Best 3d printer for jewelry casting

7 Best 3D Printers for Jewelry (Casting), Rings & Glasses – 3D Printerly

3D printing is implemented in a wide variety of fields all across the world. From the automotive industry to making miniatures and figurines, the possibilities are seemingly endless with this groundbreaking phenomenon.

One of its applications includes making jewelry pieces. The whole process, however, is long since you then have to create a mold and then pour molten metal into the mold to create the actual jewelry, but it is well worth the time and effort.

Jewelry-making with 3D printing is much more favorable with a resin 3D printer that uses the technology of Stereolithography Apparatus (SLA) or Digital Light Processing (DLP), which is basically an advanced version of the latter.

However, there are many resin 3D printers out there that do not perform well and can cause several issues when you’re printing.

This is why I decided to gather 7 of the best 3D printers out there that you can comfortably use for printing jewelry, rings, and glasses in high quality.

I will enlist the features, specifications, major pros and cons, and customer reviews of these resin 3D printers so you can decide which one sounds the best for you. Let’s begin.

Anycubic is one of the most popular 3D printing manufacturers known for making highly capable resin 3D printers. What’s even more well-known is the company’s Photon printer line-up that has always delivered ahead of expectations.

The Photon Mono X (Amazon) is a sturdy and well-built MSLA 3D printer that’s particularly liked for its performance when printing jewelry. Some people have gone as far as to call it the best resin 3D printer for casting jewelry.

The Mono X is one premium piece of technology. It costs somewhere around $800 (Amazon) but given the number of features it has, it surely comes off as competitively priced.

The build quality is solid and the MSLA 3D printer is made out of anodized aluminum. The build plate and the resin vat are both compact and rigid to ensure smooth and stable printing.

In terms of value for money, there’s no beating the Photon Mono X. This is a comparatively low-cost entry into the field of resin 3D printing and is highly recommended for printing jewelry, rings, and glasses.

Let’s move forward with the features and specifications.

Features of the Anycubic Photon Mono X

- 8.9″ 4K Monochrome LCD

- New Upgraded LED Array

- UV Cooling System

- Dual Linear Z-Axis

- Wi-Fi Functionality – App Remote Control

- Large Build Size

- High-Quality Power Supply

- Sanded Aluminum Build Plate

- Fast Printing Speed

- 8x Anti-Aliasing

- 3.5″ HD Full-Color Touch Screen

- Sturdy Resin Vat

Specifications of the Anycubic Photon Mono X

- Build Volume: 192 x 120 x 245mm

- Layer Resolution: 0.01-0.15mm

- Operation: 3.5″ Touch Screen

- Software: Anycubic Photon Workshop

- Connectivity: USB, Wi-Fi

- Technology: LCD-Based SLA

- Light Source: 405nm Wavelength

- XY Resolution: 0.

05mm, 3840 x 2400 (4K)

05mm, 3840 x 2400 (4K) - Z-Axis Resolution: 0.01mm

- Maximum Printing Speed: 60mm/h

- Rated Power: 120W

- Printer Size: 270 x 290 x 475mm

- Net Weight: 10.75kg

The Anycubic Photon Mono X is loaded with convenient features. There is a built-in cooling system that not only provides a stable printing performance but also increases the durability of the important components of the resin 3D printer.

Another thing to brag about is the Wi-Fi function that you can use with the Anycubic 3D phone application. This can allow you to remotely control the Mono X, change important settings, and review past prints.

One of the best features of this resin 3D printer that makes it so good for printing jewelry is its 8.9-inch 4K monochrome LCD. It has a super high resolution of 3840 x 2400 pixels that make for stunning print detail.

For making rings and jewelry where depth and detail matter a lot, this feature of the Mono X simply shows how worthy of an MSLA 3D printer it actually is.

The build volume is also large, measuring up to 192 x 120 x 245mm to offer you unmatched flexibility when making large prints. Since you will be buying this for making small-scale jewelry, a little extra room never hurts.

User Experience of the Anycubic Photon Mono X

The Anycubic Photon Mono X is a top-notch Amazon product with a solid overall rating. A majority of the people who bought it have left a very positive review for this MSLA 3D printer.

Customers can confirm that the Mono X is what they use consistently for jewelry making. May it be a ring, glasses, or gold jewelry, the prints that it is capable of producing makes it a perfect fit for this category.

In addition, the Mono X is highly suitable for lost wax casting. A customer writes that this is a must-have machine for jeweler designing with CAD.

The quality of prints that this printer produces is on par with much more expensive machines, according to customers who have multiple resin 3D printers.

Its capacity to print at an exceedingly high resolution makes it optimum for jewelry businesses and everything of the like.

Pros of the Anycubic Photon Mono X

- You can get printing really quickly, all within 5 minutes since it’s mostly pre-assembled

- It’s really easy to operate, with simple touchscreen settings to get through

- The Wi-Fi monitoring app is great for checking on the progress and even changing settings if desired

- Has a very large build volume for a resin 3D printer

- Cures full layers at once, resulting in quicker printing

- Professional looking and has a sleek design

- Simple leveling system which stays sturdy

- Amazing stability and precise movements that lead to almost invisible layer lines in 3D prints

- Ergonomic vat design has a dented edge for easier pouring

- Build plate adhesion works well

- Produces amazing resin 3D prints consistently

- Growing Facebook Community with plenty of helpful tips, advice, and troubleshooting

Cons of the Anycubic Photon Mono X

- Only recognizes .

pwmx files so you may be limited in your choice of slicer software

pwmx files so you may be limited in your choice of slicer software - The acrylic cover doesn’t sit in place too well and can move easily

- The touchscreen is a little flimsy

- Fairly pricey compared to other resin 3D printers

- Anycubic doesn’t have the best customer service track record

Final Thoughts

The Anycubic Photon Mono X is the printer of choice for thousands around the globe simply due to its feature-rich build, amazing print quality, and great price. I highly recommend it for jewelry making and printing rings.

Buy the Anycubic Photon Mono X directly from Amazon today.

The Formlabs Form 3 comes from a top-tier manufacturer and uses the technology of Low-Force Stereolithography (LFS). This relatively new 3D printing technique makes prints with stunning features down to the smallest detail.

The Form 3 is by no means, a pocket-friendly 3D printer. It costs somewhere around $3500 and is a high-end machine that’s born to impress.

This LFS 3D printer is a big upgrade over its predecessor, the Form 2 which came out in 2015.

The fancy reiteration has brought a new technology to implement, a host of new features, but the same ease of use and simplicity that comprises the winning formula of the Massachusetts-based Formlabs.

The Form 3 pays unflinching attention to precision and detail. This is one of the main reasons why it is a perfect fit for printing jewelry and rings, among other applications.

Let’s see how the features and specifications look like on this bad boy.

Features of the Formlabs Form 3

- Low-Force Stereolithography (LFS) Print Technology

- Pinpoint Precision Printing

- Improved Model Clarity

- Hassle-Free Cartridge System

- Sensor-Powered Interface

- Automatic Temperature Adjustment

- Plug and Play Out of the Box

- Fast Printing

- Sturdy Build Quality

- Wi-Fi Connectivity

- PreForm Slicer Software

- Automatic Bed Leveling

Specifications of the Formlabs Form 3

- Printing Technology: Low-Force Stereolithography (LFS)

- Laser: Light Processing Unit (LPU), 250m W405nm

- Build Volume: 145 x 145 x 185 mm

- Z-Layer Resolution: 0.

025 – 0.3mm

025 – 0.3mm - XY Resolution: 0.025mm

- User Interface: 5.5-inch Touchscreen

- Connectivity: WiFi, Ethernet, USB

- Bed Leveling: Automatic

- Materials: Formlabs Resin Cartridges

- Software Bundle: PreForm, Dashboard Printer Management

- File Types: STL, OBJ

- Weight: 17.5 kg

- Dimensions: 405 x 375 x 530mm

The Formlabs Form 3 is jam-packed with features. It has automatic bed leveling, Wi-Fi connectivity, and a PreForm slicer software that takes away all hassles and is a breeze to deal with.

Instead of a laser beam that stays constant throughout the print process, the Form 3’s Low-Force Stereolithography (LFS) technology prints the resin edge-to-edge so every corner is precisely detailed.

That is what makes the Form 3 keenly appropriate for printing jewelry accessories, rings, and similar items. In this application, details matter significantly, and luckily for us, that’s what the Form 3 is all about.

The printing starts the moment this machine is delivered to you. With minimal assembly, you don’t have to worry about the setup of this printer at all.

With minimal assembly, you don’t have to worry about the setup of this printer at all.

The design is also one of the most impressive traits of this LFS 3D printer. It’s compact, well-built, and highly sturdy. In addition, there’s a 5.5-inch touchscreen to make navigation effortless for you.

Customer Reviews of the Formlabs Form 3

The Formlabs Form 3 is well-respected for its capabilities all across the globe. People who have bought this high-end printer truly love what it can do for them.

It prints consistently without breaking a sweat and is exceptionally reliable. For those looking to print rings and gold jewelry where accuracy and quality cannot be compromised, the Form 3 is your best bet.

Sure, there are cheaper 3D printers out there that can also offer great quality prints, but by spending extra and getting yourself the Form 3, you’re getting a machine that can provide you with professional quality.

Users of the Form 3 are extremely satisfied with its print speed. It may not best the speed of some top-level 3D printers, but it still gets the job done in due time.

