Aurora labs 3d printer price

Revolutionary? Aurora Labs Reveals Their S1 Metal 3D Printer For Under $4,000 - 3DPrint.com

After reading the title of this article, many of you probably are thinking that this post must be some kind of extremely early April Fools joke. After all, most laser sintering machines, which work with metal alloys, cost upwards of $1 million, some even much more than that. Back in July of this year, we saw a company called MatterFab announce their entrance into the realm of more affordable powder bed fusion metal 3D printers. Although a price was not announced, speculation still has these printers priced well above what most individuals could afford (likely $80-$120k).

Today, a Perth Australia-based company, called Aurora Labs may have just opened the metal laser sintering 3D printer space wide open with the launch of a Kickstarter project for their S1, S2, and S2+ 3D metal printers.

There is no doubt that if the cost of metal 3D printers were to come down in price to under $10,000 that the world would change as we know it. There are only so many applications one can use printed plastics for. The ability to fabricate metal objects at the push of a button, from one’s own garage could be transformative, not only for the manufacturing industry, but society as a whole. This is why, if legitimate, the Aurora 3D printer Kickstarter project may be one of the most exciting projects we have seen yet.

Aurora Labs’ S1 Metal 3D Printer

The company is working on three different printers, starting at just $4,499 AUD (approximately $4,000 USD) for the S1, if you are one of their earliest backers. All three printers are capable of printing with a variety of metals, including:

- 316 Stainless Steel

- 420 Stainless Steel

- Inconel 625

- Inconel 718

- Hastelloy C

- Brass

- Bronze

- Mild Steel

- Over a dozen others

The main difference between the various printers, the S1, S2, and S2+, are their sizes, number of powder rollers, and price. Below is a quick comparison:

Below is a quick comparison:

- S1 – Build Envelope: 150mm x 150mm x 200mm, 2 powder feeders – Kickstarter Price: $3,998 USD

- S2 – Build Envelope: 150mm x 150mm x 200mm, 3 powder feeders – Kickstarter Price: $6,219 USD

- S2+ – Build Envelope: 180mm x 180mm x 500mm, 3 powder feeders – Kickstarter Price: $7,110 USD

Currently the printers can all use, both direct metal laser sintering, as well as powder bed fusion techniques. The S2 and S2+ will be capable of printing with multiple metals at once, and according to the company their internal testing showed that objects printed with these three machines had a 99.5% density level, similar to a high quality casting.

“We see a time in the near future where every engineering workshop has a couple of these and most homes have one as well,” stated the company. “With this machine people can build a 10,000 pound (4,500 kg) thrust rocket motor – for about the price of a plasma TV ($500-$1,000) in materials.

”

If this company does come through, it will certainly make waves within the industry. They have also stated that they are working on a selective laser sintering system for these printers, as well as a capability to print with plastics and ceramics as well. Let’s hear your thoughts on these incredible machines. Have Aurora Labs, and their founder David Budge actually figured out a way to bring metal 3D printers into the home affordably? Discuss in the Aurora Labs metal printer forum thread on 3DPB.com. Check out the company’s Kickstarter pitch video provided below.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: aurora labs • cheap 3d printer • DMLS • metal 3d printer • s1 metal printer • s2 printer

Please enable JavaScript to view the comments powered by Disqus.

Aurora Labs announces sales boost from the S-Titanium Pro in Q1 FY2019 report

0Shares

Aurora Labs, an Australian metal 3D printer manufacturer, has reported a boost in the sales of its metal 3D printer Aurora Labs S-Titanium Pro.

According to the most recent quarterly financial returns of the company, “Aurora is pleased with the continued progress from its S-Titanium Pro with sales revenue increasing to near 70% of the total of FY2018 in the first quarter of FY2019 with a good pipeline of future sales and enquiries.”

