Sq4D 3d printed home

SQ4D 3D prints 1,900 sq ft home in 48 hours

0Shares

SQ4D, an offshoot of the New York-based S-Squared 3D Printers (SQ3D), has completed construction of a new building, in what it claims is the “largest permitted 3D printed home in the world.”

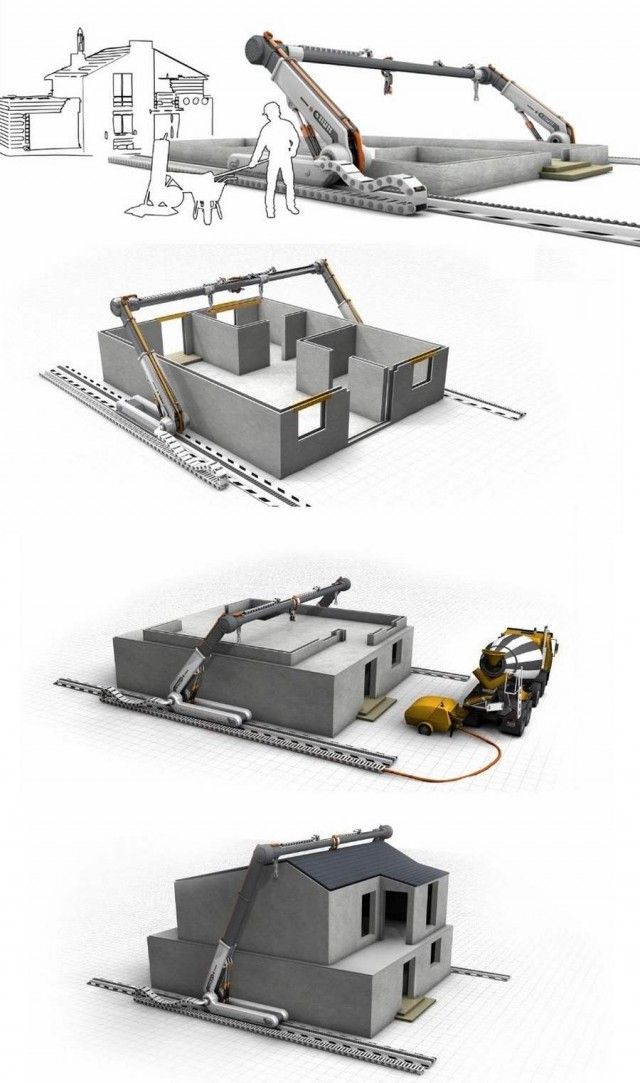

Although many are seeking to claim various titles, the size of the structure is certainly grand, spanning 1900 square feet. Even more impressive is that construction of the 3D printed home reportedly took place over an eight-day period, with a total of 48 hours in print time. It was entirely printed and built onsite, while using less than $6000 in materials. The large 3D printed home was built using SQ4D’s patent-pending Autonomous Robotic Construction System (ARCS) technology, designed for construction 3D printing applications.

SQ4D’s 3D Printed Home. Photo via SQ4D.Autonomous Robotic Construction System

SQ3D, based out of Long Island, NY, is a 3D printer manufacturing and service company. In 2019, the company branched out to SQ4D, a firm focused on revolutionizing the housing and construction industries using 3D printing, specifically its ARCS technology.

SQ4D’s ARCS technology was initially unveiled in 2018. Capable of constructing homes, roads, bridges, and commercial buildings, the specialized ARCS 3D printer has been described as being able to outperform traditional construction methods by reducing both time and cost up to 70%.

SQ4D explains that the system is able to reduce the labor required to construct a home for as little as 3 people, accounting for up to 41% of the total construction of a house. It eliminates over 20 manual labor-intensive processes like siding, framing, sheathing, etc., helping to achieve faster build times. These 3D printed structures are said to be mold and fire-resistant and built to withstand severe weather.