It may not best the speed of some top-level 3D printers, but it still gets the job done in due time.

There is also a wax-castable SLA resin made by Formlabs that jewelry makers can use to make castable jewelry items. Combine that with the power of the Form 3, and you have at your disposal stunning end-products.

Pros of the Formlabs Form 3

- Easy operation and simple set up

- Prints are of stunning detail and quality

- Comes with a one-year manufacturer’s warranty

- Sensors all over the printer make the experience much more convenient

- The printer is consistent and reliable

- Ships with a toolbox called Finish Kit that helps with post-processing

- The build quality is excellent

- Automatic bed leveling makes the printer beginner-friendly

- The 5.5-inch touchscreen makes navigation very easy

Cons of the Formlabs Form 3

- Dust can easily accumulate on the Light Processing Unit (LPU) of the printer

- Limited lifespan of the resin vat

- Firmware updates require a USB connection despite Wi-Fi being available

Final Thoughts

For what it costs, the Form 3 with its heavily loaded specs-sheet and rigid build quality, is the printer to go for if quality and precision are what you’re looking for. For printing pieces of jewelry, it is a must-have.

For printing pieces of jewelry, it is a must-have.

Buy the Formlabs Form 3 directly from their official website today.

Elegoo is another highly reputable name in the 3D printing industry. Just like Anycubic, they have gained widespread popularity over the years with their range of top-class and affordable resin 3D printers.

The Elegoo Saturn continues the winning formula of its predecessor—the Elegoo Mars—and furthers the brilliant MSLA 3D printing experience.

The way this 3D printer is built just shows how much care and attention was put into making the Elegoo Saturn (Amazon) an efficient machine for printing jewelry items like rings, glasses, and even gold.

A large build volume, high resolution, precise print quality, and fast printing are some of the many features that this remarkable printer packs.

Elegoo also boasts excellent customer service that’s always there should anyone run into any issues with their resin 3D printers. The same cannot be said about Anycubic, however.

Let’s explore more about the Elegoo Saturn by diving into the features and specifications.

Features of the Elegoo Saturn

- 8.9″ 4K Monochrome LCD

- 54 UV LED Matrix Light Source

- HD Print Resolution

- Double Linear Z-Axis Rails

- Large Build Volume

- Color Touch Screen

- Ethernet Port File Transfer

- Long-Lasting Leveling

- Sanded Aluminum Build Plate

Specifications of the Elegoo Saturn

- Build Volume: 192 x 120 x 200mm

- Operation: 3.5 Inch Touch Screen

- 2Slicer Software: ChiTu DLP Slicer

- Connectivity: USB

- Technology: LCD UV Photo Curing

- Light source: UV Integrated LED Lights (Wavelength 405nm)

- XY Resolution: 0.05mm (3840 x 2400)

- Z-Axis Accuracy: 0.00125mm

- Layer Thickness: 0.01 – 0.15mm

- Printing Speed: 30-40mm/h

- Printer Dimensions: 280 x 240 x 446mm

- Power Requirements: 110-240V 50/60Hz 24V4A 96W

- Weight: 22 lbs (10 Kg)

Specs-wise, the Elegoo Saturn is heavily loaded. It comes with a 4K 8.9-inch monochrome LCD, the same as the Anycubic Mono X. The print quality is therefore simply amazing and can be used for making jewelry pieces comfortably.

It comes with a 4K 8.9-inch monochrome LCD, the same as the Anycubic Mono X. The print quality is therefore simply amazing and can be used for making jewelry pieces comfortably.

Since the monochrome LCD has an ultra-high resolution of 3840 x 2400 pixels, the main benefit here is reduced curing times of the resin.

The time taken to print each layer is decreased by almost 2 seconds, making the Elegoo Saturn 60% faster than the Elegoo Mars Pro, which is another affordable yet great MSLA 3D printer.

The Elegoo Saturn boasts a sanded aluminum build plate that’s much higher quality than ordinary print beds. It has been specially sanded to promote print adhesion and ensure a smooth printing process.

What’s more, is that the build volume is spacious to lend you more flexibility in printing, and there are two linear rails on its Z-Axis as well, so stability and precision never have to be sacrificed.

Customer Reviews of the Elegoo Saturn

The Elegoo Saturn has a tremendous rating on Amazon, making it a top-tier product with no exceptions. Tons of people who bought it have said several positive things about it.

Tons of people who bought it have said several positive things about it.

The initial impression of this MSLA 3D printer is nothing short of pure delight. Customers say that it is effortless to set up and get going with, and the print quality is the best they’ve ever seen.

Words like these reinforce the fact that the Elegoo Saturn is one of the best resin 3D printers out there for printing jewelry, rings, and glasses.

In addition, users say that this printer is a lot quieter than most other resin 3D printers. This is probably due to fewer fans in this machine.

Also, Elegoo’s customer support service is quick and agile to respond and deal with customers’ issues. This is essential when it comes to 3D printing since this field is highly complicated and you need all the help you can get.

Pros of the Elegoo Saturn

- Outstanding print quality

- Accelerated printing speed

- Large build volume and resin vat

- High accuracy and precision

- Rapid layer-curing time and faster overall printing times

- Ideal for large prints

- Overall metal build

- USB, Ethernet connectivity for remote printing

- User-friendly interface

- Fuss-free, seamless printing experience

Cons of the Elegoo Saturn

- Cooling fans can be slightly noisy

- No built-in carbon filter

- Possibility of layer shifts on prints

- Build plate adhesion can be a little difficult

- Been having stock issues, but hopefully, that gets resolved!

Final Thoughts

There’s no denying that the Elegoo Saturn is a phenomenal piece of tech. It’s well-built, makes top-quality prints, and is just great to work with. If you’re looking to print jewelry with it, look no further than this superstar.

It’s well-built, makes top-quality prints, and is just great to work with. If you’re looking to print jewelry with it, look no further than this superstar.

You can check out the Elegoo Saturn for yourself on Amazon today.

Peopoly started its journey from humble beginnings, but fast-forward to this day, the US-based brand has produced some top-notch MSLA 3D printers with the passage of time.

Speaking of top-notch printers, the Peopoly Moai 130 is what shines in the spotlight.

The original Peopoly Moai launched back in 2017 as part of a Kickstarter campaign, but due to its overwhelming success, the brains over at Peopoly decided to upgrade this machine and released the Peopoly Moai 130.

This MSLA 3D printer has everything the first one had, and many other improvements. It’s compatible with a variety of resins so you don’t have to worry about purchasing expensive and select liquid resins like with the Formlabs Form 3.

For printing jewelry, rings, and glasses, the Moai 130’s sensational surface quality and precision are going to pay off well for its price. It does cost somewhere around $1400 (Peopoly) but it’s worth every single penny.

It does cost somewhere around $1400 (Peopoly) but it’s worth every single penny.

Let’s check out the features and specifications of the Moai 130.

Features of the Peopoly Moai 130

- Compact Design

- Easy-Level Print Plate

- FEP Resin Vat Included

- Chamber Heating Unit

- LEV UV Lamp For Post-Processing

- Asura Slicer Software

- Simple Printing Operation

- Excellent Print Quality

Specifications of the Peopoly Moai 130

- Printing Technology: SLA

- Laser: 150mW 405nm

- Build Volume: 130 x 130 x 180 mm

- Z-Layer Resolution: 0.005mm (Resin Dependent)

- XY Resolution: 0.07mm

- User Interface: Color LCD, Scroll Wheel

- Connectivity: SD Card

- Build Platform Leveling: Assisted Leveling

- Materials: Compatible With Most Liquid Resins

- Software Bundle: Asura

- File types: STL

The Peopoly Moai 130 improves upon the original entry in quite a few ways. After all, this is a product of all those hardware upgrades that the first Moai received after its launch.

After all, this is a product of all those hardware upgrades that the first Moai received after its launch.

The first new feature is an easy-level print bed leveling system that may not be an automatic process, but it isn’t a manual one either.

All you have to do is loosen the M4 screws, wait for the print plate to adjust by itself, and then tighten the nuts back again. That’s about it.

Then there’s also the inclusion of an FEP resin vat that offers extra durability and has better longevity than the one used on the original Moai.

Furthermore, there is a specialized heating chamber unit that the Moai 130 has for maintaining temperature during printing. This heater block goes a long way in making sure your prints turn out looking excellent.

Customer Reviews of the Peopoly Moai 130

The Peopoly Moai 130 is the 3D printer of choice for a huge number of people. Its worth is widely acknowledged by the 3D printing community, and users of this machine vouch for zero regrets.

This SLA 3D printer can handle jewelry like a walk in the park. Since it’s exceptionally precise and can print with a Z-Axis resolution that’s as low as 0.005mm, you can count on the Moai 130 for your 3D printing needs.

People like how this machine is well-built and sturdy, especially how smooth it runs during printing. Additionally, it is compatible with third-party liquid resins as well, so you do not have to purchase brand-specific resins only.

The flexibility in this regard can pay off decently when printing rings, and glasses where versatility matters. Combine that thought with the Moai 130’s heater block, and you can picture top-quality jewelry pieces coming out elegantly.

However, some users say that the initial setup and assembly can seem difficult for many. Still, it isn’t something that a bit of time and effort can resolve. Once you set it up, it’s only smooth sailing!