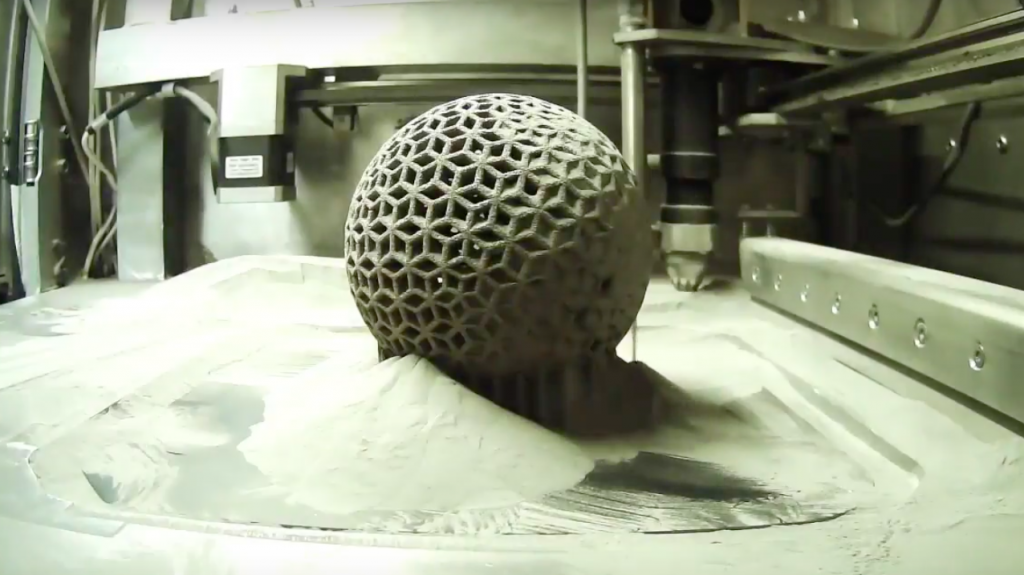

Metal 3D printed samples from Aurora Labs. Image via Aurora LabsAurora Labs S-Titanium Pro

In an earlier interview with 3D Printing Industry, Nathan Henry, Aurora’s Director of Marketing and Business Development, talked about the company’s commitment to bringing metal 3D printing to the masses. Priced at $49,999, the Aurora Labs S-Titanium Pro has helped build Aurora’s reputation in this direction.

The S-Titanium Pro weighs about 150 kg and has a build envelope of 200 x 200 x 250 mm. The 3D printer comes with three independent hoppers for powder loading and can print with a minimum layer thickness of 50 μm.

Aurora’s open source approach to materials lets the client use metal powders from third parties. This makes the S-Titanium Pro especially useful for research institutes who need the freedom to choose materials for specific experiments

This makes the S-Titanium Pro especially useful for research institutes who need the freedom to choose materials for specific experiments

Furthermore, the S-Titanium Pro has three different printing modes which can be used for different tasks. These modes are Direct Metal Laser Sintering (DMLS), Direct Metal Laser Melting (DMLM), and Directed Energy Deposition (DED), which is particularly used in the aerospace and automotive industry.

The S-Titanium Pro goes to university

This year, the Rey Juan Carlos University, Madrid acquired the Aurora Labs S-Titanium Pro. Joaquin Rams, Deputy Director of Applied Mathematics at the University, explained, “I consider the flexibility of the Aurora Labs S-Titanium Pro system perfect for academic use, as it allows modifying many parameters including types of powders and even mixtures of powder, which is not commonly seen in metal 3D printing systems. ”

”

Furthermore, two of the S-Titanium Pro 3D printers were installed in Denmark, including the Technical University of Denmark (DTU) in Lyngby.

In August 2018, Hyon Engineering in Germany also acquired the S-Titanium Pro. The company provides a range of 3D printing services to its clients in the aerospace and automotive sector.

Odon Szinyi, Managing and Technical Director at HYON Engineering, explained the motivation behind acquiring the S-Titanium Pro. Szinyi said, “The Aurora Labs S-Titanium Pro will be used to print parts for customers and the ULC.EVs (ultra-low-consumption electric-vehicles) we are developing.”

Szinyi continued, “It was the right choice for us due to the large build volume and it has excellent value for money considering 3D printers of this size and abilities often cost over more than a quarter million euro.”

In addition to making metal 3D printers more accessible, Aurora is also concerned with speeding up the process of 3D printed part validation. To achieve this end, the company has collaborated with the oil & gas and marine standards organization DNV GL, a partner of NAMIC on a marine 3D printing research project.

To achieve this end, the company has collaborated with the oil & gas and marine standards organization DNV GL, a partner of NAMIC on a marine 3D printing research project.

For the latest business news related to 3D printing, subscribe to our 3D printing newsletter. Also join us on Facebook and Twitter.

Visit our 3D Printing Jobs to start a new career in 3D printing.

Featured image shows metal 3D printed samples from Aurora Labs. Image via Aurora Labs.

