3D printing large scale

Large Format 3D Printing Service

Back

-

Materials

Materials by Service

Injection MoldingCNC Machining3D PrintingSheet Metal

Materials by Type

PlasticsMetalsElastomers

Related Links

Customer Supplied ResinsColors

Definitive Guide to

CNC MachiningOur downloadable guide offers tips on optimizing your design for machining, tolerances and threading considerations, choosing the right material for your parts, and much more.

Download

-

Resources

Design Tips Toolkits Guides and Trend Reports Case Studies Design Aids Webinars and Trade Shows

Blog Videos FAQs Educators and Students Glossary

Industries Medical Aerospace Automotive Consumer Electronics Industrial Equipment

-

About Us

Who We Are Why Protolabs? Factories x Network Digital Quoting Platform Research and Development Cool Idea Award Sustainability and Social Impact

Careers Investors Locations Press Procurement Partnerships

Contact Us

Proto Labs, Inc.

5540 Pioneer Creek Dr.

Maple Plain, MN 55359

United StatesP: 877.479.3680

F: 763.479.2679

E: [email protected]Digital Factories x

Partner NetworkOur digital factories produce low-volume parts in days while our digital network of manufacturing partners powered by Hubs unlocks advanced capabilities and volume pricing at higher quantities.

Learn More

Get a QuoteSign In

GET LARGE 3D PRINTS

Certifications

ISO 9001:2015 | AS9100D | ITAR Registered

Jump to Section

→ Build Sizes

→ Our Large Format 3D Printers

→ Part Bonding

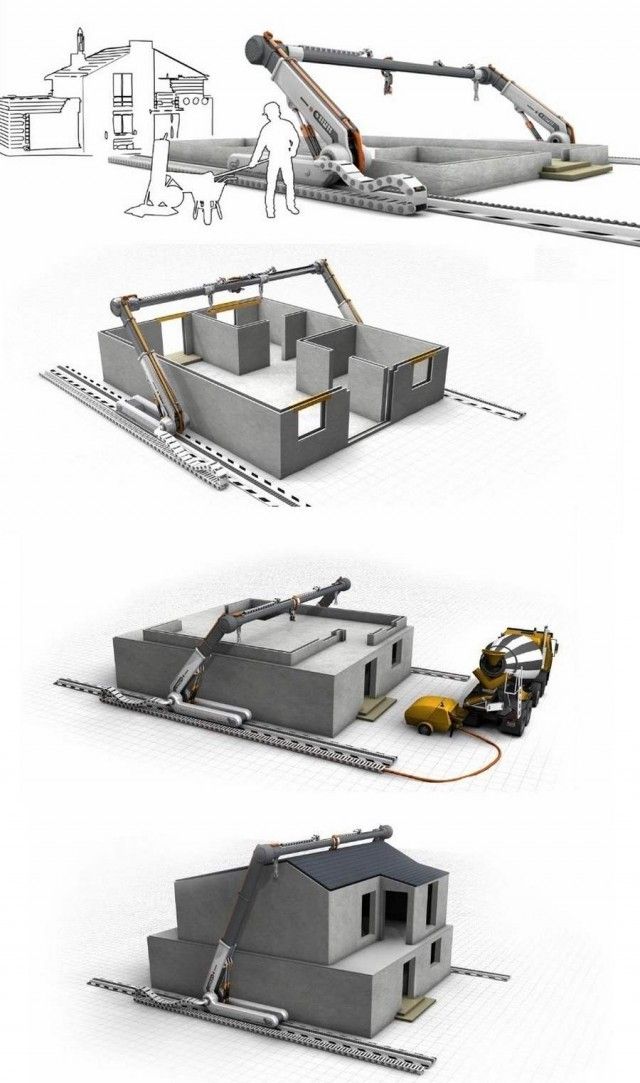

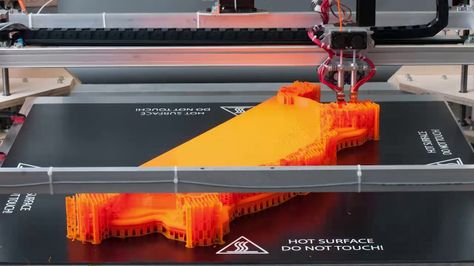

Large format 3D printing is used for large, complex geometries and reducing multipart assemblies into a single design. 3D print metal parts as large as 31.5 in. x 15.7 in. x 19.7 in. and plastic parts as large as 29 in. x 25 in. x 21 in.

“I haven't found a better process out there that makes executing a 3D print project any easier.

”

Maximum Part Sizes for Large Format 3D Printing

| Material | Build Size | ||

|---|---|---|---|

| Metal | Aluminum (AlSi10Mg) | 31.5 in. x 15.7 in. x 19.7 in. | 400mm x 800mm x 500mm |

| Inconel 718 | |||

| Plastic | ABS-Like White | 29 in. x 25 in. x 21 in. | 736mm x 635mm x 533mm |

| ABS-Like Gray | |||

| ABS-Like Translucent/Clear | |||

| PC-Like Translucent/Clear | |||

| PA 12 | 19 in. x 19 in. 17 in. | 482mm x 482mm 431mm | |

Large Format Metal 3D Printer

For large metal parts, we use the Concept Laser X Line 2000R 3D printer. This machine provides a build volume of 400 x 800 x 500 mm. The X Line 2000R was designed specifically for the production of large, quality parts.

Large, 3D-printed parts are often used in industrial settings, aerospace applications, automotive, and energy.

Large Format Plastic 3D Printing

Stereolithography (SLA): Large SLA parts are built on 3D System iPros, which provide large build volume, while still producing detailed parts.

Selective Laser Sintering (SLS): For large parts built in PA 12, we use sPro140 machines.

Bonding for Large Plastic Parts

Need a part that exceeds our machine's build volume? Part cutting and bonding is available for SLA, SLS, and MJF to achieve even larger part sizes.

Wall thickness needs to be sufficient for a good cut. For large geometries we need a minimum of a 0.1” (2.54mm) or 0.12” (3mm) thick wall to get a decent cut. Keep in mind, the thicker the better to achieve the best cut. If a part is too large to print in one piece then you will likely want to have thick walls regardless to overcome potential part warpage.

The cutting and bonding process will leave stark visible seams at the cut and bond interface. These can be unsightly, but may be allowable if you are using the part for function only. If the part is meant to be aesthetic, custom finishing can be performed to smooth, fill, prime, and paint the bond interface seams. Note, this is difficult to achieve with functionally clear parts.

Related Resources

PODCAST: Large-scale 3D printing with GE Additive’s X Line

Explore the history of large-format 3D printing and how to design your parts for best results on these machines with GE Additive.

Read Blog

Combining Part Assemblies with Additive Manufacturing to Reduce Cost and Increase Performance

How to find the right opportunities to consolidate multi-part assemblies into single components with industrial 3D printing

Read White Paper

Large Format 3D Printing for Aluminum and Inconel Parts

When you’re printing really large parts in metal, it’s great to have a choice of materials. Aluminum and Inconel 718 both make a lot of sense, but which one is the best for your application?

Aluminum and Inconel 718 both make a lot of sense, but which one is the best for your application?

