Best sla 3d printer under 1000

Best 3D printers under $1,000 in 2022

We may earn revenue from the products available on this page and participate in affiliate programs. Learn more ›

Written By Gabriel Morgan

Updated Jul 13, 2022 12:30 PM

Load up the filament, transfer your slices … the best 3D printers under $1,000 have all the tools that most makers will need to give form to their visions. You might be a hobbyist separately printing and carefully-painting each gargantuan wing of the great gold-dragon for your next D&D campaign. Maybe you’re printing a grip for your old film camera to make it more comfortable to hold. Or perhaps you’re creating a custom prop for a photoshoot for much less than the cost of buying it. Whatever your aims, 3D printers at the sub $1000 price point should give you enough power to achieve them. If you want to go even cheaper, you can check out the best 3D printers for kids.

This article focuses on 3D printers at the high-hundreds price-point, that still hover below $1000. At this price point 3D printers get quite capable, delivering some really great features like auto-leveling trays, blistering extruders capable of working with wider sets of materials (such as nylon), extremely high-resolution resin prints, air-filtration, quieter operation, better-connectivity, and dual extruders. Read on for a look at some of the best 3D printers under $1000, and just what it is that makes them so.

- Best overall: R QIDI X-Plus

- Best resin: ANYCUBIC Photon Mono X 6K

- Best dual extruder: BIBO 3D Printer Dual Extruder

- Best kit: Original Prusa i3 MK3S+ kit

- Best budget: Creality Ender-3 S1

3D printers are stuffed full of tech, from their blistering-hot extruders, to their auto leveling trays, to WiFi, and 4k+ LCD arrays for curing liquid resin, Even the Bowden mechanism that’s often used to channel filament comes from an important invention for bicycle construction. With so many mechanical inventions and systems crammed into one device, 3D printers are inherently technical. Because of this, it’s a good idea to familiarize yourself with some parts of how the technology works before you buy.

Because of this, it’s a good idea to familiarize yourself with some parts of how the technology works before you buy.

With the first functional 3D printers built in the 1980s, 3D printers didn’t begin to pervade the mass market until the 2000s. While a few inventors and scientists were concurrently working on different elements of technology that would be incorporated into the 3D printer systems of today, Bill Masters was the first inventor who filed a 3D printer patent.

The inventor was camping on the banks of the Chattanooga river one night, staring up at the stars, when the idea came to him. He imagined using one star as a seed point, and then combining the other dots of starlight to create any shape he liked. His analogy for the additive manufacturing process that defines FDM printers of now, is great, likening the tech to “spit wads,” similar to the ones so many children familiarize themselves with at a day in the mall, “When you shoot a lot of wads, they begin to take shape. If you can control the direction of the wads and the motion of the device shooting them, you can produce any desired shape.” We love it.

If you can control the direction of the wads and the motion of the device shooting them, you can produce any desired shape.” We love it.

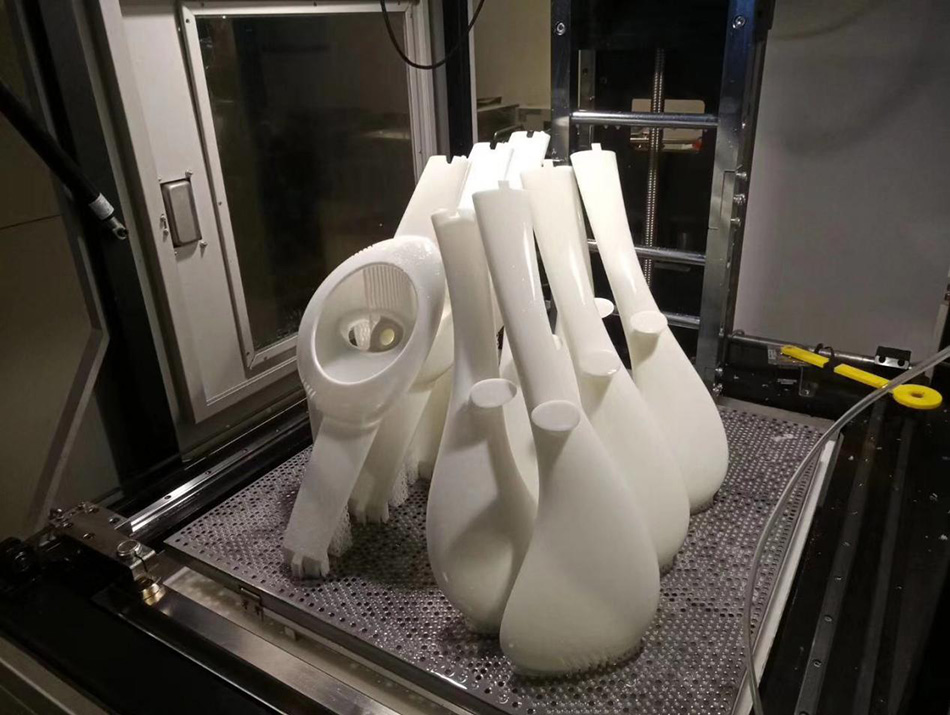

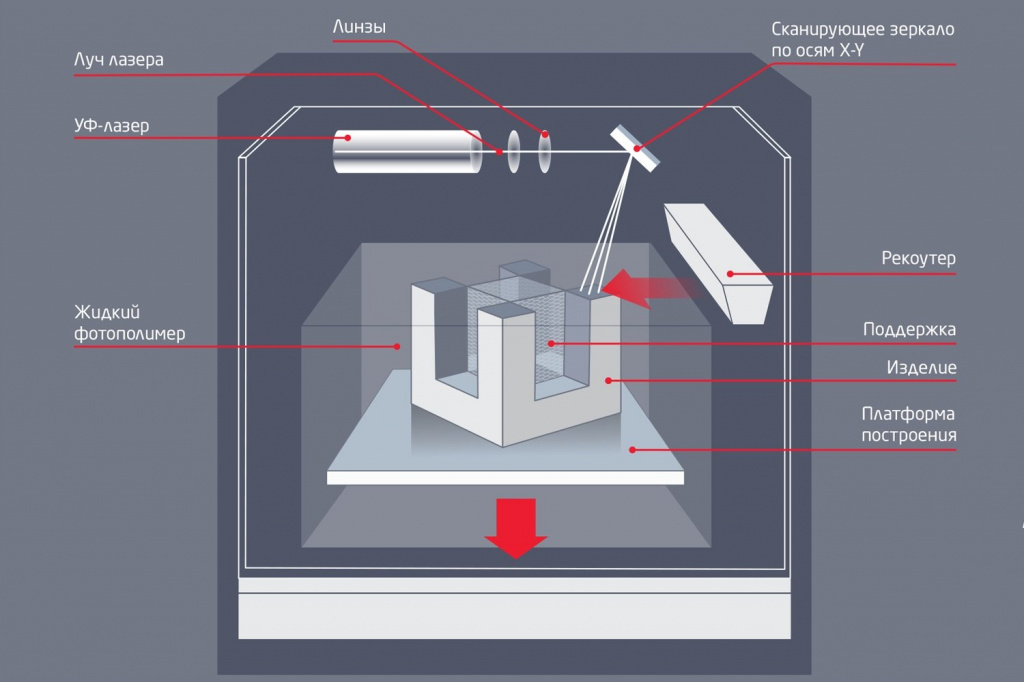

While there are numerous classes of 3D printers, there are three main families. These are fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Selective laser sintering uses a laser to fuse powdered material, which is distributed across a bed with a roller. SLS printers are capable of delivering strong functional prints that are sturdy enough for immediate incorporation into manufactured systems. However, the SLS process is very expensive, and is out of reach for most DIY tinkerers. At the sub-$1000 price point, this article focuses on FDM and SLA printers.

