Gizmo 3d printer review

Gizmo 3D Printers GiziMax 430 Super Speed 3D Printer

| Brand | Gizmo 3D Printers |

| Machine type | 3D Printer |

| Technology | SLA (Stereolithography) |

| Materials | Resin, Dental SG Resin, Flexible Resin |

| Website | https://www.gizmo3dprinters.com.au/3d-printers |

| Average Price | Contact manufacturer |

Build Height = 430mm (31.49in)

Build Area = 200mm x 113mm (7. 87in x 4.44in)

20L resin included in price, super speed add-on not included.

Features:

Quality parts & reliability

We don’t believe in dressing our machines up in fancy clothes. Instead, the Gizmo 3D printer is proud to show you what it's made of - quality parts that scream reliability! One of the main reasons people get frustrated with other 3D printers is that they are constantly having to replace low quality parts. You won’t find this with the Gizmo 3D; our machines are built to last, and it shows.

Different materials to suit your projects and budget

Our machines are compatible with Fun To Do Resin, which is affordable and widely available in many countries. Included in the prices of our machines is enough Fun To Do resin for you to dive straight in and start printing right away. We are currently testing more brands of resin so that we may be able to recommend resin types to you to suit your individual needs. These include resin from pro3dcure, Monocure and Vitang.

These include resin from pro3dcure, Monocure and Vitang.

Innovative software features

Our 3D Printer Software, Gizmetor, includes features never before seen anywhere in the 3D printing world, including full layer manipulation, which is the ability to select a particular layer within a print job, and specify how you would like it printed (i.e. hollow, solid, detailed or faster). The machines are highly configurable, allowing you to easily switch between ultra-detailed high res prints and super speed prints with ease.

Consistent results, remote repeatability

We’re all about the user, and do everything we can to deliver you the best experience possible. This is because we are just like you; we love 3D printing! However, we also aim to provide users with as much flexibility, capability and functionality as possible, giving you the ability to configure the printer in any way you see fit. While this is surely enough to raise the pulses of experienced users or those with some mid-level 3D printing know-how, it could leave absolute beginners feeling a little overwhelmed. Don’t be disheartened; enjoy the experience, progress along the learning curve, and invest some time and effort in developing your skills. Believe us, it’s worth it!

Don’t be disheartened; enjoy the experience, progress along the learning curve, and invest some time and effort in developing your skills. Believe us, it’s worth it!

Expandable

Each machine is built in such a way that it grows with the user and their needs. If your situation changes and you find you need a bigger vat, this is not a problem; you can simply purchase the add-on. With other 3D printers, such an upgrade would require the purchase of a whole new machine.

Save time and costs while printing

Our top down system means that the vat doesn’t need to be emptied between prints because the unwanted hardened chunks of resin sink to the bottom. This means users can start printing as soon as the previous print is complete, saving even more time in between already super fast prints. Have you experienced all the hassle and inconvenience of a bottom up printer? Not even an issue with the Gizmo 3D.

