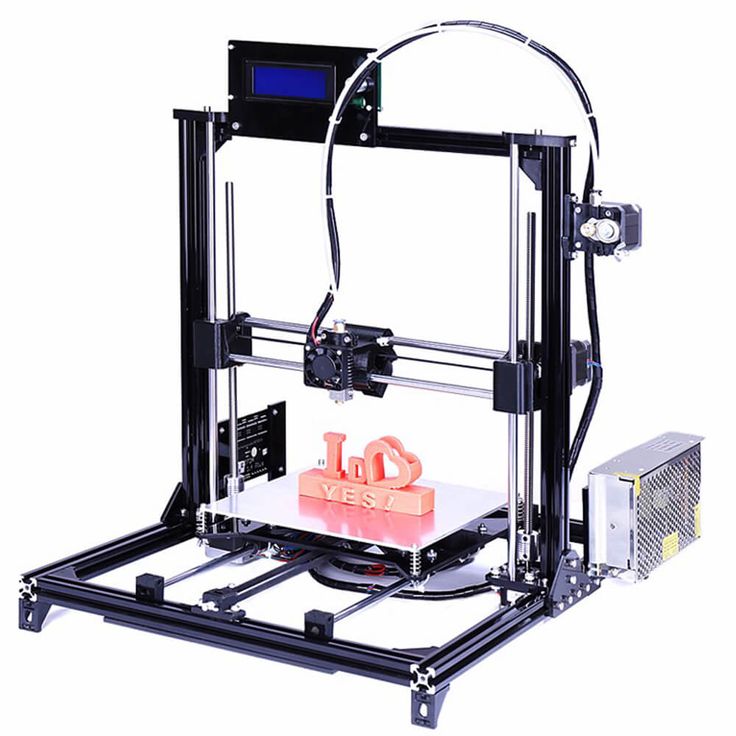

200Mm 3d printer

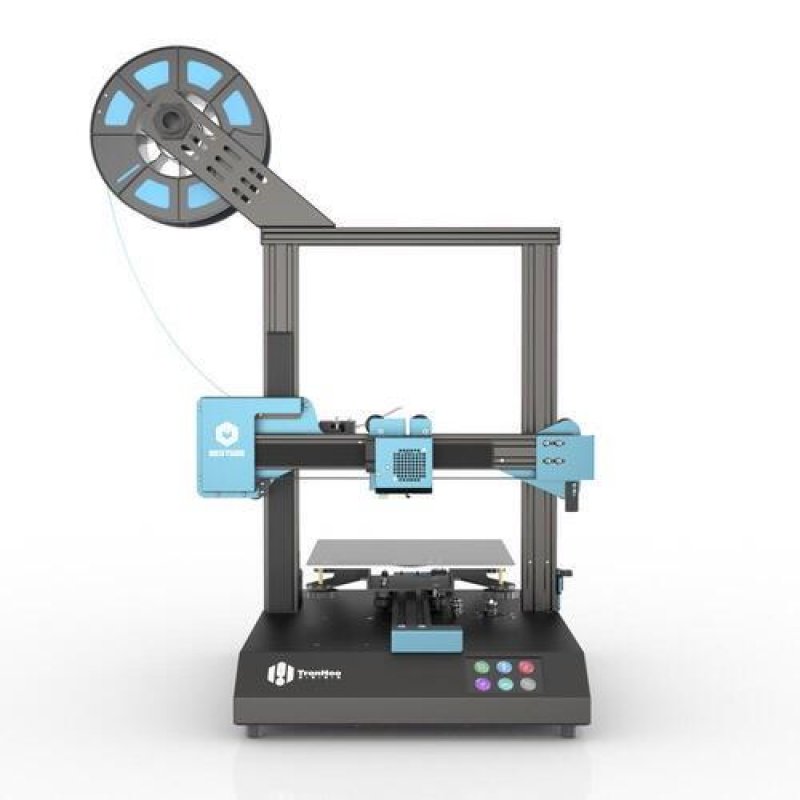

Monoprice MP10 Mini 3D Printer EU – Monoprice Europe

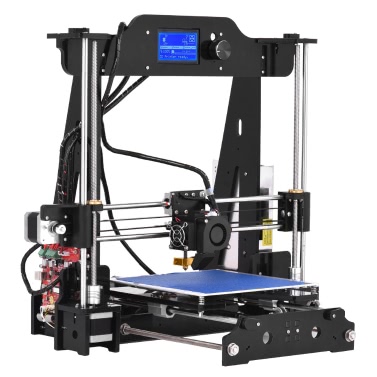

The MP10 is a feature rich 3D printer with a heated, flexible, and removable steel spring build plate, and an all metal extruder. It has an assisted level sensor on its magnetic extruder assembly, allowing easy changes to the Z offset in the menu for easy and perfect first layers. Wiring is no issue, as all of the components are already prewired and ready to go, with the connections hidden in the cable management sleeve. The Resume Print funtionality allows a print to be resumed after a power outage, power failure, or a sudden power loss from accidental unplugging.

Features:

- Build Volume: 200x200x180mm

- Material Support: PLA, ABS, PETG, Nylon, Wood Fill, Metal Fill

- Filament Diameter: 1.75mm

- Layer Thickness: 50-300 microns

- Software: Cura, KISSlicer, and Simplify 3D

- Print Speed: up to 100mm/sec

- Input Power: 110-220 VAC, 50/60 HZ

- Dimensions and Weight: 15.

7 x 21 x 15.7 inches ( 400 x 533 x 400 mm), 20.9 lbs (9.5 kg)

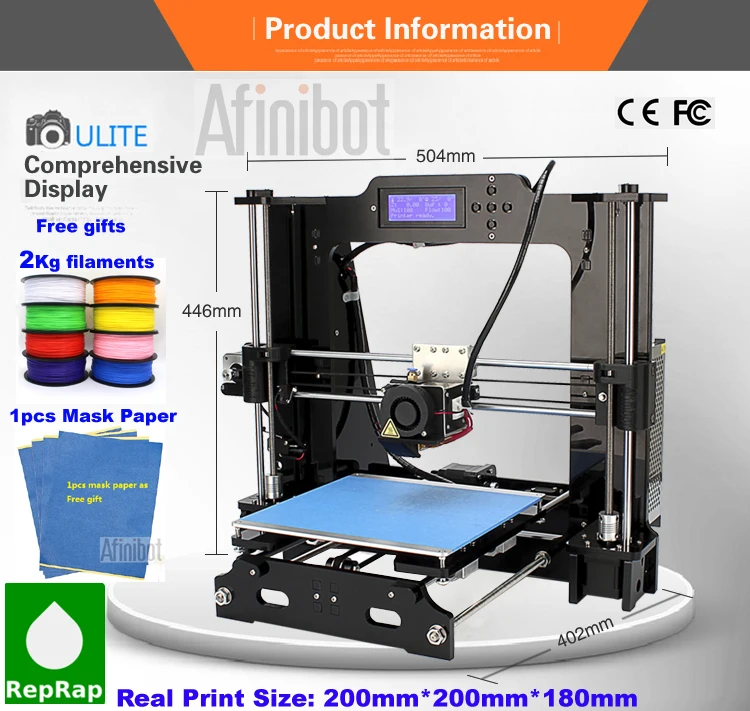

| 21666 | 15365/21711 | 34438 | 34437 | 33820 | |

| MP Mini Delta 3D Printer | MP Select Mini 3D Printer V2 | Maker Plus 10 Mini 3D Printer | Maker Plus 10 3D Printer | Voxel Adventurer 3D Printer | |

| Build Area | ø100 x 120 mm | 120 x 120 x 120 mm | 200 x 200 x 180 mm | 300 x 300 x 400 mm | 150 x 150 x 150 mm |

| Resolution | 50-200 microns | 100-300 microns | 50-300 microns | 50-300 microns | 100-400 microns |

| Filament Diameter | 1.75mm | 1.75mm | 1.75mm | 1.75mm | 1. 75mm 75mm |

| Nozzle Diameter | 0.4mm | 0.4mm | 0.4mm | 0.4mm | 0.4mm |

| Hotend Setup | Bowden | Bowden | Bowden | Bowden | Bowden |

| Print Speed | up to 150 mm/sec | up to 55 mm/sec | up to 100 mm/sec | up to 100 mm/sec | up to 100 mm/sec |

| Maximum Extruder Temperature | 260°C | 250°C | 280°C | 280°C | 240°C |

| Maximum Build Plate Temperature | 60°C | 60°C | 110°C | 110°C | 100°C |

| Heated Built Plate | ✔ | ✔ | ✔ | ✔ | ✔ |

| Removable Build Plate | ✔ | ✔ | ✔ | ||

| Filament Sensor | ✔ | ✔ | ✔ | ||

| Calibration | Manual leveling | Manual leveling | Assisted leveling | Assisted leveling | Assisted leveling |

| Camera Monitoring | ✔ | ||||

| Connectivity | Color LCD screen, Micro USB, microSD™ card, Wi‑Fi® | Color touchscreen, Micro USB, microSD™ card, Wi‑Fi® | Touchscreen, Micro USB, microSD™ card, Wi‑Fi® | Touchscreen, Micro USB, microSD™ card, Wi‑Fi® | Color touchscreen, USB drive, Wi‑Fi® |

| Supported Slicing Software | Cura, Repetier-Host | Cura, Repetier-Host | Cura, Repetier-Host, KISSSlicer | Cura, Repetier-Host, KISSSlicer | MP Flashprint, Slic3r, Skeinforge, Cura |

Support Files:

- Quick Install Guide (July 09, 2019)

- User's Manual (Mar 29, 2019)

- Benutzerhandbuch (Deutsch) (Mar 29, 2019)

- Manual del Usuario (Español) (Mar 29, 2019)

- Manuel d'Utilisation (Français) (Mar 29, 2019)

- Gebruikershandleiding (Nederlandse) (Sep 18, 2019)

- Manuale dell'Utente (Italiano) (Mar 29, 2019)

- Cura for Windows® 64-bit v4.

