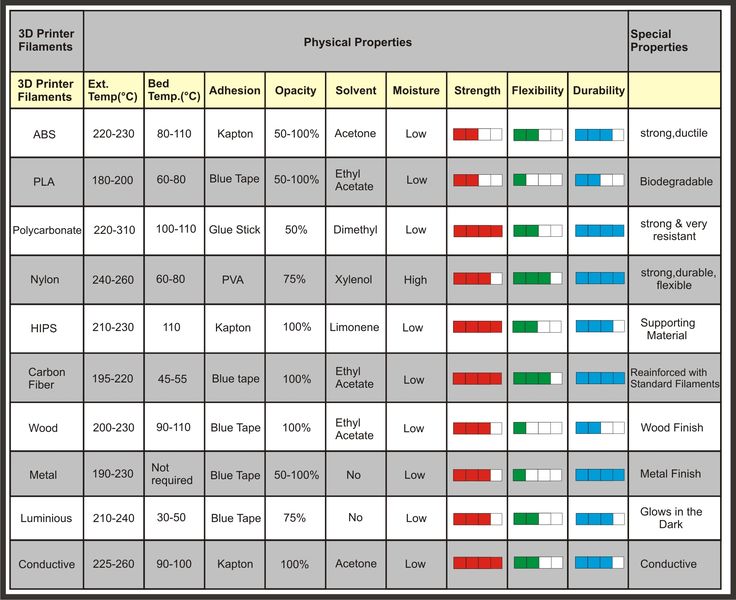

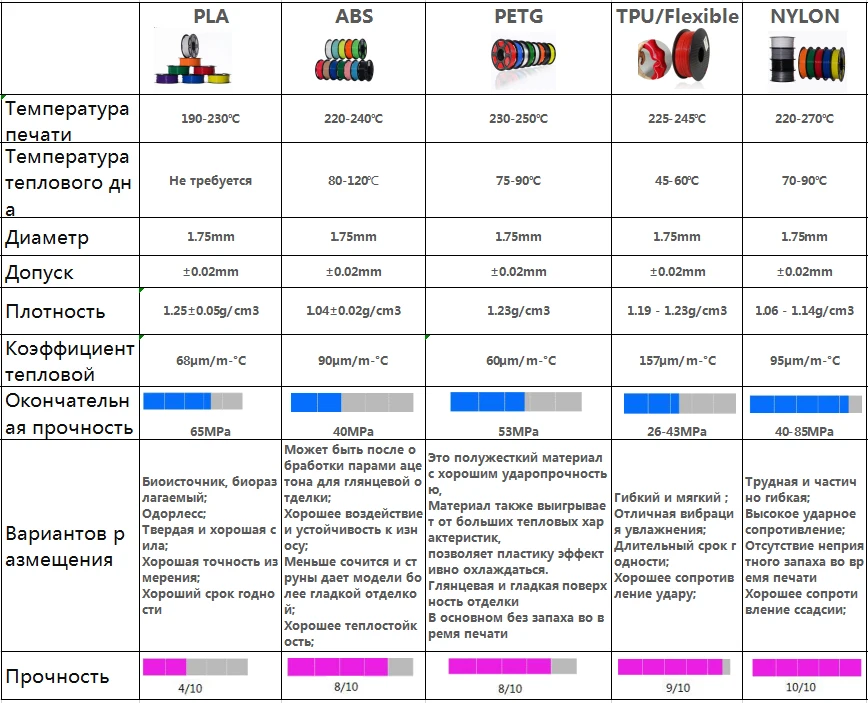

Comparison of 3d printer filaments

Types and Uses of 3D Printing Filaments

Comparison Guide: Types and Uses of 3D Printing FilamentsGUIDES

3D Printing

3D Printing

3D Printing

Quality prints need the right materials. Before starting another project, you must choose which 3D printing filament can meet your desired product durability, appearance, and uses.

This comparison guide will show you the nuances between each filament to make sure you’re using the right material for your 3D printed item.

Key points

- Thermoplastic filaments are the main material used for FDM 3D printers. For SLA printers, it’s best to use resins.

- Thermoplastics melt when heated which makes it easier to shape and mold before it cools down.

- PLA and ABS filaments are the most common and cheapest 3D printing filament types. It’s a good choice for beginners.

- The standard diameters of 3D printing filaments are 1.

75 mm and 2.85 mm.

- You must choose a filament based on the end-use of the item you’re planning to print. For example, if your product needs to be sturdy, your filament must be durable.

