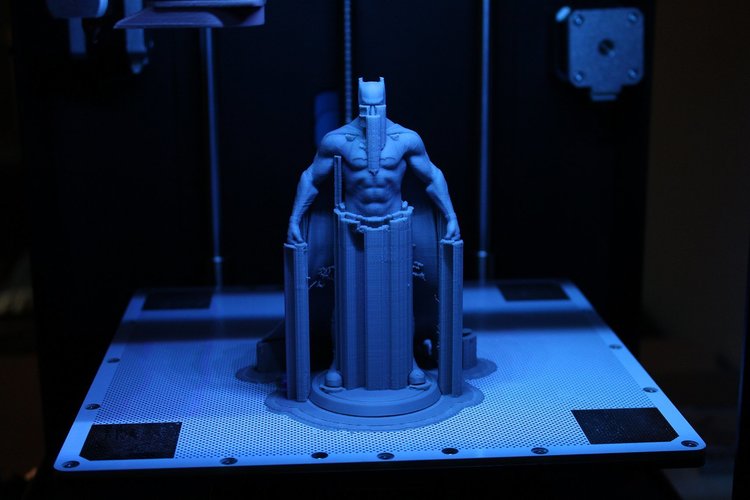

Anycubic 3d printing uv sensitive resin

3D Printing Resin for LCD/ DLP/ SLA 3D Printer – ANYCUBIC 3D Printing

3D Printing Resin for LCD/ DLP/ SLA 3D Printer | Anycubic Eco-friendly Resin – ANYCUBIC 3D Printing Skip to contentSort SortFeaturedBest sellingAlphabetically, A-ZAlphabetically, Z-APrice, low to highPrice, high to lowDate, old to newDate, new to old