Pros of the Peopoly Moai 130

- The design is solid and the build quality is quite compact

- Printing is effortless with the Moai 130

- Great for jewelry-making

- Compatible with third-party resins

- Cura slicer software can also be used

- Helpful support materials and guides are readily available

- Superb customer support service despite being a small company

Cons of the Peopoly Moai 130

- Can be difficult to calibrate when working outside the Asura slicer software

- Some users have reported persistent issues with the SD card reader

- The initial set up is hard

Final Thoughts

The Peopoly Moai 130 is a phenomenal SLA 3D printer. Everyone looking for a machine to rely on for printing jewelry, rings, and glasses, can comfortably opt for this 3D printer with no second thoughts.

Everyone looking for a machine to rely on for printing jewelry, rings, and glasses, can comfortably opt for this 3D printer with no second thoughts.

Buy the Peopoly Moai 130 directly from Peopoly today.

The Qidi Tech S-Box comes from an industry-leading manufacturer that’s been at it for quite a while now. Qidi Technology is China-based and is known for making a wide array of high-performance and affordable 3D printers.

The S-Box is no exception to that and is a resin 3D printer that costs somewhere around $700.

It boasts a fairly large build volume, a compact design, a unique bed leveling system, and two air filtration units that do well in reducing resin odor.

It does, however, have a 2K LCD comprising 2560 x 1440 pixels, which is a bit of a downgrade from the Anycubic Photon X and the Elegoo Saturn.

Still, the Qidi Tech S-Box (Amazon) is incredibly precise and is one of the best 3D printers for making jewelry items on the go. You can comfortably use it to print high-quality rings, glasses, and other types of jewelry.

Furthermore, there’s a free one-year warranty that comes alongside this resin 3D printer. If your machine arrives at your doorstep damaged or unusable, you can get a free replacement right away.

Let’s take a look at the features and specifications of the S-Box.

Features of the Qidi Tech S-Box

- Sturdy Design

- Scientifically Designed Leveling Structure

- 4.3-Inch Touch Screen

- Newly Developed Resin Vat

- Dual Air Filtration2K LCD – 2560 x 1440 Pixels

- Third-Generation Matrix Parallel Light Source

- ChiTu Firmware & Slicer

- Free One-Year Warranty

Specifications of the Qidi Tech S-Box

- Technology: MSLA

- Build Volume: 215 x 130 x 200mm

- Layer Height: 10 microns

- XY Resolution: 0.047mm

- Z-Axis Positioning Accuracy: 0.00125mm

- Printing Speed: 20 mm/h

- Bed Leveling: Manual

- Materials: 405 nm UV resin

- Operating System: Windows/ Mac OSX

- Connectivity: USB

The Qidi Tech S-Box has been given its fair share of features. Right off the bat, you’ll observe a dual Z-axis guide rail design that’ll take away a significant amount of wobbling or shaking during printing.

Right off the bat, you’ll observe a dual Z-axis guide rail design that’ll take away a significant amount of wobbling or shaking during printing.

While the interior of this resin 3D printer is made from aluminum CNC technology, the outer design is no joke either. Overall, the machine just seems genuinely compact.

There’s also a 4.3-inch touchscreen to help you navigate around the interface of Qidi Tech S-Box. One thing that’s going to play a key role in making your jewelry pieces come out great is the aluminum casting resin vat.

The vat has been redesigned to fit a variety of FEP films and increase the lifetime of those that work alongside it. Seeing this feature on the Qidi Tech S-Box is outright convenient.

Resin 3D printers use the ChiTuBox slicer and that works pretty nice with this 3D printer. The ChiTu firmware is also a breeze to set up and start working with, though you can still use other resin slicers out there like LycheeSlicer and PrusaSlicer.

Customer Reviews of the Qidi Tech S-Box

The Qidi Tech S-Box takes pride in its amazing ratings on Amazon and has over a majority of ratings in the positive category that reflect this machine’s top-tier standard.

Customers who have bought it can’t get enough of this printer’s performance. One user says that they love how reliable is this 3D printer.

It’s shipped with delicate, carefully thought-out packaging that’s bound to leave you impressed when you first start unboxing the S-Box.

Users say that using the ChiTuBox slicer works perfectly with this resin 3D printer, as the machine is already highly user-friendly.

If you own a jewelry business and are looking to print jewelry items on a regular basis, take it from me and thousands of other happy customers that the Qidi Tech S-Box is one excellent resin 3D printer.

Pros of the Qidi Tech S-Box

- The machine is easy to set up, and even beginners can use it with the instruction guide that comes with it.

- Qidi Tech S-Box has a sleek and modern construction and provides it extra durability for long-lasting service.

- You will get a smooth operation –no more complexity- with minimal settings.

- The customer service after the purchase and during the use is fantastic and satisfactory.

- As compared to other 3D resin printers, it offers excellent print precision.

- The S-Box uses a matrix LED array with 96 individual points of UV light for uniform lighting and better quality.

- The smart chip present in the Z-axis motor machine provides you the incredible precision that you demand.

Cons of the Qidi Tech S-Box

- As the machine is quite new, the community is not that large, so the customers feel difficulty interacting.

- Fairly expensive resin 3D printer compared to budget options.

- It does not have any connectivity option other than USB.

- The size is a bit large as it is almost two feet long and over a foot and a half high.

- It weighs almost 55lbs, and that is high too – the vat and built plate are pretty heavy!

- The connectivity ports and touchscreen electronics are at the machine’s side that covers the whole side of the table.

Final Thoughts

The Qidi Tech S-Box with all its features and sensational print quality is a great option for printing rings, glasses, and other jewelry.

You can get yourself the Qidi Tech S-Box directly from Amazon today.

Being the second resin 3D printer on the list from Elegoo, it’s safe to say that this Chinese manufacturer means serious business when it comes to going up against the competition.

The Elegoo Mars 2 Pro (Amazon) is a budget-friendly yet highly efficient MSLA machine that comes after its predecessor, the Elegoo Mars Pro.

The Elegoo Mars Pro is also an upgrade over the original Elegoo Mars, and this means that the Elegoo Mars 2 Pro has some exciting improvements, new features, and a great resin 3D printing experience to boast about in general.

It costs just a bit under $300 and is still up there with top-ranking MSLA 3D printers. At such a cheap price, however, you can get the Elegoo Mars 2 Pro to print rings, glasses, and other jewelry pieces/molds effectively.

There is a lot to love and little to hate about this sturdy 3D printer. Features such as an in-built active carbon to negate toxic resin fumes and a lightweight but compact resin vat make this machine well worth the purchase.

Let’s advance to the features and specifications of the Elegoo Mars 2 Pro.

Features of the Elegoo Mars 2 Pro

- 6.08″ 2K Monochrome LCD

- CNC-Machined Aluminum Body

- Sanded Aluminum Build Plate

- Light & Compact Resin Vat

- Built-In Active Carbon

- COB UV LED Light Source

- ChiTuBox Slicer

- Multi-Language Interface

Specifications of the Elegoo Mars 2 Pro

- System: EL3D-3.0.2

- Technology: UV Photo Curing

- Layer Thickness: 0.01-0.2mm

- Printing Speed: 30-50mm/h

- Z-Axis Accuracy: 0.00125mm

- XY Resolution: 0.05mm (1620 x 2560)

- Build Volume: 129 x 80 x 160mm

- Light Source: UV Integrated Light (wavelength 405nm)

- Connectivity: USB

- Weight: 13.67lbs (6.2kg)

- Operation: 3.5-Inch Touch Screen

- Power Requirements: 100-240V 50/60Hz

- Printer Dimensions: 200 x 200 x 410mm

The Elegoo Mars 2 Pro has a 2K monochrome LCD with 2560 x 1440 pixels that attribute to magnificent print quality, almost optimum for printing jewelry accessories and items.

The monochrome screen also increases the printing speed and comprises a longer lifespan as compared to the ordinary RGB screen slapped on the Qidi Tech S-Box.

The Mars 2 Pro has a specialized COB UV LED light source for making sure that light emissions are constant, and heat dissipation is equal throughout. This increases the overall quality of the print – something that your jewelry pieces are going to need.

In terms of the resin vat of the Mars 2 Pro, it looks and feels outright premium. It is made up of an aluminum alloy that makes it lightweight and firm.

The build quality is also solid, and there’s even a sandblasted build plate that improves adhesion and grips in models just perfectly. This dispels a dozen print problems just like that.

Customer Reviews of the Elegoo Mars 2 Pro

With an amazing 4.7/5.0 overall rating at the time of writing, the Elegoo Mars 2 Pro has rightfully earned the “Amazon’s Choice” tag. 86% of the people who bought it have left a 5-star review, wishing they could praise it more.

This MSLA 3D printer’s performance is easily matched with professional-grade resin 3D printers that cost thousands of dollars, according to the users of this machine.

One customer says that they use their Elegoo Mars 2 Pro routinely for printing gold jewelry, rings, and glasses. From ordering, to delivery, to printing, it has never let them down, not even once.

Other buyers have praised the ease of use and simplicity of this machine. Leveling the bed has been made uncomplicated because of the well-written instructions manual that comes with the printer.

The Elegoo Mars 2 Pro is also qualified to work with a comprehensive array of liquid resins. Rest assured, this MSLA 3D printer packs amazing value for money.

