Bionic hand 3d printer

BUILD A HAND – Enabling The Future

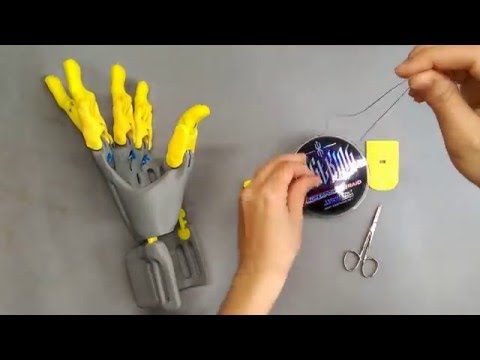

Find the files and assembly instructions you need to build a hand!

The e-NABLE community has developed a collection of different 3D-printable assistive devices that are free for download and fabrication by anybody who would like to learn more about the designs or fabricate a device for somebody in need.

If you are interested in building your own 3D printed upper limb device and have access to a 3D printer, here is the information you will need to get started:

- Decide which kind of device is recommended for the limb different person in need.

Visit our Which Design page to see what your options are and choose from the designs that are currently available and recommended for those types of limb differences. Please note, that the e-NABLE Community does not currently have designs for above elbow limb differences, so the recipient or user must have a functional wrist or elbow to make these devices function properly. - Make sure to take photographs correctly to ensure a proper fit. Watch the tutorial video to learn how to take images that will help you get the measurements you need to create a device that will fit properly.

- Refer to the e-NABLE Device Sizing page to learn how to properly size an e-NABLE device.

- Check out our e-NABLE Devices page for tutorials, assembly kits and other helpful information!

If you have any questions along the way, feel free to ask our volunteers by posting a message in the forum.

If you would like to make your own device but do not have access to a 3D printer, check our our e-NABLE Chapters page, which includes a searchable map of e-NABLE Chapters. This map includes many libraries and makerspaces that may have 3D printers available for public use. You can also check this Google Map for libraries with 3D printers available.

Please note: It is very important that you work with your physician, occupational therapist, physical therapist or prosthetist when using a 3D printed open-source e-NABLE device.

ACCEPTANCE

By accepting any design, plan, component or assembly related to the so called “e-NABLE Hand” , I understand and agree that any such information or material furnished by any individual associated with the design team is furnished as is without representation or warranties of any kind, express or implied, and is intended to be a gift for the sole purpose of evaluating various design iterations, ideas and modifications. I understand that such improvements are intended to benefit individuals having specific disabilities and are not intended, and shall not be used, for commercial use. I further understand and agree that any individual associated with e-NABLE organization shall not be liable for any injuries or damages resulting from the use of any of the materials related to the e-NABLE hand.

Like this:

Like Loading...

Teenagers develop 3D-printed bionic arm 30 times cheaper than existing prosthetics

Article

Seeking to create affordable solutions for people with disabilities, Global GenU winning team eBionics developed a 3D-printed bionic arm which allows anyone to print and assemble it themselves.