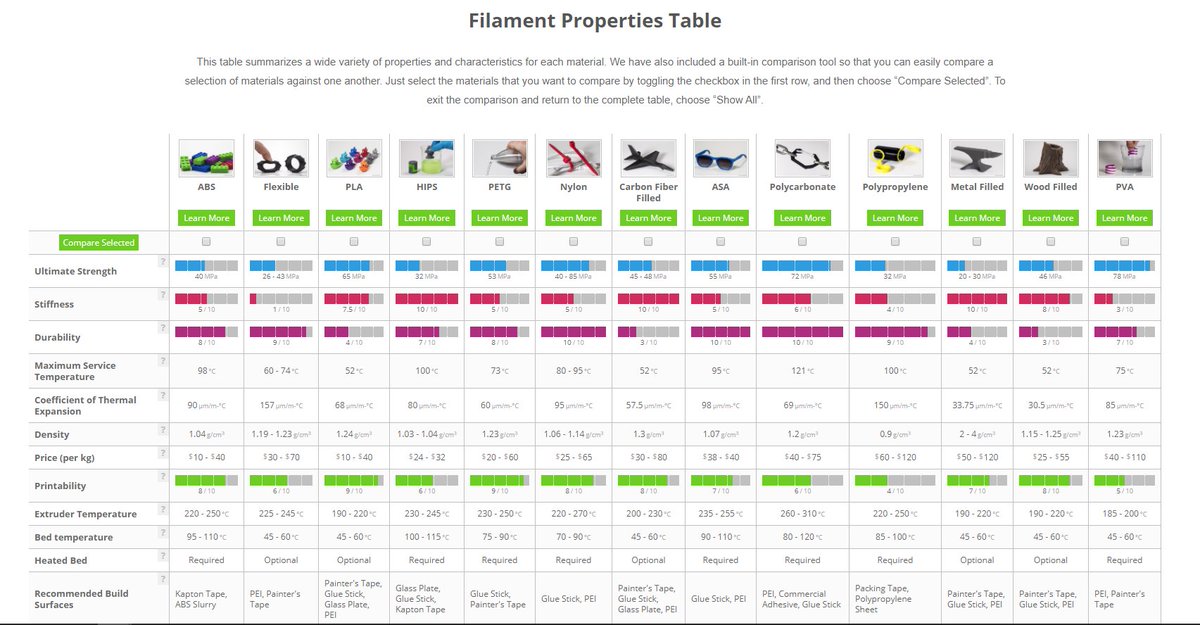

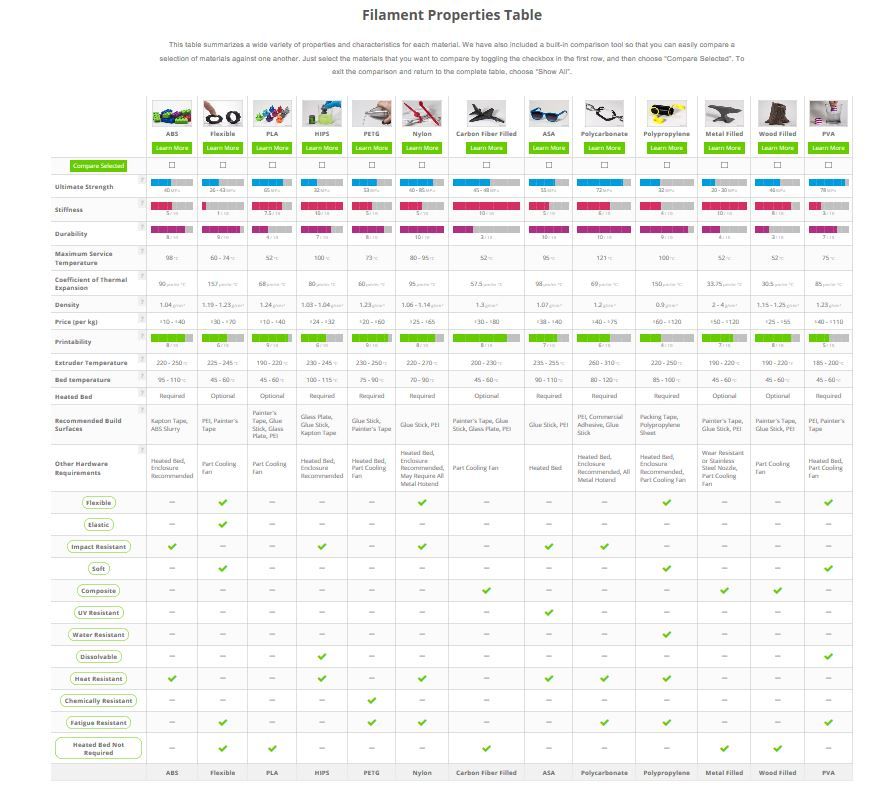

A Quick Comparison of 3D Printing Filaments

Quality prints need the right materials. Before starting another project, you must choose which 3D printing filament can meet your desired product durability, appearance, and uses.

| Filament | Strong Points | Uses | Difficulty to use | Print Temperature | Bed Temperature | Shrinkage / Warping | Food Safe |

|---|---|---|---|---|---|---|---|

1. PLA PLA |

|

Decorative and non-durable item | Low | 180°C – 230°C | 20°C – 60°C (optional) | Minimal | No |

| 2. ABS |

|

Items requiring strength, durability, and resistance to heat | Medium | 210°C – 250°C | 80°C – 110°C | High | No |

3. PETG PETG |

|

Functional objects | Low | 220°C – 250°C | 50°C – 75°C | Minimal | Yes, as long as there are no harmful additives |

| 4. TPE |

|

High-wear objects or items that need to be bent, stretched, or compressed | Medium | 210°C – 230°C | 30°C – 60°C (optional) | Minimal | No |

5. Nylon Nylon |

|

Functional prototypes, gears, mechanical parts, and aesthetic objects | Medium | 240°C – 260°C | 70°C – 100°C | High | See manufacturer guidelines |

| 6. PC |

|

High-wear items such as automotive, electrical, and mechanical parts | Medium | 270°C – 310°C | 90°C – 110°C | High | No |

7. ASA ASA |

|

Outdoor objects, sports equipment, electrical installations | High | 220°C – 245°C | 90°C – 110°C | High | Yes, depending on the grade of the material |

1. PLA

Best for: Prototypes, decorative items, bobbleheads, containers, architectural models

Not recommended for: High-wear toys, phone cases, heat resistant items

Variant/s: PLA+ (more durable version of PLA)

PLA (polylactic acid) is one of the best 3D printer filaments in the market because it’s easy to use, widely available, and biodegradable. It’s made from natural sources such as sugarcane and corn starch, making it odorless and sometimes, sweet-smelling.

It’s made from natural sources such as sugarcane and corn starch, making it odorless and sometimes, sweet-smelling.

It also has a low printing temperature. You won’t need to use a heating bed when using this filament because it doesn’t warp easily. On the contrary, it cannot withstand temperatures above 60°C. Don’t use it for products that will be exposed to heat.

If you’re working on 3D printing projects that need different colors and styles, PLA is a good choice. It’s also used as a base material for funky filaments such as glow-in-the-dark and wood-infused filaments.

One of its downsides is its brittleness. PLA has a lower tensile strength than ABS and PETG. This material is more suitable for aesthetic purposes rather than mechanical objects. When used for 3D printing, PLA is not food-safe because it tends to develop bacteria and molds.

2. ABS

Best for: Toys, automotive parts, kitchen appliances, musical instruments, industrial uses

Variant: ABS+ (reduced shrinkage and warping)

ABS (acrylonitrile butadiene styrene) is a widely-used heat-resistant 3D printing filament. However, when it comes to everyday and casual use, it’s less popular than PLA. It’s more difficult to print. It also warps more. You need a hot print bed and bed adhesive to prevent it from warping.

