Second hand 3d printers for sale

Refurbished 3D Printers and Machines

MatterHackers refurbished 3D printers are fully functional printers that are certified and tested by the Pros here at HQ - plus, they come with a six-month warranty. These reconditioned, gently used 3D printers are the perfect source for makers, manufacturers, and educators that need high-quality 3D printers at an affordable price. Of course, all refurbished 3D printers come with lifetime support via email or phone. We realize that cost can be a factor for some buyers, that’s why we are excited to offer this option for everyone! Refurbished 3D printers come in two classifications; A Stock and B Stock. Don’t see the machine you are looking for? Check back often - we could be testing the affordable 3D printer of your dreams right now!

Guides & Articles

Tech Breakdown: Ultimaker S5 3D Printer Review

The Pros at MatterHackers break down and review all the new and improved tech in the first 3d printer from Ultimaker in their new 'S' line of products.

Tech Breakdown: Raise3D E2 3D Printer Review

The E2 is the first Raise3D 3D printer to feature independent dual extrusion for clean multi-material prints and duplicated print jobs.

Tech Breakdown: Lulzbot TAZ Workhorse 3D Printer Review

MatterHackers' pros take a look at why the Lulzbot TAZ Workhorse lives up to its name, making it a 3D printer to be reckoned with.

Tech Breakdown: Ultimaker S5 Pro Bundle Review

Building off the success of the Ultimaker S5, the Pro Bundle takes the printing experience to the next level.

Tech Breakdown: Ultimaker S3 3D Printer Review

A machine you can trust is absolutely essential for any professional, and the Ultimaker S3 passes with flying colors. Read on to see what makes it so reliable.

Tech Breakdown: Creality Ender 3 V2 Bundle 3D Printer Review

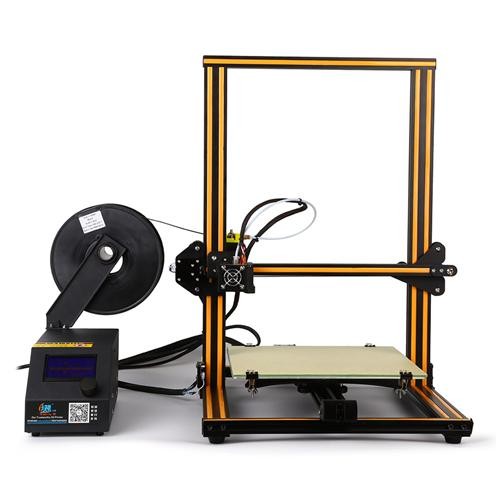

From the creators of the CR-10 and the ubiquitous Ender 3, the Ender 3 V2 improves on its predecessor in every way.

Tech Breakdown: BCN3D Epsilon W27 and W50 3D Printer Review

When you need to 3D print something big and in two materials, considering any of the BCN3D Epsilon 3D printers is a smart choice.

Tech Breakdown: Ultimaker 2+ Connect 3D Printer Review

The 3D printer that laid the foundation for Ultimaker gets spruced up and modernized. Let's take a look at the Ultimaker 2+ Connect and what makes it so special.

Tech Breakdown: Peopoly Phenom Resin 3D Printer Review

Building on the success of their other printers, Peopoly unveils the next edition to their resin 3D printer lineup.

Tech Breakdown: Craftbot FLOW 3D Printer Review

The latest line of 3D printers from the company known for their robust machines has a lot going on under the hood, read more to find out.

Tech Breakdown: Zmorph FAB All-In-One 3D Printer Review

The latest machine from Zmorph is more than just a 3D printer, it's a full-fledged workbench in one platform.

Tech Breakdown: BCN3D Sigma D25 3D Printer Review

BCN3D has done it again with the inaugural Sigma D25, the first entry into BCN3D's Desktop series of 3D printers and continuing their IDEX legacy.

Refurbished "A Stock" description:

- Fully functional printer, professionally inspected and tested

- Used, like new condition

- May contain minor cosmetic blemishes

- A nonessential item may be missing (thumb drive etc.)

- Comes with a 6 month warranty

Refurbished "B Stock" description:

- Fully functional printer, professionally inspected and tested

- Used, good condition

- May contain minor cosmetic blemishes

- May or may not include the original packaging

- Some nonessential items may be missing (filament, SD cards, etc.)

- Comes with a 6 month warranty

Used Industrial 3D Printers - CNCMachines.com

When you are searching for a used 3D printer for sale, youll notice a number of types of technologies with different names. To help you compare similar types of printers, below are five common technologies with their synonyms and similar technologies as you may find advertised on our used 3D printers catagory page:

To help you compare similar types of printers, below are five common technologies with their synonyms and similar technologies as you may find advertised on our used 3D printers catagory page:

Fused Deposition Modeling

Similar Technologies/Names: (Fused deposition modeling (FDM)), fused filament fabrication, plastic jet printing, filament extrusion, fused filament deposition, and material deposition.

