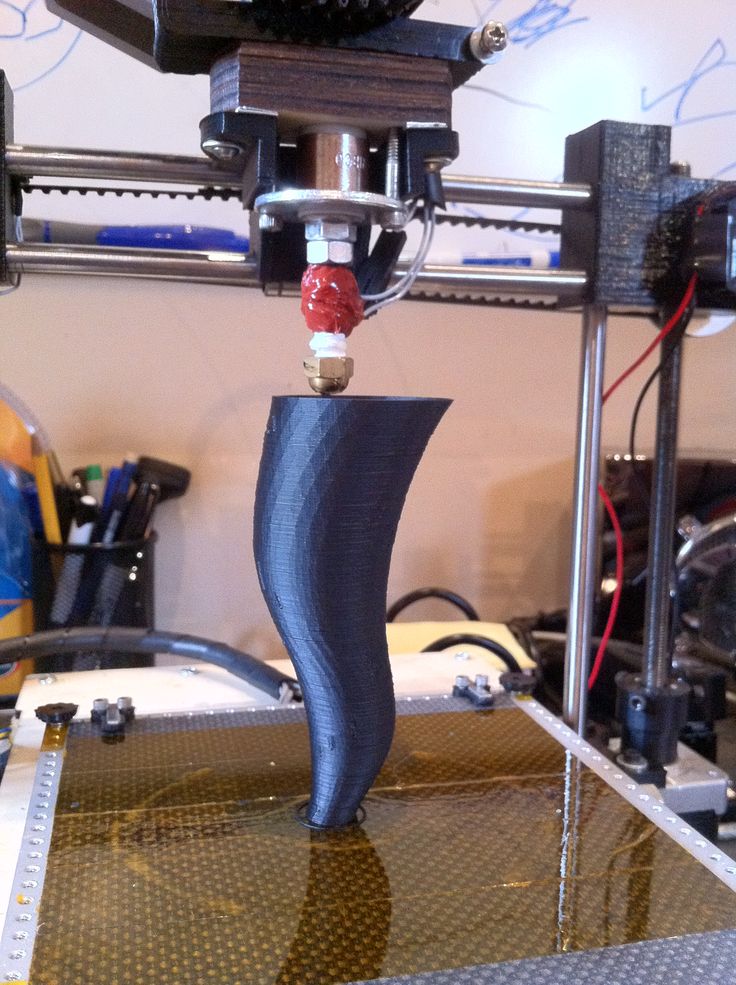

- Keeping the heat in is what most people think of when they think of enclosing a 3D printer. This can be a factor to some degree but too much heat is also a problem for a lot of materials and printers. There are lots of designs for 3D printers which try to completely seal in a printer and insulate it and people try to add heating elements to make it even hotter inside. If you look at your printer it most likely have some or even a lot of plastic parts to it. Even if you have an all metal printer you might still have plastic fans, wire components, belts and so forth.

Plastic gets weaker as it gets warmer, long before it gets to the melting point. So if your printer has any mechanical or structural components in it made of plastic then they can wear out or fail if it gets too warm inside a completely sealed enclosure. So heat is a friend and an enemy at the same time. Another problem with too much heat is that most extruders have a passive fan cooling the heat sync part. So if that gets too warm then you face heat creep and your extruder jams. So our enclosures have intentional openings on them to allow excess heat to escape while still preventing drafts over the build plate. It’s a delicate balance of retaining heat and releasing heat. A great example is a competitor out there completely seals up a Ultimaker printer top completely. Then as a user prints higher temp materials for a long time the plastic clips on the gantry soften and then entire XY axis drops out of the printer. Causing damage that if you weren’t watching it would be extremely expensive to repair.

We have seen Prusa printers completely melt inside a hot box and even Raise3D recommends removing their hood while printing PLA so you don’t get heat creep on your extruder and it jams. So a little heat is ok but a lot is bad.

We have seen Prusa printers completely melt inside a hot box and even Raise3D recommends removing their hood while printing PLA so you don’t get heat creep on your extruder and it jams. So a little heat is ok but a lot is bad. - Keeping pets and little fingers out of the printer. It’s a minor concern but one to think about none the less. Your cat will like the warmth of the heated bed and may even think it’s a moving toy to swipe at. With the hot parts and moving parts it could hurt your curious pets if they go snooping around. The same is true for kids. However with kids it has an additional factor. At home or in school people will bring kids right up to the machine so they can see the magic of 3D printing. As close range a tiny hand sticks out at touches the hot end and now you have a crying child to deal with.

- Volatile Organic Compounds. Even the words sound scary. There have been lots and lots of studies about it so we don’t have to go into the fine science of the issue.

