Best handheld 3d scanners 2023

Best 3D Scanner - The Top 10 3D Scanners for 2023 [Reviews]

Much like a regular scanner, laser scanning 3D uses various methods to analyze a physical object and then relay that data to a computer to create digital 3D models. The 3D digitizer process might be automatic or users might need to complete the model to their requirements by using software. The aim is usually to get an accurate model to the right standard and format, ready for 3D printing, for virtual reality applications or other purposes.

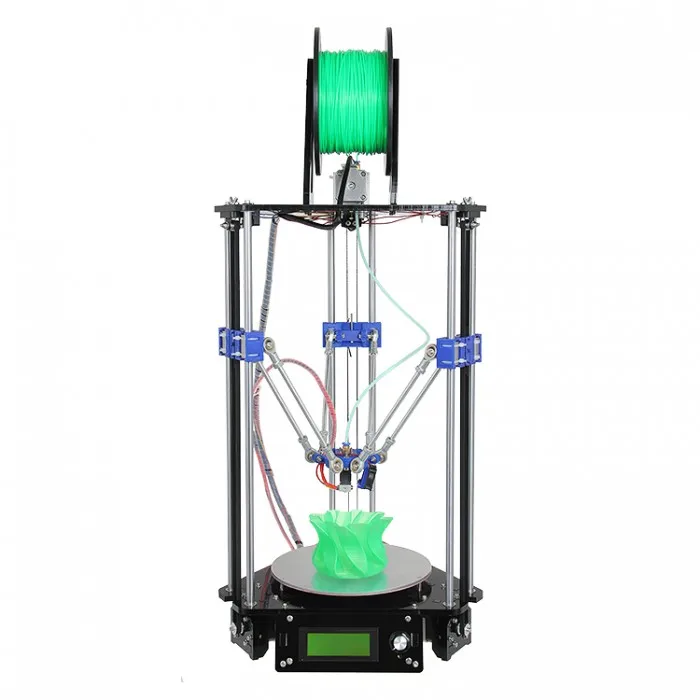

Such scanners are used in many professional industries, but with advances in home 3D printing, there are now also a good variety of home options. They are sometimes called portable 3D scanners or handheld scanners if they’re designed as such. These allow you to easily scan small to medium-sized objects for 3D printing.

Some come completely assembled while others, like 3D printers themselves, you’ll have to put them together by yourself. The benefit for those that are good with that type of thing is it reduces the price and allows for easier upgrades and modifications.

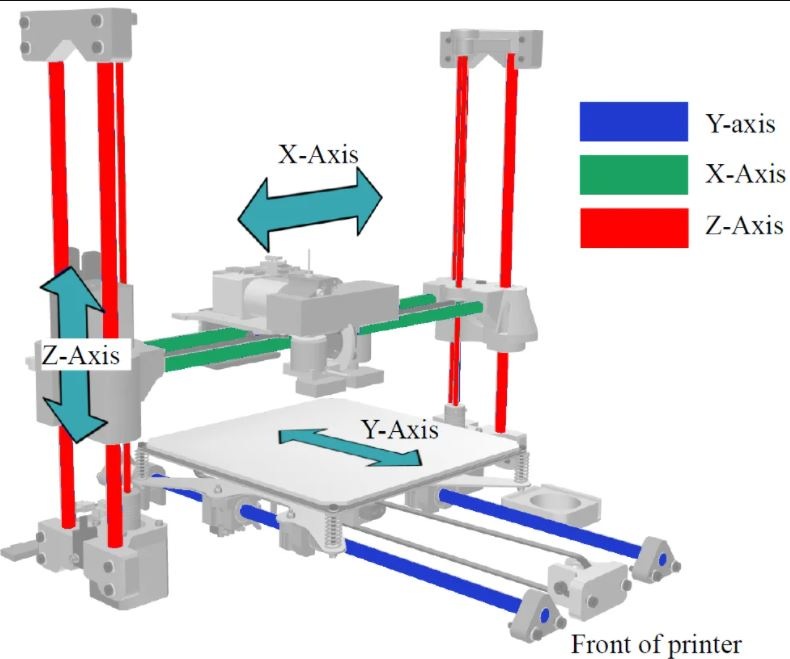

Scanning is typically done using laser triangulation or various forms of structured light to surround the object and measure its 3D dimensions or ‘geometry’. High-quality 3D scanner camera lenses also capture the color and surface texture of the object. Using accompanying or third-party software, the model can then be scaled up or down, or completely modified.

It’s never been easier to scan 3D objects!

How Do 3D Scanners Work?So, how do you scan 3D objects into a computer? Whether it’s on an industrial scale, at a small business, or on a desk at home, 3D scanners all share similar characteristics in the way they work.

The majority use laser and/or white light technology and cameras. The physical object is placed in a bed, tray, or suitable location. Electromagnetic light bounces off the object, measuring its circumference, full dimensions, and all its finer details.

Depending on the scanner it may use multiple light sources, cameras, and other tech to aid this process. The collected data is called a point cloud, which refers to the number of points captured by the laser.

The more points collected the more accurate the scan. A high-resolution scanner can capture hundreds of thousands of points in seconds and reach millions overall. The whole process only takes a few minutes.

While the light tends to be a measure of the object’s geometry, HD cameras tend to capture the surface detail and color.

The data recorded can then be fed into a computer-aided design program or similar software for inspection and manipulation. E.g. if you’re planning to use it for 3D printing, the model might need scaling up or down, hollowing, have added support structures, be re-colored or have brightness/contrast changes, etc.

There are, of course, different types of 3D scanner and scanning technology. So, let’s take a closer look at each one:

So, let’s take a closer look at each one:

There are several 3D scanner types. Before making your decision check out the section below:

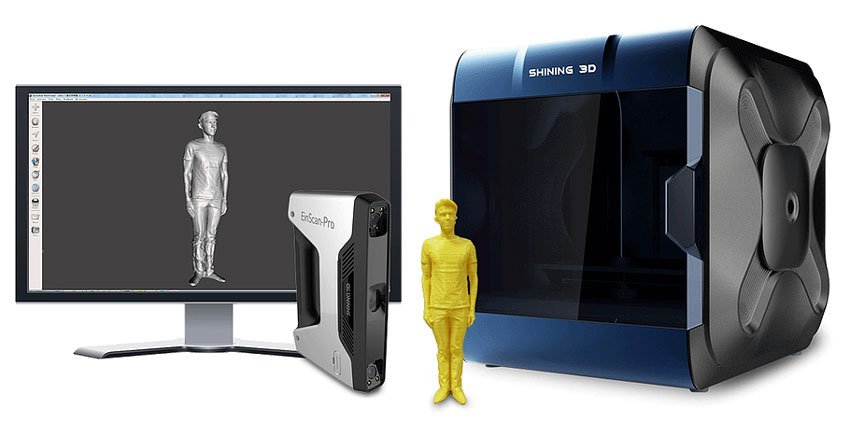

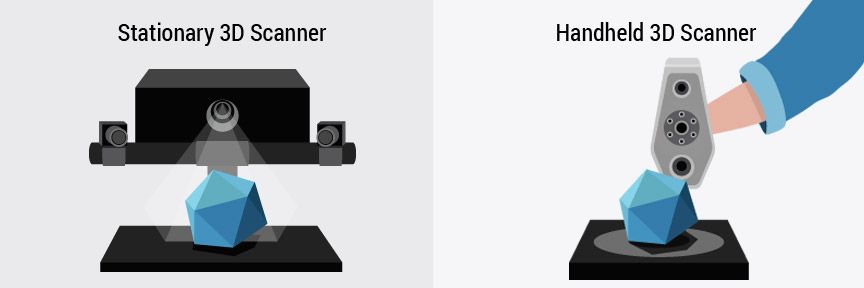

Handheld vs StationaryHandheld and stationary 3D scanners often use the same technology and can overlap in their functions. The difference lies mainly in the design.

A handheld scanner has a grip and lets the user move around the object themselves to capture it at every angle.

A stationary scanner has to be positioned in front of the object, which is typically placed on a rotating plate and captures it as it spins 360 degrees. The user may have to reposition the object several times to capture every angle.

Newer designs are becoming smaller and more easily portable.

Laser TriangulationThe most common technology used in 3D scanning is laser trigonometric triangulation. It records millions of different points on the surface of the object to build an accurate overall polygon mesh. These are common in handheld options and industrial-grade scanner machines. They can also work long-range and for laser-tracking objects.

It records millions of different points on the surface of the object to build an accurate overall polygon mesh. These are common in handheld options and industrial-grade scanner machines. They can also work long-range and for laser-tracking objects.