Pros of the Elegoo Mars 2 Pro

- Outstanding printing quality

- Fast layer curing time

- Inclusion of an angled plate holder

- Rapid printing process

- Large build volume

- Less to no maintenance

- High accuracy and precision

- Robust build and sturdy mechanism

- Supports multiple languages

- Long lifespan and high reliability

- Stable performance during long-term printing

- Comes with extra FEP sheets

Cons of the Elegoo Mars 2 Pro

- LCD screen lacks a protective glass

- Loud, noisy cooling fans

- Z-axis does not have a limiter switch

- A slight decrease in pixel-density

- No top-down removable vat

Final Thoughts

If you are wanting to print high-quality jewelry pieces and molds but you’re not willing to spend more than $500 on a 3D printer either, the Elegoo Mars 2 Pro is a fantastic option to cover all your needs.

Buy the Elegoo Mars 2 Pro directly from Amazon today.

3D Systems is a 3D printing pioneer and was co-founded by Chuck Hull who created the first 3D printer ever.

Rest assured, this company has been making outstanding FDM and SLA 3D printers over the years, and the FabPro 1000 is one shining example of their veteran experience.

This is undeniably one of the best DLP 3D printers out there that boast unmatched precision, smoothness, and print quality.

The FabPro 1000 costs somewhere around $3700 and is surely not your typical budget-friendly machine. It does, however, bring a standard of luxury to the table.

Some may complain that the printer’s build volume isn’t too big, but it’s still highly satisfactory for printing jewelry pieces with great precision.

In addition, I could talk about the build quality for days that we get to see on this DLP 3D printer. It’s just too good!

Let’s see what the features and specifications look like on the 3D System FabPro 1000.

Features of the 3D Systems FabPro 1000

- Three Times Higher Print Speed

- Excellent 3D Print Software

- Industry-Grade Durability

- Highly Reliable

- Easy to Operate

- One-Year Free Warranty Included

- Responsive Customer Support Service

- Two-Step Post-Processing

- Professional Print Quality

- 0.03mm Layer Thickness

Specifications of the 3D Systems FabPro 1000

- Technology: DLP

- Build Volume: 125 x 70 x 120mm

- Printer Size: 43 x 43 x 61.2cm (16.9 x 16.9 x 24.1in)

- Weight: 37.5 kg (82.67 lbs)

- Interface: Ethernet Connection. USB (Direct Printing)

- Software: 3D Sprint

- Power Input of Printer: 100-240V AC, 2A, 50/60 H

- Layer Thickness: 0.03-0.1mm (Material Dependent)

- Wavelength: 405 nm

- Resin Compatibility: 3DSystems Resin and Third-Party Resins

The FabPro 1000 takes the cake when it boils down to print speed. It’s faster than half the competition out there, and is easily one of the best resin 3D printers out there for consistent jewelry-making.

With a build quality that’s made to last, the FabPro 1000 is nothing but reliable. You can expect it to serve for you multiple years without demanding an awful lot of maintenance.

In addition, this DLP 3D printer is easy to set up and operate. From loading the material to configuring the file, using this premium-class machine is everything but difficult.

In terms of precision, the FabPro 1000 can print models with a 0.03mm of layer height, making them turn out absolutely stunning. For jewelry molds of rings, or pendants, this is a great option for high quality and long-term success.

There’s also a one-year warranty included with your purchase if, in the unlikely case, you run into any hiccups with the FabPro 1000. It’ll be duly replaced.

Customer Reviews of the 3D Systems FabPro 1000

The 3DSystems Fab Pro 1000 does not have the best of Amazon ratings, but it still has a fairly decent one. A 4.0/5.0 overall rating at time of writing means that this DLP machine has been conceived well enough by the public.

Customers who have bought it love how fast it can run. They can get plenty of work done in a day as compared to other resin 3D printers that take three times longer in many cases.

Third-party liquid resins, and not just those coming from 3DSystems, also work with the FabPro 1000. One customer said that you can also print using a black resin with this 3D printer, and this isn’t something that every resin 3D printer can pull off.

Users say that the print quality is just what you expect from a professional-grade SLA or DLP 3D printer. It’s high enough to cast molds from thereby being highly suitable for making jewelry pieces, rings, etc.

The minimal setup also gets it going right for the people who’ve purchased it. The FabPro 1000 is one terrific package if you’re going to get it for printing gold jewelry, and glasses.

Pros of the 3D Systems FabPro 1000

- Ideal for jewelry-making applications

- Excellent for prototypes

- Printing is exceptionally fast and reaches up to 21mm/h

- Print quality is second to none

- Sturdy and compact build quality

- Can print with black resin as well

- Prints come out extremely dimensionally accurate

- Fairly easy to set up

Cons of the 3D Systems FabPro 1000

- Relatively small build volume

- Pretty expensive

- Not as popular as other resin 3D printers

- 3DSystems slicer software isn’t free

Final Thoughts

The 3DSystems FabPro 1000 is one expensive machine, but the price is justified soon after you make the purchase. Due to its insane print speed, and precision, I highly recommend the DLP 3D printer for everyone in the jewelry business.

Due to its insane print speed, and precision, I highly recommend the DLP 3D printer for everyone in the jewelry business.

Check out the 3DSystems FabPro 1000 directly on Amazon today.

Best Resin for 3D Printing Jewelry

You’ll want to have a high quality resin when it comes to casting your mold for 3D printing jewelry, and there are some pretty good options out there.

One of the best resins for 3D printing jewelry has to be the Anycubic Wax Resin from Amazon.

It has high precision, as well as low shrinkage so you can count on your models being dimensionally accurate and smooth. You can expect this resin to delivery quality at a higher level as compared to ordinary resins.

The Anycubic wax Resin is designed to cure pretty fast so you can enjoy a reduced printing time. You’ll be left with a 3D print that has good strength and flexibility, along with impact-resistance and great formability.

This castable resin is perfect for lost wax casting and jewelry casting so you can create some fantastic pieces. Whether you are a beginner or expert, you’ll be happy with the results you get from this resin.

Whether you are a beginner or expert, you’ll be happy with the results you get from this resin.

One user described this resin as one of the best he’s ever used, by far! When printing two of the same model using this wax resin and standard eco-resin, he found that the details were more crisp and defined, even on small miniatures.

The resin itself is fairly thin which leads to easier cleanup, but it is relatively pricey compared to other resins. If you do want the best detail on your 3D prints, it’s definitely worth the extra cost.

Get yourself a bottle of the finest Anycubic Wax Resin from Amazon today.

5 Best 3D Printers for Jewelry in 2023

Design accessories with ease by using 3D printers for jewelry

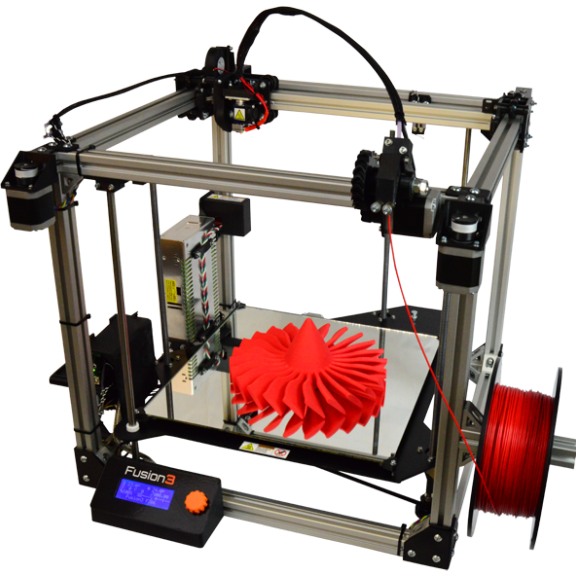

If you are familiar with 3D printers, you should also know that there are special models for printing accessories. They support additive manufacturing technology, which makes them similar to other 3D printers. However, this type handles casting materials and metals. Such printers are highly accurate and can be used for creating accessories.

Such printers are highly accurate and can be used for creating accessories.

These devices form layer by layer and allow you to create stunning designs without taking cumbersome steps associated with traditional methods.

Top 5 3D Printers for Jewelry

- ELEGOO Mars - Our choice

- ANYCUBIC Photon S - With Dual Z-axis Rail

- Creality LD002R - 3d printer for jewelry LCD

- ANYCUBIC Photon UV - Photon

- Dremel Digilab 3D20 - With 230°C

In this article, I will tell you about various options available on the market and everything you have to know about printing jewelry. After reading this guide, you will easily find the best 3D printer for jewelry.

After reading this guide, you will easily find the best 3D printer for jewelry.

1. ELEGOO Mars

Our choice

Print technology: LED Display Photocuring | Filament Diameter: None| Build Area: 120 x 68 x 155 mm | Minimum layer resolution: 10 microns | Maximum layer resolution: 200 microns

- ✚ Speedy slicing software

- ✚ Saves resin, great print quality

- ✚ Smart and user-friendly

- ✚ High resolution and precision

- — Doesn’t print tall items

- — Loud performance

$

VIEW ON AMAZON

Rating

This 3D printer for jewelry utilizes UV photocuring technology. It’s convenient to use and has a good design, due to which you will easily master it even if you don’t have experience with similar devices.

It’s convenient to use and has a good design, due to which you will easily master it even if you don’t have experience with similar devices.

