3D printer printing clothes

What Will 3D Printed Fashion Clothes Look Like

Imagine that at the beginning of every week, you have a new wardrobe of clothes custom-made for what you’re doing and where you’re going, fit you perfectly, and match your tastes, too. No — you’re not a celebrity. You’re just in possession of a 3D printer, a not-so-distant reality that experts say has the potential to transform the entire fashion industry to not only be more nimble, personalized, and adaptive — but more sustainable, too.

The idea is simple: Using a lump of raw materials, you print out your new looks on-demand. When you’re sick of them, you melt them down to create a new batch of clothes. This futuristic process helps you stay fresh, style-wise, and also keeps waste to a minimum. As NYC's Fashion Institute of Technology Muhammed Shahadat sees it, 3D presents an innovative solution to fashion's overproduction problem.

Advertisement

“Throw-away culture is deeply rooted in the fashion industry. If a new spring collection comes out, then what happens to the old collection?” said Shahadat. One printer, according to Shahadat, can be the single source of all our shopping and recycling. “The normal fashion industry doesn't do that.”

On top of reducing material waste, 3D printing can drastically decrease the number of animals killed for materials like leather. (Shahadat cites that 59 million animals were slaughtered in 2018 in the U.S. alone according to the food and agricultural department of the U.N.) According to the FIT professor, it can also alleviate the textile industry's harmful impact on local farmland and wildlife and the people in the surrounding community. Then there's the vast amount of water it can preserve: According to WorldBank, “[it takes] 3,781 liters of water to make a pair of jeans, from the production of the cotton to the delivery of the final product to the store.”

The benefits are clear. But, how do we switch to a 3D-printed fashion society?

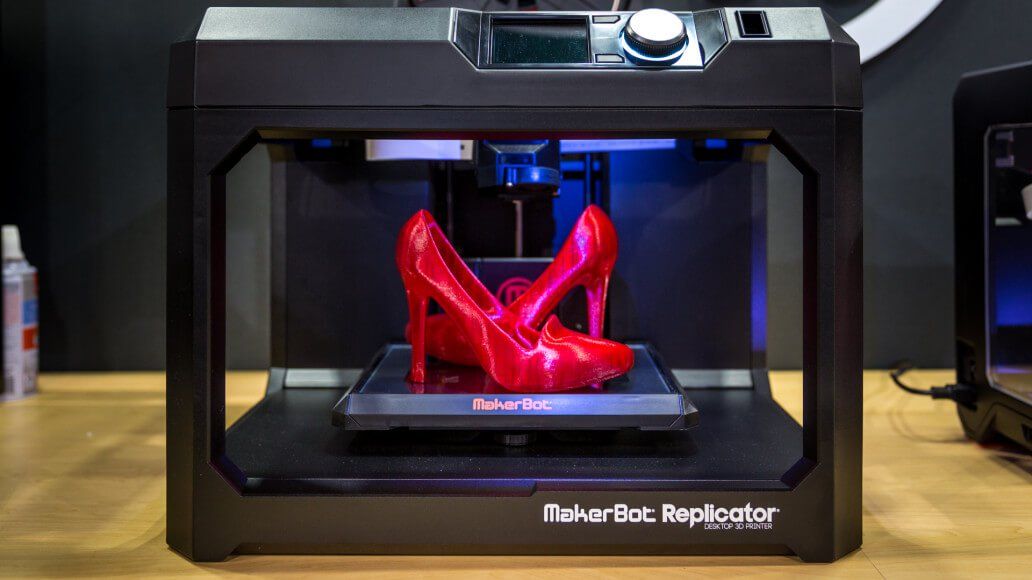

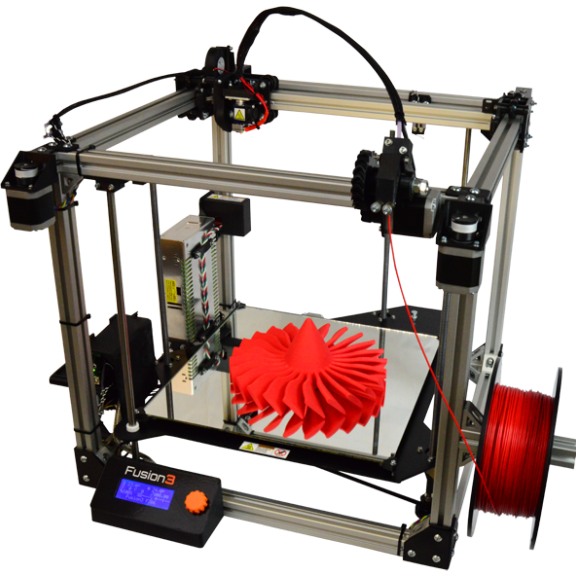

We’re not quite there yet. Today, 3D printers are available for at-home hobbyists, but cost thousands of dollars and require advanced computer know-how. Not to mention, they use plastic to print which can be extremely harmful, particularly to sea life and ocean environments.

Today, 3D printers are available for at-home hobbyists, but cost thousands of dollars and require advanced computer know-how. Not to mention, they use plastic to print which can be extremely harmful, particularly to sea life and ocean environments.

But the technology is advancing at a rapid pace, which encourages experts who believe that there’s immense potential for 3D printing that doesn’t exist for traditional manufacturing. Central to the optimism is the idea that, unlike cutting and sewing, 3D printing doesn’t generate waste. Using filaments — melted material ranging from plastic to recycled wood — to slowly build a product from nothing to something, 3D printing could one day utilize recycled materials that you theoretically shred and melt at home (imagine a compost bin but for your closet instead of your garden).