Similar and often used interchangeably with laser triangulation, structured light or ‘white light’ projects itself in a grid-like pattern over an object. It can then measure the structure of that grid as it applies to the object by using sensors/3D scanner cameras and triangulation.

Long RangeLonger range scanners use phase shift or pulse technology that can capture millions of points while rotating 360 degrees with the aid of mirrors. This is more commonly used to scan large objects like cars or buildings.

They might also use ‘time of flight’ technology that measures the distance of an object in relation to the speed of light and the time it takes for it to return to a sensor.

This is less relevant for everyday 3D scanning and printing.

3D Scanning ApplicationsThere are many different applications for 3D laser scanning - from those for 3D printing at home, to prototyping, industrial scale medical supply production and even architecture.

Hobbyist 3D printingCheaper 3D scanners are typically used by home users for scanning simple objects and 3D printing them for fun.

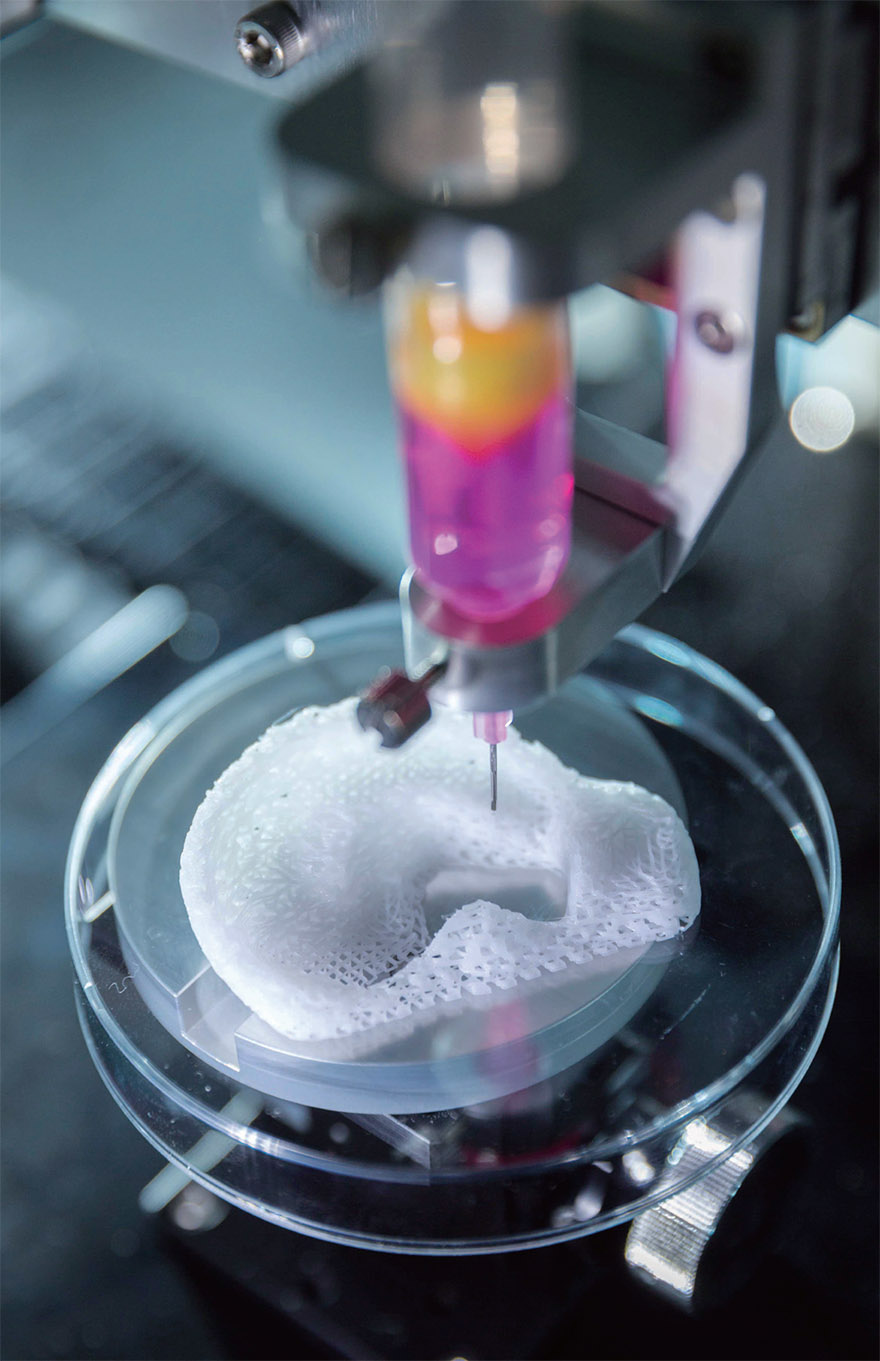

MedicalThe medical field and dentistry commonly use 3D scanning to create implants and aids to serve their patients’ needs. For example, scanning people’s feet with a high-quality 3D scanner allows for the creation of orthotics (shoe inserts). It is also used in the creation of prosthetics.

Virtual EngineeringIndustrial 3D scanners are used both in the creation and quality control of cars, planes, and even aerospace. It ensures existing parts are as accurate as their original models and that new viable parts are made.

From the home computer desk to the manufacturing floor, 3D scanning allows users to reverse engineer or copy existing objects. Saved models also allow for the reconstruction of damaged objects.

Virtual RealityFrom creating realistic 3D worlds to the people that occupy them, 3D scanning devices are integral to the growing virtual reality industry. This ranges from AAA video games, virtual cinematography, and computer-generated imagery (CGI), to virtual tours and office meetings. It is also a side industry to motion capture.

ForensicsCSI has come a long way. Forensic experts nowadays don’t just have to rely on memory, photos, and evidence of a crime scene. They can capture the entire location in a full 3D model for closer inspection and for running through different scenarios.

Archeology and ArchivingFrom museums to libraries, 3D scanning is being used to log and preserve everything from artifacts to digitizing books. This also gives experts and the public remote access.

This also gives experts and the public remote access.

3D scanning can also help architects map the areas they will be designing their buildings in, take inspiration from existing architecture, and aid in building miniatures/prototypes.

What Should I Know Before Buying a 3D Scanner?Before you buy a 3D scanner, there are several things to consider:

- your budget

- what you’ll actually be using it for

- it’s speed and accuracy

- the device’s other features.

3D laser scanner price ranges vary greatly. On the cheaper end, you may be able to pick one up for home for just shy of $300, like the XYZprinting 3D Scanner 1.0 A. However, if you want the highest overall quality and the ability to scan small and large objects. Or, if you’re a professional and need a 3D part scanner in a field like medical implants or automotive parts, you’re looking at anywhere between $3,000 and $35,000.

Typically, it’s best to look for 3D scanners for sale online where you can find the best selection and prices.

3D PrintingWhile a dual 3D printer scanner combo is rare, if you want to scan models for 3D printing, you will need to make sure it has good accuracy and resolution. The software also must be able to export to a usable format. You will need to check your 3D printer and its own software to see what file types it accepts and then choose your scanner accordingly.

Fortunately, almost all of our 3D scanner reviews include devices that can export in common file types like OBJ and STL.

It’s typically only the more expensive scanners that are good for other applications, like VR, full-body scanning, architecture, and engineering.

Handheld vs StationaryWe already explained the difference, but basically, a handheld scanner is mobile, while the stationary one will require you to move and adjust the object. Neither is necessarily better than the other, it’s all down to your needs.

Neither is necessarily better than the other, it’s all down to your needs.

How fast is the scanner? Do you have a lot of spare time or require the job to be done as fast as possible? All 3D scanners will take a few minutes to complete, while many scanning complex objects in high resolution can talk half an hour or longer.

Accuracy and ResolutionAccuracy refers to how close to the object being scanned your digitized model will be, measured in millimeters. Therefore, the smaller the better. The term resolution may be used interchangeably with accuracy or refer to the resolution of any cameras being used as part of the scanning process.

Generally, the lower the millimeter, the better. Other factors also play a role in overall quality, such as lighting conditions, color, and depth.

Object Size and SpaceSome types of 3D scanners excel at scanning small objects while others are better at medium to large. Others are all-rounders. Before buying a scanner, you should decide the general size of the items you will be scanning.

Others are all-rounders. Before buying a scanner, you should decide the general size of the items you will be scanning.

You will also need to make room for the scanner. Although all the products on our list are small and relatively portable, stationary scanners at least need a table to work from. Likewise, there will be a minimum and maximum distance the scanner must be in relation to the object being scanned.