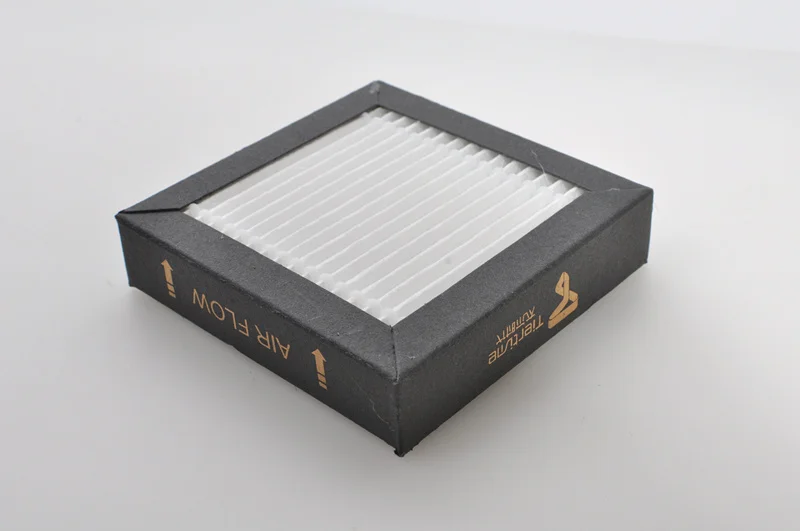

One thing that is not mentioned and is commonly misunderstood is VOC’s and HEPA. So lets get some simple numbers out there. HEPA ratings matter but you would be surprised by how much they don’t matter. Confused? That is the way they want it. Basically a 99.97% HEPA filter will capture a .3 micrometer particle, also called a h24 class filter. At the low end you have a 85% HEPA filter which is 85% or E10 rating. At the extreme high end you get into ULPA filters up to 99.9999% or U17 rating. OK, I said I would keep it simple and I haven’t, so I’m sorry for that. Let me try again and simplify these numbers even more for you. Most HEPA filter options are from 85% to 99.97% and capture particles down to .3 micrometers. The closer to 99.97% you get then the fewer amount of those particles get through the filter. You will rarely find a higher filter rating above 99.97% that won’t cost less than a car and require almost monthly replacement but those filters get you down to .1 micrometer particle sizes.

One thing that is not mentioned and is commonly misunderstood is VOC’s and HEPA. So lets get some simple numbers out there. HEPA ratings matter but you would be surprised by how much they don’t matter. Confused? That is the way they want it. Basically a 99.97% HEPA filter will capture a .3 micrometer particle, also called a h24 class filter. At the low end you have a 85% HEPA filter which is 85% or E10 rating. At the extreme high end you get into ULPA filters up to 99.9999% or U17 rating. OK, I said I would keep it simple and I haven’t, so I’m sorry for that. Let me try again and simplify these numbers even more for you. Most HEPA filter options are from 85% to 99.97% and capture particles down to .3 micrometers. The closer to 99.97% you get then the fewer amount of those particles get through the filter. You will rarely find a higher filter rating above 99.97% that won’t cost less than a car and require almost monthly replacement but those filters get you down to .1 micrometer particle sizes.

A quick summary: Most HEPA filters capture around .3 micrometer particle sizes and the better quality ones let fewer .3 micrometer particles get through.

Now to quickly shorten up all of those research papers for you about VOC’s and 3D printing.

- The particle size of the emissions from a 3D printer are between .1 and .3 micrometers.

- The amount varies depending on what material you print with.

- Most HEPA only filters will only capture the largest of these particles.

- An open window or well ventilated room will drop the levels below safety standards.

What about those particles smaller than .3 micrometers?

Well you can get one of those filters that cost as much as a car every month or you can used activated carbon. Activated carbon comes in many flavors and some of the facts can be misleading but to simplify it I will keep the scope limited. Basically the size of the activated carbon matters, smaller the size of the carbon the better. Then the amount of activated carbon matters. More is better. Activated carbon works using adsorption. No that is not a misspelling, I said adsorption which is different than absorption. Basically activated Carbon holds those VOC’s to its surface. So the size of the activated carbon matters because the smaller it is then the more surface area it has and the more VOC’s it can trap. Then there is the amount. Small amounts trap less than large amounts. The worse activated carbon filters out there are the woven mat filters like you find on a fish tank filter. They weigh nothing and are usually a plastic or cloth mesh covered in a thin coat of activated carbon and you can see light pass right through it. So even if they captured every particle passing through them then it would fully adsorption all of the VOC’s in a week or two.

Then the amount of activated carbon matters. More is better. Activated carbon works using adsorption. No that is not a misspelling, I said adsorption which is different than absorption. Basically activated Carbon holds those VOC’s to its surface. So the size of the activated carbon matters because the smaller it is then the more surface area it has and the more VOC’s it can trap. Then there is the amount. Small amounts trap less than large amounts. The worse activated carbon filters out there are the woven mat filters like you find on a fish tank filter. They weigh nothing and are usually a plastic or cloth mesh covered in a thin coat of activated carbon and you can see light pass right through it. So even if they captured every particle passing through them then it would fully adsorption all of the VOC’s in a week or two.