0.0 (May 20, 2019)

0.0 (May 20, 2019) - Firmware Update (Dec 06, 2019)

Certain filaments that can be used with this product may contain a chemical known to the State of California to cause cancer or birth defects or other reproductive harm.

SD™ and microSD™ are trademarks of SD-3C, LLC.

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

Wi‑Fi® is a registered trademark of Wi‑Fi Alliance.

How long will it take for my order to arrive?

After the order has been placed, shipping takes about 5-7 business days. Our warehouse is located in the Netherlands.

How much do I have to pay for shipping?

Shipping costs to Finland, Greece, Ireland, Portugal, Spain, Sweden, Austria, Belgium, Bulgaria, Croatia, Czechia, Denmark, Estonia, Hungary, Italy, Latvia, Liechtenstein, Lithuania, Luxembourg, Monaco, Netherlands, Poland, Romania, Slovakia, Slovenia, Andorra, San Marino, Vatican City, France:

- Orders above 30€: Free Shipping

- Orders below 30€: 3,79€

For deliveries to Cyprus, Malta, Norway, Switzerland, shipping costs vary by weight:

- 10kg – 4.

99 kg: 7,68 €

99 kg: 7,68 € - 5kg – 9.99 kg: 8,79€

- 10kg – 19.99 kg: 11,33€

- 20kg – 29.99 kg: 11,67€

- 30kg – 39.99 kg: 19,91€

What are the returns policy?

You can return your items to us for free within 30 days without giving a reason.

How does the return work?

If you do not like an article, you can return it to us within 30 days of delivery. Please contact us at [email protected] to receive a free return label. Please print the return label, stick it on the carefully sealed package and hand it over to your local post office. Please keep the document with the tracking number carefully.

Join our newsletter

... and get 10€ OFF your next purchase.

The Best 3D Printers in October 2022 (For Every Price)

With so many 3D printers available, from different price ranges to different technologies entirely, it can be difficult to pick the best 3D printer for you.

We’re here to help: we continuously update this best 3D printer guide with the latest 3D printer reviews, and we’ve tested over a dozen 3D printers on this site to create this buyer’s guide.

If you’re in a rush, here’s our 3 top picks:

BUDGET OPTION

Creality Ender 3 V2

Reliable low-cost 3D printer

Easily upgradable with a wide range of printable or purchasable upgrades

Improved print bed for better adhesion

Available at:

Creality hereAmazon hereRESIN PICK

Anycubic Photon Mono X

High-quality mid-range resin 3D printer

Fast 60mm/h resin printing

Powerful 4K LCD screen for precise details and miniatures

Available at:

Anycubic hereAmazon herePREMIUM PICK

Prusa i3 MK3S+

Gold standard in DIY FDM 3D printing

Super reliable workhorse

Upgradable to print 5 colors simultaneously

Available at:

Prusa hereWhat makes a good 3D printer?

We used the following criteria, along with our hands-on experience, to make our top picks:

- Print quality: resolutions, accuracy and consistency

- Build volume: not a problem if you just want to print miniatures, but bigger can be better

- Reliability: especially important in cheap printers, we picked durable printers that work reliably

- Versatility: from the range of materials you can print, to any extras such as a dual extruder, enclosure, and more

- Easy to use: easy assembly, simple and intuitive to set up, and straightforward slicer software

We’ve split our recommended picks into different categories to help you find the best 3D printer based on your needs.

Then, below we have our full product reviews of each printer with the full details, and where to get the best price.

The Best 3D Printers in 2022 – Reviews

Best under $300: FDM — Creality Ender 3 V2, Anycubic Kobra

Best under $300: Resin — Anycubic Photon Mono 4K, Elegoo Mars 2 Pro / Mars 3

Best for kids — Toybox 3D printer

Best for $500: FDM — Anycubic Vyper, Prusa Mini, Creality Ender 3 S1 Pro

Best large-format resin printer — Anycubic Mono X, Elegoo Saturn S

Best large-format FDM — Creality Ender 5 Plus

Best FDM 3D printer for $1000 — Prusa i3 MK3S+

Best dual extruder under $1000 — Flashforge Creator Pro 2, Sovol SV04

Best 3-in-1 3D printer, CNC, laser — Snapmaker 2.0 AT

Professional resin printers — Prusa SL1S Speed, Formlabs Form 3

Professional FDM — Ultimaker S3, S5

Here’s the full list:

| 3D printer | Price | Best place to buy | Alternative |

|---|---|---|---|

| Creality Ender 3 V2 | $279 | Creality Store here | Amazon here |

| Anycubic Photon Mono 4K | $219 | Anycubic here | Amazon here |

| Elegoo Mars 2 Pro / 3 | $250-$350 | Elegoo here | Amazon here |

| Toybox | $299 | Toybox here | |

| Anycubic Kobra | $299 | Anycubic here | Amazon here |

| Prusa Mini | $350 | Prusa Store here | |

| Anycubic Vyper | $359 | Anycubic Store here | Amazon here |

| Creality Ender 3 S1 Pro | $479 | Creality Store here | Amazon here |

| Anycubic Mono X | $449 | Anycubic here | Amazon here |

| Elegoo Saturn S | $549 | Elegoo here | Amazon here |

| Sovol SV04 | $539 | Sovol 3D here | |

| Ender 5 Plus | $579 | Creality Store here | Amazon here |

| Prusa i3 MK3S+ | $749 / $999 | Prusa (DIY) here | Prusa (built) here |

| Flashforge Creator Pro 2 | $649 | Flashforge here | Amazon here |

Snapmaker 2. 0 AT 0 AT | $1,199-$1,799 | Snapmaker here | Amazon here |

| Prusa SL1S Speed | $1,999 | Prusa Store here | |

| Formlabs Form 3 | $3,499 | Dynamism here | |

| Ultimaker S3 | $4,030 | Dynamism here | Matterhackers here |

| Ultimaker S5 | $5,995 | Dynamism here | Matterhackers here |

Best Under $300

For new and experienced makers alike, finding the best 3D printer without breaking the bank is important.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Creality Ender 3 V2 — best 3D printer for the price

- Price: Check price at Creality Official Store here / Available on Amazon here

- Build volume: 220 x 220 x 250 mm

One of the leading 3D printers for $200, the Creality Ender 3 V2 is a very powerful machine for the price. It can be assembled in under an hour, and also features a heated bed.

It can be assembled in under an hour, and also features a heated bed.

An affordable workhorse 3D printer, the Ender 3 V2 is known for its reliability, churning out part after part without issue. The open printing area means it isn’t ideal for tougher filaments like ABS or Nylon, but as a PLA 3D printer it works well.

The Ender 3 V2 features a number of small but useful improvements on the best-selling Ender 3. The print volume is the same, but the print bed is now carborundum glass mounted on an aluminum bed, improving adhesion and making removing finished prints easier than on the previous magnetic bed. The HD screen is better than the original LCD interface, a small but pleasant quality-of-life improvement.

If you’re going to be spending $200 on a 3D printer, you can’t expect the quality to be flawless. If you want a Creality 3D printer and you have an extra $200 – upgrade to the Ender 3 S1 Pro, which also features on this ranking.

Read more: comparing the Ender 3, Ender 3 Pro, Ender V2 and S1

Anycubic Photon Mono 4K

- Price: Check price at Anycubic Official here / Amazon here

- Build Volume: 165 x 132 x 80 mm

- Bed Leveling: Manual

- LCD: 6.

23” 4K monochrome LCD

23” 4K monochrome LCD - XY Resolution: 35 microns

- Filament Compatibility: Resin

- Connectivity: USB

The Anycubic Photon Mono 4K is a major upgrade on the standard Photon Mono, retaining the simplicity of the original while pumping up the XY resolution from 50 to 35 microns to put it in line with the pricier Mars Elegoo 3.