However, when it comes to everyday and casual use, it’s less popular than PLA. It’s more difficult to print. It also warps more. You need a hot print bed and bed adhesive to prevent it from warping.

Before using it, you must have a well-ventilated workspace. The fumes coming from melting ABS are toxic and foul-smelling.

Despite its drawbacks, ABS is superior to PLA. It has stronger material properties — it can withstand high temperatures and stress. Use it for objects you always handle, heat, or drop.

3. PETG

Best for: Functional objects or any items exposed to sudden or prolonged stress such as protective and mechanical components.

Base form: PET

Variant/s: PETT (more rigid than PETG)

PETG CF (PETG infused with carbon fiber - higher durability, easier printing, and better surface finish)

PETG (polyethylene terephthalate glycol) is known for its durability, flexibility, and resistance to high temperature and impact. You can use this in printing functional objects that will be exposed to sudden or prolonged stress.

This filament is clearer, easier to print, and less brittle compared to its base form (PET). If you’re torn between PLA and ABS, PETG can meet your needs halfway. It’s easy to print like PLA and it’s also flexible and durable like ABS.

When working with this filament, make sure to store it properly because it’s susceptible to moisture. Its surface also scratches easily.

4. TPE

Best for: High-wear objects or any items that you need to bend, stretch, or compress.

Variant/s: TPU (more rigid, more durable, and easier to print; can better maintain elasticity in the cold compared to TPE)

TPC (higher resistance to heat, chemical, and UV exposure).

TPE (thermoplastic elastomers) is a rubber-like filament used to produce stretchable and durable items. It can withstand stress and impact that PLA and ABS can’t handle. Because of its properties, you can use it in 3D printing automotive parts, toys, and medical supplies to name a few.

This filament is clearer, easier to print, and less brittle compared to its base form (PET). If you’re torn between PLA and ABS, PETG can meet your needs halfway. It’s easy to print like PLA and it’s also flexible and durable like ABS.

If you’re torn between PLA and ABS, PETG can meet your needs halfway. It’s easy to print like PLA and it’s also flexible and durable like ABS.

However, it can be difficult to extrude. It also has a slower printing speed. To solve this dilemma, you can use its variant, TPU, for a better 3D printing experience.

5. Nylon

Best for: Functional prototypes, gears, mechanical parts, and aesthetic objects

Variant: Nylon CF (nylon infused with carbon fiber)

Nylon is a durable filament used to create functional prototypes, gears, and other mechanical parts. It has a high moisture property which makes it easy to dye before or after the printing process.

Like ABS, it also requires a high print bed and nozzle temperature. Not using a heated bed will lead to warping and subpar output. Though nylon is more difficult to print due to its high-temperature requirement, this exact property makes it tough and resistant to impact and abrasion.

Another challenging part of using nylon is its hygroscopic property or the ability to absorb moisture from the air. Even a short exposure to humidity can affect its quality. Using an exposed nylon filament in printing will leave “bubbles” in your 3D printed output instead of a smooth finish. Make sure to store it in a dry place to keep it in its optimal condition.

Even a short exposure to humidity can affect its quality. Using an exposed nylon filament in printing will leave “bubbles” in your 3D printed output instead of a smooth finish. Make sure to store it in a dry place to keep it in its optimal condition.

6. PC

Best for: High-wear items such as automotive, electrical, and mechanical parts

PC (polycarbonate) is one of the strongest filaments, thanks to its durability and resistance to high temperatures and sudden physical impacts. It’s transparent and moderately flexible, making it a vital material in producing automotive, electrical, and mechanical components. Like nylon, polycarbonate is also hygroscopic so remember to store it properly to maintain its quality.

7. ASA

Best for: Outdoor applications, electrical installations, sports equipment, automotive parts

Considered as a substitute to ABS filament, ASA (acrylonitrile styrene acrylate) prints are rigid, strong, and heat-resistant. It’s best used for outdoor applications due to its high resistance to UV and harsh weather conditions. Also, it’s resistant to chemical exposure.

Also, it’s resistant to chemical exposure.

Though it’s considered as the improved version of ABS, ASA can still warp during printing. To prevent it, you need to use a heating bed. Take note that it’s also hygroscopic so make sure to store it in a cool, dry place.

Right Filament for the Right 3D Printed Object

Are you looking for the best filament for your 3D printing project? MakerCarl offers the following filaments: PLA, PLA+, ABS, ABS+, ABS Max, PETG, ASA, nylon, nylon CF, PETG CF, and TPU. Send us your ideas today!

Read more blogs on this topic

3D Printing in Automotive: A Metamorphosis Ahead

As it requires intensive labor, automobile manufacturing needed a change. Then comes, 3D printing paving the way for smarter additive manufacturing. Discover its benefits, applications, and real samples of 3D printed projects in this article.

Read More

What Are the 6 Different 3D Printer Filament Types?

Consumer 3D printers are no longer restricted to ABS and PLA filaments. The popularity of additive manufacturing technology has led to the influx of many engineering plastics. Although ABS and PLA remain popular, many 3D printing enthusiasts have switched to newer materials.

So, here is everything you need to know about different 3D printing filaments and how to choose one for your specific needs.