Finally! Why we don’t put a small HEPA filter hanging off the back of our enclosures.

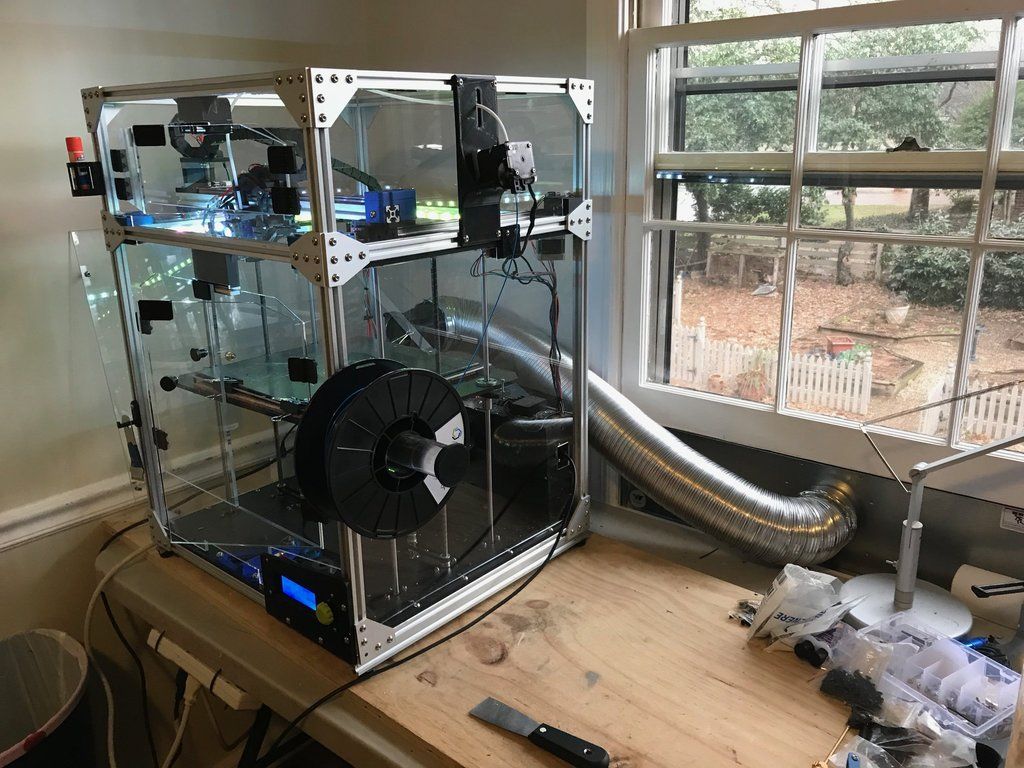

Those tiny fans with “HEPA” filters hanging off the back of some enclosures or printers do almost nothing and even less after a week of being on. It’s great marketing for sure and that is it. They barely move enough air to pull VOC’s through the filter. A total build volume of a printer is around 2 cubic feet. The recommended exchange rate at that size would 30 CFM after the filter. So those tiny filters that say 30 CFM fans are saying the fan moves 30 CFM but after the filter that number can drop to under 5 CFM. So not only do those small filter not capture enough particles, wear out in a week or two but they don’t even move enough air to actually move the particles through the filter to be captured.

It’s great marketing for sure and that is it. They barely move enough air to pull VOC’s through the filter. A total build volume of a printer is around 2 cubic feet. The recommended exchange rate at that size would 30 CFM after the filter. So those tiny filters that say 30 CFM fans are saying the fan moves 30 CFM but after the filter that number can drop to under 5 CFM. So not only do those small filter not capture enough particles, wear out in a week or two but they don’t even move enough air to actually move the particles through the filter to be captured.

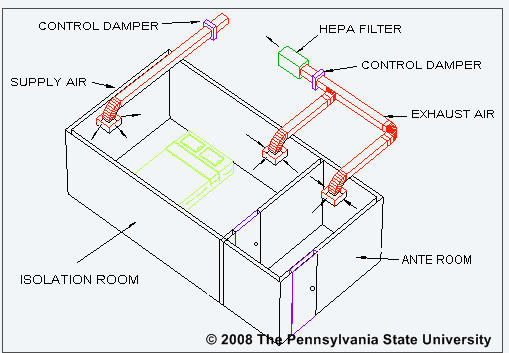

Another issue is that a one way filter like those negate the entire purpose for an enclosure. The filaments with the highest particle emission’s like ABS, Polycarb, Nylon are the ones that need a warm enclosure. So if you are filtering air out of your printer then where is the new air coming from to fill the void? You’re not creating a vacuum so air is coming into the printer from somewhere. Cold air from outside the printer is being drawn into the printer and creating cold drafts across the print area and creating warping and de-lamination of your prints. Or worse those small filters are pulling cold air from gaps near the filter and not your print area and not capturing any particles, making you believe you are being safe and actually not filtering anything.