It’s semi-assembled so you won’t have to spend much time installing it. In 5 minutes, you will be able to begin printing your first model. You can also easily slice it by using the latest CHITUBOX slicing software.

2. ANYCUBIC Photon S

3D printer for jewelry with Dual Z-axis Rail

Print technology: LED Display Photocuring | Filament Diameter: None| Build Area: 115 x 65 x 165 mm | Minimum layer resolution: 25 microns | Maximum layer resolution: 100 microns

- ✚ Good entry-level model

- ✚ Dual rails

- ✚ LED array

- ✚ Has a touch screen

- — Expensive

- — Bulky

$

VIEW ON AMAZON

Rating

This is a DLP 3D printer for jewelry, which uses a technology similar to SLA but is less expensive. It’s more than twice cheaper than leading SLA brands and has the same price as many Fused Deposition Modeling (FDM) printers.

It’s more than twice cheaper than leading SLA brands and has the same price as many Fused Deposition Modeling (FDM) printers.

3. Creality LD002R

Best affordable 3D printer for jewelry LCD

Print technology: LCD | Filament Diameter: None| Build Area: 120 x 65 x 165 mm | Minimum layer resolution: 20 microns | Maximum layer resolution: 50 microns

- ✚ Has an air filter

- ✚ Fast slicing software

- ✚ High resolution and great precision

- ✚ Anti-aliasing

- — Bulky

- — Noisy during operation

$

VIEW ON AMAZON

Rating

This printer features an air filtering system and the newest CHITUBOX slicing software. With it, you will need just 1 minute to slice 30Mb .stl model files. To compare, an open-source slicing software takes about 10 minutes to do the same.

With it, you will need just 1 minute to slice 30Mb .stl model files. To compare, an open-source slicing software takes about 10 minutes to do the same.

Due to amazing precision and high resolution, it is considered to be the best 3D printer for jewelry. It boasts robust 30W UV light, which provides fast printing (4s per layer). It’s simple to install.

You can quickly select a file to print and monitor the printing process via a convenient 3.5-inch full-color touch screen.

4. ANYCUBIC Photon UV

Best 3D printer for jewelry casting photon

Print technology: LCD | Filament Diameter: None| Build Area: 115 x 65 x 155 mm | Minimum layer resolution: 20 microns | Maximum layer resolution: 100 microns

- ✚ Simple to use

- ✚ High resolution

- ✚ Top-quality

- — Expensive

- — Heavy

$

VIEW ON AMAZON

Rating

ANYCUBIC has a powerful R&D team both inside the country and abroad. Having taken a smarter and more practical approach, it has designed top-quality 3D printers for professional and regular use.

Having taken a smarter and more practical approach, it has designed top-quality 3D printers for professional and regular use.

This printer has an XY resolution of 47 microns and a Z layer height of up to 10 microns. Thanks to this, it can create flawless 3D printed models with a high level of detail. It has a user-friendly interface, which lets you view and control the print status in real-time.

5. Dremel Digilab 3D20

Best 3D printer for jewelry making with 230°C

Print technology: FDM | Filament Diameter: 1.75 mm | Build Area: 230 x 150 x 140 mm | Minimum layer resolution: 100 microns | Maximum layer resolution: 300 microns

- ✚ High-quality printing

- ✚ Excellent protection

- ✚ High speed

- — Expensive filament

- — Manual hotbed leveling

$

VIEW ON AMAZON

Rating

This is an affordable 3D printer for jewelry, which is suitable for amateurs and beginners. Thanks to a plain design and great customer support, you can create amazing prints even if you don’t have any prior experience. This model is fully assembled and comes with a 0.5 kg spool of Dremel filament. Using simple setup instructions, you can quickly start printing.

Thanks to a plain design and great customer support, you can create amazing prints even if you don’t have any prior experience. This model is fully assembled and comes with a 0.5 kg spool of Dremel filament. Using simple setup instructions, you can quickly start printing.

| IMAGE | NAME | FEATURES | |

|---|---|---|---|

| ELEGOO Mars Our choice |

| CHECK PRICE → | |

| ANYCUBIC Photon S With Dual Z-axis Rail |

| CHECK PRICE → | |

| Creality LD002R 3d printer for jewelry LCD |

| CHECK PRICE → |

How to Choose the Best 3D Printer for Jewelry?

Before spending a lot of money on a 3D printer, you have to decide what you want to get from it. There are some important aspects to pay attention to when looking for the best 3D printer for jewelry casting.

There are some important aspects to pay attention to when looking for the best 3D printer for jewelry casting.

Accuracy

This is a very significant factor for such printers. An inaccurate design can spoil the whole piece. Even if you create something plain, you need to have a printer with good accuracy.

Surface Finish

Even though you can improve your designs during post-processing, it will take additional costs and more time. Therefore, you should get a printer that allows you to create projects with stable surface finishes or a model that is easier to use.

Color Print

With color printing, you can get more customers and extended possibilities. While jewelry printed in one color is still good, printing in multiple colors provides you with larger opportunities regarding market share.

Speed

This is essential if you are planning to do bulk printing or run a small scale production. You may need to spend a lot of time to complete your work if your printer is not very fast.

You may need to spend a lot of time to complete your work if your printer is not very fast.

FAQ

Yes, there are 2 ways to do it. The first is via direct metal laser sintering (DMLS), which utilizes powder layers and a laser to strengthen a model, which is after that extracted from the powder residues. You can also use the lost wax casting method.

This process can take from 30 minutes to 7 days or longer. The time depends on the size, shape of an object and the technology used for printing.

Yes, Reprap is very popular among those who are interested in 3D printing. You can get details and build your printer. There is also a large community where you can look for tips.

It’s not safe so don’t keep it on if you’re not there.

Choice of technology and 3D printer for jewelry making, pros and cons

Currently, there are many new technologies that are designed to simplify production in various industries. Progress does not stand still and, despite some opponents, 3D printing has its own niche in the production of jewelry.

3D printing can speed up and reduce the cost of jewelry production due to the low cost of consumables. With 3D printers, jewelers have the ability to quickly change the design of a product and make prototypes at least several times a day. For many jewelry industries, 3D printing is becoming a good alternative or addition to milling machines and other equipment.

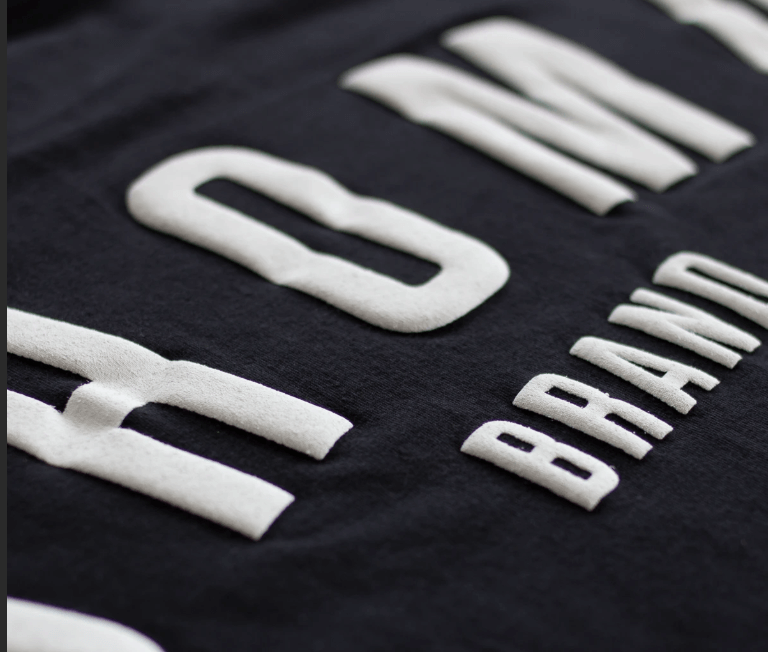

Until now, some believe that handmade is a sign of craftsmanship, especially when it comes to creative work, and models made using 3D modeling and printing are amateurish. But many people forget that behind the computer is the same person who not only mechanically presses the buttons, but also puts his soul into his creation.

Benefits of 3D printing

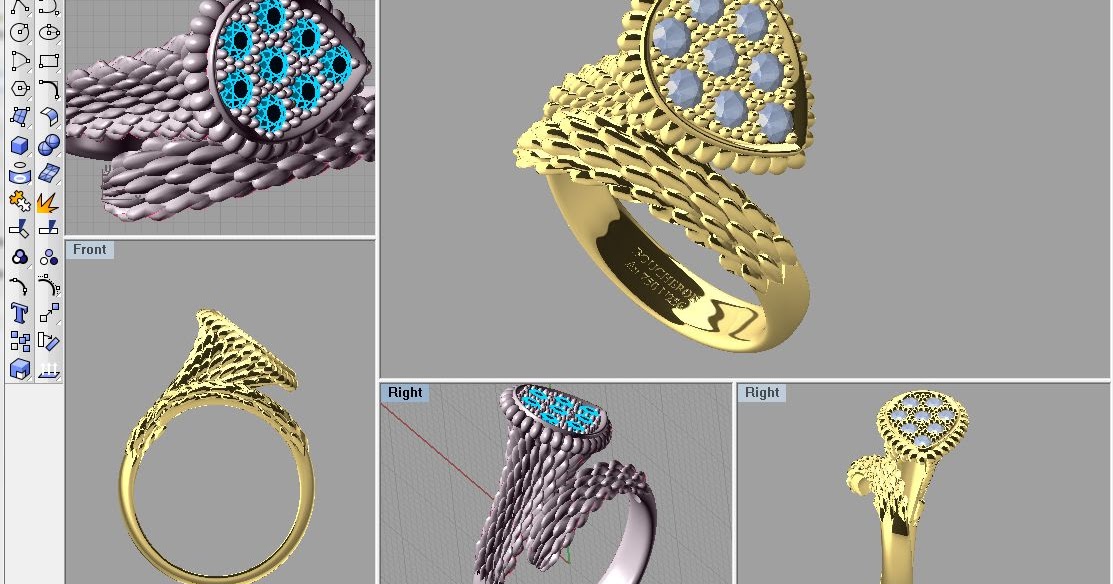

In order to understand how justified the use of a 3D printer is, you need to know how jewelry is made. This is very painstaking work. No wonder the expression "jewelry work" appeared, denoting a very delicate and complex work.