Previously the ARCS system had been used by SQ3D to build a 500-square-foot home with less than 12 hours of print time. Now that construction of the larger 1900-square-foot home is complete, SQ4D has explained that it expects the print-time of houses to be halved in the future thanks to additional enhancements implemented within ARCS technology.

The possibilities of 3D printed homes

The field of 3D printed homes is heating up in both size and scope. Recently, a 3D printed two-story building, standing at 9.5 meters tall with a total area of 640 square meters (around 6888 square feet), was unveiled in Dubai. Developed by 3D printing construction firm Apis Cor, in collaboration with the University of Nantes, it was built in Warsan, and has undergone a year of testing, meeting all the required building standards. It holds the Guinness World Record for the largest on-site 3D printed construction. Significantly, the 3D printed home is the latest in a series of developments for 3D printing construction in Dubai, in a bid to realize the city’s vision for 2025 where at least 25% of every new building in the city will be 3D printed.

Texas-based construction technologies company ICON, along with non-profit organization New Story, has been hard at work in Tabasco, Mexico as it seeks to construct a community of 3D printed homes for low-income families in the area. Thus far, two 500-square-foot liveable homes have been built, with plans for 50 homes in total to be 3D printed.

Thus far, two 500-square-foot liveable homes have been built, with plans for 50 homes in total to be 3D printed.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows SQ4D’s 3D Printed Home. Photo via SQ4D.

Tags ARCS Autonomous Robotic Construction System S-Squared 3D Printers SQ3D SQ4D

Anas Essop

Anas Essop is an English and Film graduate, who loves writing about the advancement of technology.

Are 3D-Printed Homes the Answer to the Housing Shortage?

Casey Dunn

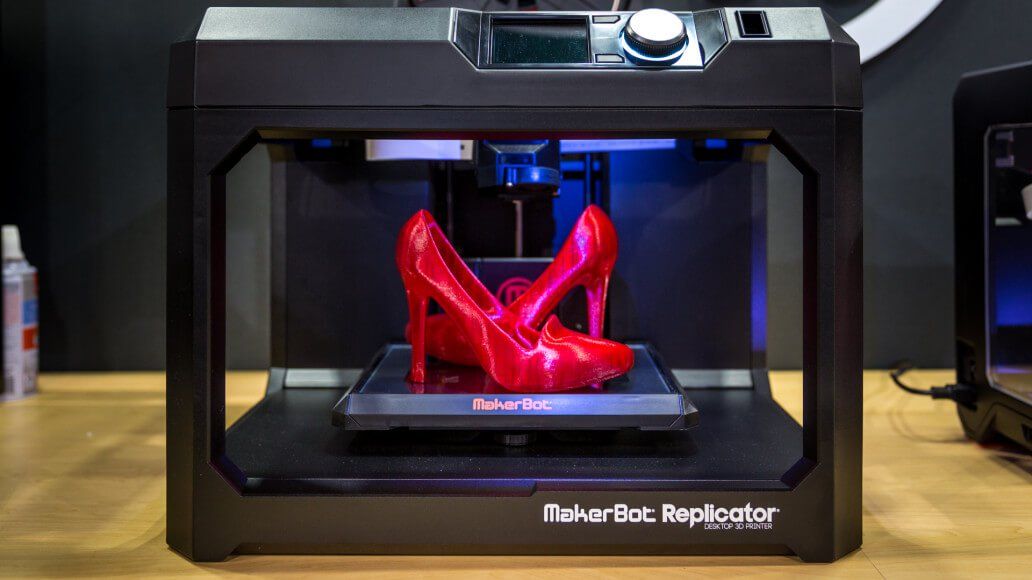

House hunters have their work cut out for them. A limited number of available houses combined with soaring home values have thrown a wet blanket on the hopes of many would-be buyers. Enter 3D house printing: Though the technology is still in its infancy, it’s making a big splash in the building world. In 2021, we reported on the first 3D-printed home to hit the market in Riverhead, New York. Since then, 3D-printing construction companies have been ramping up production and one day, these affordable, cutting-edge homes might represent a significant share of the housing market.