Tags Aurora Labs S-Titanium Pro DTU HYON Engineering Joaquin Rams Odon Szinyi Rey Juan Carlos University Technical University of Denmark

Umair Iftikhar

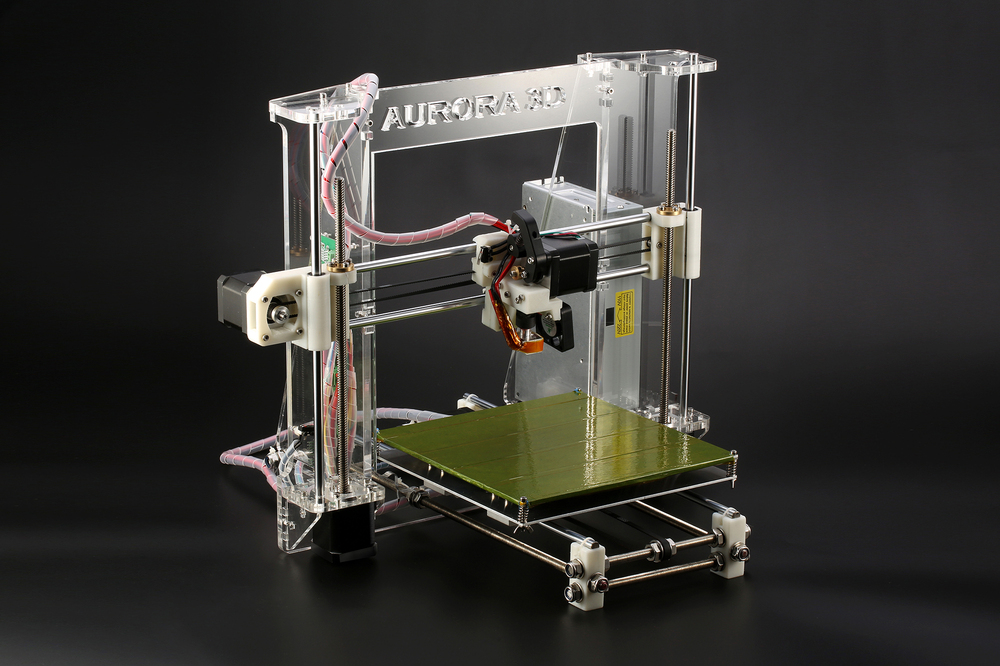

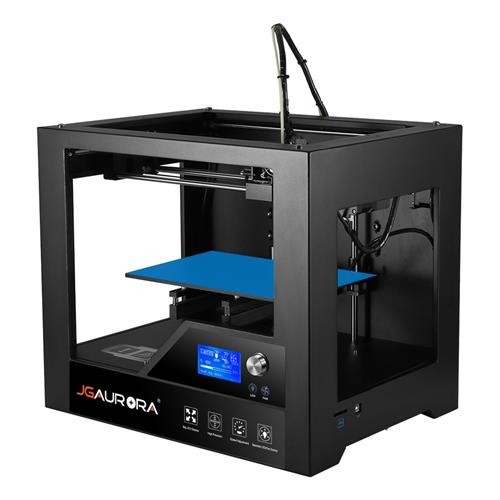

Aurora Labs S-Titanium Pro Metal 3D Printer Mini Review / Habr

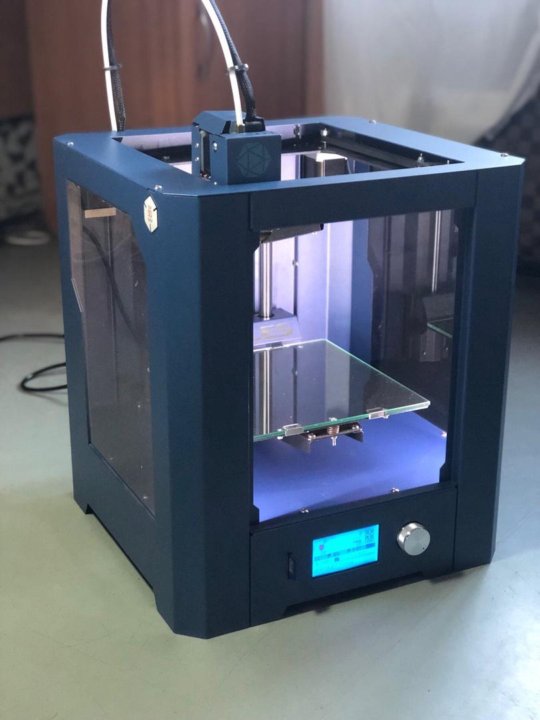

Hello! This is a mini review of the Aurora Labs S-Titanium Pro, a 3D printer that prints metal by fusing or laser sintering powder particles into a single whole.

