3D printer developers

3D Printing For Designers And Developers

3D printing is not a new technology, but recent advances in several fields have made it more accessible to hobbyists and businesses. Compared to other tech sectors, it’s still a small industry, but most analysts agree it has a lot of potential. But where is the potential for freelance designers and software engineers?

A fellow Toptaler asked me this a couple of weeks ago, because I used to cover 3D printing for a couple of publications. I had no clear answer. I couldn’t just list business opportunities because this is a niche industry with a limited upside and mass market appeal. What’s more, 3D printing is still not a mature technology, which means there is not a lot in the way of standardisation and online resources for designers and developers willing to take the plunge.

However, this does not mean there are no business opportunities; they’re out there, but they are limited. In this post, I will try to explain what makes the 3D printing industry different, and what freelancers can expect moving forward.

3D Printing For Hobbyists And Businesses

First of all, I think we need to distinguish between two very different niches in the 3D printing, or additive manufacturing industry.

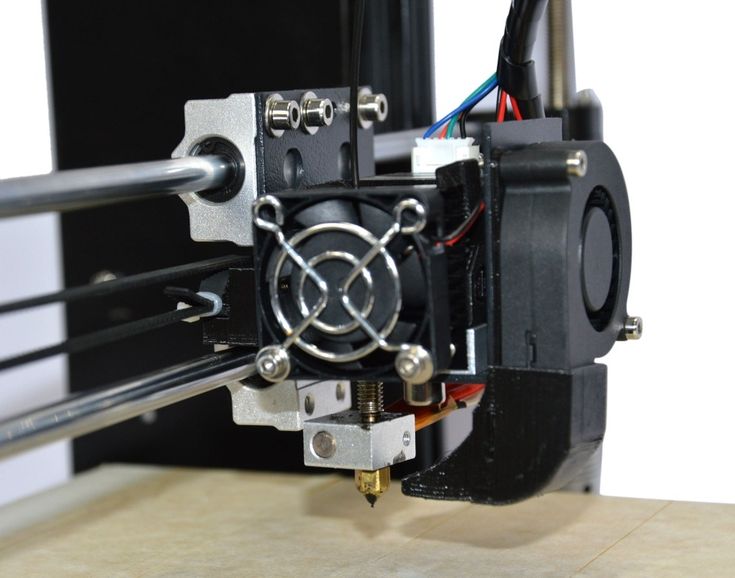

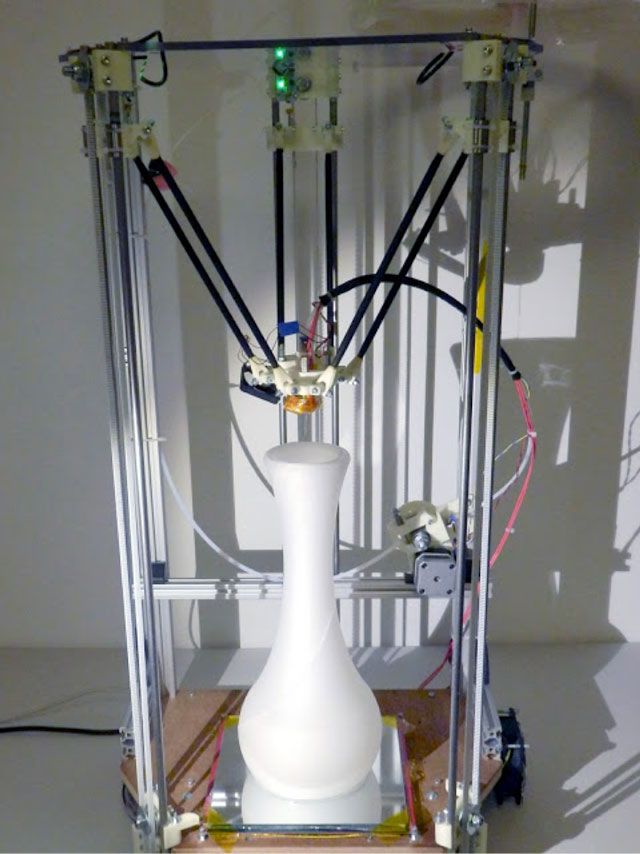

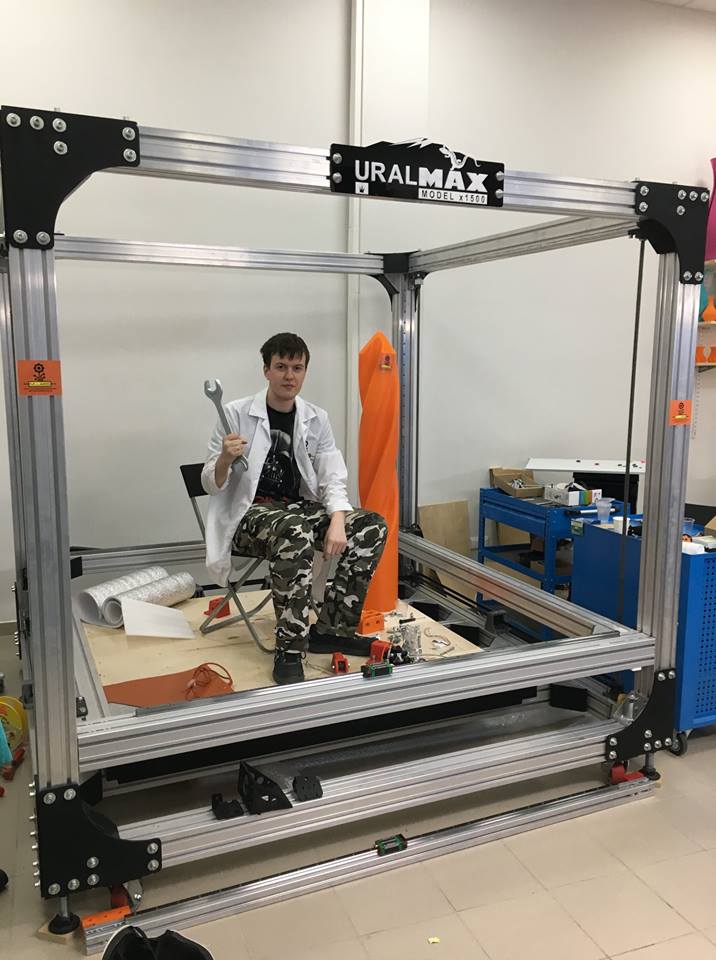

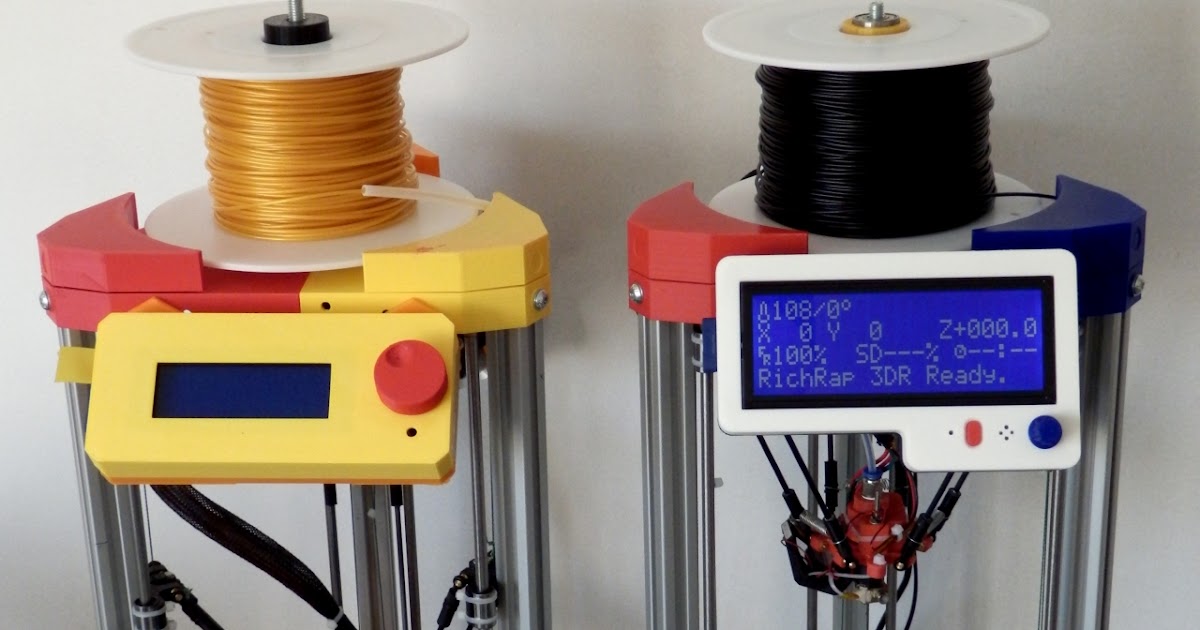

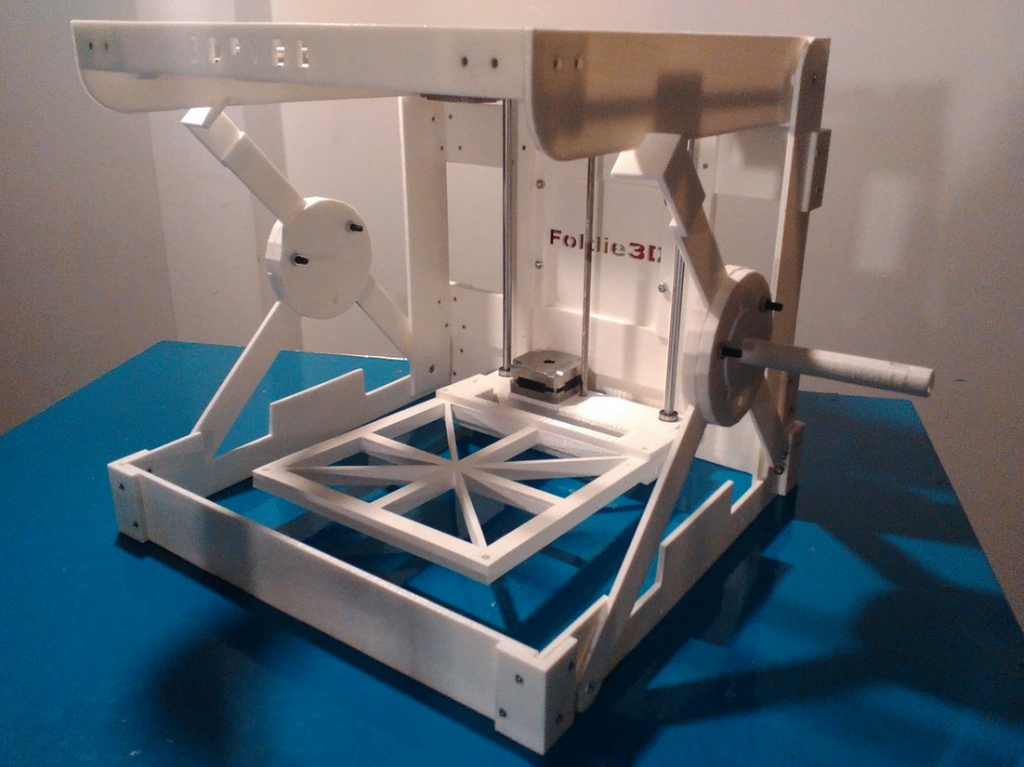

On one end of the spectrum, you have countless hardware enthusiasts, software developers and designers working on open-source projects. The RepRap project embodies this lean and open approach better than any similar initiative in the industry. RepRap stands for Replicating Rapid Prototyper and it’s basically an initiative to develop inexpensive printers based on fused filament fabrication (FFF) technology. Essentially, that is Fused Deposition Modelling (FDM) technology, but RepRap can’t use that name because it was commercialised by Stratasys. When the company’s patent on FDM expired, FDM was embraced by the open-source community, albeit under a different name.

3D printing is not a new technology, but recent advances in several fields have made it more accessible to hobbyists and businesses.

Tweet

RepRap turned ten this year, with the first printers showing up a few years after launch. By 2010, the RepRap project was on its third generation design, and the RepRap community saw a lot of growth over the next few years.