Fused deposition modeling is the most widely used form of 3D printing with models available at the consumer level as well as the industrial level. This technology builds parts layer-by-layer from the bottom up. It heats and extrudes a thermoplastic filament. Thermoplastics are available with special properties like toughness, translucence, biocompatibility, electrostatic dissipation, UV resistance, and high-heat deflection. The relative weakness of this technology is that you may have visible layer lines and the parts are weaker along the layer lines. Larger FDM machines require compressed air for high-performance plastics.

PolyJet Technology

Similar Technologies/Names: (PolyJet technology), multi-jet printing, photopolymer jetting

PolyJet 3D printers work similarly to a traditional inkjet printer, but instead of jetting ink onto paper, the print head jets liquid photopolymers onto a build tray. Each droplet is cured in a flash of UV light. This type of 3D printer can provide sharp precision, smooth surfaces, and very fine details. It can mix photopolymers in specific concentrations to many materials, even rubber, and human tissue. 3D printers with photopolymer jetting make amazing realism with a full gamut of colors.

Stereolithography (SL)

Similar Technologies/Names: (stereolithography), SLA, vat photopolymerization

A 3D printer with stereolithography (SL) technology is an excellent option for very tight tolerances and smooth surfaces. A UV laser cures and solidifies very fine layers of photopolymer in an open vat with this technology. Designers like this technology for quick build times for strong parts made of transparent, heat-resistant, moisture resistant materials. A relative weakness of this technology is UV sensitivity (parts are often painted for this reason) and extra post-curing steps. 3D printers of this type required dedicated manufacturing space with ventilation and a specialty multi-stage alcohol treatment.

Designers like this technology for quick build times for strong parts made of transparent, heat-resistant, moisture resistant materials. A relative weakness of this technology is UV sensitivity (parts are often painted for this reason) and extra post-curing steps. 3D printers of this type required dedicated manufacturing space with ventilation and a specialty multi-stage alcohol treatment.

Laser Sintering (LS)

Similar Technologies/Names: (laser sintering), selective laser sintering, SLS, power bed fusion

If you are looking for a 3D printer capable of building parts with good mechanical properties and extremely complex geometries like undercuts, thin walls or interior features, then finding a laser sintering 3D printer for sale might be your best bet. A laser sintering 3D printer uses a high-powered CO2 laser to melt and fuse powdered thermoplastics selectively. Parts made with this technology can be watertight, airtight and flame retardant since materials can hold excellent isotropic properties equally strong in all directions.

Metal Powder Bed Fusion (MPBF)

Similar Technologies/Names: (metal powder bed fusion), selective laser melting, metal laser melting, direct metal laser melting

MPBF is a type of 3D printing that makes it possible to produce complex geometries not possible with conventional metal manufacturing processes. It uses a precise high-wattage fiber laser that micro-welds powdered metals and alloys to form components similar to wrought counterparts. Strong and durable parts can be made with additive metals like Inconel, aluminum, stainless steel, and titanium. Its possible to make features like internal cavities, thin walls, undercuts and interlocking components which are difficult or impossible to make with machining. Usually, this selective laser melting 3D printing is used for prototypes, low-volume runs, or for parts that cannot be cast or machined.

Buying a used 3d printer

Section 1 - theory.

(Hate to read - feel free to see section 3)

Sooner or later, someone from the vast number of the human population of the planet has an interesting idea - to buy a 3d printer.

And if the person who wants what is called “in the subject”, then in the mind there is already a certain established image of what is desired, an understanding of the terminology and a community in which one can ask for advice.

But a person who encounters this for the first time, a beginner, does not know anything about it.

We go into the store and our eyes run wide from various models, and the seller diligently broadcasts to us about the latest achievements, famous brands and improved features of new versions.

Here our eyes fall on the price tag and the understanding comes that the cost of a new "good" printer from the seller's point of view, in principle, coincides with the cost of a used domestic car.