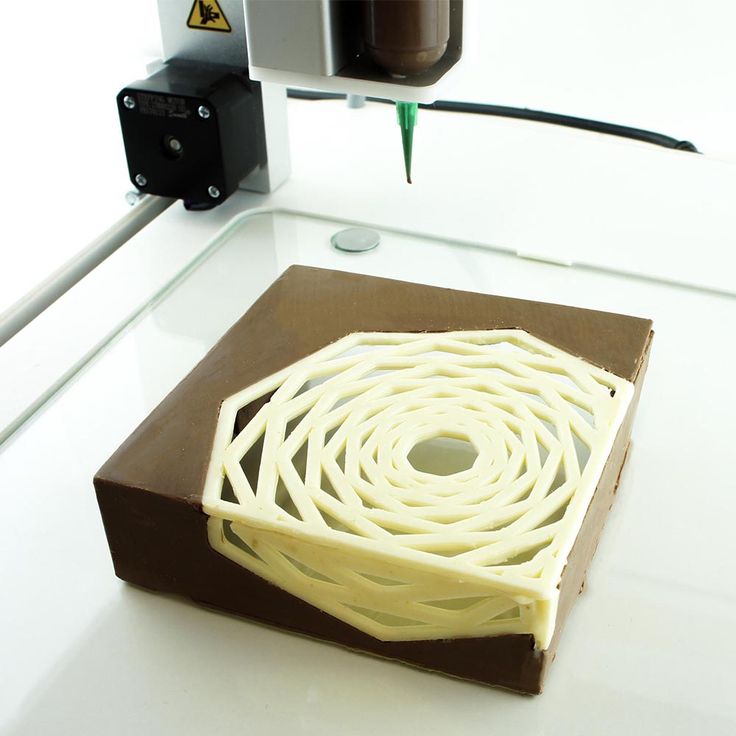

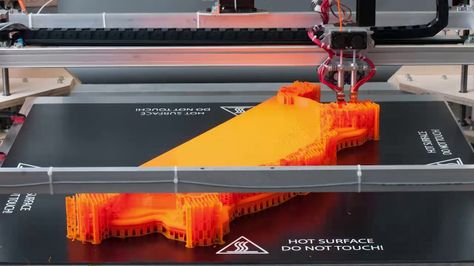

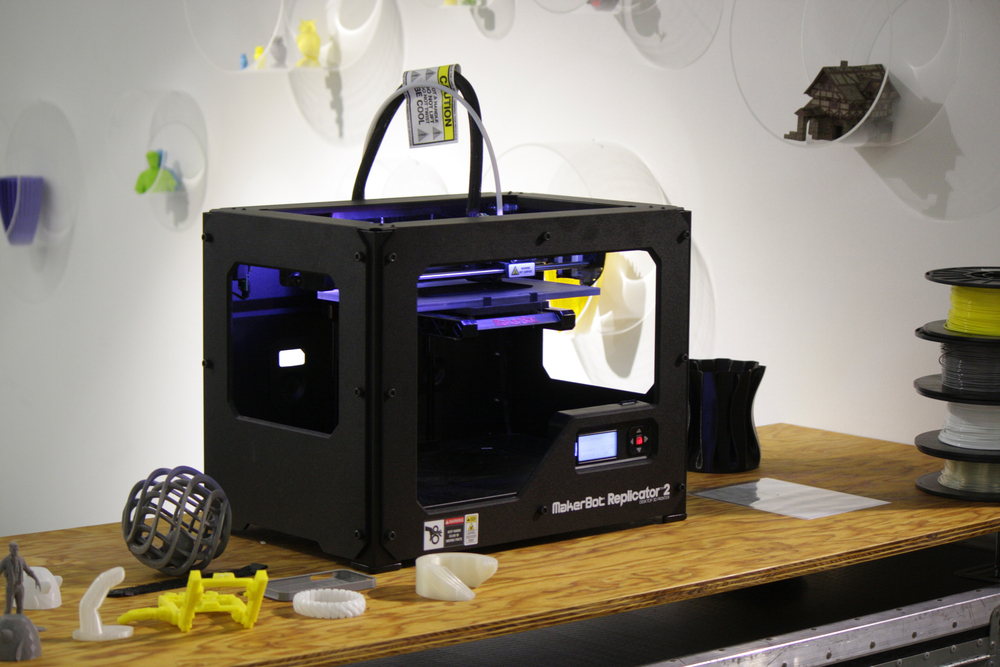

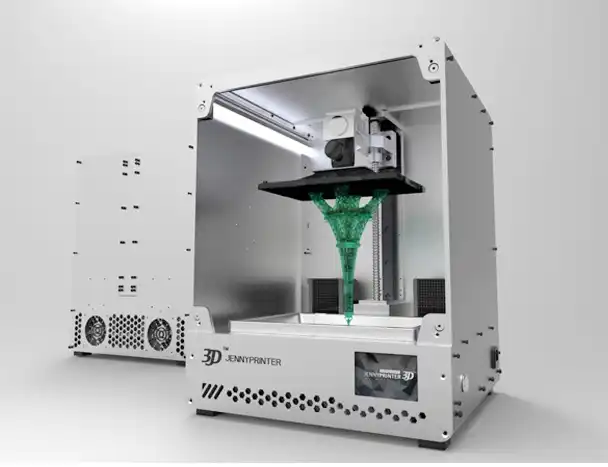

Fused deposition modelingFDM printers are the most common and economical 3D printers on the market. These printers use a superheated nozzle to extrude filament downward onto a heated, leveled tray, building the model up slice-by-slice. FDM printers are suitable for quick prototyping, proof of concepts, and finished projects, and tend to be more economical and user-friendly. FDM printers usually also deliver a greater build area than SLA printers for the price.

FDM printers are suitable for quick prototyping, proof of concepts, and finished projects, and tend to be more economical and user-friendly. FDM printers usually also deliver a greater build area than SLA printers for the price.

FDM printers create objects out of thermoplastics. These common plastics have chemical properties that allow them to melt, form into a shape, and then melt again. These plastics are inherently recyclable, and many are quite cheap. The most common thermoplastics used in FDM printers include ABS, PLA, PETG, and TPU. Some also print nylon, and more.

These thermoplastics have different properties, some are food safe, while others are biodegradable, others are non-toxic for skin contact. However, the manner in which thermoplastic deposits fuse is primarily mechanical, rather than chemical, which runs the risk of leaving voids (or open spaces) in the walls of the print, which leads to inferior structural integrity on the Z axis.