Advertisement

“It would be nice to think we could hit a few buttons and produce mass amounts of clothing for the world, especially for those in need. To set up a pop-up maker factory or run a 3D fabric printer out of a truck using recycled filaments to make clothes would be no different than the idea of printing homes on Mars using locally sourced sand,” Shahadat said, explaining how, in an ideal universe, material sourcing would be abundant and immediate. “However, to reach a mass scale, 3D printers need to become a fixture in people’s homes.” When that time comes, instead of buying clothes from stores, we may be downloading digital files from retailers’ apps to then print out garments at home.

To set up a pop-up maker factory or run a 3D fabric printer out of a truck using recycled filaments to make clothes would be no different than the idea of printing homes on Mars using locally sourced sand,” Shahadat said, explaining how, in an ideal universe, material sourcing would be abundant and immediate. “However, to reach a mass scale, 3D printers need to become a fixture in people’s homes.” When that time comes, instead of buying clothes from stores, we may be downloading digital files from retailers’ apps to then print out garments at home.

If 3D printers one day become democratized, as ink and paper printers did in the early 2000s, then sustainable clothing will become the norm. Arming consumers with the potential to close the loop themselves is powerful; what used to be summer shorts one day can transform into fall pants the next, all with flawless customization. Key to this is accessibility, and experts say this transformation must begin at the household level.

One of the more encouraging aspects of 3D’s potential to influence the widespread implementation of sustainability within fashion is that its most attractive qualities, to many consumers, have nothing to do with sustainability at all. “How many times have you been to the mall and those Jordans or H&M dresses are sold out in your size?” said Shahadat, pointing out that 3D printing has the potential to render exclusivity a moot point. “The issues consumers face when shopping in a store often lead to them settling for something they didn’t want. [With 3D printing,] that would no longer be a problem.”

“How many times have you been to the mall and those Jordans or H&M dresses are sold out in your size?” said Shahadat, pointing out that 3D printing has the potential to render exclusivity a moot point. “The issues consumers face when shopping in a store often lead to them settling for something they didn’t want. [With 3D printing,] that would no longer be a problem.”

Advertisement

“

Instead of buying clothes from stores, we may be downloading digital files from retailers’ apps to then print out garments at home.

”

The need is there, as is the vision. When will the technology come? Shahadat said that when 3D printed clothes first hit fashion runways in the 2010s, the materials were nylon-based and, thus, weak. In some cases, clothes would break if a model even sat down. Today, formulas have already improved to be more durable and comfortable, too.

One brand well on its way is Spain-based ZER Collection that makes 3D-printed pullovers, casual bottoms, and formal dresses. Minimal and crisp, it’s spec-ops-gone-chic. What started as a university dissertation project for Núria Costa and Ane Castro has now morphed into an award-winning, new-age grassroots fashion house.

Minimal and crisp, it’s spec-ops-gone-chic. What started as a university dissertation project for Núria Costa and Ane Castro has now morphed into an award-winning, new-age grassroots fashion house.

“I believe every designer at some point in their careers asks themselves what they want to contribute to society. We were not sure if the fashion world was for us,” said Costa and Castro in an email to Refinery29. “We needed something else, something different, and that pushed us towards this path instead of the more traditional one.”

Since launching, the brand has won the Global Change Award by the H&M Foundation and were finalists in Who's on Next by Vogue Spain. Now, they’re breaking into commercial streetwear, a line they’re calling ZER Era.

“The project is aimed at tackling one of the biggest environmental issues in the fashion industry: the unnecessary production of tons and tons of textiles,” said Castro and Costa. “Using new manufacturing methods, we avoid the loss of resources that are being wasted away in the current industry.” One of these methods makes it possible for ZER shoppers to send in old pieces for ZER to melt into filaments in order to produce new designs. Additionally, Costa and Castro said they use almost exclusively biodegradable components.

“Using new manufacturing methods, we avoid the loss of resources that are being wasted away in the current industry.” One of these methods makes it possible for ZER shoppers to send in old pieces for ZER to melt into filaments in order to produce new designs. Additionally, Costa and Castro said they use almost exclusively biodegradable components.

“At first we believed that this was a pipe dream, but [after] speaking with different providers, we slowly started believing that something could be done,” the founders said. “That is the same thing that will happen with the 3D printers. It is a technique being introduced in different areas, and getting very competitive projects. It is time that fashion has a place, too.”

Advertisement

The Shattering Truth of 3D-Printed Clothing

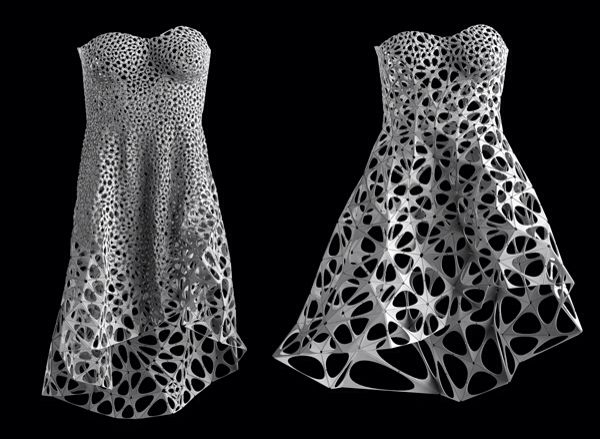

threeASFOUR’s Harmonograph Dress, part of the fall 2016 show collection, BIOMIMICRY. Designed in collaboration with Travis Fitch and 3D printed by Stratasys.Schohaja

Roni Jacobson

Backchannel

Fashion visionaries are using 3D printing to create mind-bending textiles that are nearly impossible to wear.