Enter 3D house printing: Though the technology is still in its infancy, it’s making a big splash in the building world. In 2021, we reported on the first 3D-printed home to hit the market in Riverhead, New York. Since then, 3D-printing construction companies have been ramping up production and one day, these affordable, cutting-edge homes might represent a significant share of the housing market.

When the Covid-19 pandemic took hold in 2020, supply chains—including those in the building material industry—tightened, driving up prices for new-construction homes and reducing the number of new housing starts. Zillow data suggests that the meteoric rise of home values will tick down somewhat at the beginning of next year. As long as strong demand for houses continues to outpace inventory, though, market conditions will likely remain tight through 2023.

RELATED: This New Construction-Grade Building Material Recycles the World’s Worst Plastics

How can 3D printing help?Thanks to supply chain problems builders are still struggling to source construction materials, which adds to the time it takes to build a traditional house. The 3D-printed home in Riverhead, N.Y., was built by SQ4D, a pioneer in the industry. Since then, SQ4D also has constructed the largest 3D-printed home.

The 3D-printed home in Riverhead, N.Y., was built by SQ4D, a pioneer in the industry. Since then, SQ4D also has constructed the largest 3D-printed home.

It takes two workers just 6 to 8 hours to get the printer ready, and then the machine can print at an average speed of 400 to 700 inches per minute. While a traditional house averages at least 7 months to finish, a 3D-printed house can be ready to move in 2 or 3 months after construction begins.

Regan Morton Photography

Cost Comparison: Traditional vs. 3D-Printed HomesThere isn’t just a demand for houses in America—there’s a particular demand for affordable houses. Zillow estimates the value of the average home in America will be around $400,000 at the end of February 2023. Many types of construction materials have doubled (or even tripled) in cost in the past couple of years—for example, the steel mill price index was up 127 percent in 2021. The good news is that the price of concrete has not increased at the same rate as other materials.

Alquist, the construction company that built the first 3D-Printed Home for Habitat for Humanity, says that they were able to build the Virginia home for an estimated 15 percent per square foot less than it would have cost had it been stick built.

iconbuild.com

Where can buyers find 3D-printed houses?The technology is new and still relatively rare, so 3D-printed homes are probably out of the question for most homebuyers. However, companies like ICON, a Texas-based builder launching a 100-home, 3D-printed housing community in Austin, Texas, are looking to change all that. The issue isn’t a lack of demand for the homes but rather a lack of the massive 3D-printing machines required to construct the houses. As the machinery becomes more widely available, the number of builders creating 3D-printed dwellings will likely increase.

Regan Morton Photography

The Pros and Cons of 3D-Printed ConstructionWe may well see the day soon on which homebuyers can easily schedule a walk-through of a 3D-printed home, or even have one built to their custom specifications. While opinions may differ, many will agree that the benefits of 3D-printed construction outweigh the concerns.

While opinions may differ, many will agree that the benefits of 3D-printed construction outweigh the concerns.

- It takes just 2 to 3 months to build a 3D-printed home.

- Buyers can save 15 percent or more over traditional construction costs.

- Eco-friendly, 3D-printed homes reduce the number of trees that must be harvested for homebuilding.

- Reduced demand for jobs in the homebuilding industry

RELATED: Would You Buy a 3D-Printed House? Take a Peek Inside the First of Its Kind to Hit the Real Estate Market

iconbuild.com

What’s the long-term outlook for 3D-Printed houses?It’s been more than a year since the first 3D-printed house hit the market and since then, more construction companies have invested in the machinery that makes computer-automated building possible. Concrete is structurally sound, durable, and less expensive than other construction materials.

While it’s likely to be years before 3D-printed homes are the rule rather than the exception, the current trend points toward a more sustainable, affordable way of building. In time, 3D-printed homes could very well be a solution to housing shortages.

How are the 3D printed houses?

The idea of 3D printed houses has been around for a long time. In this article, you will learn about the first projects of 3D printed houses, brought to reality.