One noteworthy feature to come out of the RepRap initiative is self-replication; the ultimate goal of the project is to create a 3D printer that will eventually replicate itself. We are not there yet, but some RepRap designs allow users to print three quarters of the printer. You still can’t print extruders and electric servos, but it’s a start.

However, RepRap was never supposed to be a commercial success. It was created as a tech-first initiative, so it was never consumer-centric. It was all about pioneering various technologies and bringing them to the hobbyist market at low cost. RepRap was never supposed to be a cash cow.

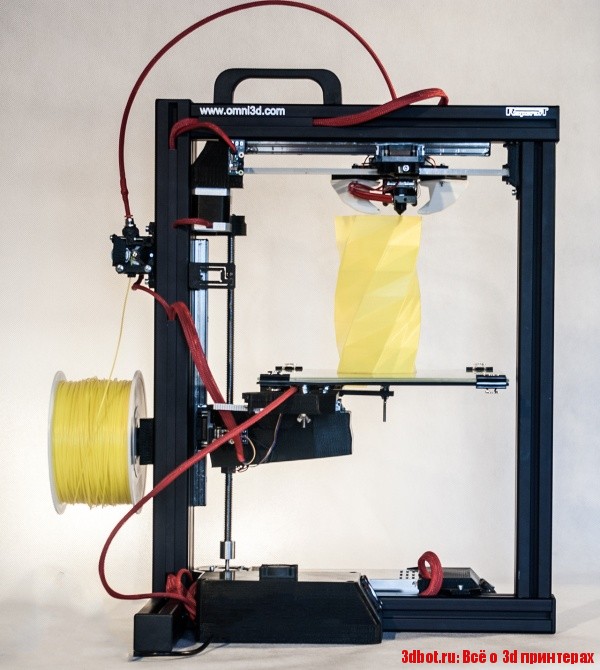

So what about big business? A number of industry pioneers have already become 3D printing heavyweights. These include Stratasys, 3D Systems, Ultimaker and Printbot. RepRap printers still command a big market share, and they’re not being squeezed out by proprietary platforms. In fact, most vendors have no choice but to embrace some RepRap standards in order to guarantee compatibility.

RepRap printers still command a big market share, and they’re not being squeezed out by proprietary platforms. In fact, most vendors have no choice but to embrace some RepRap standards in order to guarantee compatibility.

However, simply listing 3D printing companies and their respective market share does not paint the full picture. For example, RepRap is limited to FFF technology, which is the most widespread 3D printing technology today. The problem is that FFF printers have a lot of limitations, which means they cannot be used in many industries.

Different Technologies For Different Applications

To get a better idea of what’s out there, we need to take a look at currently available 3D printing technologies. This might not seem interesting if you’re not a hardware geek, but it’s important to understand the difference between various printing technologies (and I will try to keep this section as brief as possible).

Although hobbyist FFF printers are relatively inexpensive, certain types of professional 3D printers can cost as much as your home.

Tweet

-

FFF/FDM usually relies on thermoplastic “filament” heated by the printer extruder prior to being deposited on the print bed. Most FFF printers rely on ABS and PLA plastic filament, but the latest models also use polycarbonate (PC), high-density polyethylene (HDPE), high-impact polystyrene (HIPS) filament. Some even use metal wire instead of plastic, while others use sawdust to create quasi-wood objects. Some can even print food, chocolate, pasta and so on.

