Biocompatible 3d printing resin

3D Printing Materials For Healthcare

3D Printing Materials For HealthcareSkip to Main Content

WHEN PATIENTS AND PRECISION COUNT

Access a library of over 35 SLA materials to fuel innovation in 3D printing medical applications.

Talk to our Medical ExpertsVisit the Formlabs Store

Our BioMed Resins are designed for healthcare professionals who are seeking medical-grade materials for a wide range of applications where performance and biocompatibility are critical. Materials in our BioMed Resin family are developed and manufactured in an ISO 13485 certified facility and are compatible with common disinfection and sterilization methods.

Print a wide variety of biocompatible and engineering applications on intuitive and affordable 3D printers that make rapid innovation possible on the desktop.

See the future of healthcare firsthand and assess our materials for your application: we’ll mail you a free 3D printed sample part.

Request a Free Sample Part

Need more information or help choosing the right material for your medical application? Interested in ordering resin in bulk? A Formlabs Medical expert is here to help!

Talk to a Medical 3D Printing Expert

Formlabs is an industry-leading provider of 3D printers and materials that are used by healthcare providers to support the practice of medicine. Please consider local regulations, material data sheets, PHI, and institutional requirements before 3D printing and/or using anatomical models.

Learn how Clinical Innovators safely leverage 3D printing today.

Data Sheets

Download safety and technical data sheets for all Formlabs materials.

Handling & Safety

Handling & Safety

Resin should be handled with care. Proper handling will ensure safe printing and efficient use. Our resins have been designed to be similar or safer to handle as other household chemicals or adhesives. Formlabs materials do not contain volatile solvents so special ventilation is not required. Skin contact should be avoided.

Formlabs materials do not contain volatile solvents so special ventilation is not required. Skin contact should be avoided.

The Safety Data Sheets (SDS) are up to date for every resin product and follow the latest government guidelines. Always consult the SDS as the primary source of information to understand safety and handling of Formlabs materials. For more information about handling resin, learn more tips for resin maintenance in our Help Center.

Technical Data

Technical Data

Plastics are complex materials, and finding the right one for your specific application requires balancing multiple attributes. Our library of resins is ideal for product development, rapid prototyping, and a variety of specialized applications. Download our Technical Data Sheets to explore the mechanical properties of each material.

Material

– Select –BioMed AmberBioMed BlackBioMed ClearBioMed WhiteBlackCastableCastable WaxCastable Wax 40CeramicClearColor BaseColor PigmentsCustom TrayDental LT ClearDental LT Clear V2Dental SGDigital DenturesDraftDurableESDElasticElastic 50AFlexibleFlexible 80AFull Materials LibraryGreyGrey ProHigh TempIBTModelModel V3Nylon 11Nylon 11 CFNylon 12Nylon 12 GFPU Rigid 1000PU Rigid 650Permanent CrownReboundRigid 10KRigid 4000Soft TissueSurgical GuideTemporary CBToughTough 1500Tough 2000White

Language

– Select –BulgarianChineseCroatianCzechDanishDutchEnglishEstonianFinnishFrenchGermanGreekHungarianIrishItalianJapaneseKoreanLatvianLithuanianMalteseNorwegianPolishPortugueseRomanianRussianSlovakSlovenianSpanishSwedishTurkish

Technical Data Sheets

There is no technical data sheet available for the chosen material.

Safety Data Sheets

There is no safety data sheet available for the chosen material.

Are Biocompatible 3D Printer Resins Truly Safe? « Fabbaloo

By Kerry Stevenson on February 1st, 2021 in materials, research

Tags: biocompatible, formlabs, materials, resin, safety, standards

Cells affected by exposure to 3D printer resin [Source: Science Direct]New research has uncovered previously unrecognized toxicity issues with certain biocompatible resins.

