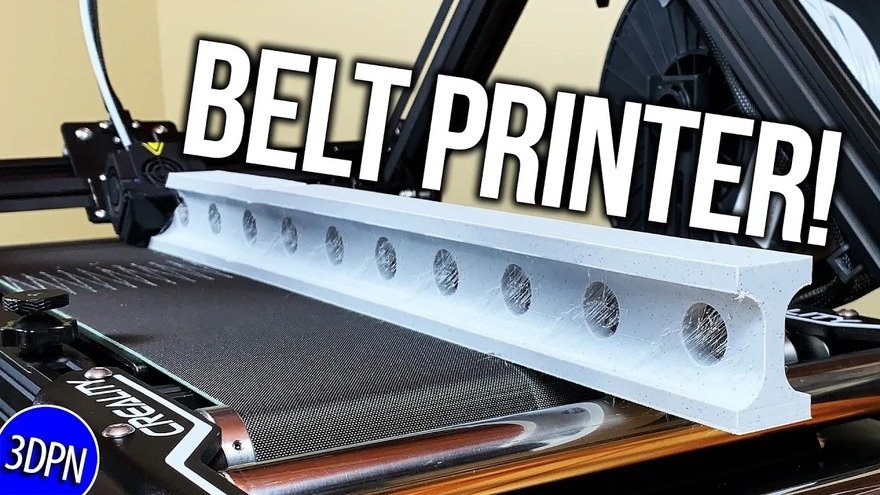

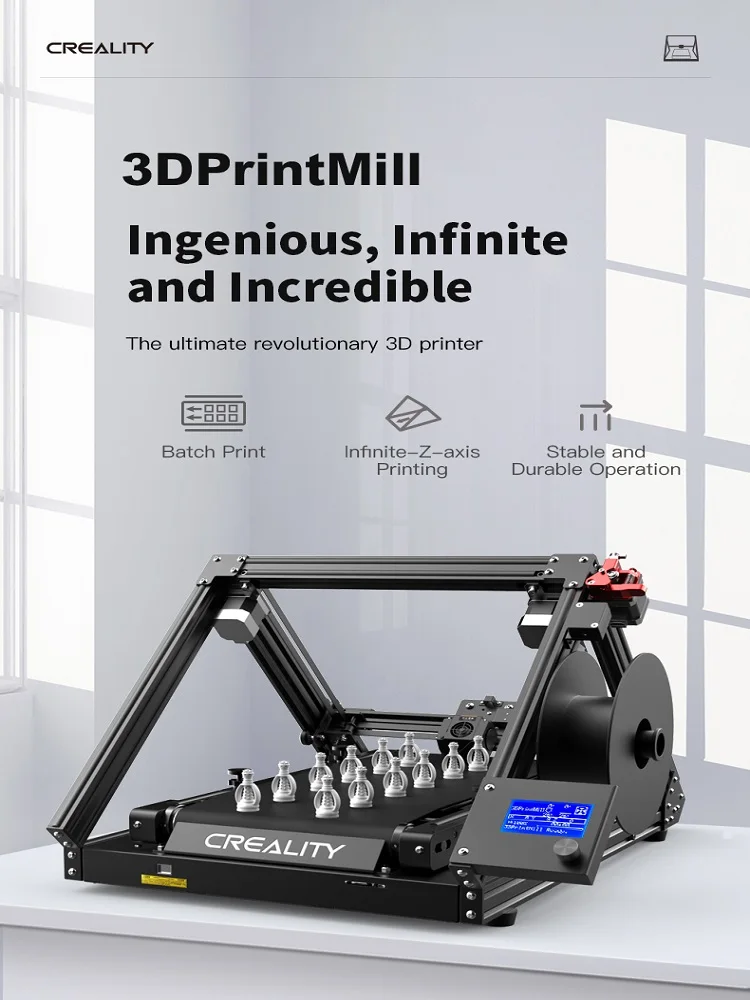

Creality 3d print mill

Creality's CR30 Belt 3D Printer, CR-30 3DPrintMill US/AU/UK FREE SHIPPING

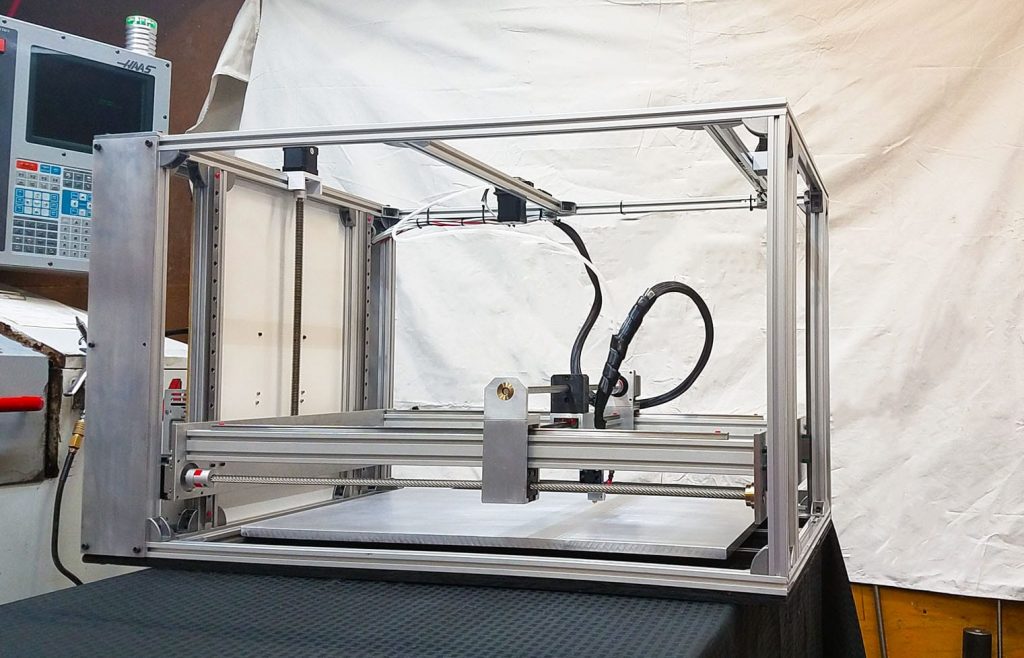

An Infinite-Z volume 3D printer created by Naomi Wu & Creality3D, building on the work of Karl Brown and Bill Steele. 3DPrintMill is a feature of infinite-length printing and bulk printing, thereby time-saving in printing and cost-efficient. The special infinite-Z belt is the first Creality 3D printer to realize infinite build volume in the world.

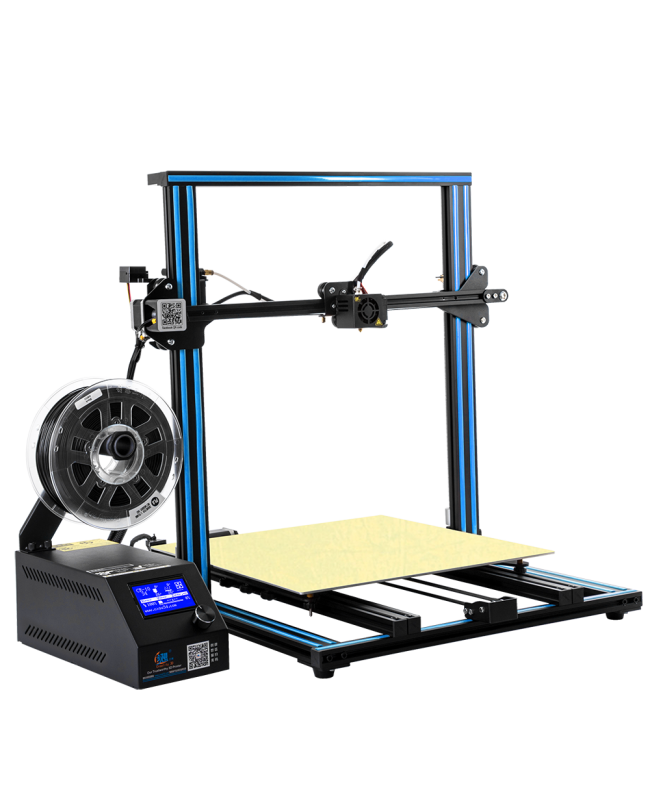

Infinite-Z-axis for Endless Printing: Equipped with the rolling conveyor belt, it realizes continuous printing. No worries to print the infinite length model. High productivity, time-saving, and cost-efficient (Print dimension: 200*170*∞mm) *A removable extension bracket is available for installing to prevent the model from falling during printing.