When the fashion trio threeASFOUR debuted its first collection of 3D-printed clothing, a parade of auburn-haired models marched down a runway at the Jewish Museum in New York City. Their gowns looked both ethereal and geometric—the garb of angelic robots. One dress, for example, was composed of white, angular bubbles that made their wearer look like she had emerged from a very foamy bath. But the woman who shepherded it down the runway couldn’t sit down, or the dress would shatter. “The model that was wearing it hated us,” says Bradley Rothenberg, an architect who collaborated on the project with threeASFOUR.

That was in 2013, when threeASFOUR began to realize that reaching the future of fabric might require taking a few steps back. The trio at its helm — Gabi Asfour and his design partners Angela Donhauser and Adi Gil — never meant to create clothing so prone to wardrobe malfunctions. They wanted to do the opposite: stretch clothing to superhero heights. They dreamed of 3D-printing textiles that were bulletproof, fireproof, pressure-resistant, or able to trap heat or cold. In a run-of-the-mill dystopia, the garments they had in mind would fly off the shelves.

The trio at its helm — Gabi Asfour and his design partners Angela Donhauser and Adi Gil — never meant to create clothing so prone to wardrobe malfunctions. They wanted to do the opposite: stretch clothing to superhero heights. They dreamed of 3D-printing textiles that were bulletproof, fireproof, pressure-resistant, or able to trap heat or cold. In a run-of-the-mill dystopia, the garments they had in mind would fly off the shelves.

That time might be more or less now. At a moment when Silicon Valley’s elite are building personal bunkers, refugees are sneaking across the border into Canada, and Margaret Atwood is once again en vogue, threeASFOUR’s vision is not so far from where the apocalyptically minded have already gone. But where hoarding cans of Doomsday beans is within just about anyone’s reach, achieving sartorial superpowers has proven more elusive.

threeASFOUR debuted its 2014 spring/summer line at the Jewish Museum.

The Jewish Museum/YouTube

The reason is simple. Thousands of years of refinement have allowed traditional weaving and sewing to produce wearable, durable clothing more efficiently than an upstart method like 3D printing. But that hasn’t stopped the team behind threeASFOUR and other entrepreneurial designers from pushing the limits of fabric to see just how far — and how weird — it can go.

Thousands of years of refinement have allowed traditional weaving and sewing to produce wearable, durable clothing more efficiently than an upstart method like 3D printing. But that hasn’t stopped the team behind threeASFOUR and other entrepreneurial designers from pushing the limits of fabric to see just how far — and how weird — it can go.

“With fashion there is the potential to control the weave and control the structure to get exactly the properties you want,” says Rothenberg. “The issue is that today, it’s still potential. That’s why I think Gabi [Asfour] is, like, the most exciting person in fashion. We need people like him to push the limits, to show what’s conceivable.”

Gabi Asfour has a cerebral, esoteric bent that soon becomes clear in his work. Since becoming curious about 3D printing around 2009, he has been trying to manipulate the internal geometry of textiles.

Traditional fabric is essentially two-dimensional — strands are arrayed horizontally, vertically, and in crisscross to form a weave. Asfour—who has degrees in mechanical engineering and architecture from the University of Maryland—had a vision, along with Donhauser and Gil, to create “three-dimensional interlocking weaves,” which they would achieve with the help of laser cutting. The desire to mess with fabric’s third dimension drew them naturally to 3D printing.

Asfour—who has degrees in mechanical engineering and architecture from the University of Maryland—had a vision, along with Donhauser and Gil, to create “three-dimensional interlocking weaves,” which they would achieve with the help of laser cutting. The desire to mess with fabric’s third dimension drew them naturally to 3D printing.

Most Popular

So far, Asfour says, “the most advanced fabric has been a four-way stretch.” That’s what’s possible with most normal fabric, which stretches along the X and Y planes. 3D printing would allow a material to stretch in the Z plane, Asfour theorized. He figured that such fabric would be more breathable and make movement easier. Best of all, it would eliminate wrinkles.

Asfour and his collaborators started asking around about 3D printing, and those inquiries eventually led to a collaboration with Materialise, a 3D-printing firm, and Rothenberg, who had designed the 3D-printed wings in Victoria’s Secret’s 2013 fashion show.

“When we started, Gabi was just like, ‘Can we make a textile out of this? Can we 3D print a fabric out of this material?’” Rothenberg says from his seat behind a table at his studio in New York’s Chinatown, where he and Gabi work. It turned out to be harder than anyone imagined.

The main challenge was that 3D-printing materials are far more rigid than the fabrics used in clothing. Over and over, they would alter the internal geometry of various materials to add more stretch to them, but once a printer deposited them in layers, those new materials would always shatter. “The practicality at the end comes and kicks your ass,” Asfour says.