- [Christmas Sale!] Mystery Box🎁

- Colored UV Resin

- Plant-based UV Resin

- UV Tough Resin

- DLP Craftsman Resin

- Water-Wash Resin+

- Standard Resin+

- ABS-Like Resin+

- ABS-Like Resin Pro

Save $18

Quick view

{Get 3 for the price of 2} Colored UV Resin 3-6KG Package

ANYCUBIC

Regular price $97.00 Sale price from $79. 00

Save $31

Quick view

{Get 3 for the price of 2} Anycubic Plant-based UV Resin 3-6KG Package

ANYCUBIC

Regular price $110.00 Sale price from $79.00

Save $38

Quick view

{Get 3 for the price of 2} Anycubic Standard Resin+ 1.5KG

ANYCUBIC

Regular price $76.00 Sale price from $38.00

Save $1

Quick view

Anycubic Standard Resin+ Package

ANYCUBIC

Regular price $36.00 Sale price from $35.00

Save $19

Quick view

Anycubic Water-Wash Resin+ Package

ANYCUBIC

Regular price $78.00 Sale price from $59.00

Save $60

Quick view

Anycubic UV Tough Resin Package

ANYCUBIC

Regular price $120.00 Sale price from $60. 00

00

Save $3

Quick view

Anycubic DLP Craftsman Resin Package

ANYCUBIC

Regular price $43.00 Sale price from $40.00

Save $18

Quick view

Anycubic Plant-based UV Resin+ Package

ANYCUBIC

Regular price $78.00 Sale price from $60.00

Save $17

Quick view

Anycubic ABS-Like Resin+ Package

ANYCUBIC

Regular price $76.00 Sale price from $59.00

Save $35

Quick view

{Get 3 for the price of 2} Anycubic Water-Wash Resin+

ANYCUBIC

Regular price $70.00 Sale price from $35.00

Quick view

{Get 3 for the price of 2} Anycubic Standard Resin+

ANYCUBIC

$36.00

Save $32

Quick view

{Get 3 for the price of 2} Anycubic ABS-Like Resin+

ANYCUBIC

Regular price $66. 00 Sale price from $34.00

00 Sale price from $34.00

Save $42.99

Quick view

{Get 3 for the price of 2} Anycubic Plant-based UV Resin 1KG

ANYCUBIC

Regular price $69.99 Sale price from $27.00

Save $41.99

Quick view

{Get 3 for the price of 2} Colored UV Resin 1KG

ANYCUBIC

Regular price $68.99 Sale price from $27.00

Save $37

Quick view

{Get 3 for the price of 2} Anycubic Plant-based UV Resin+

ANYCUBIC

Regular price $74.00 Sale price from $37.00

Save $42

Quick view

{Get 3 for the price of 2} Anycubic ABS-Like Resin Pro

ANYCUBIC

Regular price $84.00 Sale price from $42.00

Quick view

{Get 3 for the price of 2} Translucent UV Resin

ANYCUBIC

from $27. 00

00

Quick view

{Get 2 for the price of 1} Anycubic UV Tough Resin

ANYCUBIC

from $60.00

Save $40

Quick view

{Get 3 for the price of 2} Anycubic DLP Craftsman Resin

ANYCUBIC

Regular price $80.00 Sale price from $40.00

Clear UV Resin for Casting and DIY Project – ANYCUBIC 3D Printing

Get 3 for the price of 2, coupon code: B2G1

Please note that the code will be applied successfully, more than 3 bottles of Resin must be ordered.

- Professional LCD molding resin. Optimize the formation of LCD low light source and printing efficiency is higher than the market compatible DLP / LCD / SLA resin. The resin is only designed for the LCD model of the resin, not recommended DLP or LCD machine.

- High-speed solidify. This resin ensures the strength of molded parts and not excessive shrinkage, but also improve print speed, shorten the curing time and enhance the printing efficiency of LCD machines as much as possible.

- Strong adhesion of the model and easy to detach after forming. Not only high success rate of printing and precision, but also to minimize resin release force and adhesion, so that the model attached to the forming platform can easily shovel and low viscosity makes it easier to clean the machine and model.

- The material is rigid and tough. Strong material in the shovel model can easily lead to the model fragmentation, but too flexible material will be prone to the details of the print tensile deformation or fracture, which will affect the molding accuracy and aesthetics.

- Model's performance is stable. The resin is stable under different climatic conditions and is also easy to store, overcoming the shortcomings of other resins easily damp softening and environmental corrosion

Product Description

Parameter information:

- Main material: resin monomer & photo initiator

- Exposure parameters: Bottom exposure time(s) 20-60s, normal exposure time(s) 5-15s

Precautions:

- Storage method:

- Keep away from light seals at room temperature.

(Sunshine contains a lot of UV light, will solidify photosensitive resin. After testing, the light is not affected as long as it is not UV light).

(Sunshine contains a lot of UV light, will solidify photosensitive resin. After testing, the light is not affected as long as it is not UV light). - It is recommended to save at 15 ℃ -35 ℃ ambient temperature, the lower the temperature, the higher the viscosity of the resin. Sealed storage, excessive dust or moisture can affect print quality. Sunshine contains a lot of UV light, will solidify photosensitive resin.

- Usage:

- Shake well before use, prohibiting the use of resin in places where there is a lot of sunlight.

- Wear gloves before use to avoid direct contact with the skin and keep the room ventilated.

- Inadvertent contact, as soon as possible to use a lot of water rinse. If you feel unwell, seek timely medical attention.

- Printed models need to use high-concentration alcohol to clean about 30S (recommended concentration of 95% or more, the higher the better).

- Do not pour the resin in the resin vat into the unused resin, do not leave the resin in the resin vat for a long time without use to avoid resin pollution affect the printing effect(long time without the resin can be introduced into airtight containers or sealed with plastic wrap shading save).

The ANYCUBIC resin is most suitable for the Photon /Photon S 3D printer.

The light source design, exposure time and other printing parameters of different brands of LCD 3D printers are different.The resin composition ratio of ANYCUBIC designed for the photon is special , it is the most consistent with resin photon print parameter.