Let's face it, 3D-printed houses are still quite the out-of-the-box trend. Although construction 3D printing has been in development for several years, it is only recently that some “real” projects have seen the light of day. We are still far from technology replacing traditional building methods. But with each new project, the technology is becoming more and more popular.

This is partly due to the many benefits of 3D construction printing. For example, the cost of a 3D printed house can be much lower than an equivalent house built in the traditional way. In addition, the cost of construction is also much less.

In addition, the cost of construction is also much less.

To interim fix the first results, this article will focus on some "first" 3-D projects. These buildings will always remain important to the construction 3D printing industry as they set the stage for future advances in the field.

Germany's first 3D printed house

Germany is a country often associated with cutting-edge engineering, so let's start our list with the world's first 3D printed house in Germany.

The house itself is located in Beckum, a city that is part of North Rhine-Westphalia, next to the Netherlands and Belgium. And that's important because it's the first 3D printed house to be fully certified to the national government's building codes. The implications of such an achievement are expected to pave the way for many other 3D printing construction projects in Germany as well as the rest of Europe.

The project is a collaboration between Peri, a German construction company, and COBOD, a Danish firm that specializes in 3D construction printing technology. Peri is a large corporation operating not only in Germany, but throughout the EU. They have many products, including scaffolding and formwork solutions, that every construction site needs.

Peri is a large corporation operating not only in Germany, but throughout the EU. They have many products, including scaffolding and formwork solutions, that every construction site needs.

Peri followed the construction 3D printing business for many years before acquiring a stake in COBOD in 2018 to further develop the technology. Both parties started building the house in Beckum just two years after the acquisition of the share.

COBOD BOD2 Modular Concrete 3D Printer was used for a printing process that took just over 100 hours.

First privately owned 3D printed home in the US

There have been several 3D printed homes built in the US, but CNN claims this is the first officially owned home. Alquist 3D has partnered with Habitat for Humanity Peninsula and Greater Williamsburg to design, develop and build the home.

From a distance, you might think that this is an ordinary house. However, as you get closer, the layered concrete structure of the walls reveals the building's secret: it's made using 3D printing.

Surprisingly, the concrete structure of this 1,200-square-foot home was completed in about 12 hours, significantly faster than traditional construction methods would have allowed.

Reportedly, the house was bought by April Springfield, who will live there with her son and dog. She purchased the house through the Habitat for Humanity housing program. Given that the goal of the non-profit organization is to make a positive impact on the global housing crisis, it makes sense to use 3D printing to create homes that can be offered at very affordable prices, thereby making many people's dreams of owning a home come true.

The first five-storey 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story apartment building with a height of 10 meters, making it the tallest 3D printed building.

The building is located in Suzhou Industrial Park in Jiangsu Province in east China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at WinSun designs, you can't help but notice that they look like they weren't even 3D printed. Typically 3D printed structures are gray in color and clearly show layer lines. But WinSun loves to add some color and make the walls smoother, making their projects more like the buildings we're used to. Although it is not stated how they do it, we assume that the workers manually level the walls.

First 3D printed biodegradable house

Most 3D printed buildings are made from some sort of concrete mix. But this project is different. With the aim of creating housing solutions with virtually no environmental impact, the Italian company WASP 3D printed the Gaia house using soil and agricultural waste.

To create the perfect blend of wall materials, WASP partnered with Ricehouse, a company that specializes in the use of natural and agricultural materials such as clay and rice in construction.

The house is called Gaia because the soil is used as a binder in the walls. In fact, 25% of the mixture contains local soil as well as 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

In addition to the mix of materials, innovations are also reflected in the design of the walls themselves. A special corrugated structure was used to provide ventilation on warm days as well as insulation during cold periods, virtually eliminating the need for air conditioning.

The Gaia House is indeed a small building of about 215 sq. m. ft. However, the wall printing only took 10 days, and the estimated cost of materials is just under $1,000.