This major shift comes courtesy of a pivot to a 6.23″ LCD pushing 3,840 x 2,400 pixels. Although the 165 x 132 x 80 mm tails behind the Mars 3’s 143 x 90 x 165 mm, it still offers ample space for most resin-based home projects and then some.

The 1-2 second cure time remains identical to the original Mono, but you’re effectively able to produce the same prints in the same time frame but at a higher overall quality. Elsewhere, the 4K jumps to a new 15-LED matrix parallel light source that allows for more uniform light distribution, resulting in richer details.

So why opt for the Anycubic Photon Mono 4K over the Elegoo Mars 3? While the Mars 3 offers a sleeker overall printing experience, the Anycubic Photon Mono 4K just about keeps in pure specifications and print quality, all for $80 less.

If you’re after that sweet spot between spending as little as possible but still want a reliable, quality resin 3D printer, the Anycubic Photon Mono 4K hits the mark.

Elegoo Mars 2 Pro / Mars 3

BUDGET PICK

Elegoo Mars 2 Pro

Print Volume: 129 x 80 x 160 mm

Screen size: 6.08″ 2K Monochrome LCD

XY Resolution: 50 microns

Speed: 30-50 mm/h

Cleaning/Curing: Elegoo Mercury Plus/X

Available at:

Elegoo hereAmazon herePREMIUM PICK

Elegoo Mars 3

Print Volume: 143 x 90 x 175 mm

Screen resolution: 6. 6″ 4K LCD

6″ 4K LCD

XY Resolution: 35 microns

Speed: 1.5-3 seconds per layer

Cleaning/Curing: Elegoo Mercury Plus/X

Available at:

Elegoo hereMatterhackers hereAmazon hereWe were very impressed when we tried out the Elegoo Mars 2 Pro – especially for such a low price. It was easy to set up and get started, and the surface finish on our prints was fantastic.

However, you can upgrade from the Mars 2 Pro’s 2K screen to the Mars 3’s 4K screen if your budget can stretch that far, offering crisper details and ultra-fast 1.5-second layer curing.A dinosaur model we 3D printed on the Elegoo Mars 2 Pro

The Elegoo Mars 2 Pro’s quality is great, and should be more than enough to print good-looking miniatures and models. The Mars 3 is not a necessity, but if you do want to overhaul the resolution and quality, go for the Mars 3.

The Mars 3 also has a larger build area: 143 x 90 x 165 mm, vs the Mars 2 Pro’s 129 x 90 x 150 mm. You can print 15mm taller models, and you have 14mm on the X-axis for printing more miniature models at the same time.Clank video game 3D print on the Elegoo Mars 2 Pro.

For XY resolution, the Mars 3 clocks in at 35 microns, an improvement on the Mars 2 Pro’s 50 microns. However, both are very well-made, with robust parts and CNC machined aluminum bodies.

So, if you’re fine with the 2K LCD screen, smaller build area and slightly slower print speed, then the Mars 2 Pro is a great budget pick. But if you want those extra upgrades, go for the Mars 3 – or even the Mars 3 Pro. The Mars 3 also comes with a year’s free ChiTuBox Pro, which usually costs $150+.

Read more: our review of the Elegoo Mars 2 Pro

Toybox: Best For Kids & Complete Beginners

- Price: $299 – Available at Toybox Official store here

- Build volume: 70 x 80 x 90 mm

The Toybox isn’t your high-tech, workhorse 3D printer to start a business with, but it is one of the simplest and most accessible 3D printers we’ve ever tested – ideal for kids and beginners.

The build volume is small – just 70 x 80 x 90 mm, but if you have modest 3D printing goals to print miniatures and other fun characters, it’s a great choice.

Toybox have partnered with numerous big players to bring you a huge range of free models you can 3D print too, from Batman and Wonder Woman, to fun 3D printable dragons, tanks, cars, and so much more.A fun seal we 3D printed with the Toybox.

For kids it’s super safe: it only prints low-temperature PLA, and any hot parts are kept well away from prying hands. You get small spools of many different color filaments to print away with – affectionately called 3D printer “food” by Toybox – and we found it to be reliable yet super accessible.

If you’re brand new and want a hassle-free run, or want to get your kids into 3D printing cheaply, the Toybox is great.

The full review: Toybox 3D printer review

For beginners: the best 3D printers for beginnersGetting the Toybox set up.

Anycubic Kobra – best under $300

- Price: Check price at Anycubic here / Amazon here

- Build Volume: 220 x 220 x 250 mm

- Bed Leveling: Yes, LeviQ automatic bed leveling

- Build Platform: PEI-coated spring steel heated bed

- Filament Compatibility: PLA / ABS / PETG / TPU

- Connectivity: USB, SD Card

The Anycubic Kobra delivers incredible value for the asking price, with a spec sheet that reads like one for a printer twice its price. We were lucky enough to review the Kobra, and despite some minor slicer issues, we were thoroughly impressed with Anycubic’s latest entry-level printer.

Standout features include Anycubic’s in-house developed LeviQ automatic bed leveling and homing system, a PEI-coated spring steel heated bed, a direct drive extruder, and one of the sharpest touch screen UI’s we’ve seen at the price point. It’s frankly baffling to see these types of features on a printer costing less than $300.An owl we 3D printed on the Anycubic Kobra during our test.

It’s frankly baffling to see these types of features on a printer costing less than $300.An owl we 3D printed on the Anycubic Kobra during our test.

The Anycubic Kobra’s budget appeal also extends to the quality of the prints. With a bit of software wrangling, the Kobra is capable of fantastic prints for the price, and the bang-on average 220 x 220 x 250 mm build volume should cover all your everyday 3D printing needs.

A layer thickness range of 50 to 300 microns and print speeds pushing up to 180 mm/s have you covered for everything from sharp, detailed prints through to quick, functional parts.

Overall, the Anycubic Kobra is an affordable printer that stands out for taking some of the more frustrating and time-consuming aspects of the hobby out of the picture so that you can concentrate on the actual printing.

If you’re a first-timer looking for a gentle introduction to 3D printing, the Anycubic Kobra is arguably the best option out there currently.

And if the build volume isn’t enough, upgrade to either the Kobra Plus or Kobra Max:

- Kobra Plus: 300 x 300 x 350 mm build area – Available here

- Kobra Max: 400 x 400 x 450 mm build area – Available here

Read the full review: Anycubic Kobra review and test

Best Under $500

Prusa Mini – Best Premium-Budget Printer

- Price: $350 – Available at Prusa Official here

- Build Volume: 180 x 180 x 180 mm

- Bed Leveling: Yes, SuperPINDA probe

- Build Platform: Removable magnetic spring steel sheets

- Filament Compatibility: PLA, PETG, ASA, ABS, Flex

- Connectivity: USB, Ethernet

With the Prusa Mini, the company leverages all the Prusa i3 MK3S+’s usability and specs into a comparatively affordable printer. The Prusa Mini’s price is entry-level, only marginally higher than you’d pay for the ever-popular Ender 3 and Anycubic Kobra.

The Prusa Mini’s price is entry-level, only marginally higher than you’d pay for the ever-popular Ender 3 and Anycubic Kobra.

It’s a sophisticated 3D printer that focuses on simplicity. It features automatic mesh bed leveling courtesy of a superb SuperPINDA probe, a classy PEI-coated spring steel removable bed, and instructions that are as clear and user-friendly as they come.

The Prusa Mini also pairs well with a broader range of materials than your standard budget printer, covering PLA and ABS along with PETG, ASA, HIPS, and produces decent results with demanding exotics like PC blends and CF-PETG.

However, for all the Mini’s fantastic attributes, it’s abundantly clear where Prusa trimmed the fat, with a rather measly 180 x 180 x 180 build volume.

For the average maker, especially first-timers, the Mini’s build volume should be more than enough for most common print projects. However, if you want to print large models, or large terrain areas for miniatures, opt for an Ender 5 Plus.

Volume aside, the Prusa Mini is a solid premium-budget option for those buying a first printer and even more experienced makers looking to add to their printer line-up.

Ender 3 S1 Pro

- Price: Check latest price at Creality here / Amazon here

- Build volume: 220 x 220 x 270 mm

- Minimum layer height: 0.05mm

- Bed leveling: Automatic

- Max extruder temperature: 300°C

We highly recommend the standard Ender 3 or Ender 3 V2 for a very low-cost FDM kit, but if you want premium features for a couple hundred bucks extra, the Ender 3 S1 Pro is one of the best printers under $500.

We were really impressed with the quality when we printed out some test prints during our Ender 3 S1 3D printer review.

The build volume is mostly the same (270 mm vs 250 mm on z-height) as the standard Ender 3, but the S1 Pro has an all-metal and direct drive extruder, versus the Ender 3’s PTFE bowden extruder. This makes it much easier to print flexibles like TPU, and reduces filament jamming from the generally higher quality extruder.We 3D printed a cat…for our cat…on the Ender 3 S1 Pro.

This makes it much easier to print flexibles like TPU, and reduces filament jamming from the generally higher quality extruder.We 3D printed a cat…for our cat…on the Ender 3 S1 Pro.