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries: nine0053

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning. nine0053

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface. nine0053

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable. nine0053

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes. nine0053

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance. nine0053

nine0053

Pros:

Cons:

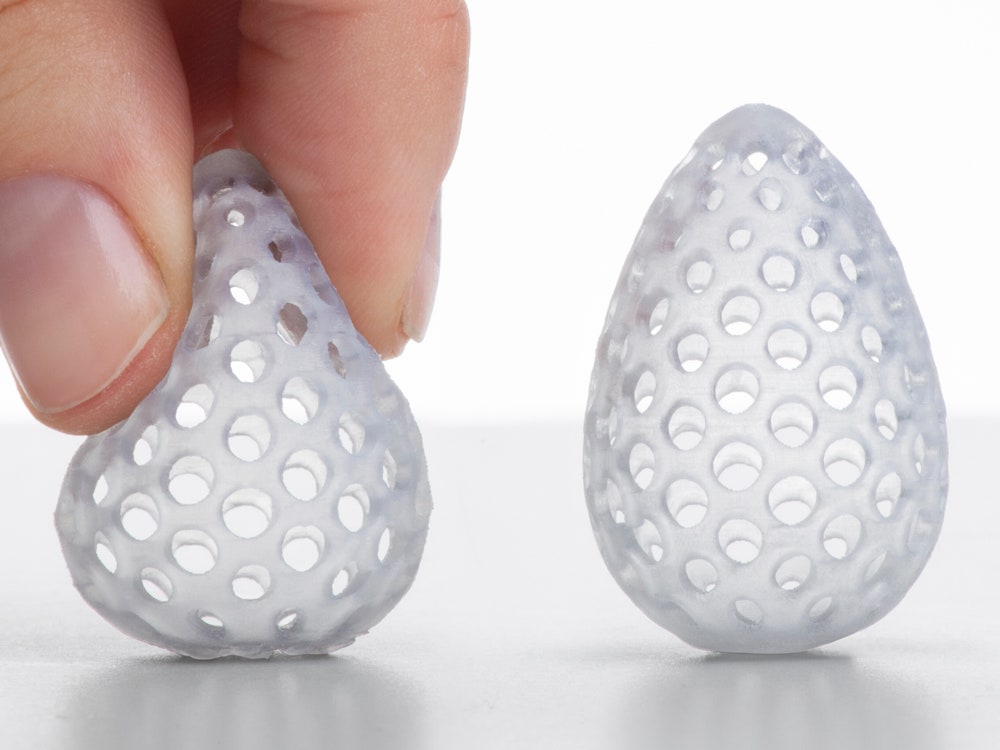

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips. nine0053

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber nine0053

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping. nine0053

nine0053

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

nine0053

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models. nine0053

nine0053

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness. nine0053

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity. nine0053

nine0053

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs nine0053

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

0114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price nine0053

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin nine0053

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds nine0053

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Cast resin allows you to get the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

nine0113 Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you! nine0053

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

INSTAGRAM nine0053

In contact with

My Favorite 3D Printing Resin Washing and Curing Station

Contents

Oh-ho-ho! For those of us using resin 3D printers, things get easier. If you're new to printing with resin, the bottom line is this:

If you're new to printing with resin, the bottom line is this:

After you've printed your model, you need to rinse it to remove excess resin, and then cure it with UV light. Ideally, you want to limit exposure to uncured resin. nine0053

I recently got an EPAX X1 3D printer and everything I used to wash and cure my prints was handmade.

I used a cucumber basket to wash the prints in alcohol. To be honest, I still use it to do the initial dipping of prints before putting them in the washer.

I used either the sun or a bad UV lamp for curing. I had to flip the print over to get it cured on all sides. nine0053

If you're on a tight budget, you can get by with these items. I'm sure you can even make a cool curing station yourself.

If you want everything to run smoothly and be much easier, safer and cleaner, get a rinsing and curing station.

My favorite all-in-one machine is the Elegoo Mercury. Although in reality they are all the same.