You’ll need more room when scanning larger objects in full.

Connected DevicesAll 3D scanners need to be connected to a computer or device to help monitor the process and for saving the digital model. This is usually done via a USB or HDMI cable. You will need to check that your computer or laptop meets the minimum requirements for the scanning and modeling software. Also, make sure that you have a tablet to make real-time monitoring easier.

SoftwareYour device will either come with its own software or a popular third-party program to aid the process and to help touch-up the model once it’s scanned. Different 3D printing software is better suited to different skill levels. Some programs have a lot of features for experienced users and others do most of the basic tasks automatically. Check our 3D scanner reviews to see the software each device comes with and how advanced and easy to use it is.

Different 3D printing software is better suited to different skill levels. Some programs have a lot of features for experienced users and others do most of the basic tasks automatically. Check our 3D scanner reviews to see the software each device comes with and how advanced and easy to use it is.

10 Best 3D Scanners In 2023

- Last Updated: February 10, 2023

- Pat Nathaniel

Are you looking for a top-notch 3D scanner that’ll capture accurate models of real-life things?

Whether you want to scan small or bigger objects like a shoe or a hippo, there’s a scanner on this list for you!

If you’ve tried to look for a scanner, you’ve come across many different technological terms. FPS, scan dimensions, resolution, accuracy — it’s a confusing salad of scan terminology (there’s no kale and lettuce here, just lasers and cameras!).

With our guide to the best 3D scanners, we’ll outline important aspects of each scanner and explain the technobabble in layman’s terms. Let’s get right into it!

Shining 3D EinScan SE

Check Latest Price

Scantech iReal 2E

Check Latest Price

Artec Eva 3D Scanner

Check Latest Price

Table of Contents

- Best 3D Scanners At A Glance

- 1. Shining 3D EinScan SE (Best Value)

- 2. Scantech iReal 2E (Best Choice)

- 3. Artec Eva (Premium Choice)

- 4. Scan Dimension Sol (Best Affordable Scanner for Professional Use)

- 5. Revopoint POP (Best Budget Scanner)

- 6. Revopoint POP 2 (Best Affordable Handheld Scanner)

- 7. Matter and Form 3D Scanner V2 (Best for Hobbyists on a Budget)

- 8. Creality CR-Scan Lizard Scanner (Best for Basic Scans)

- 9. Creality CR-Scan 01 3D Scanner (Best Affordable Scanner for Large Objects)

- 10.

Shining 3D EinScan Pro HD (Best 3D Scanner for Professional Use)

Shining 3D EinScan Pro HD (Best 3D Scanner for Professional Use)

- What is a 3D Scanner?

- Laser Triangulation

- Photogrammetry

- Structured Light Scanning

- Types of 3D Scanners

- Handheld

- Stationary

- How to Scan Objects to 3D Print?

- What are the Uses of 3D Scanner?

- Manufacturing

- Healthcare

- Art and Film

- Architecture and Interior Design

- Archaeology

- Reverse Engineering

- Factors to Consider When Buying a 3D Scanner

- Accuracy

- Resolution

- Scan Volume

- Scan Modes

- Scan Speed

- Software

- Scan Technology

- So Which Is the Best 3D Scanner?

Best 3D Scanners At A Glance

1. Shining 3D EinScan SE (Best Value)

2. Scantech iReal 2E (Best Choice)

3. Artec Eva (Premium Choice)

4. Scan Dimension Sol (Best Affordable Scanner for Professional Use)

5. Revopoint POP (Best Budget Scanner)

Revopoint POP (Best Budget Scanner)

6. Revopoint POP 2 (Best Affordable Handheld Scanner)

7. Matter and Form 3D Scanner V2 (Best for Hobbyists on a Budget)

8. Creality CR-Scan Lizard Scanner (Best for Basic Scans)

9. Creality CR-Scan 01 3D Scanner (Best Affordable Scanner for Large Objects)

10. Shining 3D EinScan Pro HD (Best 3D Scanner for Professional Use)

If you’re looking for a mid-range scanner that performs at a high-end level, you’re in the right place. Let us tell you what this scanner SCAN do (ha!)

The EinScan SE, with its 0.1 mm accuracy, makes high-quality scans with super-accurate color reproduction. And the not-heart-attack-inducing price tag makes it a suitable purchase for those who want quality scans.

It has an automatic scan setting where you can scan objects up to 200 mm3 — and with the fixed scan setting, 700 mm3.

This scanner comes with a turntable for 360° scans. You can choose a full rotation anywhere from 8 to 120 steps.

Keep in mind — the more steps, the more time the scan takes, but also the more detail you’re going to get in the final result. If you want even higher quality, you can use the HDR option for sharper resolution and detail capture.

Want a quick mesh scan? No problem! You can do one in just 10 seconds, and if you want full color, it takes 30 seconds. You can go and make yourself a coffee in that time. Maybe.

Also, the best thing about this scanner is its robust and stable software, unlike some other scanners… *cough* Not going to name any names!

With the EinScan software, you can ensure your models are entirely free of any gaps and holes. You can also export in low, medium, and high poly files.

One issue with this scanner is that it’s sensitive to light — so if you’re capturing a scan outdoors, you’ll need to make some adjustments to ensure a good scan.

- Amazingly accurate scans

- Powerful software

- Multiple scan settings

- Sensitive to bright light

Check Latest Price

2. Scantech iReal 2E (Best Choice)Are you looking for a premium scanner that’ll get crisp and clear scans fast? The Scantech iReal 2E is our best choice for 3D scanners — and here’s why.

The iReal 2E can capture medium to large objects — which makes it perfect for human scanning. It uses infrared light technology that makes life easier by avoiding common scanning issues.

First of all, there’s no need for markers. Scanning is way more fun when you don’t have to spend 10 minutes peeling off stickers and applying them to your chosen object.

Scanning is way more fun when you don’t have to spend 10 minutes peeling off stickers and applying them to your chosen object.

And not just that — where most scanners struggle with capturing details like eyes and hair, the iReal 2E succeeds! And with a 0.2 mm resolution, you bet you’re getting those details in crisp clarity.

The scanner has a sizable 580 x 550 mm scan volume and is capable of full HD color reproduction. It can also easily capture reflective and dark textures.

You can bet it’s speedy, too — it captures 1.5 million points of data per second, as well as operates at a whopping 15 FPS. Overall, we highly recommend this scanner if you can afford it.

- 0.2 mm resolution for crystal clear details

- Can capture dark and reflective surfaces

- Fast scanning

- Expensive

Check Latest Price

3. Artec Eva (Premium Choice)

Artec Eva (Premium Choice) Are you looking for the best 3D scanner the market has to offer?

With its powerful Artec Studio software and unparalleled high-res scans, the Artec Eva is best suited to those who want to splurge on a Certified Gosh Darn Awesome Scanner.

This 3D scanner offers full-color, intricately-detailed scans with an accuracy of 0.1 mm and a resolution of 0.5 mm. This makes it perfect for various uses and professional applications — VR, archaeology, film, you name it.

The Eva can primarily capture medium to large objects from 10cm up. It can also catch some fantastic details on people — down to their hair and folds in their clothes.

And guess what? This scanner can actually do black and shiny surfaces, the bane of lesser 3D scanners. Amazing.

Another cool thing is that the Eva requires no markers or lengthy calibration. It comes in two scan modes — default and autopilot for lazy folk (like us).

The awesomely powerful Eva software allows you to process and fine-tune your scans, which you can export in typical formats like OBJ and PLY.

One downside of this scanner is that it’s super pricey and best suited to small businesses or companies that can afford it.

Also, it’s not suited for scanning small objects — so if that’s your aim, consider another 3D scanner.

- Super accurate detail capture

- No need for markers or calibration

- Autopilot mode

- Really expensive

Check Latest Price

4. Scan Dimension Sol (Best Affordable Scanner for Professional Use)Want an affordable 3D scanner to capture high-quality images for professional use?

Whether you want eye-catching images of your merch or amazingly detailed 3D models for printing, the Scan Dimension SOL is the best 3D scanner for pros on a budget!

It offers a 0. 1mm scan resolution — super high-quality, detailed scans. This is a scan resolution provided by much more expensive scanners — and this scanner gives it to you for half the price!

1mm scan resolution — super high-quality, detailed scans. This is a scan resolution provided by much more expensive scanners — and this scanner gives it to you for half the price!