AirBnB's first 3D printed house

There are many different types of accommodations on AirBnB, but what about a 3D printed house?

The so-called Fibonacci House is the first 3D printed house to be booked through AirBnB. Given that it is located in rural British Columbia, this is a wonderful and exciting place to stay.

Although it may seem small, the house has a lot to offer. In fact, the internal area is approximately 375 square meters. feet, which is enough to accommodate up to four people.

The house's concrete walls were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced off site in just 11 days from material provided by Laticrete. The parts were later delivered and assembled at their current location.

So how much does a visit cost you? It's hard to tell if you're visiting AirBnB as there aren't any available places, but in 2021 Designboom said it was $133 per night.

The first floating 3D printed house

Prvok is not only the first 3D printed house in the Czech Republic, but also the first floating 3D printed house in the world, as it stands on a pontoon.

Scoolpt, a construction 3D printing startup, is responsible for this project, which took just 22 hours to 3D print the concrete structure of a houseboat.

Approximately 465 sq. feet of living space divided into a bathroom, bedroom and living room with kitchen. And while weight isn't usually discussed in the context of houses, given that this one stands on water, it's interesting to note that Prvok weighs 43 tons, according to its creators.

Since the house is separated from the ground, it has a built-in recirculating shower and tanks for drinking and industrial water. All things considered, the house should last at least 100 years.

Europe's first inhabited 3D printed house

Even in the past few years, 3D printed houses have mostly been showcases designed to showcase the possibilities of the technology. Most have no record of anyone actually driving into them. That changed back in 2017 when the couple moved into a 3D printed house located in Nantes, France, making the Yhnova house the first of its kind to be inhabited in Europe.

The house was created as part of a project between the University of Nantes and the Nantes Laboratory of Digital Sciences. And besides the main claim to fame, a very interesting aspect of the project is the specific technique used in its construction, which came from BatiPrint3D. Instead of 3D printing a concrete structure, the manipulator created wall shells from polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

And besides the main claim to fame, a very interesting aspect of the project is the specific technique used in its construction, which came from BatiPrint3D. Instead of 3D printing a concrete structure, the manipulator created wall shells from polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

In total, it took 54 hours to complete the 3D printing phase of the construction process. However, it took a little over 4 months to complete the construction. This was mainly due to the fact that the roof, doors, windows and installations were made using conventional means. But it doesn't help that the Yhnova isn't all that small, with about 1,025 feet of interior space.

India's first 3D printed house

India's first ever 3D printed house was built back in 2020. The project was carried out by a construction 3D printing startup called Tvasta, which was founded by graduates from the Indian Institute of Technology in Madras. In fact, the campus of the institute in Chennai was chosen as the site for construction.

In fact, the campus of the institute in Chennai was chosen as the site for construction.

The significance of this project lies in its impact on the housing crisis worldwide and in India in particular. The ability to build such a structure in a matter of days and for a minimal fraction of the cost of a standard equivalent home demonstrates the possibility of greatly reducing the country's housing crisis.

The internal area is 600 sq. m. feet, which is distributed in a simple layout with one bedroom and a combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the pieces were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground.

Africa's first 3D printed house

Back in 2019, the construction of Africa's first 3D printed house by Spanish firm Be More 3D began in the Moroccan city of Ben Guerir. The project was born out of the group's participation in Solar Decathlon Africa, an event that requires members to design and build homes powered only by the sun.

The project was born out of the group's participation in Solar Decathlon Africa, an event that requires members to design and build homes powered only by the sun.

For their application, Be More 3D made a 345 sq. feet, which was printed in about 12 hours. This feat earned them first place and the title of Most Innovative Startup.

Be More 3D didn't stop at Africa, it later created Spain's first 3D printing house and also developed its own concrete 3D printer in partnership with several corporations working in the automation and materials industries.

First 3D printed house in the US

Last on our list is the first 3D printed house for sale in the US.

This concrete house was printed on site by SQ4D, a company specializing in the development of robotic building systems. The building was built using the Arcs concrete extrusion system and the printed structure comes with a 50 year guarantee.