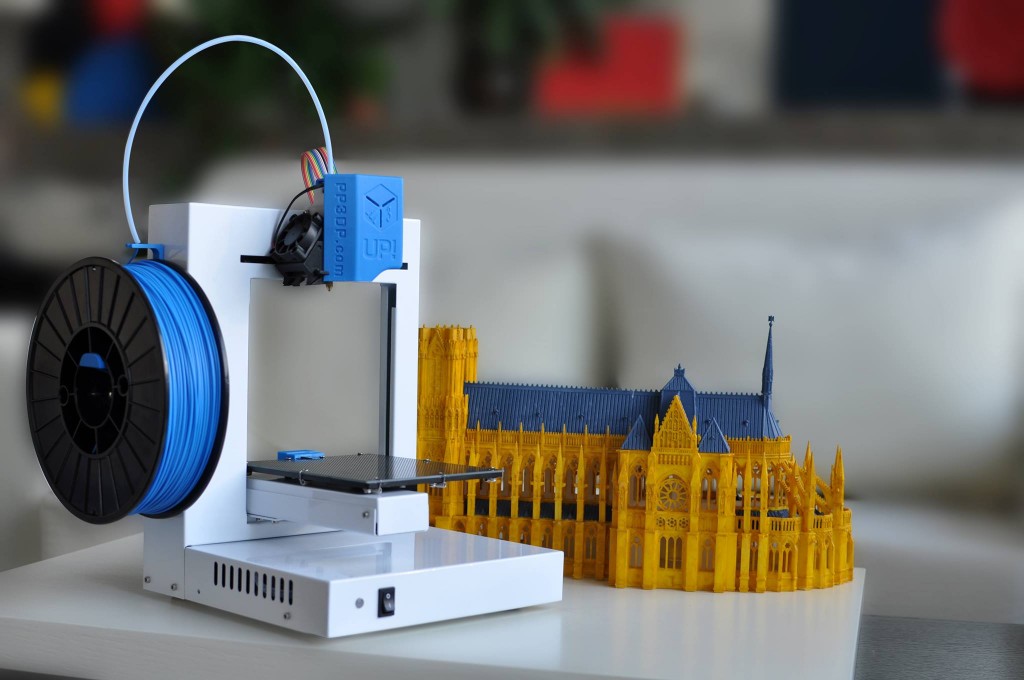

Catching Up With Gizmo 3D Printers « Fabbaloo

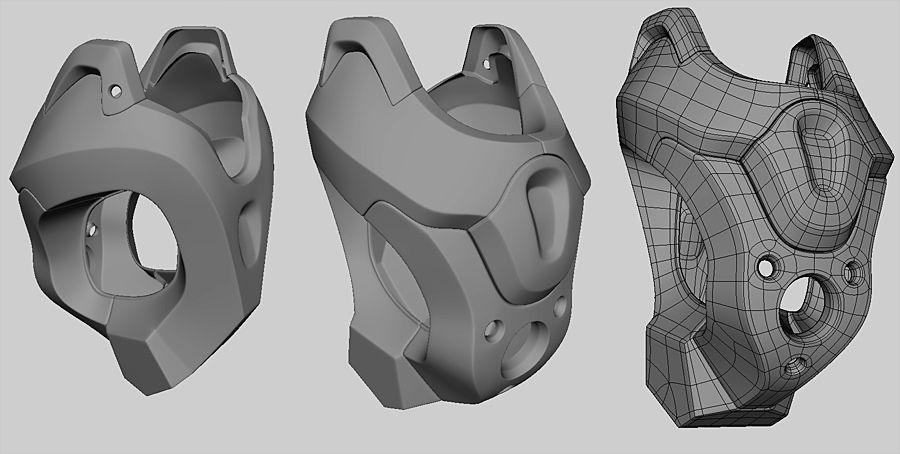

Umbilic Torus by Artex: 3D printed in only 1. 5 hours at a size of 120mm x 120mm on an industrial Gizmo Resin 3D Printer [Image: Gizmo 3D Printers]

5 hours at a size of 120mm x 120mm on an industrial Gizmo Resin 3D Printer [Image: Gizmo 3D Printers]Gizmo 3D Printers has some major news to share in super-fast industrial DLP 3D printing.

It’s been a little while since we last caught up with the Australian team. We first met them at CES 2016, where in the startup zone they were showcasing live demonstrations of an unbelievably speedy DLP 3D printer — that prints, uniquely, from the top down.

Their offerings are interesting, but it seems like the team has been a little quiet. It turns out that’s because they were keeping their heads down as they were hard at work, and — phew. They have quite a lot to share now in terms of upgrades, new product launches, and add-ons to be released this year.

Ahead of our conversation, they sent over a few tantalizing points of discussion:

- We’ve doubled the speed of our already super-fast industrial, top-down DLP 3D printers – now printing up to 33 times faster than the average in the market

- Optional skins are now available for our machines with integrated PCs

- We’ve introduced an additional and exclusive 3D printing method to Gizmo 3D printers (which now has 3 in total)

- Released a Wiper/Recoater add-on

- NEW: The 1st 4K Industrial Grade Gizmo 3D Printers is hitting the market.

This is big news because people can finally get an industrial 4k top-down DLP printer for less than USD $15 000

This is big news because people can finally get an industrial 4k top-down DLP printer for less than USD $15 000 - NEW range of more affordable desktop options – we call it the GiziBuddy Range

- We keep on discovering more benefits of top-down printing. A research paper by a University has concluded that our top-down machine is better for ceramic printing for example.