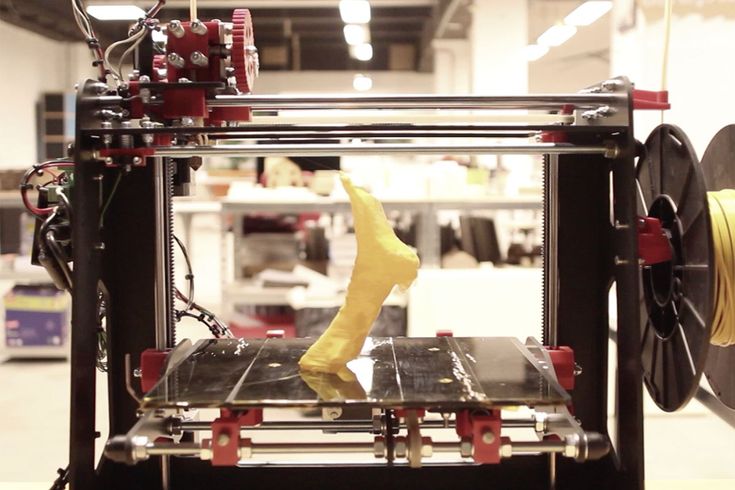

As materials slowly improved, however, threeASFOUR worked up to dresses like Pangolin, a collaboration with 3D-printing company Stratasys and architect Travis Fitch, for the brand’s Fall 2016 Biomimicry collection. Pangolin took 500 hours to print, with 10 printers going at once, followed by a painstaking process of assembly. The garment, named after the world’s only scale-covered mammal, looks like something a contemporary Joan of Arc would wear: a dark yet feminine piece of armor. (Björk wore it to open her tour in Australia last year.) To achieve Pangolin’s scales, the designers used an algorithm that simulates cell division to produce its interlocking weave.

The garment, named after the world’s only scale-covered mammal, looks like something a contemporary Joan of Arc would wear: a dark yet feminine piece of armor. (Björk wore it to open her tour in Australia last year.) To achieve Pangolin’s scales, the designers used an algorithm that simulates cell division to produce its interlocking weave.

Schohaja

Most Popular

threeASFOUR’s Pangolin Dress, also part of the BIOMIMICRY collection. Designed in collaboration with Travis Fitch and 3D printed by Stratasys.

Schohaja

When I visit threeASFOUR’s Chinatown studio to see Pangolin in person, I pass 15 to 20 women who are working on traditional sewing machines, stitching traditional fabric swatches. The scene of their workshop looks like it could have taken place at any point in the last 50 years. Inside threeASFOUR’s studio, just one floor up, daylight streams in, hits the studio’s silver walls, and is refracted in a disco ball overhead. Up close, Pangolin’s breastplate, detached from the rest of the dress, looks and feels something like a bike tire without its tread, cut up and woven into a fish scale pattern. The piece even flops like a fish tail. It doesn’t look like a notable achievement—but just a few years earlier, that heavy droop was not possible.

Up close, Pangolin’s breastplate, detached from the rest of the dress, looks and feels something like a bike tire without its tread, cut up and woven into a fish scale pattern. The piece even flops like a fish tail. It doesn’t look like a notable achievement—but just a few years earlier, that heavy droop was not possible.

Asfour hands me a piece of another dress from the Biomimicry collection: Harmonograph, which was modeled after the geometry of a sound wave. This dress was made out of a rubber mesh that can stretch and contract, like a memory foam mattress. Its latticed bustle compresses when its wearer sits and springs back into shape upon standing.

With newfound flexibility, wearers of these 3D-printed garments can now sit down, but the clothes are still far from pleasant. “It kind of looks like fake leather,” says Rothenberg—and though that’s not a bad thing in itself, it’s “very uncomfortable, and it sticks to you.”

When it first gained momentum in the early 20-teens, in the heyday of 3D printing, the idea of churning out clothing at home seemed within easy reach. But as with so many buzzy technologies, 3D-printed clothing refused to follow optimistic timelines, settling instead into a pattern of slow, stitch-by-stitch progress.

But as with so many buzzy technologies, 3D-printed clothing refused to follow optimistic timelines, settling instead into a pattern of slow, stitch-by-stitch progress.

Few people know this better than Aaron Rowley, who in 2013 cofounded Electroloom, a startup for 3D-printed apparel. At first he enjoyed significant attention from big fashion brands, before watching them drop out one by one as their hopes faded. “There was this thought that people were going to want to print a spare hammer at their house,” Rowley says of the heady, hype-y days of 3D printing, which peaked around the time of Electroloom’s launch. Clothes seemed like a natural extension of that idea — a universal, everyday item that had the bonus of needing regular replenishment. But the similarities ended there. “Fundamentally the process to make a fabric is just so different from making a solid good,” Rowley says.

Most Popular

“Textiles are an extremely mature technology,” says Scott Hudson, a researcher at Carnegie Mellon who has collaborated with Disney to 3D print soft materials. Calling textiles a technology is not an exaggeration, because the loom is often considered an early version of a computer. In the mid-1700s, Joseph Marie Jacquard figured out how to store fabric designs on a punch card, which set the pattern for the loom to weave and automated the process.

Calling textiles a technology is not an exaggeration, because the loom is often considered an early version of a computer. In the mid-1700s, Joseph Marie Jacquard figured out how to store fabric designs on a punch card, which set the pattern for the loom to weave and automated the process.

3D printing has not had the benefit of the same level of refinement. With 3D printing, Hudson explains, “you run into this trade-off between stiffness and robustness.” Because 3D printers build objects by depositing layers of melted plastic one on top of the next, the layers fuse together in a manner wholly unlike the way fibers become fabric.

In Electroloom’s case, Rowley and his collaborators took the raw components of fabric and created blends closely resembling those of existing textiles. When he set out to print his designs, however, his 3D printer spat out what he says looked like a “chaotic web.” It took countless iterations before they wound up with a soft flexible, foldable, lightweight, fibrous material that superficially resembled fabric. But even that concoction didn’t work. Give it a tug, and the material would tear. No good for clothing.

But even that concoction didn’t work. Give it a tug, and the material would tear. No good for clothing.

“When you have these fibers physically bonded [as in 3D printing], they aren’t going anywhere, whereas with a woven textile the fibers move and slide along each other,” Rowley explains. Electroloom shuttered last October.

