3D printer filament home depot

MakerBot 3D printers coming to some Home Depot locations

X-SciTech

/ CBS News

What if you could 3D print a replacement part instead of going to the hardware store?

Bringing 3D printing into everyday life 01:28If you live in New York City, Illinois or California, 3D printing may be as close as your nearest Home Depot.

MakerBot and Home Depot announced a new partnership on Monday to bring 3D printing capabilities to the masses. Several models of 3D printers will be sold in select stores and on Home Depot's Web site, and MakerBot kiosks will be available in a dozen Home Depots in nine cities to demonstrate how the technology works.

"This is a step towards bringing MakerBot 3D Printers to the mainstream," MakerBot spokesperson Jenifer Howard told CBS News in an email. "Home Depot customers are DIY'ers, gardeners, tradesmen, professionals and families -- they are also a great community that likes to create and build things, which goes very well with 3D printing."

This is not the first time MakerBot has ventured into retail stores. The company has three locations of its own in New York, Boston and Greenwich, Connecticut. The company's 3D printers are also available in Microsoft stores and MicroCenter retail stores -- totaling about 70 locations across the U.S.

From ears to guns - 3D printers coming of age 6 photosThe company has sold more than 44,000 MakerBots, CEO Bre Pettis said at the 2014 Consumer Electronics Show.

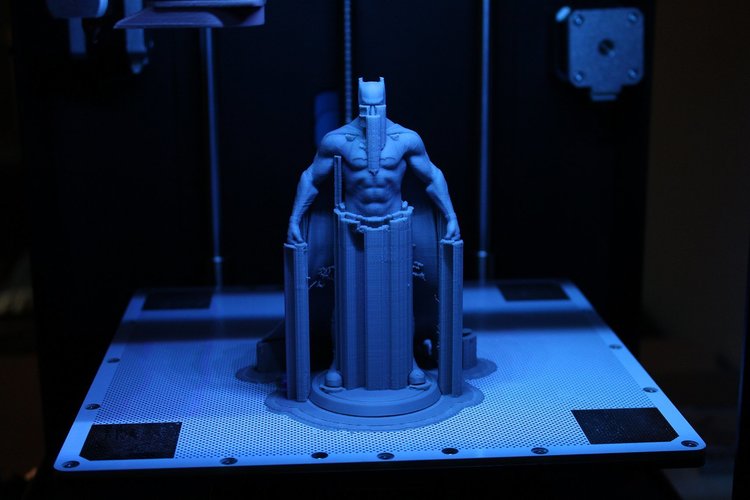

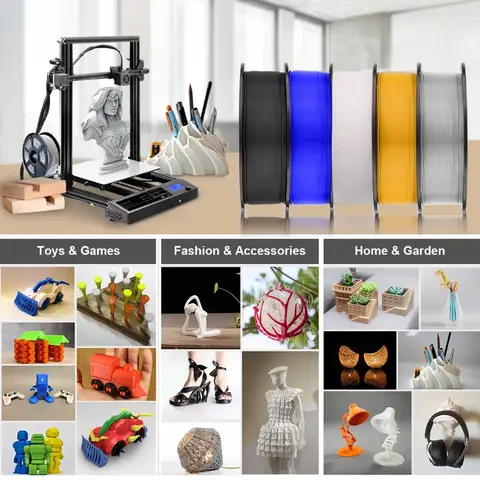

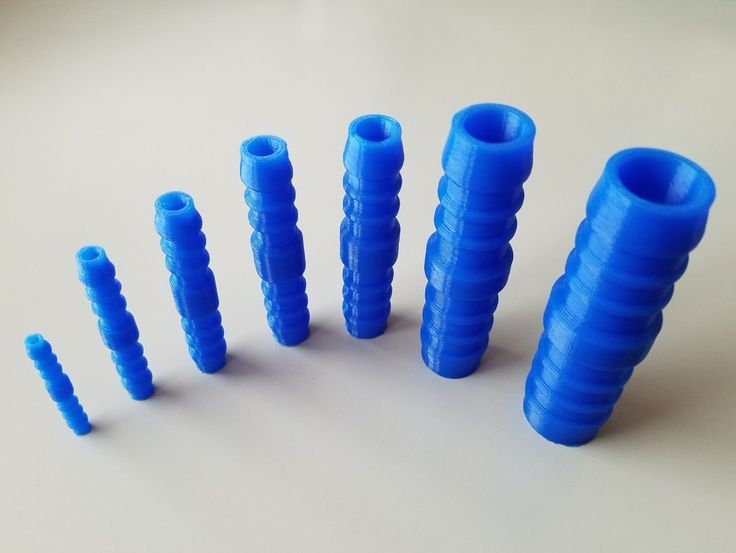

MakerBot hopes that by making the technology available at Home Depot, it can introduce more consumers to 3D printing by demonstrating production of various objects, such as replacement parts, product prototypes and collectable items.

"Imagine a world where you can 3D print replacement parts and use 3D printing as an integral part of design and building work," Pettis said in a press release.