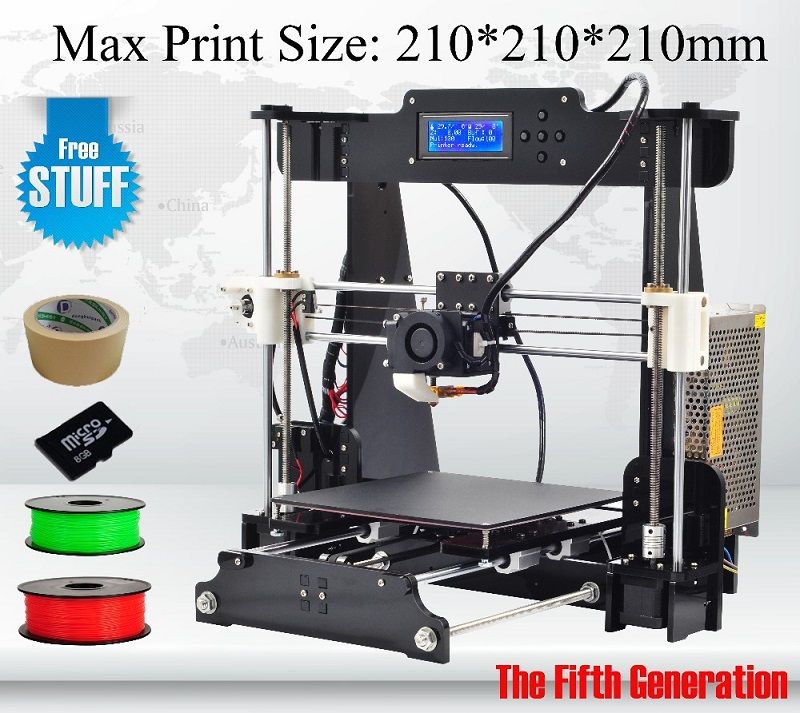

We are looking at models of the lower price range and they clearly demonstrate to us the brilliance and poverty of the simplest construct.

Acrylic or plywood body, liquid shafts, plastic connectors.

Searching for similar products on the Internet gives us a bunch of offers to get about the same thing cheaper from Chinese trading floors, but assemble it yourself in the form of a constructor.

Not at all doubting my own abilities to hold screwdrivers with keys in my hands, I personally dismissed this opportunity right away.

Since I can perfectly imagine all the complexity of fitting knots, which, in theory, should be precision.

I respect the choice of those who follow this path, but I have no desire to follow it myself.

What else is there?

Avito and others like them, headings of announcements of companies and individuals.

Companies mainly sell the same kits from Ali and ebay, brought, assembled and with a 2-3 times wrap.

But private traders are more interesting.

Someone sells a new one at a small discount, still not being able to figure out what it is eaten with.

Someone who has learned the basics moves on to a better model, giving away the used one for half the price.

And someone has killed his own and just wants to shake it off.

Now this is something you have to figure out.

Section 2 - personal experience.

I'm a 3d printing person who ended up basically by accident.

A fall from 6 meters at work led to a spinal injury, as a result of which it was prescribed to lie at home in bed for two months, getting up only as a last resort.

Realizing the fact that I'll just go crazy from idleness in two months, I began to think over options on what to use this time with benefit.

I settled on a 3d printer, which I considered with interest when buying a 3d pen in a local store for my daughter.

Then, realizing that in my usual mode of work with an irregular schedule, I will not have time to study work with him, I safely forgot about them.

Having studied the rest of the contents of my own wallet, I found that I have exactly 28 thousand rubles of money, and given that my work is not formalized in any way, there will obviously not be more of them in the coming months.

Looking through the catalogs of online stores for this amount, I found several options for printers, but their external technical data did not impress me at all.

Weak frame, dangling wires, display sticky on top or side.

Having a more or less decent case, prints started from 30 thousand, which was already not enough.

And, as they say, "I got into the used section."

Avito happily confirmed that I can buy a used printer in my city for 15 thousand or 12 thousand, but the external fragility of the design again made me sad.

But then I saw something that I liked.

Rigid frame made of steel, domestic manufacturer (probably, we still have patriotism in us, no matter how much the West tries to burn it out of our souls), thought-out design.

The price tag is the same as the new Chinese one - 27.500 wooden ones.

I'm looking for offsite and I see that this is exactly half of its retail price.

Mmm.. tempting…

After digging through everything I found on the net using this print, I am convinced that the device is technically quite worthy.

For a couple of days I was sleeping with thoughts about buying, weighing what is closer to me - a new Chinese, or a bushy Russian.

Looking through the ad again, I find out that the printer has been used for 7 months and is even still under the manufacturer's warranty.

Judging that it is difficult to break the equipment in 7 months, I made up my mind and called the owner.

The owner turned out to be a pensioner, who, according to him, bought a printer for his project, but never managed to apply this project anywhere.

Agreed to bring the printer to my house and demonstrate how it works.

The longed-for hour has come, the printer is on my desk, we connect it.

Immediately the extruder blower squealed, the owner brushes it aside - it is necessary to lubricate, it does not affect the "speed".

The table is embarrassing, it is varnished to a terrible state, 0.2 mm in dozens of layers.

But how should I know how to do it, I'm a lamer…

Here we insert a flash drive, select a file, start heating.

The owner of the printer takes out a can of "charm" and pours a certain layer of varnish on the table.

I have a shock, shafts, belts, body - naked, varnish gets on them, albeit less.

Well, who knows….

The seal has begun, this is an amazing act for those who look at it for the first time.

But what is it, why is the top of the part full of holes?

The owner of the printer complains about the old file, which has thin walls and a different nozzle.

Draw walls more and everything will be ok.

Okay, I will study so that I have time.

Having received a short educational program on working and preparing files in 20 minutes, I pay off the happy owner (now the former one) and stay with the printer one on one.

