Mbot 3d printers

Software | MBot 3D Printer by Magicfirm

MPrint 2.0

Windows 7/10

MPrint 2.1.0

MAC

MPrint 2.0.10

Linux

MPrint

Windows Vista/Win7

MPrint 1.3.0.6

MAC

MPrint 1.2.3.6

User Guide

MPrint User Guide

Windows 7/10

Cura 4.6

MAC

Cura 4.6

User Manual

MBot Grid IV

User Manual English

MBot Grid IVs

Spark 3D Cloud quick start

ReplicatorG

Windows XP/Vista/Win7

MBot3D ReplicatorG Install for Windows

MAC

For Mac

Linux

For Linux

Firmware

Firmware

Sailfish 4.5 / 7.5 Release Notes

MBot3d's Firmware

Firmware updater

AvrdudeTool

USB Driver

Change Log

2019/12/23 MPrint 2.1.0

1. Change print setting panel, fix many bugs in setting;

2. Add Grid 2+, Grid 2+ Dual, Grid 4S, Grid 4 Dual, Grid Pro printers.

3. And Gcode Preview

4. Fix many bugs.

5. Upgrade slicer engine to latest version.

6. Add software update function.

2018/12/19 MPrint 2.0.10

1. Update new UI

2. Add T480S printer

2018/8/28

1. Add Grid 4 Dual, support dual head Grid 4 printer.

2018/8/23

1. New MPrint 2.0 release

2016/7/18

1. MPrint 1.3.0.6 is upgrade only for Windows OS

2. Added Slic3r Slicer. It only supports a single head

3. All MBot3D printer with motherboard Atmega 2560 able to print from PC via USB connection. MBot Grid II+ and MBot T480 will detecte automatically. Rest of other model need to select manually

4. MBotslicer and Slic3r both will show approximate the filament consumption and printing time

5. Added calibrate print size function

Added calibrate print size function

6. Added model viewing by holding right button on the mouse and move the mouse to view

7. Added cooling fan setting on MBotslicer

8. Creating custom profile bug is fixed

9. Optimize slicing and printing process

2016/3/7

1.MPrint 1.2.6.1 is upgrade only for Windows OS

2.The slicing engine is optimized, speeding up slicing by two times

3.Time estimation of slicing is deleted

4.Parameters of raft printing is optimiazed

2015/12/16

1.Add the new function building plate auto commissioning to MBot Grid II+ SH ex factory after Dec 2015

2.Renamed Grid M to Grid T480, and modified certain parameters

3.Added user manual and user help to software

4.Fixed several bugs

2015/10/29

1. The new version is for Windows

The new version is for Windows

2.Some printing paramaters are adjusted

3.Some bugs are fixed

2015/8/24

1.Fixed bug in maximizing models

2.Cube Dual(17) is available now

3.Models can be scaled at the original aspect-ratio even without "selecting all"

4.Fixed bug in the conflict between "selecting all" and "adding shortcut keys"

5.Fixed bug of immovability of extruder and plate when canceling online printing

6.Added reminder of checking a new version

7.Added machine dynamic configuration and display of the current machine type

8.Added GPX configuration file

9.No support to online printing from Cube and Grid II any more

2015/6/5

1. New function: parameter can be saved.

2. Bug fix: a suspend won’t ruin a online-printing .

3. Bug fix: easy change of param-set between single head and double head printing.

4. New function: Instant alert if the model extend beyond the operation interface.

5. New function: Fracture surface repair for Meshfix Model.

6. New function: printing pause when Z-axis reaches the determined position.

2015/4/20

1.Software is updated to Mprint1.1.0

2.Parameter is optimized, including the default parameters of printing temperature and switch of fans in specific printing stages.

3.The exported file generates a default name same as the input name.

PS: file of a single model is named as stl format, and file of multiple models is named as MultiMesh.x3g or MultiMesh.gcode format.

4.Precision of rotation angle reaches to 0.1degree.

5.Multiple models can be processed simultaneously, including moving, rotating, and scaling the models synchronously.