The SOL has a scan volume of 170 x 170 mm — not too big, but ideal for capturing scans of small to medium-sized objects. If you want to scan large objects, we’d recommend taking a peek at other scanners on this list.

This scanner comes with Turbo mode, which turns up the speed — and allows you to complete a scan in as little as 10 minutes.

Speaking of modes, you can use Near Mode for small objects and Far Mode for larger objects.

- 0.1 mm scan resolution for highly-detailed scans

- Quick scan mode

- Affordable

- Small scan volume

Check Latest Price

5. Revopoint POP (Best Budget Scanner)

Revopoint POP (Best Budget Scanner) Are you a student, hobbyist, or professional on a budget? Take a look at the Revopoint POP! It’s one of the cheapest 3D scanners available and packs quite a punch — in fact, it can rival the results of some more expensive scanners.

First off, it has a resolution of 0.3 mm. This allows it to deliver well-detailed and clear scans — though it’s not the highest resolution, it’s pretty remarkable considering the price.

This scanner uses structured infrared light technology and has an RGB camera for detecting surface textures and colors. This feature gives you pretty good replications of faces and objects. Cool!

The POP is ideal for scanning small to medium-sized objects.

You can use the POP with your PC via USB cable or by phone with the HandyScan app. It can be used as a handheld (with a smartphone) and a desktop scanner (with a PC and turntable).

Our only gripe with this scanner is the software — it often froze up when we were using it, and we could have done without the extra hassle.

For a budget option, this scanner is pretty good — it’s fast, lightweight, and suited to newbies. It just takes a bit of time and effort regarding the software issues. Besides that, it’s generally easy to use and basic enough for any beginner to get a quick grip on.

Also, a note: Environment is a big deal with this scanner, so ensure you scan in suitable lighting and minimize any visual noise that could disrupt the scan.

- Very affordable

- Delivers high-quality scans for the price

- Software is prone to freezing

Check Latest Price

6. Revopoint POP 2 (Best Affordable Handheld Scanner)The Revopoint Pop 2, as the name suggests, is an upgraded version of the Revopoint Pop. And trust us, it’ll make your 3D models POP! (Not explode. We wouldn’t want that.)

And trust us, it’ll make your 3D models POP! (Not explode. We wouldn’t want that.)

This is the best 3D scanner you’ll find on a budget. The Revopoint Pop 2 has an accuracy of 0.05 mm (which is great for making many exact models) and a scan speed of 10 FPS. It’s speedier and more precise than its predecessor while still being an affordable purchase.

If you’re looking for an even cheaper option, the Revopoint Pop will suit you better — but keep in mind that as the price downgrades, so do the features.

Typical to Revopoint scanners, the Pop 2 uses blue light technology. Blue light is unique in eliminating any noise and distortion that can mess up your scan model.

The Revopoint Pop 2 comes as a handheld scanner — but if you prefer fixed mode, you’re in luck! It can be converted to a desktop scanner with a turntable, which is included.

This scanner has a minimum scan volume of 20 x 20 x 20 mm, which enables you to scan smaller things if you like.

- Accuracy of 0.05 mm

- Can be converted into a desktop scanner

- Blue light technology cancels out visual noise

- More expensive than the Pop

Check Latest Price

7. Matter and Form 3D Scanner V2 (Best for Hobbyists on a Budget)Are you an artist, animator, or designer on a budget? Listen up! Thanks to its easy-to-use software and affordability, the Matter and Form 3D Scanner V2 is the best 3D scanner for creators.

With its simple and intuitive software, you can set up a scan quickly and easily. Once you’re done scanning, you can edit the 3D model and transfer it to other programs.

Then you import your scan into your chosen 3D printing software via WiFi or USB and print!

This scanner has an accuracy of 0.1 mm and can replicate details with high resolution, mainly as it uses laser scanning — one of the most accurate scanning technologies out there. As is typical of laser scanners, it’s got a slower scan speed of 65 seconds — but hey, if it works, it works!

The Matter & Form has a scan volume of 250 x 180 mm, perfect for scanning smaller objects — not people unless you shrunk them!

This is a desktop scanner and does not come in a handheld version.

- Very affordable

- Detailed scans

- Easy-to-use software

- Slow scan speed

Check Latest Price

MatterHackers Price

8. Creality CR-Scan Lizard Scanner (Best for Basic Scans)

Creality CR-Scan Lizard Scanner (Best for Basic Scans) Are you looking for a budget scanner to capture basic scans of real objects? If super-fine details aren’t a priority, the Creality CR-Scan Lizard can get the job done.

Cheaper than its predecessor, the CR-Scan 01, this is a very affordably-priced scanner that can be used in 3 modes: handheld, stationary, and a mix of the two.

The stationary mode can scan objects from 15 to 300 mm, while the mixed mode can scan up to 500 mm. The handheld mode enables you to scan objects up to 2 meters high — but beware of arm strain!

Similarly to the iReal 2E, this scanner doesn’t require the use of markers thanks to its unique tracking technology.

However, this scanner has some downsides as well. First of all, the software has a lot of confusing translations in the dialogue boxes and options. It also has non-standard control shortcuts, which you usually wouldn’t get in a typical scanning program. It also can get a bit buggy at times.

Also, it doesn’t capture super-fine details — so if you want high precision, this is not the scanner for you. If you want to create decent models with basic detailing and require something affordable, this scanner is perfect for you.

We recommend the Lizard primarily for intermediate to advanced 3D scanner users. If you can take some time to learn the ins and outs of the software, then we can highly recommend it.

- Very affordable

- Doesn't require markers

- Comes with 3 different scanning modes

- Buggy and poorly designed software

- Doesn't capture intricate details

Get Discount (Official Store)

Check Latest Price

Banggod Latest Price

9.Are you on a budget and want to scan the previously mentioned hippo? This is the scanner for the job!

The CR-Scan 01 is an affordable 3D scanner with an accuracy of 0.1 mm and a scan resolution of 0.5 mm. This scanner can capture details well — but be warned, the model won’t be super high-res. So it’s perfect for simple applications that can do with lower-resolution 3D models.

This 3D scanner uses structured light scanning technology to scan objects. Let’s de-sciencify — light is beamed onto an object from different directions. Then, a camera captures the light around the object to create a 3D scan.

The CR-Scan 01 has a scanning area of a whopping 536 x 378 mm and a scanning range of 400-500 mm. In addition, it’s a handheld scanner, giving you more flexibility of movement — but, if you like, you can use a tripod and turntable to make a fixed scan.

Also, with the CR-Scan, you can scan objects in color. Pretty neat for making large images with full-color detail!

Creality offers free CR Studio software, which is free to download.

- Affordable

- Allows you to scan large objects

- 0.1 mm accuracy

- Scan resolution is on the lower side

Get Discount (Official Store)

Check Latest Price

Banggod Latest Price

10. Shining 3D EinScan Pro HD (Best 3D Scanner for Professional Use)Are you a professional looking for a high-end scanner that can capture minute details with blazing clarity?

With an accuracy of 0. 04 mm and a 0.2 mm resolution, this scanner really puts the HD in EinScan Pro HD!

The Pro HD allows you to capture crystal clear edges and smooth surfaces — heck, even hard-to-scan details easily show up. It’s perfect for accurately scanning humans too.

This is truly a fast scanner — it captures 3 million points per second (10 FPS) in stationary mode and 1.5 million points per second (30 FPS) in handheld mode.

With a scan volume of 310 x 240 mm, you can scan objects, faces, and complex geometries.

Some tips: If using this scanner outdoors, keep your scan object shielded from sunlight. Also, dark, reflective, or transparent surfaces require a mattifying spray beforehand.

This scanner comes with ExScan Pro software and can export scans in OBJ STL and ASC.

- Captures lots of details

- Fast and accurate

- Expensive

Check Latest Price

What is a 3D Scanner?

Source: Youtube The RT4A 3D scanner is a device that captures the shape or image of an object to create a 3D scan. Neat!

How is this possible, you may ask? Well, let’s take a look at a few of the most common scanning technologies available.

Laser Triangulation

Laser triangulation sounds like a super cool high-tech name — but the principle is quite simple.

The 3D scanner projects a laser beam onto the object’s surface. Then, it measures the deformation of the laser. This creates a “point cloud” of data (points that make up the object). The point cloud is then converted into a triangulated mesh and, finally, a CAD model.

This process is perfect for scans that require finer detail. However, it can get pricey.

Photogrammetry

Photogrammetry measures an object just by taking pictures of it! It’s the cheapest and most accessible scanning technology, but the results may not be as super-precise as laser-based technologies.

