Cbc 3d printing

3D printing could help build homes with unique designs more cheaply, advocates say

The Fibonacci House in Procter, B.C., boasts spectacular views of the nearby mountains — but that's not what makes the tiny home a one-of-a-kind vacation rental.

It is Canada's first 3D printed house — a spiral structure with a standout feature: Curved walls. (It was inspired by — and named after — the mathematical Fibonacci sequence.)

Also known as additive manufacturing, 3D printing is a process where an object is built using layers of materials as directed by a digital design.

While 3D-printed construction is still considered to be in its infancy, advocates say that in the future, the technology could be used to build houses with unique designs quickly and more cheaply, with less of a need for scarce skilled labour.

Ian Comishin is the president of Twente Additive Manufacturing, the company behind the Fibonacci House, which is listed on Airbnb. He said 3D printing allows builders to construct complex, curved walls for the same price as a straight wall.

"So now, architectural features that are exciting or adding aesthetics can be done for virtually no cost comparison," he said.

How it works

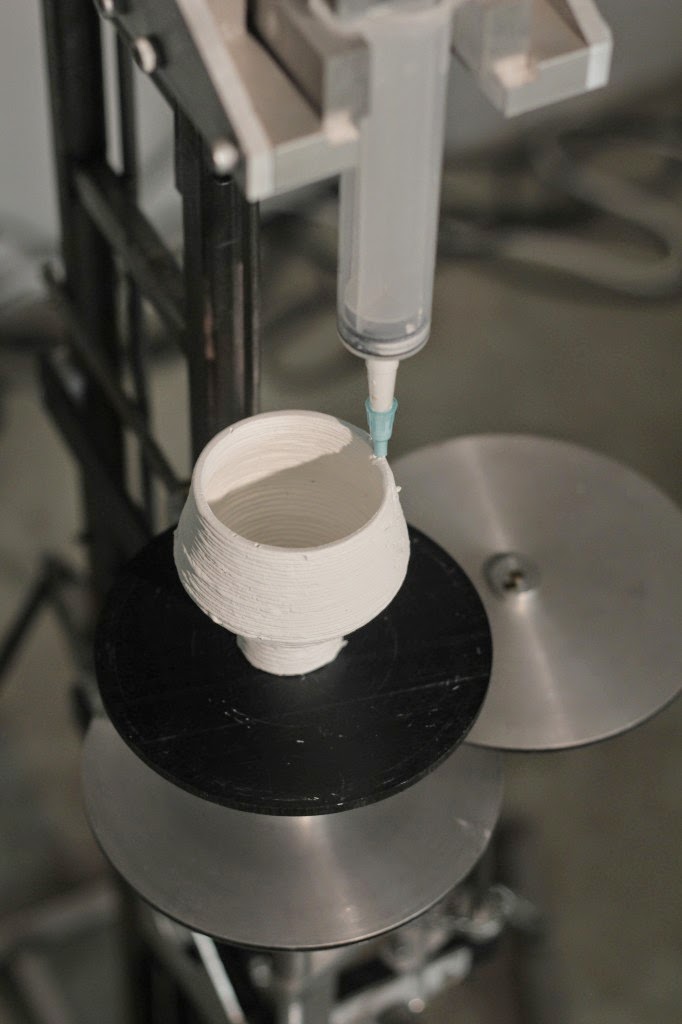

To construct such a home, the building is first designed digitally. Designers determine which aspects of the house can be 3D printed; typically, it's parts like foundations and walls made of concrete — a material that lends itself well to 3D printing. The instructions are then sent to a robotic printer, which can either build the elements at the construction site or elsewhere, like in a factory.

The walls of the Fibonacci House were printed off-site in 11 days, then brought to the build location for workers to assemble.

This is the home as viewed from the inside. Concrete parts were printed off-site using a 3D printer, then assembled at the site. It's inspired by the famed mathematical Fibonacci sequence. (Twente Additive Manufacturing)"The robot itself has a hose and a nozzle," Comishin said.