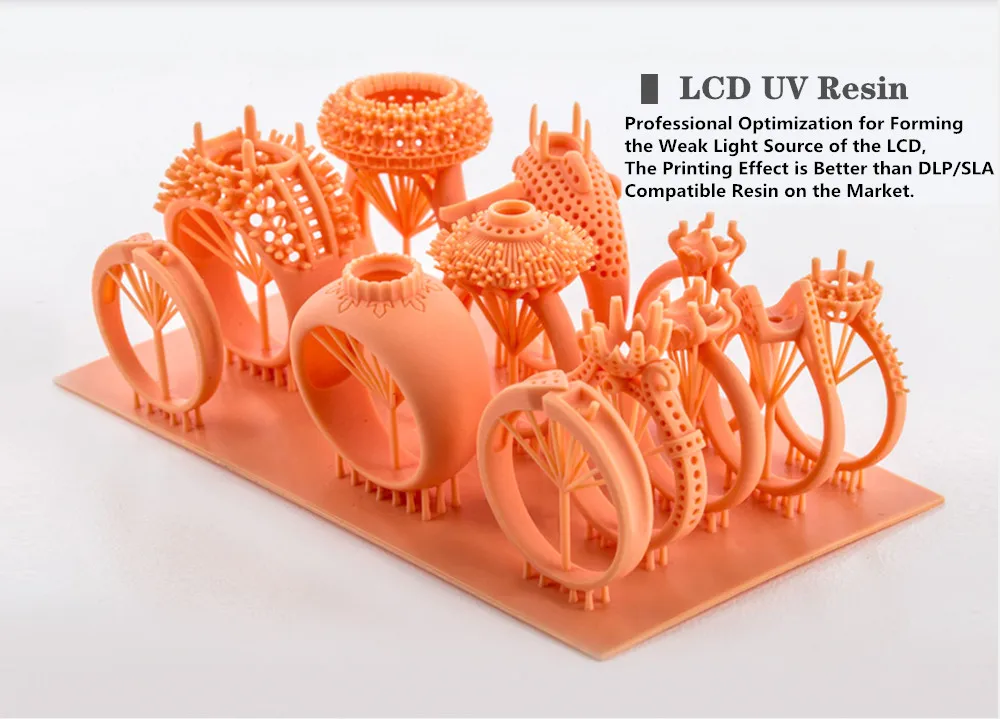

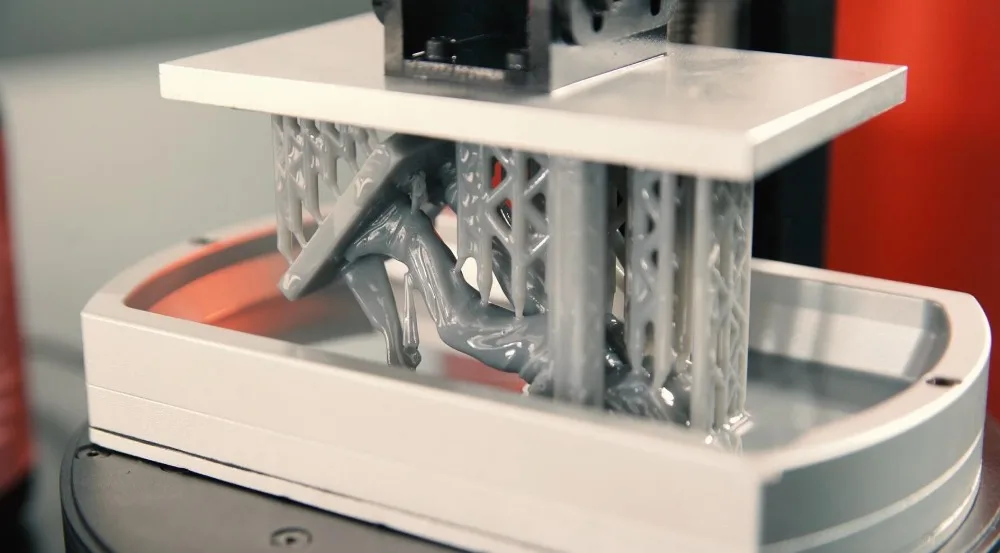

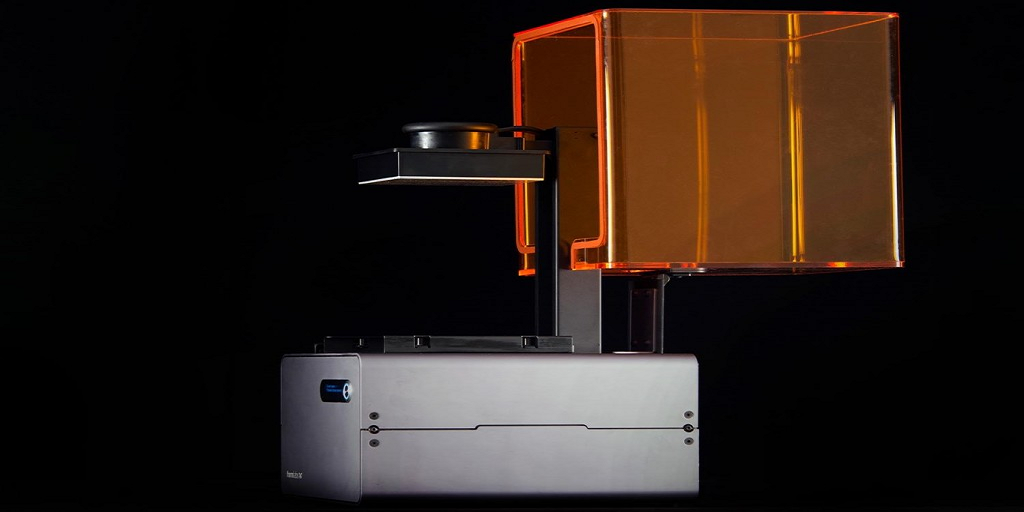

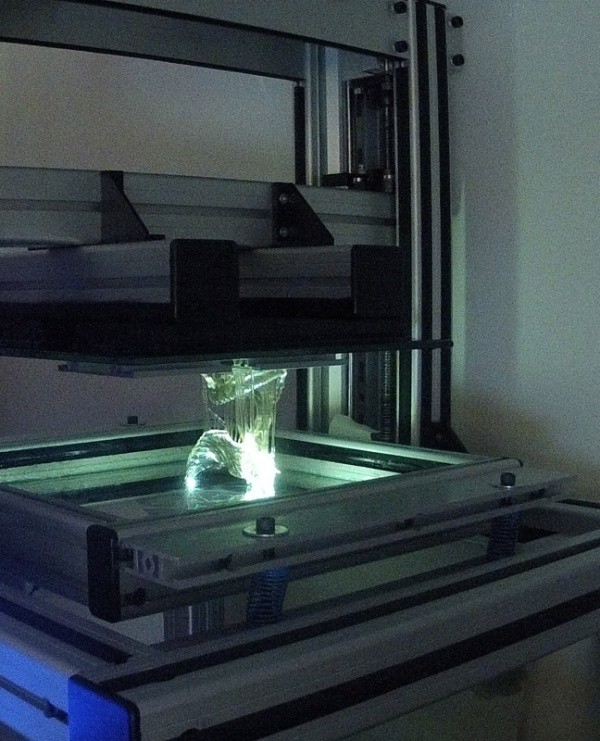

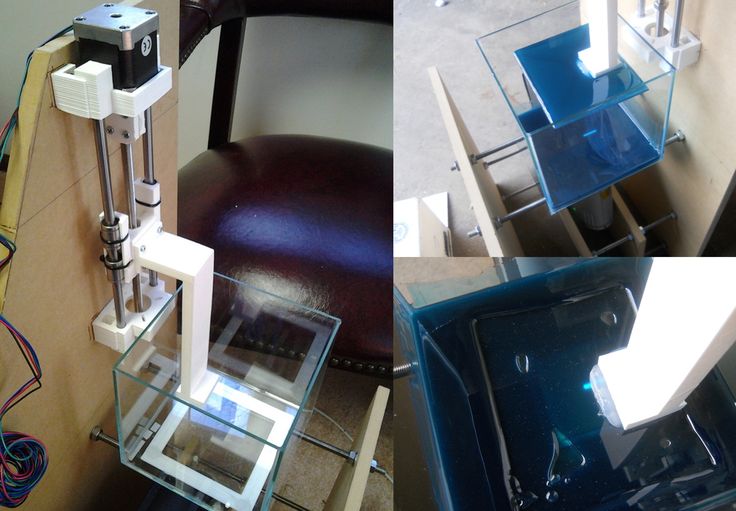

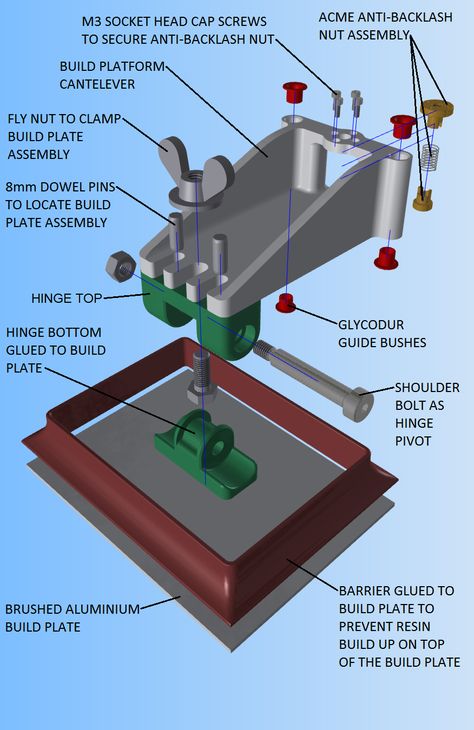

SLA printers use a different process from FDM printers, whereby a laser, or LCD array cures resin in a liquid resin bath, and extrudes it upwards slice by slice. These printers fuse the print onto a heated tray, and lifts it, upside-down, from the liquid resin. They are capable of printing parts and models with greater structural integrity and detail. Because of their high print resolution, SLA printers are the go-to for most hobbyists looking to build intricate models and figurines.

Thermosets in SLA printersSLA printers use thermosetting plastics (thermosets). These resins cure into shape, and cannot be heated to dissolve, rather, heat causes their decomposition. This means that thermosets are not recyclable. However, the curing process of resins give them superior structural integrity to thermoplastics, as the plastic chemically fuses, creating covalent bonds between molecules. These resins achieve prints with better detail, resolution, and strength. Thermoset variety is also wide, including clear resins, wiggly resins, high temp resins, and even dental grade resins.

Thermoset variety is also wide, including clear resins, wiggly resins, high temp resins, and even dental grade resins.

Because there’s so much that goes into great 3D printers there were a lot of features to factor when we were researching the five best. We researched numerous printers from multiple manufacturers, looking for the best feature sets, wherein all parts collaborate for a gestalt of function that’s the most useful for the makers of today. Along the way we looked for a few specific features which we detailed below:

Versatility is always nice. At the mid-level price point below $1000, we start seeing FDM printers that are capable of nylon and some more advanced thermoplastics. We also start seeing SLA printers that are capable of more. We noted this wherever it stood out.

Tray functions are so important to overall printer quality. We looked for printers with trays that get hot enough to keep your models well-secured. We also looked for printers that have auto-leveling functionality, or at least excellent semi-auto leveling.

We looked for printers with trays that get hot enough to keep your models well-secured. We also looked for printers that have auto-leveling functionality, or at least excellent semi-auto leveling.

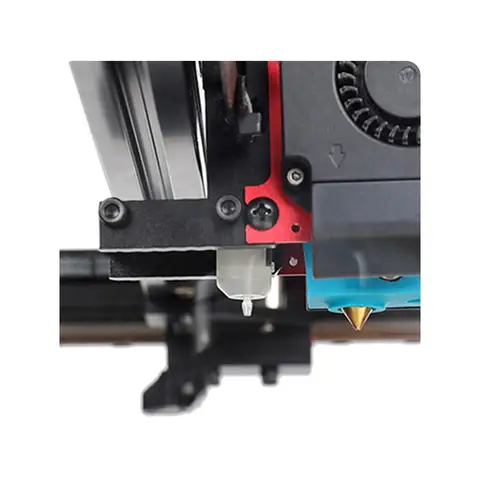

Extruder & LCD (or laser) quality is extremely important for 3D printing. Extruder quality plays a big role in which thermoplastics the printer can handle. Great extruders get hot, and are light enough to work well with the system. Different extruder dimensions also play into their use for different situations. Some systems even use two extruders. For SLA systems the LCD array (or laser) is extremely important in getting good print resolution and smooth forms.

Overall precision is achieved through lots of factors, but we like to see FDM printers with a multi-column lift system. We looked for FDM printers that don’t leave lines, burrs, or slice edges visible on the sides of the print. We also looked for SLA printers that yield high-res prints with smooth curves.

Connectivity & slicing software can define the quality of your print experience just as much as some of the more mechanical components of your system. Wireless connection is always nice, and printers with a few gigabytes of internal storage also offer a boon. Compatibility with lots of slicing software or one especially good one is also important and we noted this.

User experience and assembly also cannot be overlooked. Some printers get loud — we mean infernal giant-water-bears crawling from the pit sort-of loud (do water-bears roar?). Where we found printers that deal well with sound and fumes, we highlighted them. We also noted the required assembly of each printer. Some want highly customizable printers that might require longer assembly but are capable of modding, but not all do.

The best 3D printers under $1,000: Reviews & RecommendationsBest overall: R QIDI X-Plus

R QIDI TECHNOLOGY

SEE IT

Why It Made The Cut: An FDM printer with easily-serviceable standard parts, an optional auxiliary-extruder that enables it to print more technical materials, and outstanding customer service.

Specs:

- Print technology: FDM

- Build size: 10.6 x 7.9 x 7.9 inches

- Supported materials: PLA, TPU, PETG, ABS, Nylon, PC, Carbon fiber, and more

- Best slicer software: QIDI Print Slicer (included free)

Pros

- Second extruder for technical-material free upon request

- Excellent customer service and support

- Very easy assembly & simple repair

- High res-smooth prints

Cons

- Manual bed leveling

- Wifi issues with non-QIDI software

Something of a plug-and-play machine, the R QIDI X-Plus is a highly capable FDM printer that has an expanded range of materials, possible via a free supplementary extruder. With easily repaired standard parts, and great customer support, it’s an easy best-overall choice for most.

Shipped from China, the semi-enclosed X-Plus takes hardly any set up. It comes with a standard extruder suitable for PLA, ABS, and TPU. A second technical-material extruder is also available with your purchase free-of-charge by request (which belies the companies communication-forward ethos), and is capable of materials like Nylon, PC, Carbon fiber, and more. To be clear, this second extruder is swappable, rather than supplementary, this isn’t a dual-extruder rig, and the second extruder won’t work in tandem with the standard. However, the technical nozzle is a nice touch, that firmly differentiates this machine from cheaper FDM’s in the sub-$500 price range.

It comes with a standard extruder suitable for PLA, ABS, and TPU. A second technical-material extruder is also available with your purchase free-of-charge by request (which belies the companies communication-forward ethos), and is capable of materials like Nylon, PC, Carbon fiber, and more. To be clear, this second extruder is swappable, rather than supplementary, this isn’t a dual-extruder rig, and the second extruder won’t work in tandem with the standard. However, the technical nozzle is a nice touch, that firmly differentiates this machine from cheaper FDM’s in the sub-$500 price range.

QIDI is all about customer support and easy repairs. Not only are the majority of the parts in this system standard and easily replaceable, but the majority of replacements are also easy to DIY, with included tools for most hardware in the system. QIDI offers exceptional customer service, with knowledgeable agents ready to send you repair parts as needed, and help troubleshoot issues.

While the X-Plus doesn’t have the automatic leveling you might like at this price point, it does have a semi-auto, single-point quick-level system that is reliable and easy. It features QIDI Print Slicer software, that’s free to use with any QIDI system All-in-all, while this system might not be as appealing to hardcore tinkerers as some, those who want consistent quality with easy set-up, good customer support, and a wider than average range of available materials will love it.

It features QIDI Print Slicer software, that’s free to use with any QIDI system All-in-all, while this system might not be as appealing to hardcore tinkerers as some, those who want consistent quality with easy set-up, good customer support, and a wider than average range of available materials will love it.