Lisar Morina

UNICEF North Macedonia

28 January 2021

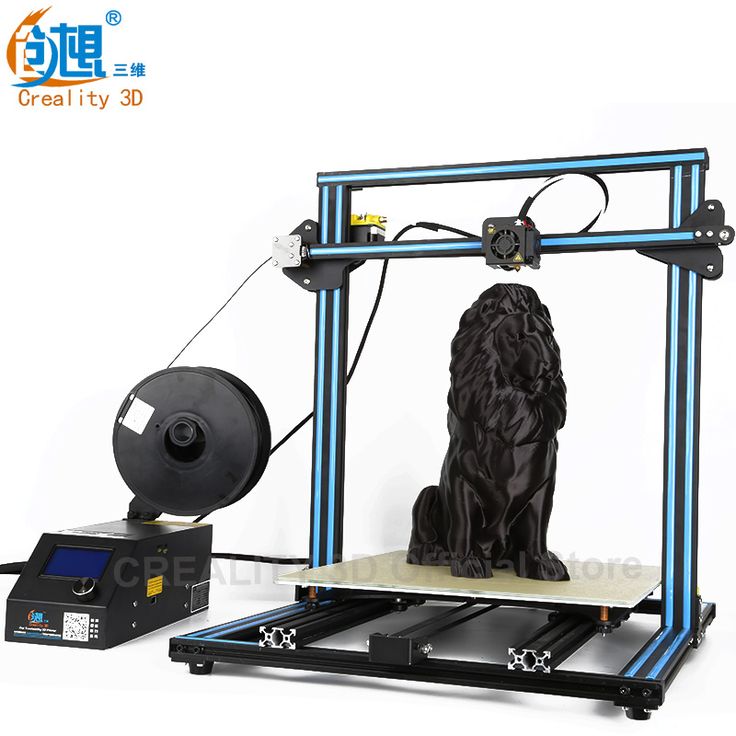

Skopje, North Macedonia – Somewhere in downtown Skopje, amid the purring of engines and honking of sirens, 17-year-old Boris meanders the many streets and alleys of the city to make his way into an inconspicuous building not far from the plaza. He steps into a small makeshift workshop lined with shelves full of odd machines, wrenches, screwdrivers, crates and canisters with labels of all kinds. Joining three other teenagers, he sits in front of a 3D printer. It is printing a prosthetic arm.

One glance suffices to realise that Boris and his friends are not just high-school students. They are also remarkable innovators with a zeal and fervor about their work that is contagious.

“People look differently at young innovators like us—they don’t believe that we are capable of creating impactful innovations that help people at large,” says Boris. “But we like to think differently. ”

”

Driven by a deep desire to create affordable solutions for people with disabilities, 17-year-old Boris Nocheski, 17-year-old Anamaria Ilieva, 16-year-old Teo Kitanovski, and 17-year-old Orhan Bahashov are using 3D printing technology to create a user-friendly bionic arm that is 1/30th of the price of existing prosthetics. And it can “grow” with children!

Globally, millions of people suffer from upper limb deficiencies, which can affect physical and mental health and inhibit people from leading productive lives. Prosthetic arms and artificial limbs can vastly improve the ability of people living with upper limb disabilities to be independent and engage in daily activities. But prosthetic limbs are expensive, need to be routinely replaced because of wear and tear, and are therefore out of reach for millions of people across the globe.

“Currently-available bionic arms are inaccessible—they cost thousands of dollars, can only be bought in a few developed countries, and must be continuously changed if you’re a young person, as your body is constantly growing,” says Boris, who is the co-founder of eBionics. “We believe that these problems can be solved by approaching the [bionic arm] technology differently.”

“We believe that these problems can be solved by approaching the [bionic arm] technology differently.”