Until the material problem gets solved, 3D-printed clothing will continue to look a whole lot more like an art project than an actual industry. One year ago, threeASFOUR’s dresses landed in the Costume Institute’s exhibition at the Met as part of the annual May event funded by “fashion’s biggest night out”—the Met Gala. Along with the gala, the 2016 exhibition, titled Manus x Machina, riffed on the role of technology in fashion, compelling celebrities to show up clad in a sea of silver and Zayn Malik to strut around with robot arms — efforts at futurism that were easily eclipsed by threeASFOUR’s otherworldly designs.

This year, threeASFOUR has a new 3D-printed dress: a blue-and-white ombre latticework piece that encases a mannequin in the studio. It was printed in 30 pieces that were then carefully assembled. “Like an airplane,” Asfour says.

It was printed in 30 pieces that were then carefully assembled. “Like an airplane,” Asfour says.

Asfour would prefer it to be less like an airplane, and for the garment to emerge from the printer more or less ready to wear. “We are hungry for the new technology,” he says. “I feel like there is this tremendous opportunity awaiting.”

Meanwhile, other aspects of apparel, such as jewelry and athletic wear, are taking to 3D printing with much greater success. Nike and Adidas are using 3D printing to create high-performance padding and shoe soles, which typically are made out of foam with a uniform stiffness. The goal is to create a sole with “the perfect energy absorption for your foot — making it more stiff where there’s more pressure, and more flexible where there is less pressure,” Rothenberg says. NASA has a project more in line with Pangolin: a 3D-printed chain mail material meant to protect astronauts from the elements.

Or maybe not just astronauts. Though shirts and pants still rely on traditional manufacturing, protective armor might soon be ready for printing at home. Just in case there’s a revolution. Or an alien invasion. Or you need to dash for the border.

Just in case there’s a revolution. Or an alien invasion. Or you need to dash for the border.

Freelance journalist aka modern day cowboy. Frequent quoter of 30 Rock. Articles @backchnnl, @sciam, @thscienceofus ++

TopicsBackchannel3-D printing

More from WIREDDress on a 3D printer (from NOT smart sequins) / Sudo Null IT News

Prologue

Hello everyone! We develop "smart sequins" - electromechanical color-reproducing devices for designer clothes. The results of the previous stages of work can be found here, here and here.

After the not-too-successful end of our crowdfunding campaign, we continued our work.

Today I will tell you how we printed our first dress on a 3D printer!

What is it all for

After reading sci-fi, we decided that we could make clothes that could change their color and texture at the request of the owner!

For this, miniature electromechanical devices designed to be placed on fabrics were invented, we called them “smart sequins” (by analogy with the shiny plastic scales known to everyone).

Combined into a matrix, they form a kind of monochrome LED display. The difference is that each pixel works on reflected light. This principle allows you to minimize the power consumption of the matrix when displaying static images. Energy is spent only at the moment of switching sequins.

Here's what we've already done:

Overview of existing solutions

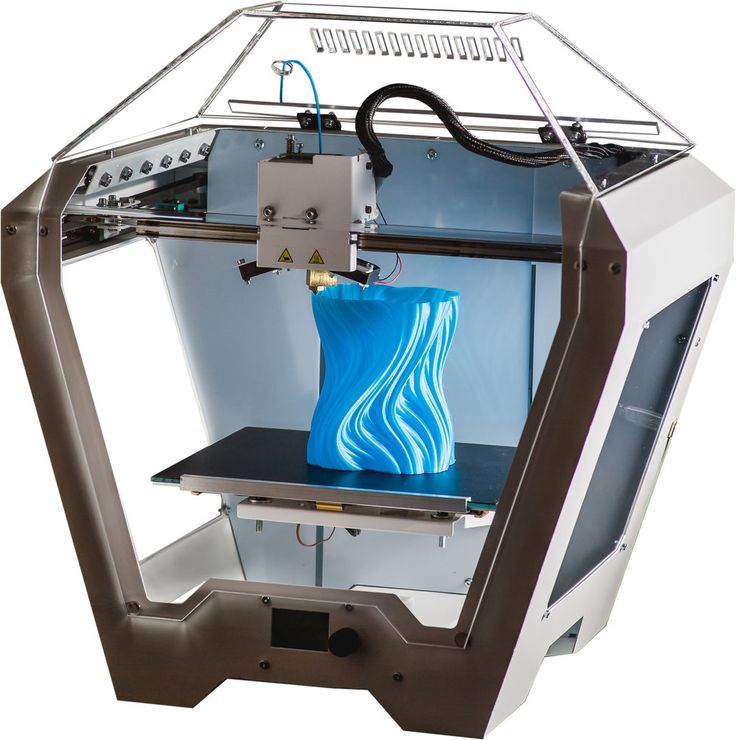

The fashion industry is one of the most dynamically developing areas. At each regular show, designers present their unique works. Some of the models… have little to do with reality… But fashion design is a kind of art, so it should not be utilitarian.

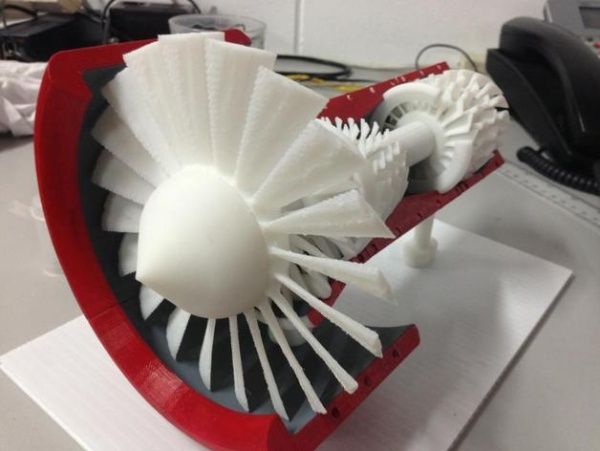

No wonder we weren't the first to come up with the idea of using 3D printing to make garments. The list of projects below is by no means exhaustive, but these examples give a good idea of the concepts and technologies behind 3D printed clothing.