This can be achieved via a dedicated photogrammetry 3D scanner — or even your smartphone and a photogrammetry app. If your phone has a LiDAR sensor, even better! It can help you get decent scan quality at little to no cost.

Structured Light Scanning

This laser-based scanning method uses a projector to project different light patterns onto an object.

The scanner then captures the way the object distorts the light, and this results in a pretty darn accurate 3D scan!

This scanning technology is most often used for facial recognition.

Types of 3D Scanners

Handheld

Source: Youtube SHINING 3DHandheld 3D scanners are like the barcode scanners you see at the checkout at the grocery store. To use it, you have to rotate it all over your chosen object while observing the scanning software on the computer.

If there are any gaps in the scan, go over the area again. Repeat until you have a full scan!

This type of 3D scanner is best suited for small to medium-sized objects where you want a lot of precision. It can also be used for face and body scanning, but not for massive things like an airplane! Unless you’re Superman, and you can fly and scan at the same time.

Stationary

Source: Youtube ruiraptorWith this type of 3D scanner, you either set your object on a turntable or put the scanner onto a tripod.

The turntable is suitable for scanning small items, while the tripod option is best suited for the aforementioned plane or any similarly large object.

To use a turntable, place your object on it and set the number of steps you want to make a full rotation. More steps mean more detail, but it can also take more time.

How to Scan Objects to 3D Print?

Source: Youtube 3D Prints&BuildsIf you want to 3D print a scan, here’s how!

First, you have to connect your 3D scanner to a computer with the appropriate scanning software.

Then, you scan the object (Captain Obvious to the rescue!).

If scanning with a handheld 3D scanner, move the scanner around the object, capturing different areas.

If you’re using a stationary scanner, set the number of steps you want it to take, and let it work its magic.

Once the scan is finished, you’ll have a complete mesh model of your chosen object. If you want to make any modifications or touch-ups, you can do so in the scanning software.

Once you’re done, all you have to do is open the model in any CAD software and, with a few clicks, convert it to a 3D solid. Simple as that!

All that remains is to send your 3D model to your printer, either via USB or WiFi.

What are the Uses of 3D Scanner?

Source: Youtube ExplainingComputersAside from the obvious uses of 3D scanners (designing a spoon with your own face on it), there’s a near-infinite amount of potential 3D scanning applications.

Manufacturing

3D scanning is handy for nondestructive testing (NDT), where technicians assess mechanical damage in industrial equipment without taking anything apart.

3D scanners also greatly assist in retrofitting, adding new components to a creation that weren’t in its original design.

Healthcare

Ever heard of dentists, those terrifying Lovecraftian beings who crawled out of the void and made it their life’s goal to mess with people’s teeth? Well, they use 3D scanners to analyze and measure patients’ teeth to create customized prosthetics! Braces, dentures, crowns, you name it. (Actually, don’t. If you say these three words super fast in a dark room, a dentist will be summoned, and he’ll start giving you a root canal while asking you if you floss regularly.)

Doctors also use 3D scanners to carry out full-body scans. They can then analyze the scan data and monitor changes and progress in the patient’s treatment.

Art and Film

Artists in the film industry are using 3D scanners to create special effects and animations — heck, even George Lucas used it for Star Wars!

Also, 3D scanning is used in developing VR games to make immersive and realistic virtual environments.

Architecture and Interior Design

With a 3D scanner, you can scan buildings — some make miniature models, and others make fully-digital replicas of famous buildings and museums that you can experience from the comfort of your home.

Archaeology

Archaeologists (you know, the Indiana Jones people) use 3D scanners to capture detailed models of ancient relics to preserve them digitally forever. Wow!

Reverse Engineering

3D scanners help greatly in reverse engineering components to restore a full 3D model of the original design. If a component has been broken or somehow damaged over time, 3D scanning allows you to scan it and restore it to its former glory in CAD software. What a time to be alive!

Factors to Consider When Buying a 3D Scanner

Source: Youtube Adam Savage’s TestedAccuracy

The accuracy of a 3D scanner describes how accurate the scan is (how close it gets to replicating the actual object). This is an essential factor if you want an exact replication of an object.

Resolution

The resolution is the minimum distance between two points on a scan, and it describes the definition or clarity of the scan.

What does that mean? Well, resolution describes the sharpness of details. High res scans have sharp and precise detailing, while low-res scans have soft detailing.

Soft details can be a pretty undesirable result, especially in face scanning. After all, no one wants their face to come out looking like a potato blob!

Scan Volume

With a small scan volume, you can scan small objects with high detail and precision.

If you want to scan larger objects, you’ll need a scanner with a large scan volume.

Scan Modes

Handheld mode is suitable for scanning small-to-medium objects with lots of detail.

If you need to scan large objects, like planes and buildings, a stationary scanner is better for this purpose. (Not too easy on your arm to scan an entire museum!)

Scan Speed

For handheld scanners, we measure scan speed by the number of data points captured per second, while for stationary scanners, we measure it in FPS. A good speed for handheld scanners is at least 1 million data points/s. For FPS, 10 is the average.

Software

When you’re purchasing a 3D scanner, the software is half the investment. You could have the best 3D scanner in the world, but if it has lousy software… you’re in trouble.

Go for responsive and robust software that is not clunky and has an easy-to-use UI. Bad software is just a pain in the butt and has a steeper learning curve, wasting your time and frustrating you.

Scan Technology

Do you need highly-precise scans? You need a laser-based scan technology, like laser triangulation or structured blue light scanning. If your main priority is to have an accessible and affordable (yet still effective) scanning method, consider photogrammetry.

So Which Is the Best 3D Scanner?

Do you want a budget scanner for professional use? Consider the Scan Dimension Sol. It’s affordable and delivers some pretty high-res scans for the price.

For a mid-range scanner with more capabilities, the Shining 3D EinScan Pro HD is a great pick.

If the idea of “budget” is non-existent to you, go for the Artec Eva. With intricate scanning capabilities and robust software, there’s nothing you can’t do with this scanner. (You probably can’t eat it. Or you could if you tried hard enough. We don’t recommend it.)

Our best value pick is the Shining 3D EinScan SE. You pay much less than you should for the excellent results it gives.

Our best choice is the Scantech iReal 2E. With a large scan volume and an incredible 0.2 mm resolution, you can scan medium to large objects in super sharp detail.

Do you want to scan large objects on a budget? Look no further than the Creality CR-Scan 01. Like the iReal 2E, it has a large scan volume — but a much lower resolution. It’s perfect for casual use where you don’t require super clear details.

Do you need something affordable to carry out basic scans? The Creality CR-Scan Lizard might suit you. It offers pretty decent detailing — and its compact structure does make it like a little 3D scanner lizard!

Our pick for the best budget scanner is the Revopoint POP — at this price tag, with some learning, it can create awesomely-detailed results.

Are you an artist on a budget? The Matter & Form is a desktop 3D scanner perfect for scanning small objects with high resolution and detail.

If you’re looking for a great affordable handheld 3D scanner, the Revopoint POP 2 is perfect. It’s quite an improvement over the original POP — so if you can pay a bit more, this scanner is worth it.

90,000 best 3D printers 2022-2023 for production and business: expert rating3D scanners

Analyst and business

The best on the topics

Experts recommend

3D-printers

Author: Semen Poladeyuk

Author: Semen Polaezhak

Summing up the results of the outgoing year, we tried to choose the most interesting solutions that appeared in 2022 on the global 3D printing and 3D scanning market. Of course, our top is far from covering even a small part of the novelties of the grandiose 3D industry. We have highlighted several developments that have attracted increased attention from users and professional industry experts.

Note that the best 3D printers and 3D scanners of 2022 roundup does not include the home (consumer) segment. In accordance with the direction of the blog, we are considering professional and industrial equipment that will reduce time, material and labor costs for manufacturing enterprises, research, educational and medical organizations, as well as in the field of business projects. Thanks to such innovations, the locomotive of the industry is moving.

Blog materials will help you navigate the typology of equipment and choose the best solution:

-

Types of 3D printers: technologies, materials, applications

-

Choosing a 3D Printer: Find the Right Solution for You

-

How to choose a 3D scanner

If you have questions about the implementation of 3D technologies, please contact iQB Technologies experts

Top 8 3D printers

HBD E500

© HBD

HBD is one of the Chinese market leaders in metal 3D printing. The manufacturer's portfolio includes more than 15 models of printers with cameras from 150 to 1500 mm. In 2022, the line was replenished with perhaps the most versatile machine - the HBD E500. It's a true workhorse for trouble-free printing of complex custom or prototype designs up to 520mm.