A mortar-concrete mix is pumped out of the hose, and it's formulated so each layer can be stacked on the next, building up the structure layer by layer. It's much like a baker's nozzle piping icing onto a cake.

It's much like a baker's nozzle piping icing onto a cake.

There's a cottage industry of people who use much smaller 3D printers at home, making and sometimes selling various knick-knacks. Some libraries and maker spaces also offer members access to 3D printers at their facilities.

But the real promise of the technology is how it will change the creation of bigger products, from planes to buildings.

A solution for homelessness?

Don McQuaid is the managing director of World Housing, an international agency focused on solving homelessness, which helped fund a 3D-printed community of 50 homes in Tabasco, Mexico.

"Our belief is that technology is going to be the solution for homelessness, and we believe that everyone deserves a home," he said.

Now the non-profit is partnering with Twente Additive Manufacturing on an ambitious project here in Canada. Called Sakura Place, it will be a community of five 3D-printed homes in Nelson, B.C., for families struggling to afford housing. Each house will be 700 square feet with two bedrooms, a kitchen and a bathroom.

Called Sakura Place, it will be a community of five 3D-printed homes in Nelson, B.C., for families struggling to afford housing. Each house will be 700 square feet with two bedrooms, a kitchen and a bathroom.

The community could one day be a proof of concept for using 3D-printing technology to build affordable housing elsewhere in Canada, as many continue to voice frustration with the country's expensive real estate market.

In September, the average home price in Canada was $604,000, up more than 17 per cent from one year earlier. And according to a report by Scotiabank, Canada has the lowest supply of housing per 1,000 residents among the G7 countries.

3D printing could also address some of the challenges posed by the short building season in some of Canada's remote communities, McQuaid said.

"It could be a solution for us to be able to come in, fly the [3D-printing] machine and use local materials and local people to assist and build in a tight window," he said.

How it cuts costs — but not that dramatically

Comishin also sees the technology addressing a shortage of skilled labour in the construction industry.

"This type of technology is something that's very easily adapted to somebody who … comes from just about any sort of computer background," he said. "It allows for job sites to have access to precision and repeatability that is sometimes unachievable just through human processes."

That predictability can reduce costs, he said, before cautioning that although 3D-printed homes are cheaper than traditional builds, it's a reduced cost — not a fraction of the cost.

"People get really excited with the technology. And then they call us up, and they think that they can build a house for $6,000, or $10,000," he said.

WATCH | A 3D printer is used by a Chinese construction company to build homes:

3D-printed houses

9 years ago

Duration 1:10

Chinese construction company says it uses 3D printer to build inexpensive homes

Many parts of the house, including windows, toilets and fixtures, can't be 3D printed, Comishin said.

"The cost on those things don't change," he said. "So from that perspective, we can still do affordable housing, but there's pretty unrealistic expectations [around] what this technology can do from a cost perspective."

A number of studies and projects have estimated cost savings to range from 10 to 50 per cent, compared to conventional construction.