Read Blog

3D Printing Materials: Select the Right Plastic or Metal for Your 3D-Printed Part

Explore material properties available for plastic and metal 3D printing processes

Read Guide

Large Scale 3D Printers Big Enough to Print Furniture

Home / 3D Printers / Large Scale 3D Printers Big Enough to Print Furniture

Use Cases

Just like all types of 3D printing, XL 3D printing has its own strengths and tradeoffs. Users are constantly finding more applications for these gigantic machines so the XL 3D printing space is getting bigger and bigger. Let’s have a closer look.

Quick jump to:

- Request XL 3D printer quote

When To Consider Large Scale 3D Printing

It takes a large scale 3D printer to print furniture, vehicle parts and architectural components. Obviously, size is the driving factor in choosing to use large-format printing but there’s more to it than that. Here’s a breakdown of some of the less-obvious considerations:

Obviously, size is the driving factor in choosing to use large-format printing but there’s more to it than that. Here’s a breakdown of some of the less-obvious considerations:

- Unibody Parts – Often, producers are already able to fabricate their large objects through traditional methods of assembly but those objects would perform better if they were produced as one solid piece, something only a large 3D printer can do efficiently.

- Weight Reduction – Large objects are usually made of wood, metal, or injection molded plastics. Printing the same objects in plastic will make them much lighter, especially when factoring that users can easily adjust the density infill of 3D printed objects. Consolidating large assemblies into single components also reduces weight by eliminating the need for fasteners like nuts and bolts.

- Faster Development – The larger an object, the longer it takes to create and setup the tooling to fabricate it through traditional means.

With 3D printing, there are essentially no setup steps so large prototypes are significantly faster to print than to make them any other way. A large object may take a while to print, but by cutting out the time-consuming tooling step, it may also be faster to do production runs of large objects, depending upon the specifics.

With 3D printing, there are essentially no setup steps so large prototypes are significantly faster to print than to make them any other way. A large object may take a while to print, but by cutting out the time-consuming tooling step, it may also be faster to do production runs of large objects, depending upon the specifics. - Reduced Cost – 3D printed large parts can be cost competitive with conventionally-made parts almost entirely because of the tooling costs of the latter. Consolidated assemblies usually cost less as well because fewer materials have to be sourced from different places.

- Design Freedom – Using conventional manufacturing methods, many geometries are just not possible, such as internal channels and complex lattice structures. Many large objects, like furniture, benefit from such features and XL printers are the only way to realize those designs.

Large Scale 3D Printing Examples

- Restoration and replication – XL 3D printing has become rather popular among paleontologists as the technology allows them to both study and preserve the delicate fossils that they regularly handle.

- Furniture – Thanks to large-scale 3D printers it is now possible to create complex functional designs within a fully digitized process chain. From full-size prototyping to production of 3D printed furniture.

- Display advertising – XL 3D printers are perfect for making high-quality, modern signage and lettering for retail stores, businesses and exhibitions.

- Props – With the introduction of large scale 3D printers, designers can now produce enormous set pieces – overnight. 3D printing can help designers quickly manifest their wildest imaginations into the physical reality, and the Film & TV industry has taken notice.

