Destiny 3d printing

Destiny 3d Printed - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(267 relevant results)

Destiny 2 Fan 3D-Prints 77 Inches-Tall Rhulk's Glaive From Vow of the Disciple

By Andrea Trama

A Destiny 2 fan manages to 3D-print Rhulk's glaive from the Vow of the Disciple Raid, and the replica is both amazing and massive.

With the release of The Witch Queen, Destiny 2 has been enjoying a burst in popularity and plenty of positive feedback on the various elements of the expansion, with a particular focus on the campaign experience and the new Raid. As for the campaign, The Witch Queen takes its themes from The Taken King in Destiny, and it builds on the lore surrounding the origins of the Hive and the Hive Gods. The Raid, on the other hand, delves more into what players know about the Darkness and a menacing new villain: The Witness.

The Vow of the Disciple Raid has been regarded as one of the best Raids ever made by Bungie, and part of that charm is due to both the astounding setting and the fact that the final boss does not stand still for damage phases, but rather moves around. The Raid boss, the glaive-wielding Rhulk, is one of the most powerful entities ever encountered by Destiny 2 players, according to the lore. In fact, before becoming the first disciple of The Witness, Rhulk annihilated entire civilizations and felled The Leviathan on Fundament.

RELATED: Bungie is Open to Destiny 2 Activities Looking More Like The Witch Queen, but Core Playlists Won't Change

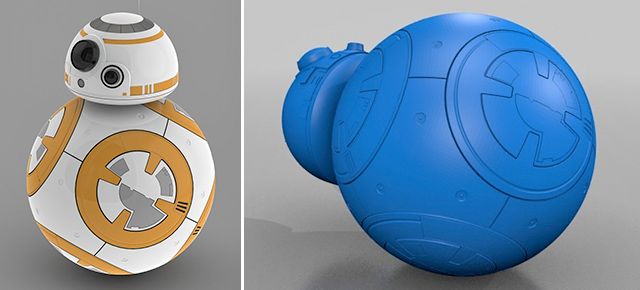

Rhulk's glaive is an iconic weapon, both because of its reference to Lubrae, the boss' now destroyed home planet, and the fact that it's a big part of the final Raid encounter itself. The glaive, called Lubrae's Ruin, has a very distinct look that a Reddit user by the name of ColonelDiddles tried to replicate with their 3D printer, ending up with a 77 inches-tall version of the weapon. While this is not exactly the same scale as Rhulk's glaive, which is much larger in the game, it's quite close to the version of Lubrae's Ruin that Destiny 2 players can get from Vow of the Disciple.

3D printed Lubraes’s Ruin! 77 inches tall from destiny2

According to ColonelDiddles, the weapon required two prints over a total of four days, with the first print being for the head of the glaive and the second for the components of the shaft. Because the glaive is so massive, it wouldn't be possible to 3D-print it as a single piece, and those interested in making their own version of Lubrae's Ruin should expect some issues with the handle because of how delicate that part is. Still, Destiny 2 fans can find this and more 3D models online, and ColonelDiddles pointed out that a good place to find more is a dedicated Discord server linked in the Reddit post.

Because the glaive is so massive, it wouldn't be possible to 3D-print it as a single piece, and those interested in making their own version of Lubrae's Ruin should expect some issues with the handle because of how delicate that part is. Still, Destiny 2 fans can find this and more 3D models online, and ColonelDiddles pointed out that a good place to find more is a dedicated Discord server linked in the Reddit post.

Destiny 2 weapons are often very unique in their design, which has inspired fans over and over to make their own replicas of their favorite guns. An example comes from the incredible Destiny 2 Rat King replica shared on Reddit a couple of months ago, this time not made with a 3D printer, but rather with resin.

Destiny 2 is now available on PC, PS4, PS5, Stadia, Xbox One, and Xbox Series X/S.