-

In 2014, Nervous System introduced the world to its SLS 3D printed dress. The key feature of the project is that the dress consists of many triangular elements connected to each other by means of hinges.

The whole dress was printed folded as a single piece. And then "fixed". The company's website even has a small 3D editor that allows you to create your own dress or accessory.

The whole dress was printed folded as a single piece. And then "fixed". The company's website even has a small 3D editor that allows you to create your own dress or accessory.

-

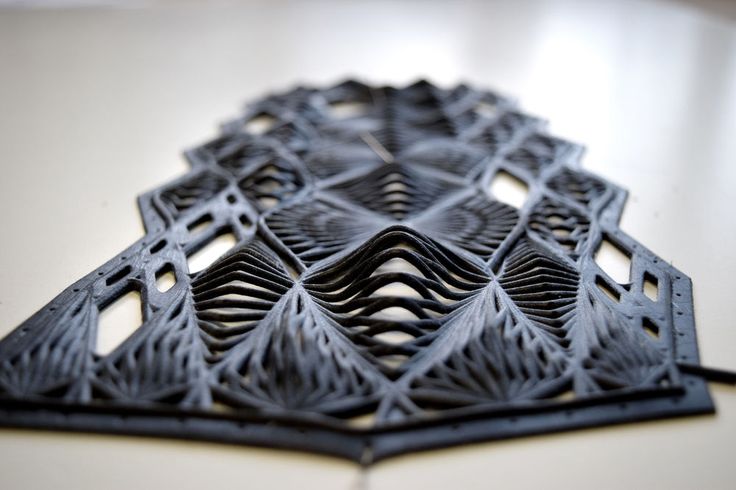

In 2016, Israeli student Danit Peleg created a whole collection of 3D printed clothes. A key feature is the ability to print with flexible plastics to create flexible webs that can be worked on like fabric blanks. Each canvas consists of individual fragments (limited by the printer's printable area), which are manually connected to each other. Not very technologically advanced, but cheap!

-

In 2015, Airwolf 3D, a 3D printing equipment company, introduced a rather interesting dress. Made on an FDM printer from ABS plastic, it consists of many rigid hexagonal "scales" that are connected to each other by means of hinges. As in the previous project, the individual pieces of the dress are printed separately and then connected to each other.

-

Another interesting concept from SHOREY DESIGNS. Dresses are made by printing with a conventional FDM printer on mesh fabric. Although they then moved on to "sealing" small plastic rings to create a hinged connection between the pieces of the dress.

-

It is gratifying to see domestic developers in this list. The team of the Moscow Aviation Institute made a dress that was presented at Geek Picnic 2019. It is a pity that there is a vanishingly small amount of information on this project on the Internet. It's hard for me to determine what technology is behind this product...

By the way, have you noticed that almost everyone prints dresses? I wonder why it would be...

After studying all the available technologies for making clothes on a 3D printer, the choice was made in favor of forming structures on an elastic substrate.

Printing on mesh fabric

I have already talked about the method of 3D printing on mesh fabric in order to obtain individual blanks for clothing elements. This method formed the basis for the production of our dress. Why did we choose it?

This method formed the basis for the production of our dress. Why did we choose it?

First, the availability of FDM 3D printing. As well as a wide selection of materials with different properties.

Secondly, the ability to pre-weave conductive threads into the laying material for subsequent connection of individual sequins to each other.

Since the backing material has a large area when unfolded, it is not possible to print the whole dress in one run. Unless you have a printer in the next room with a working area of more than one square meter ...

There is an option where we divide the model into several parts, print the individual sections and then connect them to each other. But this is a rather laborious process.

We decided that we would combine the two approaches. Printing was done in separate sections, but the substrate material was not cut beforehand. Those. after forming one section, it was moved aside and the next one was printed. After the printing of all sections was completed, they turned out to be part of the whole canvas.

With the production technology decided, it's time to talk about design.

Choice of style

Needless to say, there are a huge number of different types of dresses. They vary in length, fit, construction, and more.

When choosing a style, we will be guided by two theses: conceptual and design.

Conceptual: clothing does not have to be an exact repetition of the shape of the body, it is a separate form that blends harmoniously with the human figure0005

A dress made of plastic elements with electronics inside will have a mass greater than traditional textiles (but not all), so we will definitely provide for wide straps, as well as fixing the product at the waist.

Since traditional clasps for dresses are not suitable here, lacing will be carried out at the back seam, as is done with corsets.

Here, in fact, all the tricks ...

Development of a design support tool

Having decided on the style, we need to decide on the shape of the future elements that make up the matrix. Moreover, the matrix must be flexible in order to repeat the curves of the figure. It has been experimentally established that matrices with round elements have the greatest flexibility. However, they also have a minimum "hiding power" (gaps between the elements). Therefore, the optimal shape of the matrix elements is regular hexagons (honeycombs).

Moreover, the matrix must be flexible in order to repeat the curves of the figure. It has been experimentally established that matrices with round elements have the greatest flexibility. However, they also have a minimum "hiding power" (gaps between the elements). Therefore, the optimal shape of the matrix elements is regular hexagons (honeycombs).

We need to do the following:

-

take the basic form of the dress pattern and “pave” it with hexagonal elements, observing the gaps between them;

-

split the resulting matrix into fragments according to the size of the print area of our printer;

-

convert each fragment to STL file, pass through slicer, get G-code for printer;

-

modify the G-code so that the printer pauses during the printing process, and we can lay a fabric substrate between the layers.