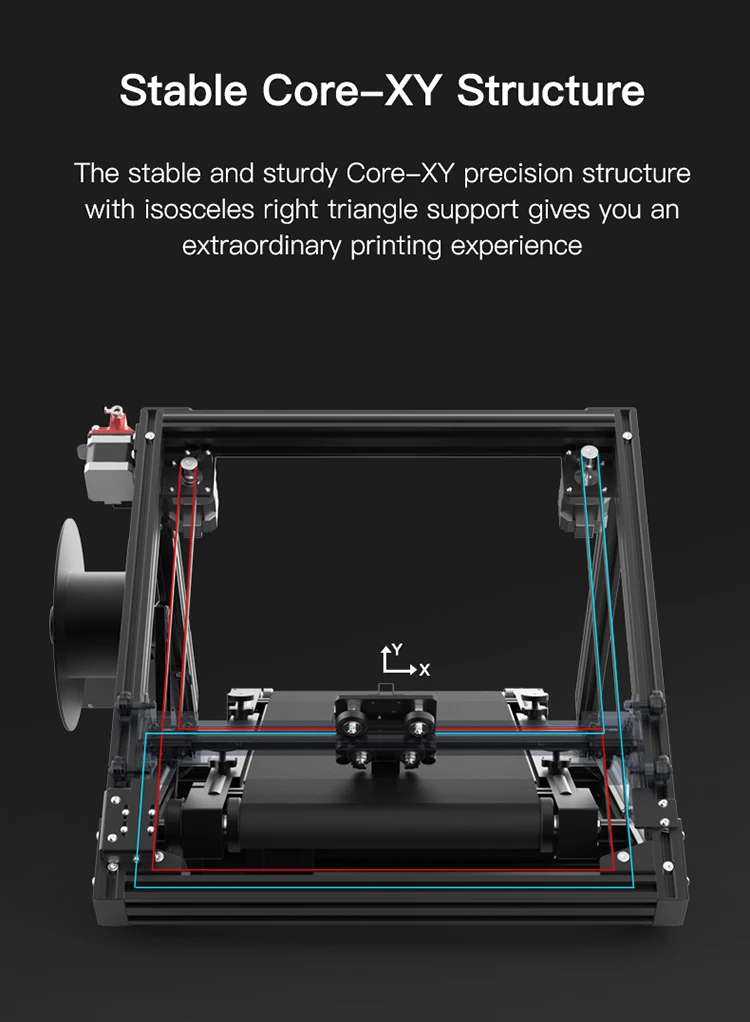

Stable CoreXY Structure: The stable and sturdy CoreXY precision structure with isosceles right triangle support gives you an extraordinary printing experience.

Nylon Conveyor Belt: Made of wear-resistant Nylon, the conveyor belt features excellent adhesion to the model. The printed model can fall off automatically as the belt rolls to the end, thus free your hand Strong adhesion| Hassle-free removal | Wear-resistant| Well-balanced conveyance *Easy to replace the conveyor belt.

Dual gears metal extrusion mechanism: High-quality dual gears metal extrusion, combined with the 45 degrees slanting nozzle realizing constant printing of >200 hours without pressure.

Unique 45° Printing Angle: The unique 45 ° angle design offsets the limitations of the vertical nozzle structure. Equipped with a high-performance nozzle kit, it achieves continuous printing along with the horizontal Z-axis.

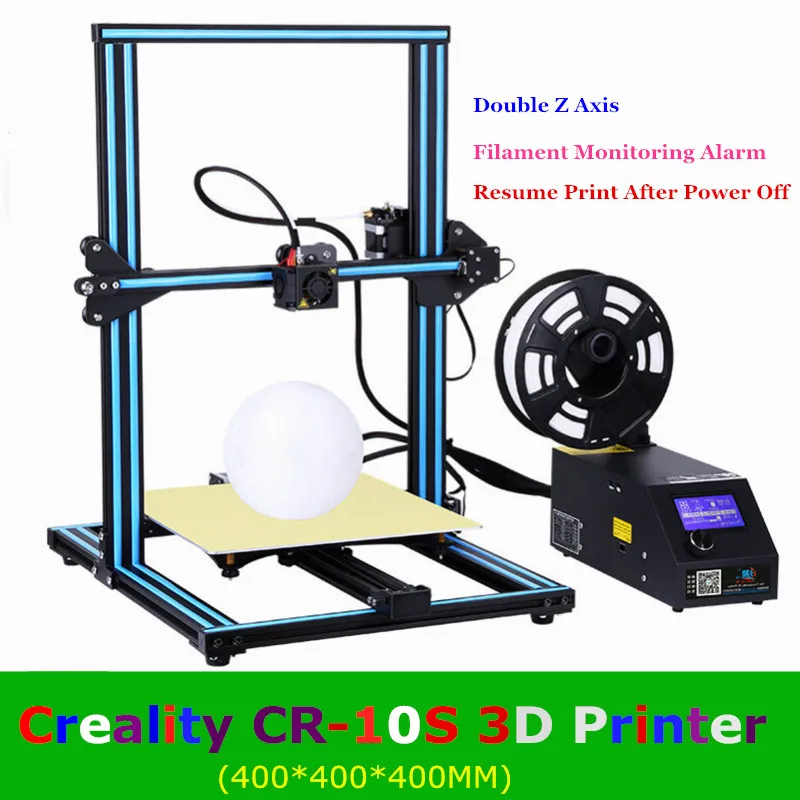

Filament Breakage Detector: Whenever there is a possible accident like filament run-out or filament breakage, the smart sensor forces the machine to suspend printing. Printing will be automatically resumed after the new filament feed-in.

Printing will be automatically resumed after the new filament feed-in.

Ultra-silent Motherboard/Fans to Cool Down Ensure/Resume Printing.

Time Lapse of #3DPrintMill Printed 6-Meter Rod

Download

Download

Download

Download

Download

Creality 3DPrintMill (CR-30) Review: Belt Printer For Batch 3D Printing

I was really interested in getting the Creality-CR30 (Also knowns as the 3DPrintMill) because I never used a 45-degree 3D printer. So, I contacted Creality and they sent me one to review. In this article you’ll read about my experience with the CR-30, so you can decide for yourself if this printer is what you need.

So, I contacted Creality and they sent me one to review. In this article you’ll read about my experience with the CR-30, so you can decide for yourself if this printer is what you need.

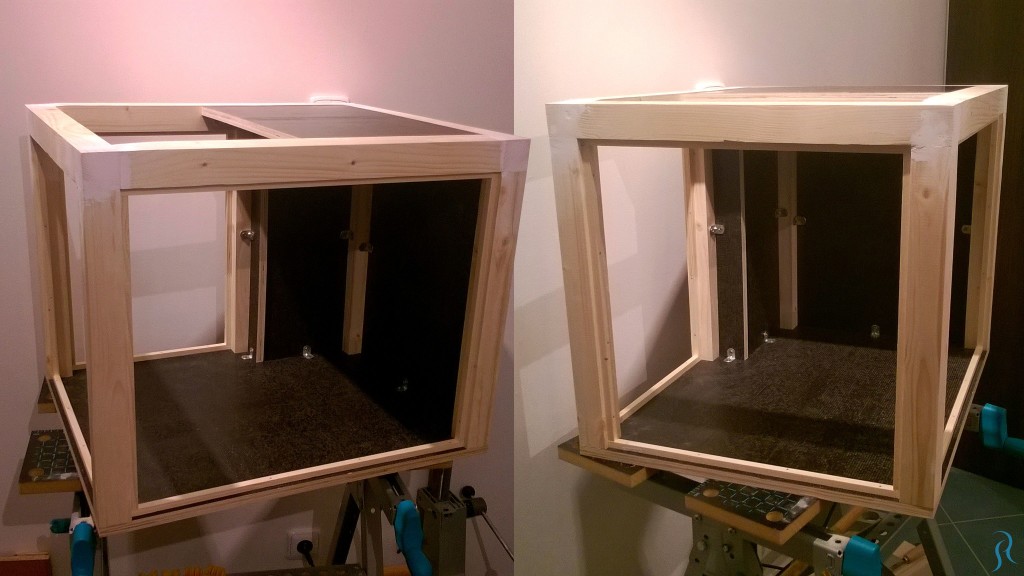

Creality CR-30 Shipping and Packaging

The Creality CR-30 3DPrintMill comes in a large carboard box with everything tightly packed to ensure a successful delivery. The printer is quite heavy so it’s nice to see that Creality used thick foam to protect the components from shipping damage.

Assembling the printer takes less than 30 minutes, and when complete, you get a really sturdy printer. While it looks quite big, the physical dimensions are smaller than expected.