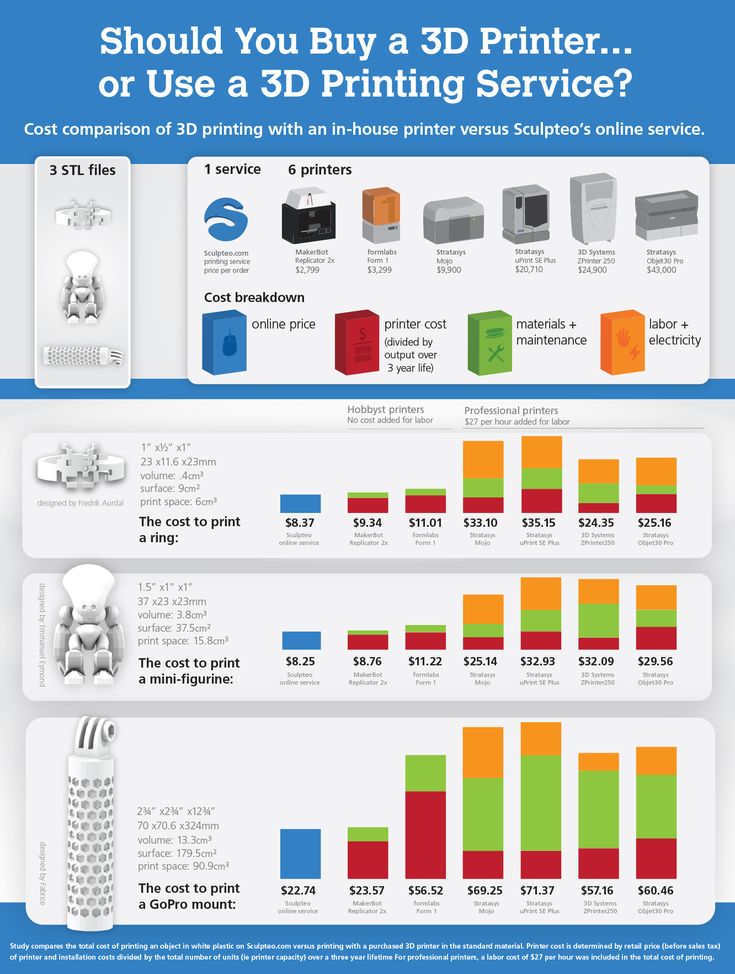

How to Choose a 3D Printing Filament

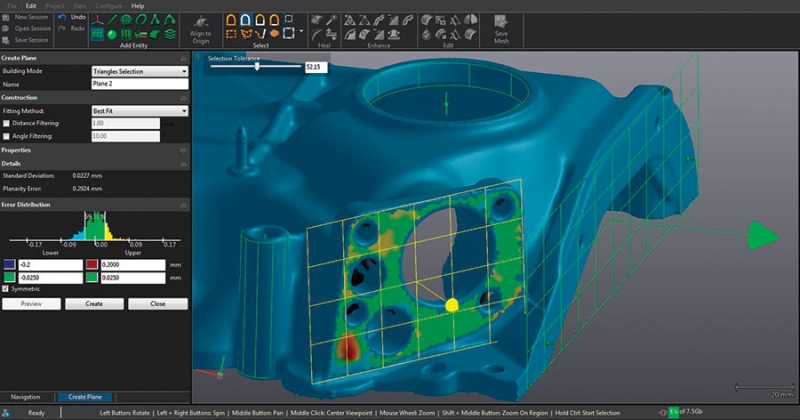

3D printing is unlike most run-of-the-mill hobbies. It involves sophisticated robots creating complicated objects using exotic materials. Like all advanced engineering endeavors, 3D printing relies on the users’ ability to read and follow technical data sheets. Knowing how to make sense of these documents is key to knowing which 3D printing filament to use for specific applications.

Image Credit: Nachiket Mhatre There’s no need to bother with this if your 3D printing needs are restricted to cosmetic prints because PLA is all you will ever need. Printing functional parts, however, needs an understanding of various filament parameters, such as tensile strength, toughness/flexibility, heat resistance, durability, creep, and warping.

So, what are the best 3D printing filaments, and when should you use one over another?

1. PLA (Polylactic Acid)

Polylactic Acid is to 3D printing what training wheels are to bicycles. It’s incredibly easy to print on even the cheapest 3D printers. With print temperatures beginning as low as 180°C, you don’t need an all-metal hot end to print this filament safely. PLA doesn’t even require a heated bed, as long as the ambient room temperature is maintained above 20°C.

Image Credits: Nachiket MhatreThe material practically doesn’t warp and can bridge extremely well if you give adequate part cooling. Not sure what all those terms mean? Check out our Ender-3 upgrade guide to learn more about all-metal hot ends and 3D printer safety.

The bottom line: it’s incredibly difficult to ruin a PLA print. This allows beginners to gradually learn the many complicated aspects of 3D printing without hitting the brick wall of repeated print failures. As a beginner, sticking to PLA makes it easy to grasp the fundamentals of bed adhesion, first layer calibration, overhangs, and bridging. PLA is the optimal way to test the limits of 3D printing without having to second-guess your printer calibration and slicer settings.

PLA Filament Properties

- Printability: Excellent

- Color Selection: Excellent

- Heat Resistance: Poor

- Tensile Strength: Excellent

- Toughness: Poor

- UV Resistance: Excellent

- Moisture Resistance: Excellent

- Creep Resistance: Poor

When Should You Use PLA 3D Printing Filament?

PLA is great for cosmetic 3D prints but not so much for anything else. Despite its high tensile strength, it lacks toughness because the material is too hard to flex. This makes it brittle and susceptible to cracking in applications requiring impact resistance and bending. Its low-temperature printability also translates into poor heat resistance. PLA prints warp when subjected to direct sunlight or in-car conditions due to the material’s low glass transition temperature of 57°C.

PLA’s tendency to creep, or to permanently deform under load at room temperature, makes it unviable for any functional print that either uses fasteners or serves any load-bearing purpose. Consequently, most 3D printing enthusiasts move to other materials once they have mastered slicer settings and 3D printer tuning with PLA.

2. PETG (Polyethylene Terephthalate Glycol)

PETG should ideally be your second filament challenge once you have mastered PLA. It is quite similar to the plastic found in water bottles and food containers, except for the addition of glycol to improve printability. PETG is better than PLA in most important parameters. It’s slightly tougher, significantly more heat resistant, exhibits excellent creep resistance, and is therefore suitable for functional 3D printing.

Image Credit: Nachiket Mhatre However, it is also slightly more difficult to print. That isn’t entirely a bad thing. While it is virtually impossible for a well-tuned printer to mess up PLA prints, getting PETG right requires a better understanding of slicing software and first layer calibration. This makes the filament a safe way to learn these concepts, which are vital to mastering other technically challenging 3D printing filaments.