The printer is equipped with two or three lasers, depending on customer requirements, equipped with a safe and reliable filtration system and provides a closed powder supply cycle. With its high print speeds of up to 10,000 mm/s, the E500 is well suited for continuous batch production in a variety of industries such as automotive, mechanical engineering, aviation, foundry, education and R&D.

SLM NXG XII 600E

© SLM Solutions

At Formnext 2022, SLM Solutions, market leader in metal 3D printing, announced its latest development, the largest additive manufacturing machine for selective laser melting technology. Based on the popular NXG XII 600 model, the new model has a larger build area of 1. 5 m in the Z-axis, which is reportedly 50% larger than the equipment of the nearest competitor.

Metal-to-metal additive manufacturing customers are demanding ever larger parts – and as quickly as possible. Serial production of products of complex geometry can now be implemented in a few hours or days, rather than weeks and months. To meet these expectations, the NXG XII 600E provides an end-to-end manufacturing process to increase machine uptime.

The system platform features an open SLM architecture that allows flexible process parameters for maximum performance at a layer thickness of 90 micron or more (when working with popular materials such as IN718, AlSi10Mg, TiAl6V4 and copper alloys).

IEMAI FAST JET 1500

© IEMAI

-

Technology: FDM/FGF

-

Construction area: 1500 × 1500 × 1500 mm

-

Features: creation of large objects from granulated thermoplastics and remote control of the printing process

The use of polymers in the form of granules in 3D printing makes it possible to save even more on materials and speed up the process of printing large-sized objects compared to filaments. Another well-known Chinese manufacturer, IEMAI, introduced the FAST JET 1500 large-format FGF printer for printing products up to 1.5 meters in length, width and height.

The 3D printer features an elevated extrusion temperature (500°C), a 3-stage extrusion temperature control system, and a closed isolation chamber to handle most thermoplastic pellets available on the market, including PLA, nylon, and high-performance materials such as PEEK and PEKK. .

The FAST JET 1500 also features a proprietary 6-axis control system and a 10″ full color touch screen with remote automatic loading. In addition, the printer is one of the first models to be sold with a built-in IEMAI cloud platform for remote control of material drying, G‑od file uploads, printing at regular intervals, and remote monitoring of the printing process.

F2 Gigantry

© F2 Innovations

The Perm company F2 innovations, which develops and manufactures industrial 3D systems, has introduced a novelty - a granule printer with the largest print area.

The F2 Gigantry is an open gantry with an extruder capable of creating parts up to 4 meters long, 2 meters wide and 1 meter high. The technology allows printing with polymer granules with a capacity of up to 10 kg/h, including recycled materials (recycled granulate).

FGF-printing technology is not new, but F2 Gigantry became the first domestic large-format 3D printer in this category. Today, the question of a quick and high-quality replacement of imported solutions, as well as the acceleration of production with an increase in the number of manufactured products, is acute. The novelty from F2 Innovations will help to solve these problems effectively.

ProtoFab PF‑S300 / PF‑S350

© ProtoFab

Professional Russian users are already familiar with SLA printers from the Chinese company ProtoFab, and this year the manufacturer introduced a series of high-precision industrial units based on selective laser sintering (SLS) technology.

The ProtoFab PF‑S300 and PF‑S350 are equipped with a new dynamic thermal control system that further optimizes temperature distribution monitoring, encapsulation and sensor performance. Nylon, carbon fiber composite nylon powder, glass fiber composite nylon powder and other plastics are used as consumables.

The speed of laser illumination is increased to 3 m/s, which significantly speeds up molding by increasing the speed of powder spraying. The printers are equipped with new, efficient powder removal accessories, which can reduce production costs and lead times. With a cylinder temperature of 220°C, the PF‑S300 and PF‑S350 are capable of sintering materials with a melting point of 225°C or lower.

Sinterit Lisa X

© Sinterit

The Polish company Sinterit sets another record: according to the manufacturer, the new SLS system is ten times faster than its predecessor, the Lisa PRO model. Lisa X is capable of sintering PA12 at speeds up to 14 mm/h and completing a full print session in just 30 hours. Relatively inexpensive and compact, a 3D printer can truly boast the performance of an industrial device and allow companies to speed up product development and time to market.

Open source software allows you to customize 32 print settings to suit your individual needs. Media changes can be done in 15 minutes, and printing and cooling can take up to 40% less time than any other compact SLS printer.

Lisa X also features a unique "airblade" system that automatically cleans the glass around the laser during production, meaning users don't have to do it manually in two out of every three sessions, speeding up print preparation.

Massivit 10000

©Massivit 3D

-

Technology: Cast-In-Motion

-

Construction area: 1200 × 1500 × 1650 mm

-

Features: production of molding equipment in the shortest possible time

Another interesting novelty for 2022 is a large-format additive machine from the reputable Israeli manufacturer Massivit 3D. The system uses a hybrid technology of photopolymer 3D printing and thermoplastic injection, called "Cast-In-Motion" (CIM). The printer is designed for the production of molding equipment for the subsequent manufacture of products from composite materials. Two printheads are used respectively to form the photopolymer gel formwork and to fill the internal cavities with thermoplastic. After heat treatment of the printed product, the photopolymer shell dissolves, and the resulting form undergoes finishing machining.

This technology, according to the manufacturer, allows to reduce the number of stages of the production process and reduce the time for the manufacture of molding equipment by 80%.

BMF microArch S350

© Boston Micro Fabrication

-

Technology: projection microstereolithography (PµSL)

-

Construction area: 100 × 100 × 50mm

-

Features: high resolution microscale photopolymer printing

And here is one of the latest new products for 2022 - a photopolymer microprinting machine from Boston Micro Fabrication (BMF). The microArch S350 is the highest performing BMF printer for the final part industry, as it can print not only high-resolution micro-scale objects (up to 10 microns), but also many small objects that require high precision and detail. The 3D printer is suitable for prototyping and additive manufacturing in the amount of one thousand to 30 thousand products and will find its place in enterprises and research laboratories.

The microArch S350 is based on BMF's projection microstereolithography (PµSL) technology, which is a form of masked stereolithography (MSLA) using ultraviolet light with microscale resolution.

Top 5 3D Scanners

FARO Focus Premium

© FARO

-

Type: ground laser 3D scanner

-

Distance measurement accuracy: ±1mm

-

Scanning speed: up to 2 million points per second

-

Features: Unsurpassed scanning quality in one minute

The super-hit FARO Focus series has been replenished with improved Premium models. The new line includes three instruments with a scanning range of 70, 150 and 350 meters and features higher speed, increased resolution, hardware noise reduction and the ability to remotely control the instrument from any mobile device.

Premium is 50% more productive than its predecessors: measurements take an average of one minute using the optional PanoCam, even when scanning in color. Remote control of the scanner and stitching of scans from a mobile device is performed using the Stream application with subsequent integration into the Sphere cloud platform.

New devices are perfect for projects in the field of manufacturing, architecture, civil and industrial construction. And a nice bonus: the official warranty period from the manufacturer has been extended to two years.

Also in 2022, FARO launched the Focus Core, a cost-effective terrestrial scanning solution with an optimal balance of speed and accuracy.

EPiC EasyScan T10

© EPiC

-

Type: terrestrial 3D laser scanner

-

Accuracy: 1cm at 10m, 2cm at 30m, 5cm at 100m

-

Scanning speed: 320 thousand points per second

-

Features: Easy-to-use entry-level device

The appearance of such devices marks a new milestone in the evolution of laser scanning technology, which optimally combines economy, quality and ease of use. The EasyScan T10 from China's EPiC (Wuhan Eleph‑Print Tech Co, Ltd.) will be in demand when processing time and measurement convenience are more important than obtaining high-precision data. The scanner is equipped with a 360 °C panoramic camera, and the signal emission system and sensors are securely and ergonomically integrated into the body.

The scanner is launched with one button. A dual scan mode is available, which allows you to combine the simultaneous operation of a panoramic camera and lidar. Data stitching is done on a mobile device. Weighing only 3.2 kilograms, the instrument is one of the lightest geodetic scanners on the market. The package includes everything you need for scanning, including a tripod, batteries and free software for data processing.

Artec Leo 2022

© Artec 3D

-

Type: Handheld Structured Illumination 3D Scanner

-

Accuracy: up to 0.1 mm

-

Scanning speed: up to 35 million points per second

-

Features: The legendary Leo - with double the power and even more accuracy

In the past year, Artec 3D introduced a new version of its popular Leo system, released in 2018. The Artec Leo 2022 Wireless Handheld 3D Scanner offers twice the processing power, improved capture of vibrant colors, an updated built-in touch screen, a multilingual interface and guaranteed high accuracy. The new Auto Temperature Control feature allows the scanner to regulate its operation and maintain the optimum operating temperature of the components.