2015/3/24

1.New upgraded software Mprint 1.0.5 is accessible.

2.New functions of Cube series are added.

PS: Manual operation is needed for selecting Cube Series model here since the hardware don’t support automatic identification of Cube series yet.

3.Printing bug of Mbot Mini are fixed.

2015/2/10

1.Updated to MPrint 1.0.4

2.Fix bug:During building,the status bar stops at 99.9% while the print is completed actually.

3.Fix bug:Dialogue pops up below the main window.

4.Translation mistakes are fixed.

5.Support more machine models.

2014/12/5

1.Updated to MPrint 1.0.3 programming with C++.

2.New UI.

3.Automatically recognize connected printers.

Note: Recommend updating to MPrint1.0.3, in order to get better printing experience. It is in beta test, only the simplified Chinese version available. The connected printers with GRID2 firmware can be recognized, and will suppoort more soon. If it doesn't work, use ReplicatorG to generate GCode.

It is in beta test, only the simplified Chinese version available. The connected printers with GRID2 firmware can be recognized, and will suppoort more soon. If it doesn't work, use ReplicatorG to generate GCode.

2014/07/25

1. Fix GCoder generator error in Win32.

2. Fix Dual printing setting.

2014/07/13

1. Update mg fast gcode generator with a user friendly interface of configure.

2. New software boot splash image.

mCreate - Makeblock

mCreate

Smart leveling

versatile 3D printer

mCreate is a versatile desktop 3D printer featuring the innovative Genius smart leveling technology for accurate printing. Our patented smart nozzle, flexible magnetic build plate and the ability to resume working even after a power outage, enable mCreate to deliver a remarkable print success rate and quality. By quickly switching to the laser engraving mode, the machine meets the needs of a broader range of applications in STEAM education or other creative projects. Built for materializing creativity, mCreate makes ideas tangible.

Built for materializing creativity, mCreate makes ideas tangible.

mCreate

Software

Tech Specs

Video

Support

Contact us

Genius Smart Leveling

Patented Smart Nozzle

3D Printing & Laser Engraving

2-in-1 Design

220 × 220 × 295 mm

Large Build Volume

Flexible Magnetic Build Plate

Full-color Touch Screen

Resume Printing after

Power Outage

Support STEAM

Education

Make ideas tangible

What can mCreate do?

Materialize your ideas

Integrate new technologies for

a higher print success rate

Genius smart leveling creates accurate prints

With a build-in AI-powered detection module, mCreate can calculate the working plan with respect to the actual conditions of the print platform for reliable 3D printing.

Watch Genius smart leveling

Why is leveling a crucial step in 3D printing?

For 3D printing, the first layer is fundamental to the rest of the print. Thus, a precise leveling ensures a proper distance between the nozzle and the build plate to achieve an optimal first layer adhesion.

Thus, a precise leveling ensures a proper distance between the nozzle and the build plate to achieve an optimal first layer adhesion.

The traditional manual leveling is a cumbersome procedure, relying on experience with a risk of human error.

The auto-leveling failure is usually caused by the height difference between probe and nozzle, or the aging of the parts.

Patented smart nozzle makes printing better and steadier

- AI-powered detection module

- Quick-change nozzle

- Ultra-quiet cooling system

- Intelligent filament sensor

The printhead nozzle is equipped with a built-in AI-powered detection module and a smart leveling algorithm. In addition, mCreate supports one-button leveling and high-precision calibration.

您的浏览器不支持 video 标签。It takes only 3 seconds to remove and install a nozzle¹, making it easy to deal with a clogged printhead. Switching to the laser engraving mode is easy by replacing the laser head the same way.

The cooling system enables consistent shrinkage of finished products. Its ultra-quiet fan design makes printing quiet.

When the filament runs out or breaks accidentally, mCreate will suspend the task and issue an alert. The machine will resume working once the filament is refilled, thus preventing printing failure.