Second day. What kind of nonsense is that?

Neither double nor triple wall and top-bottom thickness eliminates holes at the top of the part.

And the printer, when printing from a laptop, likes to hang in the middle of printing in a random place and the part is defective.

We read the forum, there 3D Tudey is just a storehouse of information for a lamer like me.

Playing with temperature, blowing speed for PLA.

So… Where is the airflow?

But there is no airflow, the impeller of the turbine lies lonely in the fan housing, broken off from the shaft.

Trouble..

A cursory search through the catalogs of local stores says that 50mm is welcome, but 40mm is not.

We call the former owner.

- “Don't know? »

- «The last 3 months did not print at all? »

- Well, I'm glad, but to do what ...

Advice to contact technical support, they say there are brave guys and in general they offered to send the printer to them for free MOT.

No, first of all, I can't get to the post office, and secondly, staying without a printer for an indefinite period only after buying it is not at all the case.

Contacted technical support and…

I was very surprised.

I was immediately offered to send me a new fan under warranty, by door-to-door delivery service, free of charge.

Here I was glad that I took the Russian device.

The fan arrived within a few days and was delivered.

The holes are gone, but in places there are bulges on the upper surface.

The bottom part repeats the broken contour of the hut of varnish layers.

Not the case. And there is no desire to pour varnish on the table of the printer standing on a stool by the bed in the room.

We read what smart people write about the first layer.

Yeah, glue stick, there is one.

Remove old deposits from glass.

Water does not help, a clerical knife and a razor blade are used.

Oh, so the glass turns out to be removed...

But it doesn't look like the previous user ever took it off.

Cleaned for more than an hour, glass, case, everything nearby.

Re-set the level of the table, went to study further.

The com port settings had no effect on the probability of stopping printing in progress.

However, I subtracted the information that it is correct to print from the card.

This method completely removed all freezes and slowdowns when printing.

But why did the plastic get stuck in the printer when printing and you can only remove it by loosening it back and forth by holding the presser foot?

Read the basics of printers again.

Air blower 30x30x10. The one that I immediately did not like how screeching.

Its performance has decreased, the radiator does not cool well and the plastic melts above the proper place.

Searching for local radio components and products in catalogs again, and again a bummer.

Unpopular size.

Available 40x40, available 25x25.

A 30x30 no.

Well, foreign countries will help us, download the adapter from the tinga, hang on it the wife bought 40x40x20.

The second time to contact technical support for another fan would be impudence on my part.

Yes! Plastic jams are almost non-existent.

Along the way, I subtracted the moment that you can not turn off the power to the printer until the nozzle cools down to 40-50 degrees. Let's take into account.

Let's take into account.

Everything is fine, the printer prints, there are no freezes, there is no plastic stop, you can try more details.

Why are there layers missing?

And everywhere and in different places on the same model.

This question haunted me for a long time.

I read a bunch of everything about 3D printers and 3D printing, more or less mastered the terminology and the essence of the operation of the printer units.

But nothing helped to cope with the problem.

Having found forum member dima_pb's articles on just such printers, I mustered up the courage to ask for his advice.

Why, you ask?

I know that old-timers don't like newbies with stupid questions.

Well, yes, the attempt is not torture, I knock on Skype "with a bow."

- Hello. Recently became the owner of MZ3D-360, there are technical questions. Can you suggest? »

The answer cools the ardor - "Good questions?"

Honestly - "Probably lamer, I'm a beginner. "

"

But luckily, the man turned out to be ready to help, and even more than that, he himself is an employee of the factory that assembles these printers.

Under his careful guidance, I disassembled the extruder and found:

- The printed base of the extruder is chipped in 3 places.

- The blower nozzle is broken on one side and has a crack, due to which part of the air blows not on the part, but to the side.

- The past owner drilled out the stuck plastic, scratching the inside of the hot end radiator channel and the drive gear.

- the thermal barrier is bent and under-twisted into the radiator, due to which there is a backlash in the nozzle with a cube.

I reprinted the base and airflow, polished the radiator as far as I could with a toothpick and paste using a screwdriver, tightened the thermal barrier.

The print quality is better because the nozzle play is gone.

Pass lanes remain.

When looking for a problem, it was replaced with a new extruder driver, RAMS and PSU fans, but it did not affect.

The last thing left is the plastic feed gear.

But where can I get it?...

You can't find spare parts for 3d printers in my city, and you have to go to find it.

In the meantime, you can't.

Again I turn to technical support, I give photos of problems, I ask if it could be from gear wear.

Summary – needs to be changed. They sent an invoice, 380 r gear and 400 delivery.

And there is no money at all…

The last thing from the family budget went to pay for the daughter's school.

I asked if the gear was under warranty, the answer was no.

I apologized for the anxiety, explained that there was no money, I was lying with an injury.

The next day there is a letter in the mail - I can't believe my eyes.

- “Please send me the exact delivery address and your contact number, I will issue it as a guarantee”

Thank you very much for your help!