S-Titanium Pro

Features

— Laser power: 300 W

– Layer thickness: 50 µm-150 µm

- Construction area: 200x200x250 mm

– Capacity: 150 kg

— XY resolution: 70 µm

- Particle diameter: 400 µm (0. 4mm)

4mm)

- Resolution Z: 25 µm

- Argon consumption: 8-11 l / min

— At first start: 25 l/min

— File format: STL/G-CODE

- Powder supply: 3 x 2.09 liter independently controlled hoppers

Site requirements:

– Space: 300x300x300 cm

- Weight (approx.): 200 kg

— Weight with packaging: 350 kg

— Good ventilation: air circulation at a rate of at least 7 room volumes per hour

About printer

The printer prints using DMLM (Direct Metal Laser Melting) and DMLS (Direct Metal Laser Sintering) technologies, that is, both direct laser fusion and direct metal laser sintering.

This feature allows one device to work with such different materials as stainless steels, cobalt-chromium and aluminum-silicon-manganese alloys, bronze, titanium and its alloys, Inconel, iron and nickel-silicon-boron.

Materials

Stainless steels:

Stainless Steel 304, 309, 316L

They are used in the production of a wide range of parts, the main requirement for which is resistance to corrosion. They are used literally everywhere, from construction and air conditioning systems, to dishes and jewelry.

They are used literally everywhere, from construction and air conditioning systems, to dishes and jewelry.

Cobalt Chrome:

CoCr ALEXIUM 21PM

and CoCr ALEXIUM 21PM Low C (low carbon)

Cobalt-chromium alloys are mechanically strong and resistant to acidic and alkaline environments, therefore they are used for the manufacture of dental crowns.

Aluminium-silicon-manganese alloys:

AlSi7Mg and AlSi10Mg

Strong structural alloys. They are used, in particular, in the production of rims, which speaks volumes about their mechanical properties.

Bronze:

Bronze LSM Brz10

Bronze is the oldest alloy known to man: at least 4000 BC. It is used everywhere: from plumbing and jewelry, to the manufacture of all kinds of figurines and monuments, from guitar strings and furniture fittings, to the shipbuilding and aviation industries, from washers and door handles, to medals of Olympic athletes.

Titanium and its alloys:

CP Ti, Ti6Al4V

Pure (CP - commercially pure) titanium and its alloys, due to their high strength and low weight, are among the most popular structural materials. Titanium is approximately equal in strength to steel, with almost half the weight. It is used wherever it is economically justified, since the material is not cheap. It is widely used in the construction of ships, aircraft and spacecraft. Titanium alloys are used to make elements of climbing equipment that are light and can withstand heavy loads.

Inconel:

Inconel 718

Inconel is an austenitic nickel-chromium alloy with high heat resistance and increased acid resistance, the combination of which is superior to tool steels. When heated, it forms a thin and durable oxide film on the surface, which performs protective functions. Inconel 718 has good weldability, which is not typical of the entire Inconel family. It is processed by slow deep cutting with a carbide tool, which makes it difficult to process it with traditional, non-additive methods.

Inconel 718 has good weldability, which is not typical of the entire Inconel family. It is processed by slow deep cutting with a carbide tool, which makes it difficult to process it with traditional, non-additive methods.

Iron:

Iron

In a relatively pure form (no more than 0.8% impurities), iron is used in electrical engineering, for the manufacture of components for batteries and transformers. It is widely used as an inexpensive material in cases where there is no need for long-term resistance to corrosion, as it is cheap, but easily reacts with oxygen and moisture. It can be used for the manufacture of decorative products, subject to mandatory painting or anodizing.

Boron nickel silicide

NiSiB (nickel-silicon-boron)

Nickel silicide is a component of high-temperature nickel alloys; alloys containing boron also have increased hardness. Adding this powder to the 3D printing mix will increase the hardness and heat resistance of the final product.

Adding this powder to the 3D printing mix will increase the hardness and heat resistance of the final product.

Sample prints

The test pieces were printed on an Aurora Labs printer.

Terminals

Since the printer operates in two modes, DMLS and DMLM, and can print a wide range of metal powders, it is the best solution for technical educational institutions and design offices.

Price and where to buy

The Aurora Labs S-Titanium Pro starts at $55,000 in the US.

This is the best metal 3D printer in its price range.

You can buy Aurora Labs S-Titanium Pro in Russia in Top 3D Shop: to find out the price of the printer in Russia and make a pre-order, write to us: [email protected].

Looking for 3D printers and other equipment for design, manufacturing, institute or college? Write to us, Top 3D Shop employees will help you choose equipment for solving any specialized tasks.