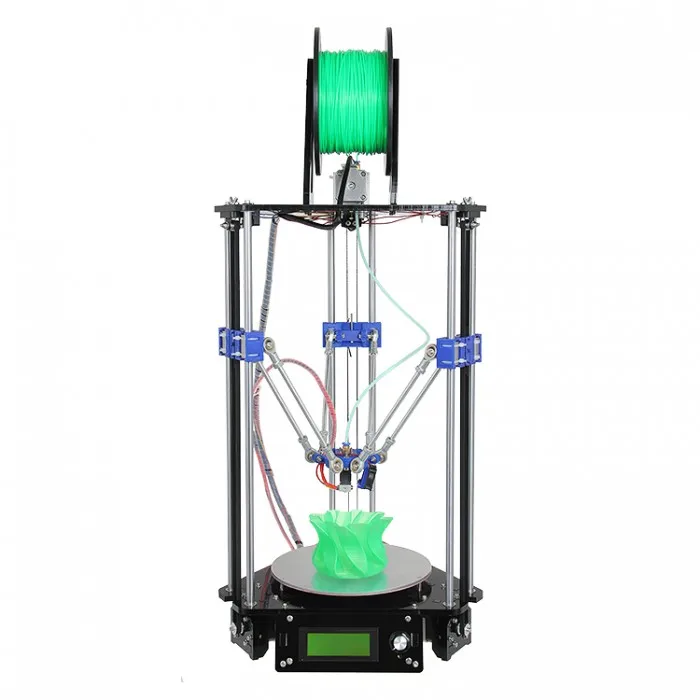

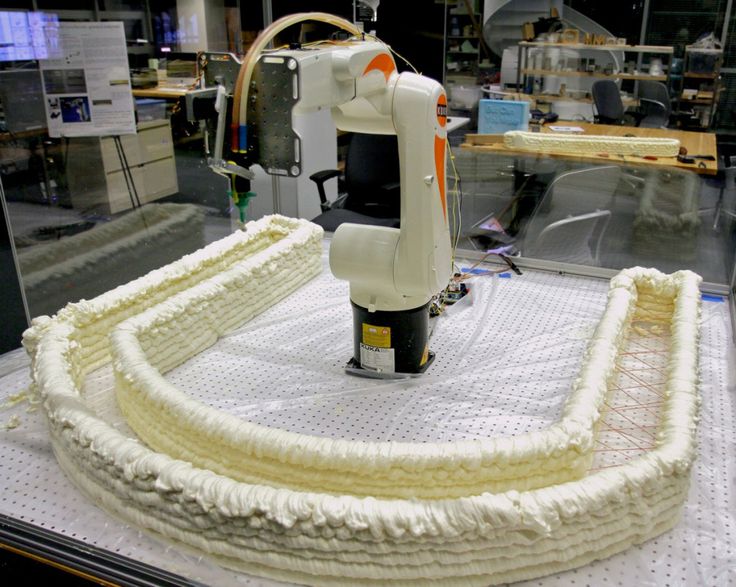

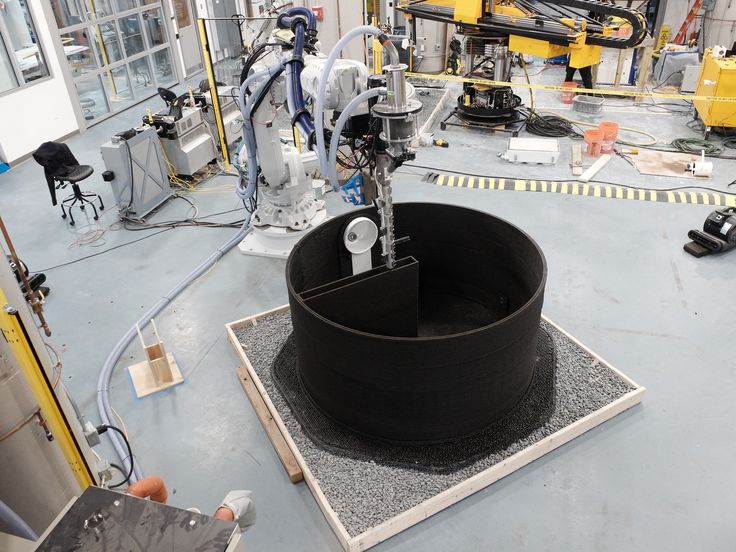

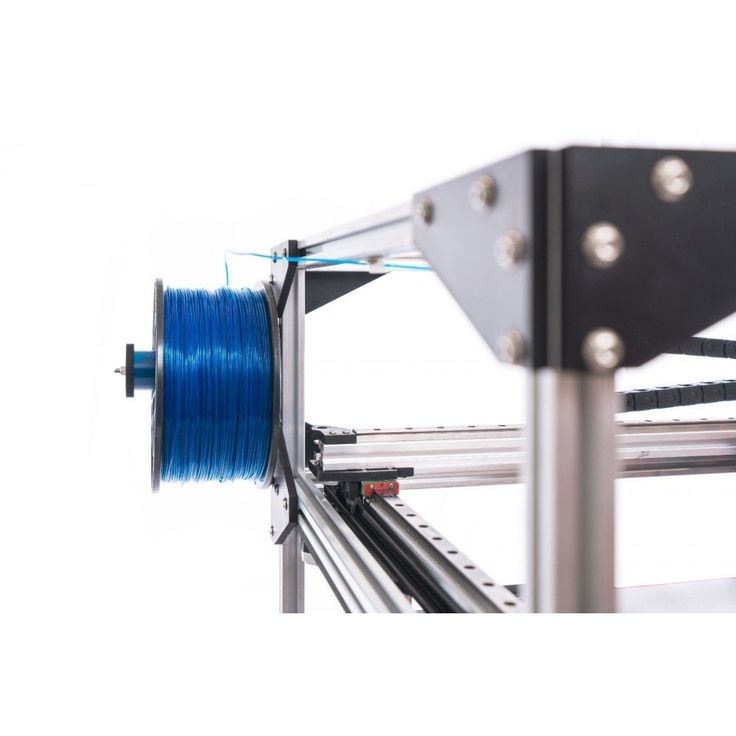

Pellet Extrusion

One of the differences between desktop-sized machines and XL printers is the possibility to utilize pellet extrusion systems on the large printers. Pellet extrusion doesn’t use spooled filament as feedstock but instead uses the same virgin plastic pellets that are used for injection molding, which are much cheaper than spooled filament. This makes it easy to mix different plastics to make custom polymer blends and colors. These systems can also take shredded plastics as feedstock, which enables users to directly recycle water bottles, milk jugs, and failed and unneeded prints into new objects. Such a degree of a circular ecosystem can not be achieved with any other form of manufacturing.

This makes it easy to mix different plastics to make custom polymer blends and colors. These systems can also take shredded plastics as feedstock, which enables users to directly recycle water bottles, milk jugs, and failed and unneeded prints into new objects. Such a degree of a circular ecosystem can not be achieved with any other form of manufacturing.

That’s all great but what compels most users to opt for pellet extrusion is its blazing speed as the technology enables output of several kilograms per hour. Printing times scale exponentially with part size so having a high extrusion rate is pretty important for large-format 3D printing. One drawback of pellet extrusion systems is that they struggle with retraction, a feature that filament extruders employ to improve surface finish by pulling back on the filament during non-extrusion travel moves; retraction reduces or eliminates blobs, dots, and stringing on prints. Some XL printers can operate with both filament and pellet extrusion systems, allowing users to choose the best toolhead for their specific application.

Get a Quote

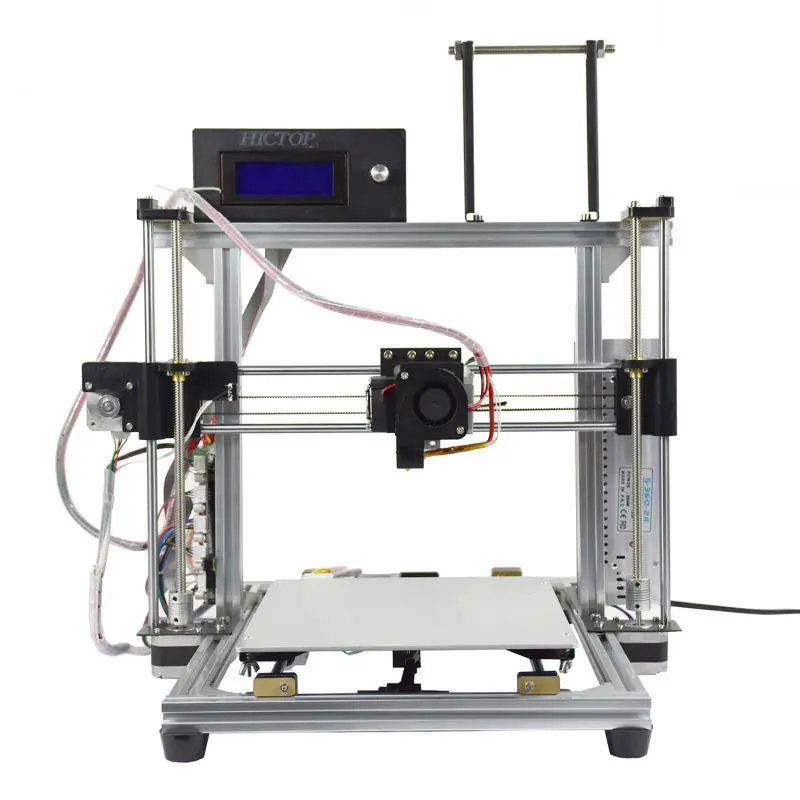

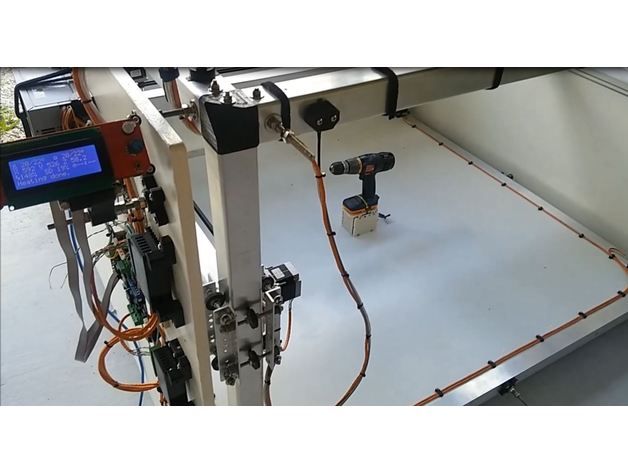

Large Scale 3D Printers

Looking to implement large scale 3D printers in your production process? Get a quote from Modix or Industry

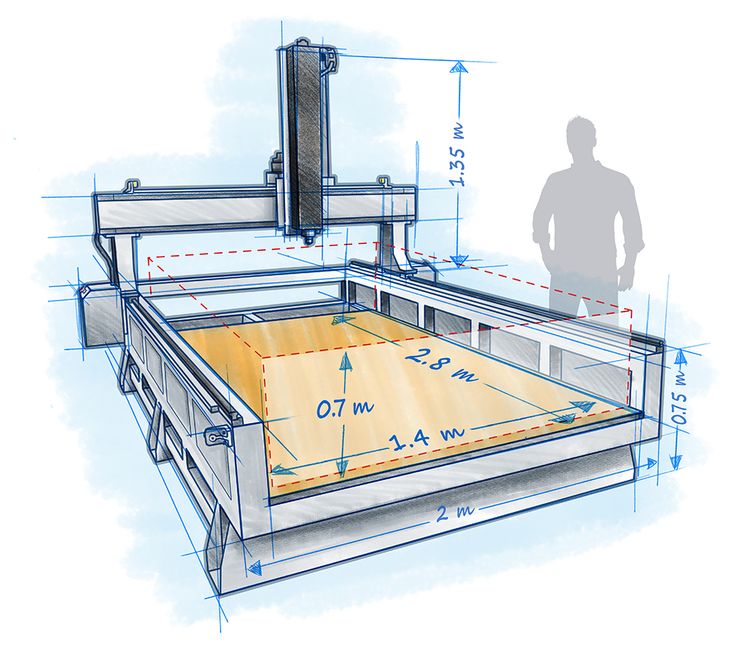

Modix BIG Meter

With the Modix BIG Meter, you are now able to manufacture objects as large as 1010 x 1010 x 1010 mm in one go!