-

Granular printers are different beasts since their material is not filament but, usually, powdered metal. These printers tend to be based on laser technology (although they don’t have much in common with your office laser printer). They use a powerful laser to selectively fuse granular materials. There are several ways of doing this: Selective laser sintering (SLS) printers fuse small metal particles by the process of “sintering,” while selective laser melting (SLM) printers melt the powder.

Electron beam melting (EBM) printers hits metal powder with an electron beam in a vacuum environment

Electron beam melting (EBM) printers hits metal powder with an electron beam in a vacuum environment -

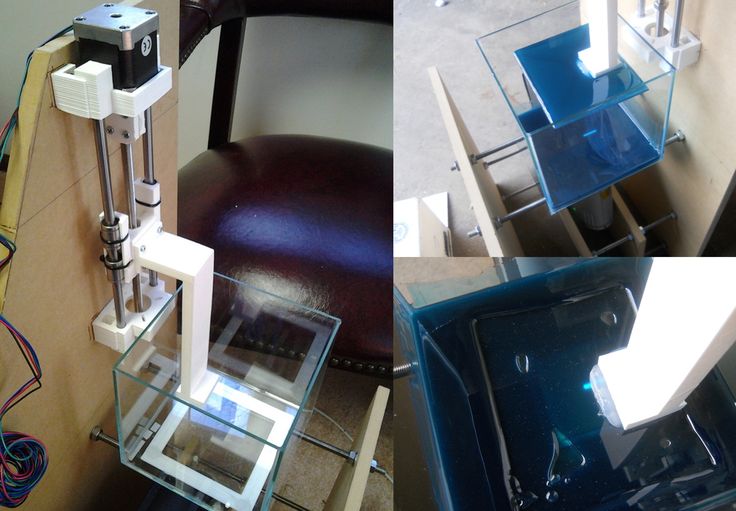

Stereolithography (SLA) printers transform liquid raw material into solids using light. These printers have a number of advantages, in terms of accuracy and the ability to produce complex objects in a single pass, because SLA prints don’t require struts or supports, in most cases. The downside is that the choice of materials is very limited. They are usually exotic liquid polymers, and can’t be used to print metal or chocolate.

There are a few more 3D printing technologies out there, but I see no point in covering all of them for the purposes of this blog post.

The Challenge

So why aren’t we all playing around with 3D printers in our homes and offices? Why can’t we print objects the same way we print invoices, sheets and emails? 3D printing is not going mainstream any time soon, and here are some challenges and issues that need to be addressed first.

- Prohibitively expensive hardware

- Limited user base (compared to traditional printers)

- Immature technology

- Speed

- Price/performance, ROI

- Running costs

- Energy efficiency

With each new generation, entry-level 3D printers become a bit cheaper, but they are still too expensive for most potential users. It’s one thing to buy a $200 printer for your home or office, you’ll probably end up using it a lot, but the same isn’t necessarily true of 3D printers. How many people need to print documents, and how many need to print 3D objects?

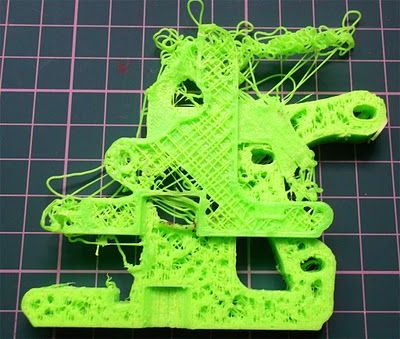

Technology is improving, but serious limitations persist. 3D printers are still slow, are sensitive to all sorts of adverse conditions, their “printbeds” tend to be small (especially on inexpensive models), the choice of materials is limited and filament can be expensive.

The reason why businesses aren’t lining up to buy 3D printers is simple: ROI. 3D printers still can’t come close to traditional manufacturing methods in terms of speed, cost and energy efficiency. This does not mean industry isn’t going to shift to 3D printing in the future; we are already seeing some pioneering developments, but 3D printers won’t render traditional manufacturing techniques obsolete soon.

This does not mean industry isn’t going to shift to 3D printing in the future; we are already seeing some pioneering developments, but 3D printers won’t render traditional manufacturing techniques obsolete soon.

Still, there are some noteworthy exceptions. A couple of years ago, General Electric set out to design and build a new fuel injection nozzle for its next generation CFM LEAP turbofan engine, which is bound to end up in hundreds of airliners. GE eventually settled on 3D-printed titanium nozzles. The reason? The new 3D printed nozzle ended up 25 percent lighter than the previous design and consisted of a single part instead of 18 on the old nozzle. Durability is expected to be five times better. These nozzles will be used in engines manufactured in 2016 and beyond. GE hopes to produce more than 100,000 3D-printed parts by the end of the decade.

A team of GE engineers decided to create a working replica of one of the company’s engines, using a new granular printing technique dubbed “metal laser melting. ”

”

Long story short, no, you won’t buy 3D-printed toys for $2 anytime soon, but you will fly on airliners powered by more efficient and reliable engines, made possible by 3D printing. There won’t be any 3D-printed chocolate in your local mall, at least not yet, but your dentist will tell you it’s probably not a good idea to eat chocolate anyway, right after you get your 3D-printed prosthetic.

There Is Another Way: 3D Printing Fulfilment Services

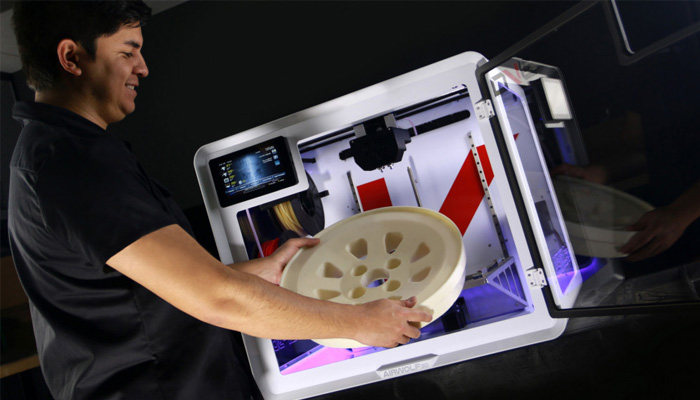

So, you have a great idea for a product, but first you need a small series of prototypes. Who do you call? Do you buy a bunch of 3D printers? Or do you simply send the design to a fulfilment service that will ship you the completed models in a matter of days?

Fulfilment services allow consumers and small businesses to take advantage of sophisticated 3D printing infrastructure without burning capital.

Tweet

A 3D printing fulfilment service seems like a hassle-free choice, and that’s the direction the industry seems to be taking. Many 3D printing outfits have launched similar services and are collaborating with other industry leaders. One example of this symbiotic relationship is Stratasys Direct Express, which recently partnered with Adobe and enabled Photoshop CC integration, offering colour 3D printing for professional designers.

Many 3D printing outfits have launched similar services and are collaborating with other industry leaders. One example of this symbiotic relationship is Stratasys Direct Express, which recently partnered with Adobe and enabled Photoshop CC integration, offering colour 3D printing for professional designers.

Google and Motorola didn’t invest billions in their own 3D printing facilities when they unveiled the Ara modular smartphone concept. They outsourced module manufacturing to 3D Systems. This example also underscores the potential flexibility of additive manufacturing: Ara is based around an alloy exoskeleton filled with various standardised modules that could be 3D printed. Since the modules have to connect to the exoskeleton, 3D Systems developed a new technique of depositing conductive materials within the printed components, which is a far cry from traditional 3D printer prototyping.