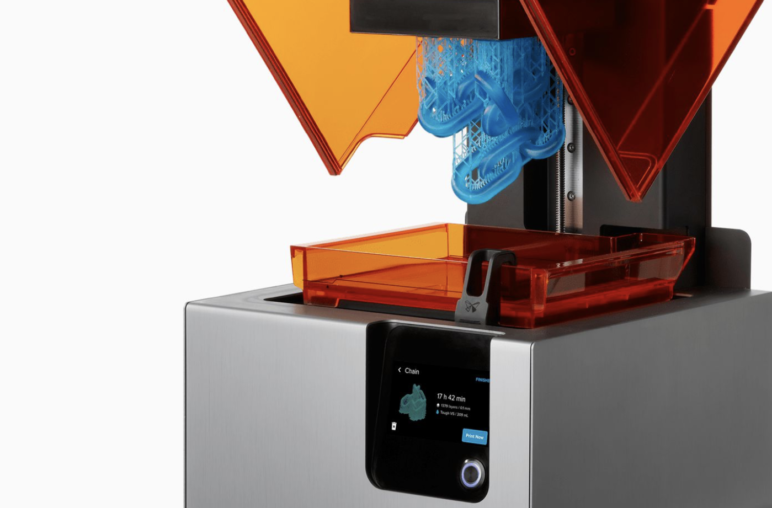

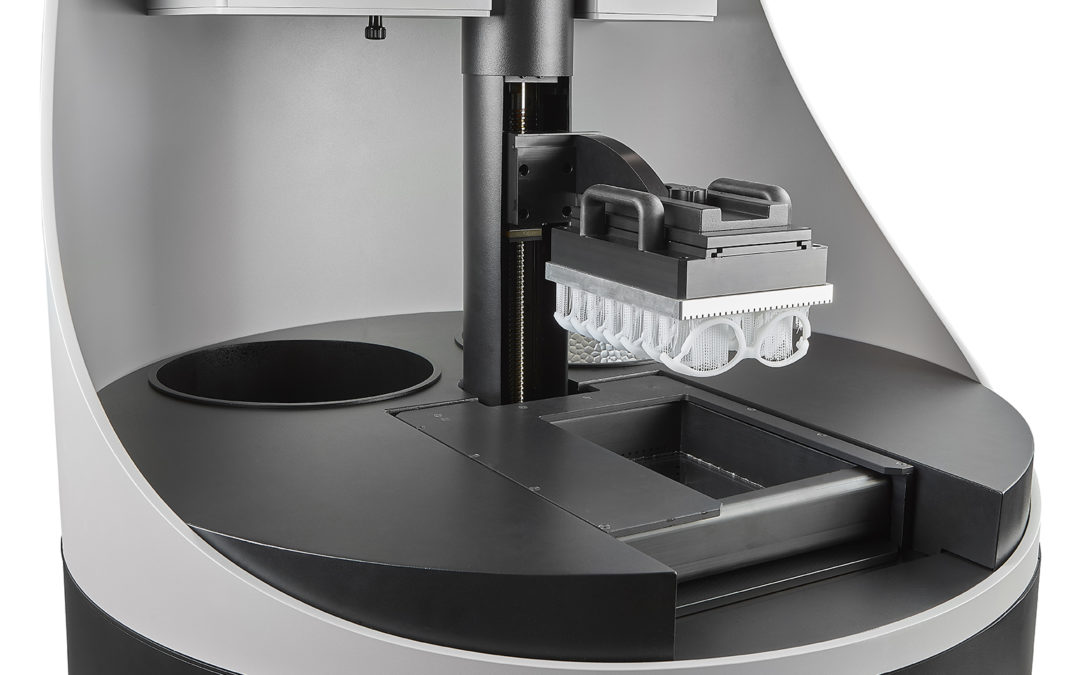

Best Resin: ANYCUBIC Photon Mono X 6K

Why It Made The Cut: 6K LCDs mean better resolution than ever, with more detail and contrast, more build volume, and faster speeds.

Specs:

- Print technology: SLA

- Build size: 9.6 x 7.8 x 4.8 inches

- Supported materials: Resin

- Best slicer software: Anycubic Photon Workshop (free), ChiTuBox, Lychee, more

Pros

- Extreme print detail and resolution

- Great contrast

- Fast, at up to 1s / layer in some instances

- Great out of the box prints

Cons

- Poor connectivity options

- Very smelly

6K — that’s a lot of LCDs, and the ANYCUBIC Photon Mono X 6K leverages them all for extremely high-resolution prints with impeccable contrast. ANYCUBIC is one of the most popular lines of SLA resin printers, and the Photon Mono X is one of the most impressive dogs in the pack.

ANYCUBIC is one of the most popular lines of SLA resin printers, and the Photon Mono X is one of the most impressive dogs in the pack.

With its 6K LCDs the Photon Mono X 6K uses an 9.25 inch monochrome LCD array, with 6% light transmittance, which means quicker printing. The machine is fast, and ANYCUBIC brags up to 1s / layer, in ideal circumstances. Its LCD’s deliver extreme contrast that’s noticeable, and the model sports a much larger build area than its cousins, at 9.6 x 7.8 x 4.8 inches.

ANYCUBIC is compatible with lots of the great slicer software packs, from ChiTuBox, to Lychee, and offers the proprietary Anycubic Photon Workshop free of charge. Sadly, getting your slices to the printer is more difficult than it could be, as the printer’s Wifi is notoriously spotty. It’s built around its LCD screen control and SD card reader, meaning SD is the best way-to-play. Those who like to keep their SLA printer on a well ventilated back porch will appreciate not having to keep their printer connected to a laptop, but those who want to set up a printer farm might groan. Otherwise, it’s a great buy, offering some of the best quality resin prints out there.

Otherwise, it’s a great buy, offering some of the best quality resin prints out there.

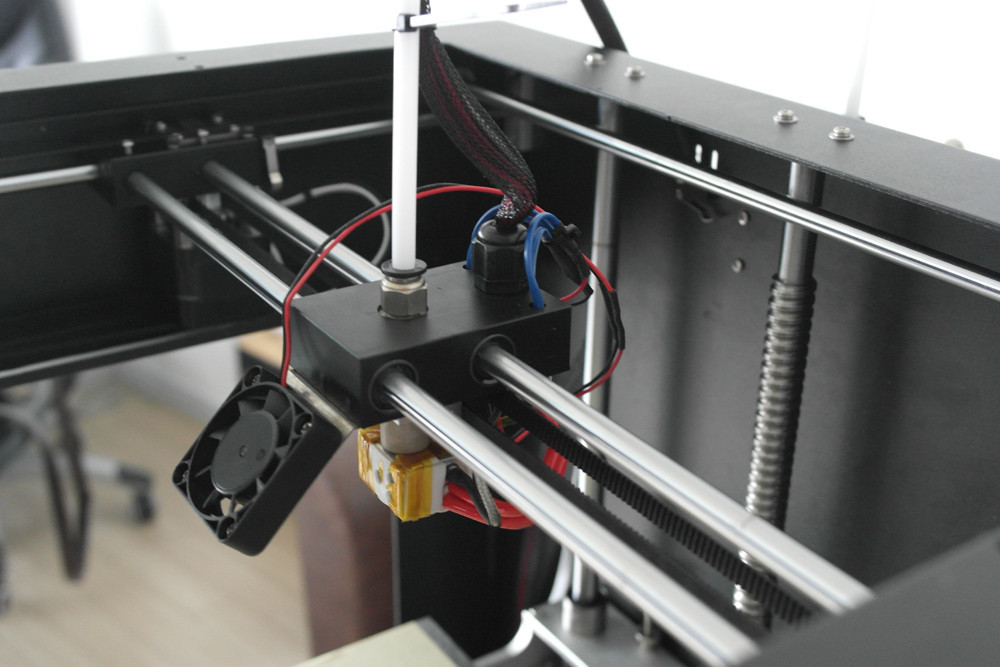

Best dxtruder: BIBO 3D Printer Dual Extruder

Why It Made The Cut: Solid dual extruder support means lots of techniques you can’t get at with other FDM printers, plus WiFi and a touchscreen make it easy to use.

Specs:

- Print technology: FDM

- Build size: 8.4 x 7.3 x 6.3 inches

- Supported materials: ABS, PLA, Dissolvable filament (PVA, HIPS), TPU, PETG, Nylon, PC, Carbon fiber, and more

- Best slicer software: Repetier-Host, Cura, Simplify3D

Pros

- Dual extruders

- Minimal easy assembly

- Wifi control

- Good customer support

Cons

- Difficult maintenance and usability

- Bed isn’t easy to level

If you’re moving up from a basic machine, the BIBO 3D’s dual extruders can open doors you didn’t even know were closed. These include printing dissolvable supports, printing with multiple colors, and 3D printing two duplicate objects simultaneously. But these dual extruders aren’t the BIBO 3D’s only bargaining chip.

These include printing dissolvable supports, printing with multiple colors, and 3D printing two duplicate objects simultaneously. But these dual extruders aren’t the BIBO 3D’s only bargaining chip.

BIBO 3D does a good job with a wider range of materials. Beyond the standards like ABS and PLA, it prints more technical thermoplastics like flexible nylon, and carbon fiber. The system uses an easy touch-screen control panel to set up prints, and can also be controlled via Wifi, meaning you can control it from your phone.

The machine does have a couple of blindspots. Its leveling control isn’t as intuitive as you would expect at the price point. The machine is also packed tight with features, with screws in odd places, and somewhat abstract engineering overall. These issues are offset by great customer service from the company, but they do make the machine’s usability somewhat less optimal than some of the competition. It’s a great option for tinkerers who want extra extruders and wider material possibilities, but in spite of its initial assembly, it may be more hands on than some want.

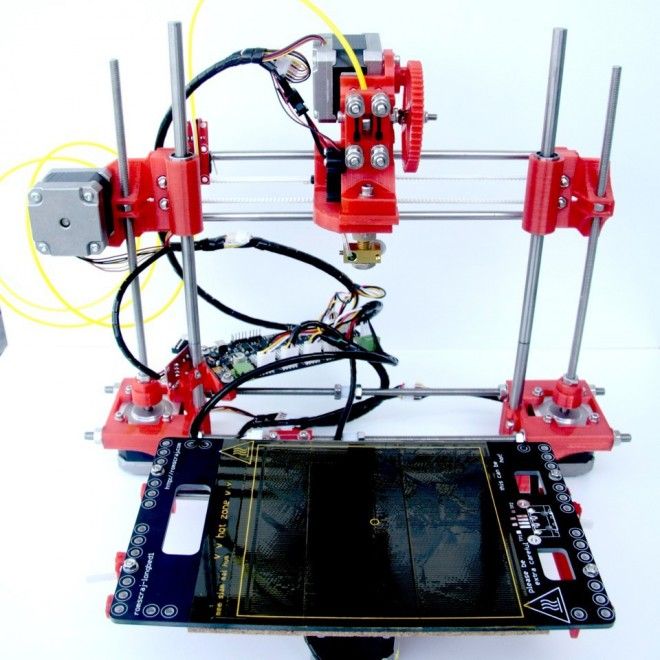

Best kit: Original Prusa i3 MK3S+ kit

prusa3d

SEE IT

Why It Made The Cut: Taking a DIY ethos all the way, the Prusa i3 kit is open-sourced and powerful, with a state-of-the-art-extruder, exceptional leveling, wide filament support and more.

Specs:

- Print technology: FDM

- Build size: 9.84 × 8.3 × 8.3 inches

- Supported materials: PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA / BVOH, PVB, HIPS, PP (Polypropylene), Flex, nGen, Nylon, Carbon filled, Woodfill

- Best slicer software: PrusaSlicer (proprietary), open source

Pros

- Mesh bed leveling details leveling for every print

- Excellent extruder that can handle an extra wide set of features

- Open source with strong user base for help with all sorts of mods and use cases

- Easy to remove prints

Cons

- Kit requires detailed and rigorous assembly

- Long lead-times for production, allow weeks before it arrives

You can’t get far into 3D printing turf without hearing the name Prusa, and it’s not hard to see why with the Original Prusa i3 MK3S+ kit (an assembled version is also available for a couple hundred more). This kit is a DIY maker’s dream, including some of the best tools in its class for 3D printing.