The S1 Pro can also handle up to 300°C temperatures, so high-temp Nylon and other filaments are no problem – a rarity at under $500. The Ender 3 standard runs up to 255°C, and the Ender 3 S1 (not Pro) can handle 260°C.

Another major advantage is the auto-bed leveling. While you can buy a CRTouch or BLTouch for the Ender 3, it’s a hassle and a time sink, so the Ender 3 S1 and S1 Pro coming with this is a big plus.

The z-axis is also generally sturdier and of higher quality for more reliable and precise printing, and if you do intend to print fine details, the Ender 3 S1 range goes down to 0.05mm layer heights, versus the 0.1mm on the other Ender 3 printers.

Read the full review: Ender 3 S1 Pro review and test

Anycubic Vyper

- Price: Best price on Anycubic Store / Also Available on Amazon

- Build volume: 245 x 245 x 260 mm

We were impressed with the Anycubic Vyper when we tested it last month. The build volume is impressive, and slightly larger than you’d expect for this price range — yet the printer is compact, and fits on most desktops.

The build volume is impressive, and slightly larger than you’d expect for this price range — yet the printer is compact, and fits on most desktops.

The auto leveling makes life easier and can be done via 1 click, and the Vyper also automatically adjusts your nozzle height for optimum printing. The spring steel magnetic platform makes it easy to remove prints, and its magnetism means you can remove the entire plate, remove your model in a more convenient place, and then click it back into place for your next print.One of the torture tests we 3D printed – an XYZ cube, which came out crisply.

Though we kept it at the standard 50-60mm/s during our test, Anycubic highlight how the Vyper’s innovative new double fan system lets you print at up to 100mm/s without creating issues. Still, if you’re going to use your printer as a speed demon, be careful when printing very small models.

The large 4.3-inch touchscreen makes printing a breeze, and the layout is intuitive and simple to operate. It doesn’t have WiFi connectivity, but it’s very easy to move models from Cura to the SD card and print them on the Vyper. Overall, it’s a good compact 3D printer for home makers.

It doesn’t have WiFi connectivity, but it’s very easy to move models from Cura to the SD card and print them on the Vyper. Overall, it’s a good compact 3D printer for home makers.

You can read more about the Vyper in our Anycubic Vyper review

Best Large-Format Resin

Anycubic Mono X

- Price: Check price at Anycubic Official Store here / Available on Amazon here

- Build volume: 192 x 120 x 245 mm

The Mono X is a big upgrade on Anycubic’s lower priced LCD printers. This home 3D printer can print intricate tabletop or D&D models in fantastic detail, and is one of the best 3D printers for miniatures. It prints at a very respectable 60mm/h.

The 4K screen makes for incredibly precise layers for the price, and in fact you’ll barely be able to see any visible layer lines if you use more accurate print settings. Additionally, the upgraded double linear Z-axis improves stability, further improving performance.

The 3.5” touchscreen makes it easy to operated, and the Mono X works over via WiFi or USB/SD. Overall, it’s one of the best 3D printers for resin molds and models under $1,000, and a great 3D printer for resin.

Elegoo Saturn S – Best Large Resin 3D Printer

- Price: Check latest price at Elegoo here / Amazon here

- Build Volume: 196 x 122 x 210 mm

- Bed Leveling: Manual

- LCD: 9.1-inch 4K HD Monochrome

- XY Resolution: 48 microns

- Filament Compatibility: Resin

- Connectivity: USB

The Elegoo Saturn S is a new-look upgrade on the standard Saturn, bring it in line with larger resin competitors like the Anycubic Mono X series.

Compared to the standard Saturn, build volume jumps from 192 x 120 x 200 mm to 196 x 122 x 210 mm.

This is a slight increase, but these numbers position the Saturn S as one of the larger format printers priced under $500 – ideal for printing batches of your favorite high-detail figurines.

Elsewhere, the Saturn S 4K screen refines the XY resolution to 48 microns, offering a slight jump in fine detail over the Saturn’s 50 microns. You could spend a further $200 on the Photon Mono X 6K to drop to 34 microns. Still, the differences at this scale are virtually indistinguishable to anyone but the most discerning makers.

When compared with the Anycubic Mono X (not the 6K version), they have similar 4K screens and resolutions, with the Saturn S having a 4mm larger X-axis, and the Mono X with a 35mm larger Z-height. So if you want to print taller models, go with the Mono X.

They’re of similar speeds, and have similar connectivity via USB – so it’s mostly down to what you plan to print: do you want to print wider, or taller? For wider, go with the Saturn S, for taller, the Mono X. And for a 6K screen, go for a Mono X 6K.

Best Large-Format FDM

Ender 5 Plus – Best Large-Format 3D Printer Under $1,000

- Price: Check price at Creality Official here / Amazon here

- Build Volume: 350 x 350 x 400 mm

- Bed Leveling: Yes, BLTouch auto-bed leveling probe

- Build Platform: Glass heated bed

- Filament Compatibility: PLA, ABS, TPU, Composite-Filled

- Connectivity: SD Card, Browser Interface

The real highlight of the Ender 5 Plus is the 350 x 350 x 400 mm build volume – far above the average found on sub-$1000 printers.

So much real estate opens the door for far more ambitious hobbyist prints – cosplay items and accessories, batch printing smaller parts, large vases or household pieces, and any other projects that benefit from the extra space.

As the most premium of the entry-level Ender line-up, it also throws in a few quality-of-life improvements, notably BLTouch-powered automatic bed leveling, which blazes through normally fiddly calibration. It also features a quality removable tempered glass plate, filament runout sensor, and a sharp 4.3″ touchscreen.

Beyond these, the Ender 5 Plus is a functional printer much like the Ender 3, with few extra bells and whistles. A possible downside for some but a genuine benefit for others as the Ender 5 Plus offers a solid foundation ripe for upgrades and tinkering.

All-metal extruder, direct drive system, enclosure, mainboard, all-metal hot end, and countless 3D printed upgrades are all possible add-ons to transform a solid printer into an exceptional one capable of handling all manner of exotic and abrasive filaments.

Some mods are more daunting than others, but the Ender 5 Plus popularity means there’s an in-depth guide, tutorial, and video available for every upgrade to walk you through every step, courtesy of an engaged and active community.

Best FDM 3D Printer For $1000

Prusa i3 MK3S+

- Price: $749 as a kit — Available on the Prusa store here / $999 fully assembled — Available on the Prusa store here

- Build volume: 250 x 210 x 200 mm

Literally the gold standard of desktop FDM kits, Josef Prusa has sold over 100,000 of his 3D printers over the years. Known as the premier 3D printer to emerge from the RepRap movement, the Prusa i3 MK3S+ is packed with features that make it a great 3D printer for both makers as well as businesses.

The MK3S+, released at the tail end of 2020, features a number of small yet beneficial improvements over the MK3S. The new SuperPINDA probe allows for fully-automatic mesh bed leveling, with other improvements including easier to mount bearings on the Y-axis that provide better support.

The new SuperPINDA probe allows for fully-automatic mesh bed leveling, with other improvements including easier to mount bearings on the Y-axis that provide better support.

You get there bed surface options for spring steel sheets – smooth, textured or satin – covering various different material printing and making finished prints easier to remove than ever. The Prusa can print almost anything, with an extruder temperature up to 300°C possible — so even filaments like Polycarbonate are no issue.

If you want to print multi-color parts, you can upgrade your Prusa i3 MK3S+ with Prusa’s multi-material upgrade 2.0 kit, allowing you to print five colors or materials simultaneously, for $300. Moreover, the high-quality Bondtech gears and E3D nozzle within their custom-designed extruder make for great quality prints as well as top workhorse-like reliability. It’s also a fast 3D printer, able to travel and print up to 200mm/s.

- You can purchase the Multi Material Upgrade Kit here.

You can buy your own Prusa 3D printer online for $999 for a ready-made printer, or save a couple of hundred dollars and assemble it yourself. Overall, it’s one of the top 3D printers for $1,000, and one of the best 3D printer kits around.

Best Dual Extruders Under $1000

Sovol SV04: Best Low-cost IDEX 3D Printer

- Price: $539 — Available at Sovol store here

- Build volume: 300 x 300 x 400 mm

If you want a dual extruder 3D printer, and don’t want to pay more than a thousand bucks, then there’s only two games in town: the Sovol SV04 and the Flashforge Creator Pro 2.

The main difference is the Sovol SV04’s much larger build volume: it’s the same as the Creality CR-10, at 300 x 300 x 400 mm. This lets you print large objects with multi-colors, or even two fairly large models at the time using the IDEX dual extrusion features.

We tested the Sovol SV04 for a few days while reviewing it, and managed to print some really cool multi-colored 3D prints like the frog and cube shown below.

We also printed some great plant pots for some flowers and a cactus using the Copy Mode feature, with each extruder printing a plant pot simultaneously for double the productivity.