PETG is also quite hygroscopic, so drying it before printing is necessary if you live in a humid area. The prints themselves aren’t prone to moisture absorption, but a wet filament will cause extrusion and print quality issues. The material can bond permanently to most 3D printing surfaces if the first layer is printed too close to the build surface.

The sticky, viscous nature of the molten filament also makes it a poor choice for bridging and steep overhangs. However, that also translates into the best layer adhesion despite its low printing temperature.

PETG Filament Properties

- Printability: Good

- Color Selection: Good

- Heat Resistance: Average

- Tensile Strength: Good

- Toughness: Good

- UV Resistance: Excellent

- Moisture Resistance: Poor

- Creep Resistance: Good

When Should You Use PETG 3D Printing Filament?

PETG is the perfect compromise between PLA and the much superior ABS filaments. While it lacks the higher temperature resistance of ABS, it is still good enough for prints to be used outdoors or car interiors. It is also considerably tougher than PLA and ideal for applications where impact resistance is desired. PETG’s resistance to creep also makes it ideal for functional prints and 3D printer components alike.

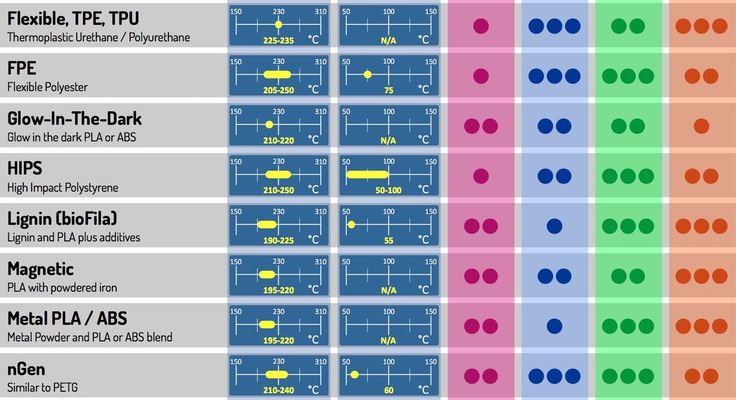

3. TPE/TPU/TPC (Thermoplastic Elastomer/Polyurethane/Copolyester)

TPE comprises a number of plastics with rubber-like properties. Such filaments are used in applications where flexibility is desired. Regular flexible filaments marketed as TPE are available in various shore hardness, which is a measure of flexibility. In fact, TPE incorporates a broad category of filaments, including urethane-based TPU, which is slightly more rigid to improve printability. TPC is a copolyester-based variant with improved resistance to heat, UV, and chemical agents.

Printing with TPE and its variants are challenging due to the inherent flexibility of the filament. These filaments are particularly difficult to print with Bowden extruders since the lack of rigidity makes it difficult to push the filament through the nozzle. Therefore, direct drive extruders, with a short filament path between the extruder gears and nozzle, are recommended for reliable printing.

The tendency of the filament to compress and elongate also makes retractions unreliable. This leads to excessive stringing in prints, which requires expertise to mitigate. It is also recommended to print these flexible filaments on an unheated bed, preferably with a release agent, such as a glue stick or hairspray. Failure to do that often results in the prints permanently bonding to the build surface.

TPE Filament Properties

- Printability: Average

- Color Selection: Average

- Heat Resistance: Average

- Tensile Strength: Average

- Toughness: Excellent

- UV Resistance: Good

- Moisture Resistance: Poor

- Creep Resistance: Good

When Should You Use TPE/TPU/TPC 3D Printing Filament?

These flexible filaments are excellent in applications where impact resistance, bendability, wear, and grip are more desirable than rigidity. TPE and TPU are regularly used to 3D print gaskets, phone covers, and wristbands for wearable devices. TPC is a more expensive alternative that offers additional temperature and chemical resistance suitable for harsh environments.

4. ABS (Acrylonitrile Butadiene Styrene)

ABS, in its injection molded avatar, is found in most consumer products in the form of automobile dashboards and switchgear, toys, pipe fittings, and as the chassis of most consumer durables. Not surprisingly, its familiarity, price, and availability made it the material of choice for the commercial 3D printing industry. It’s a terrific material with an unmatched price-to-performance ratio and good heat resistance.

Image Credit: Nachiket Mhatre Its heat resistance makes it incompatible with the cheap PTFE-lined hot ends. Most ABS filaments require nozzle temperatures of around 250°C. This makes all-metal hot ends mandatory for safe printing. The filament also off-gasses harmful VOCs (volatile organic compounds) such as styrene, which are known to negatively impact health. Learn how ABS compares to PLA in our ABS vs. PLA comparison.

ABS filament’s tendency to warp makes it difficult to print unless you own a printer with a heated enclosure, like the Voron series of DIY 3D printers. Delamination, bed adhesion, and warping are persistent issues on large ABS prints on unenclosed printers. Having said that, most modern ABS filament blends print fine, as long as you keep the build volume enclosed and use the heated bed as a passive heat source. Carbon fiber and glass fiber-enhanced ABS composite filaments mitigate these issues to a great extent.

ABS Filament Properties

- Printability: Average

- Color Selection: Average

- Heat Resistance: Good

- Tensile Strength: Good

- Toughness: Good

- UV Resistance: Average

- Moisture Resistance: Good

- Creep Resistance: Excellent

When Should You Use ABS 3D Printing Filament?

ABS exhibits good tensile strength and toughness, which makes it ideal for functional prints and even some engineering applications. The material can be used in high-temperature applications such as 3D printer hot end components and functional prints for car interiors. Any engineering scenario that demands resistance to heat, impact, and wear can be met cheaply with ABS.

5. ASA (Acrylonitrile Styrene Acrylate)

ASA is a modified form of ABS that is easier to print and exhibits improved UV resistance. Large ASA prints are easier thanks to their tendency to warp less than ABS. Most ASA filaments also tend to off-gas less VOCs while printing.