Powered by an updated NVIDIA Jetson TX2 processor, power consumption is reduced to less than 7.5W. The capture area is 160,000 cm 3 , which means the Leo 2022 can scan objects larger than 200 cm, from auto parts to people and rooms.

peel 3d peel 3

© Peel 3d

-

Type: Handheld Structured Illumination 3D Scanner

-

Accuracy: 0.250 mm/m, up to 0.1 mm

-

Scan speed: 80 sec/m 2

-

Features: A new generation of affordable scanners for reverse engineering

peel 3d, a subsidiary of Creaform, has released a completely redesigned peel 3 solution. This scanner boasts not only greater accuracy than the brand's previous models, but also improved usability thanks to its ergonomic design, tactile feedback and intuitive touchscreen capabilities. All of these improvements aim to improve the scanning experience for both novice and advanced users. Applications of the 3D scanner cover product development, cultural heritage conservation, AR/VR, healthcare, auto tuning, parts manufacturing, engineering, and more.

The scanner is also offered with peel 3.CAD proprietary software, which has been specifically designed as a complete reverse engineering solution.

Scantech SIMSCAN

© Scantech

-

Type: Handheld 3D Laser Scanner

-

Accuracy: up to 0.2 mm

-

Scanning speed: up to 2.8M points per second

-

Features: compact and high performance device for professional use

Scantech (China) has released an updated version of the compact and portable SIMSCAN 3D scanner. It aims to set a new standard in metrology with palm-sized, high scanning performance, low power consumption and 0.020mm accuracy.

Scantech engineers have been able to improve 3D scanning efficiency by 40% and reduce power consumption by 20% compared to the previous version. Thanks to its blue laser scanning technology, the device is ideal for digitizing narrow spaces. 42 laser lines further enhance scanning efficiency.

The device is designed for long-term and stable use. To ensure reliability, the 3D scanner calibration plate is made of aerospace grade carbon fiber, which is more resistant to shock and other loads. Finally, SIMSCAN is extremely portable, allowing you to carry it with you and take measurements anywhere.

Article published on 12/22/2022, updated on 03/13/2023

we choose the best in 2022 in our direction

In order to expand the user audience, SHINING3D offers universal solutions - the same 3D scanner is able to satisfy the needs of ordinary consumers and large businesses and be in demand in the conditions of industrial production of products. Based on the feedback, comments and reviews of device owners, taking into account their needs, the developers have improved the line of models, making 3D digitization and additive technologies even more accessible.

Content:

- 3D series EINSCAN

- for beginners, designers or educational directions

- Scanners for

- 3D 3D 3D 3D 3D 3D scanner EINSCAN PRO 2X 2X Transcan C

- What other indicators you need to understand in order to choose what you need

- Accuracy

- Ability to digitize in motion

- Application of 3D scanners in mechanical engineering

The application of scanning of relatively small objects requires precision and advanced settings in the capture software. The first thing users are guided by is the scanning area. With the help of two models - EinScan-SP and EinScan-SE - it will be possible to scan an object from 30 × 30 mm.

Very important for the buyer and their price, as well as mobility and ease of movement.

EinScan-SP and EinScan-SE are useful for beginners, designers and educational users. Desktop scanners SE and SP are the easiest to learn.

Key benefits:

- Simple plug and play scanner setup;

- Russian software interface;

- the ability to scan objects of different sizes - from small to large;

- texture tracking.

- one scan time 4-8 seconds;

- Russified software;

- automatic and fixed operation;

- Aligns scanned data with marks.

- 8 seconds per scan;

- Time needed to scan 360 degrees in Auto Scan mode - 2 minutes;

- Russified software;

- automatic alignment of multiple scans;

- API access service for 3D printers of any brand.

Scanners for objects of various sizes

Due to their large dimensions, some parts need to be scanned from a distance of several meters - in this case, portable devices are used. In this category, models with the “H” index successfully demonstrated their capabilities: EinScan H , EinScan HX from the line of mobile hybrid devices. If you choose by price, the most affordable is the portable EinScan H.

Two of these models stand out from the list of products that SHINING3D releases by the presence of hybrid light sources:

- EinScan H - an invisible infrared emitter spectrum has been added to the LED backlight;

- EinScan HX - white LED light combined with a blue laser.

This high-tech solution makes it possible to use these two professional scanners. Manual mode allows you to scan objects of different sizes - medium and large.

To improve the accuracy of the photographs, glossy surfaces are treated with a matting spray.

Photo of a 3d scanner EinScan HXBut with the help of some devices, the digitization of such objects is performed without preliminary application of auxiliary compositions to their surface, which saves a little time.

- Structured emission from an LED source and a scanner laser projecting crossed laser beams onto the surface.

- In Laser Scan mode, the object scan accuracy is 0.04 mm.

- Minimum dot distance 0.05 mm in laser mode.

- High efficiency in fast scan mode - 1,200,000 points/s.

- Full color reproduction of the part.

Copying accuracy is so great that when scanning objects of works of art, it is possible to obtain an almost perfect replica. For medical institutions, this is also a worthy find. Separately, it should be noted the presence of a built-in color camera.

There is a free download of PC software with many functions for setting up and calibrating equipment. The installation package is also supplied on a USB stick if you need a stand-alone installation in the absence of Internet access.

Even an operator without experience and knowledge can work with the intuitive interface of the program, which saves time on staff training.

3D scanning of people and their faces

If living objects are selected for work, a special scanning technology is required. You can get a digital copy of a fragment of a human body, face and hair using EinScan H hybrid models - thanks to two light sources and a color camera, they produce an ideal 3D model with texture preservation. A special requirement for the model: it must not move.

- Two scanning technologies - LED and infrared light, invisible to the human eye, combined in one device.

- Scanning people (portrait, full-length) and other living objects.

- High accuracy of scanned data up to 0.05 mm and volumetric accuracy of 0.1 mm/m.

- Resolution up to 0.25 mm.

- Fast scanning and large scanning FOV 420 × 440 mm.

According to experts who have been conducting research in the world of additive technologies for many years, specific criteria are set for certain tasks: the more complex the part geometry, the higher the scanner resolution should be.

But it will also take more time to digitize, and the file size will increase due to the multiplication of the number of cloud points with a smaller distance between them.

Of the three samples, the HX version is the universal laser scanner model, and the Einscan Pro HD/Einscan Pro 2x 2020 are multifunctional scanners that have the ability to perform tasks in various industries.

The EinScan Pro HD is an upgraded scanner from the older model of the Einscan Pro 2x series, thanks to its ergonomic and high quality design. Models in this range can be used with a special tripod.

This professional 3D scanner provides high precision scanning of objects in both operating modes: up to 0.045+0.3 mm/m.p. in manual mode and up to 0.04 mm. in fixed scan mode.

Manual object scanning has two submodes: Rapid and HD, the latter providing a higher level of detail (resolution). Depending on the complexity of the geometry of the object, the presence of deep holes and 3D scanner parameters, such as resolution (distance between points), the final image may require further processing in the program.

The maximum possible scanning speed for this scanner is 3 million points per second. Even if we ignore the specifications, we can see that this device is extremely fast in real-life scenarios. For example, a 220 x 71 cm low-relief sculpture takes less than one minute to digitize in color.

Scanning of human bodies is also possible with this device, it provides decent quality. Last but not least, using a 3D color scanning camera with the device allows you to get scans with color and texture and realize even more projects. To keep the best price and reduce costs, manufacturers offer such cameras as an additional Color Pack option, which is paid only by those consumers who work with texture models and who really need it.

EinScan HX is more expensive than the EinScan H scanner, and functional professional scanners, which include the EinScan Pro HD, are traditionally more expensive than other classmates and therefore are available to large manufacturers in the field of additive technologies.

EinScan Pro 2X 3D Scanner 2020

This portable and versatile handheld 3D scanner helps you get highly accurate results.

The EinScan Pro 2X 2020 3D Scanner is an excellent option for scanning small, medium and large objects.

3D scanner EinScan Pro 2X 2020The updated scanner model has improved the main characteristics, added new 3D scanning algorithms. Thus, Einscan Pro 2x 2020 has become a more affordable version of Einscan Pro HD, retaining the advantages and features of the old model.