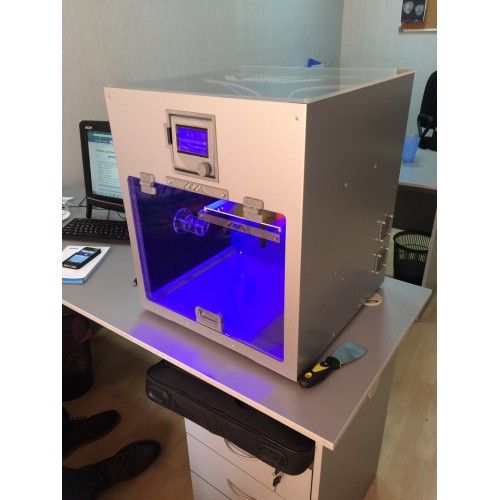

3D fulfilment services usually offer several different printing technologies, cutting-edge hardware and support. Why bother getting a $2,000 printer when you can simply send your designs to professionals and use any of a variety of professional printers, some of which cost more than your home? And let’s not forget about economy of scale; big services can and should offer a superior price/performance ratio compared to in-house printing.

Why bother getting a $2,000 printer when you can simply send your designs to professionals and use any of a variety of professional printers, some of which cost more than your home? And let’s not forget about economy of scale; big services can and should offer a superior price/performance ratio compared to in-house printing.

In my opinion, this is the way to go. This straightforward business model has a lot going for it, and it’s hard to see how individuals and small businesses could compete on an even playing field. In terms of price, size and energy consumption, a professional 3D printer has more in common with a printing press than your LaserJet, and how many people need a printing press in their home or office?

(One of my pet peeves is the name itself. When you mention a “printer” in conversation, most people think of their home inkjet printer, or office printer. While it’s true that 3D printers are printers, they don’t have much in common with traditional printers, and this distinction is often lost on laymen. If we just kept calling them additive manufacturing machines, this wouldn’t be an issue.)

If we just kept calling them additive manufacturing machines, this wouldn’t be an issue.)

What does all this mean for the average visual designer or software engineer? Will 3D printing change the way we do business? Will it enable rapid prototyping or even cheap small-scale manufacturing? When are we going to cook up some 3D-printed Barilla pasta for lunch?

I am afraid there is no simple answer because you can look at it from several perspectives. It all depends on your personal affinities and goals.

There are a few different ways designers and developers might become involved in 3D printing:

- Participation in open-source initiatives (RepRap)

- Use of professional design tools (Adobe CC)

- Integration of printing functionality to applications (Autodesk’s Spark 3D printing platform)

- Use of 3D printing fulfilment services

- Integration of 3D printing fulfilment services

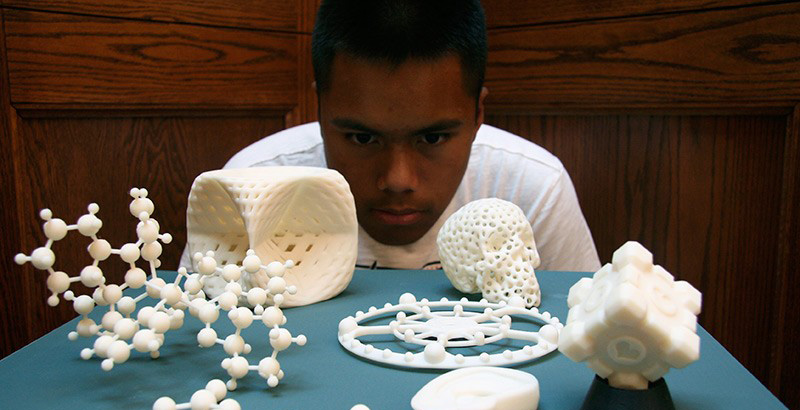

Most open-source initiatives are geared toward individual, hobbyist users. They are also valuable for education, and they can foster a lot of innovation. The downside is that there’s not a lot of money to be made in this niche. It’s mostly a labour of love. The good news is that the bar is set pretty low; you can get an entry-level printer and loads of plastic filament for under $500. You can get a cheap and relatively good 3D printer for the price of a good smartphone.

They are also valuable for education, and they can foster a lot of innovation. The downside is that there’s not a lot of money to be made in this niche. It’s mostly a labour of love. The good news is that the bar is set pretty low; you can get an entry-level printer and loads of plastic filament for under $500. You can get a cheap and relatively good 3D printer for the price of a good smartphone.

Integration of 3D design and printing capabilities could prove more lucrative in the long run. Designers don’t have to go out of their way to experiment with 3D printing because it’s already accessible through leading software packages. Sooner or later, a client will start asking questions about 3D printed prototypes or small-scale production, so depending on your niche, it could be a good idea to do a bit of research.

We’re left with the elephant in the room: 3D printing fulfilment services.

Outsourcing 3D Printing Via The Cloud

On the face of it, fulfilment services seem to be the answer to everything. They put professional services within the reach of individuals, startups, and small businesses who otherwise couldn’t afford certain printing techniques, like laser sintering or stereolithography. They’re practically the only viable way of integrating 3D printing into a range of different services, mainly through cloud-based mobile and web apps.

They put professional services within the reach of individuals, startups, and small businesses who otherwise couldn’t afford certain printing techniques, like laser sintering or stereolithography. They’re practically the only viable way of integrating 3D printing into a range of different services, mainly through cloud-based mobile and web apps.

So what are the downsides? There aren’t many.

Industrial scale fulfilment services are a relatively new concept. However, availability is still limited. Sure, if you need to print a few dozen titanium prototypes in California that won’t be a problem, but what if you need to do the exact same thing in Botswana or Bahrain? It will be more expensive because the manufactured designs will have to be shipped around the globe. On-site manufacturing sounds good, but it could prove prohibitively expensive