Creality 3DPrintMill (CR-30) Specs

| Molding technology | FDM |

| Print dimension | 200 * 170 * ∞ mm |

| Machine dimension | 535 * 656 * 410mm |

| Package dimension | 685 * 565 * 302mm |

| N.W. | 16.5kg |

G. W. W. | 20.5kg |

| Slice software | Crealitybelt or IdeaMaker |

| Print accuracy | ± 0.1mm |

| Nozzle diameter | 0.4mm |

| Number of nozzles | 1 |

| Hotbed temperature | ≤ 100 ℃ |

| Nozzle temperature | ≤ 240 ℃ |

| Layer thickness | 0.1mm-0.4mm |

| Rated Power | 350W |

| Power supply | AC 100-120v / 200-240v, DC 24V |

| Supported filaments | PLA / TPU / PETG |

| Diameter of filament | 1.75mm |

| Supported language | English |

| File transfer | USB/SD card |

Infinite Z axis belt

What makes the infinite possible is the Z belt present on the printer. It’s made from nylon and offers good adhesion for the prints if the nozzle offset is set correctly. What I don’t like too much is the location where the belt ends are connected. That particular section is not as smooth and will leave an imprint on the models, but I don’t think there’s another way of making a belt.

That particular section is not as smooth and will leave an imprint on the models, but I don’t think there’s another way of making a belt.

The belt is moved by a stepper motor located in the back of the printer, which is connected with a smaller 2GT belt to a bigger pulley. A belt tensioner is available if there’s a need to tighten it.

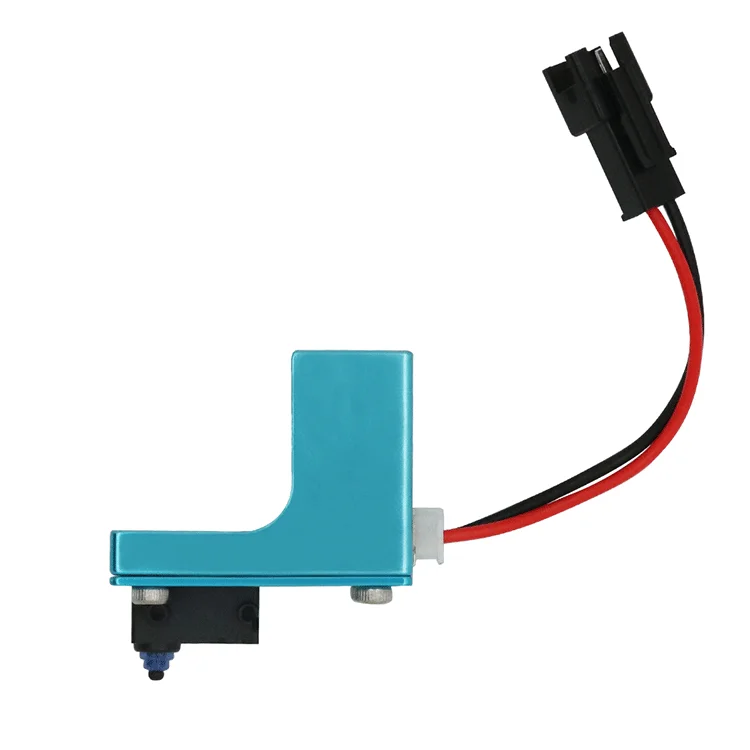

On the back left, we have the Z endstop. It’s an optical sensor which can be adjusted using the bottom screw. Ensure that the four screws holding the sensor in place are loosened before you adjust the sensor position. When you’re done, carefully tighten back.

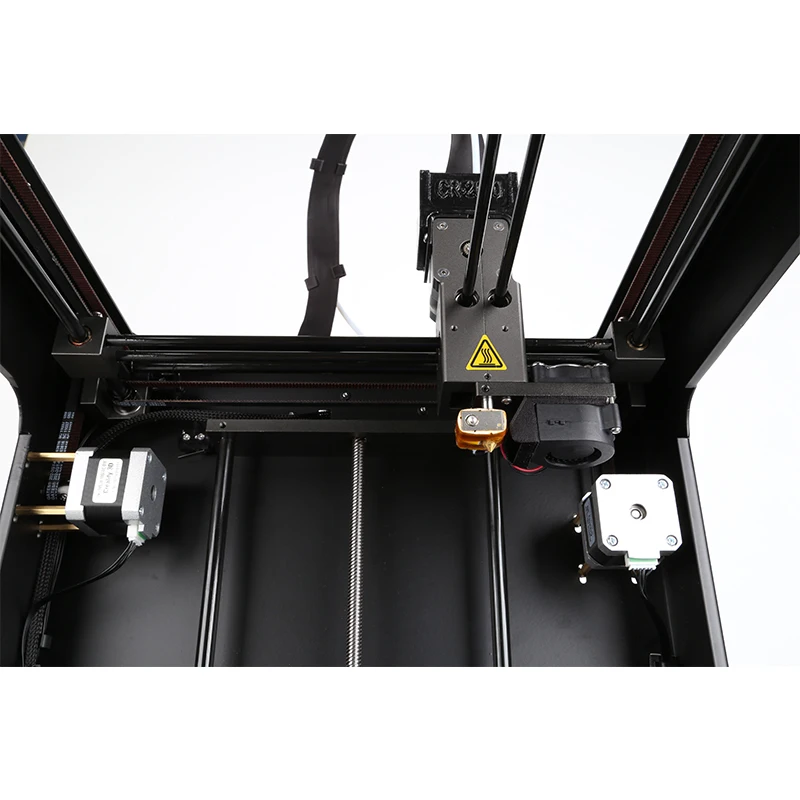

Core-XY movement with 9mm belts

The Creality 3DPrintMill uses the same Core-XY movement solution as the Creality Ender 6. It’s sturdy, the movement is accurate and the use of 9mm belts allows the printer to move quite fast.

The biggest drawback on this Core-XY setup is the right motor shaft which is taller. I’ve seen multiple reports online with the Ender 6 where the shaft broke. If Creality would have added some kind of brace to the motor shaft, this issue would not occur, so I hope they improve the design over time. There are some printable addons that can be installed to mitigate this issue, and I’ve also seen an aftermarket aluminium solution which is currently being tested.

If Creality would have added some kind of brace to the motor shaft, this issue would not occur, so I hope they improve the design over time. There are some printable addons that can be installed to mitigate this issue, and I’ve also seen an aftermarket aluminium solution which is currently being tested.

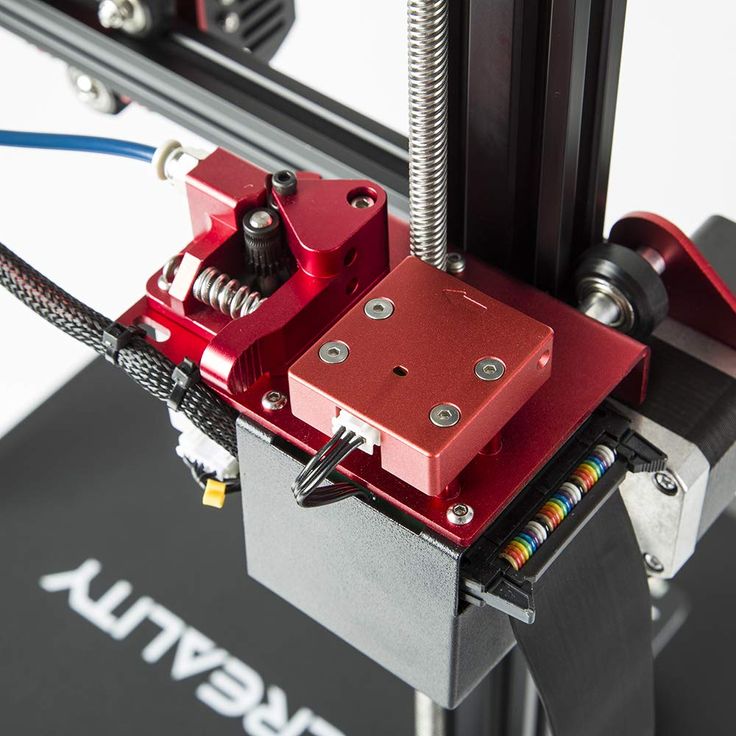

Dual-gear Creality extruder

The extruder used with the Creality 3DPrintMill is the same one used with the Ender 6 and the Creality CR-10s PRO. It does a good job extruding filament without losing grip. The two gears grip the filament from both sides which is important especially considering the long bowden tube used with the CR-30.

Generic 45° angle Creality PTFE-lined hotend

It’s not a surprise that the Creality CR-30 uses the same generic Creality PTFE-lined hotend. If you’ve been reading my Creality 3D printer reviews, you know that I am not a fan of these hotends because of their bad thermal performance. The PTFE tube touches the nozzle which means that you are limited to printing up to 240C. If you go over this temperature, the PTFE tube starts to degrade, and a clog is just a matter of time.