And all this is achieved while maintaining the strength, toughness, and temperature resistance comparable to ABS. We see no reason to choose ABS if you can afford the slight premium commanded by ASA filaments.

ASA Filament Properties

- Printability: Good

- Color Selection: Average

- Heat Resistance: Good

- Tensile Strength: Good

- Toughness: Good

- UV Resistance: Excellent

- Moisture Resistance: Good

- Creep Resistance: Excellent

When Should You Use ASA 3D Printing Filament?

ASA can be used for the same applications as ABS, with the added versatility of maintaining durability and color integrity despite heavy exposure to sunlight.

6. PA (Polyamide or Nylon)

Polyamide, better known as its brand name Nylon, is found in consumer durables in the form of gears, hinges, and sliding components—basically in any application that calls for extreme wear resistance, low friction, excellent toughness, and some degree of temperature tolerance. PA is indispensable in powder-sintered 3D printing processes employed in commercial SLS 3D printers.

Image Credit: Nachiket MhatreNylon also exists in the FDM 3D printing space in various blends offering different compromises between heat resistance, toughness, durability, and creep resistance. The latter is important because the material exhibits a tendency to heat creep in its natural state. Therefore, most engineering applications require PA blended with carbon or glass fiber to improve tensile strength, creep resistance, and temperature tolerance.

The material’s high glass transition temperature and an innate tendency to warp make it difficult to print on cheap, unenclosed printers. Furthermore, PA’s chronic tendency to absorb moisture requires filament dryers that can reliably maintain 80°C chamber temperatures. In fact, successful printing also requires the filament to be routed through a dry box while printing. It’s a great engineering filament that demands a capable printer and an experienced operator.

PA Filament Properties

- Printability: Poor

- Color Selection: Poor

- Heat Resistance: Good

- Tensile Strength: Good

- Toughness: Excellent

- UV Resistance: Average

- Moisture Resistance: Poor

- Creep Resistance: Average

When Should You Use PA 3D Printing Filament?

Functional PA prints work well as mechanical parts, such as gears, hinges, and levers. The material is also tough enough to be used to manufacture custom tools and prototypes requiring strong meshing parts subjected to friction and impact. Various glass fiber and carbon fiber blends can also be used to modify the rigidity and flexibility of the material to suit different engineering demands.

6. PC (Polycarbonate)

PC is one of the strongest 3D printing filaments accessible to consumer 3D printers. How strong, you ask? Well, the material is used to manufacture everything from bullet-proof glass to fighter jet canopies. PC can withstand temperatures as high as 110°C, with some blends even outperforming that impressive figure.

PC has the unique distinction of exhibiting high tensile strength while also being extremely impact resistant. This gives it the distinction of excelling in applications where even Nylon falls short. However, these physical properties make PC challenging to print. It isn’t uncommon for some PC blends to require nozzle temperatures of 300 °C, with the heated bed maintained in excess of 100 °C.

The material is also prone to excessive warping and only adheres well to polycarbonate build surfaces or polyimide tape. However, like Nylon, PC is available in various blends, making it more printable.

PC Filament Properties

- Printability: Poor

- Color Selection: Poor

- Heat Resistance: Excellent

- Tensile Strength: Excellent

- Toughness: Excellent

- UV Resistance: Excellent

- Moisture Resistance: Poor

- Creep Resistance: Excellent

When Should You Use PC 3D Printing Filament?

PC is employed in various industrial, automotive, and electrical applications—especially those requiring high strength and temperature resistance. The inherent optical clarity of the material also makes it ideal for transparent prints, as long as the wall thickness is kept minimal.

Choose Your 3D Printing Filament Wisely

Now that you have a handy means to compare various physical properties and performance parameters of consumer-grade filaments, choosing the right one is a matter of evaluating which parameters are best suited to your particular applications.

If you are new to 3D printing, we recommend starting with PLA and graduating to PETG before taking on more challenging materials such as ABS and Nylon.

Best 3D Printer Filaments (Review 2021)

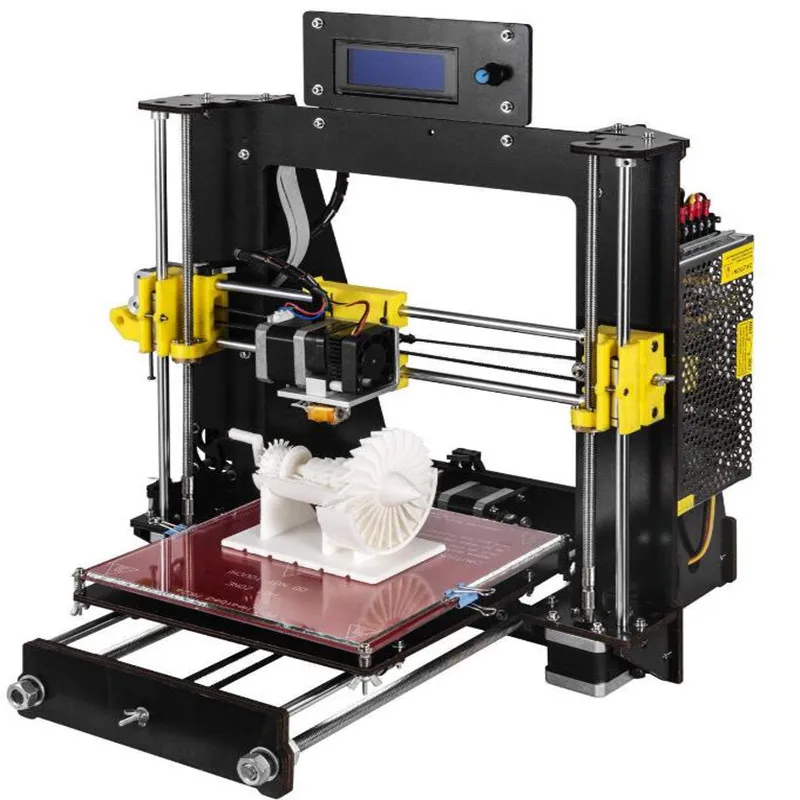

Once you've chosen your 3D printer, you need to choose the type of filament intended for your project. Filament is a raw material used in 3D printers that will be heated to a high temperature to turn it into a semi-solid state. At this point, the printer can easily create the appropriate design layers and print the entire 3D CAD model onto the plate.