3 sec Change nozzles

360° Circular airflow cooling system

<45dB Quiet operation

Zero Almost zero print failure rate when out of filaments

Flexible magnetic build plate — supports wider ranges of materials, easy to remove prints upon completion

The build plate of mCreate is heatable, attaching a flexible magnetic sheet with a frosted surface. It gives better adhesion of the 3D print to prevent edge warping and curling. After printing, you can take off the magnetic build plate and remove the print easily without a scraper.

mCreate supports various 3ʳᵈ party 3D printing filaments, including PLA and its derivatives, TPU, PP, PVA, etc.

Resume printing after a power outage

The nozzle will rise instantly during a power outage, protecting the semi-finished print. After the power is back on, the nozzle will return to its initial position to heat up and then continue printing. This feature effectively minimizes print material and time losses due to power interruptions.

Switch to laser engraving mode for more creations

Deliver awesome laser engraving effortlessly

- Auto-recognition of operating modes

- Autofocus

- Grayscale engraving

- Three filters for image-editing

Turn mCreate into a laser engraver by replacing a laser head. The operating interface will automatically switch to laser engraving mode. By inserting a portable USB drive, the machine can directly read the files and process engraving without connecting to the software.

您的浏览器不支持 video 标签。mCreate can achieve an optimal focus automatically to make the engraving more refined.

The grayscale engraving mode improves shadow and highlight details of the original photos, which can create refined portraits or figures during the laser engraving process.

Grid filters | Black-and-white filters | Sketch filters

Offer three different engraving effects.

Laser engraving on curved surfaces

A large build volume allows mCreate to engrave curved surfaces of solid objects of a certain height. Laser engraving can also be used for creative designs on food like cakes and chocolate.

mCreate can engrave different materials, including paper, paperboard, wood board, corrugated paper, bamboo board, rubber board, leather, fabric, non-transparent acrylic, plastic, etc.

The laser engraving function is not available in Europe. Other regions please contact the local sales team for more details.

Versatile and user-friendly operating tools

- 3D printing

- Laser engraving

Preset default

slicing value

Run the 3D slicing software called Cura, then install the plug-in for mCreate, and select “Makeblock” as the print device; the printing parameters will then be configured automatically. When Cura finishes slicing your model, it is ready for printing.

When Cura finishes slicing your model, it is ready for printing.

Powerful laser

engraving software

With the software “Laserbox for mCreate”, you can process images, configure the engraving area and parameters, plan the optimal engraving pathway for each project, etc.

Design software: Photoshop, Illustrator, CorelDRAW, AutoCAD, AutoDraw, Solidworks, etc.

File formats: DXF, SVG, JPG, PNG, BMP, CR2, etc.

Full-color touchscreen for better workflow visualization

- 3.5-inch color touchscreen

- Clear and intuitive function icons

- Real-time display of device status and job status

- Direct launch of printing jobs or update of firmware

- Support file search and preview

- Default OS languages are English & Chinese, yet can be set to two other OS languages.

Support STEAM education —

In and out of class

Creating fun projects

By working with the mBuild electronic modules, students can use mCreate to build

parts for their smart home prototype designs or robot design. Hands-on skills and

Hands-on skills and

creative thinking made easy in a learning-by-doing manner.

Learn More

Empowering education

Better learning and teaching in today’s classroom

mCreate turns abstract 3D concepts into visible and tangible prints, which

facilitate learning and teaching on STEAM-related areas in K-12 curriculums, e.g. 3D modeling, spatial intelligence, etc.

Meet the needs of robotics competitions and maker activities

Students can make use of mCreate to manufacture particular parts for

robotics competitions or other maker events. By this, they are developing

their hands-on skills and problem-solving abilities.

Offer professional support for vocational and higher education

mCreate brings creative ideas or industrial designs in the form of blueprints

to life, boosting students’creativity and preparing them for future careers.

More features

Aircraft-grade aluminum frameSolid all-metal frame minimizes vibration, making printing more stable. Its stunning design is also corrosion-resistant and durable.

Its stunning design is also corrosion-resistant and durable.

High printing precision, suitable for producing quasi-industrial grade parts.

