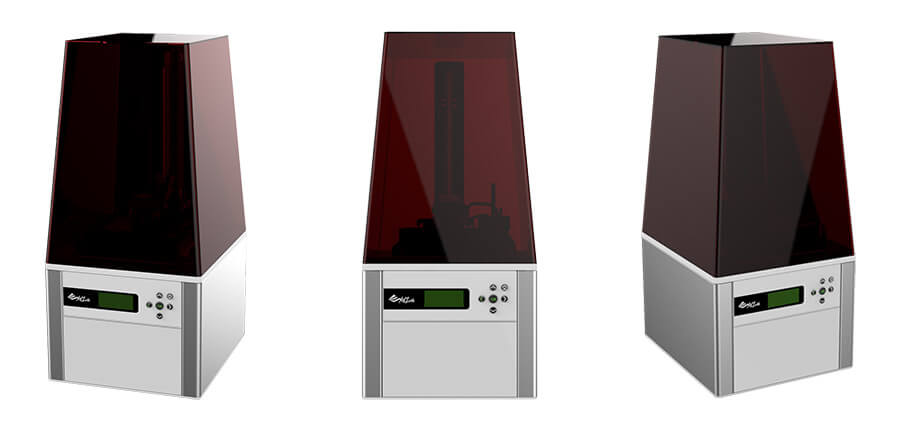

Cel rbx01 robox 3d printer

cel-robox – Robox 3D printers

Skip to contentRobox-homeRoboxAdmin2020-04-30T14:03:40+01:00

Fast

Rapid prototyping is fast by definition, having 3D print capability in-house will make you more productive provided the operation of the printer is not a task in itself.Rapid prototyping or production is more than just print speed.

To compare 3D printers in terms of speed we need to look at setup, operation, print speed; linked to print quality, success rate and, of course, cost because two low cost printers can outperform a single more expensive one.

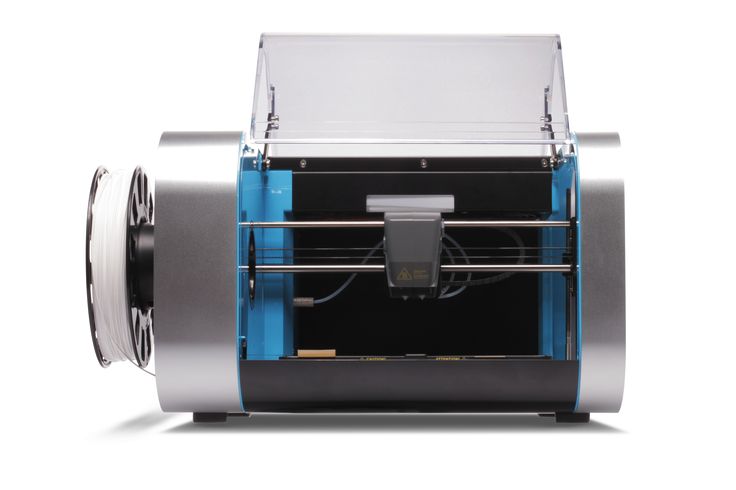

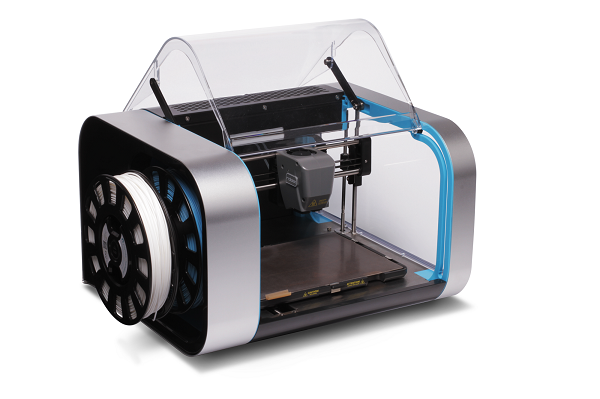

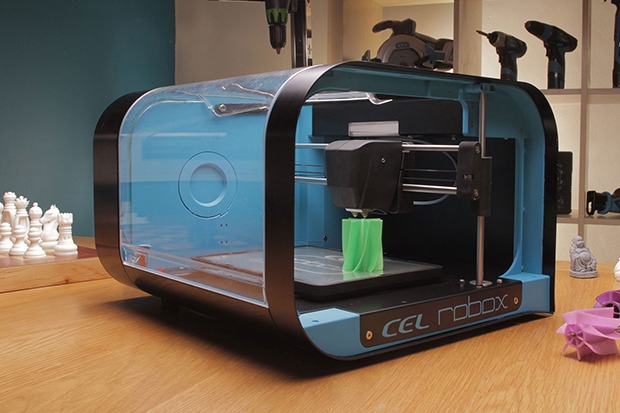

Robox design, from weight of the motion parts to the streamlined 3 click print setup, is focused on quickly achieving each print job at high quality. The design of key parts and the underlying systems show very clear gains in completing jobs faster than any other 3D print system.

