3D printer 100 dollars

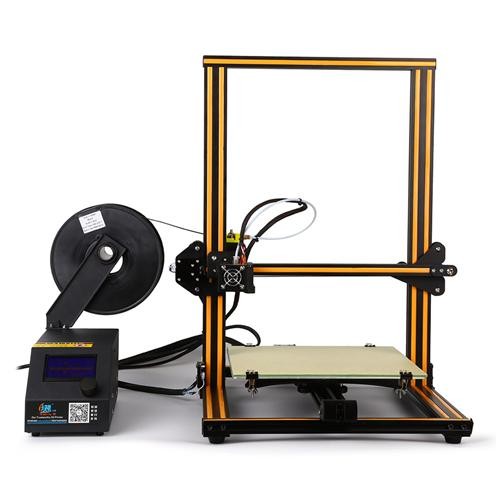

Creality Ender 3 Pro 3D Printer for $100

Expired Offers

expired

Micro Center · 8 mos ago

$100 $200

in-store only

more

Follow the link below to get a $100 off coupon, making this $119 below what Creality direct charges. Buy Now at Micro Center

Features

- 3.25" LCD screen with dial button

- 220 x 220 x 250mm print size

- removable, magnetic flexplate

- Model: Ender3 PRO

↑ less

Details

Comments

Related Offers

Newegg · 1 wk ago

Creality Ender-2 Pro 3D Printer Kit

$138 $337

free shipping

more

Features

- All Metal Desktop

- 165mm x 165mm x 180mm (6.

49" x 6.49" x 7") Build Size

- 10 lbs, with handle, so it's portable

- 8GB TF card is included

- 20 meters (66 feet) of White PLA filament is included

- Model: Ender-2 Pro

Geekbuying · 4 wks ago

Artillery Sidewinder X2 3D Printer

$259 $500

free shipping

more

Apply coupon code "NNNDBX2" for a $13 low today and $11 less than we saw it two weeks ago. Buy Now at Geekbuying

Features

- automatic bed leveling

- 150 mm/s maximum print speed

- 300mm x 300mm x 400mm printing space

- 0.4mm direct drive extruder

- touch screen control

- Model: Sidewinder X2

eBay · 3 wks ago

Anycubic Vyper FDM 3D Printer

$304 $359

free shipping

more

That's a low by $15, although most sellers charge around $400. Buy Now at eBay

Buy Now at eBay

Features

- 245 x 245 x 260mm print size

- 4.3" touchscreen

- auto leveling

- daul cooling fans

Price Analysis

|   | Discount | Last Deal Price | Current Price |   |

|---|---|---|---|---|

| Micro Center |   | $100 (exp 8 mos ago) | -- | Check Price |

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399.00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $199.95 | $199.95 | See It (Opens in a new window) |

| Amazon | $199.95 | $199.95 | See It (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $179.99 | $179.99 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $429. 99 99 | $429.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $246.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $729.00 | $729.00 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $429.99 | $369.26 | See It (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2022

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

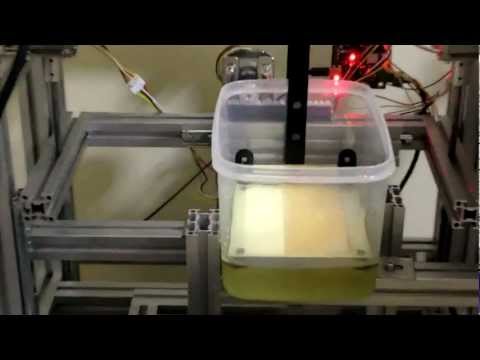

A 3D printed leg costs $100.

The prosthesis is always individual, it must take into account the personal characteristics and needs of the consumer, be durable, serving the owner for a number of years, and at the same time relatively light and comfortable. All these requirements are not easy to meet, and the manufacture of a prosthesis is delayed for weeks, or even months, and is quite expensive even in the developed countries of the world.

The prosthesis is always individual, it must take into account the personal characteristics and needs of the consumer, be durable, serving the owner for a number of years, and at the same time relatively light and comfortable. All these requirements are not easy to meet, and the manufacture of a prosthesis is delayed for weeks, or even months, and is quite expensive even in the developed countries of the world. The situation is more complicated for children: firstly, they grow up, and secondly, they break things more often than adults, which means that dentures have to be replaced regularly, and this becomes a difficult financial burden for the family or insurance authorities if the replacement of the denture is covered insurance.

Apparently, the future is not far away when many of these difficulties will be left behind.

Bioengineers from the Japanese company SHC Design have developed a system for 3D printing medical leg prostheses at home. One of the first patients to receive such a prosthesis was 41-year-old Fuminori Ando, who lost his leg below the knee shortly after birth.