$13,500Modix

Request a Quote

modix big meter

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1010 x 1010 x 1010 mm

- - Printer Dimensions: 1300 x 1470 x 1830 mm

- - Shipping Weight: 200kg

- - Included: Dual print head, E3D Aero & Volcano 1.75mm

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Automatic bed tilt calibration

- - Power Requirements: 32A, single phase, 208-240V

Mold Making, Prototyping, Research and Development, Restoration

Industry MAGNUM

Hailing from Sweden, Industry is a company that has made major waves in the world of 3D printing. The new MAGNUM large scale pellet 3D printer enables you to print parts measuring 1500 x 1200 x 1200 mm.

The new MAGNUM large scale pellet 3D printer enables you to print parts measuring 1500 x 1200 x 1200 mm.

A powerful E25 extruder manufactured to handle shredded material, granules or pellets. The MAGNUM handles nozzles between 2-8mm and has an average output between 1-8 kg / hour & a maximum output of 15 kg / hour.

MAGNUM offers powerful control features based on Bosch Rexroth MTX system control. It comes with a camera and mail/text module for external monitoring. A large touch screen display allows for easy setup and agile control.

€159,000Industry

Request a Quote

Industry MAGNUM

- Benefits

- Applications

- - Large scale pellet 3D printer

- - XL build size: 1500 x 1200 x 1200 mm

- - Granular extruder, which reduces material costs

- - Fast build rate: up to 15 kg per hour

- - Touch screen display

- - High quality linear motion modules from Bosch Rexroth MTX

Mold Making, Production, Prototyping, Research and Development, Restoration

Modix BIG-180X

The BIG-180X features a print volume of 1800 x 600 x 600 mm and comes at a competitive price of $12,000 USD. The unique extra width of the build chamber is designed per request of customers working in the automotive industry.

The unique extra width of the build chamber is designed per request of customers working in the automotive industry.

$15,500Modix

Request a Quote

modix 180

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1800 x 600 x 600 mm

- - Printer Dimensions: 2170 x 1060 x 1430 mm

- - Shipping Weight: ~240kg

- - Included: Dual print head, E3D Aero & E3D Volcano 1.75mm

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - 4 X Z axis motors are controlled individually providing automatic bed tilt calibration.

- - Minimal Electricity requirements: 32A, single phase, 208-240V

Prototyping, Research and Development, Restoration

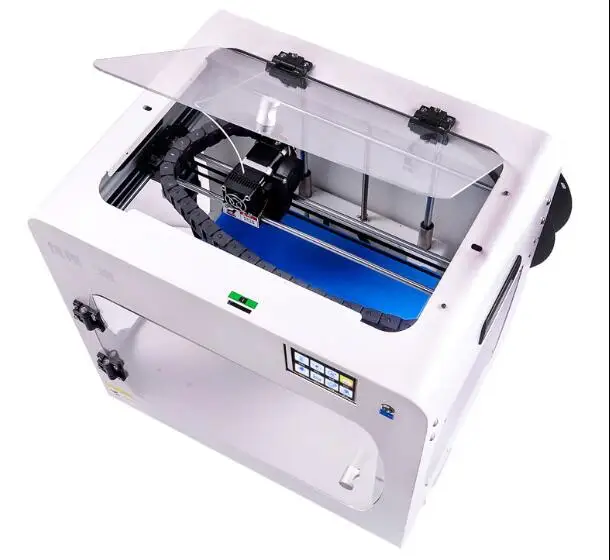

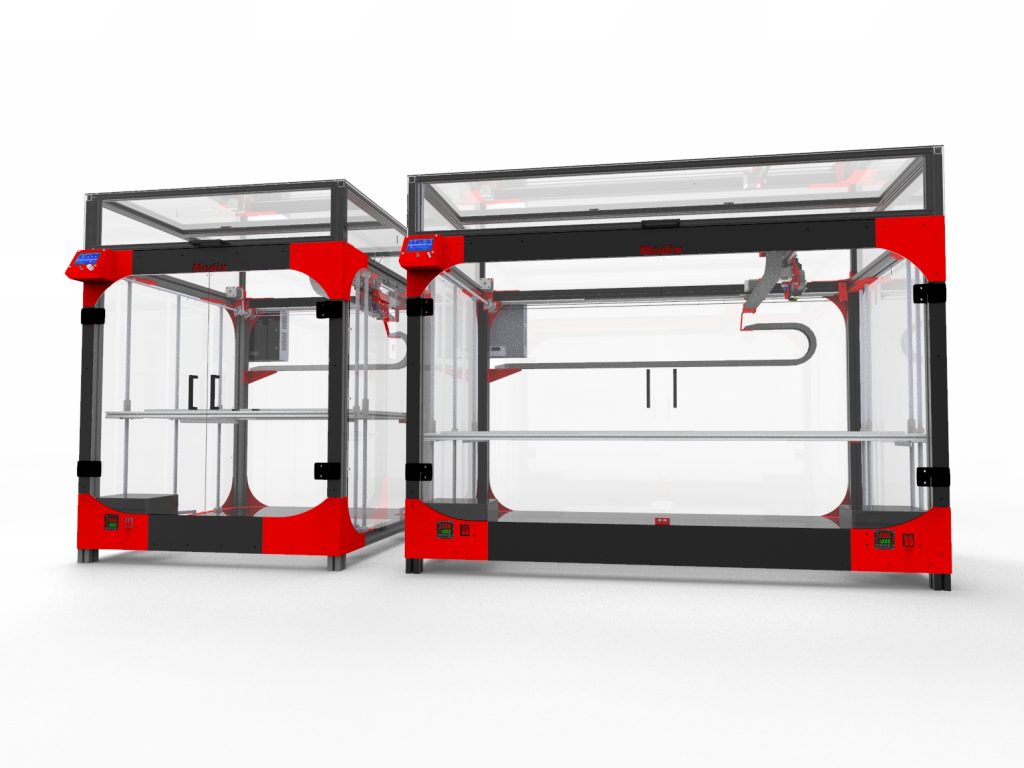

Modix BIG-120Z

The closed enclosure of the BIG-120Z is made of aluminum composite panels and polycarbonate doors. It incorporates a premium motion system including HIWIN motion rails, Gates timing belts and IGUS signal cables. This is a smart 3D printer providing several key reliability features including power-off resume, filament runout sensor, 120 probing points based automatic bed leveling, stall detection and more. The manufacturer offers an active air filter device as an add-on.