The printer comparison link below takes you to a very detailed and sortable list of the best dual extrusion printers on offer.

Accurate

Tolerance is part of any mechanical design and has an impact on usability of the produced component. 3D printers can produce very accurate motion and positioning of materials.But reaching an acceptable tolerance does not end there

Materials expand and contract with thermal changes, a controlled build chamber is the best way to reduce the effect on part construction, highly repeatable results allow for design adaptation in a loop which ensures the best possible outcome.

In Robox where there is potential for inaccuracy there are novel devices and tools built-in to compensate for this and tune systems for repeatable accuracy. As mechanical engineers CEL-UK have ensured that every step in design, construction and usage of Robox ensures the best possible accuracy while retaining the core need for a machine which is easy to procure, maintain and operate.

Reliable

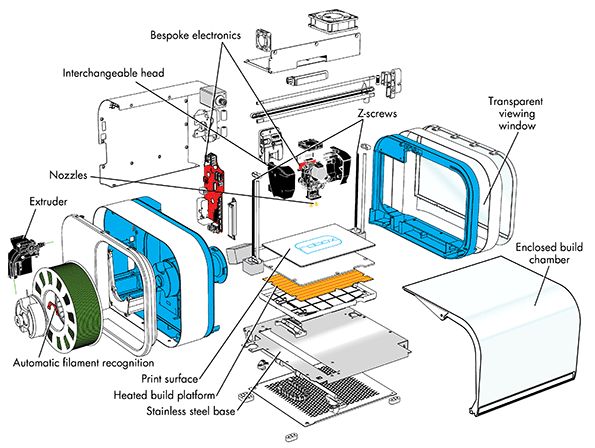

Modular design means that the hardest working parts can be swapped out in seconds without tools.

Designed for business

Smart monitoring appeared in Robox machines first and provide a software alerts and automated systems that prevent hardware damage.

Our motion frame design is the same as large format CNC because it is extremely rigid to ensure relationships between axes are maintained. Speed is a priority so a low weight of motion parts is critical to allow the best acceleration potential. Stationary and slow moving parts are precisely machined stainless steel. Electronics are designed specifically for our system right down to custom stepper motors, this ensures there is no load problems or incompatibility.

Backing this up is a best in class warranty on all parts including consumables and our excellent UK based customer service.

Contact Sales

Technical Support

Community Forum

3D printing advice

Efficient

Material usage, success rate, time to set up, time to print, effect on productivity, resource availability.

Additive Manufacturing is more efficient in terms of material usage than traditional subtractive methods such as CNC machining.

AM also allows shapes and structures which are impossible using other methods. As a technology it is easy to access and low cost machines can achieve complex shapes accurately without a labour cost as the machinery runs through program without supervision.

Robox systems have won awards for ease of use and our dual extrusion systems save between 10 and 30% material with every job.

Cost Effective

3D printers have dropped in price significantly since a patent expired in 2009. Many remain significantly over priced for the value offered.Finding the right balance between expensive and cheap is about trust

At the bottom end there are hundreds of unsupported copies of copies of the basic frame and extrusion systems, many of these can produce nice looking models but will not be capable of printing in materials with desirable mechanical or chemical properties. Mid-high cost printers are a big jump from the bottom end in terms of pre-configured setup, support and per-print success. The high cost printers are being challenged by this mid range.

Mid-high cost printers are a big jump from the bottom end in terms of pre-configured setup, support and per-print success. The high cost printers are being challenged by this mid range.

RoboxDual will outperform any printer even 10 times the price. For a larger printer with the same capabilities RoboxPRO is feature rich and has a very large build capacity.

Innovative

We made 3D printing

faster, more reliable and easier.