“We’ve got so much news about developments we’ve been quietly working on,” Co-Founder and Managing Director Michelle du Toit told me as we started speaking.

4K Gizmo 3D Printer

The projection setup for Gizmo 3D Printers’ top-down process [Image: Gizmo 3D Printers]The big, fast, high-resolution news is a new 4K projector version of Gizmo’s machine.

“We not only have UV HD projectors, we also have 4K projectors now,” Co-Founder and CEO Kobus du Toit explained. “It’s very low cost: you can get a 4K top-down DLP printer for less than $15,000.”

To put that in perspective, Gizmo points out that most industrial-grade 4K DLP 3D printers “can cost more than US$50,000” — and the “smallest and most basic 4K Gizmo 3D Printer [is available] for less than US$13,000. ”

”

A few comparisons can be made as well between the new 4K version of the system and the original that debuted in 2016 as an already-impressive machine. Gizmo 3D Printers explains:

“Using a projection area size (refer to the image [above] to understand what a projection area is) of 192mm x 108mm as an example, the difference between printing with or without a 4K projector would be DOUBLE the resolution! The resolution of a Gizmo 3D Printer with an HD projector would be 100um XY. At the same projection area size of 192mm x 108, the resolution of a Gizmo 3D Printer with a 4K projector would be 50um XY. “

So that’s twice the resolution — what about speed?

“When we launched at CES I believe 2016, we were using Acer projectors, using a single projector, and had a super-speed projector option of two Acer projectors. A 100 micron layer would have taken 2 minutes,” Kobus explained — now, though, “with the current setup this takes 6 seconds.

”

Michelle added to this speed discussion, noting that “Gizmo is already 33 times faster than other 3D printers out there.” She credits the top-down method for their success here.

Bottom-up / top-down 3D printing [Image: Gizmo 3D Printers]“We use the top-down method, which not a lot of 3D printing companies use, and which has proven over and over to be more efficient. We’re not only talking printing speed, but efficiency,” she said. “For instance, prints that are printed on bottom-up machines are exposed to suction forces caused by a peeling step in the printing process. It can cause the prints to be pulled from the build plate where it’s hanging upside down from and fall off. Our top-down printing method has no peeling step and prints are formed sitting on top of the build plate which means it has no risk of falling off. We can print as big as we want to without needing to worry that gravity might cause prints to loosen from the build plate as one could experience with a bottom-up 3D printer.

Plus ours are some of the biggest DLP 3D printers available in the 3D printing industry.”

The 4K option is also available as an upgrade option for current Gizmo systems.

Gizmo 3D Printers

Catching up with Michelle and Kobus du Toit [Image: Fabbaloo]Further launches include a new Plus range to come this year, as well as more budget options.

“The Plus range is a fully enclosed system, mostly for universities and big companies that want a fully enclosed system,” Kobus noted.

The Plus range will be “very much high-end, industrial-grade” systems, including powerful internal systems. Rather than “a Raspberry Pi or something like that,” these 3D printers will have a full PC, and the “customer can upgrade the CPU to a higher version, and can upgrade memory; it comes with a 250gig hard drive, it’s a nice PC inside the machine,” Kobus added.

Because Gizmo 3D Printers have always been focused on customization — like, but definitely not limited to, that PC upgrade capability — this is a big area of updates.

“Most machines have a standard way of printing, we call that standard speed,” Kobus said. “We have a two-phase wiper or recoater printer so the user can change the printing method in a print as they wish. They can program the print for high speed, for high quality — for what they want.”

Sometimes in 3D printing, speed is more important than finish; think rapid prototyping. One major use for resin-based 3D printing systems, though, is finish, and so being able to change over to a highly detailed method is always in high demand.

“We have the recoater wiper system, which has been in the works for three years to make something upgradeable, configurable, and can be used with all our vats. It can be 85mm wide to 400 mm wide,” Kobus continued. “We can change the wiper on the machine to work with any of our vats, and the wiper has attachments to add a spray system in the future. We’re testing a spray system; that’s still in the works.”

The Wiper or Recoater add-on for Gizmo Resin 3D Printers is available for $800, and a step-by-step guide for installation is available.

Later this year, Gizmo is planning to release the GiziBuddy 3D printer as well.