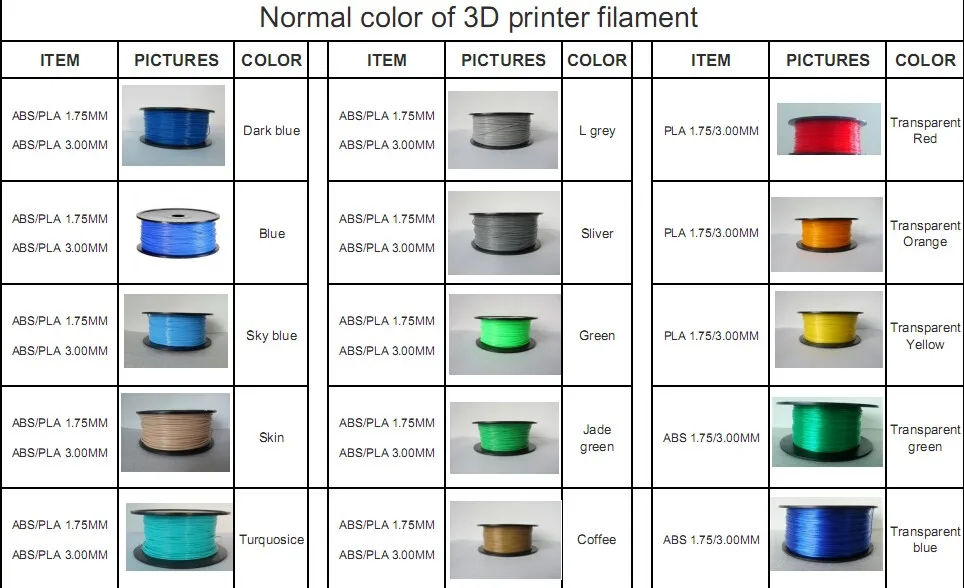

Home Depot is offering several of MakerBot's latest models, including the Replicator Mini 3D printer, the Replicator 2-Desktop 3D printer, Replicator Desktop 3D printer and the Digitizer Desktop 3D scanner. The store also sell several types of filaments for the printers.

On Home Depot's Web site, the printers range in price from $1,375 to $2,899.

Although trained staff will be demonstrating the company's 3D printers in Home Depot kiosks, the MakerBot 3D ecosystem is accessible to anyone, with files, designs, software and apps made available on the company's website, Thingiverse. com. The printers can also be purchased through the MakerBot Web site.

com. The printers can also be purchased through the MakerBot Web site.

Trending News

First published on July 15, 2014 / 6:04 PM

© 2014 CBS Interactive Inc. All Rights Reserved.

Thanks for reading CBS NEWS.

Create your free account or log in

for more features.

Please enter email address to continue

Please enter valid email address to continue

MakerBot taking 3-D printers mainstream at Home Depot

This is a carousel. Use Next and Previous buttons to navigate

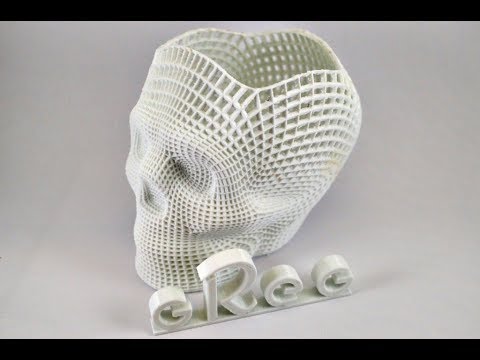

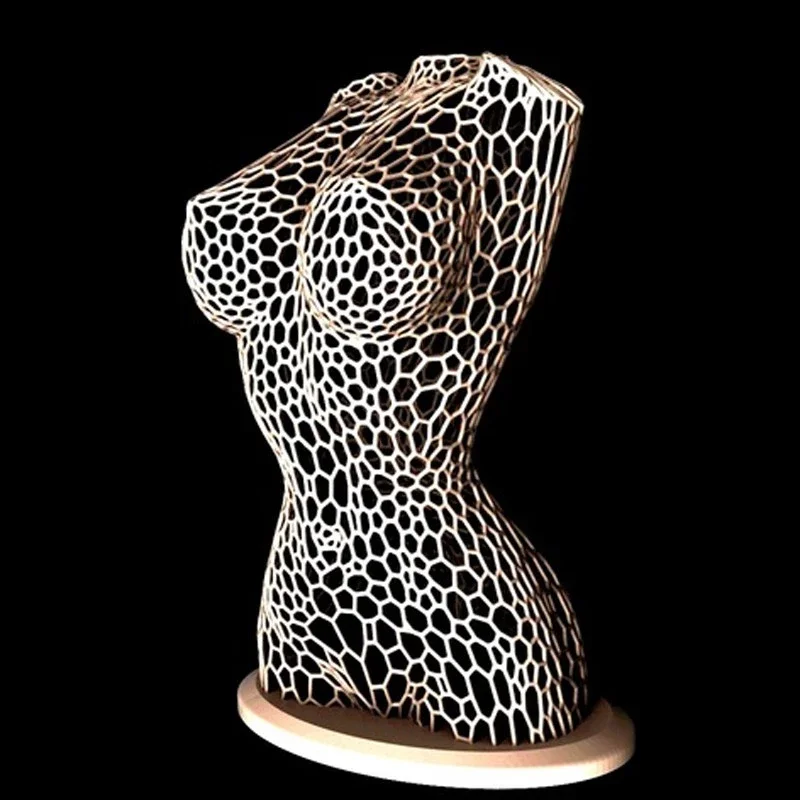

1of15Ivan Rodriguez of El Cerrito, left, talks with Esha Horton, a retail operator for MakerBot 3-D printers, at the Home Depot in Emeryville, Calif. on Monday, July 14, 2014. Certain branches of the home improvement chain will carry MakerBot 3-D printers nationwide, including stores in Emeryville, East Palo Alto and San Carlos. Kevin N. Hume/The ChronicleShow MoreShow Less2of15Some assorted items printed using a MakerBot Replicator 3-D printer sit on a reflective clear plastic display case at the Home Depot in Emeryville, Calif. on Monday, July 14, 2014. Certain branches of the home improvement chain will carry MakerBot 3-D printers nationwide, including stores in Emeryville, East Palo Alto and San Carlos.Kevin N. Hume/The ChronicleShow MoreShow Less3of154of15This 3-D printed wrench, created by MakerBot user Daniel Noree, comes fully assembled and working right out of the printer.BarspinShow MoreShow Less5of15Gyrobot Ltd., a mechanical design consultancy company in Swindon, Wilts, UK, created this birdhouse bauble.GyrobotShow MoreShow Less6of157of15Francis Bitonti Studio, a multidisciplinary design studio in New York, organized a workshop at the Metropolitan Exchange in Brooklyn that resulted in the creation of this 3-D printed dress. A MakerBot web interface allowed people to configure the skirt from a super structured mini to an expanded flare skirt.