Clog detectionCheck whether the nozzle is clogged during operation.

Open filament systemSupport 3ʳᵈ party 3D printing filaments. We recommend using filaments from brands eSun and Innofil.

Multiple connection modesSupports 3D printing or laser engraving via a USB drive. Printing jobs can also be sent to mCreate via the software Cura or Laserbox for mCreate.

Tech Specs

3D printing

Additive Manufacturing Process

Build Volume

(L × W × D)

Layer Resolution

Slicing software

Supported File Type(s)

File Extension

Supported Materials

Nozzle Temperature

Heated Bed

Fused Deposition Modeling

220 × 220 × 295 mm

50-300μm

STL, OBJ, X3D, 3MF, JPG, PNG, GIF, BMP, etc.

PLA and derivatives, TPU, PP, PVA, etc.

260°C(Max.)

80°C(Max.)

Laser

engraving

Work Area

Laser Power

Software (Laser Engraving)

File Type(s)

Material capability

225 × 225 mm

Laserbox for mCreate

SVG, DXF, JPG, JPEG, PNG, BMP, PDF, TIF, CR2, etc.

Paper, wood, bamboo, rubber, leather, fabric, acrylic, anodized metal, painted metal plastic, etc.

Full Tech Specs

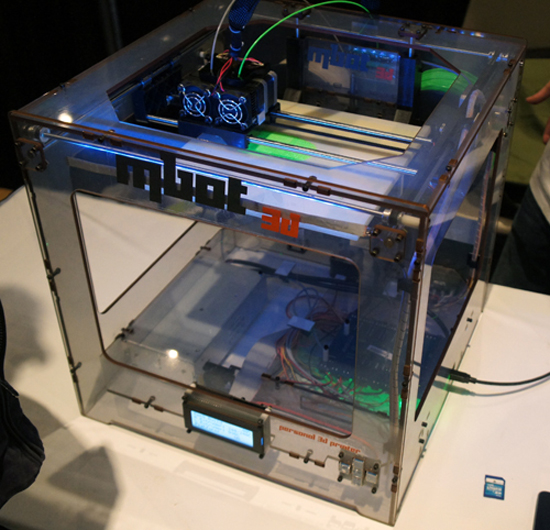

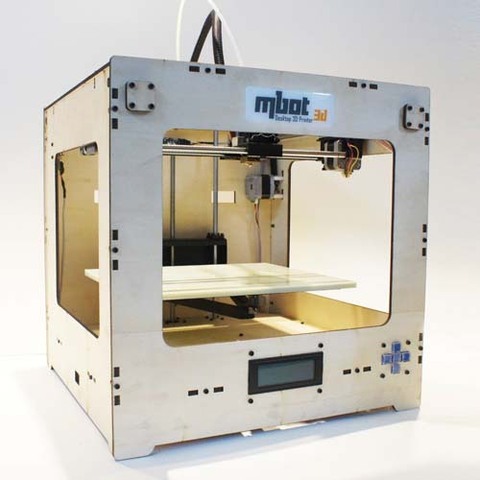

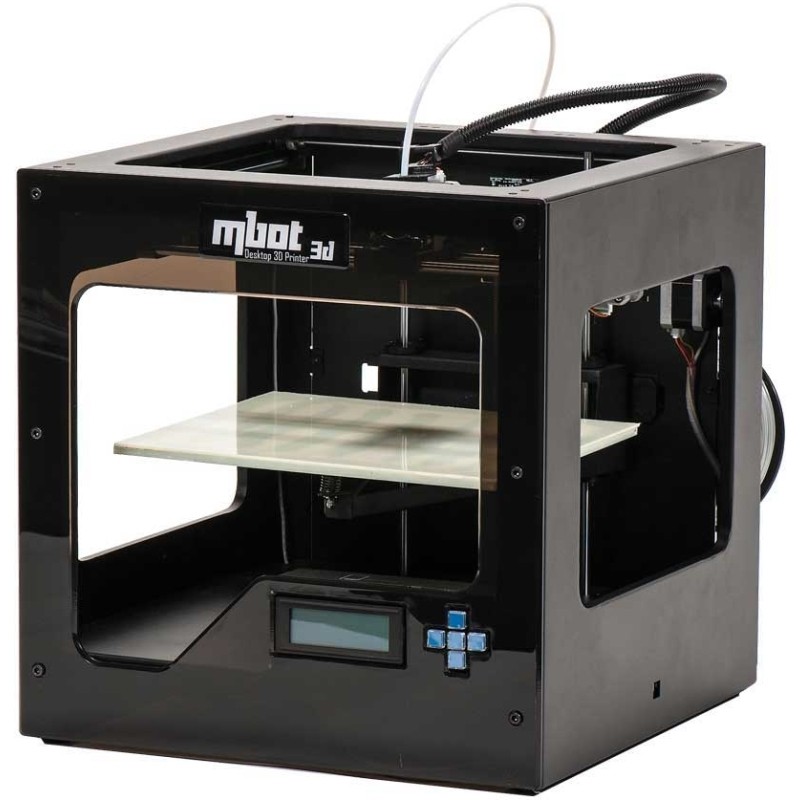

Review of MBot