If you go over this temperature, the PTFE tube starts to degrade, and a clog is just a matter of time.

The hotend sits at a 45° angle to which allows the printer to use the belt as the Z axis and print really long models or have serial production of smaller parts without the user interfering to remove the models when done.

Considering that the Creality 3DPrintMill is designed to be a workhorse that should work for days, their choice of hotend is a bit unfortunate and I would have liked to see a better hotend installed. One with the PTFE tube sitting higher in the heat break for more consistent extrusion and less downtime to fix it.

I am not sure if this is an isolated issue, but I was not able to do bigger prints with the stock hotend. I had probably ~10 failures, where the nozzle would just clog and stop extruding. The small 30mm fan doesn’t have a lot of airflow which leads to higher temps in the heat break. Higher temps are not great for PLA which starts to swell then cause a clog.

Frustrated with all the failures, where after each clog I had to take everything apart, then re-adjust the Z offset, I decided to install a better hotend (the Trianglelab Spiral Tower I had laying around). I understand that my review will be less accurate now, but this was the only way I could test the rest of the printer.

After changing the hotend, all my prints were successful with no other clogs, so I recommend budgeting for a better hotend if you plan to purchase a 3D Print Mill. The stock hotend will only cause issues, and you don’t want that on a week-long print.

Creality V4.2.10 32-bit silent board

Inside the Creality CR-30, we have a Creality V4.2.10 board running silent stepper drivers. As with all Creality boards, the stepper drivers are not removable. Other than that, nothing major to report.

350W Huntkey 24V power supply

Considering that the 3D Print Mill is quite an expensive printer, I was expecting to see a Mean Well power supply inside. But my unit came with a Huntkey 24V 350W power supply. I don’t know too much about this brand, but the power supply is silent, and I can’t really complain about its performance.

But my unit came with a Huntkey 24V 350W power supply. I don’t know too much about this brand, but the power supply is silent, and I can’t really complain about its performance.

As you can see in the pictures, the power wires have ferrite cores which are installed to minimize electrical interference. Creality started adding these on more expensive printers, which is a nice addition.

12864 monochrome screen

The included 12864 screen is the same one you get with the popular Ender 3. It doesn’t have any special features, and you still need to turn the knob for moving through the menus (instead of the newer touchscreens). But I’m ok with that.

What I don’t like is the shiny plastic covering the screen. The piano black cover is a fingerprint and dust magnet, which can be easily scratched, and it gives the printer a cheap look. I would have liked a metalic bracket better (like the Ender 3).

Filament sensor and power failure recovery

Most of the 3D printers out there use filament sensors so this shouldn’t come as a surprise, especially considering that the 3DPrintMill will work for days without stopping. When the filament spool is done, the sensor stops the printing process and notifies you to replace the filament and continue the print.

When the filament spool is done, the sensor stops the printing process and notifies you to replace the filament and continue the print.

I also tested the power failure recovery (without planning to do so) when there was a 1-hour long power failure during the rifle print. When power came back, the printer asked me if I want to continue the print. I chose “Yes” and after heating up, the nozzle homed then continued the print.

Usually, I don’t even bother testing the power failure feature because the model will surely detach from the heated bed after it cools down, but with the CR-30, the belt adhesion is great, and the power loss recovery feature can actually be used.

Heating time and power consumption

I tested the heating time for both hotend and heat bed and here are the results:

Hotend

- 200C in 54 seconds

- 250C in 1 minute and 10 seconds

Heatbed

- 60C in 1 minutes and 25 seconds

- 100C in 4 minutes

Power Draw

Idle power draw is around 6W. When the hotend and heatbed are heating up, the Creality 3DPrintMill draws around 280W. After it starts printing, the power draw stabilizes to around 60W.

When the hotend and heatbed are heating up, the Creality 3DPrintMill draws around 280W. After it starts printing, the power draw stabilizes to around 60W.

All these measurements were taken with a Blitzwolf smart power socket which indicates the power draw, and it can also be used for remotely powering on and off the printer.

Bed Temperature Uniformity

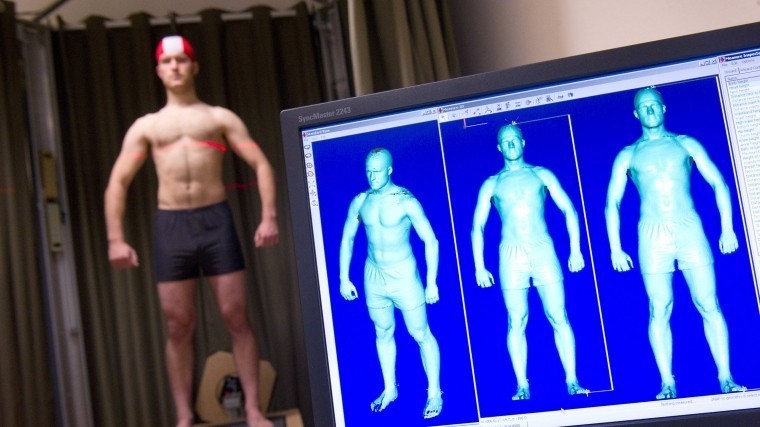

I tested the temperature uniformity for the Creality CR-30 bed with the Flir Camera installed on the CAT S62 Pro. The bed has been set to 60C and I waited 2 minutes after reaching that temperature for the temperature to stabilize.

The print surface on the Creality CR-30 is only heated in the first half. For good adhesion on small features, ensure that the belt is tightened and runs smoothly over the heated bed in order to heat the belt uniformly.

Creality CR-30 Noise Levels

The Creality CR-30 is more silent than I expected. All the movement speeds during printing are silent, thanks to the stepper drivers used. The hotend fan is a bit noisy but that’s understandable considering it’s only 30mm. But the CR-30 can print in the same room where you work, without being too loud.

The hotend fan is a bit noisy but that’s understandable considering it’s only 30mm. But the CR-30 can print in the same room where you work, without being too loud.

IdeaMaker Profiles for Creality CR-30

During my time with the printer, I also tuned a PLA IdeaMaker profile for the Creality 3DPrintMill using the tools available in the 3D Printer Calibration Guide using IdeaMaker article and using NAK3D’s excellent profile as a base.

Creality CR-30 IdeaMaker Profile – PLA – 3DPrintBeginner

Test prints on Creality CR-30

40x40mm cube

The first print I tested was a simple 40x40mm cube. I wanted to test the adhesion and the print quality with a simple shape. Unfortunately, I had a bunch of failures where the cube would lose its adhesion and cause a print failure.

It took a few tries until I adjusted the nozzle height so it’s touching the belt. Before, I was always using a 0.2mm shim but that doesn’t work with a belt printer. After the nozzle was set to touch the belt, adhesion issues were eliminated, and the print quality can be seen in the images below.

- Material: Sunlu Grey PLA

- Layer Height: 0.2mm

- Nozzle Temperature: 210C

- Bed Temperature: 70C

- Print Speed: 35 mm/s

Master Sword from Legend of Zelda

Now that I had more trust in the printer’s capabilities, I thought I should print a small sword to test a longer model. I scaled the sword, so it takes about 8 hours to print half and started the print. I was quite happy when the sword was completed successfully without failure.

- Material: Sunlu Grey PLA

- Layer Height: 0.2mm

- Nozzle Temperature: 210C

- Bed Temperature: 70C

- Print Speed: 35 mm/s

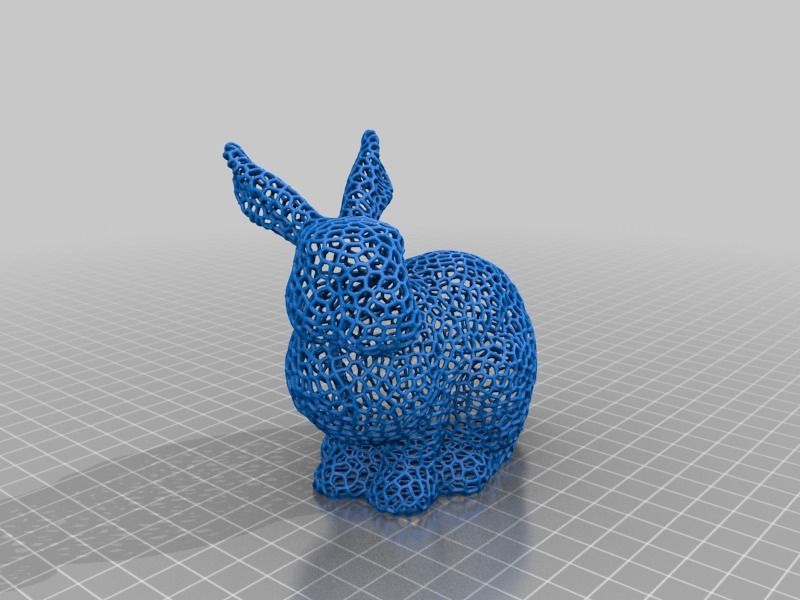

Batch 3D Benchy printing

As you might expect, when printing with a 45-degree angle, you need to change how you think about slicing a model. For example, the regular 3D Benchy cannot be printed without a bit of support. But even with that tiny amount of supports, I managed to print three benchies without too much trouble.