Or worse those small filters are pulling cold air from gaps near the filter and not your print area and not capturing any particles, making you believe you are being safe and actually not filtering anything.

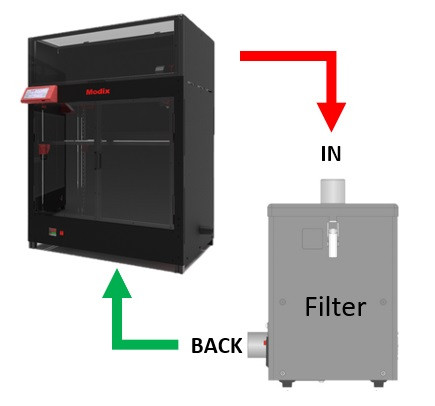

This is why we teamed up with BOFA and their line of filters. With the Print Pro 3 you get a true 88 CFM after the filter rating and a 3 stage filter with a pre-filter to capture 5 micrometer particles, then a true 99.997% HEPA filter and over 4 lbs of activated carbon to capture the .3 micrometer particles and VOC’s instead of just an ounce or two on the other solutions. On top of that it also has a supply and return hose to get the heated air back into the chamber without creating cold drafts over your print area. Then to top it off it has a warning indicator to tell you when to replace the filter. We searched high and low and found the BOFA units to be the only solution out there in this price range. While the science is still out on how the VOC’s might affect users over long time exposure, we don’t want to offer a solution that is just a placebo. We wanted a solution that actually addressed the issue. Since most consumer’s don’t have a way to test for VOC’s and UFP’s to find out if a filter is actually working we want to make sure the ones we sell actually do it.

We wanted a solution that actually addressed the issue. Since most consumer’s don’t have a way to test for VOC’s and UFP’s to find out if a filter is actually working we want to make sure the ones we sell actually do it.

Safe 3D printing without nanoparticls & VOCs

Toxic emissions

Nanoparticles & VOCs

Studies have shown high nanoparticle emissions from 10 to 100nm and significant production of VOCs from the filaments fusion. You might breathe harmful air in the presence of 3D printer, and in a repetitive way. That is chronic pollution with a long-term effect on your health which you can prevent with safety features.

Filtering system

“Filter designed for 3D printing”

Filter

HEPA & Activated carbon

The P3D range filter received special attention to strictly follow the requirements of air filtering for nanoparticles under 100 nm and provide 98% efficiency. In order to neutralize odors and symptoms of irritation a specific activated carbon was selected.

In order to neutralize odors and symptoms of irritation a specific activated carbon was selected.

AlveoONE & R

Air filtering system mountable on an enclosure

starting from 79,99€, in kit or assembled

Filtering system

PrinterCase

Air filtering system mountable on an enclosure

696,00€ incl. VAT – in stock

Add to cart

Custom-sized enclosure

Customised enclosures for desktop 3D printer

Industrial quality and volume to 1 m3

Online quotation

Melting plastic: a good idea without any protection?

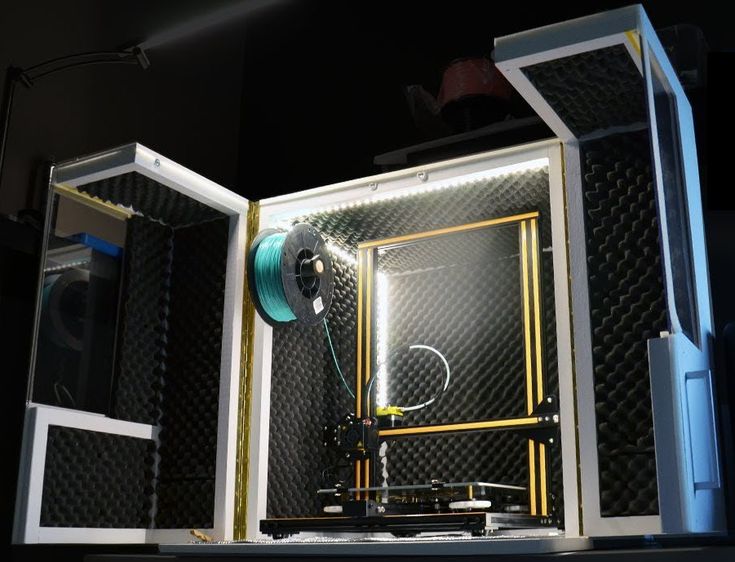

3D printer enclosure is necessary to achieve beautiful prints without the warping effect. An enclosure can stabilize temperature and protect the printing zone from draughts. However, inside the enclosure, the harmful emission will be concentrated during the printing and requires air extraction or constant filtering.

– 3D printer manufacturers –

Your clients ask us to protect their operators and machines with enclosures and efficient filters. Incorporate an Alveo3D directly on your 3D printer to get a reputed and efficient air filtering system.