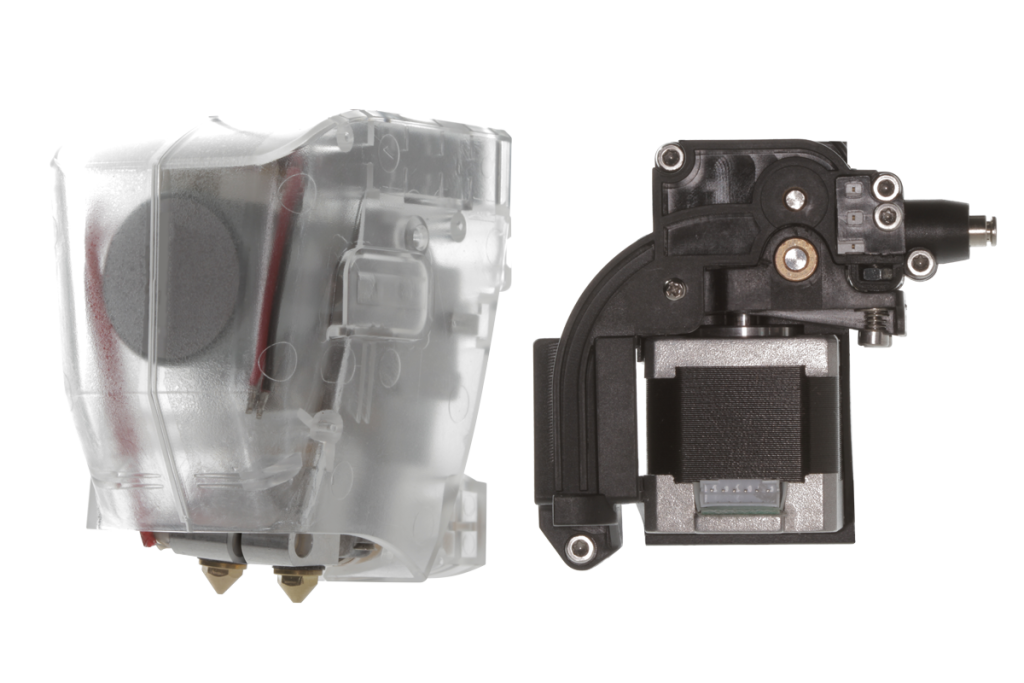

Needle Valve material control

Synchronised with the motion frame, material control is key in producing accurate parts during printing. With needle valves, viscous materials will not leak out to create stringing and blobs, dual extrusion printing will not waste material and time doing purges, wipe towers or heating/cooling operations.

Needle valves are unique to Robox and allow far faster and more efficient printing of multiple materials on the same layer. This system is currently used in all our multi-nozzle heads.

Nozzle Lift

Robox nozzles which are not in use lift out of the way, they don’t drag across the print or get stored away to dribble in the corner. Since we developed this method others have come up with varied solutions but none is as fast and efficient as the Robox system.

Since we developed this method others have come up with varied solutions but none is as fast and efficient as the Robox system.