However, as you research the various 3D printer filaments, you will hear of numerous materials that can only make it harder to choose the right one for you. This is especially true for people who are just starting to explore the world of the 3D printing process.

While most of us are not new to PLA and ABS, there are other fiber materials you should be aware of such as HIPS, PET, PETG, TPE, TPU, TPC and a few others. And to get a better idea of them, here are some of the more typical types of 3D printer filaments available on the market.

3D Printer Filament Types

PLA Filament

Polylactic acid (PLA) reigns supreme in the industrial 3D printing world. 3D printing with PLA is so easy. It has a lower plate temperature, so it doesn't need a heating bed and therefore has fewer warping issues.

It is widely used in prototyping, such as printing low-wear toys, prototype parts and containers. Please note that it cannot be used for anything that has a temperature rating of 60°C or higher as it warps at 60°C. For all other purposes, PLA is suitable for a general 3D printer.

ABS Filament

ABS (also known as Acrylonitrile Butadiene Styrene) is the second most popular 3D printing filament. In general, ABS withstands high loads and high temperatures. Thus, it is suitable for most applications. It is great for items that are frequently handled, dropped or heated. For example, mobile phone cases, high-wear items, automotive trim parts, and electronic houses.

Nylon filament

Nylon is the preferred family of synthetic polymers for many industries, professional 3D printing being one of them. As for other forms of filament, they have better performance, efficiency, versatility and durability. Given the strength and versatility of nylon, this type of 3D printer filament can be used to make loops, buckles or gears, as well as working prototypes.

PET (G) thread

The most widely used plastic in the world is polyethylene terephthalate (PET). It is best known as water bottle thread, but it is also used in clothing fibers as well as food containers. Although PET is commonly used in 3D printing, its modified version PETG is becoming more common.

The G in PET stands for glycol, resulting in a more transparent filament that is less prone to cracking and easier to use. PETG is versatile but surpasses many forms of 3D printer filament in its strength and inability to reach high temperatures or withstand strong impacts. The fulfillment of the following conditions makes it an excellent choice for 3D printing filament for practical parts such as mechanical parts, printer parts, and protective materials.

TPE, TPU, TPC filament

Thermoplastic polyurethane (TPE) is a flexible and durable plastic similar to rubber. In addition, TPE is mainly used for the production of auto parts and household appliances.

TPU (Thermoplastic Polyester E) is a special form of TPE that is very common among high end 3D printers. Compared to conventional TPE, TPU is significantly more flexible, hence allowing more control during printing.

What's more, TPC (Thermoplastic Copolyester) is also another form of TPE that is not as widely used as TPU. The key advantage of TPC over TPE is its greater resistance to chemical and UV attack, as well as heat (up to 150°C).

If you need to create items that require a lot of wear, use TPE or TPU because these filaments use 3D printed filaments that are vulnerable to deformation. Products such as toys, mobile phone cases, or wearable items such as wristbands can be some examples of its application. On the other hand, TPC performs well for comparable applications, but outperforms it in harsher environments, including outdoors.

Wood filament

Technically not wood because it contains wood fiber in enhanced PLA. Generally speaking, wood products are valued for their natural beauty rather than their practical utility. When printing items for tables, tables or shelves, it is recommended to use wood 3D printing media. Any of the application examples include chalices, figurines, and trophies. What's more, it's a truly innovative application for 3D printers, which are often used to model real buildings, structures, or trees.

Metal thread

Like wood thread, it is not 100% metal. Specifically, it is composed of metal powder, and one of the following materials is PLA or ABS. However, the effects also have a metal-like aesthetic appeal. Metal Infused can be printed for both decorative and practical purposes. Figures, prototypes, toys, including tokens, can be 3D printed from metal and give them a great look. You can also use metallic 3D printer filament to make parts such as tools or finishing components in light applications.

Biodegradable (biophila) filament

This biodegradable 3D printer filament aims to reduce the impact of all plastic waste into the atmosphere. Although biodegradable 3D filament was originally environmentally friendly, it can still produce quality printed products. Choose this biophile if you don't have special requirements for strength, versatility or endurance. For projects that require prototyping, you can also benefit from these flawless fiber prints that can be biodegraded responsibly.

Conductive thread

This is a kind of three-dimensional material with conductive carbon particles in it. It is ideal for Arduino-based open source businesses. You'll want to look into this filament if you want to make circuits, LEDs, sensors, and other low voltage projects.

Magnetic filament

PLA magnetic iron filament is as magnetic as the name suggests. This one-of-a-kind filament is made from PLA material impregnated with powdered iron. It is ideal for making fridge magnets and other custom-made decorative items. Also, it can be used to create multiple DIY structures, sensors, educational resources, etc.0003

Top Five 3D Printer Filaments

Access to a 3D printer creates a whole new world of creative printing. There are several purposes and hobbies that 3D printing serves, but they all rely on the same raw material - 3D printer filament.

While unique materials are recommended for durable and impressive models, you need to select the right material for your 3D image. need printer. You also need to consider the quality and attributes of the thread. That being said, finding the right 3D filament is no picnic.

As such, we sought the advice of tech experts and 3D printer enthusiasts to find the most popular 3D printing filaments on the market. And to give you a clearer idea of their main features and specifications, we have done a detailed analysis to better understand which filament you should pair with your 3D printer. Also, don't forget to click on the buttons below to get the best deals on Amazon!