home 3D printersArchive

. In this review, three models will be considered - MBot Printer PVC Color System, MBot 3D-Printer and MBotII. It is worth noting that all three 3D printers have one important advantage - this is a relatively low price for a quality home device. Let's start our review to know the details of the technical specifications of each device. nine0003

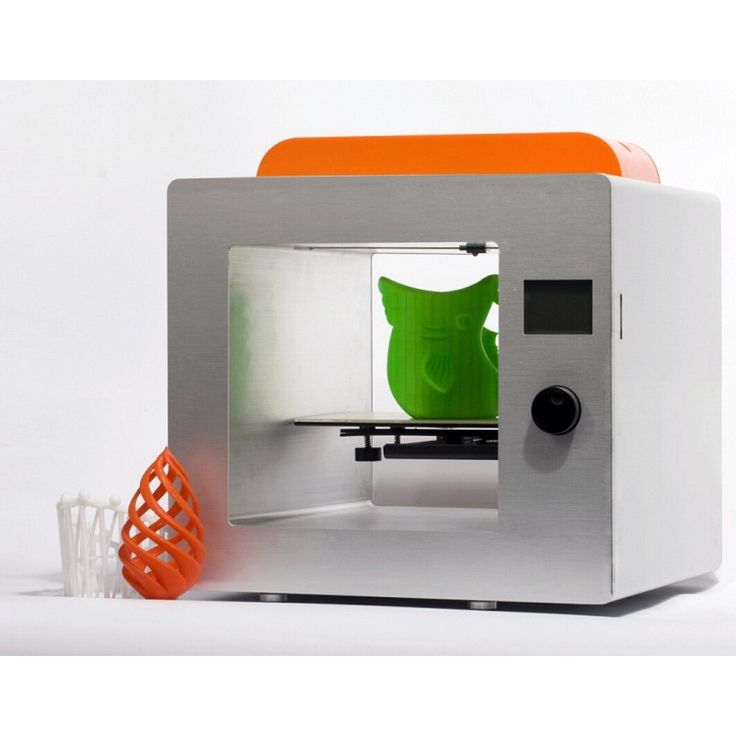

MBot Printer PVC Color System

Let's start with the MBot Printer PVC Color System, which is currently sold out.

This model is the progenitor of other products of this company. Why might this printer model be attractive to a potential client? We offer to take everything apart:

- The print area of the device is as much as 200x200x200 mm. In addition, the manufacturer offers modern software for the smooth operation of the printer. nine0022

- Most modern 3D printers can print in one color, however MBot can use two extruders at once, connected to its own consumable source. The two extruders work great together.

- The same two extruders allow you to use both the main consumable and the support material. This technology allows you to print objects with complex geometry.