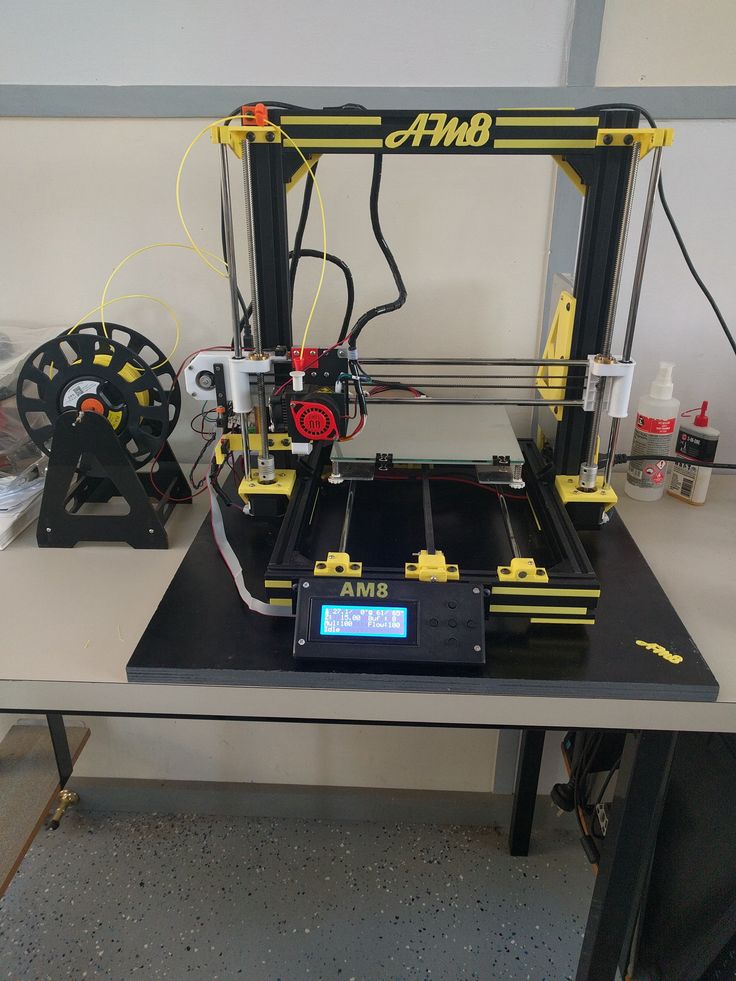

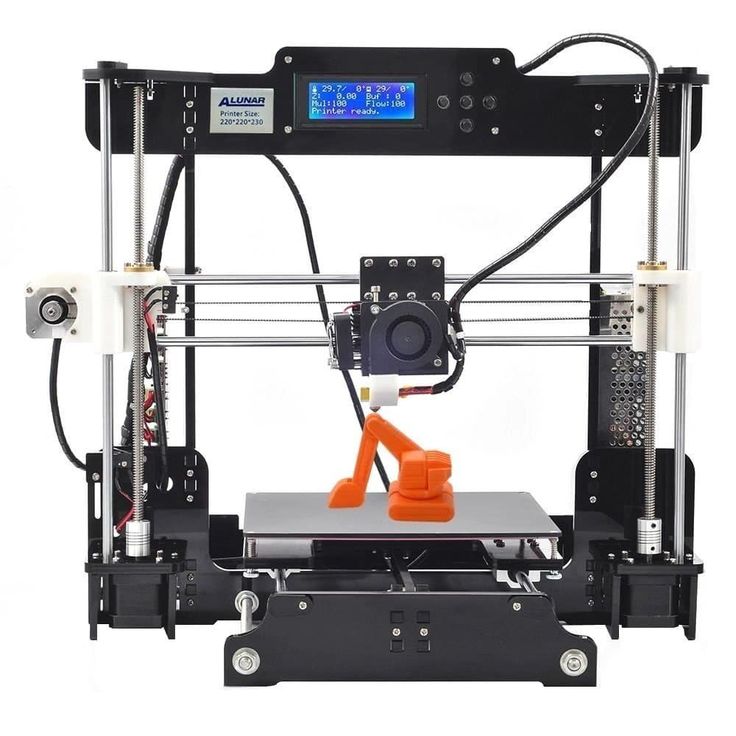

Another challenge is that while a 3D printer can build concrete structures relatively cheaply, that doesn't include the cost of the 3D printer itself, which can range from $49,000 for the small, basic models, to upwards of $125,000 for the larger models, according to 3Drific, an internet publication focused on 3D printing.

Still, at least one jurisdiction is aiming to sharply ramp up 3D construction. Dubai in the United Arab Emirates is aiming to have 30 per cent of new construction in the city-state be 3D printed by 2030.

How exactly does 3D printing work?