Any decoration begins with a sketch. Usually several sketches are made in order to accurately determine the design and location of the inserts. Not only stones are used as decor, it can be elements made of wood, bone, precious metals, it all depends on the designer's imagination.

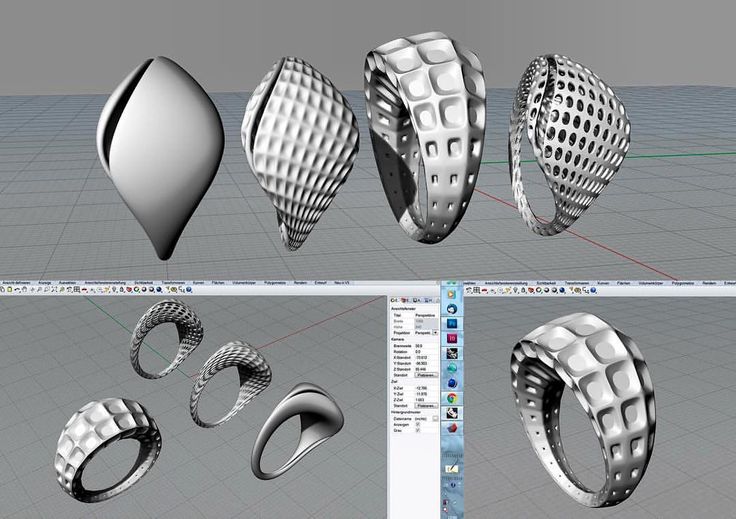

At the next stage, the product is drawn in a 3D editor. This allows not only to visualize the future product, but also to correct some errors and inaccuracies made at the design stage.

Ring model

Some craftsmen still carve "stencils" by hand. Such work requires certain skills and perseverance. Usually this is how products are made that will be cast in a single copy.

A finished 3D model can have several ways to be implemented in a physical version - this is milling or 3D printing.

Stencil milling

Currently, 3D printing is not much inferior in accuracy to a milling machine and often has a significant advantage in speed, despite the fact that after printing it is still necessary to separate the supports and clean up the points of contact with the model. Once a physical model has been obtained, it can be cast immediately if the material used is wax or a burnable polymer.

Once a physical model has been obtained, it can be cast immediately if the material used is wax or a burnable polymer.

If it is necessary to cast a large batch of products, then a mold is made from the master model made with the help of special rubber for subsequent wax casting. There are many types of rubber that vary in hardness and curing temperature. Rubber is selected depending on the material from which the master model is made.

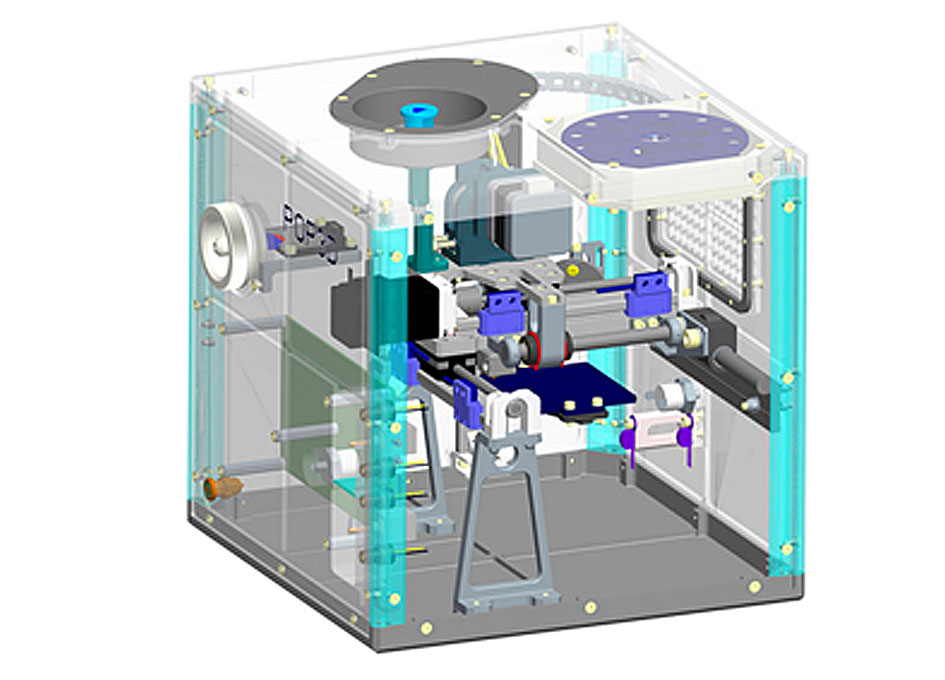

For pouring molds, a special machine is usually used - an injector. In some models, you can not only heat the wax, but also vacuum it or leave it under pressure. This helps to reduce the number and size of air bubbles for better pouring of the rubber mold.

In home workshops, silicone is used instead of special rubber. After all, a special machine is needed to vulcanize rubber. But rubber molds are too soft and short-lived for making a large batch of stencils.

After making the required number of stencils, they are collected in "Christmas trees". "Elks" are waxes soldered to a wax rod. To save space, the distance between them is very small and they resemble fluffy Christmas trees, hence the name. The finished Christmas tree is weighed to calculate the required amount of metal. In some places, stones are immediately inserted into the stencils, unless another mounting option is provided.

"Elks" are waxes soldered to a wax rod. To save space, the distance between them is very small and they resemble fluffy Christmas trees, hence the name. The finished Christmas tree is weighed to calculate the required amount of metal. In some places, stones are immediately inserted into the stencils, unless another mounting option is provided.

Stencil Christmas trees

Ready "Christmas trees" are placed in a special cylindrical "cassette" without a bottom, which is called a flask, and filled with a gypsum-based molding mass. The flask with uncured gypsum must be evacuated to get rid of unnecessary air bubbles that can lead to defects on the surface of the finished casting.

After hardening, the gypsum flask is sent to a muffle furnace to melt the wax.

The calcination mode is selected depending on the material of the wax. For wax or burnout polymer, different modes are needed in order for the material to be completely removed from the gypsum!!!!!!

When all the wax is melted, cavities are formed inside the gypsum, repeating the contours of the wax. Metal is poured into these voids. After casting, the flask is cooled and the gypsum mold mass is washed out under the pressure of water. The result is a metal Christmas tree.

Metal is poured into these voids. After casting, the flask is cooled and the gypsum mold mass is washed out under the pressure of water. The result is a metal Christmas tree.

Herringbone after casting

Finished castings are cut from the Christmas tree and washed, polished, if necessary, blackened by the master until the desired appearance is achieved.

3D printers for jewelers

There are several 3D printing technologies that may be suitable for the needs of jewelers. Each has its pros and cons. Some 3D printers are ideal for a large workshop, and some are ideal for a small workshop.

SLA

SLA or stereolithography is based on the principle of layer-by-layer solidification of a photopolymer resin under the action of a UV beam. The UV beam is focused by means of mirrors on the surface of the resin and illuminates the model in layers.

How the SLA Printer Works

SLA 3D printers were the first to be noticed by jewelers. SLA devices are compact, while they have high printing accuracy.

SLA devices are compact, while they have high printing accuracy.

Pros and cons

pros

Minuses

Print examples

From prototype to finished product

Cast and printed ring

Rating of printers.

Leadership among the production of SLA 3D printers is held by Formlabs.

Formlabs Form 3

Formlabs Form 3

Specifications:

XY resolution: 25 µm

Laser spot size: 85 µm

Laser power: One 250mW laser

Working area size: 14.5×14.5×18.5cm

Layer thickness: 25 – 300 µm

A professional 3D printer that is popular with professional jewelers and dentists.

Formlabs Form 3L

Formlabs Form 3L

Specifications:

XY resolution: 25 µm

Laser spot size: 85 µm

Laser power: One 250mW laser

Working area size: 33. 5×20×30cm

5×20×30cm

Layer thickness: 25 – 300 µm

Form 3L differs from younger models in its large print area, which allows you to produce truly large products without losing quality and accuracy.