The GiziBuddy, which can fit on a desk, is the smallest machine currently available from Gizmo. With different internals, the GiziBuddy 3D printer will have specific application focuses such as the GiziJewelry and GiziDental printers.

“Our machines are highly configurable. The customer can have a large vat in the machine and place another vat on that vat; the machine won’t stop you doing those kinds of things,” Kobus said. “We have what we call the ring vat, it’s the smallest we have now. You can put that on top of the bigger vat, and it only requires 700ml of resin. It’s also open to third party resins.”

Our relatively short chat was informative and almost head-spinning; their high speeds aren’t only for their 3D printers, but sheer amount of work to share. Which, as Kobus put it, was about “four years of work in five minutes.”

Gizmo 3D Printers is well worth the look for high-speed, configurable, affordable options in DLP 3D printing — there’s a lot that’s new there, and more yet to come!

Via Gizmo 3D Printers

New Gizmo 3D printer prints items in 6 minutes (+ video)

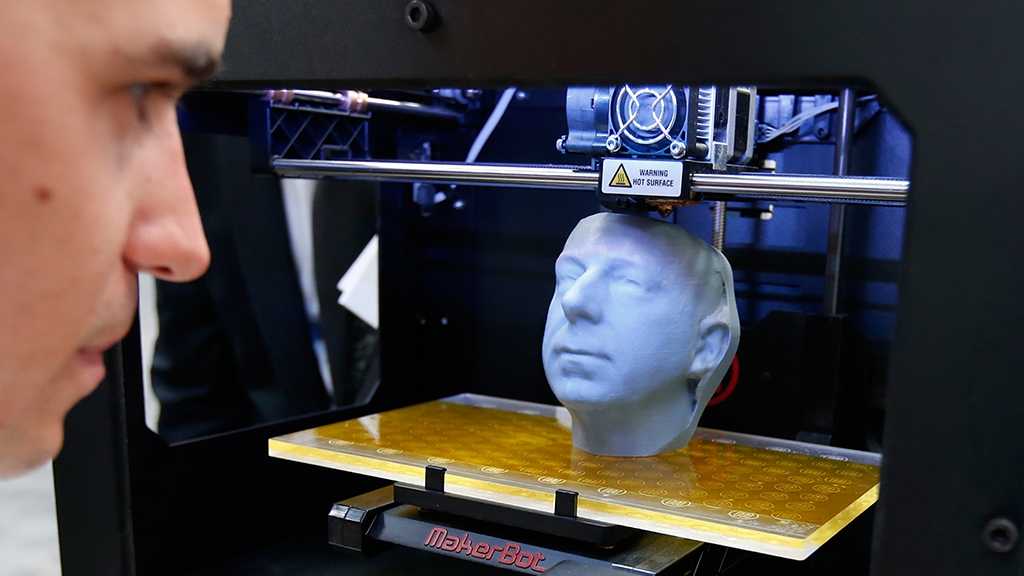

Gizmo 3D printer was introduced in a video demonstrating "continuous 3D printing" technology. According to developer Kobu du Toit, this device could be the world's fastest high-quality 3D printer.

According to developer Kobu du Toit, this device could be the world's fastest high-quality 3D printer.

Gizmo's 3D printer isn't the only device to produce resin objects using DLP (Direct Light Processing), but it uses the method in a slightly different way. Du Toit explains that this 3D printer produces objects from top to bottom: “The projector is above the resin tank. It projects images as the print bed moves deeper into the resin. A huge benefit of top-down printing is the ability to print large objects without having to worry about the suction issues that come with bottom-up DLP printers.”

The author of the development calls his technology "animation printing", because it uses a sequence of flashes of a DLP projector, the radiation of which affects the hardness of the polymer from which the printed objects are created. Printing is done in a container with a polymer, and the objects remain in this container until the end of printing. Once ready, the object is lifted and the liquid polymer is drained. The print speed using this method is very high: a 150 mm x 80 mm x 26 mm object with a resolution of 50 microns is printed in just 6 minutes.

The print speed using this method is very high: a 150 mm x 80 mm x 26 mm object with a resolution of 50 microns is printed in just 6 minutes.

Although du Toit's design doesn't actually print continuously, it does produce objects amazingly fast. Many details of the technology are trade secrets, but the developer says that top-down projection helps to significantly reduce print time. “The walls of the objects are very thin, which allows the resin to quickly flow over the already printed layer, so the print platform moves almost continuously,” du Toit explains.