– All industrial field –

With the flexibility of additive manufacturing, we are able to design custom air filters. We can adjust filter specifications to catch targeted pollutants and keep the required airflow.

Chemical risk expert

INRS recommendations

French National Research and Safety Institue : Risks for your health and Prevention solutions

Custom solutions

Efficient filtration

French and made in Alps

Available in European countries

+33 616 806 403 contact@alveo3d. com

com

Best 3D printers of 2019. Rating of the most demanded printers

Back in the last decade, many people did not even know about the existence of 3D printers, and even less could afford them. Technology does not stand still, and now everyone can pick up a 3D printer for their own income. However, an affordable price is not the main characteristic of a 3D printer. Much more important is what he is capable of. And on the basis of the combination of qualities, a popularity rating is compiled.

Consider the TOP of the best, according to 3DMALL experts, professional 3D printers in 2019of the year. So, the following trademarks were included in the rating:

- RAISE3D;

- PICASO;

- HERCULES;

- FORMLABS

Let's take a closer look at each one and look at the 3D printers that made these brands included in this rating.

RAISE3D 3D printers

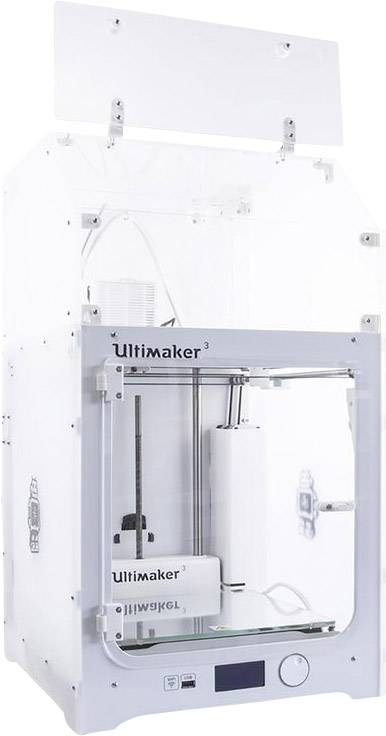

The Chinese brand RAISE3D has done the impossible - in the shortest possible time, the manufacturer managed to win a niche in the world market, making its way among famous brands. The company specializes in the production of FFF / FDM 3D printers. Characteristic features of the models of this brand are ease of use and high quality printing. In 2019two models of 3D printers of this brand were included in the world ratings:

The company specializes in the production of FFF / FDM 3D printers. Characteristic features of the models of this brand are ease of use and high quality printing. In 2019two models of 3D printers of this brand were included in the world ratings:

- Raise3D Pro2

- Raise3D Pro2 Plus

The main advantage of these 3D printers is the ability to print large and high-quality models. The devices are equipped with two extruders, which reduces the printing time. The functionality is also impressive: touch screen, HEPA filter, thread end sensor. This is equipment that can be used in the professional field, as the print quality is really high. The Raise3D Pro2 3D printer differs from the Plus model in a smaller print area and, accordingly, a more affordable price, but in general the functionality is identical. nine0003

PICASO 3D printers

It's always nice to talk about domestic manufacturers and that's exactly what PICASO is. This is the first domestic brand that started producing 3D printers back in 2011. Today, the brand's products are renowned for their ease of use, safety, and print quality. In many ways, the equipment is superior to foreign analogues.

Today, the brand's products are renowned for their ease of use, safety, and print quality. In many ways, the equipment is superior to foreign analogues.

The following 3D printer models were included in the 2019 ranking by popularity:

- Picaso 3D Designer X

- Picaso 3D Designer X Pro

- Picaso 3D Designer XL

- Picaso 3D Designer XL Pro

These are FDM printers that can print with two materials at once. The range of working materials is very wide, as the extruder has a wide temperature range. In addition, the equipment is not sensitive to the plastic manufacturer - you can work with any, most importantly, high-quality. A series of printers professional and suitable even for small-scale production. nine0003

Picaso 3D Designer Advantages

- high print speed;

- the quality of the resulting models;

- easy operation.

HERCULES 3D printers

Another domestic manufacturer producing quality 3D printers that have won the love of consumers is Imprinta. In 2019, one of the printers of this company, Imprinta Hercules Strong Duo, entered the TOP, although the Hercules 2018 and Hercules Strong 19 models are also in demand and have excellent characteristics.\

In 2019, one of the printers of this company, Imprinta Hercules Strong Duo, entered the TOP, although the Hercules 2018 and Hercules Strong 19 models are also in demand and have excellent characteristics.\

These are FDM printers with a simple and clear design. The main advantages of Hercules Strong Duo are the high quality of printed models and the accuracy of printing. The layer thickness is 15-20 microns. This means that the products are smooth. The "trick" of the printer is a light indication of the operation of extruders. In addition, it is possible to print with two materials at once.