- Equipped with an improved composite alloy printhead that can be easily removed and installed. nine0022

Let's pay attention to the specifications of MBot printer PVC 3D printer:

4 mm

4 mm Home printer called MBot Printer for $999

This product was developed by MagicfilmLLC and is currently one of the most affordable home 3D printers on the market. In fact, this model is an improved version of its predecessor - it has the same technical characteristics as the PVC model. Among the technical characteristics, it should be noted the presence of two extruders, a built-in touch screen and an SD card slot. It is also worth noting that this 3D printer model was created based on the Replicator 2 3D printer from MakerBot. Specifications are the same as MBot printer PVC. nine0003

Specifications are the same as MBot printer PVC. nine0003

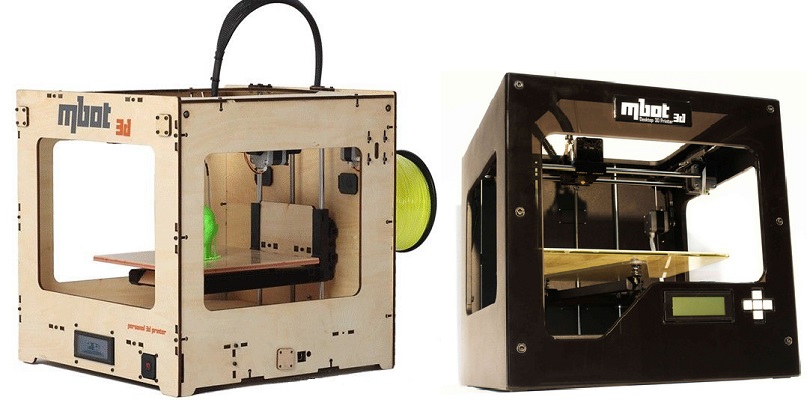

$1399 CubeII home printer

Another home printer option from MBot is the $1399 CubeII device, which was manufactured by MagicFilmLLC.

The device is also affordable in terms of price and one of the main advantages of the printer is the ability to print in two colors. This model differs from its predecessor, the Cube model, and offers more options for the modern enthusiast. This device for three-dimensional printing can be described in three words - the printer is higher, better and faster. The print area has been increased and will allow the wearer to print large objects. The developers have added a new holder in order to increase the accuracy of printing. The surface on which the object is recreated can now be removed and cleaned of dirt and remaining consumables. Print speed has also been increased. Let's take a look at the specifications of MBot's CubeII 3D printer:

Let's take a look at the specifications of MBot's CubeII 3D printer:

- Printer dimensions 405x405x410 mm

- Print area 260x230x200 mm

- Print speed 100mm/s (50% faster than most other home printers)

- Uses ReplicatorG software

- File Format - STL

- Compatible with WindowsXP/7, Linux and MacOSX

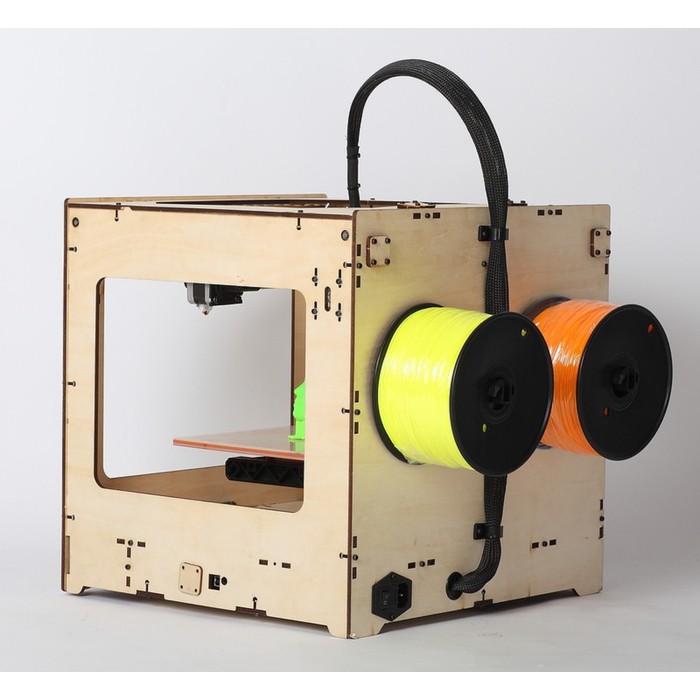

MBot Printer Kit for $669

In addition to these three models on the MBot website, you can find the MBot Printer Kit, which is a disassembled version of the MBot Cube. IKEA style assembly instructions included. The cost of such pleasure is 669$