It incorporates a premium motion system including HIWIN motion rails, Gates timing belts and IGUS signal cables. This is a smart 3D printer providing several key reliability features including power-off resume, filament runout sensor, 120 probing points based automatic bed leveling, stall detection and more. The manufacturer offers an active air filter device as an add-on.

$7,500Modix

Request a Quote

BIG-120Z

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 600 x 600 x 1200 mm

- - Z axis guides, HIWIN MGW Linear Rails

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - Dual print head

- - E3D Titan Aero extruder with E3D Volcano hotend

Displays, Fashion, Mold Making, Prototyping

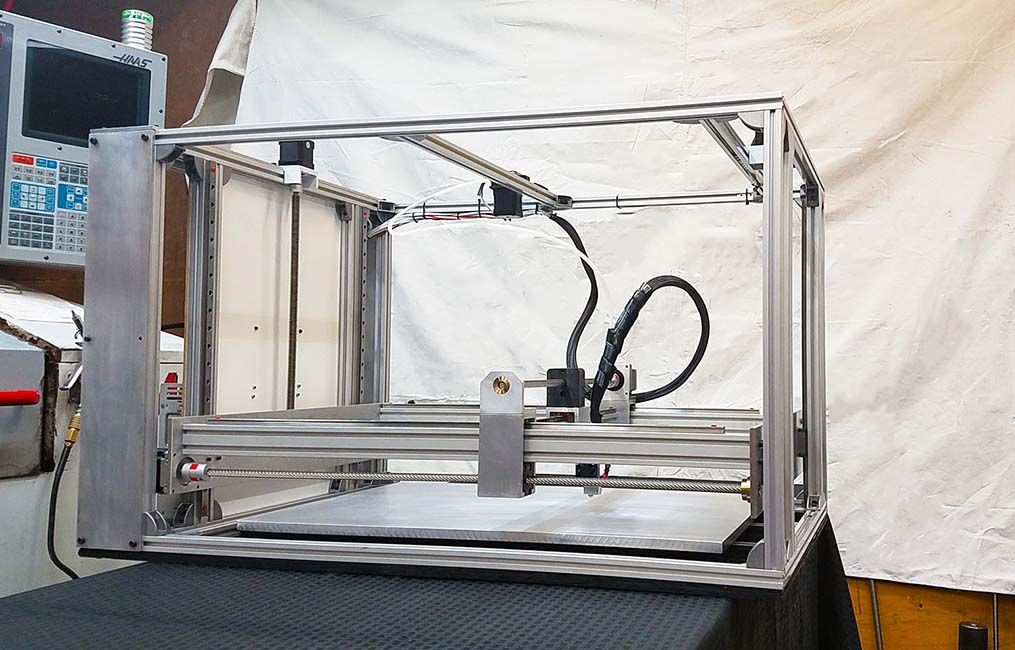

Modix BIG-120X

Modix BIG-120X Version 3 represents a major leap forward with regards to the printer reliability, print quality, ease of assembly and readiness to future advanced updates. Since Modix big60 and 120X share the same core design the new update is benefiting both models.

Since Modix big60 and 120X share the same core design the new update is benefiting both models.

$7,500Modix

Request a Quote

BIG-120X

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 1200 x 600 x 660 mm

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Closed loop motion system (optional)

Mold Making, Prototyping, Research and Development, Restoration

Large Scale 3D Printing: FUSE Pavilion / Sudo Null IT News

Different people understand the word “scale” differently. For designers and entrepreneurs, scale is the number of parts in production. For architects and designers, scale is the size of a design and how it relates to the people who inhabit or use it.

Selective laser sintering (SLS) opens up the possibilities of large-scale 3D printing in both senses. Designers can tightly pack parts to produce many things at once, and each of these parts can be unique and meet specific needs because CLM eliminates the need for machining.

To test the possibilities of the technology, we decided to print a large pavilion that will serve as a meeting place for the 2017 FUSE conference. We used the Fuse 1 printer to create over a hundred building blocks, which were then assembled over four days to build a structure covering an area of 14 square meters. m.

If you can create any shape, what will you do?

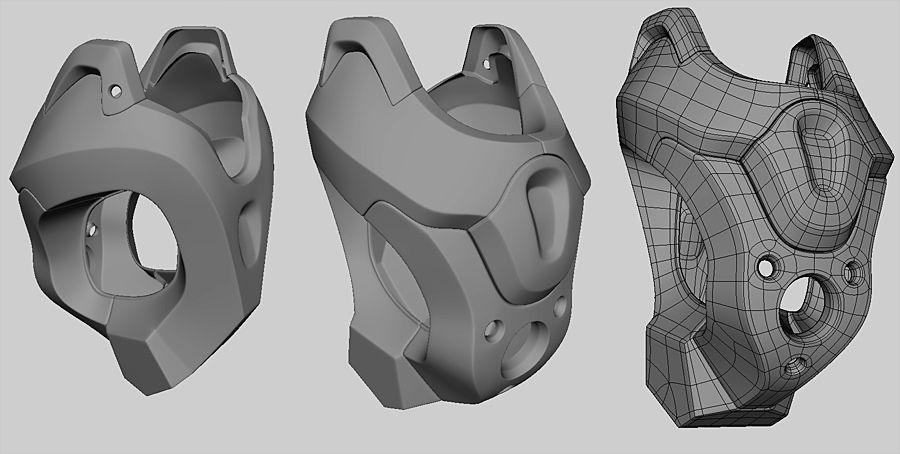

All three-dimensional shapes can be abstractly represented as points, edges, and faces - this is how a printed object is represented in an STL file. Usually, we design at a high enough resolution so that when we print out a part of the right size, the mesh disappears. But what if we use the cellular structure to our advantage by automatically translating the STL into a structured system?

Each face intersection becomes a junction, each face becomes a strut, and each face becomes a panel. This gives us the freedom to create almost any form on a scale greater than human.

This gives us the freedom to create almost any form on a scale greater than human.

Making big items is fun, and we started development by simply making popular objects bigger. We immediately thought of enlarging the Stanford bunny and the Formlabs logo. But then we settled on creating something more tailored to a specific purpose, so we started developing a pavilion for FUSE 2017.

Structural design of the pavilion

We settled on a design developed from the Möbius strip equation rotated to form a closed pavilion surrounded by three wide canvases. The canvases become rigid and provide structural support when a space frame is added at the back.

This pavilion is the largest structure known to us, created from parts of Formlabs - at 4.5 m wide and 2.5 m high, it easily accommodates three people inside.

Depending on the size you need, structural issues can be quite important. Some shapes are self-supporting, being made of a certain size and material, others require additional support inside or outside to ensure rigidity and stability.

We have chosen materials that will help us create the desired structure, which protrudes quite a lot in all directions, and does not require support by cables or columns. The connectors were printed on a Formlabs Fuse 1 printer using Nylon 12, a lightweight, tough, and extremely strong engineering thermoplastic.

For spacers we have chosen hollow fiberglass tubes. The heaviest part of the structure was made of dense polyethylene (HDPE) panels, they weighed almost 45 kg. Before the panels were added, the entire pavilion could easily be lifted by one person.