This kit is a DIY maker’s dream, including some of the best tools in its class for 3D printing.

There’s a few things that make the Prusa i3 special, but we’ll start with its basics. It features a state-of-the-art extruder, as well as an excellent filament monitor. The extruder can handle a much wider than average set of filaments, including the standards, as well as nice additions such as woodfill, and abrasive nylon carbon-fiber. The printer also features an excellent fully automatic bed-leveling system that checks your bed before every print. If that’s not enough, its removable spring steel-sheets make it easy to extract your finished print.

In the end the Prusa i3 is one of the best options out there at the under $1000 price-point, and debatably beats out our top overall pick, the R QIDI X-Plus. However, for the Prusa to reach its full potential this machine requires an operator and builder who rejoices in getting through the weeds that are a major part of its construction, and making it out the other side. This is a printer for tinkerers and DIY makers, and when it’s well understood and loved, it can do wonders.

This is a printer for tinkerers and DIY makers, and when it’s well understood and loved, it can do wonders.

Best budget: Creality Ender-3 S1

Why It Made The Cut: Markedly more affordable than the rest of the printers on this list, the Ender-3 offers some pro level prototyping features, in an upgradeable build that’s priced for beginners.

Specs:

- Print technology: FDM

- Build size: 8.6 x 8.6 x 10.2 inches

- Supported materials: PLA, TPU, PETG, ABS

- Best slicer software: Open source (No preferred), Cura, Simplify3D, PrusaSlicer

Pros

- Open sourced and upgradeable

- Very precise extruder with dual lift

- 16 point auto level

- Easy assembly

Cons

- Loud prints

- Limited feature set compared to more expensive options

Our pick for the best 3d printer under 500, the Creality Ender-3 S1 is still worth a look, even if your possible budget could maybe allow for something pricier. Alongside Prusa, Creality’s Ender series is ever recognizable, and potentially the best known series for beginners. This open-source and expandable system gives you more room to print with than some systems that cost twice as much. With an extruder that hits 500 degrees Fahrenheit it’s also not that restrictive in comparison. Sure it won’t take care of more technical materials, but it does better than most, and if you’re new that might not matter.

Alongside Prusa, Creality’s Ender series is ever recognizable, and potentially the best known series for beginners. This open-source and expandable system gives you more room to print with than some systems that cost twice as much. With an extruder that hits 500 degrees Fahrenheit it’s also not that restrictive in comparison. Sure it won’t take care of more technical materials, but it does better than most, and if you’re new that might not matter.

One of the S1’s standout features is a 16 point auto-leveling system that makes sure your print bed is up to the challenge every time, it also features a removable spring steel-plate, a power-loss recovery feature, and a filament sensor. It delivers solid precision, with a dual-motor design.

While the S1 doesn’t have some of the top features found in models that retail closer to $1000, it’s still an exceptional hobbyist’s 3D printer that’s capable of doing a lot. It’s a great foundation that can be expanded on significantly with mods.

FDM, or fused deposition modeling 3D printers are usually the cheapest, both in terms of up front cost and the cost to replenish their filament over time. They use an additive manufacturing process whereby they apply layers of molten thermoplastics onto a heated tray.

Q: What is the best 3D printer under 1000?The best 3D printer under $1000 for most users is the R QIDI X-Plus. Arriving pre-assembled, this partially enclosed FDM printer is easily serviceable, precise, good for high-quality prints, and is capable of printing a wide array of filaments. QIDI also delivers great customer support.

Q: Which brand 3D printer is best?There are lots of great 3D printer brands. Creality does a great job with powerful hobbyist printers for affordable prices. Prusa makes incredible open sourced printers with some of the best tech around. QIDI is known for precise, easy to use printers with excellent customer support. ANYCUBIC makes exceptional high-res SLA printers. ELEGOO also makes wonderful SLA printers. The best brand is the brand that brings the feature set you need.

QIDI is known for precise, easy to use printers with excellent customer support. ANYCUBIC makes exceptional high-res SLA printers. ELEGOO also makes wonderful SLA printers. The best brand is the brand that brings the feature set you need.

As with any craft business, 3D printer craft can turn a good profit, however, how profitable it will be will depend upon your business practices. Before you invest in a business based on a 3D printer, consider all the factors that will contribute to your business.

Q: Can 3D printers can be acquired for less than 1000?Yes, there are many excellent printers that can be acquired for under 1000. There are even some good ones that cost less than $200.

Q: Do you need a computer for a 3D printer?In some form, you do need a computer for a 3D printer. However, some work-arounds are possible. If you want to buy a 3D printer and can’t afford a computer as well, consider downloading files from your library or school computer and using an SD card to print them on your 3D printer at home.

In some instances enclosed 3D printers are better. Many enclosed 3D printers come preassembled and are easy for beginners to plug in and get started with. Also, 3D printers can emit harmful fumes and light. Most SLA printers, which use bright curing LCDs and / or lasers, feature a UV shield. FDM printers can also benefit from the protection and structural integrity that enclosures provide.

Final thoughts regarding the best 3D printers under $1,000With so many features and advanced processes spun into one functional system, the best 3D printers under $1000 offer astounding feats of engineering, synergized to work together, to bring wildly powerful tools of creation into your workshop. They are used by everyone from design firms who might be prototyping a new invention, to hobbyists building a fleet of figurines. For the best DIY maker’s tool in its class, we recommend the Original Prusa i3 MK3S+ kit. If you’re looking for top notch resolution, you can’t go wrong with the ANYCUBIC Photon Mono X 6K, which is the best SLA 3D printer at its price point. If you want something that’s a little on the cheaper side, the Creality Ender-3 S1 is the best for beginners, and offers a large build space and solid tools. Finally, if ease of use is your prerogative, we recommend the R QIDI X-Plus, as the best overall 3D printer for most users — it might not offer as much tweakage potential as the Prusa i3, but with the X-Plus you’ll be printing great materials within two hours of the package arriving at your door.

If you’re looking for top notch resolution, you can’t go wrong with the ANYCUBIC Photon Mono X 6K, which is the best SLA 3D printer at its price point. If you want something that’s a little on the cheaper side, the Creality Ender-3 S1 is the best for beginners, and offers a large build space and solid tools. Finally, if ease of use is your prerogative, we recommend the R QIDI X-Plus, as the best overall 3D printer for most users — it might not offer as much tweakage potential as the Prusa i3, but with the X-Plus you’ll be printing great materials within two hours of the package arriving at your door.

Creality Halot-One Plus 3D Printer Review: 4K Resolution, Sub-$400 Price

Tom's Hardware Verdict

Offering high resolution and an above-average build volume, the Creality Halot-One Plus is an impressive machine with a set of hardware features not typically seen at this price.

Pros

- +

4K+ resolution provides sharp detail and consistent surfaces

- +

Large 5-inch LCD interface is bright, fast, and responsive

- +

Halot Box slicer software is simple and easy to use

- +

Built-in Wi-Fi connectivity and remote print monitoring

- +

Integrated air filtration unit

Cons

- -

Z endstop placement at the top of the Z axis is a strange choice

- -

Creality Cloud platform appears to host many unauthorized models

- -

Four bolt build platform leveling can be messy

Why you can trust Tom's Hardware Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Find out more about how we test.

Today's best Creality Halot-One Plus deals

No price information

Check Amazon

The Creality Halot-One Plus is the flagship printer in the Halot line of MSLA printers, offering 4K resolution, a 7.9-inch mono LCD with a 3 second exposure time, and other high-end features in a package that retails for just under $400. The Halot-One Plus appears to have been designed for the prosumer market, with features like Wi-Fi connectivity, air filtration, and other features that don’t typically appear in printers in this price range.

During testing, this printer proved to be a logical next-step in resin 3D printing, showing how these features can be successfully implemented at a lower price point while still maintaining functionality. We had issues with the Creality Cloud platform and the lack of attribution on published models, but the printer hardware itself places this among the best resin 3D printers.

Creality Halot-One Plus Specifications

Swipe to scroll horizontally

| Machine Footprint | 9.29" x 9.57" x 16.46" (23.6cm x 24.3cm x 41.8cm) |

| Build Volume | 6.77" x 4.02" x 6.30" (172mm x 102mm x 160mm) |

| Resin | MSLA Photopolymer Resin |

| UV Light | 4,500 uw/m2 Integral Light Source |

| Masking LCD Resolution | 4320 x 2560 |

| Masking LCD Size | 7.9-inch |

| XY Axis Resolution | .04mm |

| Interface | 5-inch LCD Touchscreen |

Included in the Box of Creality Halot-One Plus

(Image credit: Tom's Hardware)The Creality Halot-One Plus ships with everything you need to get started printing, including a set of Allen keys, plastic and metal scrapers to remove parts from the printer, a printed user guide, and a power cable, and some paper funnels for pouring resin back into the bottle from the vat. The printer itself is well-packed and protected, with a protective plastic covering over the UV-resistant lid.

The printer itself is well-packed and protected, with a protective plastic covering over the UV-resistant lid.

Unlike with many other resin printers, including the Elegoo Mars 3, the Halot-One Plus does not include any consumables such as gloves, masks, or other cleaning supplies. This isn’t a large omission, but it means first time users will want to make sure they have all the proper supplies before they start printing.

One of the first features I noticed on the Creality Halot-One Plus was the large LCD screen. The 5-inch screen is bright, responsive, and feels like the type of capacitive screen you’d expect to see on a tablet or mobile phone. This screen is easy to read and use, and immediately sets the Halot-One Plus apart from similarly priced machines that use smaller screens. The Halot-One Plus also includes an onboard ARM Cortex-M4 quad-core 64 bit processor, which gives it more processing power than other similarly priced machines.

Image 1 of 2

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Halot-One Plus has a dark blue UV-resistant lid, something that stands out from the typical red, orange, or yellow used on similar printers. This lid is close to opaque, and I can’t easily see through it during printing. The QR code printed on the top of the lid leads to the Creality Cloud site where users can purchase models, 3D printers, consumables, as well as a social platform for sharing prints.

This lid is close to opaque, and I can’t easily see through it during printing. The QR code printed on the top of the lid leads to the Creality Cloud site where users can purchase models, 3D printers, consumables, as well as a social platform for sharing prints.