The first two steps can be done in your favorite CAD system, but manually rebuilding the matrices is a rather time-consuming process. In addition, with an increase in the number of matrix elements, the load on the computing power of the computer also increases. Therefore, we have developed a utility that allows you to design matrices and greatly simplify this process.

In addition, with an increase in the number of matrix elements, the load on the computing power of the computer also increases. Therefore, we have developed a utility that allows you to design matrices and greatly simplify this process.

MatrixCreator

The program is a graphical editor, at the output of which we get a set of STL files with fragments for printing, adapted to the print area of our printer. The program was created in the Processing environment.

A small tour of the program interface. The workspace is a mesh field. Each cell can remain empty or be “painted over” with one of 4 types of sequins.

How it works. We create several 3D models of single elements of the future matrix and convert them into STL format with the required facet size (I use KOMPAS3D). The resulting STL models are basic.

The dimensions of the sequins are as follows. The diameter of the inscribed circle of the hexagonal base is 10mm, the total height of the sequin is 3mm. I draw your attention to the fact that the origin of coordinates is located on the bottom face and is located in the center of the hexagon (this is important!). We check the resulting STL files in the Cura slicer and see that everything prints correctly.

I draw your attention to the fact that the origin of coordinates is located on the bottom face and is located in the center of the hexagon (this is important!). We check the resulting STL files in the Cura slicer and see that everything prints correctly.

Next, in the graphical editor of the program, we draw the configuration of the matrix (different types of elements are indicated by different colors). If desired, the drawn pattern can be saved to a text file via "SAVE PATTERN" and then used in new projects.

Then we indicate the dimensions of the print area "FRAGMENT SIZE" (how many elements we can print in one run). The program automatically splits your matrix into fragments for printing after pressing the "SPLIT" button. The resulting fragments for printing and their serial numbers are highlighted in the workspace.

After that, click on the "CREATE STL" button, and the program generates a set of STL files with fragments for printing. In this case, the base models are copied to the coordinates of the centers of the matrix cells and a new STL file is obtained. In this case, 4 files are automatically created. We check how the resulting files look in Cura.

In this case, 4 files are automatically created. We check how the resulting files look in Cura.

Like a mosaic is coming together. Moreover, the main field was filled with basic models of the same form. And along the edges (where we drew) there were basic models with holes. If you open one of the fragments in KOMPAS and measure the gap between the sequins, it turns out about 1 mm (an error of a couple of hundreds does not bother us).

We prepare the G-code and proceed to its modification.

Working with STL files ProcessingThe most interesting, as it seems to me, is working with STL files.

A bit of theory. STL is a storage format for 3D object models. Its peculiarity is that the model is stored in it as a surface, consisting, as a rule, of triangular faces (facets).

Let's open one of the files with notepad and see what's inside. The file must be in text (ASCII) format.

Begins with the keyword "solid" and ends with the keyword "endsolid". Everything between these keywords is our model.

Everything between these keywords is our model.

Next, the coordinates of the vertices and normal vectors of each facet of the model are described in turn.

"facet normal" - coordinates of the normal vector to the current facet.

Between the "outer loop" and "endloop" keywords, facet vertices (vertex) with X Y Z coordinates separated by spaces are listed.

You can simply read this file and place triangular planes at the specified coordinates and thus display 3D models. In fact, you don't even need normals. But Cura is very finicky, so if there is not even one vector, it will give a file read error. The same will happen if at least one facet is lost.

Facet vertex coordinates are specified in millimeters (specified during export). The countdown is from the center of the model (you need to look at where you had the origin of coordinates when building).

To shift the STL model relative to these coordinates, it is necessary to add the shift value to the corresponding coordinate of each point. We do not touch the normal vectors, because their shift in space does not change their direction.

We do not touch the normal vectors, because their shift in space does not change their direction.

The coordinates of the centers of the matrix cells are calculated in advance.

GcodeCorrector

A few words about G-code modification. Here I talked in detail about the whole process, I will not repeat myself.

Let me just say that in order to lay the fabric backing between layers when printing, we need to insert a pause command (M25) in the G-code before sending it to the printer. For this, a small utility was also written that allows you to view the trajectories. In it, you can specify before which layer you want to insert a pause and save the modified file.

Preparations completed, we can print!

Results of work

Printing took about 6 hours (an hour and a half for each of the four fragments). The print was made on glass. Heated table. Table temperature 60⁰C, nozzle temperature 220⁰C, blower off. The print material is PLA plastic. Layer height 0.2mm.

Layer height 0.2mm.

In order to identify all possible problems without spending too much time on printing, it was decided to work out all the nuances in miniature. We developed this model specifically for a 1:4 scale mannequin.

Due to the gaps between the sequins and the elastic properties of the backing fabric, the dress fit well on the figure of the mannequin. In concave places, the distance between the sequins has decreased, in convex places, on the contrary, it has increased. For "fitting" a small belt is used, which runs from the wrong side of the dress.

Not everything turned out perfect, some printing defects are visible from the back side ... But we are satisfied with the result. You can go to full-size models!

Links to program sources. And also on the CD with the release.

3D printed mesh fabric

Prologue

Hello everyone! I am developing "smart sequins" - electromechanical color-reproducing devices for designer clothes. Our team is passionate about the idea of creating clothes and accessories that can change their color at the request of the owner or depending on environmental conditions.

Our team is passionate about the idea of creating clothes and accessories that can change their color at the request of the owner or depending on environmental conditions.

In this article I would like to talk about how we used 3D printing in our project, share our experience and tools.