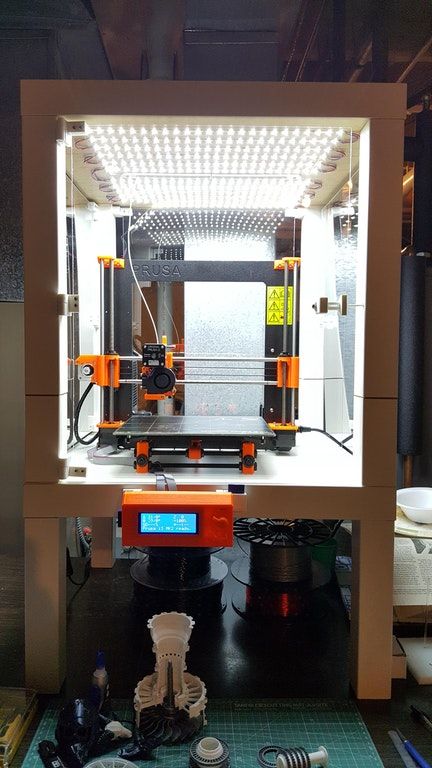

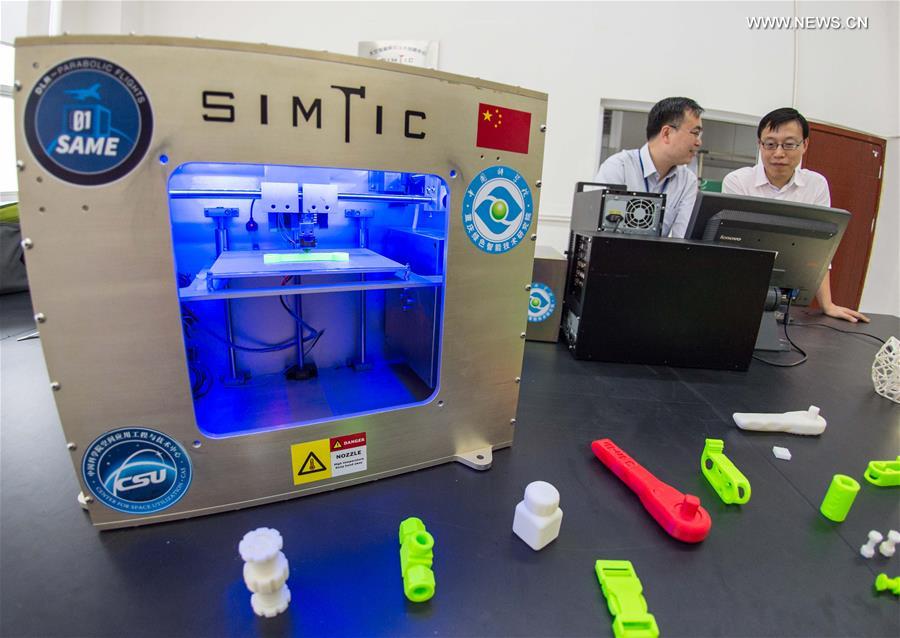

Of course, on-site manufacturing has a lot going for it; if a business needs to quickly iterate and revise designs, then the speed and convenience of 3D printer rapid prototyping can’t be matched by printing services. This is a relatively tight niche, but it’s by no means small. Design studios, architects, engineers, various maintenance departments, logistics, education; they all need on-site printers. Besides, if you need a printed replacement part on the International Space Station, you can’t exactly call Amazon. On another note, 3D printing in space would have made the exploits of the Apollo 13 crew look less impressive. No wonder NASA is already experimenting with them in space.

This is a relatively tight niche, but it’s by no means small. Design studios, architects, engineers, various maintenance departments, logistics, education; they all need on-site printers. Besides, if you need a printed replacement part on the International Space Station, you can’t exactly call Amazon. On another note, 3D printing in space would have made the exploits of the Apollo 13 crew look less impressive. No wonder NASA is already experimenting with them in space.

It’s worth noting that 3D printers can be used to print more than replacement parts and passive components. They can also be used to print working electrical components, ranging from speakers to printed circuit boards (PCB). PCB prototyping is a nice niche because traditional methods are slow and expensive. A 3D printer with a spool of conductive filament can usually do the trick on-site, on time, and on budget.

Still, as far as mass market applications go, chances are this space will be dominated by big players like Amazon, Stratasys, 3D Systems, and possibly Hewlett-Packard. As the industry matures, worldwide availability should become a non-issue, prices will go down and new hardware will offer new opportunities and superior quality.

As the industry matures, worldwide availability should become a non-issue, prices will go down and new hardware will offer new opportunities and superior quality.

In my opinion, the biggest problem the industry currently faces is the lack of use-cases. Sure, it sounds convenient, but who is it for? How do we get 3D-printed products into the hands of mainstream consumers?

This question is not as straightforward as it seems because additive manufacturing has been hyped in recent years. Just try googling for 3D printing use-cases and you’ll see what I mean: 3D printing seems to be the answer to all our problems, but in reality most of it is hype, based on long-term projections.

So, I decided to include research from an unbiased source: UK’s Intellectual Property Office. The paper, titled The Current Status and Impact of 3D Printing Within the Industrial Sector: An Analysis of Six Case Studies is extensive and examines the potential impact of additive manufacturing on several industries: automotive, domestic appliances, replacement parts, customised goods, reverse engineering, games and computer generated graphics.

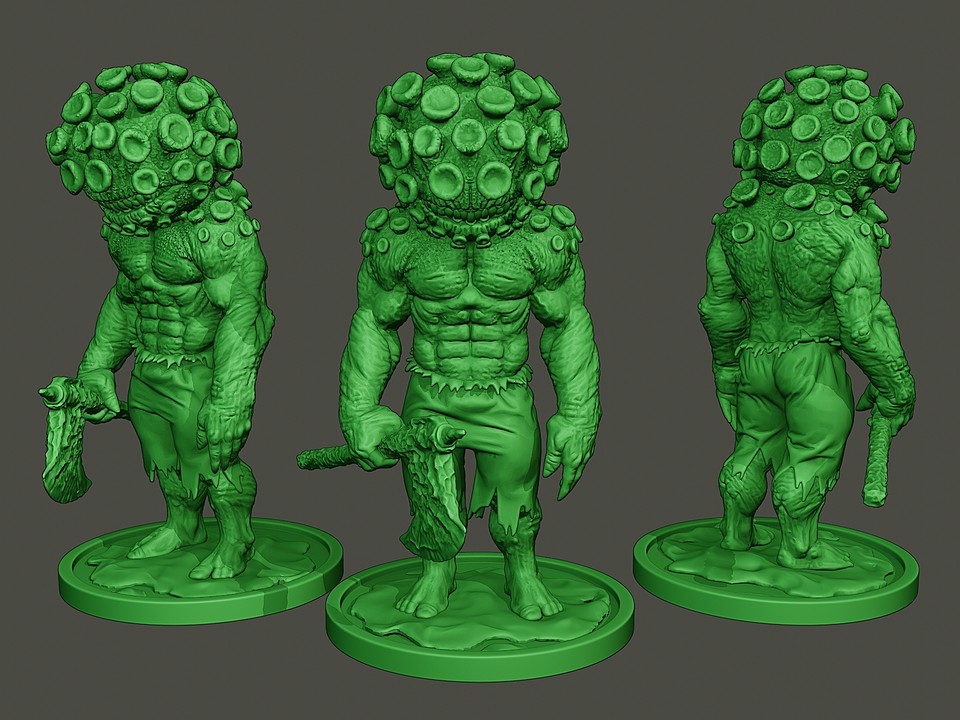

Customised goods and CGI-derived designs stand out as the most realistic use cases for freelancers, so let’s take a closer look.

Personalised Manufacturing

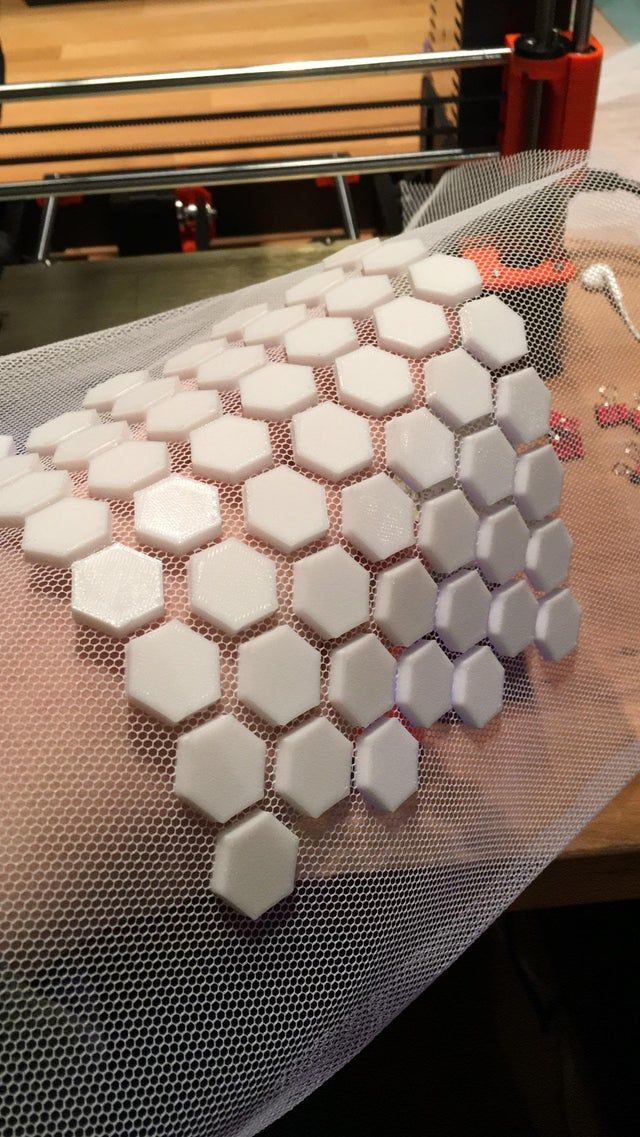

One of the biggest advantages of additive manufacturing over traditional manufacturing methods is the ability to produce one-off designs or small series. How long would it take to create a plastic toy using traditional manufacturing? You’d need loads of equipment, cast dies and whatnot. With 3D printing, it’s just a matter of selecting a wireframe and clicking. This means it’s possible to produce unique designs, tailored to meet the needs of different customers.