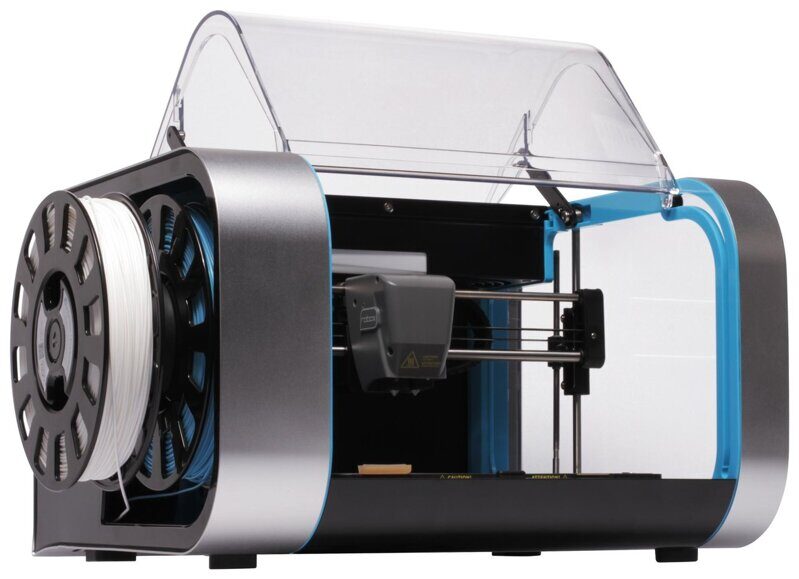

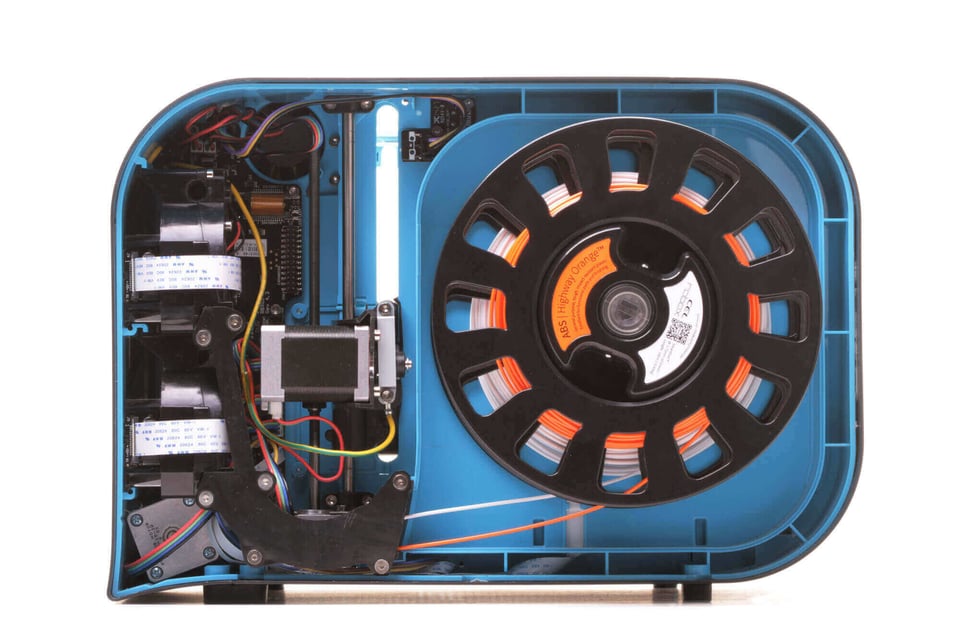

Material Recognition

This is a big one which Robox pioneered back in 2013 using our SmartReel system. Incorrect material settings for temperatures and feed rates has been the cause of many failed prints and even damage to printers. Robox automated this system and in the process have made 3D printing accessible to anyone. Swapping materials is easy on Robox and our SmartReel system has been imitated by the biggest competitors.

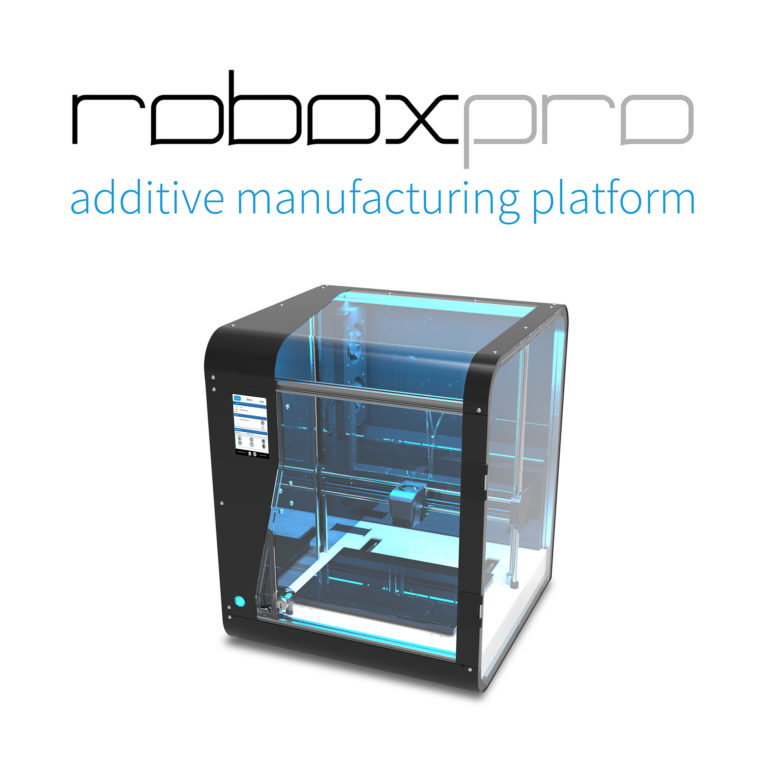

Both RoboxPRO and RoboxDual making the cut in the latest from Techradar.com

“RoboxPRO Best for commercial printing”

“RoboxDual Best for Schools and business”

Thomas Sanladerer, ALL3DP @toms3dp

The CEL Robox is, by far, the 3D printer with the greatest amount of innovative new features out right now.