To be short: if you want a dual extruder 3D printer with a large build volume that works well, go for the Sovol SV04. The IDEX is a really handy addition (the Sovol SV02 isn’t IDEX) for quickly making multiple parts.

But, if you don’t mind having the smaller build volume, and instead prefer the enclosed build chamber to better print materials like ABS and Nylon, then go for the Flashforge Creator Pro 2.

Flashforge Creator Pro 2

- Price: Check price at Flashforge Official store here / Available on Amazon here

- Build volume: 200 x 145 x 150 mm

The Flashforge Creator Pro 2 is one of the best desktop 3D printers on the market for dual extrusion. This makes the Flashforge Creator Pro ideal for low-cost multi-material or color printing.

The Creator Pro 2’s main upgrade on the original Creator Pro is it now features an IDEX 3D printer system, meaning that the two extruders can move independently on the Y-axis rather than being locked together.

This opens up possibilities for both duplication 3D printing (printing two identical parts at the same time), and mirror modes (printing mirrored parts like two opposing shoe soles), greatly improving efficiency. This comes at the cost of some X-axis size, down to 200mm.

The Creator Pro 2 is an accurate 3D printer, with a minimum layer height of 0.05mm. Its closest alternative is the Sovol SV04, a similar-priced IDEX printer, but whereas the Sovol has a larger build volume, the Creator Pro has a sturdily built enclosure for better heat control.

Overall, it’s another terrific 3D printer, and a safe and reliable printer for the price.

Best 3-in-1 3D Printer, CNC and Laser

Snapmaker 2.0 AT (A250T and A350T): Best 3-in-1 3D Printer

- Price: $1,199 to $1,799 — Best price on Snapmaker Store here / Also Available on Amazon here

- Build volumes: up to 320 x 350 x 330 mm

The Snapmaker 3D printers aren’t just 3D printers – you can switch the extruder module out and switch in the CNC carver, or the laser engraver module in just a few minutes and get working.

The 3D printer module stands on its own as high-quality – we were surprised by just how reliable, accurate, and effective it was when we tested it. It doesn’t feel like you lose anything on the 3D printing side when you add on the other options. The metal structure and linear rails are sturdy, retaining precision even on the largest A350T we tested.

You can 3D print all major hobbyist filaments like PLA, flexible filaments like TPU, and ABS. The smartphone-shaped touchscreen makes it really easy to operate, and the WiFi connectivity saves you hassle from constantly plugging in SD cards or USBs.

You get a range of premium features — auto-leveling, filament run-out detection, dynamic print speeds via the intelligent software –generally making your 3D printing experience more pleasant and productive.The three sizes of the Snapmaker 2.0 options.The 3D printer head accurately printed the precise details of this vase.

By default you get the weaker 1600mW cutting module which we still managed to laser engrave with nicely, as well as cutting through thin and soft wood (though it takes a lot longer than specialized lasers).

However, you can purchase the 10W high power laser for an extra $399, which can engrave anodized aluminum (check out our wolf engraving below), and comfortably cut through acrylic and wood – we cut out an entire rhino puzzle from black acrylic in under 15 minutes.

You can carve soft and hard woods, as well as carbon fiber sheets and acrylics. We also used the 4-axis CNC module to carve chess pieces from epoxy blocks, and the bit can comfortably carve most woods and similar materials.

We cut chess pieces using the v-bit carver, and the 4-axis rotary module add-on (this costs an extra few hundred bucks though) which lets you carve into cylindrical blocks like a lathe to create detailed characters. Snapmaker Luban software handles the four axes well, and it’s a very well-designed software and slicer generally (vs buggier 3D software like Revopoint’s RevoScan).A lion the Snapmaker CNC toolhead carved. We also carved a knight chess piece that came out smoothly.

Read our full review: our Snapmaker 2. 0 3D printer review

0 3D printer review

For more on CNC: read our Snapmaker 2.0 CNC and laser review

If you want to engrave contrasting images, you can use the laser engraver. It can engrave on woods, as well as leather, fabrics and acrylic. We engraved a few cylinder-shaped blocks to test the 4-axis engraving module, as well as using the laser cutter to cut through a thin piece of wood to make this gift box.

We recommend also purchasing the enclosure to improve your printing experience and keeping you safer — and you may want to also pick up some extras for CNC. Their wide range of extras and goodies are on their site, which you can visit here.

If you’re considering the newest A250T or A350T vs the standard Snapmaker 2.0, the newer version is upgraded for a faster and quieter 3D printing experience generally, with a newly designed 3D printing module as well as more intelligent fan speed adjustments and a more powerful power module. There’s even rumors of a dual extruder module coming soon.

Best Professional Resin Printers

Prusa SL1S Speed

- Price: $1,999 — Available on Prusa Store here

- Build volume: 127 x 80 x 150 mm

The SL1S Speed is an upgrade on the original SL1, featuring 25% larger build volume, even more improvements to part quality, and more speed than ever.

One of the fastest resin printers around, the SL1S Speed cures layers in 1.4 seconds, and can fill the entire 150mm-high build chamber in just 3 hours. The high-resolution mono 5.96-inch LCD panel accurately cures layers of resin with the UV LED array, with even very small parts retaining their quality and intricacy.

Another major benefit is Prusa’s commitment to open source — all Prusa printers are open source, and are compatible with third-party resins, though Prusa also sell their own high-quality materials. And being a Prusa 3D printer, naturally it’s reliable and durable.

We recommend you also pick up Prusa’s wash and cure machine for post-processing your resin models. It washes, dries and cures your prints after the printing process, and costs an additional $599.

It washes, dries and cures your prints after the printing process, and costs an additional $599.

Formlabs Form 3

- Price: $3,499 — Available on Dynamism Store here

- Build volume: 145 x 145 x 185 mm

Retailing at $3,499, Formlabs’ Form 3 has become the resin 3D printer. It’s popular in both the dental and 3D printed jewelry markets due to its tremendous accuracy and for being significantly faster than traditional methods. The upgraded Form 3 has a number of improvements on the Form 2, including new LFS technologies and what Formlabs call a new Light Processing Unit which improves the surface finish of prints.

- The Formlabs 3B can also be purchased here / The Formlabs 3L can also be purchased here

The build volume hasn’t drastically increased in the newer Form 3 (just 10mm taller Z axis), but it now boasts incredible 25 micron accuracy. You can buy Formlabs resins, or there are a number of third-party resins compatible with the Form 3 which we’ve linked below.

- For Formlabs official resin: you can buy 1 liter here

- For third-party resins (may result in loss of quality of print): 1 liter here for significantly cheaper, or 500ml here

Best Professional FDM Printers

Ultimaker S3

- Price: $4,080 — Available on Dynamism Store here / Available on Matterhackers here

- Build volume: 230 x 190 x 200 mm

Dutch manufacturer Ultimaker have released some of the best 3D printers of the last few years. With a dual extruder and accuracy up to 20 microns, the Ultimaker S3 is a great 3D printer for rapid prototyping, and is used by small businesses, designers, and makers worldwide.

In addition, the Ultimaker S3 has a very decent 230 x 190 x 200 mm build volume, and includes a built-in camera for remotely monitoring your prints. You can connect to the printer via WiFi, USB or Ethernet very simply. Moreover, the Ultimaker S3 has an auto-leveling system for prints to make sure printing goes smoothly.

If you’re looking for the best 3D printer in terms of accuracy, ease of use, and equipment, and don’t mind spending upwards of $4,000, the Ultimaker S3 is the printer for you.

Ultimaker S5

- Price: $5,995 — Available on Dynamism Store here / Available on Matterhackers here

- Build volume: 330 x 240 x 300 mm

Compared with the excellent S3, the S5 is more expensive, moving away from the desktop 3D printer price range, but features a number of improvements and new features designed to make the Ultimaker S5 a more viable manufacturing method for prototypes and small batch production.

Featuring a larger 330 x 240 x 300 mm maximum build size, this is certainly an advantage over the Ultimaker 3. This makes it a better 3D printer for larger prototypes, shown as the Ultimaker S5 has already been used in companies such as Volkswagen. Ultimaker have earned a tremendous reputation over the years for creating great machines, and we feel the S5 is no different.

Buyer’s Guide – Things to Consider When Buying a 3D Printer

Which type of 3D printer do you want? And which materials do you want to print?

Different technologies do different things. For accurate minis for D&D, go for a resin 3D printer (MSLA / LCD) – they can print with much finer resolutions and smoother surface areas. But for a simpler setup and generally more relaxed experience (no curing, no chemicals) with stronger prints, go for an FDM printer.

Within this, you need to decide which material – filament or resin – best suits your needs.

For many PLA filament works just fine as it doesn’t really warp, doesn’t require a heated bed or enclosure (but is still good if you have the choice), comes in a wide variety of colors and blends (even conductive, or glow in the dark!), and it’s cheap.

ABS is tougher despite being just as cheap, and still comes in a wide range of colors – but it can warp and crack if not printed under the right conditions, and requires a heated bed and chamber. Some consider PETG to be a happy medium: it’s great for adhesion and super tough – but its stickiness makes it difficult to print overhangs and supports.