Additive manufacturing can enable average consumers to design and customise various products prior to making a purchase. This can be done using professional desktop applications, or even web and mobile apps. Nobody expects the average consumer to design an item from the ground up, but even a child could customise a toy using a simplified mobile app.

The potential for personalised manufacturing is one of the key benefits provided by 3D printing.

Tweet

Such a platform would have to include loads of different colour or decal options, along with the 3D wireframes themselves. What’s more, it should be possible to create modular designs, so if kids are customising a toy car or doll, they could choose between scores of different, but compatible, components that would be assembled to make the product.

Yes, instead of customising virtual environments in apps and games, kids born today will be able to personalise their real toys, or turn their video game characters into action figures. It kinda makes you wish you were born a couple of decades later, doesn’t it?

Here are a few personalised 3D printing use-cases with mass market appeal:

- Toys

- Custom jewelry

- DIY and hobbyist products

- Fashion and gadget accessories

- Personalised appliances and household items

However, products don’t have to be personalised to match your taste; they could also be made to perfectly match your physique, like a tailored suit. These products might not have the mass market appeal of personalised toys, but that doesn’t make them less exciting. In fact, I find them a lot more interesting than a customised brooch or doll.

These products might not have the mass market appeal of personalised toys, but that doesn’t make them less exciting. In fact, I find them a lot more interesting than a customised brooch or doll.

Here are just some examples:

- Digital dentistry

- Surgery (mockups for training, 3D-printed replacement joints)

- Advanced prosthetics

- Tailored equipment and apparel for various professions

- Sports equipment and accessories

Sure, these applications don’t have nearly the same emotional appeal as the ones I mentioned earlier, but in the big scheme of things they could be just as lucrative and important, especially when you consider medical applications.

The Implications And Future Of 3D Printing

So what’s the bottom line? Will 3D printing change the industrial landscape? Is it really the next industrial revolution?

3D printing, or additive manufacturing, is a very promising, but immature, technology. It clearly has a lot of potential, but we’re still nowhere close to realising it even though the industry is seeing a lot of growth.

In fact, the market for 3D printing services, hardware, and materials, has been growing at a healthy double-digit rate for years. Most analysts expect the market to double by the end of the decade, passing the $10 billion mark. That may sound like a lot of money, but let’s put it in perspective: The same analysts expect annual smartphone shipments for 2015 to end up in the 1.3 to 1.4 billion unit range.

Looking past the hype, 3D printing is a technology with limited appeal, at least at this early stage. However, we will continue to see growth and development for the foreseeable future, backed by new use-cases. Many of these use-cases and business models will be based around 3D printing fulfilment services. This is good news for small businesses and individuals, because they will be able to use third-party infrastructure with relative ease. They won’t have to buy dozens of printers, they will simply integrate a few APIs to their platform and that’s it.

In the short term, this is the future of 3D printing, at least from a mass market perspective.

5 Biggest 3D Printing Companies

The manufacturing process known as 3D printing is one of the most promising and rapidly developing technologies with applications across a multitude of industries. 3D printing involves the additive layering of thin sheets of material that are fused together to create a physical product from a digital design.

While the industry is currently hampered by relatively slow production times, advocates believe that 3D printing ultimately will have the capability to mass produce everything from medical equipment to automotive parts to airline components.

Below, we look at the 5 biggest 3D printing companies by 12-month trailing (TTM) revenue. This list is limited to companies that are publicly traded in the U.S. or Canada, either directly or through ADRs. Some foreign companies may report semiannually, and so may have longer lag times. All data are from YCharts as of Dec. 15, 2022.

- Revenue (TTM): $659.2 million

- Net Income (TTM): $-31.

4 million

4 million - Market Cap: $818.8 million

- 1-Year Trailing Total Return: -47.76%

- Exchange: NASDAQ

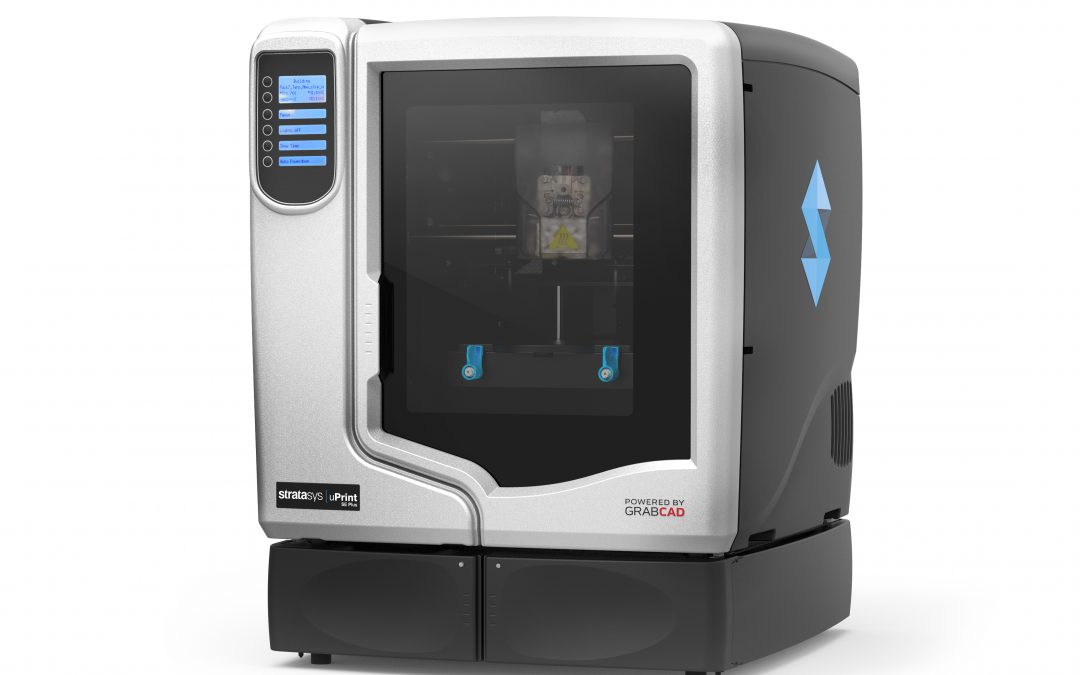

Stratasys boasts that its founder created one of the very first 3D printers and says that it continues to evolve. The company's technology provides solutions for various industries, including but not limited to aerospace, health care, and consumer products. Not only does the company produce desktop 3D printers, but it also has systems available for large-scale production that can be used in digital manufacturing. Founded in 1998, the company is based in Eden Prairie, Minnesota, and has another office in Rehovot, Israel.

- Revenue (TTM): $556.2 million

- Net Income (TTM): -$103.4 million

- Market Cap: $1.2 billion

- 1-Year Trailing Total Return: -15.27%

- Exchange: New York Stock Exchange

3D Systems invented 3D printing in 1989 with the development and patenting of its stereolithography technology, which uses ultraviolet lasers to help create highly precise parts. DDD built on that by developing new technologies, including selective laser sintering, multi-jet printing, film-transfer imaging, color jet printing, direct metal printing, and plastic jet printing. 3D Systems has three business units: products, materials, and services. The products category offers 3D printers and software and includes small desktop and commercial printers that print in plastics and other materials.

