3D molecular printer

AI-Driven Molecular 3D Printing On the Way?

Remember the early days, when 3D printing was just becoming mainstream?

“It’s like a Star Trek replicator!” they said. “Everyone can make anything! It’s like a factory in your house!”.

A decade of crappy plastic novelties later, and desktop printing finally began its crawl up to the plateau of productivity. In terms of science fiction, it missed the mark.

But what if you could reorganise matter, not on the atomic level from thin air (like Star Trek’s matter-energy converting replicators), but on a molecular level? That sounds a little more like a replicator, right?

A team of researchers have apparently come one small step closer to realizing that sci-fi promise, and have released a paper detailing efforts to create a molecular 3D printer.

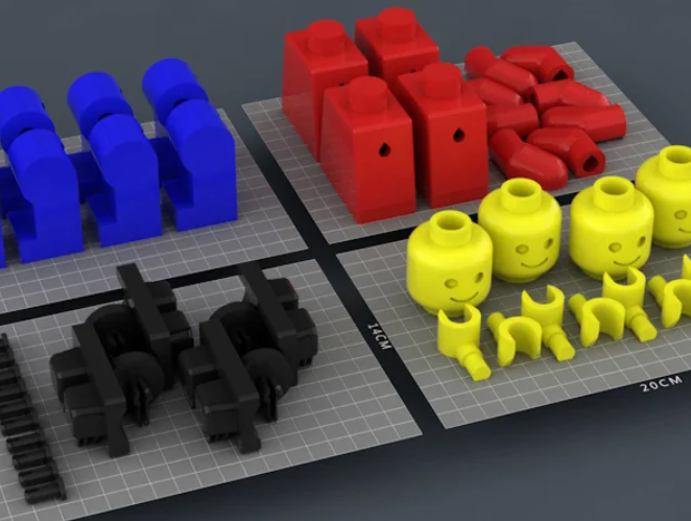

The team from Forschungszentrum Jülich, in Germany has developed a robotic system that can pick and place molecules and form nanoscale geometries, just like a nanoLego set.

However, unlike Lego, which features a uniform mating system allowing any brick to mate with any other brick, atoms and molecules behave differently. You can’t just slap one molecule onto the molecule of another substance. It will just fall off. Molecular bonding is an exact science, and each molecule has different rules for mating with other different molecules. That is where AI comes into the equation.

If this concept could be transferred to the nanoscale to allow individual molecules to be specifically put together or separated again just like LEGO bricks, the possibilities would be almost endless, given that there are around 1060 conceivable types of molecule. Dr. Christian Wagner, head of the molecular manipulation working group at the forschungszentrum.

The “printer” uses a scanning tunneling microscope to move the molecules into place much like a printhead. However, at larger scales it is easy to specify in 3D space where a filament should be deposited. At the nanoscale, this is not the case.There is way too much variability at that scale to simply calculate the location of where the molecule should go. This is where the AI helps.

At the nanoscale, this is not the case.There is way too much variability at that scale to simply calculate the location of where the molecule should go. This is where the AI helps.

“To date, such targeted movement of molecules has only been possible by hand, through trial and error,” said Prof. Dr. Stefan Tautz, head of Jülich’s Quantum Nanoscience institute. “But with the help of a self-learning, autonomous software control system, we have now succeeded for the first time in finding a solution for this diversity and variability on the nanoscale, and in automating this process.”

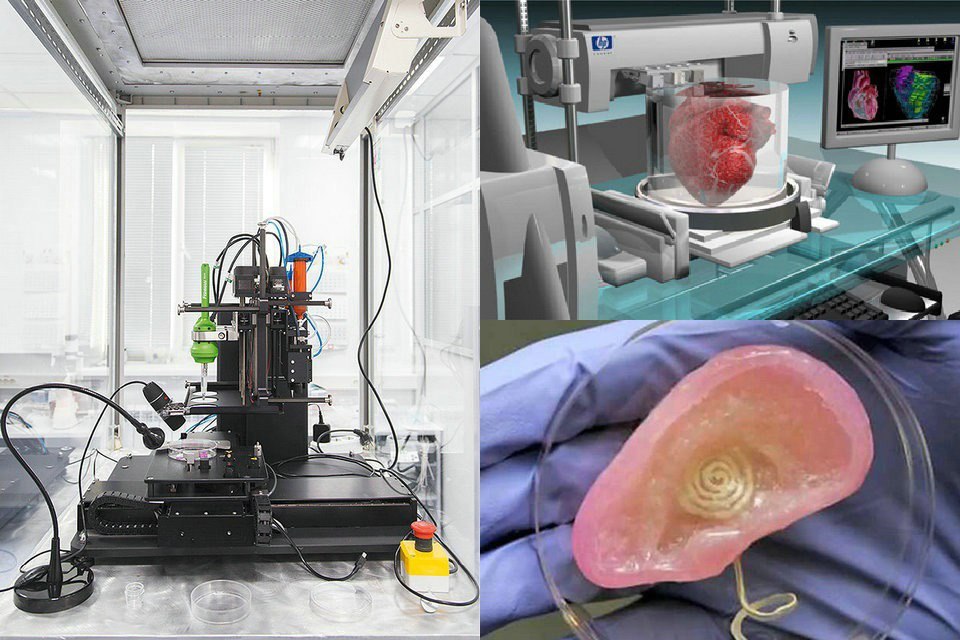

Scanning tunnelling microscope of the research group around Dr. Christian Wagner (PGI-3) at Forschungszentrum Jülich. Image credit: Forschungszentrum Jülich / Christian WagnerThe solution apparently lies in the domain of machine learning, and specifically in the sub-domain of reinforcement learning. Using this methodology, the software rewards successful moves and penalizes incorrect ones.