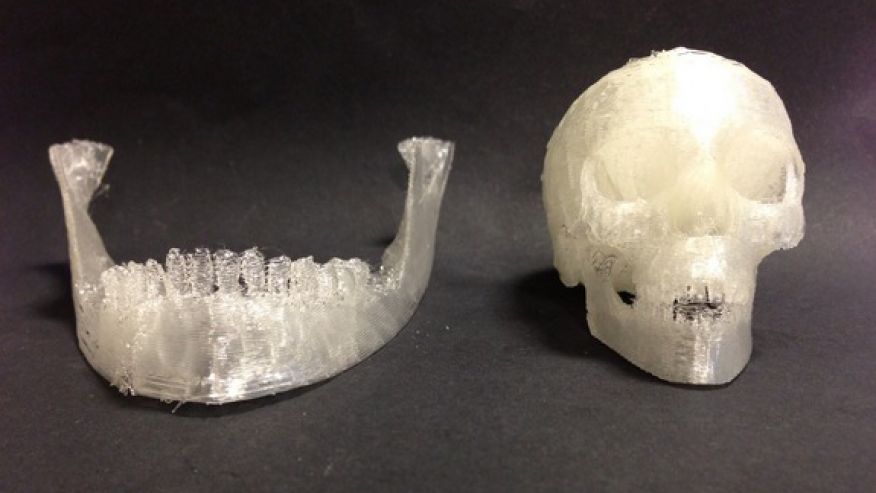

The resins in question are typically used in dental applications. The dental industry has increasingly adopted 3D printing as a solution due to its ability to mass produce customized dental appliances. 3D printed dental applications are so useful that a number of 3D printer manufacturers have been attracted to focus specifically on that industry segment.

The new research, done by Northwestern University, was in a way an accidental discovery. It seems that the researchers were originally intending on scaling up the capability of their previously developed “female reproductive tract on a chip”, which is used for ex vivo research.

To build a new device, they turned to 3D printing, as they felt it could be a useful approach for creating the necessary parts. However, they knew they’d better certify the non-toxicity of the recommended materials before proceeding, as any toxicity could screw up future experimental results.

The specific resins involved were Formlabs’ Dental SG and Dental LT Clear, and tested on a Form 2 SLA 3D printer. The paper includes the lot numbers for the resins used in their experiments.

Their toxicity screening involved testing an in vitro mammalian oocyte maturation assay. They found:

“Culture of mouse oocytes in 3DP plates using conventionally treated DSG resin resulted in rapid oocyte degeneration. Oxygen plasma treatment of the surface of printed DSG resin prevented this degeneration, and the majority of the resulting oocytes progressed through meiosis in vitro. However, 57.0% ± 37.2% of the cells cultured in the DSG resin plates exhibited abnormal chromosome morphology compared to 19.

4% ± 17.3% of controls cultured in polystyrene. All tested DLT resin conditions, including plasma treatment, resulted in complete and rapid oocyte degeneration.”

Subsequent investigation revealed that Tinuvin 292, used as a light stablizer in Dental LT, had leached out from the prints into the biomaterials, causing the toxicity.

The paper said:

“Severe reproductive toxicity induced by in vitro exposure to these 3D-printed resins highlights potential risks of deploying insufficiently characterized materials for biomedical applications and underscores the need for more rigorous evaluation and designation of biocompatible materials.”

Does this mean that these resins, and potentially other “biocompatible” resins, are not actually biocompatible?

I think the answer is a lot more complex than one might think. It’s easy to read a label that says “Biocompatible” and assume that means the product is compatible with any situation. That’s certainly not the case.

That’s certainly not the case.

In fact, the label “biocompatible” actually has significant definition behind it, provided by the regulatory agencies. If a manufacturer, such as Formlabs, meets those definitions, then they can use the label. That’s what’s happened here.

If you’ve ever read any material safety data sheets, you’ll understand that the toxicity of a material is highly dependent on the amount, type and time of exposure. A substance that may be declared “safe” is actually safe only within certain usage parameters.

Even “known safe” substances can be toxic if taken in incorrect amounts. I recall the famous proposal by physicist Bernard Cohen, who challenged environmentalist Ralph Nader to consume as much caffeine as Cohen would eat plutonium. Cohen was not taken up on his challenge.

It all depends on what you’re doing and how you’re doing it.

In this case, it may be that the official definition of biocompatibility does not include the scenario proposed by the researchers.

The researchers said:

“Although both DSG and DLT are marketed as ‘biocompatible’ photopolymers, our results demonstrate that the context for biocompatibility is critical.”

The conclusion here is that yes, the resins are biocompatible — but only for the specified use patterns. Always check, and then check again!

Via Science Direct

TwitterKerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson's posts.