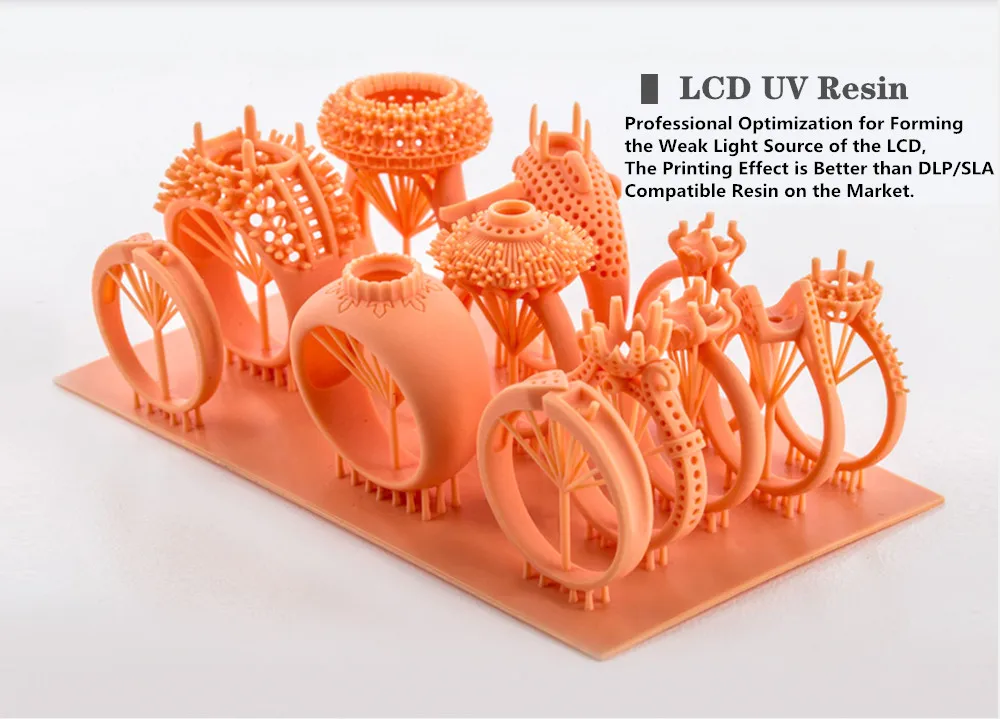

DLP/LCD

DLP is very similar to SLA, only as a source of UV radiation, to illuminate the photopolymer resin, not a directed beam of light is used, but a DLP projector. DLP printers illuminate the entire work area at once, so they greatly outperform SLA in print speed.

How a DLP Printer Works

Today it is one of the most affordable photopolymer 3D printing technologies. In terms of cost, LCD printers have caught up with the price level of amateur FDM. DLP printers are much more expensive due to the use of an expensive projector as a UV source.

The projector is of course more expensive, but more durable, on the other hand, the LCD display is not so expensive and can be easily seen, unlike the projector. What to choose each user decides for himself.

What to choose each user decides for himself.

Pros and cons.

pros

Minuses

Print examples

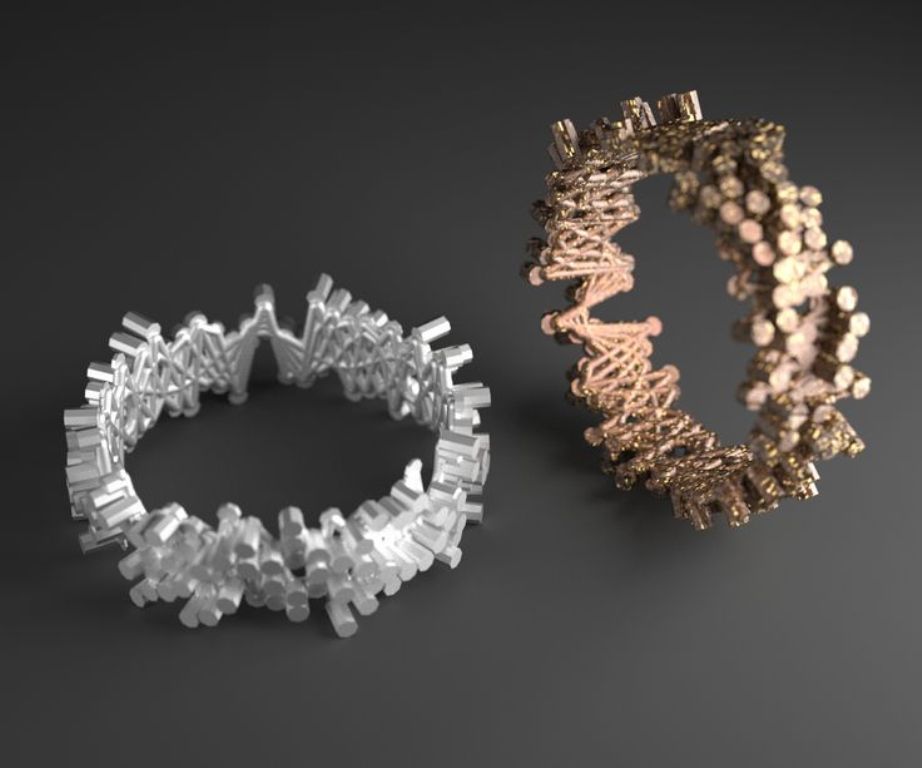

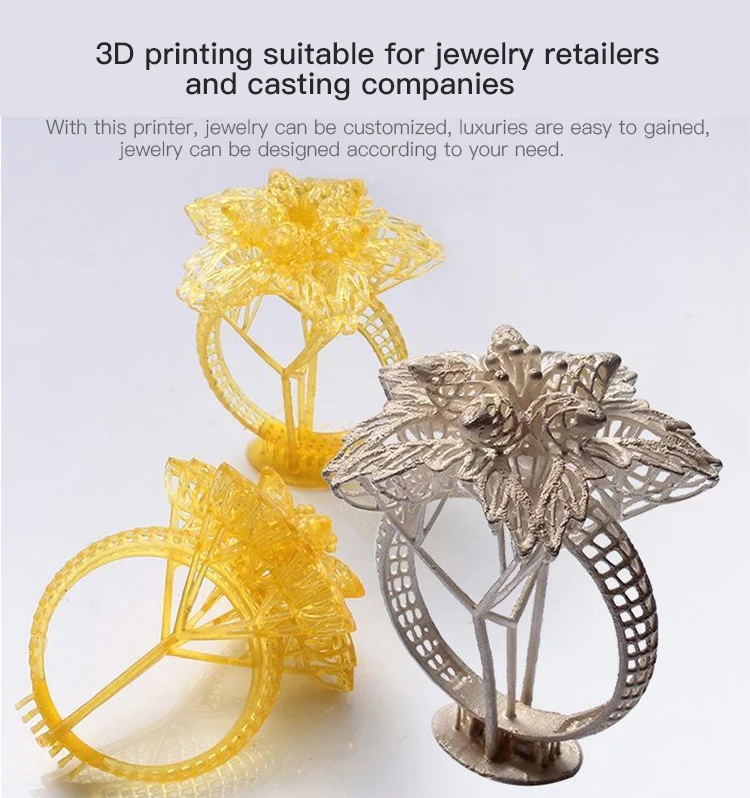

Comparison between 3D printed master model and molded part

Burnout resin model and finished product

Demonstration of products cast with burnout resin

Rating of printers.

The print accuracy of LCD printers depends on the pixel size, so you should pay attention to this parameter when choosing a printer.

Anycubic Photon Mono

Anycubic Photon Mono

Specifications:

LCD display resolution: 2560x1620 (2K)

XY Positioning Accuracy: 0.051mm

UV wavelength: 405 nm

Working area size: 130x80x165 mm

Layer thickness: 0.01-0.15mm

The Anycubic Photon Mono is an inexpensive LCD machine ideal for hobby printing. The monochrome display allows you to reduce the exposure time and speed up printing.

The monochrome display allows you to reduce the exposure time and speed up printing.

Phrozen Sonic 4K

Phrozen Sonic 4K

Specifications:

LCD resolution: 6.1" 4K Mono LCD

XY positioning accuracy: 35 microns

UV wavelength: 405 nm

Working area size: 134x75x200 mm

Layer thickness: 0.01-0.30mm

Phrozen Sonic 4K is specifically designed for use in the dental and jewelry industry. Despite its compact size, the printer is not inferior to professional machines in accuracy, and the exposure time of one layer is only a few seconds.

Phrozen Sonic Mighty 4K

Phrozen Sonic Mighty 4K

Specifications:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0. 01-0.3mm

01-0.3mm

Phrozen Sonic Mighty 4K is a professional device with a large print area. This allows you to quickly produce small batches of models.

Phrozen Sonic XL 4K

Phrozen Sonic XL 4K

Specifications:

LCD resolution: 8.9" 4K Mono-LCD

XY positioning accuracy: 50 microns

UV wavelength: 405 nm

Working area size: 190x120x200 mm

Layer thickness: 0.01-0.3mm

The Phrozen Sonic XL 4K is a professional machine with a large print area and a high resolution monochrome LCD display. This allows you to quickly produce batches of products with high accuracy.

Peopoly Phenom XXL

Peopoly Phenom XXL

Specifications:

LCD display resolution: 3840x2160 (23.8", 16:9, UHD 4K)

XY positioning accuracy: 137 µm

UV wavelength: 405 nm

Working area size: 527x296x550 mm

Layer thickness: 0. 01-0.3mm

01-0.3mm

The Peopoly Phenom XXL is a device with a huge build area, which is ideal for serial production of not only jewelry.