“In our case, the [software] agent was given the task of removing individual molecules from a layer in which they are held by a complex network of chemical bonds,” said Wagner.

“To be precise, these were perylene molecules, such as those used in dyes and organic light-emitting diodes.”

In this usage, the software is rewarded for moving the molecules without breaking the bond between the molecule in question and the microscope tip. If the bond is broken, it is penalized. And so after time, the software has developed unique movement patterns that allow the movement of molecules without breaking the bonds.

“Up until now, this has only been a ‘proof of principle’,” said Tautz.

“However, we are confident that our work will pave the way for the robot-assisted automated construction of functional supramolecular structures, such as molecular transistors, memory cells, or qubits – with a speed, precision, and reliability far in excess of what is currently possible.”

Download Paper

Breakthrough Molecular 3D Printer Can Print Billions of Possible Compounds - 3DPrint.com

What will 3D printers ultimately evolve into? No one has a functioning crystal ball in front of them I assume, but a good guess would be a machine which can practically build anything its user desire, all on the molecular, and eventually atomic levels. Sure we are likely multiple decades away from widespread molecular manufacturing, but a group of chemists led by medical doctor Martin D. Burke at the University of Illinois may have already taken a major step in that direction.

Sure we are likely multiple decades away from widespread molecular manufacturing, but a group of chemists led by medical doctor Martin D. Burke at the University of Illinois may have already taken a major step in that direction.

Burke, who joined the Department of Chemistry at the university in 2005, heads up Burke Laboratories where he studies and synthesizes small molecules with protein-like structures. For those of you who are not chemists, small molecules are organic compounds with very low molecular weight of less than 900 daltons. They usually help regulate biological processes and make up most of the drugs we put into our bodies, along with pesticides used by farmers and electronic components like LEDs and solar cells.

Martin Burke and his team

Burke and his team have created a machine which could be described as a major breakthrough in the field of chemistry, a ‘molecule-making machine’. Sound futuristic? Well that’s because it is. The machine, which was described in a paper featured in today’s issue of Science, could best be described as a 3D printer for chemicals.

“We wanted to take a very complex process, chemical synthesis, and make it simple,” explained Burke. “Simplicity enables automation, which, in turn, can broadly enable discovery and bring the substantial power of making molecules to nonspecialists.”

The way the machine works is quite extraordinary. It is able to break down very complex molecules into their basic chemical building blocks. To put things into perspective, imagine each chemical building block as a different LEGO brick. They all share the same connectors, but may be totally different from one another. The machine is able to use a catch-and-release method to automate the process of connecting these building blocks together, one brick at a time, while releasing the byproducts of each chemical reaction. It was this technique of releasing the unwanted byproducts which made this breakthrough a reality. Using this process the machine can utilize over 200 different building blocks along with thousands of other molecules to ‘print’ billions of different organic compounds, many of which make up 14 classes of small molecules, including the ratanhine molecule family. Also, according to Burke, it can even synthesize chemicals which were never before created by human beings.

Also, according to Burke, it can even synthesize chemicals which were never before created by human beings.

“The vision for the future is that anyone who needs a specific small molecule can essentially print it out from their computer,” explained Burke. “We are really excited about the immediate impacts that this will have on drug discovery.”

A new company, co-founded by Burke, called REVOLUTION Medicines, Inc. has already licensed the technology and is investing heavily in developing next generation molecule-making machines which will be much more powerful and easier to scale. If things go as planned, these machines have the potential to do to chemistry what 3D printing has done to engineering; making it fast, less complicated and accessible to pretty much anyone. In fact, the company already is working to improve upon an anti-fungal compound known as Amphotericin B, which is found in nature and used to treat patients with life-threatening fungal infections.

“Perhaps most exciting, this work has opened up an actionable road map to a general and automated way to make most small molecules,” stated Burke. “If that goal can be realized, it will help shift the bottleneck from synthesis to function and bring the power of making small molecules to nonspecialists….A 3D printer for molecules could allow us to harness all the creativity, innovation, and outside-the-box thinking that comes when non-experts start to use technology that used to only be in the hands of a select few.”

The potential this new machine could have for new rapid drug discovery as well as new chemically spawned technologies could be staggering. Imagine a website like Thingiverse, where instead of open sourcing 3D design files for printing, you could open source medications and other chemicals. That’s where the future may be headed!