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

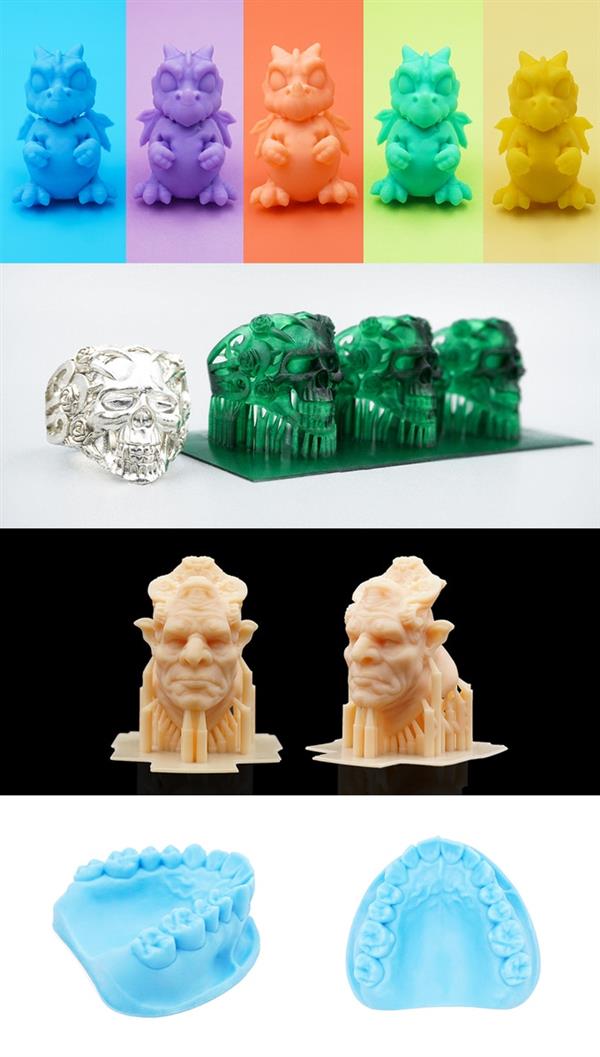

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries: nine0053

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning. nine0053

SLA 3D Printing Resin Overview

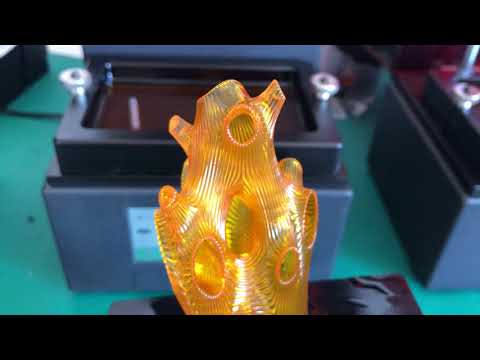

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface. nine0053

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable. nine0053

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes. nine0053

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance. nine0053

nine0053

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips. nine0053

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber nine0053

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping. nine0053

nine0053

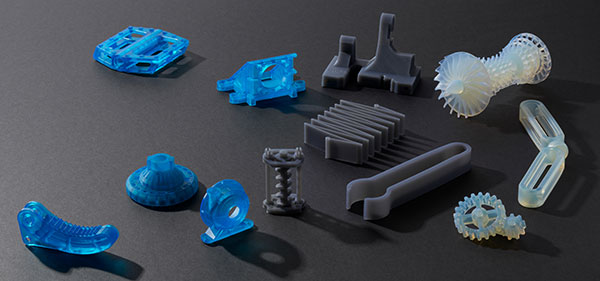

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

nine0053

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models. nine0053

nine0053

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness. nine0053

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity. nine0053

nine0053

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs nine0053

Pros:

Cons:

- Moderate wear and tear resistance

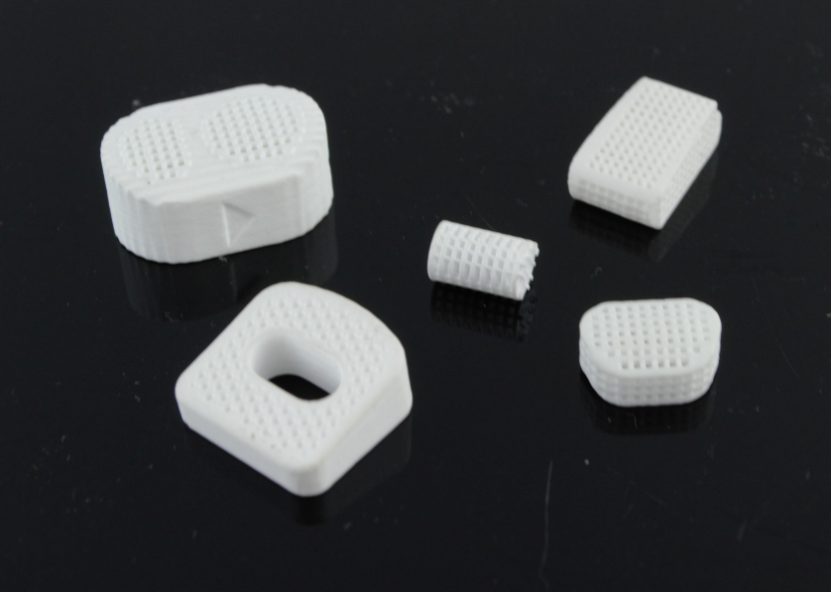

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

0114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price nine0053

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin nine0053

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds nine0053

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Cast resin allows you to get the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

nine0113 Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you! nine0053

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

INSTAGRAM nine0053

In contact with

Formlabs Medical Resins material properties characteristics

Formlabs BioMed Medical Resins are materials designed for 3D printing of biocompatible prints. Parts printed with these polymers can be sterilized using standard methods. Resins are produced in an ISO 13485 certified facility to help medical device and point-of-care manufacturers reduce costs, quickly iterate and print a wide range of end-use tools and devices that support medical practice. nine0053

Parts printed with these polymers can be sterilized using standard methods. Resins are produced in an ISO 13485 certified facility to help medical device and point-of-care manufacturers reduce costs, quickly iterate and print a wide range of end-use tools and devices that support medical practice. nine0053

Print Accuracy and Applications of Formlabs Medical Resins

1| Printer compatible | Bath compatible | Layer height, micron | Features and Applications | |

| BioMed Clear | Form 2 Form 3B | Form 2 LT Form 3 Tank V1 Form 3 Tank V2/V2.1 | Form 2, Form 3B - 100 µm | Biocompatible - long-term use USP Class VI certified Hard, crisp prints on medical, pharmaceutical and industrial devices Compatible with conventional disinfection and sterilization methods |

| BioMed Amber | Form 2 Form 3B Form 3BL | Form 2 LT Form 3 Tank V1 Form 3 Tank V2/V2.  1 1 Form 3L Tank | nine0614 Form 2, Form 3B - 50, 100 µm Biocompatible - Short term use Rigid translucent prints for medical or industrial use Compatible with conventional disinfection and sterilization methods |

1 Data as of March 2021. nine0002 • BioMed Clear V1 • Biocompatible photopolymer resin for Formlabs SLA printers. It is a tough, biocompatible material for 3D printing of parts that are suitable for long-term skin or mucosal contact. The material is USP Class VI certified for wear resistance and low water absorption. BioMed Clear prints are compatible with conventional sterilization methods. BioMed Clear Resin is manufactured in an ISO 13485 facility and supported by an FDA device master file. nine0152 BioMed Clear photopolymer can be used to print medical devices and their components: components for respirators and ventilators, drug delivery devices, surgical planning and implant sizing tools, devices and instruments, masks. 1 Material properties may vary depending on part geometry, print orientation, print settings, temperature, and disinfection or sterilization methods used. Samples printed with BioMed Clear Resin have been assessed according to ISO 10993-1:2018, ISO 7405:2018, ISO 18562-1:2017 and meet the requirements associated with the following biocompatibility endpoints: 3 BioMed Clear resin has been tested at NAMSA Headquarters, Ohio, USA. - BioMed Amber resin is designed for 3D printing of rigid and strong biocompatible precision parts. This material is designed specifically for printing on Formlabs printers. It is rigorously tested and manufactured in an ISO 13485 certified clean room facility to ensure consistent quality between batches. Parts made from this polymer are compatible with conventional disinfection and solvent sterilization methods. The material is used for various 3D printing for drilling templates and guides for implants, fixation trays, medical equipment components, surgery planning tools. nine0053 1 Material properties may vary depending on part geometry, print orientation, print settings, temperature, and disinfection or sterilization methods used. BioMed Amber resin has been assessed in accordance with ISO 10993-1:2018, Biological evaluation of medical devices - Part 1: Evaluation, testing and risk management process ISO 7405:2009/(R)2015, Dentistry - Biocompatibility assessment. medical devices used in dentistry and meet the requirements for the following biocompatibility risks: 3 BioMed Amber resin was tested at NAMSA Headquarters, Ohio, USA.