Photo courtesy of wsj.com

He received an artificial leg made of soft and light polymer material, outwardly almost exactly copying the real one, reproducing the natural curve of the heel, and even the distance between the toes. This is important for Ando: he has long dreamed of wearing sandals to match his Japanese-style summer suit.

And one more important advantage: now a man can go to the pool and swim with a beautiful and comfortable artificial leg.

Once he gave up swimming because of the weight and unaesthetic appearance of the old prosthesis.

A high-quality, custom-made prosthesis costs about $4,200 in Japan. SHC Design senior Yutaka Tokushima predicts the price of a new prosthesis printed on their company's 3D printer to be around $100.

Photo courtesy of wsj.com

This was made possible not only by their development, but also by the creation of a new material - elastic polymer - rubber manufacturer JSR, who joined forces with SHC Design.

So, first, the patient's healthy leg is scanned, then, using a computer program, a template of a symmetrical prosthesis is created that takes into account the parameters of the shoe at the request of the patient, the feeder supplies the material for printing, and after a while, a soft but strong prosthesis is ready. Its low cost will allow the patient to have several spare prostheses for different shoes and different activities.

However, SHC Design is not only going to meet the needs of patients who care about greater comfort and aesthetics. In a poor country like the Philippines, where their 3D printer is currently being tested, nearly 350,000 people need a prosthetic leg and 90% cannot get it because of the high price and lack of specialists.

“I would like to deliver my product to those who are really in need,” says SHC Design CEO Tsuneo Masuda, who founded the company after 26 years of medical device manufacturing experience. The company received subsidies from the Japanese government to develop a system for printing prostheses.

Senior developer Yutaka Tokushima believes that the company will start selling its 3D printers bundled with software in Japan and the Philippines as early as April next year. They will cost $ 2,000, but the scanner will need to be purchased separately from another provider.

Major prosthesis manufacturers are also interested in 3D printing. Its elements are used by the German company Ottobock, which prints coatings for prostheses that make it possible to hide its mechanical parts from the eye. The Icelandic company Ossur uses 3D printing to create prototypes and some parts of the microprocessor-controlled knee.

Photo from dailycaller.com

The use of a 3D printer is productive not only for printing lower extremities. The Massachusetts Institute of Technology has developed a computer-aided design for a prosthetic hand that can be printed for as little as $50 for the Enable Foundation.

Bioengineers predict the rapid development of prosthetics using 3D printing. Over time, printing artificial limbs will become as commonplace as printing a document today.

Over time, printing artificial limbs will become as commonplace as printing a document today.

Even a child can print a hand for special needs, such as an extendable one, to effortlessly reach the floor and pick up a dropped object.

The development of new technologies for scanning and modeling body parts, created by companies such as Body Labs (New York), is of great importance in this matter.

And when 3D printing combines with propulsion systems, integrated sensors and sophisticated algorithms to easily control the prosthesis, artificial limbs will look little different from real ones.