Kevin N. Hume/The ChronicleShow MoreShow Less2of15Some assorted items printed using a MakerBot Replicator 3-D printer sit on a reflective clear plastic display case at the Home Depot in Emeryville, Calif. on Monday, July 14, 2014. Certain branches of the home improvement chain will carry MakerBot 3-D printers nationwide, including stores in Emeryville, East Palo Alto and San Carlos.Kevin N. Hume/The ChronicleShow MoreShow Less3of154of15This 3-D printed wrench, created by MakerBot user Daniel Noree, comes fully assembled and working right out of the printer.BarspinShow MoreShow Less5of15Gyrobot Ltd., a mechanical design consultancy company in Swindon, Wilts, UK, created this birdhouse bauble.GyrobotShow MoreShow Less6of157of15Francis Bitonti Studio, a multidisciplinary design studio in New York, organized a workshop at the Metropolitan Exchange in Brooklyn that resulted in the creation of this 3-D printed dress. A MakerBot web interface allowed people to configure the skirt from a super structured mini to an expanded flare skirt. Chris VongsawatShow MoreShow Less8of15Le Fab Shop created this little articulated elephant for friends in Nantes, France, at IRT Jules Verne. The city is well known for its giant puppets; the most famous one is a huge robotic elephant, the size of a building.Le Fab ShopShow MoreShow Less9of1510of15Seth Moser made this custom sleeve for coffee cups out of frustration with disposable cardboard sleeves on the new Starbucks $1 reusable cup. “The geometric designs are highly customizable and look great on a plain cup,” he said online.sethmoserShow MoreShow Less11of15A MakerBot 3-D printer creates a small plastic chain at the Home Depot in Emeryville, Calif. on Monday, July 14, 2014. Certain branches of the home improvement chain will carry MakerBot 3-D printers nationwide, including stores in Emeryville, East Palo Alto and San Carlos.Kevin N. Hume/The ChronicleShow MoreShow Less12of1513of15Gustavo Gaona of Oakland holds a plastic nut and bolt set made with a MakerBot 3-D printer at the Home Depot in Emeryville, Calif.

Chris VongsawatShow MoreShow Less8of15Le Fab Shop created this little articulated elephant for friends in Nantes, France, at IRT Jules Verne. The city is well known for its giant puppets; the most famous one is a huge robotic elephant, the size of a building.Le Fab ShopShow MoreShow Less9of1510of15Seth Moser made this custom sleeve for coffee cups out of frustration with disposable cardboard sleeves on the new Starbucks $1 reusable cup. “The geometric designs are highly customizable and look great on a plain cup,” he said online.sethmoserShow MoreShow Less11of15A MakerBot 3-D printer creates a small plastic chain at the Home Depot in Emeryville, Calif. on Monday, July 14, 2014. Certain branches of the home improvement chain will carry MakerBot 3-D printers nationwide, including stores in Emeryville, East Palo Alto and San Carlos.Kevin N. Hume/The ChronicleShow MoreShow Less12of1513of15Gustavo Gaona of Oakland holds a plastic nut and bolt set made with a MakerBot 3-D printer at the Home Depot in Emeryville, Calif. on Monday, July 14, 2014. Certain branches of the home improvement chain will carry MakerBot 3-D printers nationwide, including stores in Emeryville, East Palo Alto and San Carlos.Kevin N. Hume/The ChronicleShow MoreShow Less14of15Esha Horton, a retail operator for MakerBot 3-D printers, sets up a printing demo for customers at the Home Depot in Emeryville, Calif. on Monday, July 14, 2014. Certain branches of the home improvement chain will carry MakerBot 3-D printers nationwide, including stores in Emeryville, East Palo Alto and San Carlos.Kevin N. Hume/The ChronicleShow MoreShow Less15of15

on Monday, July 14, 2014. Certain branches of the home improvement chain will carry MakerBot 3-D printers nationwide, including stores in Emeryville, East Palo Alto and San Carlos.Kevin N. Hume/The ChronicleShow MoreShow Less14of15Esha Horton, a retail operator for MakerBot 3-D printers, sets up a printing demo for customers at the Home Depot in Emeryville, Calif. on Monday, July 14, 2014. Certain branches of the home improvement chain will carry MakerBot 3-D printers nationwide, including stores in Emeryville, East Palo Alto and San Carlos.Kevin N. Hume/The ChronicleShow MoreShow Less15of15 Shoppers at the Emeryville Home Depot pushing carts laden with lumber and lightbulbs did doubletakes as they passed a 3-D printer churning out little plastic doodads.

"This is amazing," said Luis Rojas, 11. "I want one. I'd make a lot of stuff. I wanna be an architect, so making little houses would be cool."

His dad, Enrique Rojas, a contractor, was similarly entranced. "I could print models of designs for kitchens and bathrooms," he said.

In a step toward making 3-D printers mainstream, a dozen Home Depot stores nationwide, including those in Emeryville, East Palo Alto and San Carlos, are now showcasing models from MakerBot Industries, a leading maker of consumer 3-D printers and scanners.