A Dutch architect recently announced plans to construct a house using 3D printing, a technology that has been around for decades but has only entered the public consciousness in the last few years.

Janjapp Ruijssenaars, who works with the Amsterdam-based architecture studio Universe Architecture, recently announced his plans for Landscape House, a looping infinity building that he expects will be completed in 2014, according to the Guardian.

Expected to cost between $5 million and $7 million, the building will be made from 3D-printed pieces.

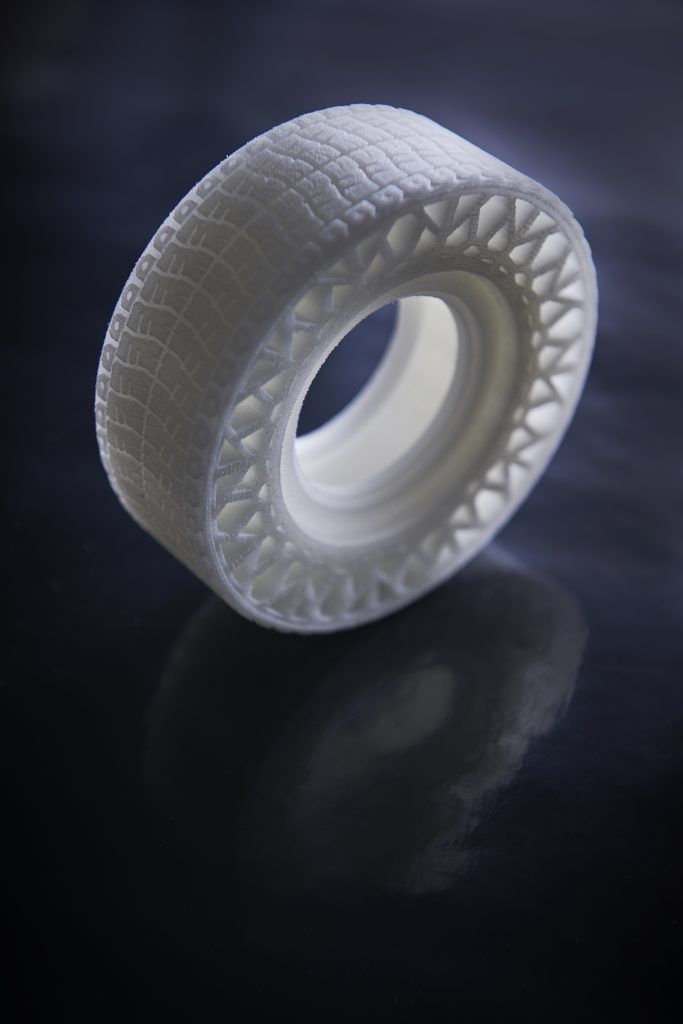

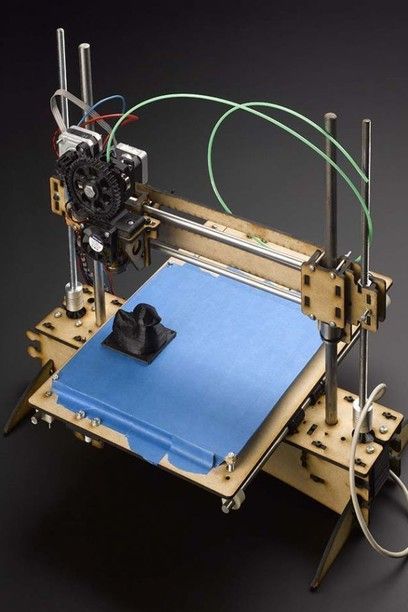

Frequently portrayed as a seemingly magical process, 3D printing — also called additive manufacturing — involves creating a solid object by layering thin slices of material including plastic, metal and ceramic.