For example, the regular 3D Benchy cannot be printed without a bit of support. But even with that tiny amount of supports, I managed to print three benchies without too much trouble.

The print quality is not as good as with a regular printer, but this is also influenced by the model. Some model can look much better on a regular printer compared to one which prints at a 45-degree angle.

- Material: Anycubic Blue PLA

- Layer Height: 0.2mm

- Nozzle Temperature: 210C

- Bed Temperature: 70C

- Print Speed: 30 mm/s

Mandalorian’s Rifle

Finally, I wanted to do a really long print, and I found the Mandalorian Rifle split by NAK3D on the 3DPrintMill discord server. Each half of the rifle took around 46 hours. When both parts were finished, I spent around 90 hours of printing and close to a full roll of PLA filament. I can’t say that the print quality is excellent but is good enough considering the ~155cm length of the model. With a bit of sanding and primer, you can make this look nice as a prop.

With a bit of sanding and primer, you can make this look nice as a prop.

- Material: Anycubic Blue PLA

- Layer Height: 0.2mm

- Nozzle Temperature: 210C

- Bed Temperature: 70C

- Print Speed: 30 mm/s

Conclusions: Is the Creality CR-30 worth it?

To answer this question, we need to first decide the purpose for which this printer is purchased.

If you are a prop maker, who will print a lot of swords or long objects, then yes, the printer is great for this purpose. You will be able to print your models in less pieces, with less post processing.

If you are a person who need to batch print a lot of smaller items, then you need to consider if those particular models can be printed well at a 45-degree angle. Sure, you can start the print, and the printer will continuously produce the model, but if you need to add supports, and post process those particular parts afterwards, it’s not really helpful.

Besides that, print speed is quite low, so there’s not a lot of time saved. You would be better off with purchasing a few regular printers and building a print farm compared to buying a single CR-30.

If you are a regular user who thinks the Creality 3DPrintMill is cool, but you don’t have a specific use for it (long model prints or batch printing) I can’t really say the printer is worth the money. For any other kind of print scenarios, the CR-30 is slower, and the print quality is lower compared to a regular printer.

Overall, the Creality CR-30 is a printer which has some nice use cases for some people, but for the vast majority, a regular printer will be better.

Where to buy the Creality CR-30?

The Creality CR-30 can be purchased from the following websites:

AliExpress

Amazon

Banggood

Creality3DOfficial

Creality Store

I recommend checking out the Discount Codes page before purchasing. I regularly update the article with discount codes for various online shops, and you might find one for this particular model.

The Creality CR-30 3DPrintMill was provided free of charge by Creality for the purpose of this review. While the article includes affiliate links, all opinions are my own. Nobody reviewed the article before it was posted, following the Review Guidelines.

Liked it?Consider supporting 3DPrintBeginner if this content helped. You can also join Patreon for exclusive perks! |

Metal 3D Printing - The Essential Guide

There is no hotter trend in 3D printing today than metal. We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials.

Metal 3D printing has grown in popularity over the past few years. And this is quite natural: each material offers a unique combination of practical and aesthetic qualities, can be suitable for a wide range of products, prototypes, miniatures, decorations, functional details and even kitchen utensils.

The reason metal 3D printing has become so popular is because the printed objects can be mass-produced. In fact, some of the printed parts are just as good (if not better) than those made with traditional methods.

In traditional production, working with plastic and metal can be quite wasteful - there is a lot of waste, a lot of excess material is used. When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings.

So, what do we need to know about metal 3D printing?

Metal 3D printing at home

If you want to make objects at home that will look like metal, your best bet is to look at metalized PLA filaments (Photo: colorFabb)

Where to start if you want to print metal objects at home ? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this.

It is unlikely that in this decade it will be possible to print with liquid metal at home. Until 2020, you probably will not have a printer specialized for this purpose at home. But in a few years, as nanotechnology advances, we may see significant developments in new applications. This can be 3D printed with conductive silver, which will emit in much the same way as it does in 2D home printers. It will even be possible to mix different materials like plastic and metal in one object.

Materials for metal 3D printing at home

Even though you can't print actual metal objects at home, you can turn to plastic filament that has metal powders added to it. ColorFabb, ProtoPasta and TreeD Filaments all offer interesting metal-PLA composite filaments. These filaments, containing a significant percentage of metal powders, remain pliable enough to be printed at low temperatures (200 to 300 Celsius) on virtually any 3D printer. At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions.

Iron-based filaments even rust under certain conditions.

But you can go further. Typically, up to 50 percent metal powder is added to 3D printing filament. Dutch company Formfutura says they have achieved 85 percent metal powder with 15 percent PLA. These filaments are called MetalFil Ancient Bronze and Metalfil Classic Copper. They can be printed even at "moderate" temperatures from 190 to 200 degrees Celsius.

Metallic 3D Printing Filament Spools, in this case from SteelFill and CopperFill colorFabb (Steel and Bronze), Ancient Bronze (Ancient Bronze) from Formfutura

Here are the key points about metal printing at home

- Gets a unique metal surface and look

- Ideal for jewelry, figurines, housewares, replicas

- Durability

- Objects are not flexible (structure dependent)

- Objects do not dissolve

- Not considered food safe

- Typical print temperature: 195 - 220°C

- Extremely low shrinkage on cooling

- No table heating required

- Printing complexity is high, requires fine tuning of nozzle temperature, feed rate, post-processing

Preparing Your Home Printer for Metal 3D Printing

Since getting metal 3D prints is more difficult than usual, you may need to upgrade your 3D printer nozzle, especially if you are an entry-level printer. The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

You will also need to take care of the final finishing of the surface (cleaning, grinding, oiling, waxing or priming) so that the printed metal object shines as it should.

How much does metal filament for 3D printing cost?

And what about metal filament for 3D printing? - you ask. Here are a few examples:

- ColorFabb's 750 gram Bronzefill spool is $56.36

- ColorFabb 750g Copperfill Coil $56.36

- Protopasta's Polishable Stainless Steel PLA Composite is $56 for 56 grams of

- Protopasta's Rustable Magnetic Iron PLA Composite is $34.99 for 500 grams of

Industrial metal 3D printing

But what if you want a better result or even full metal 3D printing? Should a real "metal" 3D printer be purchased for business needs? We wouldn't recommend it - unless you're going to be doing it every day. A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

Lowering Metal 3D Printing Costs

If you are not going to start a metal 3D printing business, but still need a professionally 3D printed metal part, it is best to contact the appropriate company that provides such services. 3D printing services like Shapeways, Sculpteo and iMaterialise offer direct metal printing.

They currently work with the following metal materials in 3D printing:

- aluminum

- steel

- brass

- copper

- bronze

- sterling silver

- gold

- platinum

- titanium

If you are a jeweler, you can also order wax models for casting in precious metals.

If we talk about wax models, then in most cases they (with subsequent melting) are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services.

The reason big companies love 3D printing so much is that it can be used to build fully automated lines that produce "topologically optimized" parts. This means that it is possible to fine-tune the raw materials and make the components thicker only if they must withstand heavy loads. In general, the mass of parts is significantly reduced, while their structural integrity is preserved. And this is not the only advantage of this technology. In some cases, the product turns out to be significantly cheaper and affordable for almost everyone.

Please note that metal 3D printing requires special CAD programs for modeling. It is worth paying attention to the recommendations of Shapeways - 3D printing metal guidelines. To delve further into the topic, check out Statasys’ information on related 3D printers and the nuances of metal 3D printing.

Here are some examples of Benchy test model prices for metal 3D printing:

- Metal plastic: $22.44 (former alumide, PLA with aluminium)

- Stainless steel: $83.75 (plated, polished)

- Bronze: $299.91 (solid, polished)

- Silver: $713.47 (solid, mirror polished)

- Gold: $87.75 (gold plated, polished)

- Gold: $12,540 (solid, 18K gold)

- Platinum: $27,314 (solid, polished)

As you might expect, solid metal 3D printing prices are quite high.

Metal 3D printing. Applications

GE LEAP aircraft engine parts 3D printed at Avio Aero (Photo: GE)

There are several industries already using 3D printers to make everyday objects - you may not even know that these objects are printed.

- The most common case is surgical and dental implants, which are considered the best option for patients today. Reason: they can be tailored to individual needs.