How to turn STL into a structure?

We used Rhino to turn the basic NURBS surface into a 3D wireframe, giving the surface rigidity and structure. To create the shape, we used parametric design, which allowed us to choose the "resolution" of the structure (the number of faces and edges approximating it) on the fly. This is important because the resolution is closely related to the cost and complexity of the assembly.

In Rhino, we used the Grasshopper scripting system to create models of connectors and edge lengths. The module generation system works with a 3D mesh that can be drawn in any CAD editor. The script takes into account corners with adjacent faces to prevent our round edges from intersecting. It also assigns a part number, which is then automatically applied to each connector.

Download the Grasshopper script for Rhino

We have optimized the shape of the connectors to reduce weight and print efficiency. A solid outer round connector would be very strong, but it would use the most material and take up the most space at the same time. The inner connector uses little material and is the fastest to print.

Three options for pavilion connectors: external, optimized external, internal

Achieving the desired shape from the panels was much easier - we used Rhino's Unroll function to get a two-dimensional diagram from the surface for laser cutting. Having filled the folder with connector models, a list of edge lengths and panel drawings, you can start creating the structure.

Having filled the folder with connector models, a list of edge lengths and panel drawings, you can start creating the structure.

How to create hundreds of unique parts?

All 144 Nylon 12 connectors up to 8 cm were printed in one run that lasted 36 hours. SLM technology does not require support for models, so the entire print volume can be used to print hundreds of unique parts at a time. We hope that our pavilion's connectors symbolize the future possibilities of custom-made mass production, in which each part can meet unique requirements.

Packing of three-dimensional parts

To accommodate 144 dissimilar parts in the print area, a technology is needed that is more complex than simply arranging them in stacks. Fortunately, using 3D packing algorithms, we can calculate an optimized layout of parts where they are all close together. This strategy has long been used to get the most out of SLP printers.

We have tried several ready-made solutions, with varying success. Netfabb uses Monte Carlo search for packaging, and has produced the best results of any commercial solution. We were able to fit about 50 nodes in Fuse 1. However, Netfabb had difficulty working with the non-convex geometry of our nodes, and the simulation took most of the day.

Ideally the connectors should be packed very close together so as to fill each other's concavities. To do this, we built a physical simulation on the Blender engine that packed the connectors into a virtual volume for printing. Nodes move and turn when they meet, and settle down when they don't overlap.

Parts tremble chaotically until none of them overlap each other. The entire simulation takes about a minute.

We greatly accelerated the simulation by using simplified intermediate models for collision calculation rather than the final high resolution models. This method does not guarantee a mathematically optimal solution, but it works well. More importantly, we were able to fit nearly three times as many nodes into the same working volume.

More importantly, we were able to fit nearly three times as many nodes into the same working volume.

Already at the production stage, we used the virtues of parametric design to match the resolution of the parts to suit our time constraints and the overall project. The ideal resolution gives a good reproduction of the initial curved shape, allows you to fit all the details in the print volume, and makes it possible to complete the project in a week. By speeding up the packing of parts and increasing efficiency, we have improved flexibility in shaping the final structure.

Left – naive packing of convex parts, right – dense packing of non-convex parts.

After the conference, Michael Fogleman, now at Formlabs, released an open source solution for 3D part packaging. We will include automatic packaging in PreForm for Fuse 1.

High-volume printing in SLA

To fix the panels, we could use ready-made fasteners, but we were pressed for time by the schedule and geometric features of the design. We decided to make fasteners using laser stereolithography (SLA) from Durable Resin.

We decided to make fasteners using laser stereolithography (SLA) from Durable Resin.

Over 500 fasteners printed in five passes on the Form 2

We used the Form 2 to quickly create 505 brackets in a few days. We designed the parts in CAD to stack, and left the task of generating the supports to PreForm, which allowed us to print 98 brackets in one pass. Tearing off the props was as easy as tearing perforated paper.

How to assemble a large set of parts?

The hardest part of creating a large modular structure is assembly.

Three people assembled the pavilion, working four hours a day. To facilitate the work, we sorted all the details in advance by projecting a three-dimensional diagram of the structure onto the wall. And still, the assembly was a test of spatial thinking and patience. Simply finding the part and finding its correct orientation took quite a bit of time.

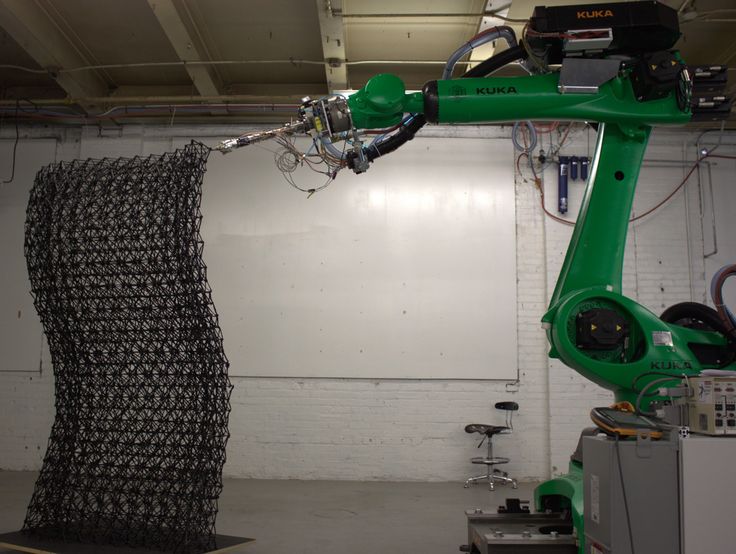

Working with a small budget and a fairly modest structure, we decided to assemble the structure by hand. But what if someone wants to build a larger structure, or increase its resolution? Robots can help – machines are far better than humans at moving parts into precise positions, and architects are already starting to create structures suitable for robotic assembly.

But what if someone wants to build a larger structure, or increase its resolution? Robots can help – machines are far better than humans at moving parts into precise positions, and architects are already starting to create structures suitable for robotic assembly.

The future of digital manufacturing and architecture

As designers, we envision a future where turning a digital spatial concept into a real structure is as easy and automatic as 3D printing. The system used to build the pavilion for FUSE can be applied to room design, furniture, sculpting, and more. Combining advanced design techniques with digital manufacturing devices like the Fuse 1, architects will have no barriers to realizing any form they can imagine.

Wax and plastic 3D printing in 1-2 days. Volume discount

Affordable 3D printing products

Wax

- Price

- from 700 ₽ for 1 cm³

- Timing

- 8 hours

- Precision

- 16 micron

- Print file format

- .

STL

STL

Photopolymer

- Price

- 85 ₽ for 1 cm³

- Timing

- 8 hours

- Precision

- 100 micron

- Print file format

- .STL

Important information

- What if I need to print not just one product, but a whole series?

- For small-scale production, we recommend using photopolymer resin printing.

Ready to discuss all your questions!