Phrozen Sonic MEGA 8K

Phrozen Sonic MEGA 8K

Specifications:

LCD resolution: 15" 8K Mono LCD

XY Positioning Accuracy: 43 µm

UV wavelength: 405 nm

Working area size: 330 x 185 x 400 mm

Layer thickness: 0.01-0.3mm

This is the first LCD printer with 8k monochrome matrix resolution, and a huge working area allows you to produce large batches of products in one print.

MJM/MJP

MJM (or similar PolyJet technology) is a technology for layering photopolymer or wax through many fine nozzles. Typically, the print head is located from 96 to 448, depending on the printer model.

If a photopolymer is used as a material, it is immediately cured by a UV lamp, which is located on the printer's head.

How the MJM printer works

In addition to photopolymer, MJM 3D printers can use wax as a material for printing.

MJM printers can print multiple materials at the same time. This allows you to print complex models with soluble or investment supports. This makes it possible to produce complex models with a smooth surface quickly and easily.

Pros and cons

pros

-

Ability to print multiple materials at the same time. This means that another, soluble material can be used as a support. This allows you to save a lot of time on removing the support from the finished model and cleaning up the places where the supports come into contact with the print.

Minuses

-

To install the printer, most likely, you will need a separate room. 3D printers based on MJM technology are quite bulky in their dimensions, this is not a device that can simply be placed on a desktop or nightstand.

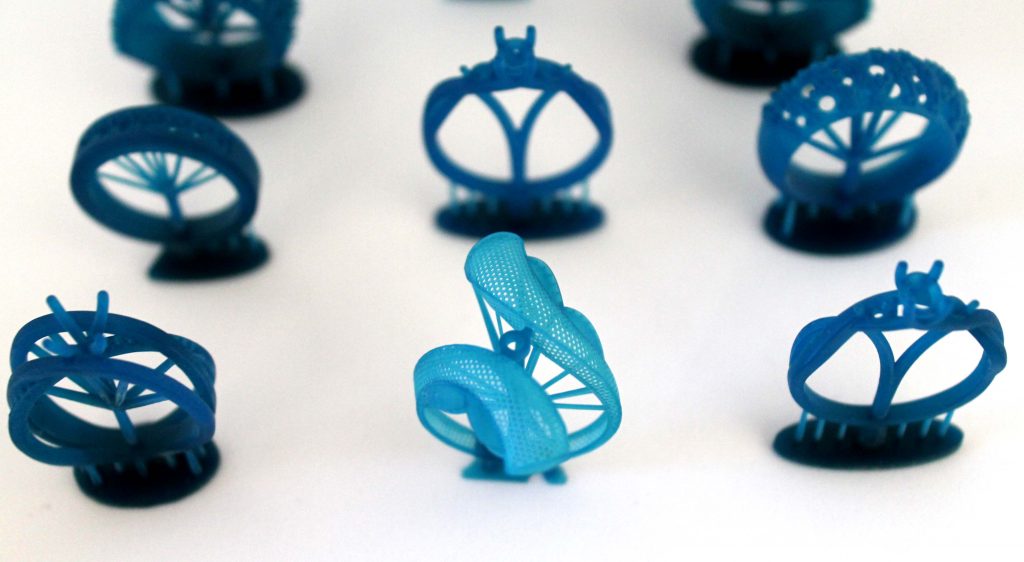

Print examples

Seal of a lot of stencils

Ring printed with wax

Master models made on MJM printer

Lot of jewelry stencils for further casting

Printer rating

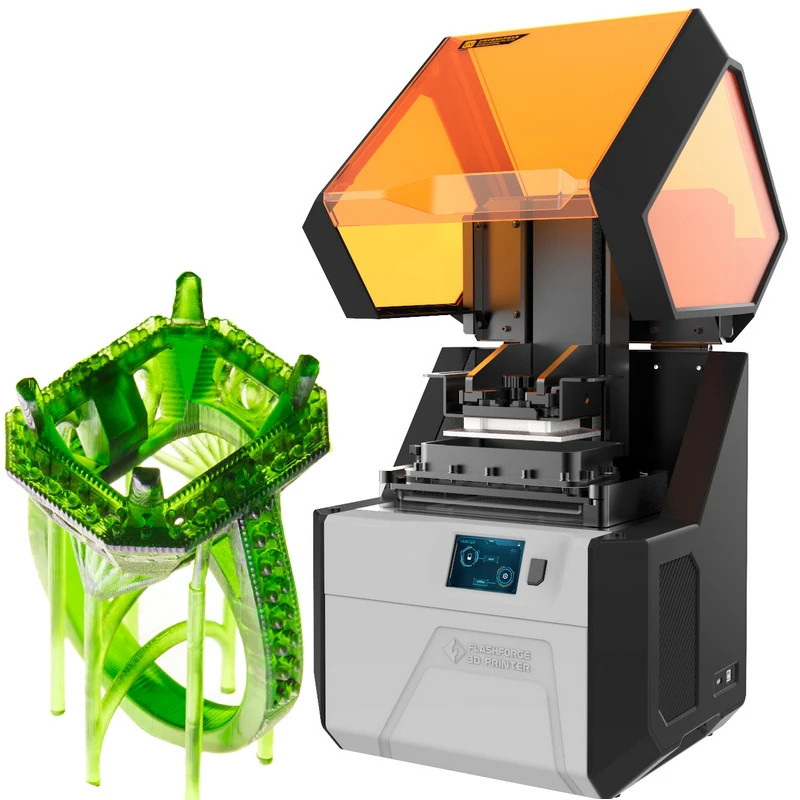

FlashForge WaxJet 410

FlashForge WaxJet 410

Specifications:

Materials: Wax, support material.

Resolution: 1200*1200*1600

Building area size: 289*218*150mm

Layer thickness: 16 microns

Accuracy: ±0.04mm / 20mm

The FlashForge WaxJet 410 is an industrial machine designed for serial printing of wax models, which will then be cast from metal. Machines of this class can be useful not only in jewelry production, but also in the dental industry, aerospace, mechanical engineering, prototyping, etc.

Totals

Photopolymer 3D printers are no longer inferior in detail to professional milling machines. The main advantage of a 3D printer is the ability to produce models of complex geometry with many internal cavities that are physically impossible to produce on a router.

Large firms will appreciate the flexibility that allows them to quickly adapt to customer requirements, as well as quickly produce large and small batches of products due to the shortening of the production chain.

And for a small workshop, a small photopolymer printer with a can of burn-out resin can be a good help, eliminating the need to purchase some expensive machines.

Which LCD 3D printer to choose for jewelry making

In this fast-paced world, even jewelry can now be created using 3D printing. Everything from rings to necklaces can be easily printed with the touch of a finger. Resin 3D printing allows the creation of high-quality jewelry with intricate detailing that would be extremely difficult to achieve with traditional manufacturing.

In the traditional process, jewelers create intricate and fine patterns in wax or by hand. Although they put a lot of love and diligence into their work, this method remains very time consuming and the risk of human error is high. One mistake and you have to start the whole process from scratch.

Thanks to the advent of photopolymer 3D printing, a piece of jewelry can now be created digitally and then printed. If necessary, the design can be modified using a CAD program. Phrozen's Wax-Like Castable Violet imitates wax commonly used in jewelry. A sample of this resin is placed in a mould, filled with plaster, hardened and cast. It burns out, and the final product of gold or silver remains.

What types of jewelry can 3D printers create?

Photopolymer 3D printing allows you to think outside the box and create all kinds of jewelry in the most unique shapes and designs. Also, LCD 3D printers allow you to make custom jewelry at a much more affordable price.

Also, LCD 3D printers allow you to make custom jewelry at a much more affordable price.

3D printers can be used for prototyping, rubber molding, and jewelry casting.

Let's see which Phrozen LCD 3D printer is suitable for creating jewelry:

Phrozen Sonic Mini 4K 3D printer - for highly detailed jewelry models

The 6.1" LCD resolution of the Phrozen Sonic Mini 4K is best suited for creating jewelry models. It prints delicate pieces in 4K resolution.

The Sonic Mini 4K is capable of printing a full platform of intricate details such as rings, brooches and pendants in a single print session. For example, it can be 10-20 rings on one platform. With fast printing capabilities, this 3D printer prints out a platform full of decorations in the minimum amount of time.

With extremely precise printing, Sonic Mini 4K ensures that all the fine details on jewelry are executed without error.

The Sonic Mini 4K Desktop Resin 3D Printer can be easily stored at home, in the workplace or in a jewelry studio.

Specifications of the Phrozen Sonic Mini 4K 3D printer:

- LCD resolution 6.1" 4K Mono LCD

- Display 2.8" Touch Panel

- Construction area size 134x75x130 mm

- 35 µm XY resolution

- print speed 80 mm/hour

Sonic Mini 8K - for extremely detailed jewelry models

With a 7.1" LCD display resolution, the Phrozen Sonic Mini 8K is the best choice for those who want to create extremely intricate jewelry in 8K resolution.

The Sonic Mini 8K is able to print a full platform of the most intricate jewelry such as rings, brooches and pendants in a single print session. One plate may contain, for example, 10-20 rings.

Sonic Mini 8K comes with a matte laser cut platform, while allowing your jewelry to attach more firmly to the build plate. This increases the likelihood of printing success.

With a matte pattern print platform on the surface, 3D models are firmly attached to it during printing, greatly increasing the success rate of 3D printing.