The Halot-One Plus features an integrated 100W power supply, so there’s no need for an external power brick. The build size, printer size, and other information is printed on a sticker on the back of the printer, as well as a QR code that appears to contain information specific to the printer. The base of the Halot-One Plus is heavy and dense, and feels very sturdy despite the plastic shell.

(Image credit: Tom's Hardware)The integrated air filtration system on the Halot-One Plus is a welcome addition and worked very well throughout our testing. The resin used in the MSLA printing process can have an odor during printing, and the integrated air filtration system significantly reduces the amount of odor from the Halot-One Plus. The air intake is located directly behind the resin vat, and runs automatically throughout the duration of printing.

The air intake is located directly behind the resin vat, and runs automatically throughout the duration of printing.

The Z axis on the Halot-One Plus uses a threaded rod with a captive nut for travel, and the dual linear rails allow for smooth and consistent movement. Most small format MSLA resin 3D printers use a single linear rail for travel, with dual rail systems being more common on larger machines like the Elegoo Saturn or the Anycubic Mono X. The build platform is suspended from a lightweight metal arm and doesn’t deflect, even when printing large and heavy parts.

(Image credit: Tom's Hardware)The Halot-One Plus has the Z endstop located at the top of the Z axis, an unusual design choice for an MSLA resin 3D printer. Typically, the leveling process involves dropping the platform to Z0 (the bottom of the Z axis) and ensuring the platform is planar with the LCD screen. The Halot-One Plus requires the entire platform be brought to the top of the printer to define Z0, and then lowered to the LCD screen and leveled. It’s hard to say if this is a less accurate process, but it’s definitely a more time-consuming one.

It’s hard to say if this is a less accurate process, but it’s definitely a more time-consuming one.

The resin vat on the Halot-One Plus is smooth and easy to clean, with printed labels that indicate 250mL, 450mL, and 650mL fill levels. The vat also has a spout molded into the front right and back left corners, which makes pouring resin out of the vat and back into the bottle a simple and mess-free process. One of the screws that secures the vat to the frame had some flashing on the molded thumbscrew, and this meant the screw couldn’t actually fit into the mating hole without being trimmed. Not a major issue, but definitely a QC issue that should have been caught before the printer was packed and left the factory.

Image 1 of 3

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The light source of the Halot-One Plus is what Creality calls the “Integral Light Source”, which is a high-powered 4,500 uw/cm2 LED array that is projected through the masking LCD via an angled mirror in the base of the printer. This light source generates a substantial amount of heat during printing, which causes the onboard fan to run continuously during printing.

This light source generates a substantial amount of heat during printing, which causes the onboard fan to run continuously during printing.

The 7.9-inch masking LCD has a resolution of 4320 x 2560, a resolution that is slightly above the typical 4K resolution (4098 x 2560) used on similar resin 3D printers like the Elegoo Mars 3. This 4K resolution translates to an XY pixel size of .04mm (40 microns), which is high enough to capture fine details and texture when printing.

Image: Creality

(Image credit: Creality)Build Platform on Creality Halot-One Plus

The Creality Halot-One Plus uses a four bolt leveling system to ensure a planar relationship between the build platform and the masking LCD. Because the Z endstop is located at the very top of the printer, this process involves loosening the build platform connecting bolts, sending the built platform to the top of the printer to trigger the endstop, then reversing direction and sending the platform to the bottom of the Z axis. Once the platform is sitting flush on the masking LCD, the four bolts are tightened and the platform is leveled.

Once the platform is sitting flush on the masking LCD, the four bolts are tightened and the platform is leveled.

The Halot-One Plus has four upward-facing bolts that secure the build platform to the gantry arm, and these bolts tend to fill with resin during printing. This is a poor design choice, as resin tends to pool inside the bolt cap heads, in the knurling, and around the bolts, which is very difficult to clean and remove. Elegoo has solved this on their Mars 2 Pro and Mars 3 printers by using a simple captive ball joint that can be leveled with only two screws. Those platforms are easy to level and clean without additional effort.

(Image credit: Tom's Hardware)Printing Safety with Halot-One Plus

(Image credit: Tom's Hardware)The Creality Halot-One Plus uses 405nm UV resin, a material that you need to handle safely when in an uncured state to avoid injury. The resin can be harmful when making contact with skin, so make sure to wear gloves when pouring, cleaning up, or handling uncured resin. I also make sure I’m wearing gloves when removing the build platform after a print, as the resin tends to pool on top of the platform and can drip off while the platform is being removed.

I also make sure I’m wearing gloves when removing the build platform after a print, as the resin tends to pool on top of the platform and can drip off while the platform is being removed.

Make sure you use the Halot-One Plus in a well-ventilated room to minimize the danger from inhaling fumes. Any spills or uncured resin stuck to a surface should be cleaned using 99% isopropyl alcohol and the container for the resin should be kept closed and secured when not actively pouring material.

Printing the Included Test Print on the Creality Halot-One Plus

The test print included with the Creality Halot-One Plus is one of the best demonstration prints I have ever seen. The 8 hour print is titled “Kholek Suneater”, and it fills nearly the entire build area of the Halot-One Plus from corner to corner. This model comes pre-sliced using the same settings as in Halot Box (.05mm layer height, 3 second layer exposure time, 40 second base layer exposure time, etc.), and is ready to print directly from the USB thumb drive.

Creality has apparently identified one of the common applications of resin 3D printing (tabletop gaming and miniatures) and has embraced this by including a detailed miniature model with the Halot-One Plus. My previous experience with Creality’s test prints was poor; the Creality LD-002R (a budget MSLA resin 3D printer) included a test model that took over 19 hours to print and was not particularly impressive.

Image 1 of 3

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)This model has a very dense support structure, which is required to support all the various fine features including a long hammer and tail. The support structure was removed easily and left minimal marks on the printed model. Unfortunately, I broke the hammer during washing, but was able to glue it back on without much effort. The spikes on the armor, the thin tail, and the other details present on this model are sharp and in focus, and I believe that anyone who purchased this printer to make miniatures would be immediately delighted to see such a high-quality model come out of the printer without any additional preparation.

Preparing Files for Printing with Creality Halot Box

(Image credit: Creality)While resin 3D printers tend to be much more mechanically simple than filament FDM 3D printers, the software typically requires more setup work and the part preparation is a very important part of the process. Creality includes a copy of Halot Box with the Creality Halot-One Plus, which is the slicer design for the Halot series of printers.

Halot Box offers two separate menus for slicing parts: Basic Options and Advanced Options. As expected, Basic Options contains parameters like layer thickness, exposure time, build platform raise height, and more which users will likely adjust the most often. These options are pre-populated with parameters that are more focused on success as opposed to speed, with a 3-second layer exposure and a 40 second initial layers exposure. Advanced Options contains more complicated parameters, such as shrinkage compensation for X, Y, and Z axes, anti-aliasing, and other parameters.

Halot Box is a fully featured slicer and is capable of importing models, hollowing them for resin printing, adding support structures, and even more advanced features like adding text, slicing a model into pieces, and measuring between two points. These features make Halot Box just as feature-rich as ChituBox and Lychee slicer, both of which are also compatible with the Halot-One Plus.

(Image credit: Tom's Hardware)I prepared this model of a dragon using the default Halot Box settings, including a 5mm shell after hollowing, medium support settings, and default slicer settings. Sliced with a .05mm layer height and a 3 second exposure time, this print took just over 12 hours to print out using Anycubic Water Washable Aqua Grey resin. The process of importing a model, hollowing, adding drain holes, adding support, and slicing took about 5 minutes and was intuitive and easy.

Image 1 of 3

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)Comparison of the Creality Halot-One Plus vs.

Elegoo Mars 3(Image credit: Tom's Hardware)

Elegoo Mars 3(Image credit: Tom's Hardware)The 4K resolution mono LCD on the Creality Halot-One Plus makes it a natural competitor to smaller resin printers like the Elegoo Mars 3, but the larger build volume and Wi-Fi capabilities help it to edge out most competition. Instead of focusing on Z height, the Halot-One Plus has a large surface area on the build platform, providing additional space for printing multiple parts.

Swipe to scroll horizontally

| Header Cell - Column 0 | Creality Halot-One Plus | Elegoo Mars 3 |

|---|---|---|

| Masking LCD Resolution | 4320 x 2560 | 4098 x 2560 |

| Masking LCD Size | 7.9 inches | 6.7 inches |

| XY Resolution | .04mm | .035mm |

| Build Dimensions | 6. 77 x 4.01 x 6.29 inches 77 x 4.01 x 6.29 inches | 5.64 x 3.52 x 6.89 inches |

| (172mm x 102mm x 160mm) | (143mm × 89mm × 175mm) | |

| Build Volume | 170.76 cubic inches | 136.79 cubic inches |

| Printer Dimensions | 9.29 x 9.57 x 16.46 inches | 8.93 x 8.93 x 17.28 inches |

| (23.6cm x 24.3cm x 41.8cm) | (22.7cm x 22.7cm x 43.85cm) | |

| Printer Volume | 1463 cubic inches | 1378 cubic inches |

| Build / Footprint Ratio | 11.70% | 9.90% |

| (higher is better) | ||

| Price | $399 | $299 |

The Halot-One Plus has a somewhat squat appearance in contrast with the taller and narrower Mars 3, and the large LCD screen on the front gives it an appearance that is closer to an appliance than a 3D printer. The build volume is somewhere between the Elegoo Mars 3 and the Elegoo Saturn, and the price also sits between the two.

The build volume is somewhere between the Elegoo Mars 3 and the Elegoo Saturn, and the price also sits between the two.

The Halot-One Plus is slightly larger in size than the Mars 3, but the differences in build volume and X/Y area are clear when comparing the two. In addition, the built-in air filtration system, large LCD, and dual Z axis linear rails give the Halot-One Plus a more industrial appearance. The front-facing USB port makes swapping out USB drives easy on both printers, but the power button on the Halot-One Plus is located on the back of the machine as opposed to the front-mounted power button on the Mars 3.

The build platform of the Halot-One Plus has a lightly textured surface, which gives printed parts a more complex surface to bond to during printing. Placing the platform of the Halot-One Plus and the Mars 3 side-by-side highlights the difference in build area, with the Halot-One Plus being a full inch longer in the X axis and just under half an inch wider in the Y axis. The difference in build area is complemented by an increase in pixel resolution, which makes the Halot-One Plus XY pixel size .04mm, a 5 micron difference from the .035mm resolution of the Mars 3.

The difference in build area is complemented by an increase in pixel resolution, which makes the Halot-One Plus XY pixel size .04mm, a 5 micron difference from the .035mm resolution of the Mars 3.