3D printing on fabric

One of the tasks that I had to solve was to figure out how to make an elastic fabric out of plastic sequins, which in its properties would resemble textile materials. At the same time, it is necessary to provide for the possibility of easily creating electrical connections between the sequins.

There are quite a few articles and materials about making clothes on a 3D printer. Many different methods have already been invented, from creating hinges right in the printing process to printing with elastic plastics.

While looking for a solution, I came across this video. From it, I first learned about the method of printing on mesh fabric using a conventional FDM 3D printer.

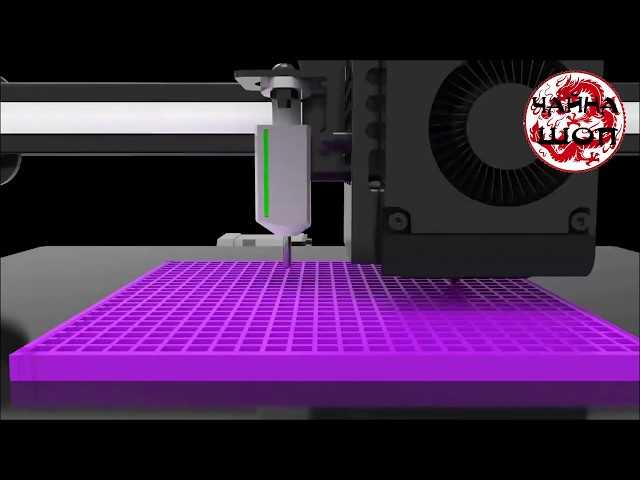

The author himself claims that he spied the idea here: Shorey Designs.

The essence of the method is very simple. We create a 3D model of a fragment of the future canvas, then arrange a lot of fragments so that we get a whole canvas. We start the slicer and prepare the G-code. Before sending it to the printer, you need to insert a pause and raise the extruder before printing a certain layer. The printer will stop during operation. At this point, we cover the printed layers with a mesh cloth. We continue to print. Due to the presence of large holes in the fabric, the layers of plastic will interlock with each other, as in conventional printing, and the mesh fabric will be firmly integrated into the parts.

Modify G-code

I use Cura version 3.2.1 as a slicer. 3D printer - homemade H-bot controlled by a board based on ATmega2560 (RAMPS 1.4) with Marlin firmware.

To pause the printer, there is an M25 command. Command for lifting in Z by 20mm: G0 Z20. It is noteworthy that the M25 must go before the ascent, otherwise the next command is processed first. Why this happens is a mystery to me, apparently somehow connected with the processing of commands by the printer.

It is noteworthy that the M25 must go before the ascent, otherwise the next command is processed first. Why this happens is a mystery to me, apparently somehow connected with the processing of commands by the printer.

Add commands to G-code:

Operation automation

Manually searching for the required line in the G-code file and inserting commands is not the most modern solution, I thought and wrote a simple program that allows you to open and view toolpaths.

For the convenience of viewing the layers, the "explode" command is provided, which allows you to visually increase the distance between the layers of the model. After pressing the "insert pause" button, the distance between the marked layer (red) and the previous one increases. This means that the print will be interrupted precisely between these layers.

To understand where one layer ends and the next begins, I used the comments that Cura kindly provides in its output files. The keyword ";LAYER:X" allows you to accurately find the boundaries of layers in a text file.

The keyword ";LAYER:X" allows you to accurately find the boundaries of layers in a text file.

Pressing the "write file" button allows you to save the modified G-code in the specified location.

Save the file to the SD card and bring it to the printer.

It's funny that only when preparing this article, I came across a video in which they tell how you can do the same thing using standard Cura tools ... But the process is already running, it's too late to slow down! Here, starting at 7:30, it is described in detail how to do it. Well ... hurry up - learn how to parse G-code!

Trying to print

Formation of the first layers. We print on glass. Heated table. Table temperature 60⁰С, printing temperature 220⁰С. The print material is PLA plastic. Layer height 0.2mm.

During the pause, lay down the fabric and fix with magnets. Since the table is aluminum (paramagnetic), we put the magnets on the top and bottom sides of the table. Fixation is made in 4 places, in the corners of the part. This is quite enough. The main thing is not to place them too close to the print area, otherwise the magnets will stick to the print head.

Fixation is made in 4 places, in the corners of the part. This is quite enough. The main thing is not to place them too close to the print area, otherwise the magnets will stick to the print head.

After 40 minutes, this is the structure. The thickness of each 6 carbon element is 1mm. The gap between the elements is 2mm.

In this experiment, tulle was used as the backing fabric. It is a lightweight mesh fabric of medium stiffness, woven from polyester threads.

Experiments have also been made with mosquito net printing. In the hardware store, there were two types of them: fabric and fiberglass. Fabric mesh is softer than tulle, but has greater mechanical tensile strength, as well as less elasticity. The fiberglass mesh is harder than tulle, its mechanical strength is the highest of all participants in the experiment.

Hexagonal sequin printing on fiberglass mosquito net. The gap between the elements is 1mm. The matrix is very hard.Clearance is clearly not enough.

Round sequin printing on fiberglass mosquito net. The gap between the circles is 2mm. It has a lot of flexibility, but there is too much unfilled space between the sequins.

After several test prints, the fabric mesh was chosen. She formed the basis of the matrix of smart sequins. The resulting matrix can bend in all directions.

The video demonstrates the operation of the program, the printing process and the final result.

Conclusion

The method of printing on the net fabric proved to be very good. This is an ideal solution for our task, because the fabric substrate allows us to weave conductive threads into it, which are used to provide electrical connection between the individual sequins of the matrix. Moreover, the formation of a “pattern” of conductors can be carried out at the preparatory stage.