"Have you seen a 3-D printer before? You wanna look at it? You should come over," Esha Horton said to curious looky-loos who flocked to the MakerBot kiosk. Horton is a "retail operator" for MakerBot at Home Depot, doing continual demonstrations of the devices.

In fact, that's part of the game plan.

"We're not just plopping it on Home Depot's shelves, we have dedicated staffers to explain it," said MakerBot CEO and co-founder Bre Pettis. "For so many people, it's new technology - still almost science fiction. One of our biggest challenges is educating people about what 3-D printing is and what they could personally do with it. Where it gets exciting is when they take their passion and connect it to a MakerBot."

"For so many people, it's new technology - still almost science fiction. One of our biggest challenges is educating people about what 3-D printing is and what they could personally do with it. Where it gets exciting is when they take their passion and connect it to a MakerBot."

Toys for cats

Horton herself exemplifies that. A graphic artist, she immersed herself in all things 3-D to land her job. In her spare time, she uses her home MakerBot to make toys for her cat and presents for her friends' kids.

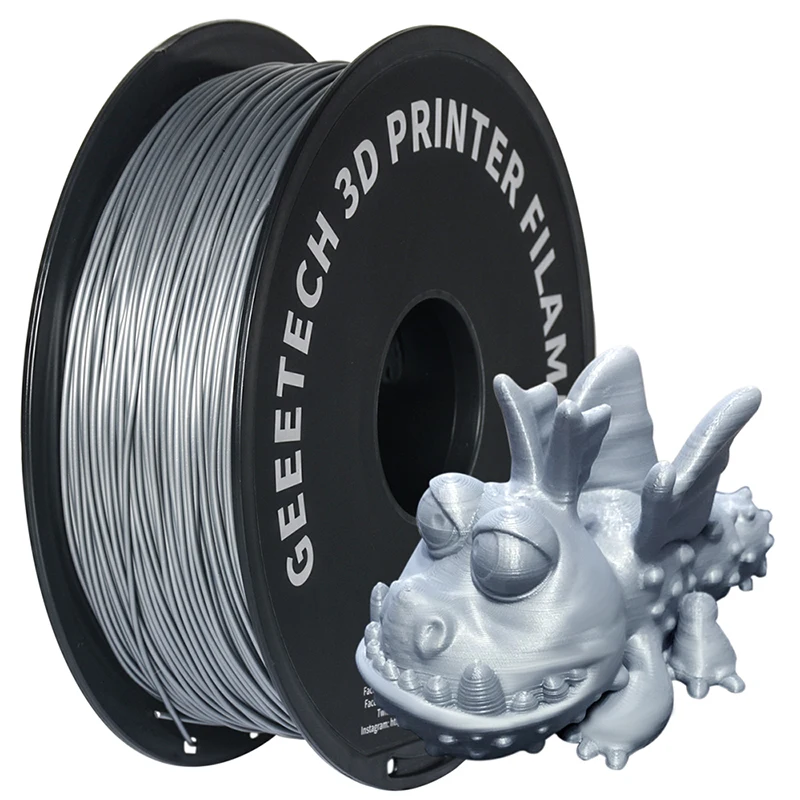

"It works just like a glue gun, laying down layers of melted plastic filament," she explained to Gustavo Gaona, an electrician. "It's made out of cornstarch that comes in spools like this in different colors."

The nozzle chugged back and forth, squirting molten filament to make a nut and bolt, a small chain and some other miniature items that she offered as keepsakes to shoppers.

"I often need small replacement parts for irrigation systems," said Ivan Rodriguez, a landscape contractor. "I've been thinking and thinking about getting one of these, but my wife thinks it's very pricey."

"I've been thinking and thinking about getting one of these, but my wife thinks it's very pricey."

Size of an old Mac

The models at the store include the $1,375 MakerBot Replicator Mini. About the size of an old Mac SE computer, it can make items as large as 4 by 4 by 5 inches. At the high end is the $2,899 MakerBot Replicator, the size of a microwave, which can make items as large as 8 by 10 by 6 inches.

Pettis noted that 3-D printers have followed a trajectory similar to that of personal computers.

"When we started MakerBot (in 2009), there were only mainframe 3-D printers, expensive things the size of a refrigerator," he said. "We started with kits (for hobbyists to construct their own 3-D printers), then desktop printers. We built an infrastructure, and now we have models launching at Home Depot."

Cartridges of the biodegradable filament derived from corn ("When you make things, it smells like waffles," Pettis said) cost $48 a roll, enough to make almost 400 chess pieces. Small items can cost a few cents each, medium items a dollar or two. Printing time depends on size and density. Something fist-size would take about 80 minutes, Pettis said.

Small items can cost a few cents each, medium items a dollar or two. Printing time depends on size and density. Something fist-size would take about 80 minutes, Pettis said.

CAD software, which can be purchased or downloaded for free, is needed to generate 3-D models to be printed. MakerBot sponsors an active online community, Thingiverse, at www.thingiverse.com where users share designs that can be modified or used as-is.

"We've seen all sorts of stuff," Pettis said. "One of my favorite things on Thingiverse is a model to connect Brio tracks to Lego blocks, making what used to be two sets into one."

Wide range of users

MakerBot users range from humongous companies like JPL and Lockheed Martin, which use the devices to create prototypes of next-generation aerospace parts, to people who use the printers to fix stuff around the house or make favors for kids' birthday parties, he said. "It's a mix of rocket scientists, moms and dads, entrepreneurs and educators."

Brooklyn's MakerBot, now owned by industrial 3-D printer maker Stratasys Inc. , has sold about 50,000 printers. The Home Depot pilot project also includes stores in Southern California, Illinois and New York.