Some consider PETG to be a happy medium: it’s great for adhesion and super tough – but its stickiness makes it difficult to print overhangs and supports.

For resins, you don’t have the same range of options as you would with FDM, in materials or colors. There are a few color options, but most use standard resins – though companies like Formlabs have developed dental, jewelry casting, tough ABS-like resins, and a few other types.

What size models do you want to print?

Don’t waste your money on an enormous 3D printer if you just want to print miniatures, but also don’t skimp on a smaller machine if you want to print huge cosplay swords.

Think about what you want to print right now – and what you might want to print in the future. With good 3D printers starting in the $300 price range, it can be an expensive decision to get wrong. Also consider the size of your workspace – 3D printers are deceptively big and you need to make sure it’ll fit.

Also, resin 3D printers typically have smaller build volumes than FDM printers, so if size matters, go FDM.

What do you want to 3D print generally?

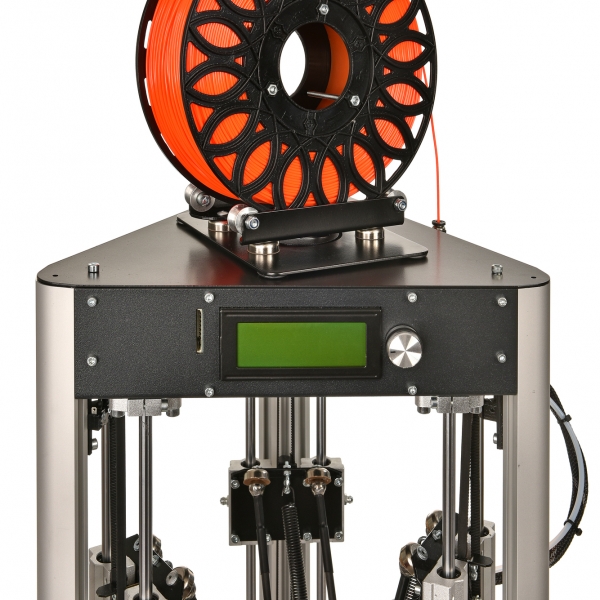

Beyond size, think about exactly what you want to 3D print for your projects. If you’re not as fussed about perfect quality, go for a printer with high top speeds (delta 3D printers are generally better for this) – especially if you’re printing cubes and similar shapes that don’t have details.

But, if you want high-resolution, pick printers that can handle lower layer heights and take smaller nozzle sizes – or resin printers with the most precise XY resolutions.

For high-temperature filaments, either get an enclosed 3D printer like the Creator Pro 2, or buy an enclosure for your printer – Creality sell their own enclosures, and there are popular DIY projects for the Prusa and other best-selling printers.

If you want to print PC, Nylon, carbon-fiber mixes, and other abrasive blends, you’ll need a printer with a hot end that can handle these temperatures – either go for a Prusa or higher-spec printer, or buy a hot end upgrade kit.

And if you want to print flexible filaments like TPU, opt for a 3D printer that’s either a direct drive 3D printer, or has a direct drive kit like the Ender 3 range – though while you can use a Bowden extruder, it requires a lot more oversight to prevent issues coming up.

Do you want an easy 3D printing experience?

While you shouldn’t be discouraged if you’re a beginner, we recommend you pick 3D printers with features such as auto-leveling, WiFi connectivity, filament run-out sensors and print resume functions, and easy-to-use software and touchscreens to save you hassle if you’re newer or less technical.

Self-leveling is a nice extra that saves you manually re-leveling the printer every few prints, and should guarantee you crisp prints rather than janky blemish-full messes.

WiFi connectivity saves you from taking SD cards back and forth from your laptop to your 3D printer for every print, and is generally a nice addition to have that boosts print productivity.

Filament run-out sensors and print resume features (in case of a power cut or similar) are fairly ubiquitous now – even most entry-level 3D printers have them. But they can be a lifesaver, especially if you lose power during the latter stages of a 24-hour or longer print of a large prototype or cosplay costume piece.

For easy-to-use software, Cura should have you covered for the slicer, but some 3D printers have more intuitive interfaces than others. Most now have touchscreens (though turnable knobs on printers like the Enders and Prusas are fine), and we particularly liked the Snapmaker’s easy-to-use touchscreen interface and design.

Go for a trusted brand and model if buying on the cheap side

There are hordes of low-cost 3D printers in the $160-$300 range. Most aren’t that reliable, and we recommend sticking with FDM kits like the Ender 3 range, Anycubic entry-level printers, and Elegoo or Anycubic resin printers for lower price printers that actually work well.

The last thing you want to do is get burned and left with an expensive brick. Opt for a highly-reputed printer with large communities and active forums, in case you run into trouble – we recommend these here.

Do you want to print in multiple colors?

For fully multi-colored prints – as in, colored by the pixel (or voxel in 3D) – you’re going to struggle. XYZ made a full-color 3D printer a few years back but the colors looked washed out and it cost $3,500.

But you can get multi-color prints from a few other ways. You can pick a dual extruder 3D printer and print with two colors, or use a filament splicer like a Palette to print with up to four different colors simultaneously.

Color options for resin LCD or MSLA printers are very limited, unfortunately. To get multi-color resin prints, you mostly need to rely on post-processing.

FAQs

Which are the best 3D printer brands?

The best 3D printer brands for low-cost printers include Creality, Prusa, Anycubic and Elegoo for FDM and LCD printers.

For mid-range 3D printers, Prusa make the fantastic i3 MK3S+, and other brands such as Flashforge, Dremel, Qidi Tech, Formlabs, Ultimaker, Makerbot and Raise3D are highly-reputed.

In professional ($10,000+ price ranges) 3D printing, brands like Markforged, Desktop Metal, Carbon 3D, Stratasys and 3D Systems are widely adopted.

Which is the best 3D printer right now?

The Ender 3 range (including V2 and S1) are some of the best 3D printers for FDM kits, with Anycubic’s Mono range and Elegoo Mars dominating the low-cost resin market.

Prusa 3D printers are some of the best 3D printers under $1,000, with brands like Ultimaker manufacturing some of the best prosumer 3D printers for small businesses and prototyping.

If you enjoyed this article, you may also enjoy:

- Our guide to the best 3D pens

- Our ranking of the best 3D scanners

- Our ranking of the best 3D printers for beginners

- Our ranking of the best SLS 3D printers

- Our ranking of the best FDM 3D printers

- Our ranking of the best resin 3D printers

- 3D printer deals

Nexa3D NXD 200 3D printer

With a build volume of 8. 5L, a printable area of 275x155x200mm, intelligent optimization, and revolutionary patented LSPc technology, the NXD 200 3D printer is the ideal machine for the dental industry.

5L, a printable area of 275x155x200mm, intelligent optimization, and revolutionary patented LSPc technology, the NXD 200 3D printer is the ideal machine for the dental industry.

Characteristic description

The NXD 200 is equipped with a full featured set of tools including auto orientation, support generation, mesh recovery and detail editing options. Proprietary LSPc (Lubricant Sublayer Photo-curing) stereolithographic 3D printing technology and optimal platform filling guarantee the accuracy of prints, the uniformity of their structure and the repeatability of models from one edge to the other.

The printer has more than double the footprint capacity of currently available machines, allowing for much larger parts, high productivity and ultimately cost savings.

NXD 200 from Nexa3D is a turnkey solution for dentists. The design of the device consists of modules and easily replaceable elements, which, with constant modernization of technologies, eliminates equipment obsolescence.

The unique xCure post-processing system unleashes the potential of the printer consistently and quickly. Proven post-processing workflows provide the optimum balance of temperature, UV wavelength and material-specific cure time to ensure perfect cure. These efficient cycles guarantee consistent mechanical properties and predictable product throughput. The end result is less post-processing, faster time-to-market, better 3D printer throughput, and of course, a quality part.

The patented Everlast membrane increases the life of the liquid-liquid separation surface on Nexa3D membranes exponentially. As the name suggests, the product is more durable, resilient and extends the period of trouble-free operation of the printer by 25 times. Everlast membrane provides less downtime for element replacement and long continuous cycles in complex batch production operations. The development demonstrates stable optical transmission, so even the thousandth part will be identical to the first. Everlast membranes have a stronger but more resilient surface that allows you to print objects from difficult technical materials. The membrane is fully compatible with Nexa3D hardware workflows and settings, including dynamic monitoring of its condition as predicted by the applied feedback.

Everlast membranes have a stronger but more resilient surface that allows you to print objects from difficult technical materials. The membrane is fully compatible with Nexa3D hardware workflows and settings, including dynamic monitoring of its condition as predicted by the applied feedback.

Intelligent software

Nexa3D's proprietary NexaX v1 software integrates hardware and materials into a powerful, user-friendly system, delivering a new level of intuitive operation and affordable maintenance. Materialize MagicsPrint software is responsible for the optimal placement of models and automatic placement of supports.