The main improvements of the new model:

- The new principle of 3D scanning of the device in manual HD mode, which allows scanning without the use of markers (as Einscan Pro HD does). The old model could not scan without markers in this mode. The quality and detail of scans have also been improved.

- Higher device scanning accuracy in manual HD mode, improved volumetric accuracy for scanning large objects.

- Higher scanning speed in manual HD mode.

- Increased 3D scan area.

- Added alignment modes in manual HD mode: alignment by markers, by geometry, hybrid alignment. This expands scanning capabilities and efficiency in a wider range of tasks and areas.

Einscan Pro 2x 2020 3D Scanner is compact and lightweight, you can take it with you anywhere. It has a comfortable handle and is light (namely 1.13 kg) and easy to hold in your hand, and if you need HD mode accuracy, put the scanner on a tripod. The scanner is connected via USB 3.0 to a computer or laptop.

According to experts, the latest developments in the field of data capture and optimized algorithms make the 3D scanner Einscan Pro 2x 2020 a truly breakthrough - its scanning speed reaches 1,500,000 points per second (at 30 frames per second) in manual scanning mode.

If you need to expand the functionality of the scanner, Shining 3D offers several optional options:

- The Color Pack 3D Scanner is an optional camera that allows you to scan with color and texture.

- Industrial Pack - accessories such as turntable and tripod. Suitable for high quality scanning of small objects in the studio.

Transcan C

3D Scanner The Transcan C 3D Scanner is a professional scanning grade scanner capable of capturing "exceptionally" accurate, high-resolution scans of small to medium objects thanks to two 12-megapixel color cameras with adjustable scan range and multi-level switching permits within a single project.

The 3D scanner features a sliding design that allows you to easily switch between 150 x 96mm and 300 x 190mm scanning ranges when working with objects of different sizes. The multi-resolution fusion algorithm makes it possible to mix high, medium and low resolutions in one project, which makes the scanner much more efficient, and its two cameras can capture a 24-bit color map to capture detailed 3D color data and provide better results.

TheTranscan C has a structured light scanning mode with an automatic turntable that, in combination with the scanning software's stitching algorithm, allows efficient 3D model acquisition without manual intervention.

What other indicators you need to look at in order to choose what you need

The technical characteristics of the devices determine their use in a particular area: in jewelry, high detail is required, in industry - accuracy, in art - the possibility of color digitization, in the field of education - ease of setup and others. Of course, the properties are considered in a complex: the most important parameter is considered as the basic one, the rest are considered as auxiliary, but at the same time mandatory.

3D Scan Accuracy

The degree to which the copy matches the original is perhaps the most important indicator. The technical characteristics of scanners indicate the maximum allowable deviation of the scan size from the real object. The indicator is measured in millimeters or microns (1 micron = 0.001 mm). The smaller the number, the more accurate the 3D scan will be. But the deviation in reality can be larger, since it is quite difficult to create ideal conditions for the device to work, the result is affected by:

- characteristics of the object;

- user qualification;

- scanner settings.

It is important to understand that accuracy and resolution are different characteristics of scanning equipment. Detail is the smallest distance between points, the limitation of which is due to the resolution of the cameras and the principle of the scanner.

Ability to digitize in motion

Triangulation 3D scanners will help to scan moving objects, which can lead to an increased cost of devices of this type. This technology is not usually found in handheld 3D scanners, but among the offerings of the company with a rich history of SHINING 3D is the 2020 model EinScan HX, which at that time implemented triangulation technology.

The use of professional 3D scanners in metrology

3D scanners cope with the processes of measuring sizes and shapes of models in a matter of minutes, unlike traditional coordinate measuring machines, in which coordinates are read by contact sensors. The non-contact mode of operation enables the device to scan and measure surfaces of complex shapes (internal corners and edges), recesses and other hard-to-reach places.

After receiving all the necessary data during the processing of the object, they are transferred to the computer for processing. The program performs a comparison of indicators in order to identify deviations - a mismatch in shape and size, the presence of chips, cracks and other deformations caused by mechanical stress or corrosion processes.

Innovatively adapted blue laser 3D scanning technologyOptimScan-5M, 3M and AutoScan Inspec "scanner-inspector" are designed for metrology purposes for scanning a small object. All these devices to some extent belong to the same price niche, are multitasking, provide an opportunity to obtain high-quality digital 3D models for comparison with reference samples, demonstrating:

- the highest scanning accuracy;

- the ability to upload scans to processing programs;

- compatible with CAD/CAM technologies;

- work with objects of various sizes and shapes, including those with complex geometry;

- texture tracking and color imaging.

Professional, they are also industrial, 3D scanners help to perform a wide range of tasks:

- reverse engineering;

- ultra-precise 3D quality control;

- implementation of intermediate stages of the technological chain of creating products using additive technology;

- faster prototyping and other operations.

On the Russian market you can find interesting offers for the acquisition of scanning devices for photogrammetry at a fairly reasonable price. However, you should pay attention to their characteristics, especially such as the resolution of cameras, the distance between points, and some others that are important for measuring instruments, since the accuracy of the results depends on them.

3D scanning in mechanical engineering

The integration of 3D scanning technologies into production processes gives undoubted preferences. Properties of modern industrial scanners:

- high speed;

- ultra-precise measurement and digital copy saving;

- processing of objects regardless of the size and complexity of the form;

- possibility of implementation in automated process control systems.

With the help of 3D scanners and specialized software, numerous processes can be performed:

- reverse engineering, or reverse engineering;

- metrological control;

- test measurements of geometrical parameters for the purpose of quality control and detection of defects;

- creation of archives of digital models.

Reverse engineering

Reverse engineering of complex shapes is one of the areas of industrial engineering. A physical sample is translated into a digital copy using a 3D scanner, which can be reproduced on CNC machines and turned into a finished product. To do this, the resulting polygonal model is converted into a popular CAD format. The digital copy is modified and modified to achieve the specified parameters. This allows you to move from traditional design to a new level, when it takes several times less working time to work. The finished object becomes the basis for serial production of products.

With a large selection of laser and optical 3D scanners on the market, there are not so many budget devices in this segment that are used for prototyping and solving other engineering and everyday tasks related to 3D modeling.

Quality control

Metrological 3D scanners make it possible to obtain a point cloud of the test sample, on the basis of which an ultra-precise 3D model of the part is formed. It is compared with a digital copy of a reference sample or with an existing CAD model.

Benefits of 3D quality control:

- Absolutely accurate data for reference comparison;

- measurement of millions of surface points;

- high speed operation;

- possibility of automatic operation.

The obtained data can be used for reverse engineering.

Scanners from the metrological category are recommended for quality control. It can be either stationary or portable.

FreeScan UE

Shining 3D FreeScan UE Laser Handheld 3D Scanner is the latest addition to the FreeScan high performance 3D scanner line.

The device uses the patented blue laser technology and features high accuracy and stable repeatability.

Sunny Wong, product manager of Shining 3D, states: “Innovative adaptation of blue laser 3D scanning technology, high precision and stable repeatability, and easy and convenient operation of hardware and software, allow FreeScan UE to effectively and accurately upgrade digital workflows in engineering and inspection tasks, ensuring the quality of the final product.

The metrology-grade FreeScan UE system delivers 0.02 mm accuracy and 0.02 mm + 0.04 mm/m volumetric accuracy. With a maximum scan area of 510 x 520mm, users get a field of view suitable for large-scale reverse engineering projects.

High precision stationary 3D scanner AutoScan Inspec

AutoScan Inspec- The interface is immediately clear to the user.

- The accuracy of the 3D model reaches the metrological level with an error of 10 µm (0.01 mm).

- The device can be used for non-contact measurement and quality control.

- The process is fully automated.

Works with native software developed by SHINING 3D programmers for industrial applications. The PC communication program supports STL format output files. This simplifies further 3D printing of parts from various transparent photopolymers on a 3D laser printer and saves time on intermediate data processing.

OptimScan-5M 3D Metrology Scanner

OptimScan-5MOptimScan-5M professional metrological 3D scanner shows the best consumer characteristics required just for 3D inspection:

- accuracy - 0.015 mm;

- two 5-megapixel cameras;

- high processing speed;

- blue light scanning technology.

AutoScan Inspec Desktop Scanner is a two-in-one scanner-inspector that works in automatic mode. The scanner performs 3D scanning with the highest precision and 3D inspection of objects. For working with complex parts and the smallest elements, this is one of the best devices:

Solutions for dentistry

In dental orthopedics, 3D scanners – intraoral and dental – have become indispensable assistants for orthopedists and dental laboratory specialists.

Learn more