Behind the traditional exterior lies a large living space of 1407 sq. m. feet with three bedrooms and two bathrooms. There is also a detached garage for 2.5 cars.

m. feet with three bedrooms and two bathrooms. There is also a detached garage for 2.5 cars.

The house was listed on Zillow in January 2021 for $299,999 and has a pending offer at the time of writing. Considering the size of the house and the fact that its price is 50% less than the cost of comparable newly built houses in the area (according to the agency), we would say that this is a pretty good deal!

Source: all3dp.com

Read the article about the first 3D printed houses?

3D printing has been used in construction for several years now. In this article, you will learn about the first real houses printed on 3D printers.

3D printing of houses is still quite new to the layman. While construction 3D printing technologies have been developed for many years, only a few "real" projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

But with each new project, she is getting closer to becoming mainstream.

There are many benefits to 3D printing. For example, the cost of a 3D printed house can be much lower. And it will take much less time to build.

In order to draw a line under what has already been achieved in this area and show some interesting projects, we have devoted an article to the "first" and the best. These projects will always remain milestones in the 3D construction printing industry as they set the stage for future advances in the field.

First 3D printed house in Germany

Germany is a country often associated with cutting-edge engineering, so let's start our list with Germany's first ever 3D printed house.

The house itself is located in Beckum, a city that is partly located in North Rhine-Westphalia, next to Holland and Belgium. This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

The project is the result of a collaboration between German construction company Peri and Danish construction 3D printing firm COBOD. Peri is a large corporation that operates not only in Germany, but throughout the EU. Its portfolio includes many products, including scaffolding and formwork solutions that every construction site needs.

Peri followed the construction 3D printing segment for many years before acquiring a stake in COBOD in 2018. Now they are pushing the technology together and further. The construction of the house in Beckum began two years after the acquisition of the share.

For 3D printing at home, a BOD2 modular 3D printer from COBOD was used. The printing itself took just over 100 hours.

• Built: (started) September 17, 2020

• Commissioned: summer 2021

• Where: Beckum, North Rhine-Westphalia, Germany

• By: Peri, COBOD

First occupied 3D printed home in the US

Several homes have been printed in the US, but this home is the first officially occupied home, according to CNN. Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

From a distance, you might think that this is an ordinary house. However, when approaching it, the layered structure of the concrete walls becomes noticeable. After all, 3D printing creates an object in layers.

Surprisingly, the 111.5 square meter concrete structure of the house (was printed in about 12 hours, significantly faster than traditional construction methods would allow.

The house was reportedly purchased by April Springfield, who lives there with her son and dog She bought the house through Habitat for Humanity's housing program, and given that the nonprofit's goal is to help solve the global housing crisis, it makes sense to use 3D printing to create affordable homes that will make many people's dreams of home ownership come true.0003

• Built: 2021

• Commissioned: December 22, 2021

• Where: Williamsburg, Virginia, USA

• By: Alquist 3D, Habitat for Humanity Peninsula, Greater Williamsburg

The first five-story 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

The house is located in Suzhou Industrial Park in Jiangsu province in eastern China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at WinSun designs, you can't help but notice that they don't look like they've been 3D printed. Usually 3D printed structures are gray in color, the layer lines are clearly visible. But WinSun adds color and makes walls smoother. Nowhere is it stated how the company achieves the smoothness of the walls, but we assume that the workers smooth them by hand. WinSun projects are not like the ones we're used to.

• Built: Winter 2014

• Commissioned: Not specified

• Where: Suzhou, Jiangsu, China

• By: WinSun

First 3D printed biodegradable house

Can you guess that there is rice in the walls of this house?

Most 3D printed buildings are made from concrete mix. But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

WASP developed the sustainable blend in collaboration with Ricehouse, a company that specializes in using natural and agricultural materials such as clay and rice in construction.