sources January 8th, 2015

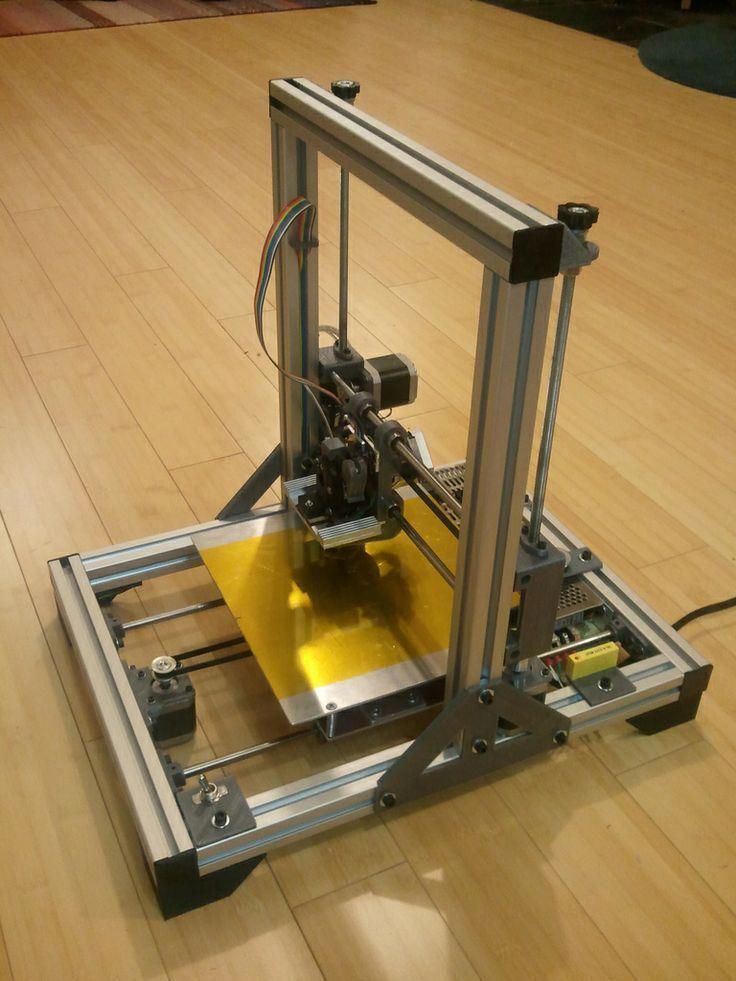

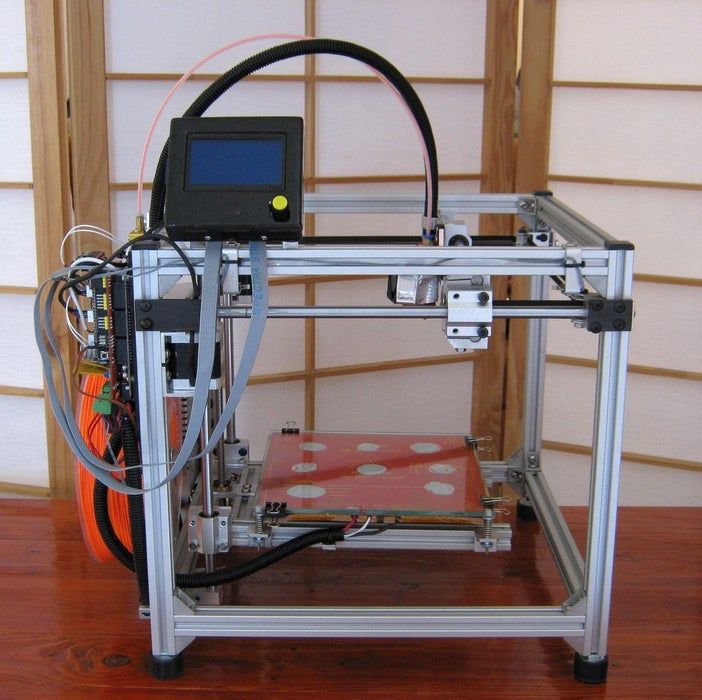

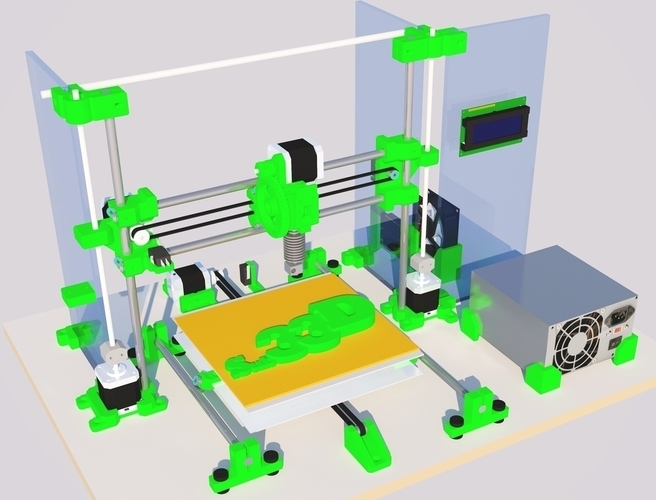

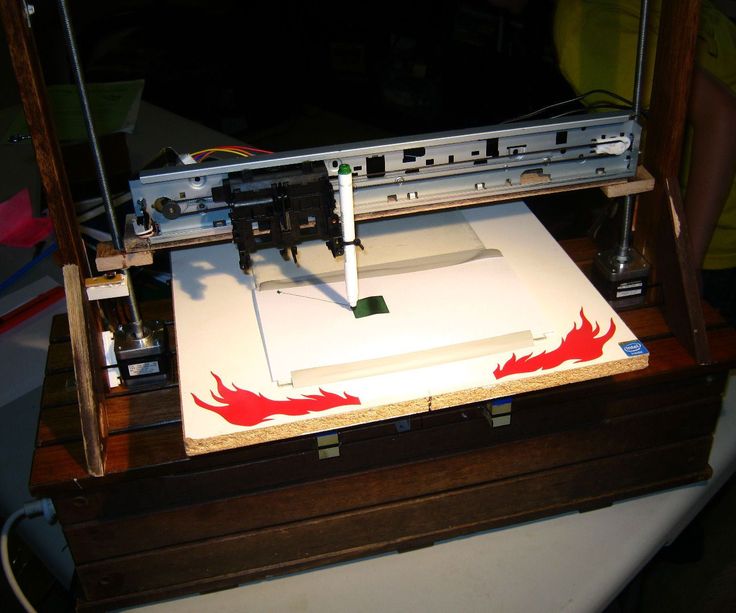

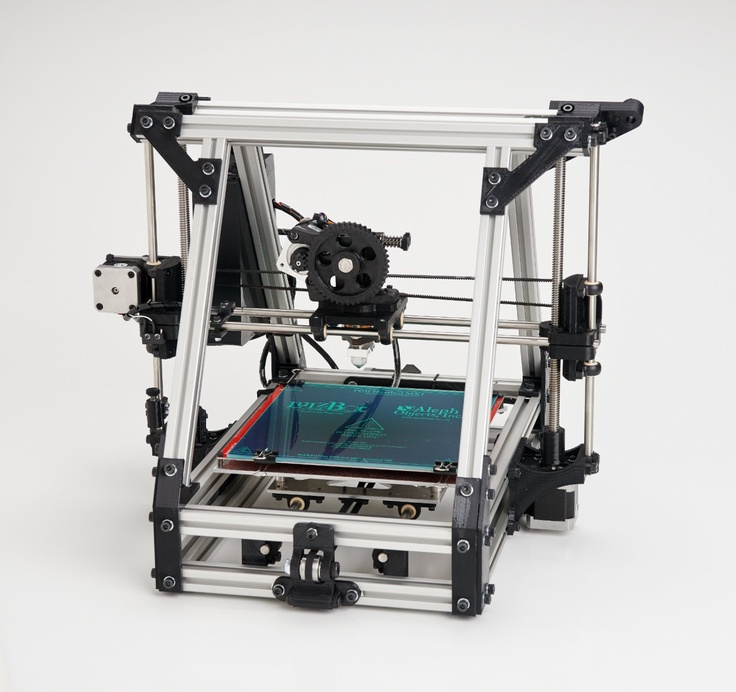

Many people would like to have their own 3D printer, but few can figure out how to create one themselves. But the inventor from West Africa (Togo) Kojo Afate Gnikow did: he created a fully functional device for 3D printing from various garbage - broken scanners, computers, printers, as well as leftover electronic and electrical equipment. Remarkably, the printer cost the inventor only $100.

Remarkably, the printer cost the inventor only $100.

Inventions from Africa

African countries are considered by many to be backward countries, but even here the industrial revolution is taking shape. For example, the talented Gnikow works in the Togolese Republic as an inventor at WoeLab. And he is developing many useful technologies that will someday be used around the world. With his homemade 3D printer, he wanted to prove that if you really want something, you can easily realize your plans. The use of garbage is also not accidental: it so happened that a lot of computer garbage has accumulated in the valley of the Republic of Ghana, which, oddly enough, is taken out of European countries and the United States. Local residents find a lot of interesting things in the landfill, which Gnikow also took advantage of.

The first printer from waste

The inventor found many useful parts, enlisted the support of like-minded people from his company, as well as experts in 3D printing. In 9 months, they were able to win a hackathon hosted by NASA in Paris. Afate's task was to draw attention to the state of the African IT community. Having collected all the necessary money - about 3,500 euros - he creates a working prototype of the first 3D printer, assembled entirely from electronic waste.

In 9 months, they were able to win a hackathon hosted by NASA in Paris. Afate's task was to draw attention to the state of the African IT community. Having collected all the necessary money - about 3,500 euros - he creates a working prototype of the first 3D printer, assembled entirely from electronic waste.