Dutch architect Janjapp Ruijssenaars has proposed building a house using 3D printed materials. To do so, he plans to use a large machine that deposits sand and a binding agent in layers roughly five to 10 millimetres thick to create six-by-nine-metre sections of a stone-like material. (Universe Architecture)"It’s been in use for industrial contexts for at least 20 years," says Matt Ratto, assistant professor at the University of Toronto and director of the information faculty’s Critical Making Lab.

However, 3D printing has caught the public eye over the last few years as the technology has become more refined, not to mention cheaper.

Some of the proposed uses have drawn widespread attention in the media, from the ability to manufacture gun parts at home to the creation of edible entrees from pureed foods.

Anyone hoping for a Star Trek-type "replicator" able to generate myriad objects of varying complexity will likely be disappointed, as the technology is typically used to test the fit and functionality of prototype models or pieces in manufacturing and design projects.

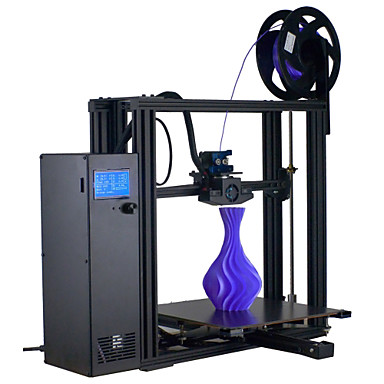

The emerging technology of 3D printing, also known as additive manufacturing, can use materials ranging from plastic to resin to metallic alloys. (Duk Han Lee/CBC)How it works

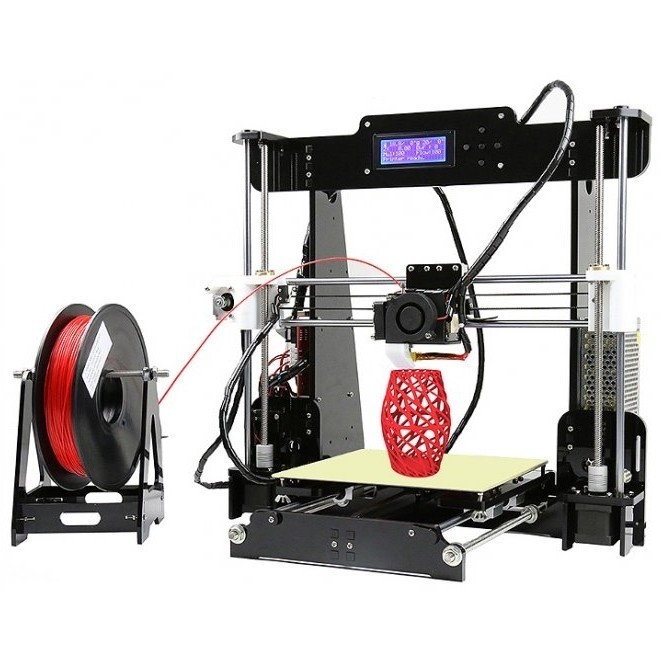

There are several types of 3D printers. They may use different materials, but all involve the same basic approach for "printing" an object: spraying or otherwise transferring a substance in multiple layers onto a building surface, beginning with the bottom layer.

Before the printing can occur, a person must first create a 3D image of the item they want printed using a computer-assisted design (CAD) software program. That object is then sliced into hundreds or thousands of horizontal layers, which are placed one on top of the other until the completed object emerges.

One type, called selective laser sintering, involves heating and solidifying granular material with a laser in a specific pattern for each slice before repeating over and over again with new layers; this technique could be used in creating figurines, for example. Another uses UV light to cure layers of resin. Others deposit material much like an automated glue gun.

Ruijssenaars, the Dutch architect who intends to 3D print a house, plans to use a large machine that deposits sand and a binding agent in layers roughly five to 10 millimetres thick to create six-by-nine-metre sections of a stone-like material. Those blocks will then be used to construct the home.

Ratto said the theory behind building a house out of 3D-printed blocks is sound, although it has never been attempted on such a scale. The machine that Ruijssenaars would use is essentially a larger version of the printers already being used.