Printing a Large Model on Creality Halot-One Plus

(Image credit: Creality)The build platform on the Creality Halot-One Plus is large enough to fit busts from Loot Studio, so I printed the bust of Korut The Mechappilian. The model prints in 5 pieces: the bust, left arm, right arm, base, and minigun. I was able to fit the bust and both arms onto a single build platform, and printed the minigun and base separately. Processing these files in Halot Box was easy, and just involved dragging the models into the window, clicking “slice”, and exporting. No additional steps were needed, and I used Anycubic Grey Craftsman Resin and the default exposure settings.

(Image credit: Tom's Hardware)The first filled build platform printed flawlessly, and the level of detail was incredible. The lizard-like texture on the model looked realistic, and the smooth armor components had a consistent and even appearance. The 3-second exposure time seemed like a perfect fit for this resin as the support material snapped off easily and without leaving major pockmarks on the model.

The lizard-like texture on the model looked realistic, and the smooth armor components had a consistent and even appearance. The 3-second exposure time seemed like a perfect fit for this resin as the support material snapped off easily and without leaving major pockmarks on the model.

Image 1 of 3

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)After washing and curing the model, the general surface quality was still very impressive. The smooth surfaces have an even appearance and there are virtually no layer lines present, owing to the .05mm layer height and the .04mm X/Y resolution. The nubs left by the support structure detach easily, and can be removed by simply running a pair of tweezers over them.

(Image credit: Tom's Hardware)The final assembled bust looks more like a resin collectible than a 3D print, and the general quality was as good as any resin 3D printer under $2,500 that I have used. The joints fit together with simple peg and hole locating features, and they were a perfect friction fit. You can clearly make out the lizard skin texture on the model, and the fine detailing on the armor is easy to see without magnification.

You can clearly make out the lizard skin texture on the model, and the fine detailing on the armor is easy to see without magnification.

Printing Models from Creality Cloud

(Image credit: Creality)Creality has implemented Creality Cloud into its Halot Box software, which allows users to download models directly from the internet into their slicer. This feature has come under scrutiny due to the widespread abuse enabled by the ability to mass upload models, regardless of their copyright or designer intent. YouTuber Bryan Vines made an excellent video discussing this topic, which shows how the platform was intended to be used versus the current usage.

For example, on the front page of the Creality Cloud, I saw the chainmail model by Agustin “Flowalistik” Arroyo. This model is currently available with a Creative Commons Attribution license, which means attribution is required when sharing the model or derivatives. The model on Creality Cloud has been uploaded by “user3265593031”, and features the picture from Printables as well as filenames with “flowalistik” in them, further proving they were uploaded by someone other than the creator.

The chainmail model was easily downloaded, sliced, and sent to the printer without any additional steps required through Halot Box. While this does make searching for and downloading models a simple process, it’s troubling to see that the original creator has no effective recourse for limiting this type of piracy. In this case, I was aware of the original creator but it would be completely understandable that most users may not, and may even think the model was being provided by Creality directly.

(Image credit: Tom's Hardware)The Halot-One Plus is also able to download models from Creality Cloud directly from the printer interface without using Halot Box or any other slicer software. While this is a convenient feature, it is still subject to the same issues as downloading models from Creality Cloud via Halot Box. For instance, I downloaded this Minion file from the printer interface, but have no easy way to determine who the original designer was, what copyright license they used, and their intent for the printed model. In addition, the model printed completely solid and used significantly more resin than I was expecting for such a small print.

In addition, the model printed completely solid and used significantly more resin than I was expecting for such a small print.

Image 1 of 3

(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)(Image credit: Tom's Hardware)The Creality Halot-One Plus is a sleek, smart, and well-performing printer that worked well during our testing and left me impressed with the quality of prints made with minimal to no adjusting of the default settings when using the Halot Box slicer. The 172mm x 102mm x 160mm build volume is larger than other similarly priced printers, and the 4K resolution of the masking LCD provides sharp detail and fine features.

The Halot-One Plus sits in the awkward spot between small and large format resin 3D printers, and it’s hard to see if there is a place in the market for this machine. The large onboard LCD and built-in Wi-Fi connectivity are something you would expect on a more expensive printer like the Prusa SL1S, but are users currently looking for these features over build volume and print speed? That’s a hard question to answer, and only time will tell if the Halot-One Plus becomes a popular model.

If resolution isn’t your primary concern and you’re looking for the most build volume for your dollar, the Elegoo Saturn (on sale on Amazon for $369) and Elegoo Saturn 2 (available as a pre-order for $550) provide larger build volumes for a similar price tag. If you want to go in the other direction and find a printer with a higher resolution and aren’t worried about the price, the Phrozen Sonic Mini 8K provides an eye-watering .022mm XY resolution at an $899 price tag.

Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

the choice of a professional and a beginner / Selections of products from Aliexpress and not only / iXBT Live

So, I continue the topic of 3D printers, this time we will talk about budget and affordable photopolymer devices. Photopolymer 3D printing is becoming cheaper and cheaper and is becoming available not only to professionals, but also to novice printers-makers-designers. The cost of a number of models has dropped significantly in recent years, especially budget startups in SLA printing, making affordable office models of compact printers such as Sparkmaker and Longer. Almost all models are available in a warehouse in the Moscow region, they are delivered quickly, it makes sense to add to the basket and compare, choose the best one for yourself in terms of cost and printing parameters. nine0003

Photopolymer 3D printing is becoming cheaper and cheaper and is becoming available not only to professionals, but also to novice printers-makers-designers. The cost of a number of models has dropped significantly in recent years, especially budget startups in SLA printing, making affordable office models of compact printers such as Sparkmaker and Longer. Almost all models are available in a warehouse in the Moscow region, they are delivered quickly, it makes sense to add to the basket and compare, choose the best one for yourself in terms of cost and printing parameters. nine0003

Easy Printer for Beginners - Sparkmaker SLA

Sparkmaker SLA Printer

Sparkmaker SLA is the most affordable printer for beginners. One of the very first available models, the price is less than $200. At the moment, a number of upgrades are available, a lot of spare parts, ready-made models for printing. Print resolution: 845 x 480 dots, working area dimensions: 98 x 55 x 125 mm. Virtually no noise, works autonomously, height calibration is provided. Printers and resin available in Moscow. nine0003

Printers and resin available in Moscow. nine0003

Professional photopolymer printer Longer ORANGE

Longer Orange 30 Longer Orange 10

One of the few 3D printers that I have appreciated. The Orange 10 and Orange 30 printers work literally out of the box and, unlike expensive models, are not capricious at all. It is easy to operate, if necessary, you can set the print height. A detailed review of the Longer Orange 30 model. All models and Longer Resin photopolymer are available in Moscow. Orange 10 has a print resolution: 854 x 480 dots, working area dimensions: 98 x 55 x 140 mm. Orange 30 has a print resolution: 2560 x 1440 dots, working area dimensions: 120 x 68 x 170 mm. Virtually no noise, works autonomously, height calibration is provided. Printers and resin available in Moscow.

Anycubic PHOTON excellent resin printer

Anycubic PHOTON Anycubic PHOTON-S

Anycubic's well-deserved large resin 3D printer. Two models are sold at the same time: PHOTON and PHOTON-S. The latter is slightly more expensive, has design changes, but both print perfectly. Of the features, I will highlight the patented hinged mechanism for attaching the table, which facilitates alignment. Both PHOTON models have a print resolution: 2560 x 1440 dots, working area dimensions: 115 x 65 x 155 mm. All models are available in Moscow, at the same time do not forget to buy a fast Anycubic photopolymer - one of the cheapest. nine0003

The latter is slightly more expensive, has design changes, but both print perfectly. Of the features, I will highlight the patented hinged mechanism for attaching the table, which facilitates alignment. Both PHOTON models have a print resolution: 2560 x 1440 dots, working area dimensions: 115 x 65 x 155 mm. All models are available in Moscow, at the same time do not forget to buy a fast Anycubic photopolymer - one of the cheapest. nine0003

Photopolymer printer Anet N4 LCD

3D printer Anet N4

An interesting model from Anet is a photopolymer printer of the “N4” model with a print resolution of 2560 x 1440 dots and a working area of 120 x 65 x 138 mm. But the price pleases - this is one of the most budget printers with 2K resolution. The minimum "pixel" size is 40 microns. Don't forget to bring Anet photopolymer resin for testing.

Interesting photopolymer 3D printer Nova

Printer Nova3D

An unusual 3D printer was released by Nova3D, a stylish office compact printer for photopolymer printing. Of the features - an accurate T-rail rail was used, the table has an inclination adjustment for easy adjustment. The size of the print area is 130 x 70 x 150 mm. Print resolution 2K (2560 x 1440 dots). Attention: offline printing (from USB Drive) is provided, as well as connection via LAN and WiFi. Printers are available in Russia.

Of the features - an accurate T-rail rail was used, the table has an inclination adjustment for easy adjustment. The size of the print area is 130 x 70 x 150 mm. Print resolution 2K (2560 x 1440 dots). Attention: offline printing (from USB Drive) is provided, as well as connection via LAN and WiFi. Printers are available in Russia.

Wanhao Professional Printers

Wanhao Duplicator D11 CGR Wanhao Duplicator D8

One of the most thoughtful and best selling 3D printers from Wanhao. Two models of photopolymer printers are now available in the store - Duplicator D11 CGR (updated model) and Duplicator D8 (2019 model). Both models are deservedly considered the best for photopolymer printing, as for the new D8, I will single out a large print area (192 x 120 x 180 mm). Of the "chips" - WiFi connection.

Kelant 9 Large Resin 3D Printer0005

Kelant S400

Well, one of the inexpensive large-format office models is the Kelant S400. The size of the print area is 192 x 120 x 200 mm, the high power of the UV matrix (total power consumption is about 140 W) - all this makes it possible to print quickly and efficiently. The printer is available when ordering from Moscow, IML delivery (courier).

The printer is available when ordering from Moscow, IML delivery (courier).

So, the selection includes the most popular, inexpensive and popular models of SLA printers. A number of models were left out of the article, I think I will make a continuation in the near future to cover everything, plus I will add photopolymer resin to the recommendations. By the way, most stores specializing in 3D printing, both on Aliexpress and locally, offer their own options for photopolymer, and there are inexpensive and good options. When choosing, consider the current store coupons, and also choose local delivery (from Russia / RU). nine0003

News

Publications

point of view of an outside observer. However, if such exists, Earthlings are not getting in touch yet :) We are all participating in this process...

Modern cities have long had street lamps every few tens of meters, and this is now the norm. This type of lighting goes back centuries: before it appeared. ..

..

Nitecore are known primarily for flashlights. And far, far from all of them I like. But the cases, bags and backpacks they make are simply amazing. And I will be happy to tell you about Nitecore BP23,...