Wash station makes prints much cleaner than my pickle basket. The curing station has a fashionable turntable and the prints cure quickly and evenly. nine0053

The curing station has a fashionable turntable and the prints cure quickly and evenly. nine0053

With this thing, I would never go back to manual washing and curing. For me, it paid off in terms of time savings and quality prints.

The prints just look and feel better when they are passed through the station! (P.S. I'm lazy and this is much easier).

So let's move on to your options and my thoughts:

The Best All-In-One Wash and Curing Stations

The easiest way to finish your resin 3D printing is to use an all-in-one wash and cure station. nine0053

These devices wash the print in a cleaning solution and then cure the form with UV light.

Elegoo Mercury

The Elegoo Mercury Plus 2-in-1 Wash and Curing Station allows you to complete your 3D printing with one machine.

This option is compatible with most SLA/DLP/LCD 3D printers including Elegoo, Mars or Photon.

However, please note that when using a washable water resin, it is better to rinse the model under running water rather than using this self-cleaning device. nine0053

nine0053

This station makes it easy to clean models, either individually or together, with the included assembly plate, which prevents contact with uncured resin.

You can adjust the height of the bracket according to the amount of liquid in the bucket.

Curing takes place with UV lamps (eight 385nm and eight 405nm) and a 360° rotatable turntable for even curing.

You can keep track of curing times thanks to the 0.96" TFT LCD screen.

Set the timer from 0 to 30 minutes or set the machine for washing or curing with simple buttons on the front panel.

If the lid is lifted during operation, the machine switches off automatically and emits a shrill beep.

When closed, the lid blocks 99.95% of UV rays for maximum eye protection.

This combination station has a maximum wash volume of 125 x 85 x 160 mm and a maximum curing limit of 140 x 165 mm. nine0053

Pros:

- Wash/curing combination allows one machine to be used.

- 360° rotatable turntable ensures even curing.

- 0.96 inch LCD screen makes it easy to keep track of the remaining time.

- UV protection through lid.

- Multiple UV lamp beads make curing quick and easy.

Cons:

- Not suitable for washing 3D models that use water-washable resins. nine0006

- Limited to 30 minutes rinse or cure.

Anycubic

The Anycubic Wash and Curing Station is equipped with a 360° rotating turntable with built-in UV lamps (405 nanometers), bottom reflector and no dead ends for thorough curing.

At the bottom of the station, a propeller causes the solution to form a tornado funnel that reverses direction halfway through the wash cycle to ensure your print is thoroughly cleaned. nine0053

Cleaning can be done by placing the model directly in the basket or by hanging it on a stand or basket.

The timer can be set from one to 60 minutes using the rotary knob, allowing you to set the wash and cure times for individual projects.

Although the lid is transparent, it blocks out up to 99.95% of UV rays, ensuring safe operation and fast curing of the resin.

Compatible with most SLA/DLP/LCD 3D printers, including NOVA, Mars, QIDI Shadow and other resin printers, the Anycubic station helps simplify the process of creating 3D models while saving space. nine0053

This station has a maximum flush size of 120 x 74 x 165 millimeters and a maximum curing limit of 140 x 165 millimeters.

Pros:

- Anti-UV hood blocks most UV rays.

- Works with most 3D printers.

- Propeller washer provides better cleaning.

- The timer operates up to 60 minutes, which allows you to increase the washing and polymerization time.

Cons:

- A strong wash cycle can damage small parts.

Creality Washing and Curing Machine

The Creality All-in-One Washing and Curing Station uses two rows of 18 dual-range 385nm and 405nm lamps plus nine LED lamps to cure 3D prints.

Rotating platform with 360° reflective coating increases curing time due to a larger irradiation area.

Safety features include an automatic stop if the lid is opened during curing, a secure lid that allows cleaning solution to be reused, and a cleaning fan that reduces odors. nine0053

With this machine you get a large washing basket measuring 190 x 154 x 200 millimeters, capable of cleaning large structures.