- Another industry is jewelry. Here, most manufacturers have abandoned resin 3D printing and wax casting, switching directly to metal 3D printing.

- In addition, the aerospace industry is becoming more and more dependent on 3D printed metal objects. The Italian company Ge-AvioAero was the first to do all-metal 3D printing. It manufactures components for LEAP aircraft engines.

- Another industry targeting metal 3D printing is the automotive industry. BMW, Audi, FCA are seriously considering this technology, not only for prototyping (3D printing has been used for this for quite some time), but also for making real parts.

Before metal 3D printing really takes off, however, there are some hurdles to overcome. And first of all, this is a high price, which cannot be made lower than during molding. Another problem is the low production speed.

Metal 3D printing.

Technologies

Most metal 3D printing processes start with an “atomized” powder

You can talk a lot about “metal” 3D printers, but their main problems remain the same as any other 3D – printers: software and hardware limitations, material optimization and multimateriality. We won't talk too much about the software, we'll just say that most of the major specialized software companies, such as Autodesk, SolidWorks and solidThinking, try to emphasize as much as possible the fact that as a result of the 3D metal printing process, you can get any shape you want.

In general, printed metal parts can be as strong as parts made by traditional processes. Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

3D printed metal can have different resolutions. At the highest resolution, layer thickness is 0.0008 - 0.0012" and X/Y resolution is 0.012 - 0.016". The minimum hole diameter is 0.035 - 0.045". formed layer)

The metal 3D printing process used by most relevant large companies today is called Powder Bed Fusion. This name indicates that some source of energy (a laser or other energy beam) melts an "atomized" powder (i.e., a metal powder that is carefully ground into spherical particles), resulting in layers of a printed object.

There are eight major manufacturers of metal 3D printers in the world that already use this technology; while we are talking here, there are more and more such companies. Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Metal 3D-printing process No. 2:

Binder Jetting (spraying the binder)

under 3DP technology EXONE Metal objects are printed due : ExOne)

Another professional approach that also uses a powder base is called Binder Jetting. In this case, the layers are formed by gluing metal particles together and then sintering (or fusing) them in a high-temperature furnace, just like it is done with ceramics.

Another option, which is similar to working with ceramics, is mixing metal powder into metal paste. A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i.e. in the mountains

This approach is used in the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

Metal 3D printing process #3: 9Metal Deposition This is not entirely true. Of course, on some desktop device, simply fusing metal threads onto the base will not work. However, very large steel companies can do it. And they do. There are two options for working with "metal surfacing".

One is called DED (Directed Energy Deposition) or Laser Cladding. Here, a laser beam is used to melt the metal powder, which is slowly released and solidifies as a layer, and the powder is fed using a robotic arm.

Normally the whole process takes place in a closed chamber, but the MX3D project used conventional 3D printing techniques to build a full-size bridge. Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military.

Metallic 3D printing. Metals

3D printing metal #1: Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing and is definitely one of the most versatile, strong and lightweight. Titanium is used both in the melting process in a preformed layer and in the process of spraying a binder and is used mainly in the medical industry (for the manufacture of personal prostheses), as well as in the aerospace industry, automotive and machine tools (for the manufacture of parts and prototypes). But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment.

3D printing metal #2: Stainless steel

Stainless steel is one of the cheapest 3D printing metals. At the same time, it is very durable and can be used in a wide range of manufacturing and even artistic and design applications. The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

3D Printing Metal #3: Inconel

Inconel is a superalloy manufactured by Special Metals Corporation and is a registered trademark. The alloy consists mainly of nickel and chromium and is very heat resistant. Therefore, it is used in the oil, chemical and aerospace (for black boxes) industries.

3D Printing Metal #4: Aluminum

Due to its lightness and versatility, aluminum is very popular in 3D printing. Aluminum alloys are commonly used.

3D Printing Metal #5: Cobalt Chrome

gap). It is most commonly used in the manufacture of turbines, dental and orthopedic implants, where 3D printing has become the dominant technology.

3D printing metal #5. Copper and bronze

With some exceptions, copper and bronze are used in wax melting processes, rarely in layer melting. The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

3D printing metal #6. Iron

Iron, incl. magnetic, also mainly used as an additive to PLA-based filaments, which are produced, for example, by ProtoPasta and TreeD.

3D printing metal #7. Gold, Silver, and Other Precious Metals

Most preformed layer companies can 3D print precious metals such as gold, silver, and platinum. Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics.

Metallic 3D printing. Printers

Do not hesitate - the purchase of a metal 3D printer will not pass without a trace on your budget. It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

Metal 3D Printer #1:

Sciaky EBAM 300 - Metal Filament Printing

If you need to print really large metal structures, Sciaky's EBAM technology is your best bet. By order, the device can be built in almost any size. This technique is used mainly in the aerospace industry and the military.

Sciaky's largest production printer is the EBAM 300. It prints objects in a volume of 5791 x 1219 x 1219 mm.

The company claims the EBAM 300 is also one of the fastest industrial 3D printers on the market. A three-meter-sized titanium part for an aircraft is printed on it in 48 hours, while the material consumption is about 7 kg per hour. In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer.

The metal layers are first cut and then ultrasonically welded. The largest Fabrisonic 7200 printer operates in a volume of 2 x 2 x 1.5 m. The metal powder 3D printer is the Concept Laser XLine 1000. It has a modeling volume of 630 x 400 x 500 mm and is the size of a house.

Its German company, one of the main suppliers of 3D printers for aerospace giants like Airbus, recently introduced a new machine, the Xline 2000.

This machine uses two lasers and has a working volume of 800 x 400 x 500 mm. Uses LaserCUSING laser technology (a variant of selective laser fusion) from Concept Laser, which allows you to print alloys of steel, aluminum, nickel, titanium, precious metals and even some pure substances (titanium and stainless steel).

Metallic 3D printing. Services

There are more than 100 companies worldwide offering metal 3D printing services. We list the most popular services for consumer needs.

Metal 3D Printing Service #1: Shapeways

The world's most popular 3D printing service, Shapeways offers two types of services. As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

3D printing metals: aluminium, brass, bronze, gold, platinum, precious metal plating, silver, steel. There are also wax molds for jewelry purposes.

Metal 3D Printing Service #2: Sculpteo

Like Shapeways and i.materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them to fabrication in a wide range of materials . Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project.

Extensive technical documentation will help identify design flaws and select the right material for the project.

Metals for 3D printing: alumide (plastic with aluminum particles), brass, silver.

Metal 3D Printing Service #3: iMaterialise

Materialise is a company that works with industrial customers to prototyp 3D printed products. For casual users and designers, Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.materalise online store or by embedding some code into their site.

3D printing metals: alumide (plastic with aluminum powder), brass, bronze, copper, gold, silver, steel, titanium.

Metal 3D Printing Service #4: 3D Hubs

Through 3D Hubs, you can search for individuals and companies that offer 3D printing services in your area, upload STL files (which are immediately evaluated for defects ) and contact service providers directly to get the job done. The online 3D printing service also allows you to sort offers by materials, customer rating, distance and many other parameters. Whatever object you wish to print, there is likely to be someone nearby who can print it. A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

The online 3D printing service also allows you to sort offers by materials, customer rating, distance and many other parameters. Whatever object you wish to print, there is likely to be someone nearby who can print it. A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

3D printing metals: aluminium, bronze, cobalt-chromium, stainless steel, titanium.

Home desktop 3D printers

Anet Anycubic Creality3D CreatBot Dremel Elegoo Felix Flash Forge FLSUN Flying Bear Formlabs IBRIDGER imprinta MakerBot Peopoly Phrozen PICASO 3D QIDI Raise3D Tiertime Ultimaker Uniz Voxelab wanhao XYZPrinting ZENIT Zortrax

Availability

In stock

Manufacturer

Phrozen Raise3D Creality wanhao FlashForge

PICASO 3D Anycubic Formlabs Tiertime Flyingbear QIDI Uniz CreatBot Dremel DigiLab Felix Zortrax XYZprinting Ultimaker imprinta Elegoo MakerBot Anet FLSUN IBRIDGER Peopoly snapmaker Voltera Voxelab ZENIT

Delivery

Assembled printer Assembly kit

Application

Architecture For large objects For beginners The medicine Education

Orthopedics Production prototyping Reverse engineering Advertising, exhibitions Sculpture Dentistry Hobby jewelry

Print technology

DLP/LCD/SLA FDM/FFF LFS

Thread diameter

1. 75 mm 2.85 mm 3.00 mm

75 mm 2.85 mm 3.00 mm

Material type

ABS PLA PETG Photopolymers Flex

Nylon (Nylon) ASA Carbon HIPS PC PEEK PP TPU other Metal (Ultrafuse 316L, Ultrafuse 17-4PH)

Number of extruders (print heads)