The programs are compatible with the Windows 10 operating system and provide for remote printer management: sending for printing, compiling job statistics. Supported input file formats are .stl and .3mf.

Used polymers

Nexa3D has developed a wide range of impact-resistant functional consumables for the NXD 200 3D printer tailored to increased productivity, making them ideal for serious production and same-day prototyping.

Portfolio includes:

- KeySplint Soft biocompatible photopolymer;

- fast curing KeyModel Ultra for precise orthodontic prototyping;

- KeyGuide for surgical models;

- KeyTray for impression trays.

The NXD200 is the fastest 3D printer for dental labs and large scale industrial applications. Due to the high precision printing with a layer thickness of 75 microns and the isotropic properties of the printed objects, the finished models are characterized by impeccable surface quality and dimensional accuracy.

Features

| Country | US |

| Purpose | Professional |

| Manufacturer | Nexa3D |

| Applications | Medicine |

| Communication interface | Gigabit Ethernet RJ-45 & WiFi |

| Layer thickness | from 75 µm |

| Media | Photopolymer |

| Print Technology | LSPc |

| Operating system | Windows 10 |

| Dimensions | 710x710x1675 mm; 160 kg |

| Construction area | 275x155x200 mm. |

8 nuances worth paying attention to / Sudo Null IT News

Sooner or later, everyone learns about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible.

What to pay attention to and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer.

You need to decide for yourself what tasks you will use this technique for? What capabilities should a 3D printer have to solve your problems?

Point 1: Decide on a 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here.

There are two main paths here.

If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models.

Prominent representatives of this segment: Form 2 3D printer or B9Creator 3D printer

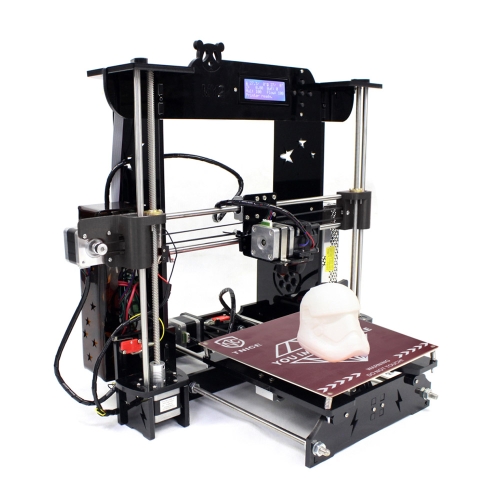

If you have a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic.

If everything is clear for SLA printers. Their scope is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

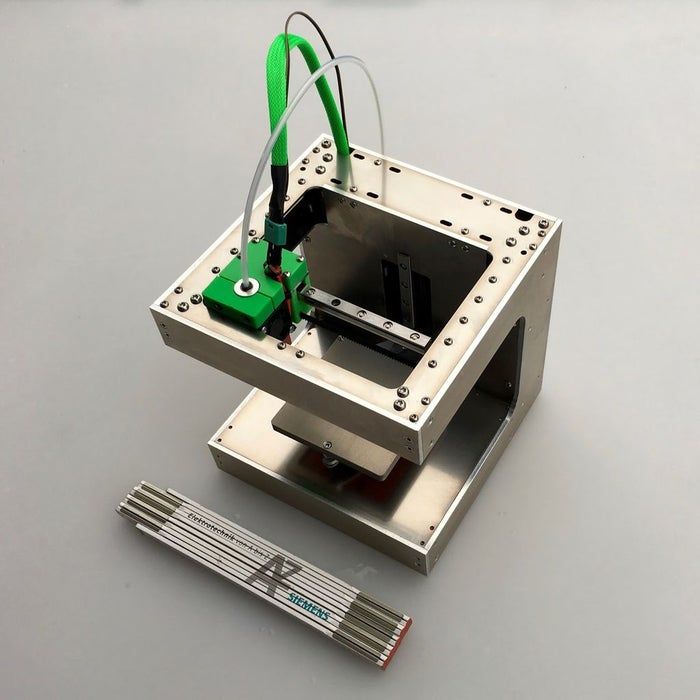

Nuance 2: Evaluate your needs

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems?

Do you need all this to solve your current problems?

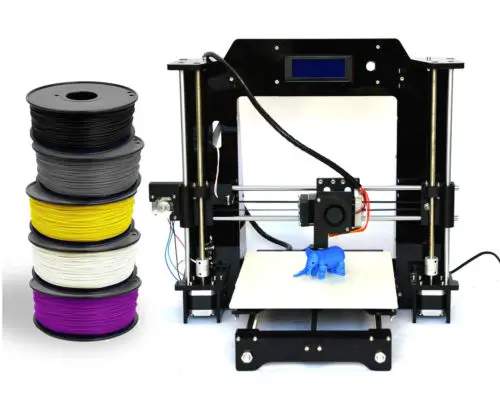

What can be an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks.

But options are possible...

If you are planning to make small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area.

In other cases, the size of the printable area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

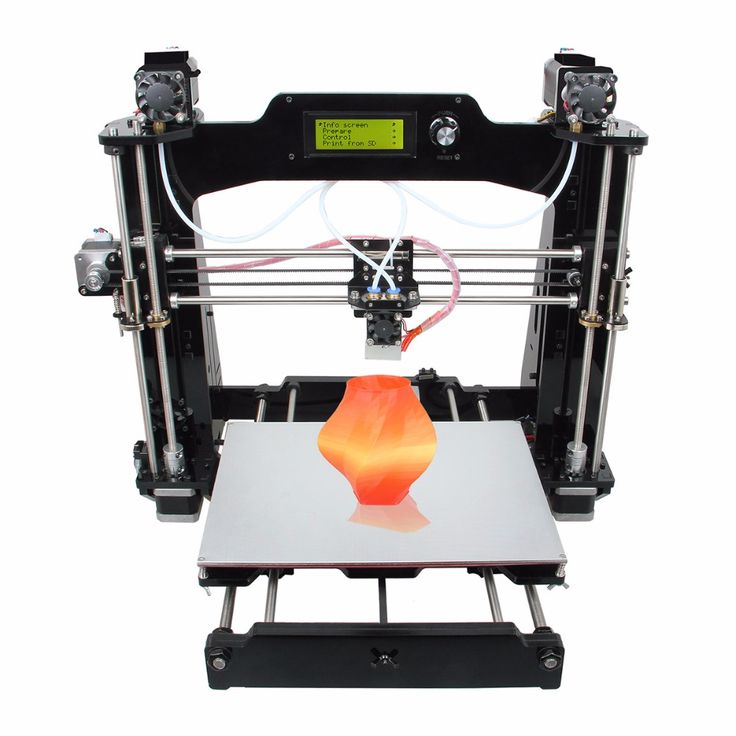

Point 3: Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles greater than 30 degrees.

Tip 4: Decide on a list of materials to use.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model.

If you plan to print with PLA only. You don't need a heated table.

But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform a full range of tasks facing a 3D printer.

One more thing. Possibility of printing with flexible materials.

Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common.

But the use of these materials in life is not very common.

Usually, for most people, this happens like this:

A couple of models are printed, the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