Let’s hear your thoughts on the possible implications of this new machine. Discuss in the 3D Molecule Printing Machine forum thread on 3DPB. com. Check out the video below where Martin Burke further explains the process and how his machine works.

com. Check out the video below where Martin Burke further explains the process and how his machine works.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d print chemicals • molecular 3d printer • molecular manufacturing • tiny 3d printer

Please enable JavaScript to view the comments powered by Disqus.

New Molecular 3D Printing Technologies - 3DPrinter

New Molecular 3D Printing Technologies

As 3D printing of the continues to advance biomedical engineering, a team of researchers from Queen Mary University of London (QMUL) is already preparing to take the next step. Lead researcher Alvaro Mata, Professor of Engineering and Materials Science at QMUL, along with co-author and PhD student Gastón Primo, are working hard to develop a new type of 3D printing specifically designed to recreate complex biological environments. nine0007

nine0007

3DEAL is a state-of-the-art biotransformation technology related to 3D electrophoresis lithography, a novel fabrication method capable of generating complex molecular structures in soft matter such as hydrogels. By giving scientists complete spatial control over the chemistry of the engineered environment, 3DEAL opens up a whole new way to recreate natural environments found in the human body, such as 3D molecular gradients or patterns. Combined with being a relatively simple and inexpensive manufacturing technology, 3DEAL is particularly promising due to its microscale resolution capabilities, which can be as deep as a few centimeters. A new type of bioengineering could be put to work that could improve drug screening platforms or build complex tissue constructs. nine0007

As Mata explains, “The human body is primarily composed of anisotropic, hierarchical and mostly three-dimensional structures. New ways of making media that can recreate the physical and chemical properties of such structures will have important implications for the way more effective drugs are designed, or more functional tissues and organ structures can be engineered. ”

”

Maintaining physical and chemical control of these recreated structures is a particularly interesting prospect and a major selling point of the team's new technology. One of the key design features of 3DEAL is the incorporation of an electric field and a porous mask that, when used together, allow researchers to navigate and localize on tees of different types of molecules within hydrogel structures. When it comes to 3DEAL, microscale resolution is possible as it operates at extremely high volumes. nine0007

As co-author Primo points out, 3DEAL has many advantages that will make it attractive for industrial applications. “The main advantage of the technology is its reliability and economy,” he says. “This technology is simple and can be used with various types of readily available hydrogels and have samples with various types of molecules.”

Dietmar Hatmacher, technology expert in regenerative medicine and engineering at the University of Queensland, confirms that new developments in the production of biomimetic and anisotropic hydrogels have attracted significant interest from the scientific community. Innovations such as the 3DEAL technology are integral to these developments and have effectively "expanded the toolbox" for scientists in the field. nine0007

Innovations such as the 3DEAL technology are integral to these developments and have effectively "expanded the toolbox" for scientists in the field. nine0007

In the future, the QMUL team hopes to create variations on their technique, ideally allowing for even more complex simulations. An increased focus on specific applications in tissue engineering and in vitro models is also on the horizon for Mata and Primo.

First molecular 3D printer under development in Britain

News

A team of British scientists and engineers from the University of Glasgow and BAE Systems are working on a Chemputer 3D chemical printer capable of building advanced drones in weeks. Judging by the description of the project, the developers are aiming at molecular additive manufacturing. nine0007

A futuristic concept was shown ahead of the Farnborough Air Show. While the idea of a molecular printer may seem like science fiction, scientists are serious about printing entire drones, from the supporting structure to the electronics. The long-term goal is to provide the armed forces with the possibility of full-fledged additive production of high-performance drones in front-line conditions, adapting to the current situation and assigned combat missions. nine0007

The long-term goal is to provide the armed forces with the possibility of full-fledged additive production of high-performance drones in front-line conditions, adapting to the current situation and assigned combat missions. nine0007

The seriousness of intentions is evidenced by the fact that the main developer is a major military contractor BAE Systems. This company, formed in 1999 as a result of the merger of British Aerospace and Marconi Electronic Systems, has a capitalization of £ 7.7 billion and ranks second in the world in terms of military orders. The company develops solutions for the aerospace and defense industries. According to company representatives, the essence of the project is to reduce the time for the development and implementation of military products. Currently, individual projects take years to complete, but the company intends to reduce the time costs to a few weeks. The task of BAE, therefore, was the "growing" of unmanned vehicles in the laboratory. nine0007

nine0007

The concept is based on a system called Chemputer, developed in open collaboration with the scientific community. The company brought in Professor Lee Cronin from the University of Glasgow to lead the project, while BAE itself took over the industrial support. The developers intend to create a technology for building physical models through the controlled growth of biopolymers instead of layer-by-layer deposition of materials. Of course, the task is ambitious, but theoretically feasible. The idea of industrial application of controlled chemical synthesis is considered by many researchers, but a lot of work remains to be done to successfully implement the technology in the production of complex electronic systems. At the same time, the technology can be used for the manufacture of load-bearing structures. This task is simpler and therefore more realistic in the short term. nine0007

Be that as it may, Professor Cronin was the first to admit that making even small, simple drones would be a task of monumental difficulty: “This is a very interesting period in the development of applied chemistry.