, has sold about 50,000 printers. The Home Depot pilot project also includes stores in Southern California, Illinois and New York.

With lots of remodelers, contractors, architects, builders, landscapers, interior designers and do-it-yourself types at Home Depot, it seemed like fertile ground for folks with specific needs for 3-D printers, Pettis said.

Despite Home Depot's plethora of amateur and professional builders, Horton said many shoppers were interested in 3-D printers for a different purpose.

"Lots of them are entrepreneurs," she said. "They have ideas for a product and want to use this to prototype it."

Indispensable equipment for a modern office - 3D printer STACKER F1

Home » Blog » Indispensable equipment for a modern office - 3D printer STACKER F1

23.07.2022

Introduction

It didn't take long for the world community to truly appreciate the benefits of 3D printing technology. It has become especially relevant with the onset of the spread of the coronavirus pandemic. Quarantine measures and restrictions have caused violations, disruptions in supplies, breaks in established ties. 3D printers have made it possible to locally produce various parts and items necessary for protection: protective screens, masks, swabs, etc.

It has become especially relevant with the onset of the spread of the coronavirus pandemic. Quarantine measures and restrictions have caused violations, disruptions in supplies, breaks in established ties. 3D printers have made it possible to locally produce various parts and items necessary for protection: protective screens, masks, swabs, etc.

Practice shows that 3D printing machines are needed in most industries, enterprises, institutions. With their help, visual aids, devices, consumer goods are made. Printers should be installed in educational institutions, medical institutions, the technology allows you to establish a productive business.

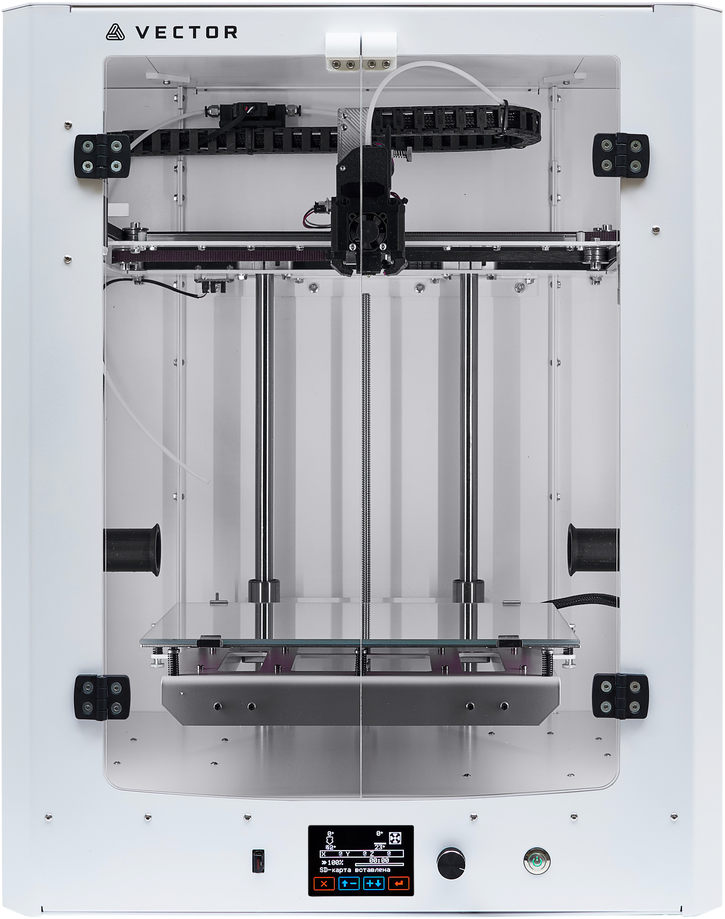

Innovative F1 3D printer, its features and benefits

Innovative stacker F1 3D printer has significant differences from analogues on the market. The main advantages are high productivity and guarantees of high-quality results. The device is reliable and ensures safe operation. At the same time, in the category of industrial printers, this model is the most affordable for the consumer. It is equipped with all the accessories necessary for productive work, high-quality printing. The designers have developed a range of innovative F-Series attachments for comfortable working. nine0003

It is equipped with all the accessories necessary for productive work, high-quality printing. The designers have developed a range of innovative F-Series attachments for comfortable working. nine0003

1. Safety guarantees

The inventors of the new printer in the development of the model took into account the features of operation. The device is intended for hospitals, schools, colleges, offices, workshops, research laboratories. It can also be used at home. Therefore, ensuring the safety of working with this technique was one of the main criteria for the authors.

Reliable protection against heat runaway . A thermal runaway in 3D printing is a failure in which the automatic termination of the heating of the end does not work. It remains hot until the appliance is turned off. This situation is observed if the firmware is frozen, the settings are not reset, the controller board is out of order, the temperature sensor is broken, it is pushed out of the heating block. nine0003

nine0003

In printers on the market, thermal runaway protection is provided by the built-in software. But this technology is not reliable. In addition, in devices from the budget segment, the software may not be included, although it is available in the firmware. Practice shows that this system does not provide protection in case of breakage of the temperature sensor, malfunction of the controller board.