Due to the design of most printers, a lot of time is wasted moving the platform up and down, and the features of the new device make it possible to avoid this. “Because the printer prints from top to bottom, it requires much less effort, especially compared to printers that print from bottom to top and have to deal with suction. I believe that this technology can be combined with a standard printing method, thereby increasing the overall speed of manufacturing objects, says du Toit. “Projecting an image takes one second, while moving the print platform and stabilizing the resin can take up to 15 seconds per layer.”

“Projecting an image takes one second, while moving the print platform and stabilizing the resin can take up to 15 seconds per layer.”

Gizmo 3D printers will also feature a large resin tank to ensure there is enough material for any size project. “There is no need to install an external reservoir to replenish resin or add resin while the printer is running. There is also no need to install wipers, so a top-down printer has fewer moving parts than bottom-up devices, and even FDM printers. As a result, such a printer has fewer parts that can break and need to be replaced periodically - in general, there is less risk that something will go wrong during printing, ”says the inventor. Obviously, these are important factors.

Perhaps one of the most interesting features of the new development is that the device can actually handle projects of any size. Thanks to the projector, the size and number of objects are limited only by the capacity of the print platform, while the production time does not change. As for the resin 3D printer platforms themselves, they have already reached impressive proportions. The platform of a standard GiziMate 3D printer will be 400x200x200 mm, while the GiziPro model will be 400x200x350 mm. The largest version of the device, GixiMax, will have a print platform measuring 400x200x850 mm.

As for the resin 3D printer platforms themselves, they have already reached impressive proportions. The platform of a standard GiziMate 3D printer will be 400x200x200 mm, while the GiziPro model will be 400x200x350 mm. The largest version of the device, GixiMax, will have a print platform measuring 400x200x850 mm.

As you would expect from a resin 3D printer, the device produces objects of excellent quality. All printers can print 35 microns in the XY axis, depending on settings and projector, and the resolution in the Z axis is 1 micron, although this also depends on the type of resin. Although this part of the device is still in development, du Toit hopes to make it possible to install multiple resin tanks (even multiple colors) for multi-color printing (in which the three print platforms act as one). The resin itself is heated to room temperature (22°C) for optimum consistency and resolution.

Gizmo 3D will release a printer that is as fast as the new Carbon 3D

There has been a standing ovation in the media about the company Carbon 3D, which, thanks to its know-how - the mysterious CLIP technology - was able to achieve from 25 to 100 times acceleration in 3D printing. But another Australian company, Gizmo 3D, has appeared on the horizon, saying it is also working on a similar technology based on stereolithography that could rival Carbon's discovery.

But another Australian company, Gizmo 3D, has appeared on the horizon, saying it is also working on a similar technology based on stereolithography that could rival Carbon's discovery.

Gizmo uses a modified DLP 3D printing technology that, using a special LED projector, affects a photopolymer resin that hardens when irradiated with light. Cobus du Toit, the founder of the company, explains that all SLA printers that use the bottom-up model construction method have problems with the absorption of photopolymer under the part, which is why the guys from Carbon are trying to solve it by creating an air gap under the product, they are fighting nature and spend some money on it. Gizmo's 3D printer uses a top-down model, so it doesn't have these problems.

The main feature of the technology offered by Cobus du Toit is the method of illumination of the photopolymer. For traditional DLP printers, it is performed stepwise: the image of the first layer is projected, turns off, the platform goes down one layer (or up), the second layer is illuminated, turns off . ..

..

In Gizmo's company, there are no gaps between the first and second images - the change occurs smoothly, as when watching a cartoon. Accordingly, the platform moves smoothly, and the resin polymerizes continuously, which can have a certain effect on both the smoothness of the surface and its strength. It seems incredible why they didn’t think of this before, because it’s so natural! Gizmo hasn't decided what they'll call their technology yet, and is vacillating between "continuous printing" and "animated printing," leaning toward the latter.

The developers say that a model measuring 150x80x26 mm with a layer thickness of 50 microns can be printed by their printer in just 6 minutes. An example of work can be seen here:

Cobus du Toit believes that there is another difference between their invention and Carbon printers. The fact is that the continuous printing method is only great for creating thin walls (1-2 mm).