Dual extrusion, PEI build platform, wireless, scalable these are all desirable 3D printer features and are all part of the formidable RoboxPro. Aimed at the commercial market, this large scale FFF printer balances quality, ease of use and value like no other.

Nicolae Mihalache, France

Thank you again for your fantastic help during the last couple of weeks! On top of Robox being a great machine, your support is a serious reason for which I will wholeheartedly recommend Robox to anyone interested in 3D printing!

Patrik Hasler, Switzerland

It was one of the best customer support experiences that I’ve ever had. (Unfortunately) that isn’t something you can expect in these days. So thank you very much and keep up the good work.

M.J. Wallner, Germany

I work in the last 6 years with a Dimension Elite 3D Printer for € 42.000,00 investment. This printer can’t beat the quality of your Robox printer in printing quality and tolerances.

Jason King, UK

Thank you for fast fix and turn around, very impressed with service without a doubt 5 star.

John Revill, Australia

I must say your service is excellent. The Robox is a great printer but combined with your service is awesome.

Steven Fagg, UK

I am very impressed with this 3D printer and its simplicity to use. This is my first 3D printer and have found it incredibly easy to use and set up. Thanks for that!

Matthew Hajicek, US

I had fun showing my prints to the Stratasys rep. He was like “You made that on a $1500 printer?!” His demo prints from a $35000 printer looked crude by comparison.

Contact Us

Shop for 3D printers

Subscribe for updates

Go to Top

Materials – cel-robox

Skip to contentMaterialsRoboxAdmin2022-05-20T14:15:41+01:00

Shop for Materials

Recycle your reels

Robox 3D printers support the most diverse range of materials of any desktop 3D printer with its SmartReel system, which enables material recognition with automatic print settings and job costings. Robox is able to use materials from any manufacturer, but by using SmartReel materials a user can be certain of consistent and repeatable results.

Robox is able to use materials from any manufacturer, but by using SmartReel materials a user can be certain of consistent and repeatable results.

The table below is divided into Temperature Compatible and Secure Lamination sections. Some materials will laminate well but could have feed or other issues when used at temperature extremes.

Dual Material compatibility matrix

Temperature Compatible Secure Lamination| PLA | TITANX ABS | COMMON ABS | ASA | CO-PET | NYLON PA12 | COMMON NYLON | COPA | TPU | POLY SUPPORT | HIPS | PVOH | ||

| PLA | PLA | ||||||||||||

| TITANX ABS | TITANX ABS | ||||||||||||

| COMMON ABS | COMMON ABS | ||||||||||||

| ASA | ASA | ||||||||||||

| CO-PET | CO-PET | ||||||||||||

| NYLON PA12 | NYLON PA12 | ||||||||||||

| COMMON NYLON | COMMON NYLON | ||||||||||||

| COPA | COPA | ||||||||||||

| TPU | TPU | ||||||||||||

| POLY SUPPORT | POLY SUPPORT | ||||||||||||

| HIPS | HIPS | ||||||||||||

| PVOH | PVOH | ||||||||||||

| PLA | TITANX ABS | COMMON ABS | ASA | CO-PET | NYLON PA12 | COMMON NYLON | COPA | TPU | POLY SUPPORT | HIPS | PVOH |

Temperature Compatibility

The variety of nozzle, bed and chamber temperatures of 3D print materials is large. Some will not shrink and warp in a cool environment while some will distort and cause problems in a warm environment.

A smile indicates an easy trouble free printing.

A meh face will work but there could be challenges such as warping and reduced part accuracy.

A frown icon indicates the print could work but there will be challenges. We recommend you seek advice in these cases as a blockage can damage hardware. A Robox printer will sometimes show “PLA compatibility mode enabled” in case of wide temperature difference. Eg PLA can soften at 50°C so when combined in a print with ABS which benefits from a heated chamber there needs to be compromise.

Eg PLA can soften at 50°C so when combined in a print with ABS which benefits from a heated chamber there needs to be compromise.

Lamination strength.