MORE: Destiny 2 Player Turns Witch Queen Weapon Into Improved Version of Hush

Subscribe to our newsletter

Related Topics

- Gaming News

- Destiny 2

- Bungie

- PS4

- PS5

- Xbox One

- Xbox Series X

- Stadia

- PC

About The Author

Andrea became a gamer for life at 7, thanks to a Pokemon Red cartridge and her Game Boy. She knew she wanted to be a writer back when she got a floppy disk and wrote "My Book" on it. Her Italian lineage makes her a big pizza fan. She loves games featuring deep lore, sci-fi elements, and strategic thinking. When she is not writing, she's often found playing Destiny 2 and Pokemon games. Andrea has a BA degree in Cognitive Psychology from UNISOB and an MA degree in Copywriting and Advertising from IULM.

She knew she wanted to be a writer back when she got a floppy disk and wrote "My Book" on it. Her Italian lineage makes her a big pizza fan. She loves games featuring deep lore, sci-fi elements, and strategic thinking. When she is not writing, she's often found playing Destiny 2 and Pokemon games. Andrea has a BA degree in Cognitive Psychology from UNISOB and an MA degree in Copywriting and Advertising from IULM.

what lies ahead for 3D printing

The prospects for 3D printing

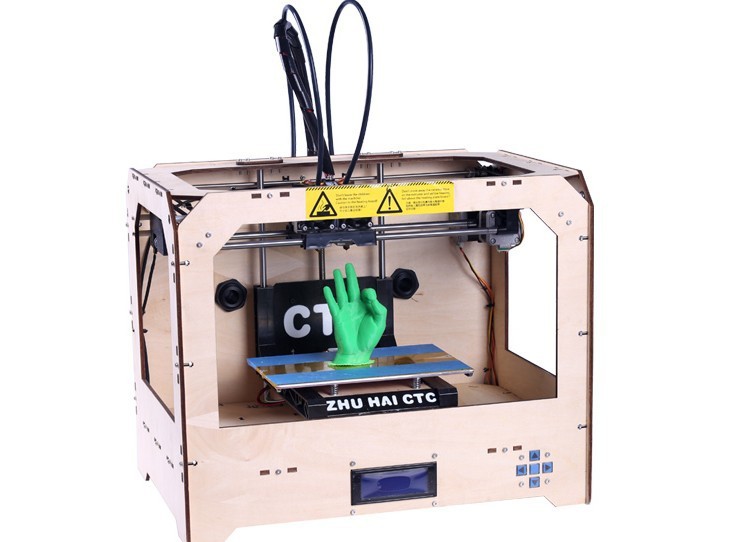

Even now, the prospects for 3D printing are extremely promising. Scientists are actively developing existing 3D printing techniques, developing new technologies and types of materials, and finding new areas of application. Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful.

Due to this, the future of 3D printing can definitely be called successful.

3D printers can significantly reduce production costs, thereby reducing the cost of products. Judging by the growing trend towards the popularization of 3D technologies, raw materials for 3D printing will become the main commodity unit in the future. In general, the prospects for 3D printing are defined for many areas. And now we will try to reveal them as much as possible.

The Future of 3D Printing

If you try to imagine the future of 3D printing, your imagination paints a rather interesting picture. Given the great interest of scientists in the 3D bioprinting technique, which is one of the most promising 3D printing technologies, the production of artificial organs on a 3D printer is not far off. It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

- Construction. 3D printing of houses, or contour construction, attracts many with its futurism and simplicity.

The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future. And just recently, the first printed house in Europe was created on a 3D printer;

The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future. And just recently, the first printed house in Europe was created on a 3D printer; - Electronics. When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer;

- Automotive and aerospace industry. The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity.

In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars.

In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars. - Pharmaceutical industry. Yes, yes, you can imagine. The future of 3D printing is in the manufacture of tablets and other medicines. This is confirmed by epilepsy pills legalized in the USA, made according to a special technique. The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one.

- Food industry. 3D food printers are gradually gaining space in cafes and restaurants. While this is probably one of the most raw 3D printing technologies out there, it has potential. Food 3D printers are especially interesting for the possibility of making food for astronauts, as well as the freedom to display culinary talent. This is confirmed by the amazing 3D-printed desserts of our compatriot.

Other questions and answers about 3D printers and 3D printing:

- Finance Which 3D printer manufacturers are best?

- Finance Which 3D printer is better to buy?

The future of 3D printers

Now let's try to imagine the future of 3D printers. There are several important points to be noted here. Below we list the most likely scenarios for the future of 3D printers.