Heating table

Yes Not

Wi-Fi or other wireless network

Yes Not

Country of origin

China Russia USA Taiwan Hong Kong

Netherlands Poland

Add to compare

Product added to compare Go

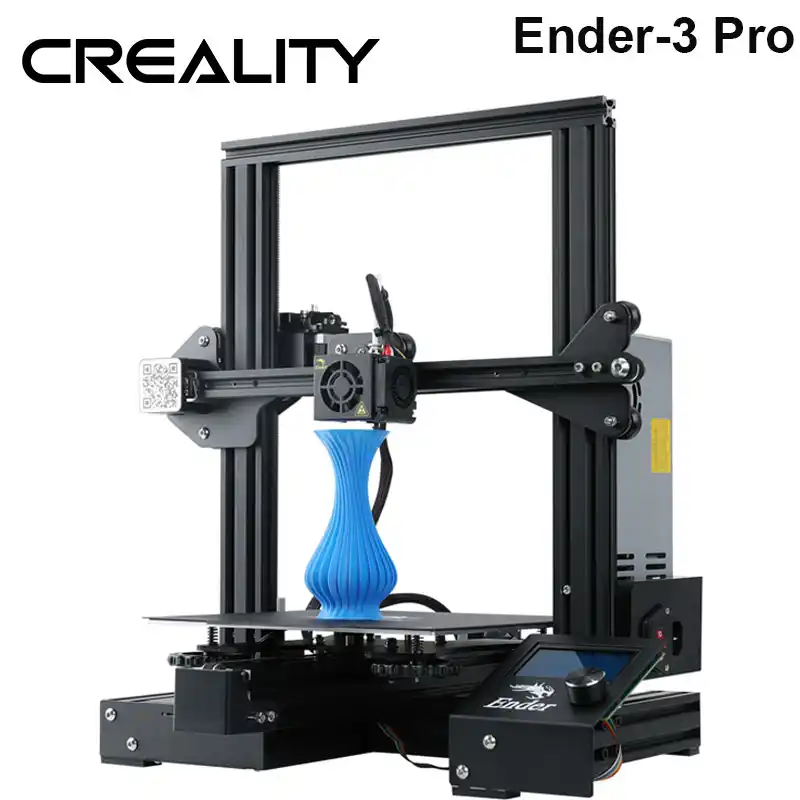

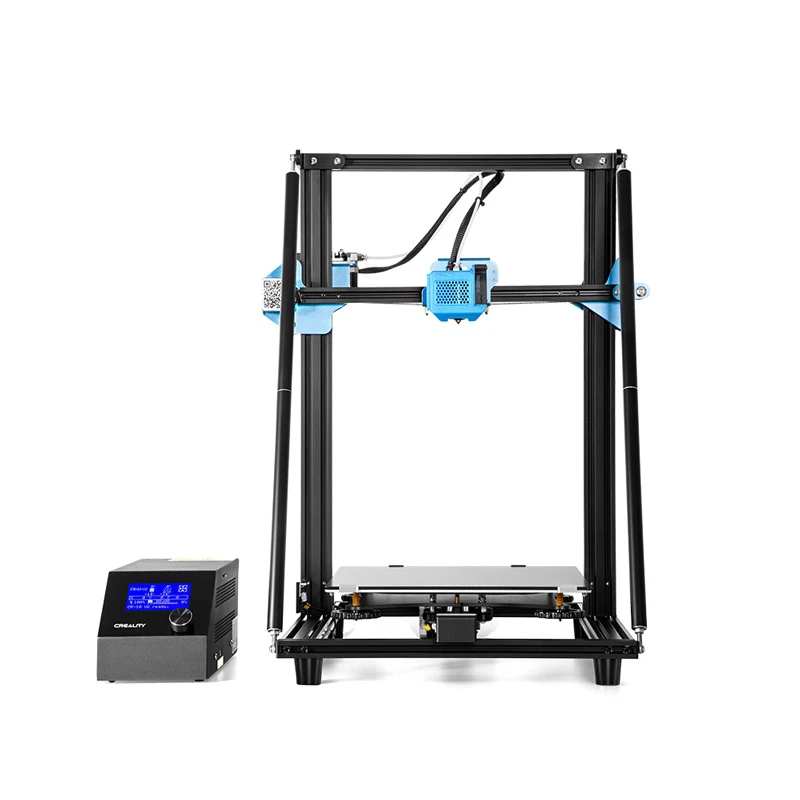

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

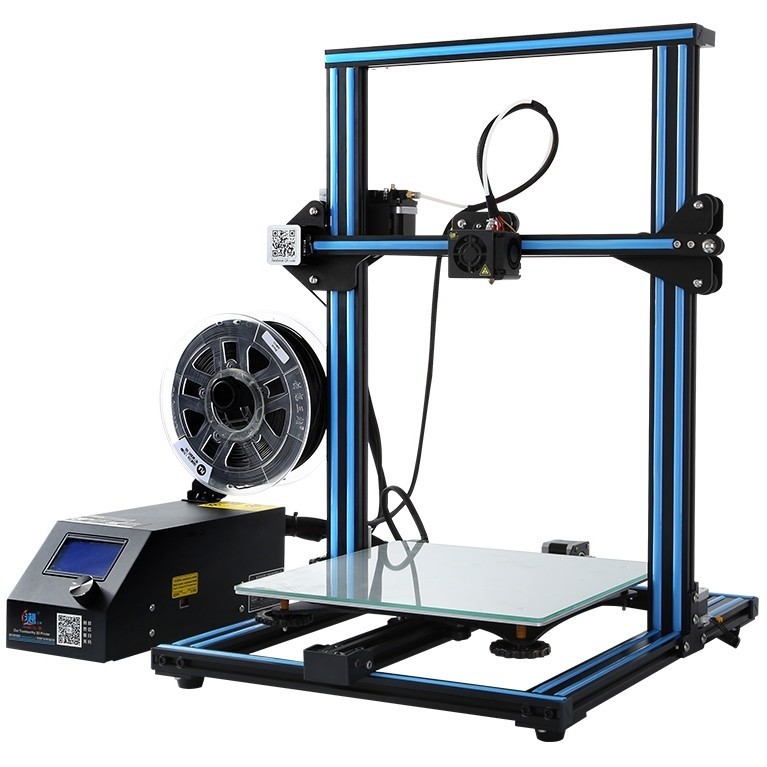

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

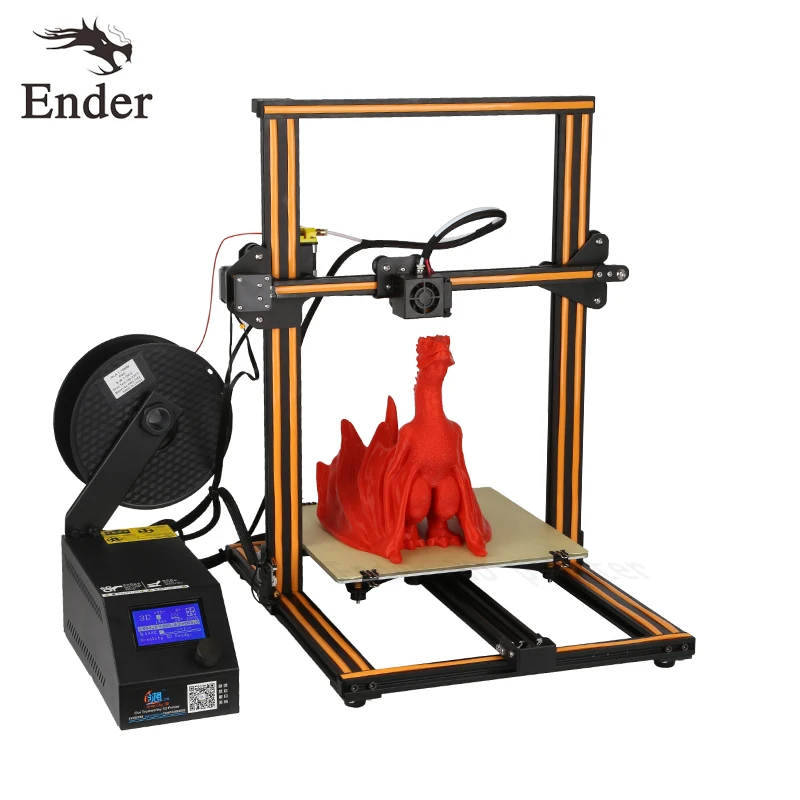

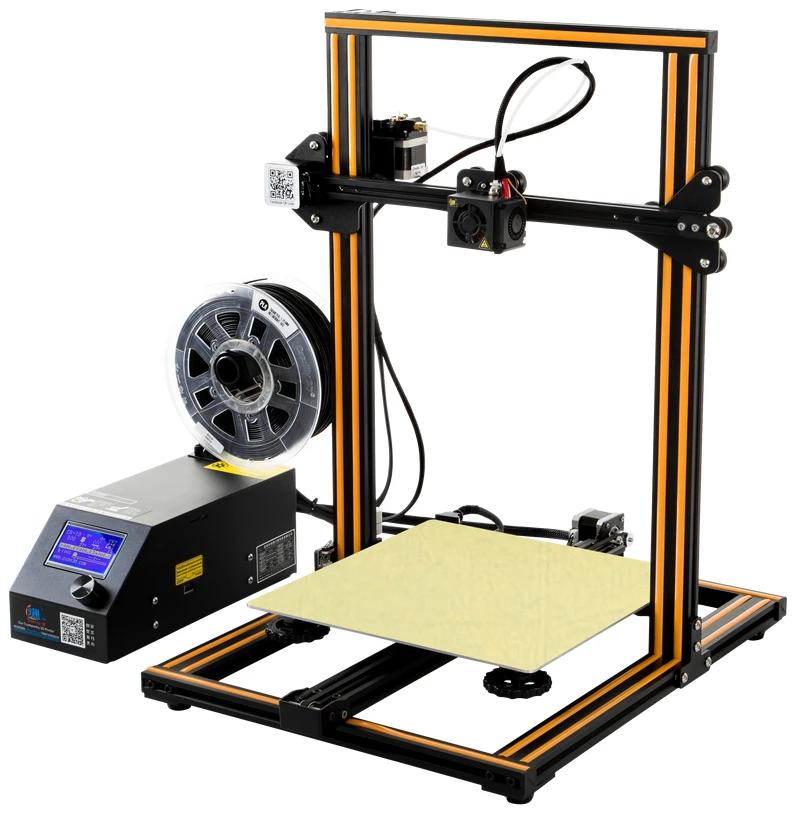

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 200x200x200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

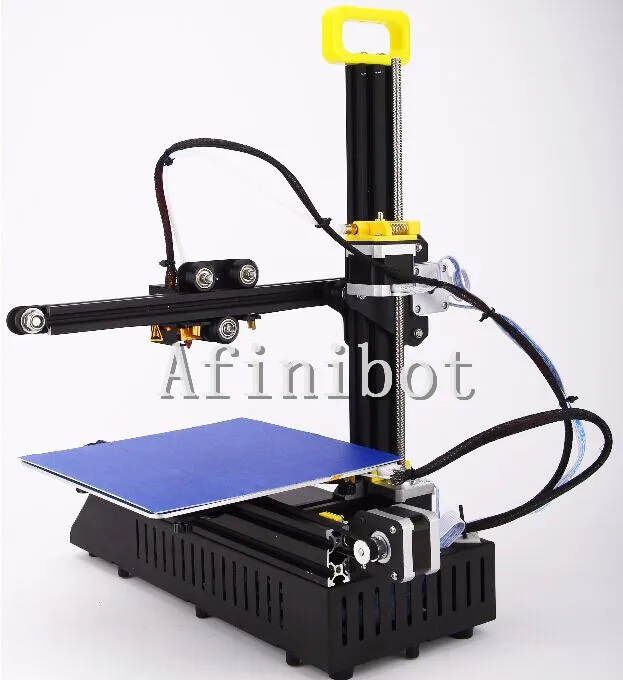

| Manufacturer | Voxelab |

| Construction area size | 200*200*200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

| On order/Transit | Goods on the way |

| Construction area size | 255x210x210 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 250x250x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 197 x 122 x 245 mm (5. 9 l) 9 l) |

| Chamber volume | 5.9l |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 134x75x130 mm |

| Country of origin | Taiwan |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 197 x 122 x 245 mm (print volume 5.9 l) |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | QIDI |