Hello everyone! Today I present to your attention the flagship product from their series of chargers using GaN transistors - CD289 with a declared power of 140 W, capable of delivering...

Hello everyone! Today I will conduct a detailed test, followed by opening a cable from Ugreen, which, according to the manufacturer, is capable of transmitting up to 240 watts. Unfortunately, at the moment...

Somewhere a couple of months ago I came across Kingstone DataTraveler Exodia classic flash drive sale 32GB, USB interface 3.2gen 1 and 5 year warranty. Promotional price tag for this flash drive...

Bought a 3D printer as a beginner. Choosing, setting up, problems and solving practical problems / Sudo Null IT News

A few months ago, I was thinking about purchasing such a device because I wanted to print a broken part of my robot vacuum cleaner. About a month ago I bought a device I liked on eBay. That's what was important to me when choosing a 3D printer. nine0069

About a month ago I bought a device I liked on eBay. That's what was important to me when choosing a 3D printer. nine0069

Which printer was needed?

Considering that I knew almost nothing about 3D printers (except for a few articles read here, on Habré), the important points were:

- Printer performance out of the box. I have seen several articles describing how long it takes to set up a "simple Chinese printer". It needs to be assembled from a large number of parts, and it is not a fact that there will not be defective ones among them. Once assembled, you can mess around with the device for a couple of days, and then it turns out that for some reason it does not work. In short, I needed a printer that didn't need to be assembled and that could work right out of the box. nine0078

- It shouldn't be too expensive. Seriously, I'm new, I was not sure that after a couple of days I would not abandon the device. And a printer for 500-600 euros would be too expensive a toy.

So I was willing to spend a couple of hundred, no more.

So I was willing to spend a couple of hundred, no more. - It should not be too big. Before buying, I allocated a little space for installing the printer, somewhere around 50 * 50 cm. Therefore, the printer had to stand on the allocated area without any problems.

- It shouldn't be too difficult to maintain. This point is closely related to the first. I didn’t want to spend a lot of time on operation and maintenance work - there is sorely not enough time, so constantly eliminating emerging glitches is not an option. nine0078

- I wanted to get a printer with WiFi, it was not critical, but important.

What did I end up buying?

Model Geeetech E180. It was shown by Google after the query “3D printer for beginners”. There were other models in the search results, but this one was liked by the design and the presence of WiFi.

The developers of this printer raised money for it with the help of Kickstarter and a couple of years ago it appeared on the free market. Its price is from 200 to 350 euros, depending on the company that sells it and the store. nine0003

Its price is from 200 to 350 euros, depending on the company that sells it and the store. nine0003

Bought on eBay, starting price was 200 euros, but the seller agreed to drop 50 euros, so the total price is 150.

Printer specifications:

- Print technology: FDM

- Working space dimensions: 130 x 130 x 130 mm

- Printing accuracy: 0.05 mm

- Positioning accuracy: X / Y 0.11 mm, Z 0.0025 mm

- Print speed: 80-110 mm/s

- Thread diameter: 1.75 mm

- Nozzle diameter: 0.4 mm

- Supported material: manufacturer claims PLA, but may work with other materials

- Operating system: Windows

- Management software: EasyPrint 3D

- File format: .STL, G-code

- Maximum extruder temperature: 230 °C

- Power supply: DC 12V 6A

- Connectivity: WiFi, USB, TF card (offline printing support)

- Display: 3.2" full color touchscreen

- Chassis: metal plate + injection molding (portable console 3D printer)

- Work table: aluminum alloy plate

- XYZ Rods: wear resistant, stainless steel screw and lead (Z axis)

- Stepper motors: 1.

8 degree stepped angle with 1/16 micro stepping

8 degree stepped angle with 1/16 micro stepping

Unpacking and setup

Before setting up, I looked at several reviews and tests of the printer. If not for them, I would not have done it myself, the explanation in the instructions is slurred. The setup is simple, but not for a beginner. nine0003

The printer "wound up" as soon as I connected it to power and a laptop. I calibrated the position of the table - it turned out to be simple - inserted a microSD card into the slot, found the contents through the menu on the printer screen, inserted the fiber into the channel and started printing. The printer made a noise and started printing. Or rather, I thought that he started typing, in fact it was not so.

Problems

The printhead moved, the temperature reached 205 degrees Celsius, but there was almost no plastic - in the first few seconds, a few plastic “hairs” came out and that was it. The printer continued to work, but the plastic was not squeezed out of the head. nine0003

The printer continued to work, but the plastic was not squeezed out of the head. nine0003

I wasted several Saturday hours trying to figure out why. I tried to look for an explanation on the net, but solutions to similar problems did not suit me.

The joy of buying disappeared in the first couple of hours of fuss. I wanted a printer that “just works”, but it didn’t work out. As a result, I realized that the fiber was not being fed - the feed mechanism hidden under the plastic cover simply did not work. It did not work because the constituent elements did not rotate. There was no movement at all.

I have decided that the printer has a defective electric motor that is responsible for feeding, and I cannot repair it. The next step is to click the Return to Seller button on eBay. After clicking the button and describing the problem, I decided to pack the printer for shipping. Before sealing it in a foam box, just in case, I decided to carefully examine those “insides” that are visible through the holes in the case. nine0003

nine0003

And the reason was immediately found - the assembler at the factory simply forgot to connect the power supply to the engine. Seriously, the cable just dangled inside the case. I connected it to the right connector with tweezers without disassembling the printer. Then I turned on the device again and this time everything was fine, the plastic feed worked as it should.

Then a few more minor problems arose:

- Misaligned table. This caused the table to skew and the print head was pressed against the surface in one place. As a result, the plastic could not be squeezed out of the head, which led to solid print defects; nine0078

- Unable to directly print models downloaded from the Internet. Being a beginner, I thought that everything works like with a regular printer - I downloaded a document, sent it to print. It turns out that slicing is also needed. I will not repeat what it is and why it needs to be perfectly described in this article on Habré;

- Slicers are not compatible with the printer model.

Slicer needs to set printer desktop size. Some slicers for some reason did not want to work with the dimensions of my printer (13*13*13 cm). Some even crashed (including the printer's native application), some did not "understand" the dimensions. As a result, I settled on ideaMaker; nine0078

Slicer needs to set printer desktop size. Some slicers for some reason did not want to work with the dimensions of my printer (13*13*13 cm). Some even crashed (including the printer's native application), some did not "understand" the dimensions. As a result, I settled on ideaMaker; nine0078 - No WiFi. As it turned out, there are two varieties of E180 - one with an integrated WiFi module, the second - without a module, you need to buy it in addition. At the seller, the inscription "need a separate module" was applied to one of the photos of the printer, small and in French (everything else was in English). Not a scam, but close to it. The module decided not to buy more, it is not really needed;

- Long printing time. I thought it would take several tens of minutes to print. I was not ready for the fact that large models can be printed for 6-8 hours. This is my own fault - I did not carefully look at the reviews. nine0078

Practical use

I didn’t buy a printer for a game, I wanted to get a device that would allow me to create things I need in everyday life, and not run to the store. Before buying, I outlined what I wanted to create:

Before buying, I outlined what I wanted to create:

The lever for separating the water tank in the iRobot Scooba robot vacuum cleaner, the repair review of which I published on Habré. His native pen broke, he did not want to spend money on buying a new one (they are relatively rare, since Scooba is no longer produced and expensive). nine0003

Finally found a suitable model on Thingiverse and printed it. To my surprise, everything fell into place the first time, the pen still works quite normally (it's been about a month since this part was printed).

Chinese electron microscope stand. I needed it for soldering small parts. I do not want to buy a professional microscope for 400 euros, since I myself do not do repairs very often. A Chinese microscope connected to a laptop is quite an option. But his native tripod is just terrible. Therefore, I wanted to make a new, normal one with my own hands. nine0003

Soldering iron stand. Just need a comfortable stand that won't let the soldering iron fall off like a Chinese stand I bought.

Paste tube squeezer. Yes, the thing is not the most necessary, but practical.

iPhone stand. Convenient, there is a hole for the cable, sound amplification.

Toys for children. Why buy another small doll or dollhouse piece when some things can just be printed out? nine0003

Stylus for Nintendo DS Lite. I had a game console bought at a flea market for a long time. The stylus was lost and I (and my daughter) played using the PDA stylus. Recently I found a stylus model for the console, printed it out - it turned out perfectly. It fits into the connector like a factory one.

Extractor for printed parts stuck to the table. Nearly all parts stick to the printer's desktop backing. You can’t do without a special device - an ordinary knife will scratch and cut a special sticker. I found a model that is compatible with the blades of a standard utility knife - works great. nine0003

The printer lived up to my expectations. It was possible to print almost everything that is indicated above. All these things fulfill their purpose, and most importantly, I am not afraid that any of them may fail. You can always print a new one.

It was possible to print almost everything that is indicated above. All these things fulfill their purpose, and most importantly, I am not afraid that any of them may fail. You can always print a new one.

There are a lot of ready-made models on the net. If you need some detail or thing, in 90% of cases you can find everything you need.

Troublesome little things

Printed parts are far from perfect. In some cases, deformation of some elements occurs and it is necessary to “finish” manually, using a knife and, in fact, a file. It doesn't happen that often, but I wish the printed part didn't need to be reworked (yes, I know you can get it by buying a professional 3D printer). nine0003

Sometimes parts are printed, but for some reason the actual and declared size do not match. So, I tried several times to print different dispensers for AA and AAA batteries, but for some reason the ready-made dispensers did not fit. The diameter of the holes into which the batteries are inserted was always somewhat smaller than the diameter of the batteries themselves. I still do not understand whether the problem is on my part, or the model is problematic. As a solution, you can simply increase the scale of the part in the slicer, by 10 percent. But it’s a pity for the spent plastic - after all, you can find out whether a quality part will turn out or not only after a solid part of it is ready. nine0003

The diameter of the holes into which the batteries are inserted was always somewhat smaller than the diameter of the batteries themselves. I still do not understand whether the problem is on my part, or the model is problematic. As a solution, you can simply increase the scale of the part in the slicer, by 10 percent. But it’s a pity for the spent plastic - after all, you can find out whether a quality part will turn out or not only after a solid part of it is ready. nine0003

It takes a long time to print a part. Some printouts take hours to complete, so making a simple phone holder for a car can take half a day.

In order to develop something of your own, you need knowledge of CAD , at least at an elementary level. Otherwise, you will have to look for ready-made objects on sites that host models created by someone. In the end, I never found a battery cover for one of the remotes. I am not able to develop it myself - there is almost no time to master CAD. nine0003

The desktop size of my printer is small .