They brought a new gear, put it on and that's it!

No gaps, even layers.

Now the printer prints the way it was designed by the manufacturer.

Then one morning the heating of the nozzle suddenly stopped working.

Remembering Dima's words, I feel the wiring to the heater and burn myself.

Glass cloth tube charred on one of the wires.

Analysis showed oxidation of the connecting terminal.

The second wire terminal was also black.

Cleaned them to a shine, installed new silicone wires, made a board with connectors for the heater, temperature sensor and both fans.

Now you can easily change fans without unraveling the wiring, you can detach the cube when disassembling or replacing.

I changed the turbine for blowing the part to a more serious server 40x40, with a current of 1.9 amperes, it helps a lot on thin elements when printing PLA.

I summarize what I can say.

When choosing a new or used printer, keep in mind that the second option is similar to buying a used car.

That is, you will probably immediately need to replace consumables that have already expired.

As for a car, you will either have to "drive the car" to the service, or master the work yourself.

There may be surprises, which you will find out about later.

Section 3 tips.

So, tips for buying a used printer if you are new to this topic:

1) Be sure to test the printer's printing before purchasing.

All extraneous sounds, curvature of the final surface of the part, sagging or dips in the thread may indicate malfunctions.

2) Carefully inspect the main components of the printer, the axis should move evenly, the print head should not have chipped plastic or missing fasteners, the table should be heated to the required temperature.

3) Pay attention to the cooling fans of the device components, they are consumables and they require periodic replacement. The howling sound of the fan when the power is turned on is a clear sign of clogging with dust, it's time to change.

4) Inspect the plastic feed gear - if it shows signs of uneven wear, or the plastic slips during operation, it will need to be replaced.

5) Check the integrity of the blower nozzle, if it has cracks, it is worth printing a new one for replacement.

6) Gently shake the nozzle, it should sit firmly and not play.

7) Inspect the wiring for damage to the insulation and signs of overheating.

8 ) You will need to learn how the printer components work to maintain them, or find someone to do it for you.

P.S. I express my deep gratitude and thank you for your help:

- Dmitry Ivanov for help with the repair and development of printing!

- Maxim Rubailo for support with spare parts and humanity!

- Andrey, the assembler, who, although he cursed, gave out a new replacement gear!

Without your help, I would have been left with nothing.

P.P.S. It can be seen that the MZTO printers are strong, since even after such a mocking attitude of the past owner, it was technically easy to completely restore the factory print quality.

A small guide for choosing a 3D printer for beginners / Sudo Null IT News

The reason for writing this article was the article “ I wanted to buy an inexpensive 3D printer, but I looked at YouTube and didn’t want ”, at the end of which the author asks to answer a few questions. I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer. First, a few caveats.

This article will not contain advice: “Buy a printer from manufacturer X - it is good, but do not take manufacturer Y in any case”, only general recommendations.

Informal classification of printers, adopted in the domestic segment of printers.

Everything written is based on the personal experience of the author and is his personal opinion.

If these warnings do not scare you - welcome under cat.

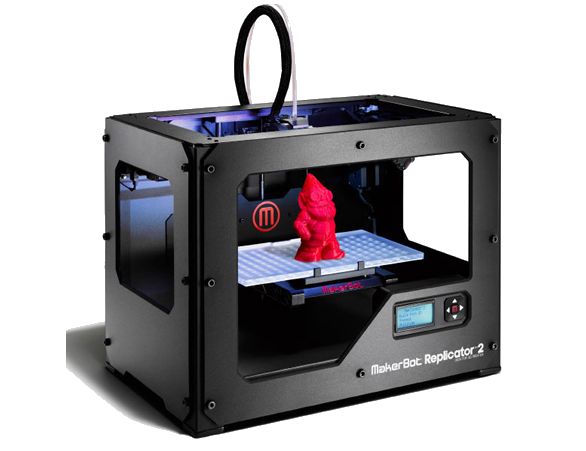

First, let me introduce myself: my name is Maxim and I bought the first printer back in 2013. It was a Chinese clone of Makerbot 2 with the hilarious name "Migce Cuble".

There was almost no information on 3D printing on RuNet, only one topic on the “Roboforum” and several scattered articles about what a cool thing it is - 3D printing, so to master it I had to google a lot in English, come up with their crutches and delve deeply into the physics and technology of the printer. We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

Currently, two types of printers are mainly used at home: printing using FDM (FFF) technology - layer-by-layer plastic fusion, fed in the form of a rod and SLA (LCD) - printing with a photocuring polymer. FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

SLA and FDMTo be honest, I almost never did SLA printing and I still don’t have an LCD printer in my home zoo (but it may appear soon), so I’ll talk mainly about FDM printers. They can be divided into 3 main categories according to the type of mechanics:

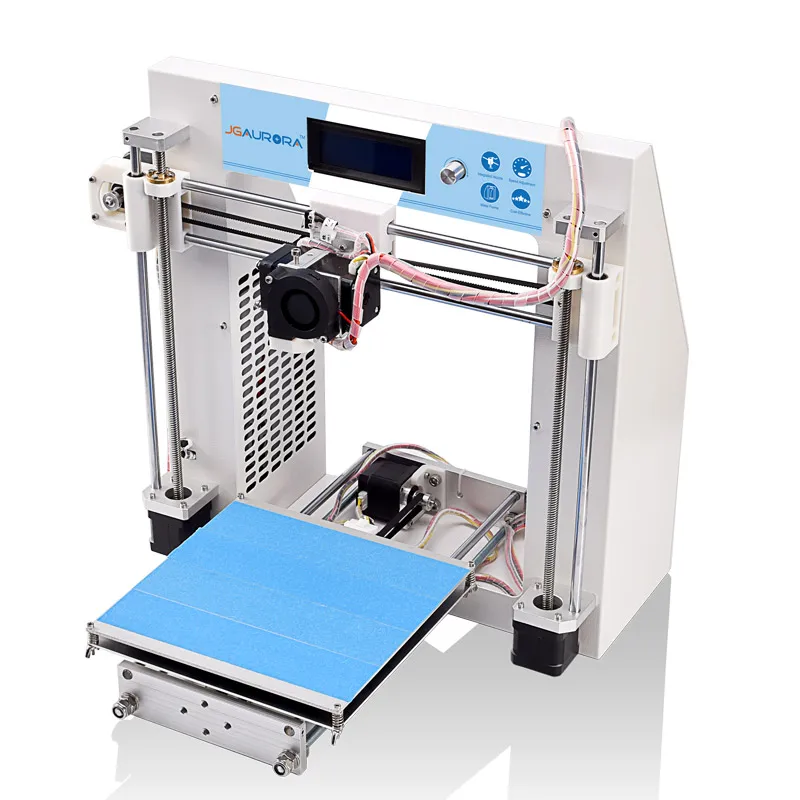

Drygotables - printers with a table movable horizontally. Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU.

Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU.