The machine that Ruijssenaars would use is essentially a larger version of the printers already being used.

"I don’t think it’s a hard thing to do. The hard thing is to build a machine that would be cost-effective and reliable," Ratto said.

The technology could also be used in the future to create customized concrete blocks, a research area that is currently being explored in the U.K., Ratto said.

‘From industry to consumer curiosity’

Most of the 3D printers available, however, are smaller and not meant to build houses.

Reuben Menezes, marketing manager at 3D Printers Canada, says his company sells a variety of machines with differently sized building areas. The smallest measures 13 x 13 centimetres with a height of 13 centimetres, while the largest is 90 x 60 centimetres and 90 centimetres in height.

Although entry-level hobbyist machines can be found in the $1,000 range, the company's heavy-duty 3D printers range in price from $9,000 to upwards of $600,000.

Menezes says 3D Printing Canada sells primarily to academic institutions and companies with research and development arms for the purpose of testing prototype parts.

The Toronto-based firm 3D Prototype Designs created this 3D-printed car vent for airflow analysis prior to manufacturing. (3D Prototype Designs)There are smaller and cheaper models available for eager hobbyists, some for less than $1,000, which are often used to design toys or gadgets.

Annette Kalbhenn, sales and marketing manager at 3D Prototype Designs in Toronto, says her company has been using 3D printing for rapid prototyping – creating short runs of test pieces for manufacturing processes – for about 15 years.

"I think the biggest trend that I’ve noticed is that there is more public awareness," she said. "It’s kind of flipping from industry to consumer curiosity."

Despite its growing popularity, Kalbhenn says some people have misconceptions about 3D printing.

"That anyone can do it and that it’s easy and it’s inexpensive and instead of going to the Volvo parts replacement you can just make it yourself for two dollars," Kalbhenn said, citing some of the misconceptions.

Some people are unaware, Kalbhenn said, that you can’t really print anything without the CAD file containing a plethora of data about the object’s dimensions.

Technology has its limitations

While there are websites offering a variety of downloadable designs, Ratto says most of the people using the CAD software are trained professionals, not the average hobbyist.

That creates major obstacles for a layperson wanting, for example, to 3D print a small piece of a closet door that is likely available at a reasonable cost in a traditional store, Ratto says.

Another limitation is that the printers create an object out of only one material when most consumer goods are made of many.

Ratto said researchers are looking at ways to solve that by creating devices that print a number of different materials. For instance, a machine could combine plastic and conductive material to create electronics, including cellphones.

Some business observers are pinning high hopes on 3D printing, believing that the technology could return a level of small-scale, custom manufacturing back to North America, Ratto said.

"I think that’s one of the claims and I don’t think it’s impossible," he says "I think it’s an interesting possibility and one that is potentially feasible."

Gone・Cults

Skip to contentBut don't panic!