Fill out the form or call +7 (495) 223 01 21

Request a call

Additional services

3D-scan

leave a request more

Examples of our work

The most interesting orders of our clients in various industries

see all works

Motorcycle frame 3D scan

- #3D scan

more

Obtaining a 3D support bearing model

- #3D-scan

more details

Mercedes car scan for video tour

- #3D scan

more details

Creation of NURBS model of rubber car mats

- #3D modeling

more details

3D-modeling and control of deviations of the mechanism body part

- #3D-modeling

more details

3D simulation of lifting unit

- #3D simulation

more details

3D jewelry stencils

- #3D print

more details

3D print car headlight

- #3D print

more details

3D printing of a combine part from casting wax

- #3D printing

more

BIM model for restoration of a cultural heritage site

- #BIM modeling

more

BIM model for church restoration

- #BIM modeling

more details

Construction control of a building in Khimki

- #BIM-modeling

more details

Fork production

- #Plastic molding

more details

Measurements of the facade of the fashion house Dior

- #Measurements

more

Scanning the interior of the apartment

- #Measuring work

more details

Scanning a church in the Tver region to obtain data for restoration

- #Measuring work

more

Our clients

Aluminum and alumina production

Russian state company. Operator of the Russian railway network

Operator of the Russian railway network

Manufacture of military and civil aircraft. Flight personnel training

Russian airline. Domestic and international passenger air transportation

R&D in the field of nanotechnology, robotics, space activities, ammunition

Design and manufacture of equipment for thermal, nuclear and hydroelectric power plants

Defense enterprise. Military-technical cooperation of the Russian Federation with foreign partners

Russia's leading underwater shipbuilding design bureau

Design, production and after-sales service of aircraft

Development and production of complexes, systems and communications equipment for the RF Armed Forces

Leading university of the Upper Volga region

002 Engineering University. One of the nine backbone universities in Russia

Leading enterprise in Russia for the production of metal spans of bridges

Russian instrument-making concern. Manufacture of electronic equipment for the Russian Navy

Creation of equipment for control systems of aviation and rocket technology, as well as for gas and oil pipelines

The largest research institute in the country, solving problems of defense, scientific and national economic importance

Development, manufacture and maintenance of engines for the aerospace industry

Development, production, testing, operation support, maintenance of aircraft equipment

Creation and maintenance of the aerospace defense system in the interests of the security of the Russian Federation and civil aviation

Manufacture of equipment for post-harvest processing, drying and storage of grain

3D printing services by category

3D printing of small objects from 2 mm to large models up to 3 m

Printing models by size is conditionally divided into two types: 3D printing of small objects is printing from 3 mm and 3D printing of large objects , the size of which exceeds 300 mm. This separation in 3D printing on a printer is due to the size of the 3D printing chambers. The 3D printer has a print chamber no larger than 3 meters in one of the dimensions. Therefore, printing a large model will be done in parts.

This separation in 3D printing on a printer is due to the size of the 3D printing chambers. The 3D printer has a print chamber no larger than 3 meters in one of the dimensions. Therefore, printing a large model will be done in parts.

3D model prototyping

3D model prototyping is performed by printing on a 3d printer. In this case, the real physical object is realized in a digital model in programs for processing 3D data, and then transferred to 3D printing software. Read more >>

Master model making

You can order a 3D printing service if you want to make a master model. Master model is a primary, trial model, which is used as a model for the production of copies of castings. Making master models using 3D printing is the fastest and most resource-saving option for producing master models.

3D casting models

Order 3D printing of casting models if your production requires complex parts with a high level of accuracy. 3D printed models will have a level of detail that is impossible to replicate when creating a model for casting with standard methods. Learn more >>

Learn more >>

Product Assembly Check (SLA)

A complex model with a large number of parts undergoes a thorough assembly test. To test a part created in 3D space, you can print its body on a 3D printer and check its parts for assembly in reality. Read more >>

Creation of exclusive souvenir products

A unique souvenir made on a 3D printer — everyone will like such a gift. On our website, you can order 3D printing of souvenirs in Moscow, St. Petersburg, other cities of Russia and the CIS. Read more >>

Printed art coloring

Parts can also be painted after 3D printing. The model is carefully inspected, supports are removed, the surface is sanded or primed and covered with spray paint. It is also possible to varnish the model with special compositions. Order service

Spare parts and replacement of broken parts

3D printing of spare parts is a popular 3D printing service. Twize accepts orders for printing spare parts for small mechanisms, household items (printing battery covers, lambrequins for curtains, etc. ) or for 3D printing parts for restoration work. Read more >>

) or for 3D printing parts for restoration work. Read more >>

3D printing of the case

3D printing is ideal for the production of plastic or closed cases. The advantages of printing a case on a 3D printer: design flexibility and almost unlimited freedom of action, speeding up the workflow (3D printing of cases is the fastest prototyping method that allows you to make copies just in time). When printing a copy of a part on a 3d printer (cases, 3d copies of people, spare parts, etc.), the price does not depend on the number of products, but on the amount of material used (wax, photopolymer). To order printing a part on a 3D printer, write to us at [email protected].

Technologies and materials for printing on a 3D printer

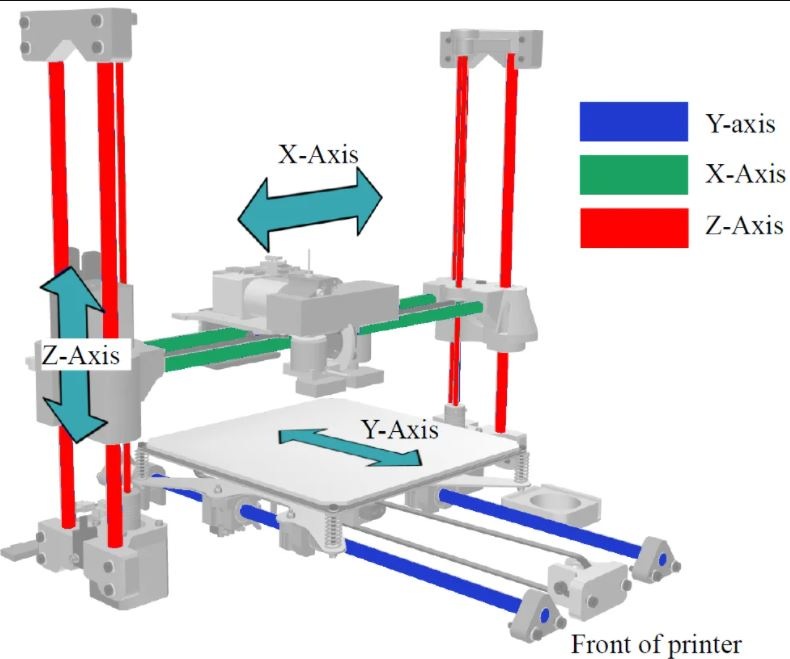

The concept of "3D printing" includes several types of three-dimensional printing:

- FDM printing - printing using a layer-by-layer application of a hot thread of wax, plastic or metal

- SLS-printing is a selective laser sintering technology in which a powder material is melted using a laser along a precisely defined trajectory