In some cases materials will not stick to each other which can cause problems during a print or in use. For support materials this is carefully tuned to hold during a print but peel away or dissolve after printing.

A smile indicates materials will stick together well during a print.

A meh icon indicates some challenges but print lamination will usually succeed.

A frown shows you should expect challenges. We advise a change of materials or testing and careful observation.

To contribute to this materials compatibility table please post in the Materials section of the Robox Community.

Data sheets for every material type are available alongside each product in our shop. Filament >

Download a zip file with all the sheets here or view below. To find a specific material on this page use the search function in your browser.

Go to Top

CEL Robox RBX01 3D printer (US plug)

JavaScript seems to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.

Proceed to Checkout

Total price

$0.00

Basket 0

Want free shipping? click here Learn more!

{{/findAutocomplete}}

SKU: {{sku}} {{#isFreeshippingEnabled}} Free shipping on eligible orders {{/isFreeshippingEnabled}}

{{#isDiscountFlag1Enabled}}

{{/isDiscountFlag1Enabled}} {{#isDiscountFlag2Enabled}}

{{/isDiscountFlag2Enabled}} {{#isDiscountFlag3Enabled}}

{{/isDiscountFlag3Enabled}} {{#isDiscountFlag4Enabled}}

{{/isDiscountFlag4Enabled}} {{#isDiscountFlag5Enabled}}

{{/isDiscountFlag5Enabled}} {{#isDiscountFlag6Enabled}}

{{/isDiscountFlag6Enabled}} {{#isDiscountFlag7Enabled}}

{{/isDiscountFlag7Enabled}} {{#isDiscountFlag8Enabled}}

{{/isDiscountFlag8Enabled}} {{#isDiscountFlag9Enabled}}

{{/isDiscountFlag9isProhibited}} More {{/isProhibited}} {{/is_combo_product}} {{#isProhibited}}

We are sorry, this product is not available in your country

{{/isProhibited}}

{{#hbk_price. stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

Partnership program Upon

Murmansk

Catalog 9000Building materials

Health and beauty

Health and beauty

Textile and leather

Textile and leather

Children's goods

Children's goods 9Ol000

All categories

LoginFavorites

CEL Robox

36 348

Cel -Fi QUATRA Range Extender

IN THE STOREMore prices and similar items

Hydraulic fitting CEL RA 28 with male thread, straight, 24° cone (art. 0796) Type: nipple, Type

0796) Type: nipple, Type

READ MOREMore prices and similar items

for Glass furnace door DTG-2S "Onego"0124 Robox For Neva Kamina 245x82 Manufacturer: without brand

More prices and similar goods

glass Robox for the Bart Bart 415x366 Manufacturer: without brand 9000,

more price

4 Robx ROBOX fireplace stove Yenisey with stove 330x240 Manufacturer: Unbranded0007

More prices and similar goods

28 990

37990

ASUS E410MA CEL N4020/4/SSD128GB/W10 FHD Manufacturer: ASUS

ANGA

,000 12 with stove 465x420 Manufacturer: Unbranded0007

Glass Robox For the Varangian Kamina Burn 9 464x250 Manufacturer: without brand

More prices and similar goods

Glass Robox For stove-stone Moscow 12 468x295 Manufacturer: without brand 9000 Hydraulic fitting CEL RA 35 with male thread, straight, cone 24° (art. 0797) Type: nipple, Type

0124 CEL /890 251235 Laboratory Portable Full Analysis Type Type: Complete,

More prices and similar goods

Glass ROBOX for the Lava Kamine 6 440x316 Manufacturer: without brand

more than price 9000 9000 Robox for Breneran stove 250*150 Manufacturer: Unbranded

DETAILSMore prices and similar products

Glass Robox for Enisey fireplace stove 330x240 Manufacturer: Unbranded

MORE DETAILSMore prices and similar products

Glass Robox for oven Termofor Fire Battery 240*90*4 mm. Type: oven, Manufacturer: Unbranded

Amur 9 390x105 Manufacturer: Unbranded

DETAILSMore prices and similar products

Glass Robox For the Narva Kamin 6m 276x304 stove: without brand

More prices and similar goods

Glass Robox for the Neva Fireplane 245x245 manufacturer: without brand 9000 Robox for Angara 12 fireplace stove with stove 465x120 Manufacturer: Unbranded

DETAILSMore prices and similar products

Hydraulic fitting CEL RA 12 with external thread, straight, cone 24° (art.

.jpg)