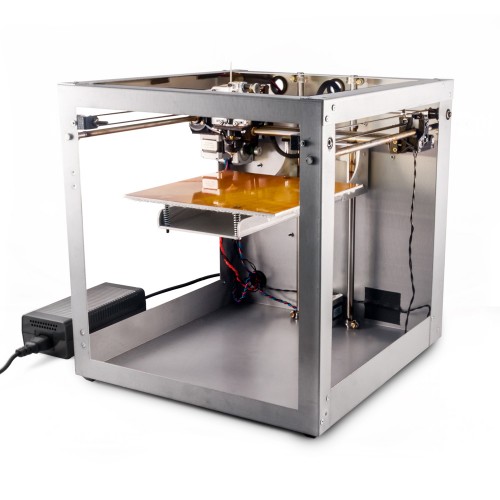

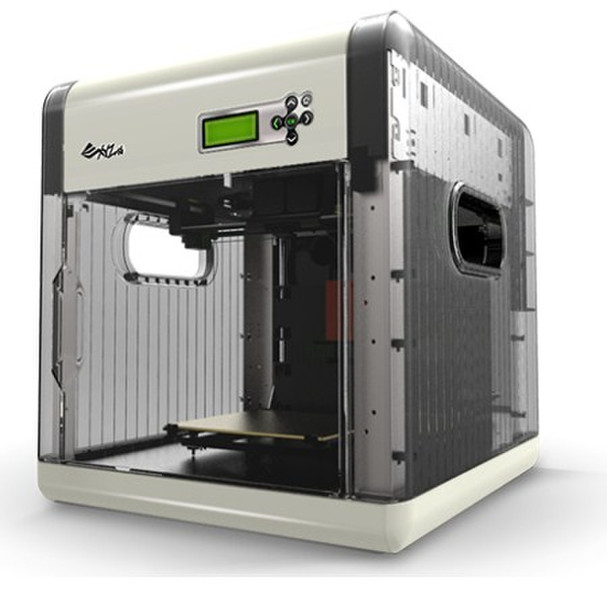

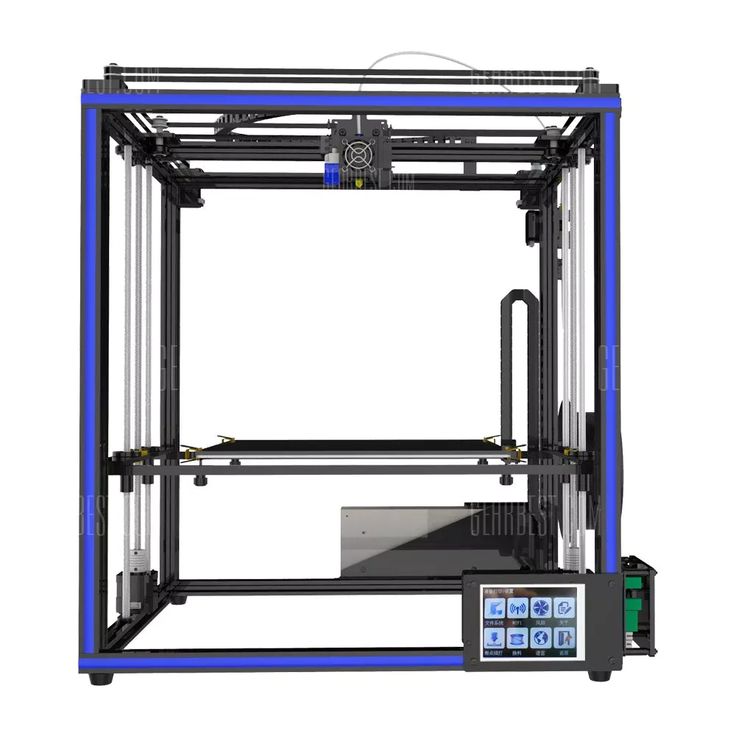

Cubes - printers in which the table travels vertically. The cost of such printers is higher, as are the requirements for straightness of hands during assembly and setup. But a properly designed die delivers faster print speeds while maintaining print quality. At the same time, the design of the printer is very easy to make closed, which allows printing with engineering plastics such as ABS and Nylon. This type of design is often used in semi-industrial and industrial grade printers. Some manufacturers manage to shove the drygost into the body of the cube, but this does not bring any special advantages for printers.

Delta - printers with the so-called delta kinematics, when the print head is attached to carriages moving along vertical guides using a system of rods. The cost of the mechanics of such printers is comparable to the cost of dry-tables. Can print at very high speeds. But they are very demanding on the correctness of keeping the dimensions, the straightness of the hands during assembly and adjustment, and the speed of the “brains” due to the complex mathematical calculations of the trajectory of the head movement.

Strongly not recommended as a first printer, although the widespread use of the table level sensor somewhat reduces the requirements for straight hands during setup and operation.

Typical deltasBy availability on the market, 3 main categories can also be distinguished:

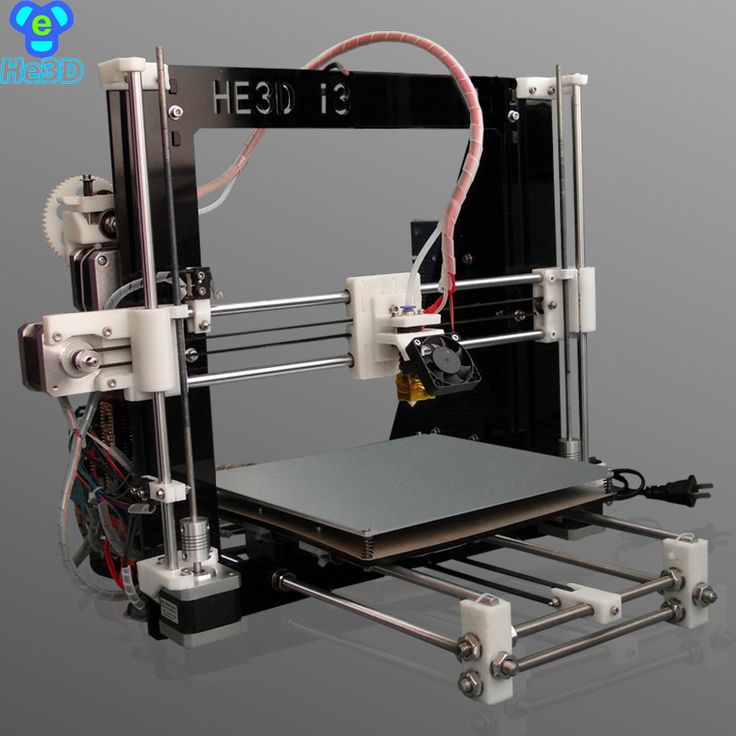

Chinese (cheap Chinese printers) are almost always designers, even if they come assembled.

-

The advantages include low cost, wide distribution and uniformity, which allows you to buy failed parts in the nearest radio shop or on well-known Chinese sites.

Popular models gather around a relatively large number of users who actively share their experience in the field of self-repair and improvement of this type of printer. The most popular models will most likely be printed right out of the box, but will require improvements during more or less long-term operation.

Popular models gather around a relatively large number of users who actively share their experience in the field of self-repair and improvement of this type of printer. The most popular models will most likely be printed right out of the box, but will require improvements during more or less long-term operation. -

The downsides include the quality of the components/assembly and the need to refine these printers to obtain acceptable print quality/speed. It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

Kits (assembly kits, mainly domestic production) - google for the words “ ZAV ”, “ UlTi ”, “ UlTi ”, etc. Usually they are a set for assembling a plywood cube. Recently, options with metal cases have appeared. Supplied in different versions - from a kit for building a case with printed parts, ending with completely finished assembled products.