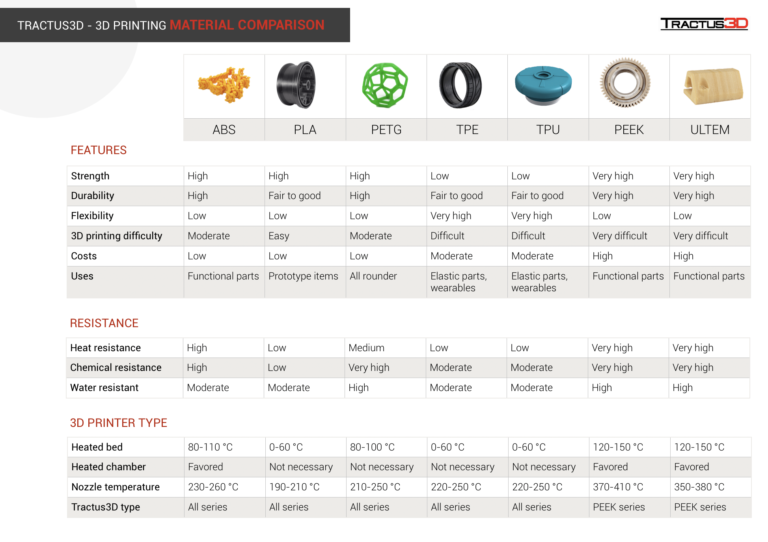

3D printing material comparison

3D printing material comparison

3dunitprint2022-02-07T14:43:04+03:00

3dunitprint Knowledge base 0 comments

ABS - PLASTIC

Acrylonitrile butadiene styrene (ABS) is one of the most popular plastics. It is an easily accessible, durable and lightweight material. ABS plastic comes in a wide range of colors. Its strength and ease of processing have led it to become the most popular of the engineering polymers.

Manufacturing techniques: FDM

- Rugged

- Flexible

- Easy to handle

- Resistant to everyday chemicals

- Temperature resistant

- High print shrinkage

- Smell of “plastic” when printing

- Not suitable for food contact

Strength

90%

Cost

20%

Moisture resistance

70%

Ultraviolet resistance

40%

Chemical resistance

9000%PLA - plastic

raw materials for PLA Plastic is corn starch (but can also be found varieties of sugar cane and tapioca), which makes it biodegradable. This is a simple material for 3D printing, when heated, it releases a pleasant sweet aroma. For this reason, many people prefer its ABS.

Manufacturing techniques: FDM

- Eco-friendly, biodegradable

- Food contact

- Hard, durable

- Low shrinkage

- High surface quality

- Low softening point 50°C

- Narrow temperature range (-20 to +40°C)

- Short-lived

- Fragile

Strength

75%

Cost

20%

Moisture resistance

20%

Ultraviolet 6,0002 25%

Chemical resistance

45%

PETG, PET, PETT - plastic

000 PetG (polyethylene terephthalate glycol) is a modified Polyethylene terephthalate (PET), most of the people on the planet know this plastic as a water bottle material. This material is the second alternative to ABS, it does not emit caustic fumes when melted, while remaining strong and flexible.

Manufacturing techniques: FDM

- Odorless printing

- UV resistance

- Wide operating temperature range.

- Good slip and impact resistance

- Non-toxic, can be printed on articles intended for contact with food.

- Lower strength and softening point than ABS.

- High printing temperature quickly destroys the PTFE insert in hotend

- Scratches more than ABS.

- Absorbs moisture from the air

strength

90% 9000 (polycarbonate) is a high strength material designed for harsh environments and engineering applications. It has extremely high thermal deflection and impact resistance. Polycarbonate also has a high glass transition temperature of -150° Celsius. This means that it will maintain its structural integrity up to this temperature, parts made with this material show significantly improved mechanical strength compared to ABS and PLA.

Manufacturing techniques: FDM

- Impact resistance

- High temperature resistance

- Naturally transparent

- Flexibility

- Durability

- Tendency to warp

- Very high print temperature required

- High tendency to shrink during printing

- Absorbs moisture from the air, which can cause print defects

Strength

90% 9000 is a dissolvable support material commonly used with ABS. When used as a support material, it can be dissolved in d-Limonene leaving the print free of any defects caused by the removal of supports. HIPS has many of the same printing properties as ABS, making it a logical partner for dual extrusion. This material is more stable and slightly lighter than ABS, making it an excellent choice for parts that wear quickly or are used to print lighter products.

Manufacturing techniques: FDM

- Low cost

- Impact resistant

- Waterproof

- Lightweight

- Soluble with d-limonene

- Heated deck required

- Closed chamber recommended

- High Print Temperature

- Ventilation required

Strength

80%

Cost

10%

Moisture resistance

80%

Ultraviolet resistance

70%

Chemical resistance

25%

Flexible - plastic (TPE), which are a mixture of hard plastic and rubber.

Manufacturing techniques: FDM

- Flexible and soft

- Excellent vibration damping

- Long shelf life

- Impact resistant

- Hard to print

- Difficulty in removing supports

- Not suitable for all 3D printers

Strength

80%

Cost

60%

Moisture resistance

80%

Resistance to ultraviolet

70%

Chemical resistance

70%

9000 . When exposed to UV radiation, these monomers quickly form molecular bonds with each other and turn into a solid polymer.

Manufacturing techniques: SLA/DLP , Polyjet

- High detail

- Smooth surface

- Faster printing process

- Finished product uniform in all axes

- High material cost

- More labor intensive removal of supports

- More limited choice of materials

Strength

80% 9000 is one of the most popular 3D printing materials used by professional 3D printing companies. Polyamide is the reference material in the technology of SLS-laser sintering of plastic powder. This technology is used for rapid prototyping and rapid production. With this technology it is possible to create complex three-dimensional objects that can be used as prototypes or as functional parts.

Given its flexibility and strength, nylon is an indispensable material for a wide range of applications from engineering to art. Nylon (polyamide) parts have a rough surface that can be polished to a smooth finish. Nylon is stronger than all other types of plastics, making it an ideal material for 3D printing products that require good tensile strength and mechanical strength.

Manufacturing techniques: SLS

- High detail

- High strength

- Finished part flat surface

- Supports not required

- Fast printing process

- High material cost

- Rough surface (can be removed with post-processing)

- Limited materials

- Available in one color (white)

Strength

90%

Cost

90%

Moisture resistance

65%

Ultraviolet resistance

80%

Chemical resistance

80% 9000 nickel, titanium) are metals that are ground to particles and are pre-base materials for most 3D printing processes producing metal parts.