Designed for professional applications such as automotive, aerospace, design and advertising. Hercules 2018 is also equipped with a high performance print head and unique kinematics to guarantee high quality and speed. The cost of this model is lower, but it also prints without visible layering. nine0003

FORMLABS 3D printers

Formlabs is an American company that has not lost its leading position for several years. Her products consistently top the charts, and 2019 was no exception. This year it is the Formlabs Form 2 model. The equipment is a professional 3D printer that prints using SLA technology. This is the best printer that uses this technology. It is characterized by its compact size and high print speed, as well as consistently high resolution. The layer thickness is from 25 microns. nine0003

Her products consistently top the charts, and 2019 was no exception. This year it is the Formlabs Form 2 model. The equipment is a professional 3D printer that prints using SLA technology. This is the best printer that uses this technology. It is characterized by its compact size and high print speed, as well as consistently high resolution. The layer thickness is from 25 microns. nine0003

The Formlabs Form 3 is newer and has improved technology. In particular, a modular light processing unit is used, due to which uniform illumination of the layer is achieved. Models are perfectly smooth and accurate. Form 3 shipments will begin in December 2019. Pre-order is currently available.

These devices are used in the jewelry industry, dentistry, etc., that is, everywhere where the highest accuracy and speed are valued.

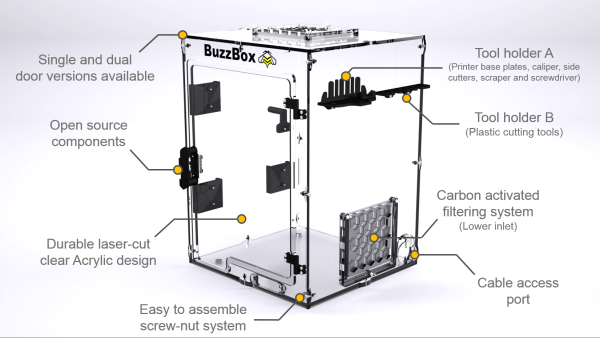

Alveo3D, filter kit for safe 3D printing at home and in the office

Alveo3D is a young French company that has developed a nanoparticle filtering system for 3D printers. Its goal is to reduce toxic emissions from machines by reducing the risk of air pollution when they operate in poorly ventilated environments. Ultimately, these particles can be hazardous to the health of users. These small filters are installed in small boxes, also developed by the startup. The whole system is made of plastic elements printed on a 3D printer. They are now available as kits or ready to use with boxes that can be customized to fit the size of the 3D printer. We caught up with Lucas Martini, CEO of Alveo3D, to learn more about these solutions. nine0003

Its goal is to reduce toxic emissions from machines by reducing the risk of air pollution when they operate in poorly ventilated environments. Ultimately, these particles can be hazardous to the health of users. These small filters are installed in small boxes, also developed by the startup. The whole system is made of plastic elements printed on a 3D printer. They are now available as kits or ready to use with boxes that can be customized to fit the size of the 3D printer. We caught up with Lucas Martini, CEO of Alveo3D, to learn more about these solutions. nine0003

3DN: Could you introduce yourself and your relationship with 3D printing?

My name is Lukas and I represent Flexee System, the company behind the Alveo3D project, which addresses the issue of toxic emissions from 3D printers. We are the three partners behind this project, which started back in 2018. Victor is an industrial product designer and Laurent is a team developer. 3D printing has become an important tool in our arsenal for prototyping our models and demonstrators. nine0003

3DN: Why did you create Alveo3D?

We quickly started using 3D printers in small spaces like our workshop or home. We have become aware of the potential hazard associated with our machines due to throat and eye irritation and the unpleasant smell of melted plastic. We know of some manufacturers that have mentioned the same symptoms, especially when using thermoplastics such as ABS or HIPS. Some reported headaches, and the symptoms were more severe in smaller, less ventilated spaces. The same descriptions were found on the forums, with some members suggesting homemade filter solutions. nine0003

During 3D printing, we can actually encounter two types of harmful emissions: toxic emissions associated with volatile organic compounds (VOCs) and nanoparticles. That's all it took to convince us to equip our 3D printer with a filter system. Speaking a little about toxic emissions, it is important to point out that this is a long-term risk with potential chronic consequences. Pollutant emissions enter the air in low concentrations, and the regular presence of a 3D printer can be harmful. When 3D printers are used in poorly ventilated areas, the accumulation of nanoparticles and VOCs can pose a risk of air pollution. nine0003

Pollutant emissions enter the air in low concentrations, and the regular presence of a 3D printer can be harmful. When 3D printers are used in poorly ventilated areas, the accumulation of nanoparticles and VOCs can pose a risk of air pollution. nine0003

VOC risk is well known to industry and air quality authorities. Some gases emitted by thermoplastics are known to be carcinogenic. Even in PLA, which is naturally based, the amount of additives added to it makes it toxic. Other filaments, such as POM, naturally release formaldehyde and there is a risk of inhaling toxic air when opening a bag from a spool. For nanoparticles, the risk is less well defined, but probably even more dangerous. They can be found in the body, organs and brain and are difficult to eliminate by the human body. nine0003

CNRS recommends using a HEPA filter for nanoparticles and activated carbon for VOCs. We searched for existing filtering solutions and were surprised to find that there were few 3D printing solutions available for less than 150 euros. Many manufacturers create their own air filtration systems that they place on the body of their printer to draw air in and filter it before it enters the room.