- Improving the reliability and quality of devices. Surely, many users are looking forward to this, because most of the existing models of 3D printers cannot boast of uninterrupted operation and the absence of printing errors;

- Large-scale distribution. It is certain that the future of 3D printers will please us with their popularization. Even now, one can observe a growing trend towards the use of 3D printing in almost all areas of industry. In parallel with the fact that more and more users learn about the possibilities of technology, the demand for desktop 3D printers is also growing;

- Availability.

In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices;

In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices; - Enlargement of the construction area. 3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft;

- Expanding the range of available materials. The future of 3D printers depends a lot on 3D printing materials, because more means more possibilities. The development of special equipment and related materials is being carried out by many companies, and news about the release of new polymers is constantly appearing.

3D technologies of the future

Summing up, it remains to consider only 3D technologies of the future. These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting. By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth.

These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting. By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth.

This was a list of the main scenarios for the future of 3D printing. Let's see how they are destined to come true. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

Our store offers a wide range of 3D printers, 3D scanners, 3D plastics and resins, as well as other accessories at the best prices on the Ukrainian market with delivery to all cities (Kharkiv, Nikolaev, Dnepropetrovsk, Lviv, Zaporozhye, Kherson, Donetsk, Odessa ). We also provide 3D printing, 3D scanning and 3D modeling services. For all questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating!

We also provide 3D printing, 3D scanning and 3D modeling services. For all questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating!

Back to main page

3D printing, universal technology for home and work

household tasks. And it is worth noting that this combination turned out great for him.

Beginning

The path to the sphere of high technologies was destined from childhood. Passion for IT technologies, automation and robotics was a good start for admission to the Tver State Technical University (TVSTU), where Dmitry focused on manufacturing and smart production.

Dmitry Lyzhenkov

2013 was a landmark year when he came across an article about 3D printers. The desire to dive into the intricacies of the unknown competence prompted me to visit many thematic exhibitions and study materials about additive technologies on the Internet.

And fate itself favored the undertaking. On February 10, 2016, the Center for Youth Innovative Creativity (TsMIT) "Technopolis" was opened at the university, in which, in addition to robotics, programming and other high-tech specializations, there were areas of 3D modeling and 3D printing. Yes, I had to start with budget Chinese models, but the dream took on a real shape.

Initially, 3D printing was a hobby, a way to popularize the technology. And even on a psychological level, the new direction met with resistance. Dmitry well remembers the laughter and disbelief in the prospects of this technology of those around him, it seemed to be something frivolous, the lot of those who did not finish playing their toys in childhood. It only remained to stubbornly hone their skills and strive with all their might to embody them in real life. Not much time has passed since then, and the global boom in additive technologies has confirmed the correctness of the choice of 2013.

3D skills at work

The main thing is a good example that sets the pace and bar of aspirations for many years. The use of additive technologies in the production of modern bionic prostheses by Motorika (Moscow) at one time became a good guide for Dmitry, who could no longer imagine his professional path without 3D printing.

The use of additive technologies in the production of modern bionic prostheses by Motorika (Moscow) at one time became a good guide for Dmitry, who could no longer imagine his professional path without 3D printing.

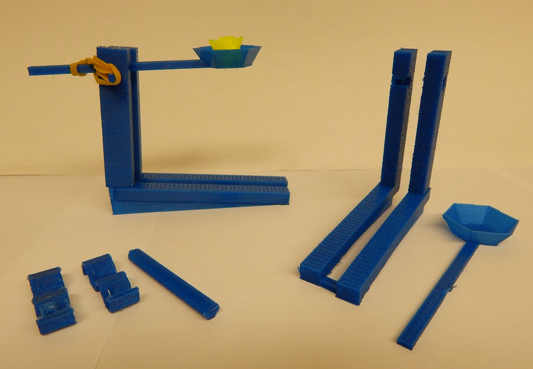

A serious test for a novice specialist was the project to manufacture clamps for the pressure roller of the Zebra printer. There were many such devices in production. And because of the somewhat free approach of operators to work, they broke very often. That's when Dmitry's skills in 3D modeling and printing came in handy.