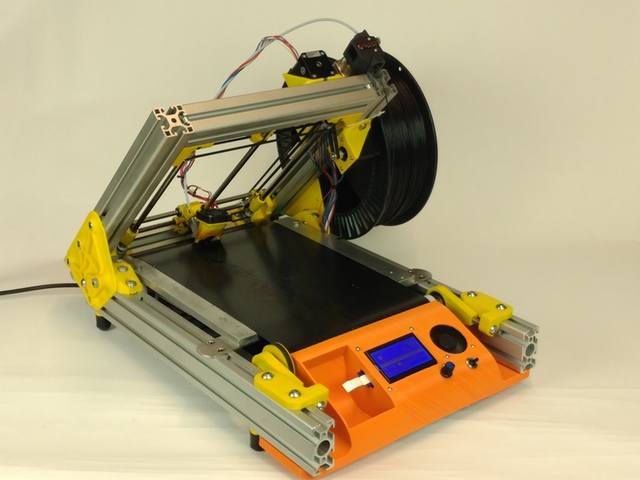

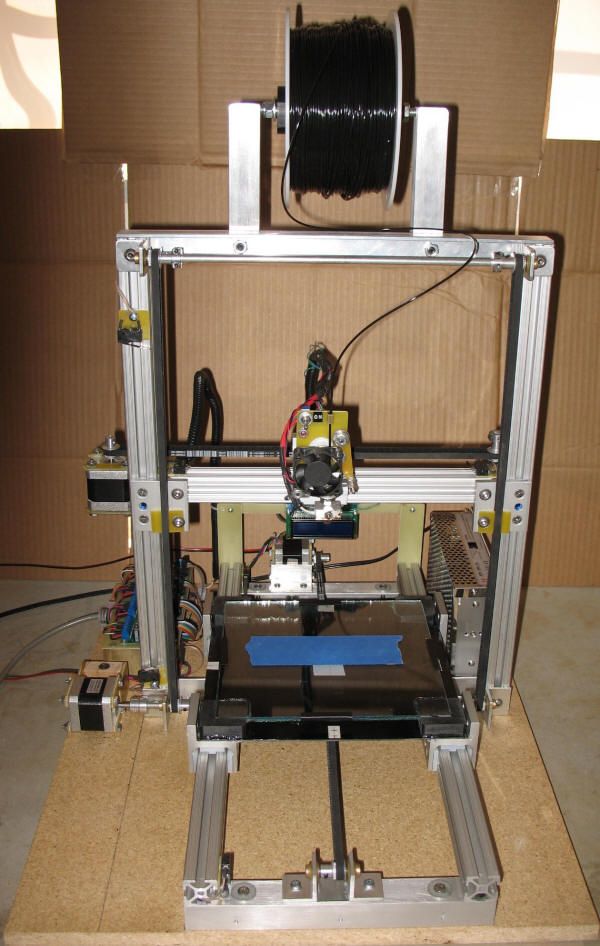

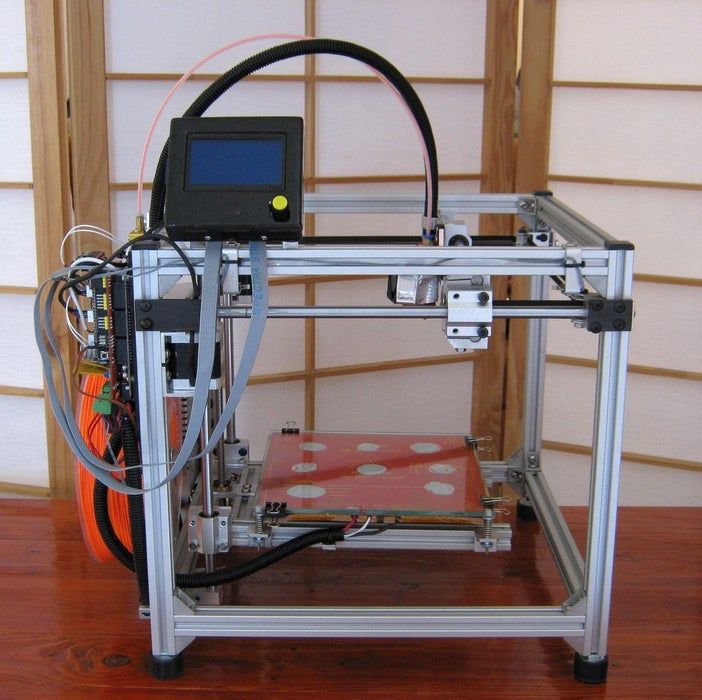

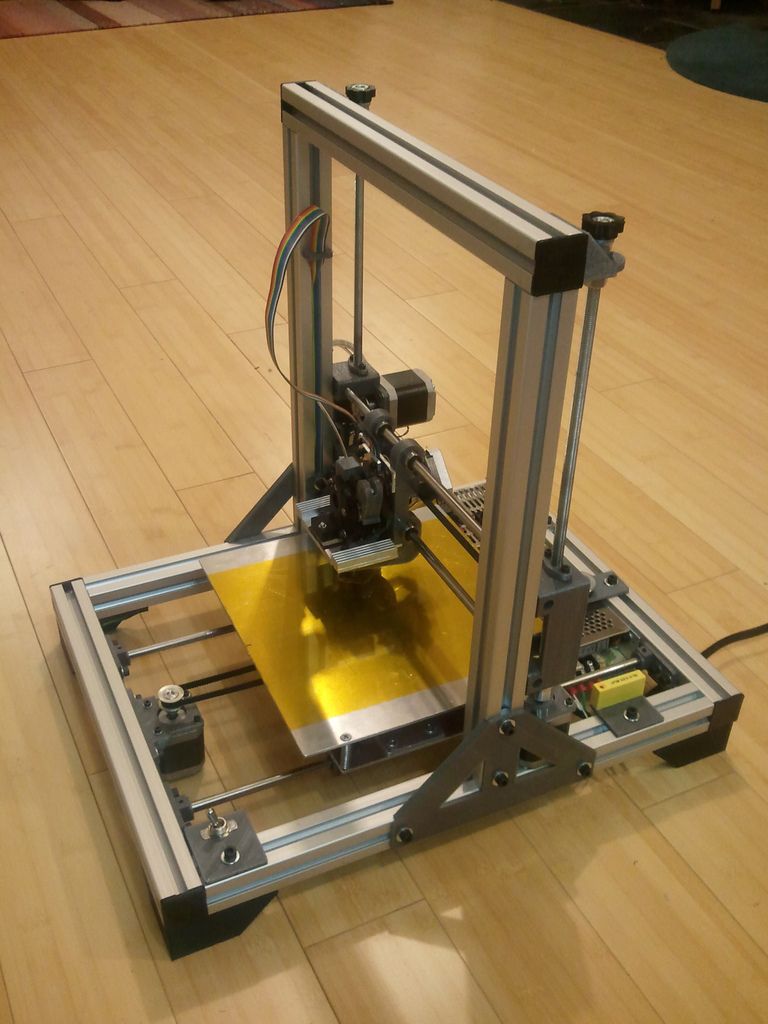

Point 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say?

Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble.

First of all, this is the so-called wobble.

Also, the lack of a closed housing can cause print quality problems with high shrink plastics (ABS, Nylon).

The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the scheme with a lifting table. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage.

Closed case printers are more rigid. This results in better quality printing.

Kinematics for moving the print head, available in various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

Point 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0.3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer.

Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary.

What do we mean by specific tasks?

This is especially true for large prints where it is important to reduce print times. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity.

So, just like with the heated table, the ability to change nozzles is a nice bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

It is not mandatory, but very useful if you do not have to pay extra for it.

Detail 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0.1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

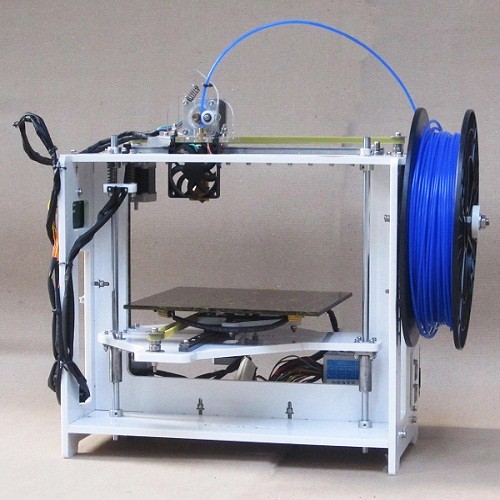

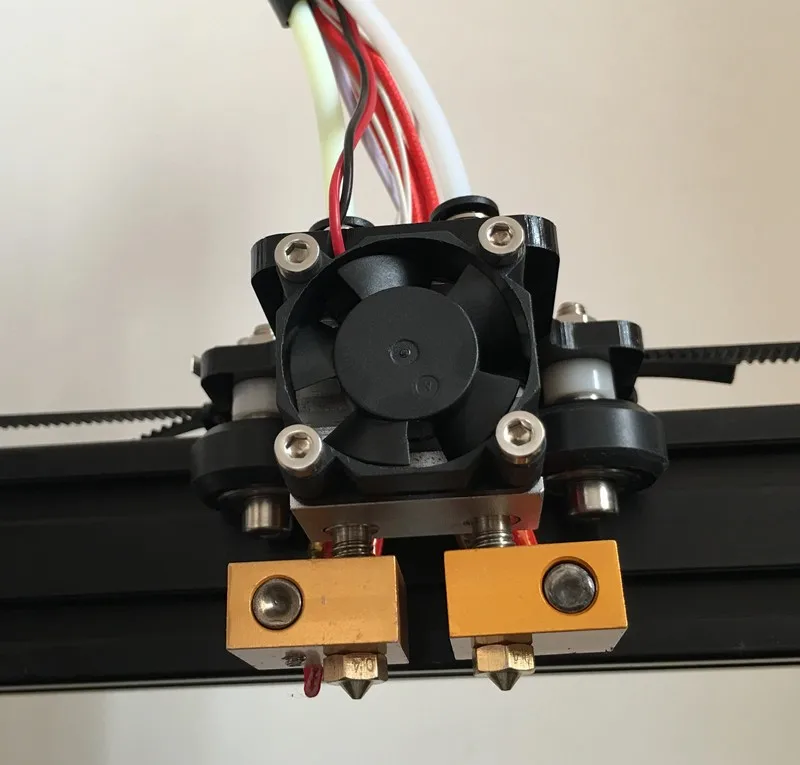

Point 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube.

And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube.

What are the advantages and disadvantages of each type of extruder?

Bowden extruder, due to the lack of a motor on the print head, has a lower weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually quite difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex.

This extruder reveals all its positive features when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1. 75mm.

75mm.

Direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy.

What do you prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types.

Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely.

And will save you time and money when choosing a 3D printer.

3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.