Protection in F1 . The stacker F1 3D printer is equipped with special electronic circuits that turn off the power. They are stand-alone, not connected to firmware, other software control options. If the firmware is faulty, the transistor is out of order, the security system continues to work, to perform its intended function. The F1 printer has 2 temperature sensors, which provide additional security assurance. The device has 2 autonomous inputs, each with its own circuit. When the temperature rises to 325°C, the power turns off automatically. nine0003

nine0003

Highly sensitive and reliable temperature sensors . The F1 printer has PT100 sensors installed. Platinum is used in their manufacture, which ensures high reliability. The specific design of the end eliminates the displacement of temperature elements during operation. The first advantage of the printer is the presence of two sensors, which increases the degree of security. The second plus is the fastening of these devices at several points. The third positive point is the metal cartridges, in which sensors are placed, which guarantee the reliability of fastening. A specially designed cable management system that feeds the end prevents loosening of temperature devices. nine0003

Thermal bimetal break and radiator . A Slice Engineering thermal bimetallic break is installed in the working unit of the printer. Thanks to this device, heat remains in the heater block, does not move to the top of the hot end. This ensures the safety of the work site, improves print quality. The printer also has a heatsink designed specifically for this device. It removes excess heat generated during a thermal break.

The printer also has a heatsink designed specifically for this device. It removes excess heat generated during a thermal break.

Protected and insulated heating unit . The heating unit is protected by a special fuse made of stainless steel. Its function is to reduce strong combustion.

Reliable connectors MOLEX . Most printers have cheap connectors made by dubious manufacturers that copy originals without a license. The F1 uses reliable, proven MOLEX products. These connectors are designed for higher power. If the maximum values are exceeded, they may melt, but do not burn. nine0003

Innovative shields Z-configuration . These components eliminate the risk of pinching, wrapping fingers, hair. Each Z-axis lead screw has its own safety lock, which makes it easy to maintain and keep them clean for a long time.

Improved firmware . The F1 printer is equipped with Repetier's advanced modular firmware. It includes the traditional heat escape protection found in other versions. Additionally, it includes a security system that detects failures in the firmware. When they appear, the printer automatically resets to fix the problems. nine0003

2. High quality result

The new F1 printer model delivers superior print quality. It was possible to provide the technique with such functionality through several technical solutions. The specialists have eliminated common defects such as z-wobbles, zero intersecting moiré fringes, resonance, thermal banding and other problems that appear in prints. All these shortcomings have been eliminated thanks to competent design, careful selection of components and numerous tests. nine0003

Engineering innovations . To begin with, the inventors gave maximum rigidity and strength to the portal system and frame. During assembly, the structure assumes an ideal position and maintains it throughout the entire service life. The next step was to develop a simple yet productive chassis damping system. The use of a polymer with increased elasticity and viscosity made it possible to provide it with impeccable performance. The damping system has excellent damping ability, dampens vibrations, provides vibration protection, and has good memory. Manufacturers of cheap printers are limited to installing rubber feet. But for the innovative F1 model, this solution is not suitable. nine0003

During assembly, the structure assumes an ideal position and maintains it throughout the entire service life. The next step was to develop a simple yet productive chassis damping system. The use of a polymer with increased elasticity and viscosity made it possible to provide it with impeccable performance. The damping system has excellent damping ability, dampens vibrations, provides vibration protection, and has good memory. Manufacturers of cheap printers are limited to installing rubber feet. But for the innovative F1 model, this solution is not suitable. nine0003

Stacker F1 3D Printer is equipped with improved filament drive, improved hot end. The increased power and accuracy of the drive is provided by the special design of the gearbox and drive gears of the glow. The gearbox is not made of polymers, but of stainless steel. Hardened steel is used in the production of gears. Advanced hot end designed to work with carbon fiber, metal. Improved performance, increased efficiency of the working unit gives a thermal break, which has a maximum operating temperature. Therefore, the hot end can work with any type of filament. nine0003

Therefore, the hot end can work with any type of filament. nine0003

Print precision . In 3D printing technology, an important indicator is the accuracy of reproduction of a given model. All manufactured parts must be absolutely identical. In a quality product, the corners should be sharp, there should be no excessive extrusion.

The high-precision printing of the F1 printer comes with an innovative feature. This is pressure balancing at the hot end. If you need to create a part of the part that does not require the use of filament, the speed of the extruder is automatically reduced, pressure is created at the hot end, allowing it to extrude, providing the desired result. The F1 printer does not require the use of various slicer techniques such as wiping, rolling. nine0003

3. Stable performance and reliability

High reliability, stable operation of the F1 printer is ensured by qualified design, the use of high-quality components and flawless assembly.

Best technical ideas

Every user of the printer experiences hot end corruption. There are several reasons for this problem. Cause could be a failure in the retraction setting, filament moisture, improper temperature setting, debris in the filament or non-standard diameter, errors in the design of the hot end. You can spoil the working tool by leaving it at maximum temperature after finishing work. The designers of the F1 printer anticipated this problem. The special design will allow easy replacement of the hot end, injectors. nine0003

High quality components

The F1 printer has a 600W Artesyn power supply. This is an expensive device, its cost exceeds $ 250. To many, this decision may seem wrong, since for this price you can buy a 3D printer in the budget segment. A $25 power supply can be installed in the device to reduce its cost. But the goal of the F1 was to create a productive, reliable, and secure printer. Only a high-quality, efficient power supply can provide such indicators. Artesyn is equipped with power factor stabilization. This ensures that current flows with optimum performance. The installation of a power supply with this function complies with international standards. In cheap power supplies, there is no such function, there is no guarantee of reliability. Artesyn devices are guaranteed for 2 years. nine0003

Artesyn is equipped with power factor stabilization. This ensures that current flows with optimum performance. The installation of a power supply with this function complies with international standards. In cheap power supplies, there is no such function, there is no guarantee of reliability. Artesyn devices are guaranteed for 2 years. nine0003

Another important component of the F1 printer are the Slice Engineering nozzles. They are made from vanadium alloyed high speed steel that has undergone a hardening process. The cost of such a nozzle is over $30, while imported analogues can be bought for $2. It may also seem irrational. But Slice Engineering nozzles have a lifetime warranty, they do not wear out during the entire period of operation. Cheap analogues do not withstand one roll of carbon fiber thread. The designers of the F1 want the customer to change the nozzles only when they need to change the extrusion width, and not because they are worn out. nine0003

Universal Printer F1

The new F1 printer in terms of performance and functionality belongs to the category of industrial equipment. But it is a versatile device that can be used in small businesses, schools and colleges, hospitals, laboratories, and at home. A wide range of applications is provided by an increased level of security.