Many manufacturers create their own air filtration systems that they place on the body of their printer to draw air in and filter it before it enters the room.

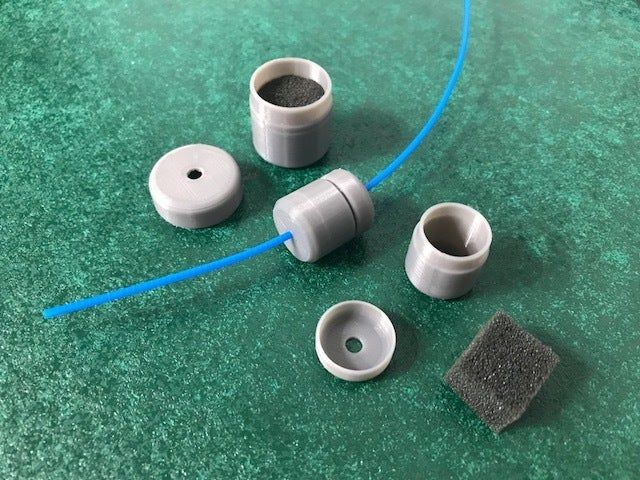

The first version of our filtration system was made by hand. HEPA filter, granular activated carbon and 3D model to fit everything on our printer body. The results were encouraging, but we wanted to make sure we were dealing effectively with all the toxic emissions. What should have been a simple accessory for our 3D printer turned out to be a real piece of work. We then mapped the risks associated with most of the gases we could detect during printing. We synthesized the results of studies on the release of nanoparticles and realized that the processing of these elements of the order of several tens of nanometers would require further development. nine0003

Over the course of 3-4 months, we tested dozens of filter configurations on our test machine. We have worked with European and Chinese manufacturers to find the right combination for capturing VOCs and nanoparticles. We wanted our work to remain accessible to all users, because the danger is no different from an entry-level machine or a professional model.

We wanted our work to remain accessible to all users, because the danger is no different from an entry-level machine or a professional model.

3DN: How do Alveo3D air filters work?

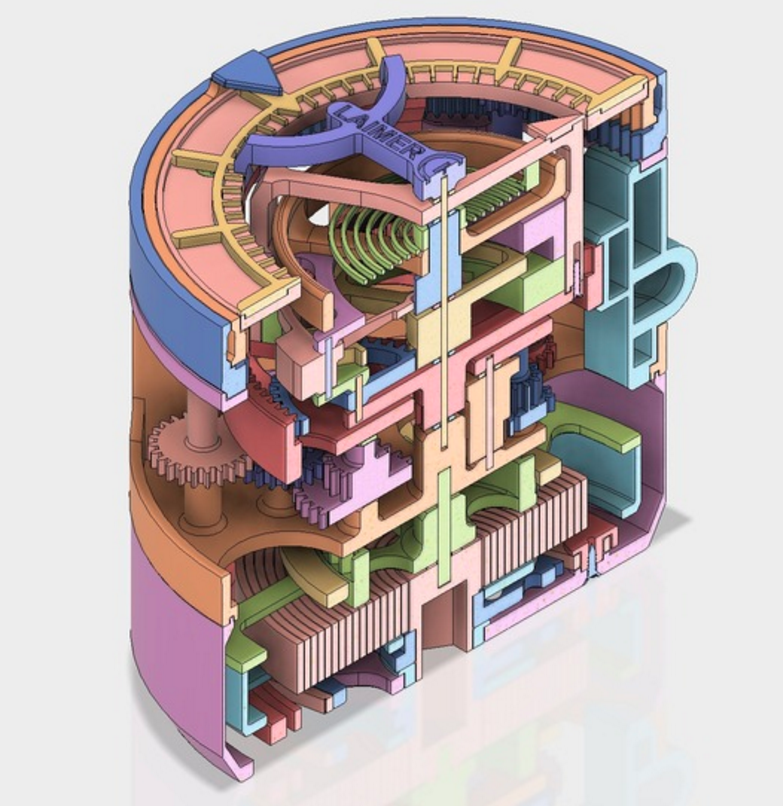

Alveo3D filter blocks have been designed for 3D printing, for easy use and easy replacement of filter cartridges. They combine a powerful high pressure fan and a filter cartridge specifically designed to combat harmful emissions from FDM 3D printing. This filtration system includes an activated carbon bed that allows it to handle a wide range of VOCs.