Want more exciting news from the world of 3D technology?

Follow us on social. networks:

Mini review of Aurora Labs S-Titanium Pro metal 3D printer

Hello!

This is a mini review of the Aurora Labs S-Titanium Pro, a 3D printer that prints metal by fusing or laser sintering powder particles into a single unit.

S-Titanium Pro

Features

- Laser power: 300 W

- Layer thickness: 50 µm-150 µm

- Construction area: 200x200x250 mm

- Capacity: 150 kg 400 µm (0.4mm)

- Z resolution: 25 µm

- Argon flow: 8-11 l/min

- First run: 25 l/min

- File format: STL/G-CODE

- Powder feed: 3 independently controlled 2. 09 liter bins

09 liter bins

Installation site requirements:

- Space: 300x300x300 cm

- Weight (approx.): 200 kg

- Weight with packaging: 350 kg rooms per hour

About the printer

The printer prints using DMLM (Direct Metal Laser Melting) and DMLS (Direct Metal Laser Sintering) technologies, that is, both direct laser fusion and direct metal laser sintering.

This feature allows one machine to work with materials as diverse as stainless steels, cobalt-chromium and aluminium-silicon-manganese alloys, bronze, titanium and its alloys, Inconel, iron and nickel-silicon-boron.

Materials

Stainless steels:

Stainless Steel 304, 309, 316L

Used in a wide range of parts where corrosion resistance is a key requirement. They are used literally everywhere, from construction and air conditioning systems, to dishes and jewelry.

Cobalt-chromium:

CoCr ALEXIUM 21PM

and CoCr ALEXIUM 21PM Low C (low carbon)

Cobalt-chromium alloys are mechanically strong and resistant to acid and alkaline environments, therefore they are used for the manufacture of dental crowns.

Aluminium-silicon-manganese alloys:

AlSi7Mg and AlSi10Mg

Strong structural alloys. They are used, in particular, in the production of rims, which speaks volumes about their mechanical properties.

Bronze:

Bronze LSM Brz10

Bronze is the oldest alloy known to man: at least 4000 BC. It is used everywhere: from plumbing and jewelry, to the manufacture of all kinds of figurines and monuments, from guitar strings and furniture fittings, to the shipbuilding and aviation industries, from washers and door handles, to medals of Olympic athletes.

Titanium and its alloys:

CP Ti, Ti6Al4V

Pure (CP - commercially pure) titanium and its alloys, due to their high strength and low weight, are among the most popular structural materials. Titanium is approximately equal in strength to steel, with almost half the weight. It is used wherever it is economically justified, since the material is not cheap. It is widely used in the construction of ships, aircraft and spacecraft. Titanium alloys are used to make elements of climbing equipment that are light and can withstand heavy loads.

Titanium is approximately equal in strength to steel, with almost half the weight. It is used wherever it is economically justified, since the material is not cheap. It is widely used in the construction of ships, aircraft and spacecraft. Titanium alloys are used to make elements of climbing equipment that are light and can withstand heavy loads.

Inconel:

Inconel 718

Inconel is an austenitic nickel-chromium alloy that combines superior heat and acid resistance to tool steels. When heated, it forms a thin and durable oxide film on the surface, which performs protective functions. Inconel 718 has good weldability, which is not typical of the entire Inconel family. It is processed by slow deep cutting with a carbide tool, which makes it difficult to process it with traditional, non-additive methods.

Iron:

Iron

In a relatively pure form (not more than 0.8% of impurities), iron is used in electrical engineering, for the manufacture of components for batteries and transformers. It is widely used as an inexpensive material in cases where there is no need for long-term resistance to corrosion, as it is cheap, but easily reacts with oxygen and moisture. It can be used for the manufacture of decorative products, subject to mandatory painting or anodizing.

It is widely used as an inexpensive material in cases where there is no need for long-term resistance to corrosion, as it is cheap, but easily reacts with oxygen and moisture. It can be used for the manufacture of decorative products, subject to mandatory painting or anodizing.

Nickel silicide with boron

NiSiB (nickel-silicon-boron)

Nickel silicide is a component of high-temperature nickel alloys, alloys with boron also have increased hardness. Adding this powder to the 3D printing mix will increase the hardness and heat resistance of the final product.

Sample Prints

The test pieces were printed on an Aurora Labs printer.

Conclusions

Since the printer operates in two modes, DMLS and DMLM, and can print a wide range of metal powders, it is the best solution for technical educational institutions and design offices.

Price and where to buy

Aurora Labs S-Titanium Pro starts at $55,000 in the US.