Material Properties

BioMed Clear by Formlabs

After polymerization 1.2 Method Tensile properties Tensile strength 52 MPa ASTM D638-10 (Type IV) Young's modulus 2080 MPa ASTM D638-10 (Type IV) Extension 12% ASTM D638-10 (Type IV) Flex properties Flexural strength 84 MPa nine0614 ASTM D790-15 (Method B) Flexural modulus 2300 MPa ASTM D790-15 (Method B) Hardness properties Shore D 78D ASTM D2240-15 (Type D) Impact properties Izod notched impact strength 35 J/m ASTM D256-10 (Method A) nine0630 Izod unnotched impact strength 449 J/m ASTM D4812-11 Thermal properties Bending temperature under load at 1.  8 MPa

8 MPa 54⁰C ASTM D648-18 (Method B) Bending temperature under load at 0.45 MPa 67⁰C ASTM D648-18 (Method B) Thermal expansion coefficient nine0614 82 µm/m/⁰C ASTM E831-14 Other properties Water absorption 0.54% ASTM D570-98 (2018)

2 Data was measured on cured specimens printed on a Formlabs Form 3B 3D printer at 100 µm BioMed Clear Resin settings washed in Form Wash for 20 minutes at 99% isopropyl alcohol and post-cured at 60°C for 60 minutes in Form Cure. Resin sterilization

BioMed Clear Formlabs

Sterilization compatible Electron Beam (E-beam) Electron beam radiation 35 kGy Ethylene oxide 100% ethylene oxide at 55°C, 180 min Gamma 29.  4 - 31.2 kGy gamma radiation

4 - 31.2 kGy gamma radiation Steam sterilization Autoclave at 134°C for 20 min

Autoclave at 121°C for 30 min Disinfection compatible Chemical disinfection 70% isopropyl alcohol for 5 minutes BioMed Clear Resin safety and biocompatibility Formlabs

ISO Test description 3 ISO Test description 3 EN ISO 10993-5:2009 Non-cytotoxic ISO 10993-11:2017 Non-mutagenic ISO 10993-10:2010/(R)2014 Non-irritating ISO 18562-2:2017 Does not emit particulate matter ISO 10993-10:2010/(R)2014 Non-sensitiser ISO 18562-3:2017 Does not emit volatile organic compounds ISO 10993-3:2014 Non-genotoxic ISO 18562-4:2017 Does not emit harmful water soluble substances

• BioMed Amber V1 • Material Properties

BioMed Amber by Formlabs

After polymerization 1.2 Method Tensile properties Tensile strength 73 MPa ASTM D638-10 (Type IV) Young's modulus 2.  9 GPa

9 GPa ASTM D638-10 (Type IV) nine0630 Extension 12.3% ASTM D638-10 (Type IV) Flex properties Flexural strength 103 MPa ASTM D790-15 (Method B) Flexural modulus 2.5 GPa ASTM D790-15 (Method B) Hardness properties Shore D 67D ASTM D2240-15 (Type D)

2 Post cured sample data was measured on Type IV tensile bars printed on a Form 2 printer at 100 µm settings for BioMed Amber resin, washed in Form Wash for 20 minutes at 99% isopropyl alcohol and post cure at 60°C for 30 minutes in Form Cure.

BioMed Amber Resin Product Sterilization

Formlabs

Sterilization compatible Steam sterilization Autoclave at 134°C for 20 min

Autoclave at 121°C for 30 min Disinfection compatible Chemical disinfection 70% isopropyl alcohol for 5 minutes The safety and biocompatibility of BioMed resin

Amber Formlabs

ISO Test description 3 EN ISO 10993-5:2009 Non-cytotoxic ISO 10993-10:2010/(R)2014 Non-irritating ISO 10993-10:2010/(R)2014 Non-sensitiser

Learn more