The most fragile parts of an imported printer were its pinch rollers. It would seem that “three-penny” elements, but in reality, a repair kit from a roller, gear and plastic clamps cost $ 120. Given the frequency and number of equipment breakdowns, the total amount was considerable.

After creating a 3D model of two clamps and printing scarce parts, a decent amount of money was saved. Tens of thousands per quarter. A unique situation when everyone is happy: workers in production continue to break “penny” spare parts (costs of work processes), but the technology of their additive production allows them to print the required volume on time.

Top right - 3D model (AutoCAD). At the top left - printed latches. PLA plastic material. Nozzle size -0.3. Nozzle temperature 230 °C. Table temperature 60-70 °C.

It happened that the employer's business partners also came with urgent orders. So it happened with the gear for the printing press. Dmitry had to urgently make a 3D model in AutoCAD and start printing. Moreover, the customer demanded that the gear had 100% filling, that is, no cavities.

Top right - 3D model (AutoCAD). Top left - printed gear. ABS material - plastic. Nozzle size -0.5. Nozzle temperature 240 °C. Table temperature 100 °C.

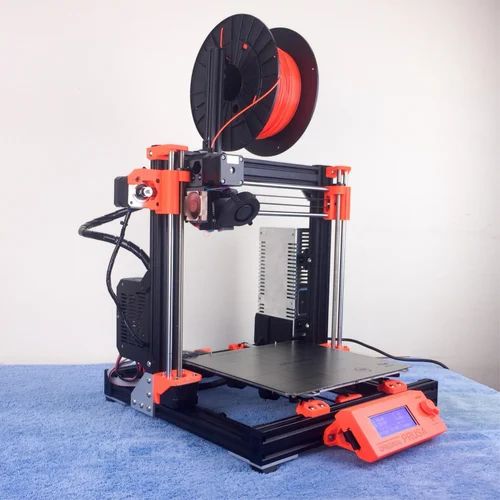

Today's job in the management company of one of the shopping centers in Moscow is also associated with the use of 3D printing. The management reacted rather loyally to Dmitry's wish and purchased a 2016 Hercules 3D printer, which is located directly in his office.

The situation is noteworthy in that there were no specific plans, such as optimizing operating costs and other points that are usually associated with investments in such equipment, here. However, this was still achieved, progress entered the company organically.

However, this was still achieved, progress entered the company organically.

And it is worth noting that Hercules 2016 is doing great. From the most voluminous work tasks: work on retainers for ventilation valves and sliding rollers for dishwasher baskets.

The fact is that the existing ventilation equipment is imported and has already been discontinued. And, as usual, there are no original parts. It was unprofitable to order production from outsourcers, and they were not particularly eager to take on a small and obviously unprofitable order. The excellent knowledge of AutoCAD and the reliable design of Hercules 2016 helped out.

Also with rollers for sliding dishwasher baskets. The original parts collapsed over time, and new ones, due to objective reasons, had to be made from scratch.

Roller for sliding the dishwasher basket. ABS material - plastic. Nozzle size -0.5. Nozzle temperature 240 °C. Table temperature 100 °C

3D printing for the soul

When it comes to using additive technologies for home or personal interests, Dmitry, as a true enthusiast, never stands idle. Cell phone stands, toys, key chains for co-workers, and even special clips for tuning car headlights are great examples of how Hercules 2016 can be used.

Cell phone stands, toys, key chains for co-workers, and even special clips for tuning car headlights are great examples of how Hercules 2016 can be used.

3D printing also perfectly solves purely “childish” tasks, such as “overhauling” the gearbox mechanism from a toy car. After all, the baby is very often “attached by the soul” to his favorite toy, and the breakdown of some gear is already a tragedy. Fortunately, the option to print and restore has become a matter of technology.

Top: printed gear on the left, original on the right. ABS material - plastic. Nozzle size -0.5. Nozzle temperature 240 °C. Table temperature 100 °C

Memorable for Dmitry was his participation in the development of prototype visualization for the Oraoke startup. According to the idea of the founders, it was a set of a wireless speaker in the shape of a tetrahedron and a microphone in the same original design.

Oraoke startup visualization project.

Learn more