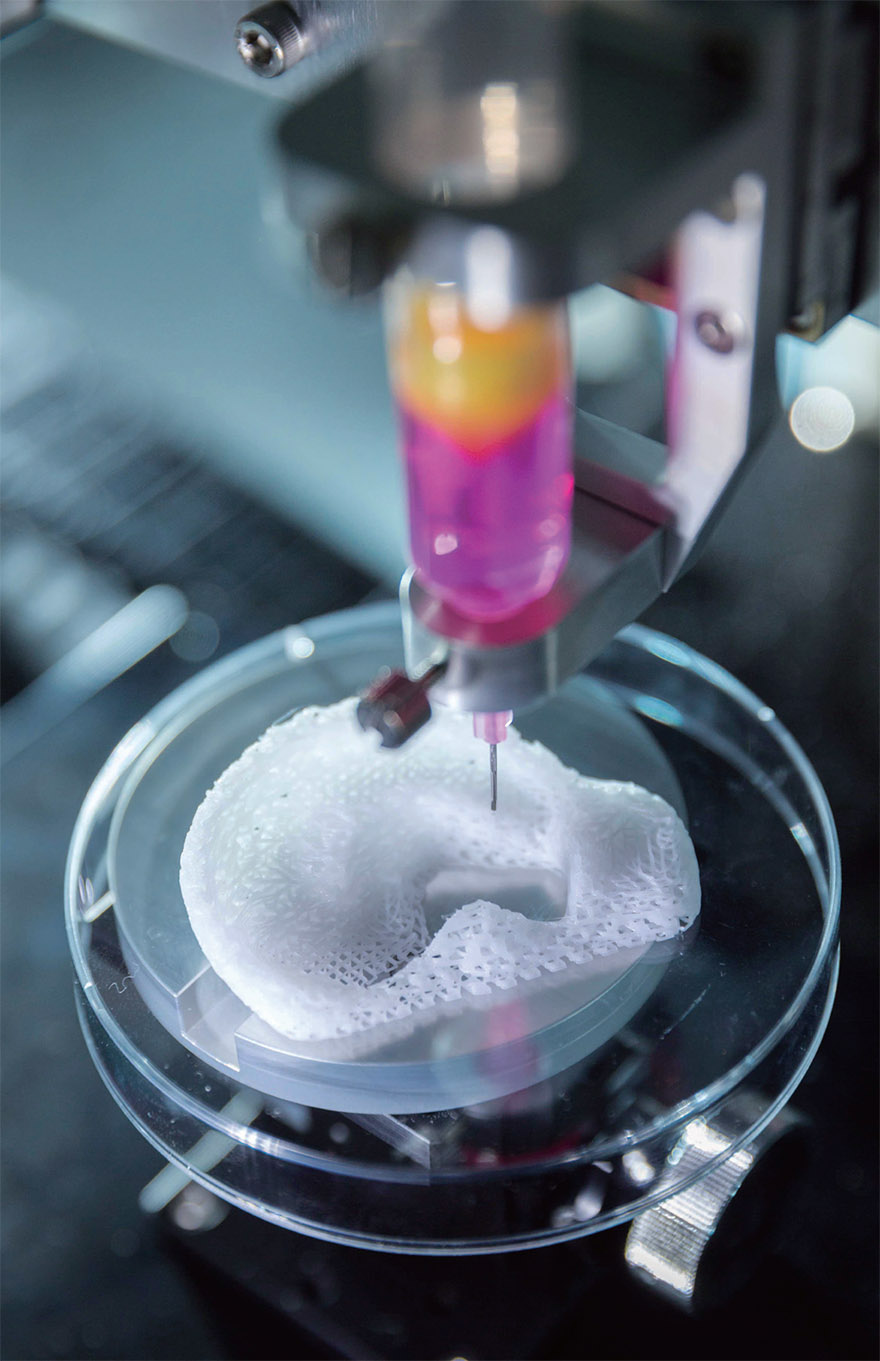

- Laser Stereolithography (SLA Printing) - Create 3D Models with a Special Liquid Resin Cured by Mercury Radiation

- Multi-Jet Modeling (MJM for short) is the most popular 3D printing method, in which the product is recreated layer by layer using liquid polymer

You can order MJM or SLA printing from Twize.

Popular printers use various resins, composite powder, wax, metal alloy powders, and foundry sand as 3D printing material.

For 3d printing, Twize uses the following materials:

- Wax - for making highly detailed investment casting master patterns. It is characterized by excellent meltability and accuracy, allows you to create products with perfect surface quality.

- Photopolymer - has increased heat resistance, strength, finished products have a smooth surface. Suitable for rapid prototyping, creating burn-out master models, molds, samples for assembly testing.

3D printer applications

3D printing has found application in architecture, agriculture, engineering, education, medicine, heavy, general, medium and light engineering, culture, art, robotics, energy, aviation and space construction. Printing samples and prototypes, making missing parts, reverse engineering, and making merchandise are all 3D printing tasks.

3D printing on order

3D printing in Moscow on 3D printers can significantly save not only time, but also labor resources. To replace worn parts, just contact our specialists and place an order, and we will quickly perform 3d printing from the required material. We will help you determine the dimensions of the product and select the best option. Spare parts or parts - we print 3D quickly, from the right material. We will select the best parameters and help you find the best solution.

To replace worn parts, just contact our specialists and place an order, and we will quickly perform 3d printing from the required material. We will help you determine the dimensions of the product and select the best option. Spare parts or parts - we print 3D quickly, from the right material. We will select the best parameters and help you find the best solution.

Reverse engineering or creating a copy of the product is also available in the Twize service catalog.

If you want to receive a copy of your product, you can write to us at [email protected], call:

+7(495)223-01-21 or leave an online application.

3D printing price

The price of 3D printing depends on the complexity of the product, the amount of printed material and other factors. Send a request to [email protected], or through the "Leave a request" form, or by phone:

+7(495)223-01-21 - we will calculate the price specifically for your request.

Attention! We only accept 3D models in STL format. Please check and archive your files before sending them.

Please check and archive your files before sending them.

Quality STL file checklist:

- without geometry errors

- without "holes" in the mesh

- adequate scale

- adequate shrink factor

- all STL files in one archive

We will consider any ideas and help you turn them into reality!

Why is it profitable to order 3D printing from us

3D printing in Moscow from Twize is:

- Fast - 3D printing from 1 day

- Affordable - Our 3D printers are cheaper than the competition

- Comprehensive - we do not just print, we provide a full cycle of 3D services from reverse engineering to 3D printing

We also provide 3D printing services throughout Russia and the CIS countries.

Payment and delivery

We deliver finished products to all cities of the Russian Federation and CIS countries. Our office is located at: Moscow, metro station Kuntsevskaya, st. Ryabinovaya, 14a. From 10:00 to 18:00.

Ryabinovaya, 14a. From 10:00 to 18:00.

You can also pick up the finished product from self-delivery points located in the capital:

- m. Minsk, st. Minsk, 2Zh. From 10:00 to 18:00 (pickup point)

- m. Begovaya, st. Rozanova, 10, building 1. From 10:00 to 20:00 (pickup point)

- m. Kuntsevskaya, st. Ryabinovaya, 14a. From 10:00 to 20:00 (office)

Lead times

The manufacturing time is determined both by the technological cycles of manufacturing and post-processing, which can take from several hours to two days, and by the loading of specific equipment. You can check the exact terms of work with our manager.

If you need 3d printing to order, please contact us to get the right amount of parts right on time, in full compliance with all stated requirements.

3D Printing Resources

Want to order 3D printing but don't know where to start? We have collected answers to the most popular questions about custom 3D printing for you.