But it is a versatile device that can be used in small businesses, schools and colleges, hospitals, laboratories, and at home. A wide range of applications is provided by an increased level of security.

F1 printer equipment

Stacker F1 has a specific equipment that distinguishes it from other printers. Convenience, safety, productivity provide:

- Top rail with T-slot for easy mounting of webcam, coil holders, tools, etc.

- Slotted V-wheels provide smooth, linear, silent and maintenance-free movement.

- The Quard-Gear drive produces powerful, flexible filament.

- Specific design for quick, easy nozzle replacement, hot end, providing a maximum temperature of 310°C. nine0122

- Slice Engineering hardened nozzle designed to work with abrasive threads.

- Dual heating blocks for fast warm-up, even heat distribution for quality extrusion.

- Electrical redundant automatic shutdown circuits provide reliable protection against thermal runaway at the hot end.

This is an additional security system that includes dual temperature sensors.

This is an additional security system that includes dual temperature sensors. - Print bed with an ultra-flat surface for a perfect fit. It features a die-cast precision aluminum finish, a 300W silicone mat heater, and Level Once levelers. nine0122

- Convenient carrying handle, LED light.

- Customizable logo front plate.

- Dual Z screw guard system to keep hair, hands safe.

- 600W Artesyn LCM 600Q-N industrial grade power supply with pulse smoothing PFC.

- 32-bit electronics for fast printing, quiet smooth operation, high security. nine0122

- Free wire regulator box, eliminating the risk of short circuit, reducing complexity, temperature.

- Safe and reliable original MOLEX wire connectors designed for maximum loads.

- Low noise motor.

- High resolution stepper motors with 2x the accuracy of standard printers.

- High strength, rigid port and frame for fast, high quality printing. nine0122

- Flexplate system with Build Tak computer, PEI bed surfaces.

A nylon surface is available as an option.

A nylon surface is available as an option. - Damping system made of highly elastic, viscous material eliminates table top damage and improves print quality.

- Special Repetier firmware balances pressure at the hot end to prevent over extrusion and has advanced scheduling. The

- Repetier with server software (requires a separate PC, embedded OC Linux or Pi devices) provides excellent conditions for printer control via web-enabled devices. It is possible to add WI-FI with IP. nine0122

- Simplify 3D licensed slicing software for high slicing precision, extensive printing options, and multiple process function. Having an industry standard allows you to create support structures that open easily.

- Compact frame that allows you to install the printer on any table.

- Ability to make large prints 285x285x285 mm.

- Several options for placing the filament coil, there are mounts for rear and front, top mounting. nine0122

- F-BOX compatible, can be mounted anywhere.

Printed sheet surfaces

Manufacturers of the F1 printer have partnered with Build Tak to produce printed sheets from polycarbonate, PEI, flexible plate systems. The choice of a business partner was made according to several criteria. This company manufactures products in the USA, does not use cheap foreign components, and has extensive experience. Such raw materials are necessary to create the best printer. F1 models are supplied with flexible steel plates equipped with mag base and sheets for each PC and PEI. Separately, a black sheet made of real garolite is offered, which is an excellent base for nylon. PEI sheets can be used to work with a wide range of materials, creating good conditions for creating details. But PC sheets hold models more tightly, especially if they are made from PC, PLA, PETG. nine0003

Improved filament drive

The creators of the F1 printer had to work hard to create a special filament drive to ensure high quality printing. They managed to create an easy, convenient, reliable option. Includes brackets:

They managed to create an easy, convenient, reliable option. Includes brackets:

- Print head (adjustable)

- Filament Output Sensor

- Sensor ABL

- Fan

- Blowers nine0121 Hot end

Thread drive also includes:

- Glow tube holder

- Wire Management

- Seat belt guard

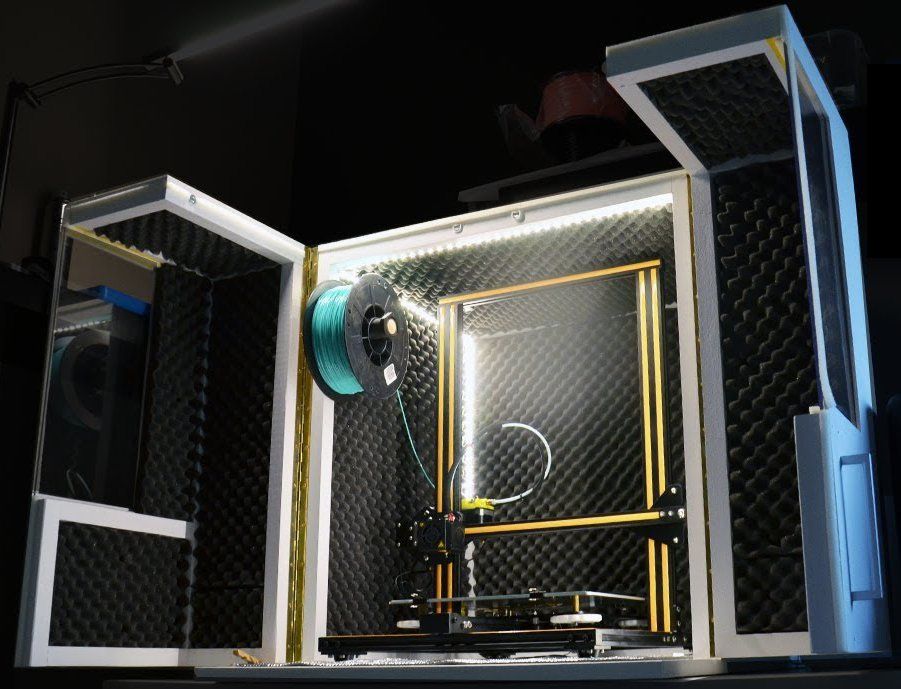

The innovative F-BOX model guarantees improved print quality and is compatible with any 3D printer. Designers have already developed bracket types for all popular models.