We are often asked about the life cycle of our filters, but the answer depends on many factors, the main ones being printing time, filament type and extrusion temperature. As a precaution, we recommend 600 hours of use. This is mainly due to activated charcoal. When it is saturated, it will let all the VOCs through, so it is important to change the filter regularly until saturation is reached. 600 hours of filtration is approximately one change every 6 months for printers that operate occasionally and every 3 months for printers that operate regularly. nine0003

nine0003

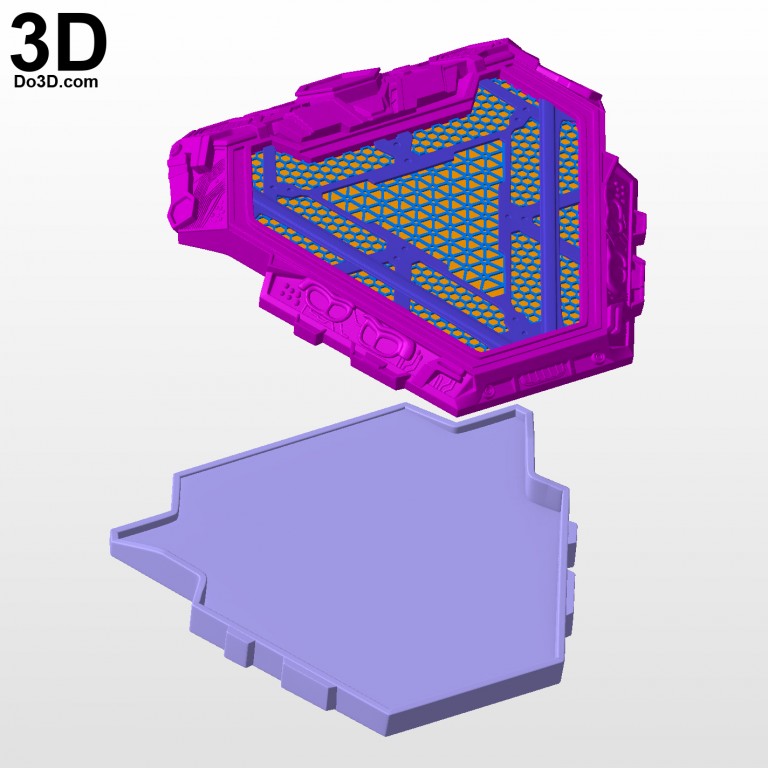

Our filtration systems are mounted on the 3D printer body. It's an essential tool to protect your equipment and print successfully, especially with some plastics that are harder to print like ABS. It also reduces the noise level of the machine. First of all, it allows you to capture all the vapors even after the plastic has cooled down. In fact, we have 3 goals: to maintain a stable ambient temperature, to limit the negative effects of deformation, and to process the air in general. We produce custom boxes according to the dimensions of each printer. Conventional design with aluminum frame and plexiglass or polycarbonate fronts. The boxes are equipped with our filtration system and we can add options according to the specific needs of our customers. nine0003

Finally, as I said, all the plastic parts of our boxes are 3D printed, allowing us to make continuous technical improvements as well as customize the final solution. They are available as kits or ready to use.

Two models have now been developed. The alveoONE filtration model is used with a box equipped with an air intake that does not need to be closed. It draws air into the case, creating a small vacuum, and exhausts clean air. It is suitable for printing common thermoplastics, PLA, ABS, PET. The alveoONE-R filtration model is used with a waterproof housing and works with internal processing. If you require an ambient temperature above 40°C, this type of internal processing allows you to increase the temperature. nine0003

3DN: Do you think users are aware of the dangers of 3D printing?

We did a little research on this topic, and according to our results, half of the users are not aware of the risks. Both professionals and novices are aware of bad odor and irritation after a few applications. The adoption of security measures is not yet automatic. However, some of them believe that the use of PLA is enough to protect against toxic emissions. Although PLA is less harmful than other thermoplastics, it does contain additives to improve certain performance and technical properties. Therefore, it can be toxic. One of Alveo3D's mission is to provide information about security risks and best practices. nine0003

Although PLA is less harmful than other thermoplastics, it does contain additives to improve certain performance and technical properties. Therefore, it can be toxic. One of Alveo3D's mission is to provide information about security risks and best practices. nine0003

3DN: What are the future projects of Alveo3D?

We have several areas of development for the coming months. By the end of July we will be able to deliver our first V2 e-cards. They are used to monitor filter housings and monitor filter wear. We are also preparing a model specially designed for companies, alveoONE PRO. This will be a filtration system capable of handling the air of two printers at the same time, or a high volume printer with individually tested and certified filters. nine0003

3DN: A few words for our readers?

Basically we have a few more agreed projects for the future. But we must also monitor current demand and developments for 2020.