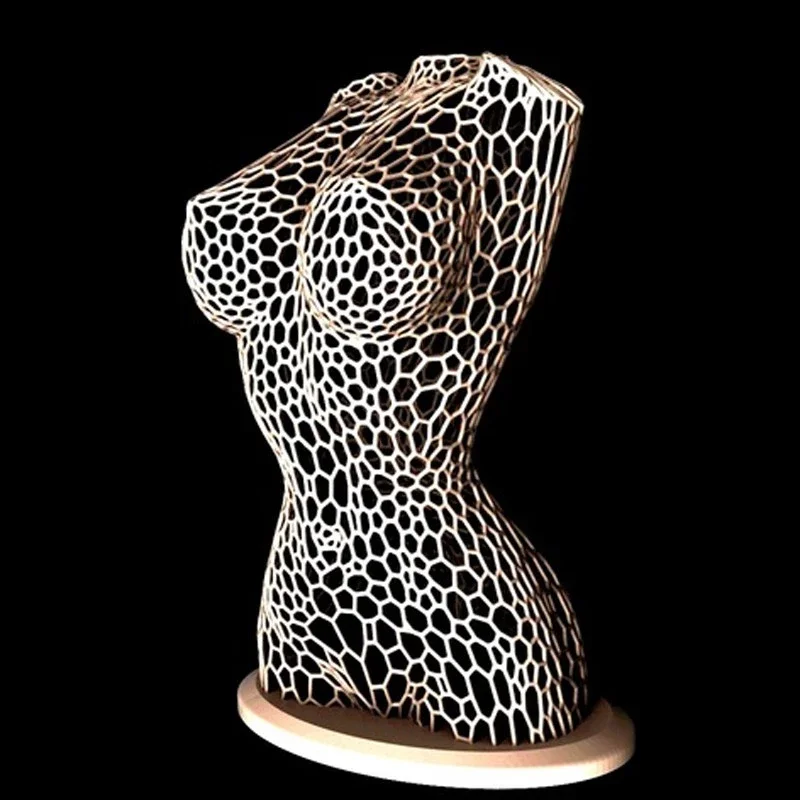

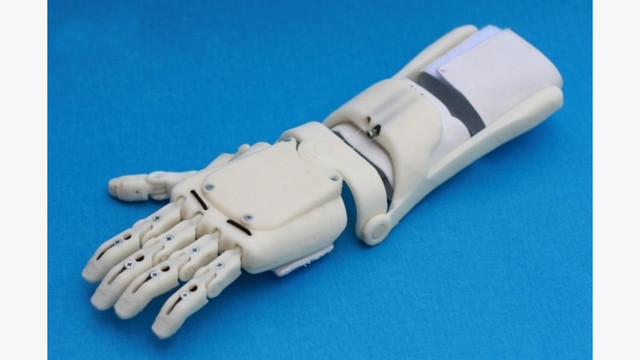

The eBionics ‘VenusArm’ is 30 times cheaper than the second cheapest bionic arm in the market. This is because Boris and his team do not charge for shipping or labor, or pay profits to suppliers. The VenusArm, Boris explains passionately, allows anyone with access to a 3D printer to print the bionic arm themselves within just a short hour, using the instructions made available on the eBionics website. The team have also provided options to purchase the individual parts from third-party sellers to assemble the arm themselves.

“Our VenusArm is entirely 3D printed and uses muscle sensors to allow for flexible movement that helps the user in everyday life,” says Boris, explaining that they also used an impression mold to create a universal socket, which means it will fit anyone, even growing children. “We want to make sure that people can get a fully functional bionic arm that is both affordable and available for everyone, regardless of where you are from. ”

”

Bionic arms pick up signals from the user around the same muscles (typically below the elbow) used to move a biological hand. Specially designed sensors pick up electric signals and use these to create hand movement relative to the electrical signal.

In a video, trying the bionic arm for the first time, a young woman from North Macedonia said, “Even on the first day, after only thirty minutes of wearing it, I started feeling it as part of my body.” The young woman is shown using the bionic arm to operate a sewing machine and even to drive a car, stating that she feels like she is in “complete control, now that she has the arm”.

From inception to incubation through Generation UnlimitedThe youngsters behind ‘eBionics’ developed the blueprint of the bionic arm—dubbed VenusArm—at the global Generation Unlimited Youth Challenge which took place in 36 countries, encouraging young people to design entrepreneurial solutions to social challenges.

The Youth Challenge is a true example of a multi-sector partnership initiative—engaging the private sector in mentorship, youth-led organizations in grass-roots outreach, young people in co-creating solutions, and governments in the judging process.

A few months after winning the local competition, eBionics was crowned a global Generation Unlimited Winner—just one of 8 teams across the world to receive further funding of up to $15,000, along with a tailored global incubation programme which is coordinated globally by UNICEF’s Office of Innovation, working with GenU partners and Country Offices.

“Step by step, we are getting closer to our goal—creating value for all people around the world, especially those who need it most” says Boris. “Every idea can bе accomplished if you work hard on it, with the right people around you. Steve Jobs once said that the people who are crazy enough to think they can change the world are the ones who do. Throughout our whole experience, we were motivated by this quote and we believe that other talented young people also should!”

“We feel that our story won’t be complete without thanking UNICEF and Foundation Telekom for Macedonia, the supporters of the Generation Unlimited Youth Challenge in North Macedonia, as well as SmartUp - Social Innovation Lab, the implementers of the challenge. Without their help it would've been much harder to succeed,” says Boris.

Without their help it would've been much harder to succeed,” says Boris.

EBionics’ vision is to create a user-generated sustainable and altruistic social enterprise with a worldwide community of makers, contributors and supporters, third-party partners, and most importantly, a business that provides affordable and reliable 3D printed bionic arms.

The

Generation Unlimited Youth Challenge 2019/20 is co-hosted globally by four Generation Unlimited partners – UNICEF, UNDP, Plan International and the World Organization of the Scout Movement, with support from Irish Aid

3D printed bionic prostheses from Unlimited Tomorrow

News

Artificial hands with six grips are created from individual 3D scans of patients and are offered for eight thousand dollars.

Unlimited Tomorrow is the brainchild of a young entrepreneur named Easton LaChapelle, who built his first remote-controlled robotic arm at the age of fourteen. Three years later, the now high school student was invited to the traditional school science fair at the White House after winning a competition at the Intel International Science and Technology Fair, and a year later, Easton joined forces with British designer and almost namesake Christopher Chappelle and launched his own startup, collecting the initial funding on the Kickstarter crowdfunding platform. nine0003

Easton is now twenty-four years old and leads a company that offers a ready-made commercial product - functional 3D printed prostheses. The idea of a startup was born back in his school years, when during one of the fairs, his attention was attracted by a girl who was carefully studying his booth with a robot. The girl was missing her right arm, and a rather simple electromechanical prosthesis with one grip replaced the limb. As it turned out, this miracle of technology cost parents eighty thousand dollars. nine0003