| On order/Transit | Goods on the way |

| Construction area size | 270 x 200 x 200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 165x72x180 mm |

| Country of origin | Taiwan |

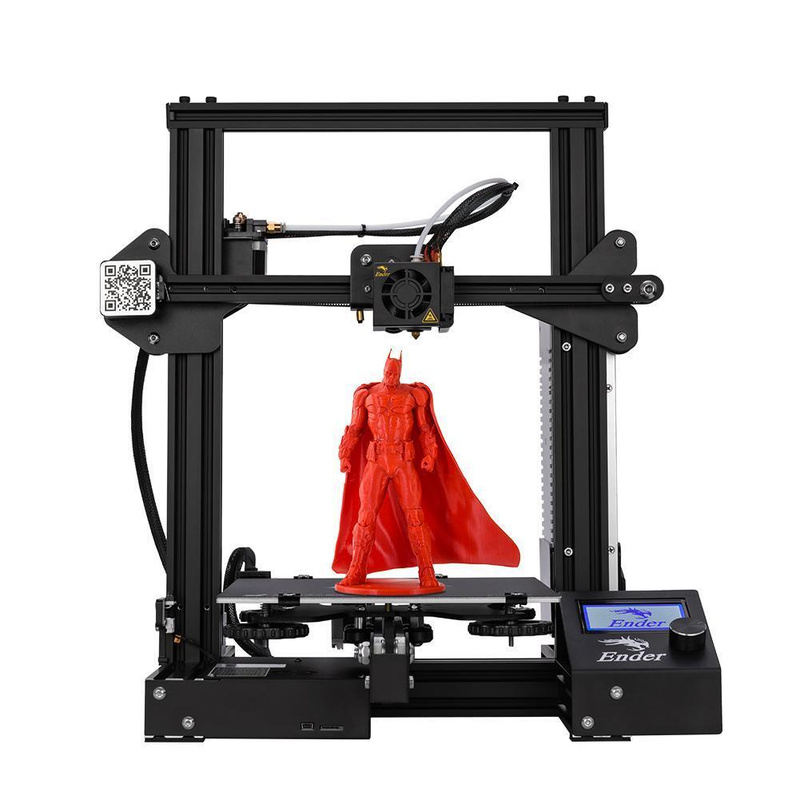

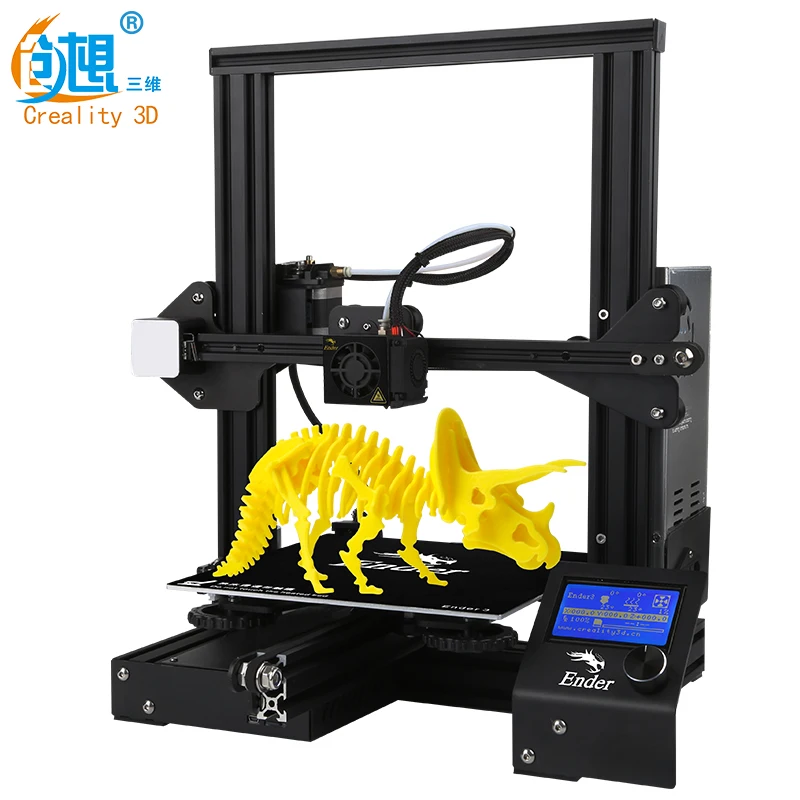

3D printing is one of the most promising areas of technological development in the 21st century. Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

You can buy a 3D printer capable of printing small models and prototyping of medium complexity today at the price of an entry-level laptop. The price of PLA or ABS plastic, which acts as a consumable, also no longer seems exorbitant. In a word, if you have long dreamed of getting to know the world of 3D printing and joining the ranks of makers, the right moment has come!

To save you time and make it easier to select equipment, we have collected in one section all desktop 3D printers optimized for home and office use. These are the real "workhorses" with the perfect balance of functionality, quality and price. Even a beginner can understand the settings, mount and calibrate a 3D printer, and as he gains experience, he will be able to print more and more complex three-dimensional models.