All MBot printers can be ordered on the manufacturer's website: http://www.mbot3d.com

Our review has come to an end, but we will still delight our readers with interesting and useful information about high-quality products from modern 3D printer manufacturers.

Subscribe to author

Subscribe

Don't want

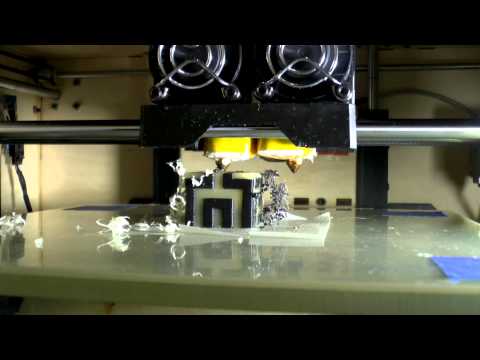

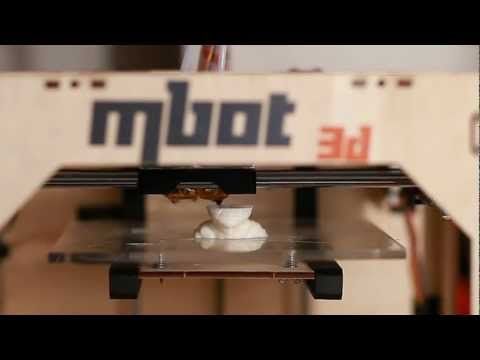

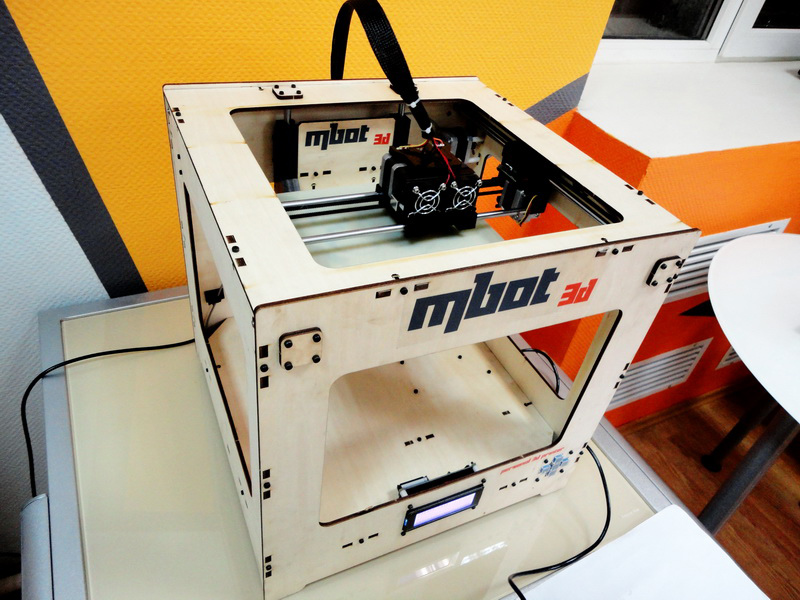

Chinese 3D printer repair (Mbot and Mbot Cube II)

At different times, we had two 3D printers from MBot3D in our office, and we had to tinker with them. Next, we will talk about the problems that arose and were successfully resolved. nine0003

Next, we will talk about the problems that arose and were successfully resolved. nine0003

The 3D printers of the Chinese company Mbot are clones of the American Replicator printer from MakerBot. We got the Mbot Cube Double Head and Mbot Cube II. And in both cases, I had to delve into the mechanics and software.