DDD built on that by developing new technologies, including selective laser sintering, multi-jet printing, film-transfer imaging, color jet printing, direct metal printing, and plastic jet printing. 3D Systems has three business units: products, materials, and services. The products category offers 3D printers and software and includes small desktop and commercial printers that print in plastics and other materials.

- Revenue (TTM): $496.4 million

- Net Income (TTM): $23.5 million

- Market Cap: $722.1 million

- 1-Year Trailing Total Return: -47.65%

- Exchange: New York Stock Exchange

Proto Labs was founded in 1999 with a focus on building automated solutions to develop plastic and metal parts used in the manufacturing process. The company expanded to launch an industrial-grade 3D printing service that allowed developers and engineers to move prototypes into the production process. The company's primary business services include injection molding, sheet metal fabrication, and 3D printing.

- Revenue (TTM): $245.2 million

- Net Income (TTM): $8.0 million

- Market Cap: $562.3 million

- 1-Year Trailing Total Return: -57.18%

- Exchange: NASDAQ

Belgian company Materialise has a 30-year history of providing 3D printing solutions and related software. It provides platforms to facilitate the development of 3D printing applications in industries such as healthcare, automotive, aerospace, and art and design. Some of the company's first 3D printing activities included anatomical models in both dental and hearing aid products. Materialise also produces eyewear and automobile products.

- Revenue (TTM): $205.1 million

- Net Income (TTM): $-499.2 million

- Market Cap: $495.4 million

- 1-Year Trailing Total Return: -71%

- Exchange: New York Stock Exchange

Desktop Metal was founded in 2015. The company designs and manufactures 3D printing systems. It pairs these systems with performance-driven materials, applications, and technologies, which provide clients with speed and reliability in their 3D printing needs. Desktop Metal serves various industries, including automotive, consumer goods, machine design, and manufacturing tooling. The company is based in Burlington, Massachussetts.

Desktop Metal serves various industries, including automotive, consumer goods, machine design, and manufacturing tooling. The company is based in Burlington, Massachussetts.

3D Printer Manufacturers: Quality 3D Printers

3D Printer Manufacturers

If you are interested in 3D printing and want to buy your own 3D printer, you might be wondering which 3D printer manufacturers are out there. In this article, we will try to answer this question in as much detail as possible and list the existing manufacturers.

Of course, it makes no sense to talk about all the developers, because there are a lot of them. Manufacturers of 3D printers today are divided not only by the type of technology used by their devices, but also by the class of devices. nine0005

In general, all 3D printer manufacturers can be divided into three groups:

- Professionals. They produce the highest quality equipment, including industrial ones. The cost of their goods, respectively, is significantly higher than the average market prices, but the buyer pays not only for the brand, but also for reliability;

- Middle segment.

The vast majority of 3D printer manufacturers fall into this category. These are companies that have already established themselves in the market, but have not yet reached a certain point. It produces good quality products at an affordable price; nine0012

The vast majority of 3D printer manufacturers fall into this category. These are companies that have already established themselves in the market, but have not yet reached a certain point. It produces good quality products at an affordable price; nine0012 - Start-up producers. Basically, these are young enthusiastic developers who are eager to bring their product into circulation. It is possible that their products can be quite good, but often such 3D printers are very raw and unfinished.

Other questions and answers about 3D printers and 3D printing:

Quality 3D printer

Of course, if you want to buy your own device for 3D printing, you want to buy the highest quality 3D printer. But what if all the manufacturers of 3D printers are touting their products? How to decide? Let's figure it out. nine0005

First of all, you should trust only proven equipment developers. See which 3D printer manufacturers have been on the market for a long time and what they offer.

Secondly, analyze the proposed options. Compare prices and features of 3D printers, see reviews. It is also a good option to get professional advice from distributors. For example, in 3DDevice you will always be helped to make a choice.

Popular 3D printers

In order to bring some clarity and help you make your choice, it is worth mentioning the most popular 3D printers. Well-known 3D printer manufacturers such as Stratasys, 3D Systems, MakerBot, Formlabs, CreatBot, Ultimaker offer good options and the market is flooded with their products. The advantage of choosing a popular 3D printer is its ease of use. After all, there is probably a training video or a review on the desired model on the network. nine0005

Of course, when choosing a 3D printer, you should not focus solely on the manufacturer. There are many selection criteria to consider. However, 3D printer manufacturers are not the last factor to consider.

If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

We would like to remind you that in our store you will find a large number of equipment for 3D printing - desktop and professional 3D printers. We also have 3D scanners, 3D plastic and photopolymer resins, as well as spare parts and accessories at the best prices on the market with delivery throughout Ukraine. In addition, we provide 3D modeling, 3D printing and 3D scanning services. For all questions, please contact us in any of the ways convenient for you using these contacts. We look forward to collaborating! nine0005

Back to Home

Top 20 Free 3D Printing and 3D Printing Software

Looking for a 3D printing software? We've rounded up the top 20 software tools for beginners and professionals alike. Most slicers are free.

What is a slicer? This is a program for preparing a digital model for printing. Models for 3D printing are usually distributed in STL files. To turn an STL file into G-code (a language that a 3D printer understands), a slicer program is required. It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object. nine0005

It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object. nine0005

Which slicer should I choose? In this article, we will tell you which slicer is best for 3D printing for each stage of your work. Which one is better for preparing a 3D model for printing? But what if you need to create a 3D model from scratch? And if you are only taking the first steps in 3D?

Don't be afraid: we've answered all of these questions, including the required skill level for each program and where you can download it. The great thing is that most of these programs are completely free and open source. nine0005

- Cura

- CraftWare

- 123D Catch

- 3D Slash

- TinkerCAD

- 3DTin

- Sculptris

- ViewSTL

- Netfabb Basic

- Repetier

- FreeCAD

- SketchUp

- 3D Tool

- Meshfix

- Simplify3D

- Slic3r

- Blender

- MeshLab

- Meshmixer

- OctoPrint

#1: Cura

For beginners who need a slicer to prepare STL files for 3D printing

Cura is the standard slicer software for all Ultimaker 3D printers, but can be used with most others , including RepRap, Makerbot, Printrbot, Lulzbot and Witbox. The program is completely open source, its capabilities can be extended using plugins.

The program is completely open source, its capabilities can be extended using plugins.

This program is very easy to use and allows you to manage the most important 3D printing settings through a clear interface. Start in Basic mode to quickly get up to speed and change print quality settings. If finer control is required, switch to Expert mode. nine0005

Cura can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: Cura

Price: Free

Systems: PC, Mac, Linux

#2: CraftWare

For beginners to prepare STL files for 3D printing 3D printers by the Hungarian startup CraftUnique to support their CraftBot crowdfunding machine. However, the program works with other printers. nine0005

Like Cura, CraftWare allows you to switch from "Easy" to "Expert" mode, depending on how confident you feel. It's a colorful app that features a visual G-code visualization with each function represented by a different color. But the most outstanding feature is the individual support service. As far as we know, only the paid program Simplify3D has this.

But the most outstanding feature is the individual support service. As far as we know, only the paid program Simplify3D has this.

Please note, however, that this program is still in beta, so bugs may occur. nine0005

Download: CraftWare

Price: Free

Systems: PC, Mac

#3: 123D Catch

-systems, smartphones and tablets, which allows you to convert images of objects into a 3D model. Pictures can be taken with a smartphone/tablet or digital camera.

You need many photos of an object from different angles - the more the better - after which they will be compiled into a 3D model. nine0005

123D Catch is more of a fun app than a professional 3D printing tool, but after some tambourine dancing, you can get good results, especially when paired with an STL editor like MeshLab or Meshmixer.