-

The pluses include a fairly good engineering study, the ability to choose the components for the mechanical and electronic parts and make the printer completely to your requirements. With good components, they provide fast, stable and high-quality printing. The price is somewhat more expensive than Chinese printers, but cheaper than semi-professional printers of domestic or European / American manufacturers.

-

The disadvantages include a decent amount of time spent on assembly and waiting for components if you decide to save money and order these components yourself from different sellers and assemble a printer from them. When assembling, direct hands are required.

factory printers (domestic or US/European semi-professional printers). There are a lot of models, the designs are very different.

-

The advantage of this class of printers is printing with acceptable quality out of the box. In addition, you get operational reliability and warranty support from the manufacturer.

-

The main disadvantage is the price. It is often not clear what factors it depends on. You can buy a high-quality printer relatively inexpensively, or you can take something incomprehensible for a high price. The second disadvantage is the presence of specific solutions that are incompatible with popular solutions on the market: these can be nozzles with their own thread pitch, special fans, electronics, belts, and even slicers. Some are demanding on the quality of plastic, there are models that work only on chipped coils.

Now that we have decided on the classification of printers, we can proceed to the procedure for choosing a printer for ourselves, beloved. If you are on fire with the purchase of a 3D printer, first decide what you are going to take it for, the type and configuration of the printer depends on it. Let's analyze a few typical situations:

I want to do something for myself and my family - if you don't plan to print products from engineering plastics that can withstand decent loads and temperatures - a Chinese drygostol or a cube will suffice. If you have a budget and want to figure out how the printer works before starting, and not during printing, you can look in the direction of domestic assembly kits - with them you can get the best quality and painlessly switch to engineering plastics.

If you have a budget and want to figure out how the printer works before starting, and not during printing, you can look in the direction of domestic assembly kits - with them you can get the best quality and painlessly switch to engineering plastics.

I can't do anything with my hands, but I have to. Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

I want to print for sale - a farm of the same type of printers, depending on the budget. If there is no budget, but there are resources for regular tuning / repair - you can even from Chinese drygosts. Additionally - a printer with a large print area, a printer with a closed case and a heated table for printing engineering plastics, an SLA / LCD printer for printing products with a high degree of detail.

Whether at work or at home, the need arises to design and print enclosures and parts. If only small prototypes are planned - an LCD printer, if functional products - a closed cube with the ability to print with engineering plastics.

Kids are growing up and this is the technology of the future, I want you to master - see what printers are used in prototyping competitions in your area. Take the same one. May be used.

I want to make figurines for desktops, beautiful little things for home - LCD printer.

I want to figure out what kind of technology and how it works in general - a kit for assembling a domestic manufacturer. By the time you collect it, you will understand.

There is no money at all, but I want to print, I will collect it myself from scratch - it will turn out better and cheaper than the Chinese. Strange as it may seem, no. The cost of components with Ali will be more expensive than a printer with Ali. Of course, if there is a machine park, the ability to use it, a set of iron, shafts and electronics lying around in the corner of the workshop, it can burn out. There are options for building printers from boards and furniture rails, but their print quality is, to put it mildly, lame. For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

Of course, if there is a machine park, the ability to use it, a set of iron, shafts and electronics lying around in the corner of the workshop, it can burn out. There are options for building printers from boards and furniture rails, but their print quality is, to put it mildly, lame. For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

If you want to completely build your printer from scratch, then it's better to treat this as a separate hobby and accept that it will not turn out very cheap. Well, or look in the direction of used printers.

I don’t know why I need a printer, but I want to try - a Chinese or a domestic assembly kit. Can be used. If it doesn't work, you can always resell.

Decided on the type of printer - what to look for first of all when buying ?

-

Firstly, on the rigidity of the structure - the accuracy and speed of printing depend on it.

It is in the direction of strengthening the rigidity that your first modifications of the Chinese printer will be directed, since the material “steel plasticine 3 (c)” is considered an unaffordable luxury for the Chinese. In the case of the purchase of domestic kits, the situation is slightly better.

It is in the direction of strengthening the rigidity that your first modifications of the Chinese printer will be directed, since the material “steel plasticine 3 (c)” is considered an unaffordable luxury for the Chinese. In the case of the purchase of domestic kits, the situation is slightly better. -

Secondly - if the printer will be in the apartment - "silent" drivers for stepper motors. 3D printing is not a fast process, and having a constant loud enough buzzer under your ear is annoying.

-

Thirdly - the presence of a heated table and ease of modification to a closed case. Over time, the desire (need) to print ABS will come, and it is problematic to do this on an open drygost.

-

Fourthly, the presence of a good plastic blowing system is also important.

-

Fifthly, when choosing printers with CoreXY, H-Bot or Delta mechanics, it is highly desirable to have a 32-bit control board, or you will encounter fading (freezes) at high print speeds.

Learn more