Soft.

The official website of the manufacturer claims support for OSX, Linux and Windows and printing through the ReplicatorG program, for which machine profiles are posted on the site. We did not have a chance to try printing on Linux, everything works very well on Windows, but ReplicatorG under OSX with profiles from the manufacturer refused to work correctly. nine0003

Since these printers are based on the MakerBot MightyBoard, and the printers themselves consider themselves The Replicator Dual (this is how they are defined when connected to a computer, and the Mbot Cube of the first model with factory firmware 6.2 even shamelessly writes this on its display), a decision was made adapt MakerWare to print on Mbot'ax.

The main problem that we encountered in this issue is the mismatch in the size of the area for printing. Due to the fact that the Replicator's print area is longer (225x145x150mm) than the Mbot's (claimed 200x200x200mm), the Mbot's printhead hit the left edge of the printer when it started printing. To avoid this problem, we changed the profile settings for RepicatorDual in MakerWare, which are written in a *.json file on OSX, they are located in Macintosh HD > Libraries > MakerWare > s3g > profiles nine0003

The file itself is modified in a standard text editor (you need to make sure that the *.txt extension is not added to the file name). In the profile file, we change the dimensions of the platform (and the starting point, if necessary).

The file is saved to the original folder, after which in the MakerWare program you need to execute the command from the top menu Services > Restart Background Service and we will see the changed working field on the screen.

After that, you can safely print without fear that the printer will beat itself. nine0003

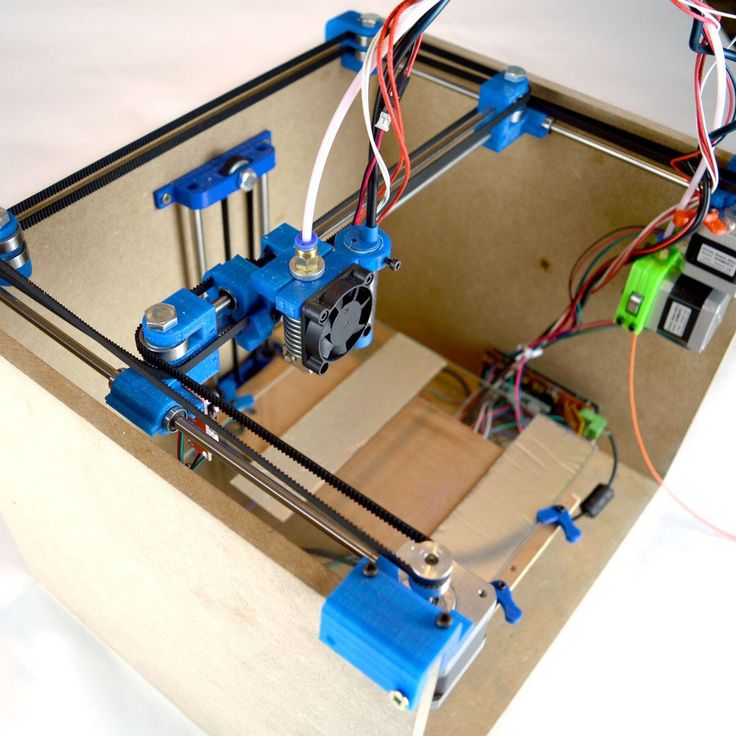

Mechanics

This is not to say that Mbot printers are assembled very poorly, but for stable operation, you will need to customize the printer for yourself.

The greatest number of problems arose with the first generation Mbot Cube printer.

It was a surprise that after aligning the nozzles in height, it was not possible to assemble the print head back, as the tube receiving the plastic began to rest against the clamping mechanism. nine0003

Plus, the clamping mechanism itself was copied

from earlier versions of the Replicator and did not provide for such a clamp, so it was immediately replaced with a clamping mechanism with a spring.

And the platform (which, by the way, unlike the Replicator, has no heating) turned out to be Curve (!!) and was urgently replaced with an MDF platform + a mirror.