Price: Free

Systems: PC, Android, iOS, Windows Phone

#4: 3D Slash

and surprisingly simple, and refreshingly new. With 3D Slash, you can design 3D models using your dice skills. nine0005

With 3D Slash, you can design 3D models using your dice skills. nine0005

You can start with a large block and, like a virtual sculptor, remove small cups from it with tools such as a hammer or drill, or start from empty space and build a model from cubes and other shapes. You can paint with flowers or use template pictures.

Other features worth mentioning are tools for creating logos and 3D text. The Logo Wizard imports an image and creates a 3D model, while the Text Wizard allows you to enter and format text, and then turn it into 3D. nine0005

Recommended!

Download: 3dslash.net

Price: Free

Systems: PC, Mac, Linux, Browser

#5: TinkerCAD

- A computer-aided design (CAD) system for 3D printing, which is a good starting point for beginners. Since its capabilities are limited compared to Blender, FreeCAD and SketchUp, many users switch to more powerful tools after some time. nine0005

As in 3D Slash, here you can build models from basic shapes. At the same time, unlike 3D Slash, TinkerCAD allows you to create vector shapes in 2D and convert them into three-dimensional models.

At the same time, unlike 3D Slash, TinkerCAD allows you to create vector shapes in 2D and convert them into three-dimensional models.

Come in: Autodesk TinkerCAD

Price: Free

Systems: Browser

#6: 3DTin

For beginners who want to create 3D printable models

another easy and intuitive online tool choice for beginners in 3D modeling. All you need is a Chrome or Firefox browser with WebGL enabled. nine0005

Choose from a huge library of 3D shapes and add them to your sketch. All sketches are stored in the cloud, access to them is free if you honor the Creative Commons license. Everything can be exported to STL or OBJ formats.

Enter: 3DTin

Price: Free

Systems: Browser

#7: Sculptris

For beginners who want to create 3D printable models

clay. This is a fantastic 3D modeling program if figurines are your main task. For example, you can make a bust of your favorite video game or comic book character. Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool. nine0005

Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool. nine0005

Download: Pixologic Sculptris

Price: Free

Systems: PC, Mac

#8: ViewSTL

For beginners who want to view STL files

Using ViewSTL is the easiest way to view STL files . Simply open a web page and drag the STL onto the dotted box.

The STL online viewer allows you to display the model in one of three views: flat shading (for a quick view), smooth shading (for a high-quality image), and wireframe. nine0005

Enter: ViewSTL

Price: Free

Systems: Browser

#9: Netfabb Basic

some nice features that allow you to analyze, "repair" and edit STL files before moving on to the model cutting stage.

A good choice if you need more than just a slicer and want to be able to quickly fix STL files without having to learn programs like MeshLab or Meshmixer. nine0005

Don't let the 'Basic' in the title fool you, Netfabb Basic is actually a very powerful 3D printing tool. It's "basic" only in the sense that it doesn't cost €1,500 like Netfabb Professional!

It's "basic" only in the sense that it doesn't cost €1,500 like Netfabb Professional!

Download: netfabb.de

Price: Free

Systems: PC, Mac, Linux

No. 10: Repetier

For advanced to prepare STL files for 3D printing

9004 If you are ready to upgrade to the next level of 3D printer slicer software, but if you want to stay open source, you should look into Repetier. It is the great grandfather of 3D printing software and a favorite of the RepRap community. nine0005To date, the program is moving by leaps and bounds from the level for beginners to advanced users. Packaged in an all-in-one configuration, it supports up to 16 extruders, multi-slicing via plug-ins, and virtually every fusing 3D printer on the market. Get ready to tinker!

What's more, Repetier Host works remotely via Repetier Server, so that the 3D printer can be controlled via a browser, tablet or smartphone. nine0005

Download: Repetier

Price: Free

Systems: PC, Mac, Linux

#11: FreeCAD

The program is a great option for developing your design skills. More technically, this parametric 3D modeling program allows you to easily change the project by rolling back through the history of the model and editing the parameters. nine00005

More technically, this parametric 3D modeling program allows you to easily change the project by rolling back through the history of the model and editing the parameters. nine00005

Download: freecadweb.org

Price: Free

Systems: PC, Mac, Linux

#12: SketchUp

For beginners who want to create 3D printable models

SketchUp is the perfect combination of simplicity and the perfect combination functionality, with a user-friendly interface and a relatively flat learning curve (i.e., as experience grows with the time spent), the ideal program for developing three-dimensional models.

The Make SketchUp version is free and includes everything you need for 3D modeling if you also download and install the free STL exporter. There is also a professional edition for architects, interior designers and engineers. nine0005

Download: sketchup.com

Price: Free (SketchUp Make), $695 (SketchUp Pro)

Systems: PC, Mac, Linux

#13: 3D-Tool Free Viewer

view and check STL files

3D-Tool Free Viewer is a sophisticated tool that, among other things, allows you to check the structural integrity and printability of your file. With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing. nine0005

With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing. nine0005

Download: 3D-Tool

Price: Free

Systems: PC

#14: Meshfix

your model for errors.

Price: Free

Systems: Browser

#15: Simplify3D

For professionals to prepare STL files for 3D printing print. A flexible algorithm checks the model for problems, fixes them, shows a preview of the printing process (ideal for identifying potential problems), and then slices it. nine0005

This slicer offers the best infill pattern options in the competition. For models that require supports, Simplify3D will create the appropriate structures on its own and give you full control over their placement. For printers with a dual extruder, when printing with different materials, the Dual Extrusion wizard will help, as a result of which, for example, it will be easier to remove the dissolving filament.

Simplify3D supports 90% of today's commercially available desktop 3D printers and is compatible with Marlin, Sprinter, Repetier, XYZprinting, FlashForge, Sailfish and MakerBot firmware. Simplify3D can also be used to directly control the printer, but then the printer and computer must be connected to each other. nine0005

Download: simplify3d.com

Price: $149

Systems: PC, Mac, Linux

#16: Slic3r

source code, which has a reputation as a carrier of super new functionality, which you will not find anywhere else. The current version of the program is able to show the model from multiple angles, so that the user gets a better preview experience.

There's also an incredible 3D honeycomb infill, the first of its kind that can extend over multiple layers rather than repeating itself like a stamp. This significantly increases the strength of the internal filling of the model and the final printout.

Another option is direct integration with Octoprint. Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Download: Slic3r

Price: Free

Systems: PC, Mac, Linux

#17: Blender

For professionals who want to create 3D printable models

Blender is a popular computer-aided design (CAD) system with a steep learning curve. Not at all the best choice for beginners, but what you need if you are quite experienced and need something more complex for modeling and printing.

In short, Blender is one of the most powerful tools out there. Its community is always ready to help, there are a lot of educational materials. It's also open source, so enthusiasts often write extensions to make it even better and more powerful. nine0005

Download: blender.org

Price: Free

Systems: PC, Mac, Linux

#18: MeshLab

For professionals to prepare STL files for 3D printing

MeshLab - advanced editor. It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

Price: Free

Systems: PC, Mac, Linux

#19: Meshmixer

For professionals to prepare STL files for 3D printing

Meshmixer is a super advanced 3D printing program to view, check, edit and repair STL files. It's especially good for identifying potential problems and fixing them automatically. For example, it will show paper-thin walls that can lead to problems with 3D printing. Meshmixer is part of the Autodesk family of 3D printer software, so it should work well with tools like TinkerCAD. nine0005

Price: Free

Systems: PC, Mac

#20: OctoPrint

start, pause or interrupt 3D print jobs. Combined with Wi-Fi capable devices, it makes for a great monitor for remotely monitoring the 3D printing process.

Octoprint understands the G-codes of almost all 3D printers and slicers and includes a gCodeVisualizer to visualize this code before or during printing.