You can use the wash basket to store your models separately or wash them all together using the build platform. The platform is regulated.

Another significant advantage is the ability to adjust the timer from two to 90 minutes for washing and curing.

The large LED touch screen allows you to set the washing or curing control, speed and time. nine0053

The speed can be selected from fast, normal or slow. Slow mode prevents fragile products from being damaged by strong impact.

Pros:

- Three speeds.

- Individual wash/treat time up to 90 minutes.

- Adjustable platform.

- Largest container for big projects.

Cons:

- Noisy operation.

3D resin curing stations

Some people prefer to use DIY or separate washing and curing stations. Resin models require a UV light source for proper curing.

Curing stations have built-in LED lights that allow models to cure faster than if they were in the sun.

They also block UV rays from escaping from the inside. Some of them have a reflective inner surface to increase cure time. nine0053

Elegoo

The Elegoo mercury curing machine is equipped with a turntable that works by absorbing UV light instead of batteries and an LED screen to keep track of the remaining curing time.

Inside the machine, a reflective sheet focuses the light from two 405nm LED strips (14 LEDs in total) for stronger and faster curing.

You can set the time from 0 seconds to 9 1/2 minutes. nine0053

The through window allows you to observe the polymerization process, while blocking ultraviolet rays, which ensures safe operation.

Overall canister size is 5.90" (150mm) long x 8.66" (30mm) high with a maximum cure limit of 142" (150mm).

3.9" long, 1.81" high handle for easy transport.

Pluses:

- The turntable rotates without batteries. nine0006

- 14 LED lights provide faster curing.

- Adjustable cure time.

Cons:

- Cure time limited to 9 1/2 minutes.

Sunlu

This UV resin curing unit from Sunlu is compatible with standard 405nm DLP, LCD or SLA 3D printer resins.

This curing unit has six 405nm UV lamps in a single strip that provide a 360° rotating turntable at approximately 10 revolutions per minute. nine0053

The timer can be set from one second to six minutes. The optical filter does not allow ultraviolet rays to go beyond the box.

The outer box is 9" high by 9.2" long by 6.1" high by 6.6" long by 8" deep. The player has a diameter of 4.72 inches.

Pros:

- Cure time adjustable from zero to 6 minutes.

- Optical filter blocks 90% of UV rays. nine0005 Fast curing.

Cons:

- One row of LED lamps may cure unevenly.

3D Resin Wash Station

3D resin prints require post-print cleaning to remove debris, dust, and excess detail.

Special wash stations make it easy to clean prints without the use of hazardous chemicals.

In addition, the wash stations allow you to reuse the cleaning solution in the future for additional projects. nine0053

Sovol Dedicated Wash Station

Sovol manufactures a dedicated wash station that is compatible with Sovol (or other brands) curing machines to create perfectly finished prints.

Cleaning basket holds your molds while washing. There is currently no way to install mold hanger brackets to reduce resin exposure.

7.2W motor creates a funnel that gently cleans the plate without damaging sensitive or fine prints. nine0053

The size of this cleaner is limited to 150 x 110 x 180 mm.

Simple push-button control, choice of five, 10 or 15 minutes, but does not allow precise minutes or seconds to be set.

Pros:

- Funnel wash gently cleans prints.

- The basket is adjustable to hold its shape while cleaning.

- Accommodates large projects.

Cons:

- It is not possible to set the exact flush time in seconds or minutes. nine0006

Lock & Lock Pickle Container

If buying a custom washer isn't your plan, you can DIY your own with this Pickle Container from Lock & Lock.

You will also need isopropyl alcohol (IPA) - 90% minimum.

This is a cheap DIY solution that can be used to wash prints in isopropyl alcohol.

Fill container with IPA, add your model and leave for three minutes. nine0053

Pros:

- Easy DIY solution.

- Affordable.

Cons:

- Needs to work with alcohol.

Related questions:

What is used to wash and clean resin 3D prints?

There are several ways to wash and clean 3D resin prints.