As it turned out, this miracle of technology cost parents eighty thousand dollars. nine0003

TrueLimb prostheses can hardly be called cheap either, but they are much more affordable in terms of affordability: Unlimited Tomorrow offers its products for $7,995 or in installments with monthly payments of $259, working directly with patients, without intermediaries, while the closest analogues cost about twenty thousand even with good health insurance. In addition, these hands are much more functional, being able to perform six different grips with individual finger control, and much more attractive to look at than many of the analogues. nine0003

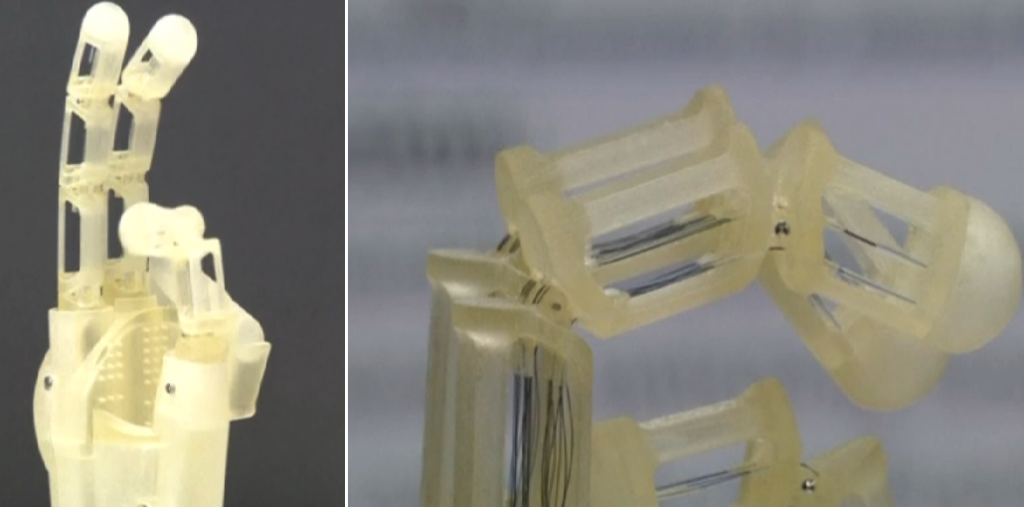

The size of the hand, color and detailing is chosen by the future user, who only needs to go through the 3D scanning procedure. Scanning can be performed at home: the company sends the necessary equipment and instructions to selected candidates. Then the company's engineers refine the 3D scans and use the resulting digital models to print components on a Hewlett Packard color 3D printer using Multi Jet Fusion technology. The minimum age of a candidate for prosthetics is seven years. nine0003

The minimum age of a candidate for prosthetics is seven years. nine0003

For now, the company is focusing on prosthetic arms, but is considering making artificial lower limbs and even exoskeletons. The most well-known Russian manufacturer of custom prostheses using 3D printing technologies is the Moscow company Motorika, which offers low-cost mechanical traction prostheses "Kibi", myoelectric prostheses "Indy" with one grip, and also working on bionic artificial hands "Manifesto" with fourteen grips. . Customers can count on compensation through the Social Security Fund. This summer, Motorika received the CE marking for all its products and announced its intention to enter the European market. nine0003

CNET publication on Unlimited Tomorrow:

YouBionic is the first 3D-printed bionic hand

News

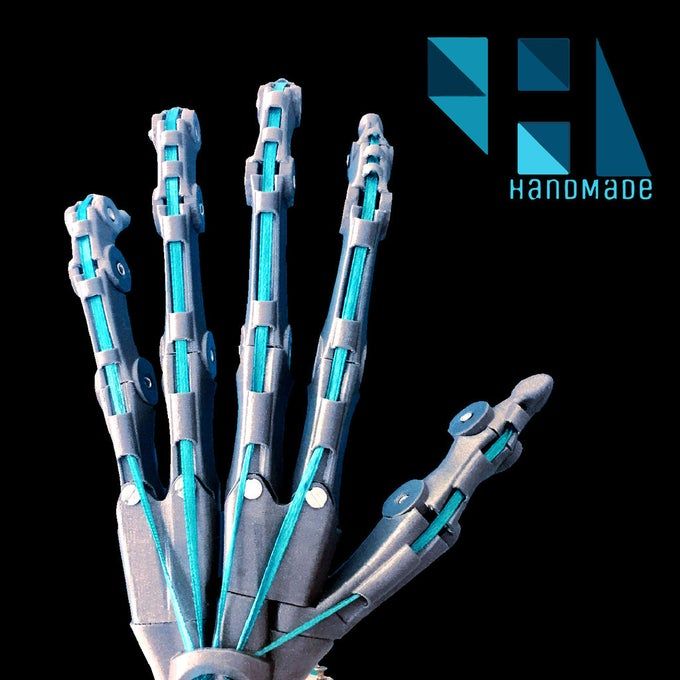

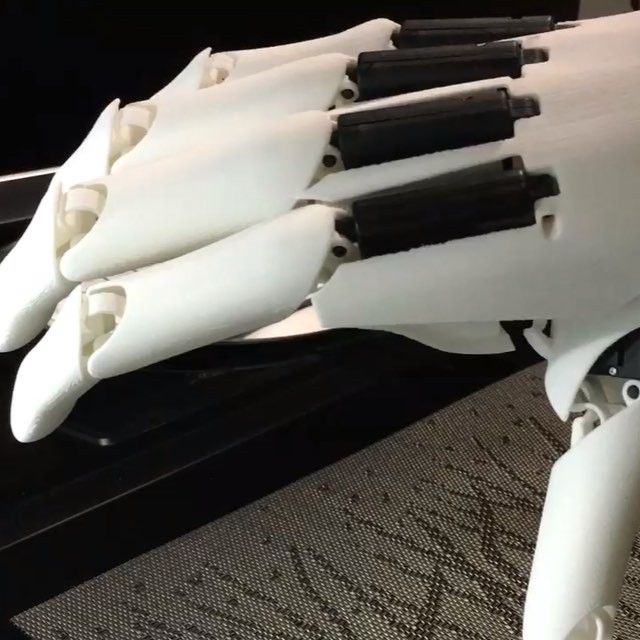

I remember once we told you about the YouBionic company, which was trying to print a bionic arm prosthesis controlled by Arduino.

Then the developers were still hard at work on the design and mechanism responsible for hand movements. And today the company announced that it had finally completed work on the first prototype. The prosthesis was printed from a flexible material using selective laser sintering, and its retail price was only 1000 euros. nine0003

Then the developers were still hard at work on the design and mechanism responsible for hand movements. And today the company announced that it had finally completed work on the first prototype. The prosthesis was printed from a flexible material using selective laser sintering, and its retail price was only 1000 euros. nine0003 We had a lot of news on our site about $50 prostheses created by members of the e-NABLE community. Yes, the YouBionic bionic prosthesis is more expensive, but it is much better.

e-NABLE prostheses are made using the most inexpensive consumer 3D printers, sometimes costing only a few hundred dollars. There are no electronics in e-NABLE prostheses, while YouBionic uses extremely complex computer systems that respond to signals from the user's brain and control hand movements. Both options have a great future, which depends solely on the desires and capabilities of the person for whom the prosthesis is intended. In any case, traditional prostheses cost $40,000 or more, so e-NABLE and YouBionic prostheses are certainly more affordable. nine0003

nine0003

“Youbionic's first prototype is capable of performing basic activities needed in daily life. Over time, it can be improved by updating the software, just like on a smartphone, explains Federico Ciccarese, founder of YouBionic. – Hand movements are based on complex internal geometric parameters, the creation of which has become possible only thanks to 3D printing technology, namely selective laser sintering technology. Before such technologies simply did not exist. It allows you to "deform the material." Each parameter, each movement of the prosthesis could be planned in advance, the required geometry could be laid for it. As a result, the need for assembly was minimal.” nine0057The Youbionic prosthesis is based on a skeletal structure, complete with rotating, moving and amplifying mechanisms. “A simple servo is responsible for the realistic movement of the prosthesis,” says Ciccarese. – Controlled by the Arduino board. All this, together with other components, allowed us to drop the price to 1000 euros.

”

YouBionic's goal is to make people's lives easier and help them avoid the awkwardness and embarrassment that usually comes with wearing a prosthetic arm. “I tried to make her movements as natural as possible and the design appealing to the eye,” says Ciccarese. nine0003

One of the key features of YouBionic is the ability to replace electronics, servos and 3D printed parts. Unlike adults, who rarely need a new prosthesis, children are constantly growing and their proportions are changing. In fact, they need to buy a new prosthesis every two years. However, insurance companies rarely agree to pay for children's prostheses, and every time they buy a prosthesis for $ 40,000 ... most parents simply cannot afford it. The cost of the YouBionic prosthesis is 40 times lower. In addition, its design can be changed as the child grows, so this is really the perfect solution to this problem.

Learn more