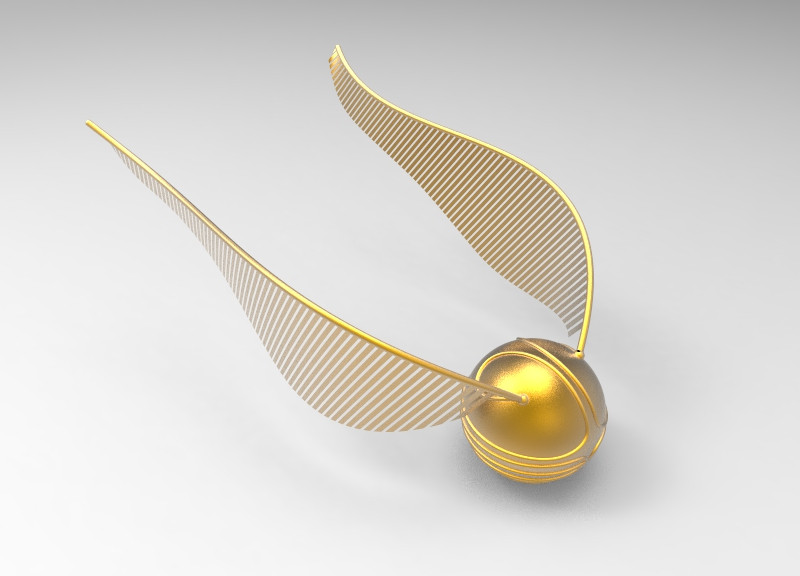

Here at Cults, we always have something to make your 3D printer happy. For example, look at these little hooligans:

01

FLEXIBLE SITE STANDING YETI

€2.93 -fifty% 1.46€

Notebook

2.60 €

03Kinetic floating Christmas tree

1.89 €

04Lazy Beaver

3. 99 €

99 €

** FOR GAMERS ** JOYSTICK HOLDER

2 € -ten% 1.80 €

HINGED CARTOON TURTLE

Free

07Organizer for multi-tools

2,50 €

08Concert piano

5.99 €

09HINGED SCORPION

€3.64 -80% 0.73 €

Lord Challenger

Free

elevenBrainiac's skull ship - classic version - with movable tentacles

6,20 €

12Chess game

5 €

13Vhagar | Dragon House

25 €

fourteen"Runaway Escapement" 3D printed clockwork car with speed control.

Free

fifteenTOYOTA LAND CRUISER LC75 RC PICKUP 1 TO 16 WPL SCALE 3D PRINT MODEL

25.99 €

16ORGANIC CONTAINER 1

1.92 €

17homer simpson key owner 2

1.88 €

eighteenGnome Yes (No support)

€2.49 -twenty% 1.99 €

Owl whistle - a whistle that sounds like a real owl!

€2.50 -fifty% 1.25 €

Pochita flexi

2 €

STL File CBC GUN TRIGGER・3D Printer Model Download・Cults

BAFL MARAUDER

0,76 €

Training knife roosters

2,54 €

Ford Bronco 1988 4x4 hub lock

3. 31 €

31 €

MARAUDER CHARGER

4.06 €

Botana for Gallo

6.35 €

POWERA SPECTRA XBOX ONE TRIGGER

1.52 €

Blowpipe sight and mouthpiece

0,76 €

Beretta A400 xtreme Shotgun Spacer

10.16 €

The best files for 3D printers in the Tools category

5mm Calibration Cube Steps

Free

Pi Command Center

Free

Bosch 12V Battery Stand

1.29 €

Calibration vase - Stringing, overhang and bridging test

Free

Regular icosahedron Dome Connector interconnection

1,50 €

Bit holder for NASA BOX

Free

GoPro Hero 3 Frame

Free

Egyptian flower clay stamping wheel

Free

Bestsellers in the Tools category

ENDER 3 S1/PRO SPRITE, V3 AIR DUCT 5015 OR 4020

€2. -fifteen% 2.08 €  46

46

Business card embossing system

3 €

Fire hydrant container

1.99 €

NEW GENERATION CAR PHONE HOLDER

2,50 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1.91 €

Ratchet holders - magnetic - holders for tool box organization

2,82 €

Version 2 Alligator 2 || Repeating crossbow || 3d printed shop || Inspired by Joerg Sprave

1.50 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2,97 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 PRO

2,97 €

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang.

CR-10, Micro Swiss direct drive and bowden compatible. Printing does not require support

CR-10, Micro Swiss direct drive and bowden compatible. Printing does not require support 1.66 €

Case for Chill Buddy lighter

0,98 €

Armadillo - flexible wire conduit

1.78 €

BMG E3D V6 direct drive for Creality Ender 3 (Pro/V2) & CR-10

4.49 €

Paint stand with scissors

5.48 €

Printer boxes for Ikea Lack Table

1,99 €

PET-Machine, make your own plastic bottle filament at home!

50€ -70% 15 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.