The house is named Gaia in honor of the ancient Greek goddess of the earth. In fact, 25% of the mixture contains local soil, 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

An innovative solution not only in terms of material, but also in the design of the walls themselves. The specific corrugated structure was used to provide ventilation on warm days as well as insulation on cold periods, virtually eliminating the need for air conditioning.

Gay's house is small - about 20 square meters. The wall printing took only 10 days, while the estimated materials cost is just under $1,000.

• Built: not specified

• Commissioned: October 7, 2018

• Where: Massa Lombarda, Ravenna, Italy

• By: WASP, Ricehouse

AirBnB's first 3D printed home

The perfect weekend getaway.

You can find many different types of accommodation on AirBnB, but what about a 3D printed home?

The so-called Fibonacci house is the first 3D printed house to be offered for booking through AirBnB. Considering that it is located in rural British Columbia, it will be a wonderful place to stay.

Although the Fibonacci house looks small, it has a lot to offer vacationers. About 35 square meters is enough to accommodate up to four people.

The concrete walls of the house were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced offsite in just 11 days. The material was produced by Laticrete. The parts were later transported and assembled at their current location.

• Built: 2020

• Commissioned: Not specified

• Where: Kootenays, British Columbia, Canada

• By: Twente Additive Manufacturing

First 3D printed houseboat

Prvok is not only the first 3D printed house in the Czech Republic, but the world's first floating 3D printed house on a pontoon.

The project was implemented by the start-up company Scoolpt. The concrete structure of the houseboat took only 22 hours to print.

Approximately 43 square meters of living space divided into bathroom, bedroom and living room with kitchen. Weight isn't usually discussed in the context of houses, but given that this one is on water, it's interesting to note that Prvok weighs 43 tons.

The house is equipped with a built-in recirculating shower and tanks for drinking and municipal water and has a service life of at least 100 years.

• Built: June 2020

• Commissioned: August 18, 2020

• Where: Prague, Czech Republic

• By: Scoolpt

Europe's first 3D printed house

Not every 3D printed house has visible line layers.

More often than not, 3D printed houses are demos made to show what the technology can do. For most of them there is no information about the actual residents. But in 2017, the couple did move to live in a 3D printed house located in Nantes, France. Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

The house is a project of the University and the Laboratory of Digital Sciences of Nantes. An interesting aspect of the project is the special technique used in its construction by BatiPrint3D. Instead of 3D printing a concrete structure, the robotic arm created wall shells using polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

It took a total of 54 hours to print. It took a little over 4 months to complete the construction. Mainly due to the fact that the rest of the components were created using conventional means. House area - 95 square meters.

• Built: 2017

• Commissioned: March 2018

• Where: Nantes, France

• By: University of Nantes, Nantes Digital Science Lab

India's first 3D printed house

This building was built in a couple of days.

India's first ever 3D printed house was completed back in 2020. The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The significance of this project lies in its possible impact on the solution of the housing crisis worldwide and in India in particular. The ability to build such a house within a few days and at a low cost cannot be underestimated.

House 55.7 sq.m. with a spacious layout, one bedroom, combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the parts were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground.

• Built: 2020

• Commissioned: Not specified

• Where: Chennai, India

• By: Tvasta Construction

Africa's first 3D printed house

Back in 2019, in the Moroccan city of Ben Guerir, Spanish firm Be More 3D created Africa's first 3D printed house. The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

Be More 3D printed house 32 sq.m. in about 12 hours, took first place and received the title of the most innovative startup.

Be More 3D didn't stop building in Africa and later created the first 3D printed house in Spain and developed its own concrete 3D printer in partnership with several corporations from the automation and materials industries.

• Built: 2019

• Commissioned: Not specified

• Where: Ben Guerir, Morocco

• By: Be More 3D

First 3D printed home for sale in the US

Last on our list is the first 3D printed home for sale in the US.

This house was printed in the same place by SQ4D, a company specializing in the development of robotic building systems. The building was printed with SQ4D's Arcs concrete extrusion system and has a 50-year warranty on the printed structure.