The first model was printed on the device on October 13, 2013 - it was a simple pen holder with the meaningful name "The right to dream". By the way, the printer is an open technology, that is, diagrams, instructions are in the public domain - you can download them and try to assemble the printer yourself.

What are the prospects?

In addition to the desire to prove that everyone is capable of more, Afate pursued another more important goal - to open access to 3D technologies to the African population. If earlier these countries imported mainly expensive European equipment that was beyond the means of local residents, now they themselves can create no less efficient and effective models of 3D printers. Today, Afate himself conducts master classes for developers from different African countries. Thanks to the search for a solution to the problem of recycling electronic waste, a way was found to create equipment from them.

Today, Afate himself conducts master classes for developers from different African countries. Thanks to the search for a solution to the problem of recycling electronic waste, a way was found to create equipment from them.

What is the printer made of?

As components for his device, Afate picked up tracks, belts of old scanners, cases of old computer models, parts from a floppy drive, some parts had to be bought in addition. With this device, you can print various household items that are sometimes very difficult to find in Africa. The printer consists of two DVD drives, a floppy drive, which drive the motors of the device. In addition to these components, the model includes wires, a power supply (it came from an old computer), and an extruder. The printer was named W.Afate - from the name of the company WoeLab "W" and the name of the inventor Afate.

By the way, Afate himself planned to create special robots based on electronic waste, which would be sent to Mars to build dwellings for the colonialists there.