Need to use dry filament

Dry filament guarantees quality prints. Therefore, it is necessary to dry it for work in order to exclude the receipt of products with defects, poor-quality design.

There are other reasons to use a dry filament. It produces parts with high strength. The presence of moisture leads to a hydrolysis reaction that destroys the polymer chains. This reduces the density, strength, since short chains do not provide high-quality grip. nine0003

nine0003

The filament must remain dry throughout the entire operation. Therefore, it must not only be dried before printing, but also be fed from a dry box. Manufacturers supply the material in plastic packaging. But this does not mean that the new thread will be dry; moisture will also have to be removed in this case.

Benefits of F-BOX

- Reduces the risk of stringing and jamming

- Improves layer adhesion, print quality

- Works with all filaments - nylon, PETG, ABS, PVA, PLA

- Keeps dry, clean, thread safe

- Reduces thread redefinition

- Provides perfect first coat adhesion

- Saves space

Features F-BOX

- The F-BOX has a square-shaped through hole that allows it to be installed on any printer.

- Seals keep out dust and moisture. nine0122

- Quick-release latches ensure tight closing.

- The design of the cover makes it easy to change coils.

- Desiccant cartridges are highly efficient and easy to change.

- The color of the dehumidifier changes with energy consumption, you can control the time it takes to recharge.

- Through hole provides viewing for filament color, filament consumption, etc.

The designers spent several months developing the design of the F-BOX. They managed to give the design not only impeccable functionality, but also ease of use. The main body, in which the coil is located, is equipped with two seals that do not allow the thread to unwind and do not allow foreign bodies to enter. There are 4 latches on the lid, they ensure tight closure. The presence of a through square hole makes the F-BOX a universal device that can be used for any 3D printer. nine0003

F-BOX development steps

The first F-BOX model, developed by designers, turned out to be too bulky, not comfortable enough. Before receiving the final version, several intermediate versions had to be created. Gradually, the designs of the central pillar, legs, latches, etc. were improved. It was necessary to give the structure acceptable dimensions, to choose the ideal gaskets. Attentive attention to every detail allowed us to get the perfect result. nine0003

Gradually, the designs of the central pillar, legs, latches, etc. were improved. It was necessary to give the structure acceptable dimensions, to choose the ideal gaskets. Attentive attention to every detail allowed us to get the perfect result. nine0003

Convenient part removal with F-FLEX tool

Certain difficulties in printer printing are associated with the removal of finished prints from the plate. Even the flexible products that come with the F1 printer, other models, do not allow you to remove small parts without a scraper.

Standard spatulas are equipped with a blade that is too thick, with too sharp corners and a dull edge. To create maximum convenience in removing prints, the F1 designers have developed a special tool F-FLEX. nine0003

The innovative fixture has several advantages. The flexible conduit has optimal dimensions, the edge of the blade is as sharp as possible, and the corners are rounded, which eliminates cutting into the plate. The tool is equipped with a comfortable soft handle. In order to “knock down” the models, the pen has a special bright-colored cap. The blade of the tool is very sharp, you should be careful when working with it, use it carefully. The hand should be behind the blade to prevent injury if the print suddenly comes off. nine0003

The tool is equipped with a comfortable soft handle. In order to “knock down” the models, the pen has a special bright-colored cap. The blade of the tool is very sharp, you should be careful when working with it, use it carefully. The hand should be behind the blade to prevent injury if the print suddenly comes off. nine0003

F-PAC Pack - Efficient Filament Desiccant

The standard filament storage option for most users is to store open spools in bulky sealed containers. This is a simple and affordable way. But to maintain the thread in the right condition, the use of foam pads is required. If the desiccant is not enough, the threads are moistened, additional manipulations are required to dry them. Eliminate these problems allows another invention of the authors F1. These are efficient F-PAC filament dryers. nine0003

Description

The product is a bag of thread desiccants. The bag has a solid capacity, containing approximately 1,130 grams of desiccant.

Purpose

The package can be used for any container. For 5-10 gallon capacities, one F-PAC is sufficient. Larger containers can hold 2 bags. The dimensions of the F-PAC are identical to those of the filament reel.

Functions

F-PAC bags are essentially a molecular sieve that absorbs moisture from the air to keep the threads dry.

Product Features

- Highly efficient, absorbs moisture from the air efficiently.

- Allows control of moisture filling, changing from orange to green indicates the need for recharging (orange tint confirms the safety of the material, blue desiccant containing cobalt is dangerous). nine0122

- Rechargeable for long life.

More information about F-PAC

- Net weight - 1130 g.

- Gross weight - 1,356 g.

- Packaging - polycarbonate box.

- Chemical description of the orange to green transition with silicone gel description.

- Drying formula SiO2 + h3O + C25h40CIN3

- Composition: amorphous silica - 98.2%, activated dye - up to 0.2%.

Convenient and high-quality 3D printing with pro...Cheap or expensive 3D printer: what's...

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment.