Arduino 3d printer instructables

Make Your Own 3D Printer for Under $60 Using Recycled Electronic Components with Instructables Design - 3DPrint.com

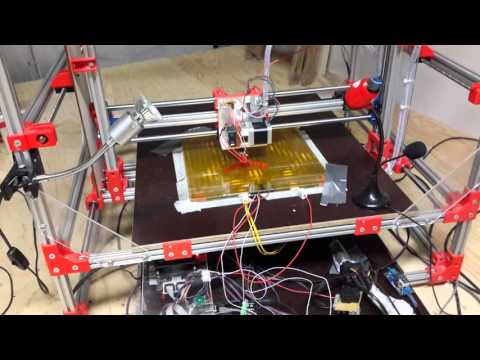

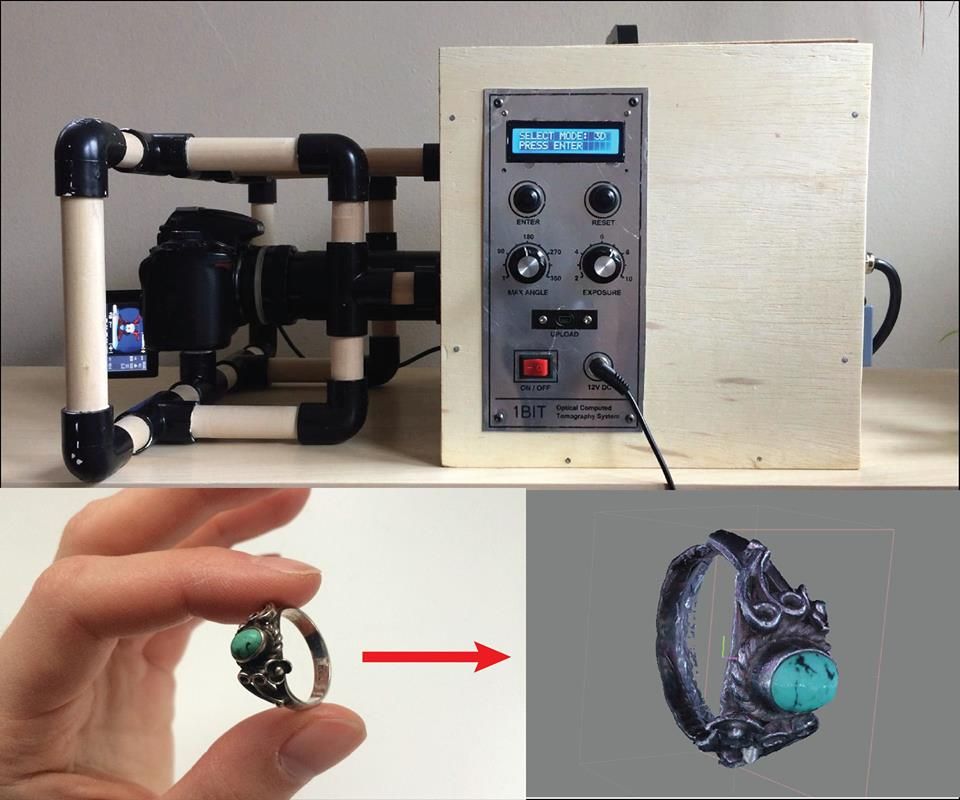

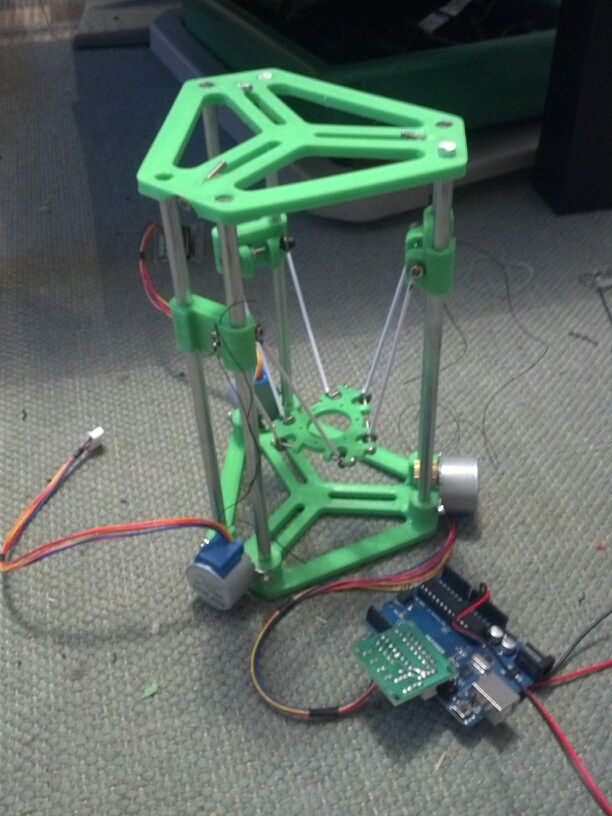

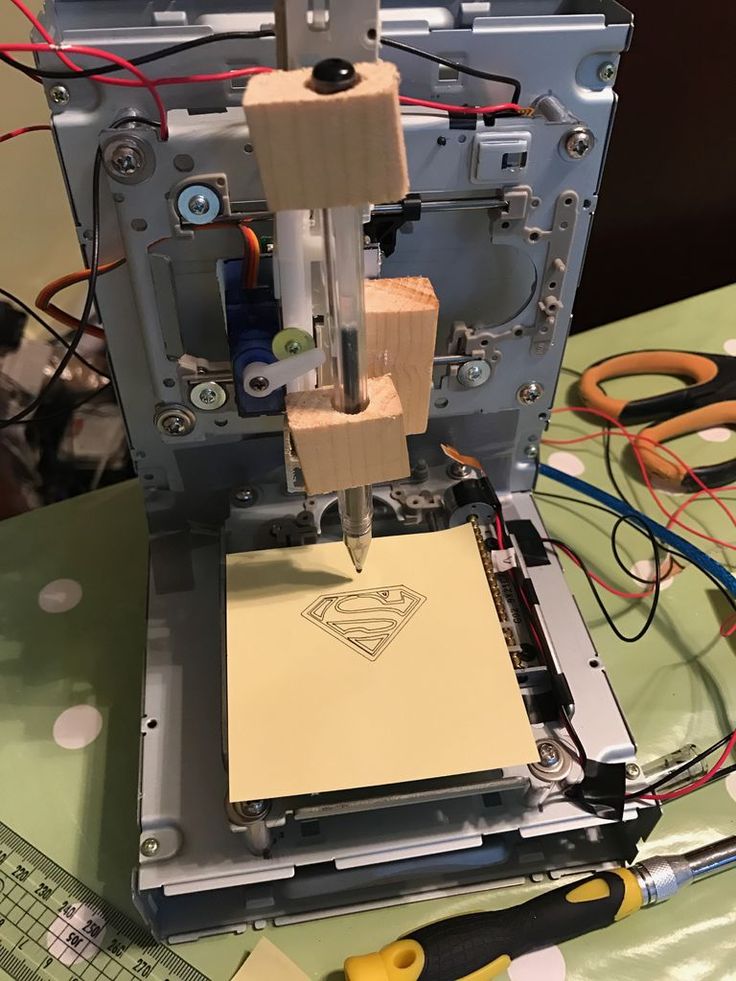

One of the obstacles to jumping headlong into the additive manufacturing milieu for many people is often the expense of the 3D printer itself. Further, for those intrepid, budding engineers, designers, makers, and artists, an initial foray might more reasonably and affordably involve using a less expensive and complex machine. Enter one Instructables contributor, “mikelllc,” who has designed a make-it-yourself 3D printer that is constructed largely from recycled electronic components.

Currently, only about 12.5% of all electronic waste, or “e-waste,” is recycled. Instead, the majority of cast-off electronic products — around 20 to 50 million metric tons per year worldwide — end up in incinerators or landfills. Many such products languishing in landfills can also release toxic chemicals into the air and soil, including high amounts of lead. So, repurposing electronic products makes great sense economically and ecologically.

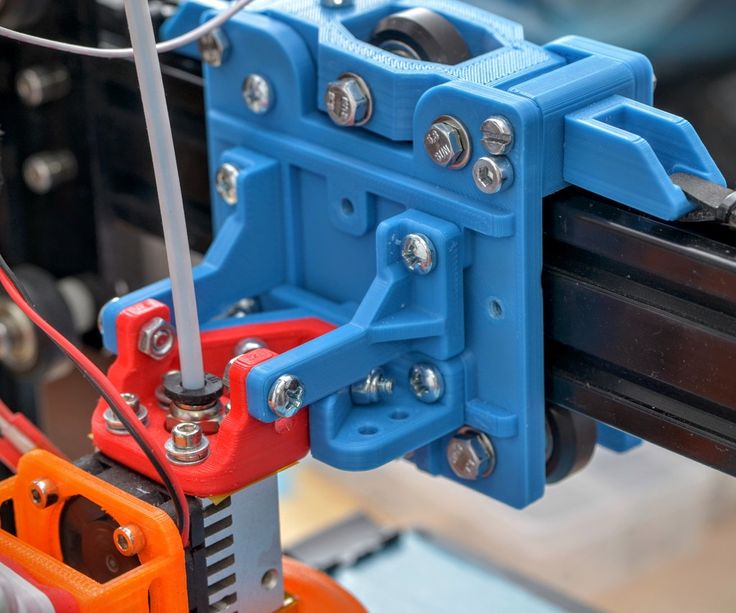

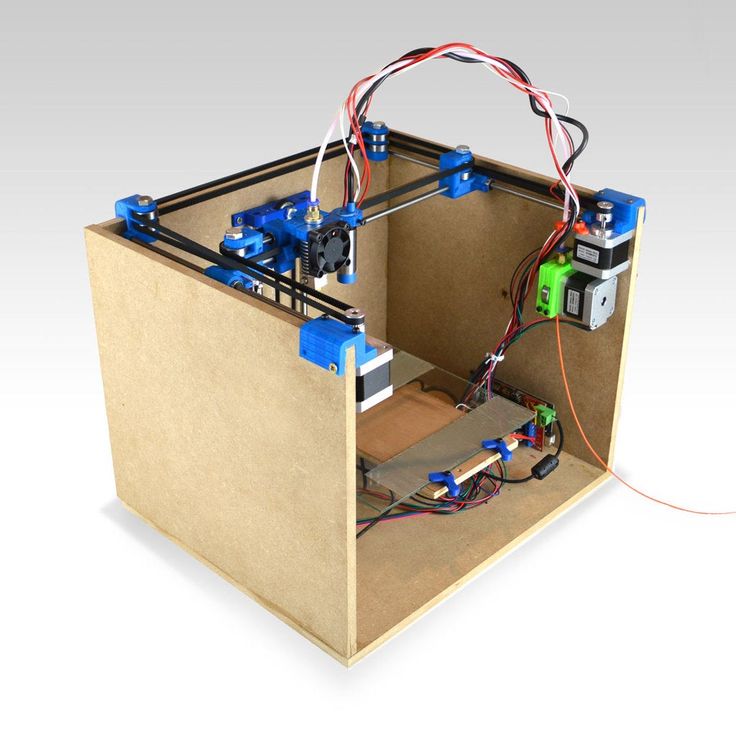

The EWaste $60 3D Printer is inexpensive to make given that you can round up the necessary components and follow the maker’s step-by-step instructions, which are clear and detailed. The process, in short, involves schooling yourself on “how a generic CNC (Computer Numerical Control) system works” and then programming your printer-in-the-making to respond to G-code instructions. With the addition and calibration of a plastic extruder, the tuning of the driver power, and other well-outlined and described steps in the construction process, you end up with a “small footprint” 3D printer that is comprised of upwards of 80% recycled components — an eco-conscious and budget-friendly alternative to springing for a new and potentially costly 3D printer.

One of the major selling points of this design for a 3D printer is that not only do you end up with a usable machine at the end of the process, but that the process of building and programming the thing yourself also provides you with a solid tech-ed mini-course (or maxi-course for the completely uninitiated). What you need to get started are two standard CD/DVD drives from a used PC, a floppy disc drive from which you extract stepper rather than DC motors (you’ll need three stepper motors in all), a PC power supply, cables, female connectors, a heat-shrink tube, and some CNC electronics. There are some components — like a NEMA 17 stepper motor — that you’ll need to purchase new, but for the most part you’ll be going with used and recycled parts.

What you need to get started are two standard CD/DVD drives from a used PC, a floppy disc drive from which you extract stepper rather than DC motors (you’ll need three stepper motors in all), a PC power supply, cables, female connectors, a heat-shrink tube, and some CNC electronics. There are some components — like a NEMA 17 stepper motor — that you’ll need to purchase new, but for the most part you’ll be going with used and recycled parts.

The Instructables page provides thorough instructions for everything from soldering the cables to the motors and doing the basic electrical work, installing and using Arduino printer control software, downloading firmware, configuring the motherboard, and so on. In the instance of components that are not accessible from previously used electronics, there are instructions and templates for making your own laser cut parts for the frame, which can be assembled without the use of glue.

The 3D printer uses 1.75 mm plastic filament, which is both easier to extrude and also much more flexible than 3 mm filament. Additionally, using the 1.75 mm filament means that you’ll require less power to run your machine, which is definitely earth-friendly, as is the use of PLA bio-plastic (as opposed to ABS). This maker is willing to be contacted for troubleshooting, and the project — and completely usable end result — seems worth the fairly complicated process.

Additionally, using the 1.75 mm filament means that you’ll require less power to run your machine, which is definitely earth-friendly, as is the use of PLA bio-plastic (as opposed to ABS). This maker is willing to be contacted for troubleshooting, and the project — and completely usable end result — seems worth the fairly complicated process.

Is this a project you’d think to undertake? Have you already? Let us know how you found the process, and what your results were, at the discussion forum for the EWaste $60 3D Printer at 3DPB.com!

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printer • diy 3d printer • ewaste • instructables • recycle 3d printer • recycled parts

Please enable JavaScript to view the comments powered by Disqus.

3ders.org - Build your own functional 3D printed robot with this easy Instructables guide

Nov 22, 2015 | By Benedict

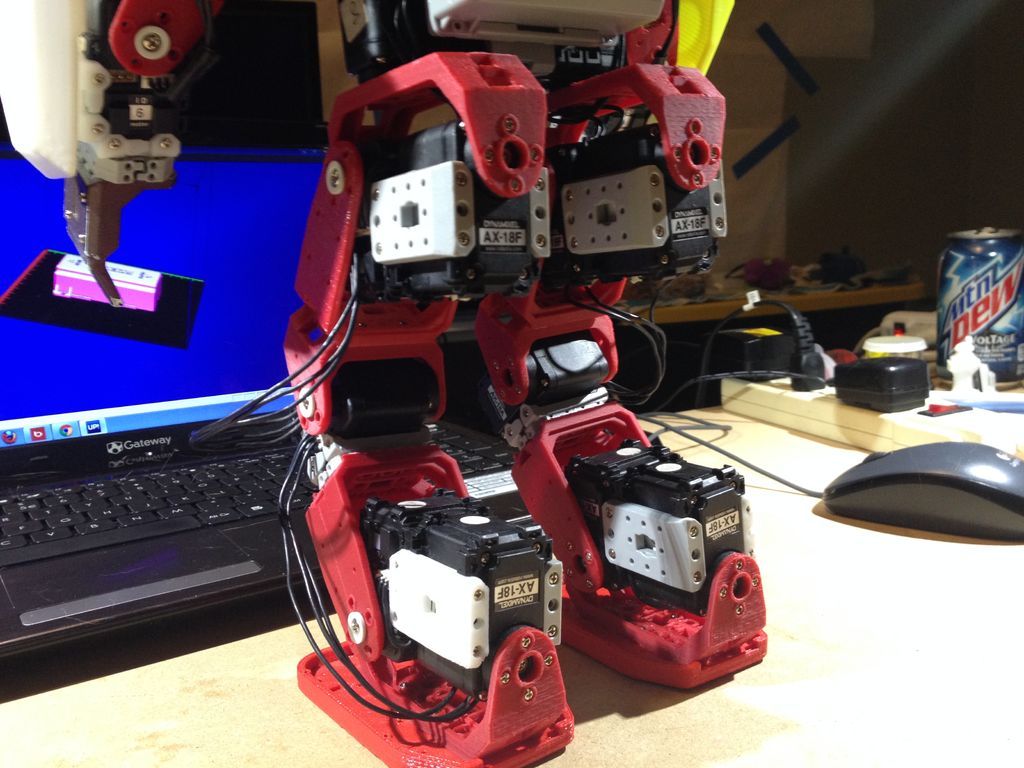

Ever on the lookout for additive android activity, we hear about a wide range of 3D printed robots here at 3Ders. Some are built for hygiene purposes, some are designed to combat bullying, and some have been built… well, just for fun. An experienced software engineer and part-time maker named J.R. Bédard has built this pair of 3D printed robots, one animated and one stationary, sharing the build procedure on Instructables.

Some are built for hygiene purposes, some are designed to combat bullying, and some have been built… well, just for fun. An experienced software engineer and part-time maker named J.R. Bédard has built this pair of 3D printed robots, one animated and one stationary, sharing the build procedure on Instructables.

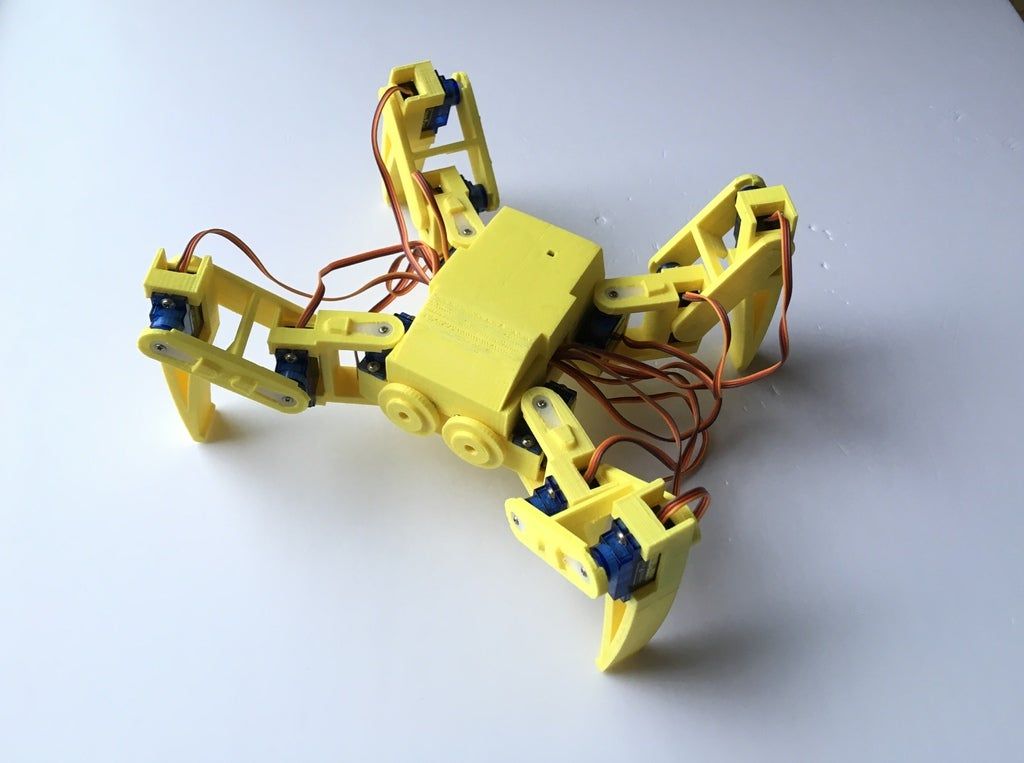

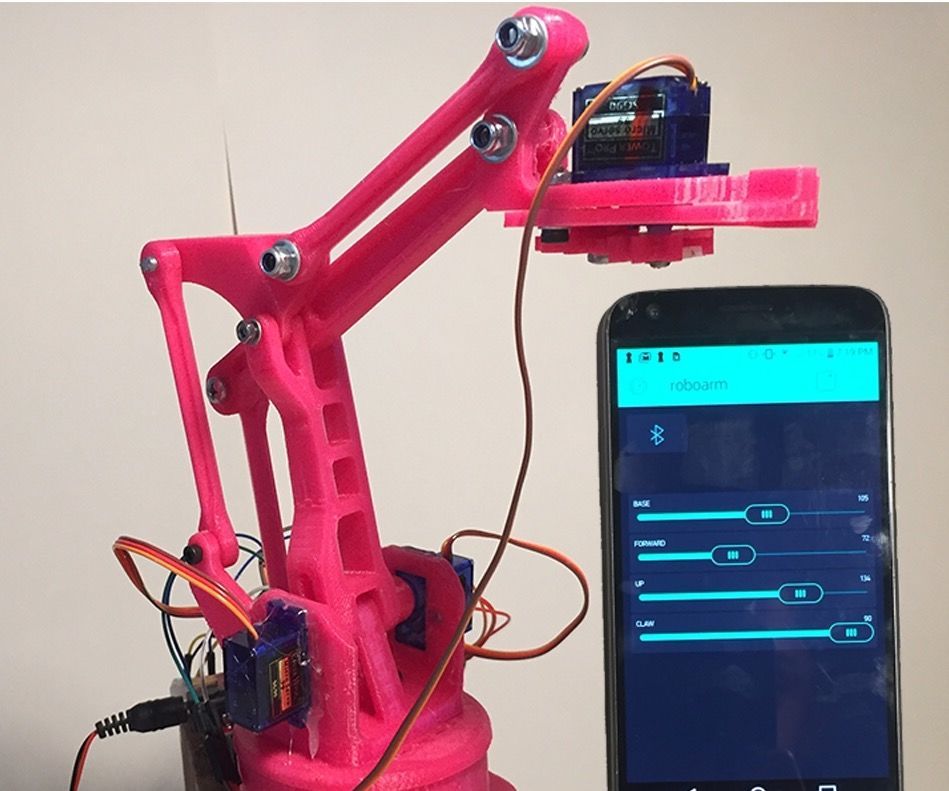

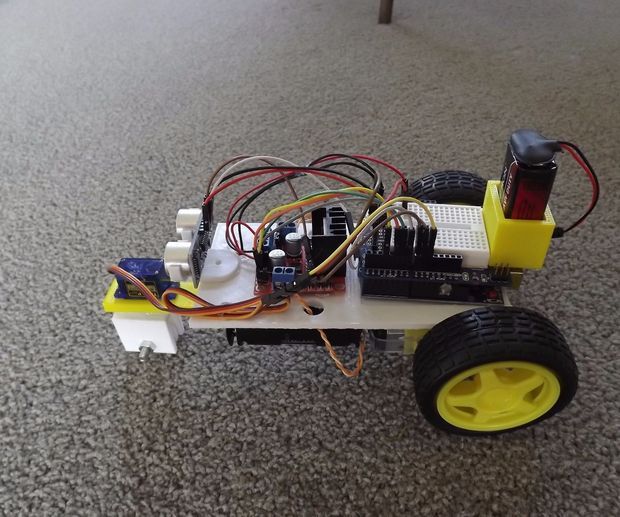

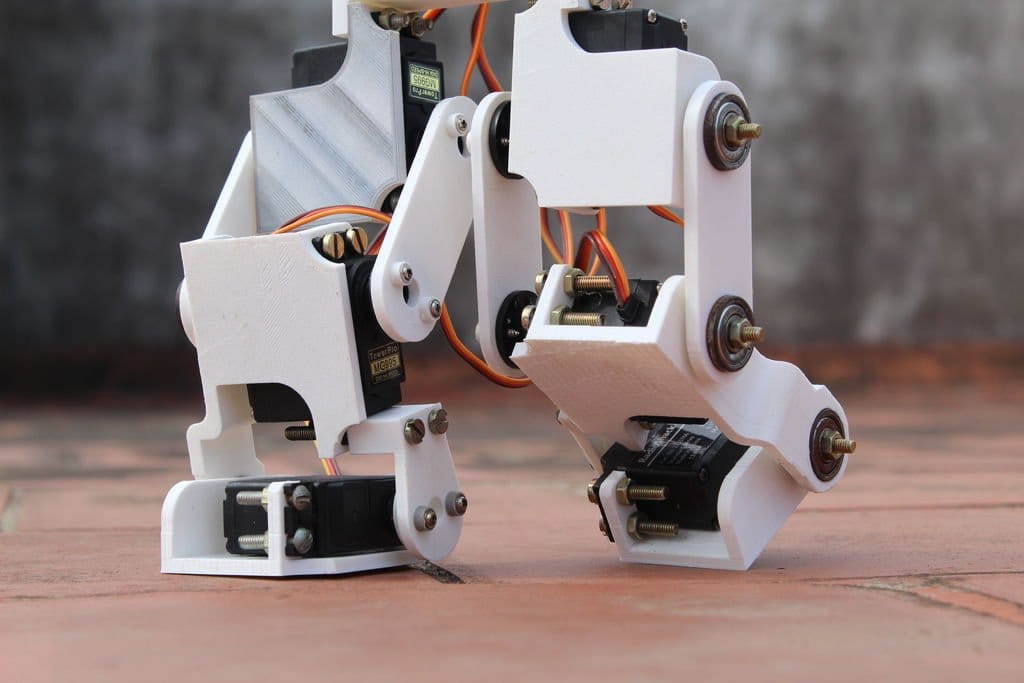

Bédard’s “MT-20” 3D printed robot is controlled by an Arduino microcontroller and can move its arms, legs and head thanks to its 5 well-positioned servos. The software guru has also designed a stationary version of the impressive bot which can be built with extra 3D printed pieces to replace the servos.

The maker used SketchUp to design his cool creation. To augment the software and produce the highest quality build, the Solid Inspector2 plugin was used to remove errors, as well as an STL exporter plugin to export the files for slicing.

The functional MT-20 is comprised of 19 3D printed parts, with its inert cousin requiring 5 printed pseudo-servos and a total of 24 3D printed parts. If it isn’t obvious from the pictures which robot is functional and which isn’t, the former has been built with blue printed parts and the latter with orange. Bédard used a Dremel Idea Builder 3D printer to print his two friendly androids, using PLA filament. Each of the parts can be 3D printed without supports, apart from the torso section which is designed with some easily breakable ones. The 3D printed robot requires surprisingly few connecting parts, thanks to the maker’s use of snap-fit ball joints, which are a little bit like those of actual human limbs!

If it isn’t obvious from the pictures which robot is functional and which isn’t, the former has been built with blue printed parts and the latter with orange. Bédard used a Dremel Idea Builder 3D printer to print his two friendly androids, using PLA filament. Each of the parts can be 3D printed without supports, apart from the torso section which is designed with some easily breakable ones. The 3D printed robot requires surprisingly few connecting parts, thanks to the maker’s use of snap-fit ball joints, which are a little bit like those of actual human limbs!

Bédard printed the two robots with a layer height of 0.15mm, a first layer height of 0.25mm, 3 shells, a 35% infill and a build speed of 80mm/s. Some of the parts are a little trickier than others to get right: the forearms and legs are each designed to contain two colors. This isn’t essential of course, but to get the intended look on a single extruder 3D printer, makers can pause printing after the first layer, change filament, then resume printing.

The talented software engineer used the popular Micro Servo 9g to get movement from the animated droid’s limbs and head. For makers who like the robot’s design, but who would rather not bother with the electronics or who simply prefer the aesthetic of the stationary bot, the servos can be replaced by 3D printed parts. These parts allow the limbs and head of the robot to be manually moved into a range of positions.

The animated version of the robot attaches to a support stand which houses the Arduino so although it won’t be walking out of your office any time soon, it can be programmed to perform a range of movements thanks to the Arduino code written by Bédard. Check out the video below and try building your own!

Posted in 3D Printing Application

Maybe you also like:

- Latex Pixels: Interactive 3D printed wall packed with 37 individually moving modules

- Drzach & Suchy uses 3D printed grates for cool shadow haiku art

- Full Circle Textiles uses shopping bag made from recycled filament to remind us of 3D printing's impact on our oceans

- Behnaz Farahi's details how to create dynamic 3D printed wearables using SMA actuators

- GUTS Labs gets ahead of the curve with 3D printed curved LEGO bricks

- 3D printed Winter Wonderland stop-motion captures the spirit of the holidays

- Gym teacher raising funds for 3D printed wheelchair recreation device for disabled children

- 5-year-old boy is first burn victim in China to receive 3D printed hand

- Children's 3D printed VR viewer the NEODiVRjr to be used as therapy in children's hospitals

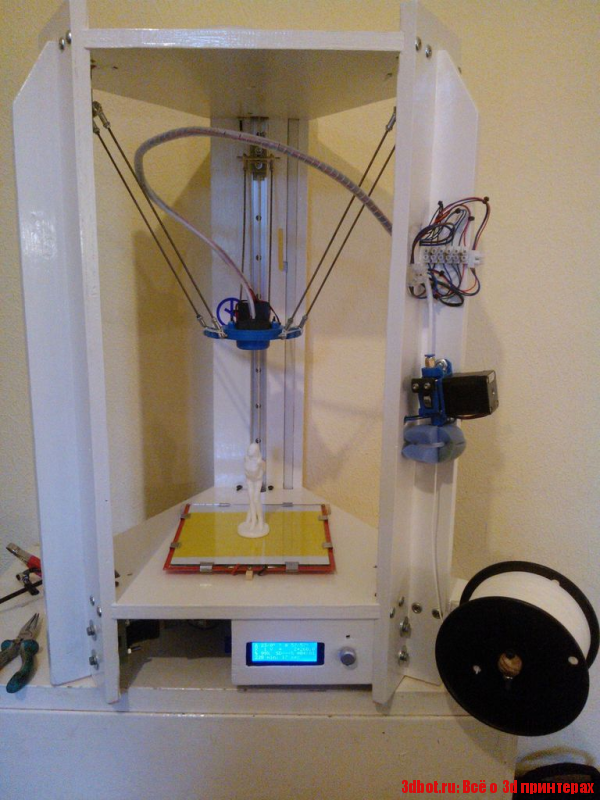

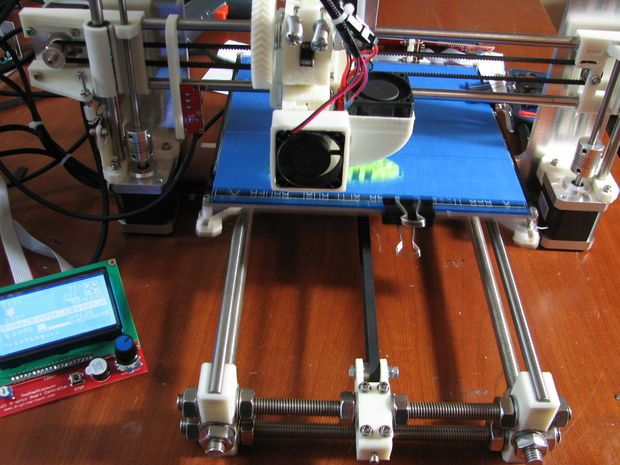

We assemble a 3D printer with our own hands.

Step-by-step instruction. Part 4.

Step-by-step instruction. Part 4. Friends, hello!

At the end of today's part, our printer will be printing.

Let me remind you what we have already done:

1. Introductory. Purchasing everything you need. 2. Assembling the printer. Part one. Body and mechanics. 3. Assembling the printer. Part two. Electronics. 3.1. Additional photos. 3.2. Connecting the electronics 4. Firmware and printer setup - Marlin.

5. Firmware and printer setup - Repetier-Firmware.

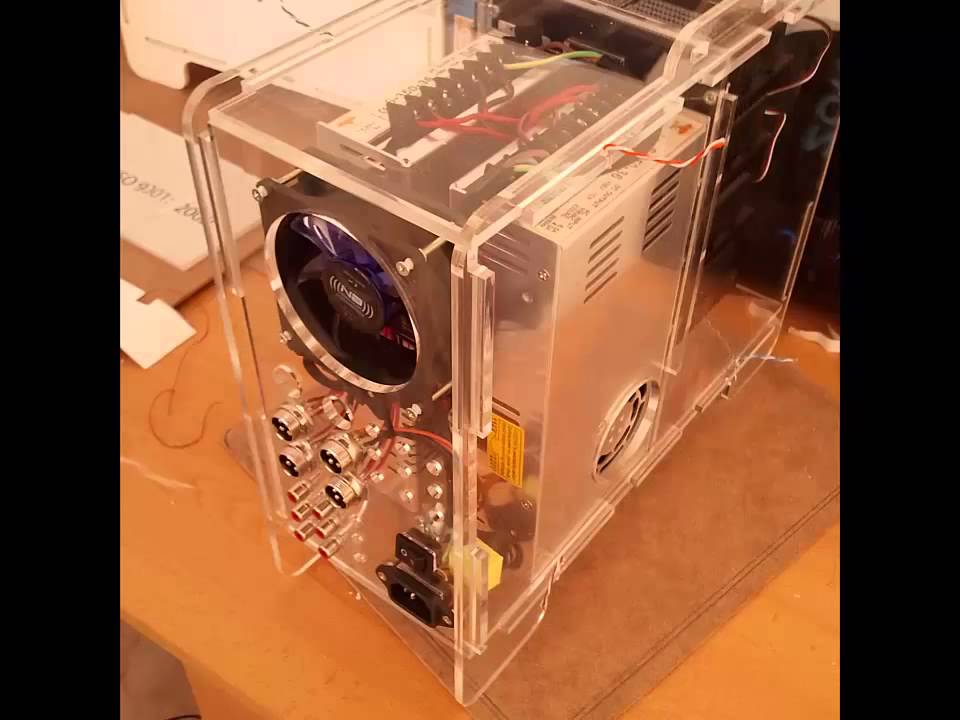

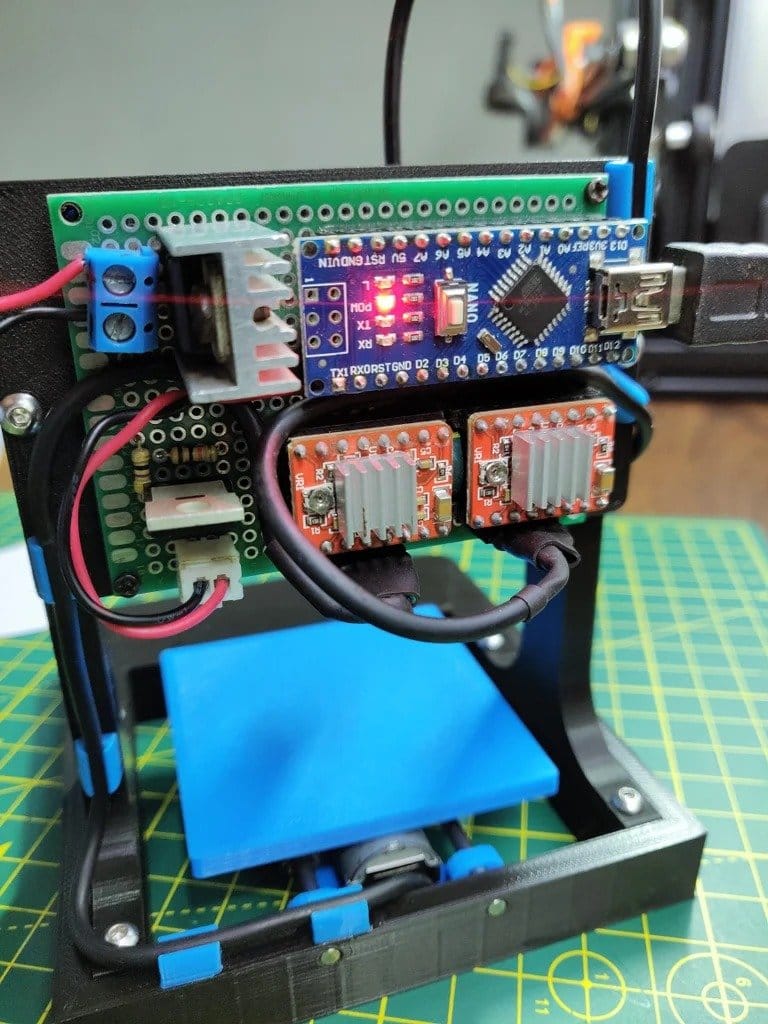

Today we need a multimeter, a computer, the USB cable that came with the Arduino Mega, an SD memory card.

I warn you right away, before plugging this whole thing into a socket, check whether everything is connected correctly 7 times, and when working with a multimeter, one awkward movement and Arduino to replace. I have already killed 3 Arduino Mega, including one when setting up this printer, and so that you do not have to wait another two weeks for this post, I quickly found a new 'dunya' on Avito. If in any doubt, double-check or ask again! If I warned.

If in any doubt, double-check or ask again! If I warned.

First things to check:

1. Position of the drivers.

2. Correct connection of limit switches.

3. Polarity of all wires.

4. General wiring diagram for all electronics.

Have you checked? 7 times? Let's go further:

Turn on our printer, turn on the switch (on the power cable connector with a fuse and do not forget to install the fuse), it should turn on:

1. The fan on the power supply.

2. RAMPS blower.

3. Print head heatsink airflow.

4. Screen backlight.

5. Printer backlight, can be turned on or off with the switch.

Working?

No - go to the previous chapters.

Yes, let's move on.

I took a picture from my neighbors:

Using a multimeter, we measure the voltage (DC Volts - V). By the way, just at that moment my hand trembled, and I first soldered the stabilizer, which is most often on fire in this situation, then I realized that not only the stabilizer had burned down, I went for the 'dunya'. On A49 drivers88 can be handled without a multimeter, just by the sound, but we follow the rules, set the voltage to 0.68V on all drivers, for A4988 you can up to 1V.

On A49 drivers88 can be handled without a multimeter, just by the sound, but we follow the rules, set the voltage to 0.68V on all drivers, for A4988 you can up to 1V.

Ready?

Let's go further:

Download here - Arduino Software, strange things have been happening with this program lately, I have version 1.6.5, my colleagues have other versions. Install on your computer.

most likely we have a 'dunya' not a 'dunya' at all, but a Chinese clone on the Ch441 chip, then we also download the driver, for example here - install it on your computer.

Download the firmware - Marlin - unpack the archive with the firmware to a convenient place.

Downloading the library - u8glib - do not unpack the archive.

We connect the printer to the computer via a USB cable, the drivers are installed and as a result you should see the following picture in the device manager of your computer:

Remembers the number of the COM port on which your Arduino board is installed.

Open the file ...Marlin-RCMarlinMarlin.ino (in Windows Explorer it can be just Marlin without extension) using Arduino Software:

Next go: Tools - Board:... - Choose your Arduino/Genuino Mega or Mega 2560 board.

Next: Tools - Processor:... - ATmega2560(Mega 2560).

Next: Tools - Port: ... - We select the same COM port that we remembered in the device manager of our computer.

Going further - open the Configuration.h tab:

All basic settings will be made in this tab.

We need to add a library to work with our screen - u8glib, we have already downloaded it, then we need to add it to our firmware.

Go Sketch - Include Library (Add Library) - Add .ZIP Library...

In the window that opens, look for your archive with the u8glib library, select it and click open.

Next Sketch - Include Library (Add library) - at the very bottom we see u8glib appeared, select it.

A line appeared in our sketch:

#include Starting the firmware configuration:

1. You need to select the controller of our printer, for this we go to the boards.h tab

We see a huge list of controllers with which the Marlin firmware can already work:

Let me remind you that we use Arduino Mega 2560 + RAMPS v 1.4 and we have a heating table, controlled blowing of the part and one print head. I think everyone has already found our board:

#define BOARD_RAMPS_14_EFB 43 // RAMPS 1.4 (Power outputs: Hotend, Fan, Bed)

Return to the Configuration.h tab line:

2. Setting the table temperature sensor.

Most likely you, just like I have a regular Chinese 100K thermistor, in this firmware it is denoted by the number 1:

// 1 is 100k thermistor - best choice for EPCOS 100k (4. 7k pullup) hotend and for the table:

7k pullup) hotend and for the table:

We can leave the maximum and minimum temperatures unchanged or adjust to our needs:

3. PID settings - I recommend doing it after you have printed on your printer for several hours.

This is done as follows, in the Pronterface program, you need to connect to the printer

and give the command

Where M303 is the calibration command, E0 is the hot end, C10 is the number of heating-cooling cycles, S260 is the typical temperature of the nozzle.

The printer runs the hotend heating 10 times, after that it outputs the values Kp, Ki, Kd. We write these values into these firmware:

The same for the table, only the command:

M303 E-1 C10 S110

Where E-1 is the table, S110 is the typical table heating temperature.

Due to prolonged table heating, a timeout error may occur, just restart the command.

Enter the obtained values into the firmware:

4. Set up the operation of the limit switches:

Let me remind you that in our case we use:

//)/uncomment the corresponding lines:

And also change the direction of the location of the 'house' in accordance with the position of the trailers:

4. Print field size settings.

In my case, it turned out exactly 200*200*190 mm:

Your values may differ slightly, literally mm, but this is established empirically later.

5. Setting the speed of moving home:

Set empirically, while leaving the default.

6. Setting the movement steps along the axes.

We need to find out how many steps our printer takes per unit of distance (in our case 1 mm) along each of the axes.

In our case, we use a motor that takes 200 steps per revolution, and we break this step into 16 microsteps.

Further along the X and Y axes we have a belt drive with a pitch of 2 mm for each tooth and a spool with 20 teeth.

Thus, our engine makes 200 * 16 = 3200 steps in one revolution and overcomes the distance 20 * 2 = 40 mm in these 3200 steps.

Therefore, in order for the printer to move 1 mm, it takes 3200/40 = 80 steps (this value is the same for the X axis and the Y axis).

A trapezoidal screw is installed on the Z axis, which has a different pitch, who purchased which one. For example, 8 mm per full turn, i.e. our printer travels 8 mm in one turn of the screw along the Z axis and does the same 3,200 for this, although to accelerate the Z axis, you can set crushing (with jumpers) and 1/8, how to do this is written in 3 parts.

So, on the Z axis, in order to move 1 mm, the printer needs to make 3,200/8 = 400 steps.

Extruder feed. In order to understand how much our extruder feeds plastic, we need to calculate the circumference, from the school geometry course, remember that the circumference is 2 * 'number pi' * radius of the circle or 'number pi' * diameter of the circle. Now we don’t need special accuracy (we will adjust it more precisely later), the diameter is approximately 5.8 mm, therefore, in 3200 steps or one revolution, our extruder delivers 3.1415 * 5.8 = 18.2207 mm of the bar, and for the feed of one mm he needs 3,200 / 18.2207 = 175.624 steps, rounding up to the whole step 176.

Now we don’t need special accuracy (we will adjust it more precisely later), the diameter is approximately 5.8 mm, therefore, in 3200 steps or one revolution, our extruder delivers 3.1415 * 5.8 = 18.2207 mm of the bar, and for the feed of one mm he needs 3,200 / 18.2207 = 175.624 steps, rounding up to the whole step 176.

We write the obtained values into the firmware:

Here, in order X, Y, Z, extruder.

7. Setting speeds and accelerations:

leave these parameters unchanged for now and will adjust them in a more precise setting:

8. Setting the screen:

Uncomment (remove the double slash //) from the lines

#define ULTRA_LCD

#define DOGLCD

#define SDSUPPORT

#define ULTIPANEL

#define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER

9. You can name your printer after yourself, for example 'Plastmaska'

To do this, uncomment the line:

//#define CUSTOM_MACHINE_NAME 'Plastmaska'

All basic firmware settings are done, check by pressing the 'Check' button :

And download by pressing the 'Load' button:

After that, our printer will reboot and show you various parameters.

Now we need to fine-tune the printer:

1. the correct direction of movement along the axes.

Should be:

X-axis - left 0 (or minus), right 200 (or plus)

Y-axis - towards you 0 (or minus), away from you 200 (or plus)

Z-axis - up 0 (or minus), down 190 (or plus)

extruder - feeds plastic is plus, rolls plastic is minus

If everything matches, move on, if not, then change the parameters, change the parameter true to false or false to true - parameter changes only where it is needed (where movement along the axis is incorrect):

#define INVERT_X_DIR false

#define INVERT_Y_DIR true

#define INVERT_Z_DIR false

#define INVERT_E0_DIR false

compile and re-upload the firmware, check, match.

2. Limit switches operation:

Place the carriage and table in such a way that the limit switches are not pressed.

Command M119 via the Pronterface program.

We see something like this:

or so

should be correct:

or

x_min: open

y_max: open

z_max: open

This is only for normally closed contacts, if you use normally open, then you should have the opposite, the limit switch did not work - open, the limit switch worked - TRIGGERED.

If something is wrong here, then most likely they made a mistake in the previous setting of the limit switches or in their connection. go back and check.

3. Proper travel home.

We send a command to the printer to go home, it is possible through the printer menu, it is possible through the programs on the computer.

The carriage should move to the left and away from you, the table should move down.

Is everything correct? moving on. Not? we return to the firmware

4. We select the dimensions of the movement:

here everything is empirically and with a ruler we select the parameters for all axes and enter them into the firmware:

5. Checking the bar feed:

Checking the bar feed:

We take a line, measure 10-20-30 cm bar, mark and give the printer a command to squeeze out 10-20-30 cm of the bar, check how accurately he did it, based on the values we correct the firmware.

6. Selection of speeds and accelerations:

No one will tell you better than Sergey Taranenko:

We enter the obtained parameters into the firmware, fill it in the printer, check it.

7. Setting the gap between table and nozzle.

The table must first be coated for good adhesion to the table, I personally use a glue stick (3M Scotch, UHU, Kalyaka-Malyaka). I put glue on cold, clean, dry glass, after that you can heat the table, one of these days I plan to try glass-ceramic glass, nothing works from a pencil that has been tested better.

We heat up the table and the nozzle to the operating temperature (110/250) send the table to point 0, then three points further (where we have the adjusting screws)

Adjust the distance with nuts so that a sheet of paper is pressed between the nozzle and the table nozzle to the table, but at the same time it could be pulled out without tearing, it is necessary to achieve this so that there is such a distance at any point of the printer, for this it is enough to align the table 2 times at 3 points.

Some of the parameters can be changed via EEPROM, this can be done either in the Repetier-Host 9 program0003

Or via commands in the same Pronterface.

That's all, I'm waiting for your questions, on the basis of which I want to make a certain FAQ on the printer.

Also the last chapter '5. Firmware and printer setup - Repetier-Firmware.' is postponed indefinitely, because the printer on which it was planned to install this firmware suddenly received MKS Sbase, and that's another story.

Finally, another video of how the printer prints:

and this is what happened:

Another well-known model, but of higher quality and better material:

Well, the new owners of the printer are happy.

Inspected:

Adhesive coating applied:

We set to work:

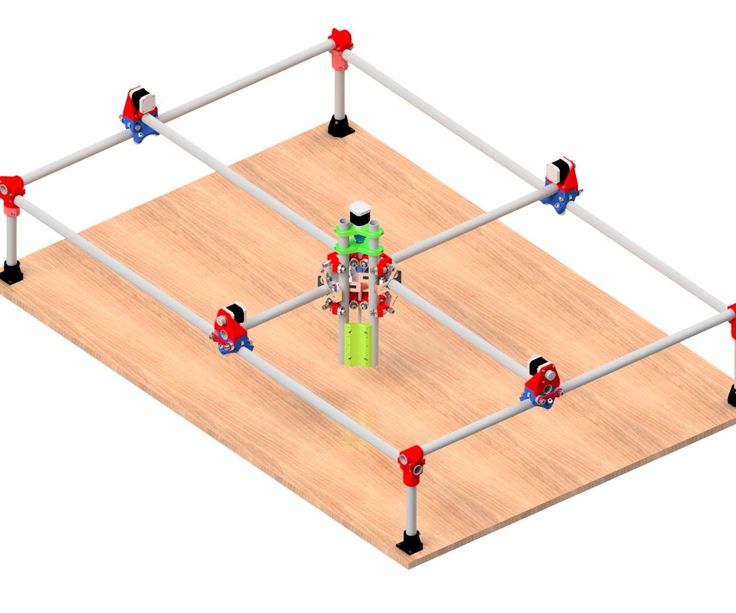

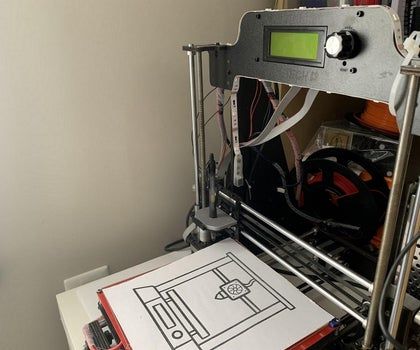

What I plan to do next, the first thing is to complete the project with a double-headed printer:

But in the near future I want to make a plywood Ultimaker Go, I really liked the idea of wearing takeaway:

It is possible that Repetier-Firmware also sells there.

I also think in the direction of mixing colors during printing, in order to achieve this, but not with a gradient bar, but by mixing colors during printing:

How interested you were in following these projects, please unsubscribe in the comments.

Update

Part 5. Updates and additions. >> http://3dtoday.ru/blogs/plastmaska/small-update-ultimaker/ Please support this project in social networks. Article repost needed!

Article repost needed!

Just in case, I'm in touch.

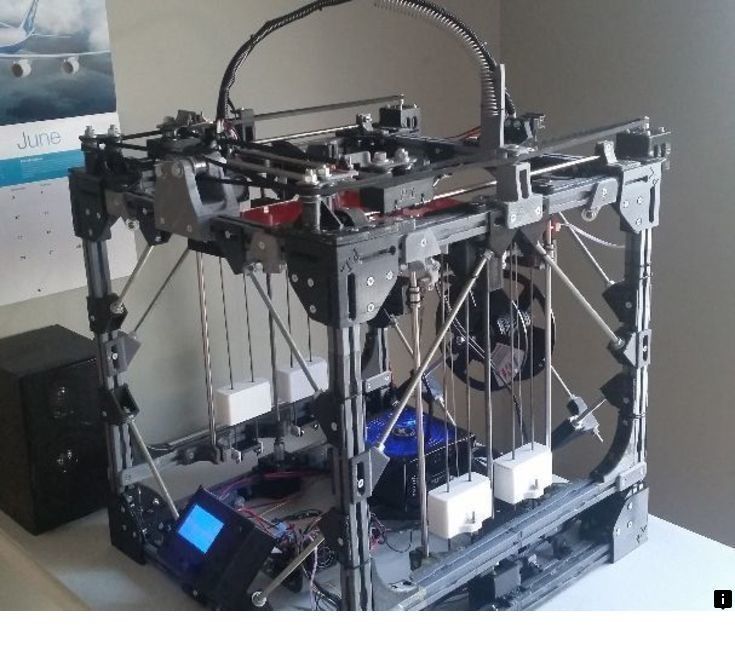

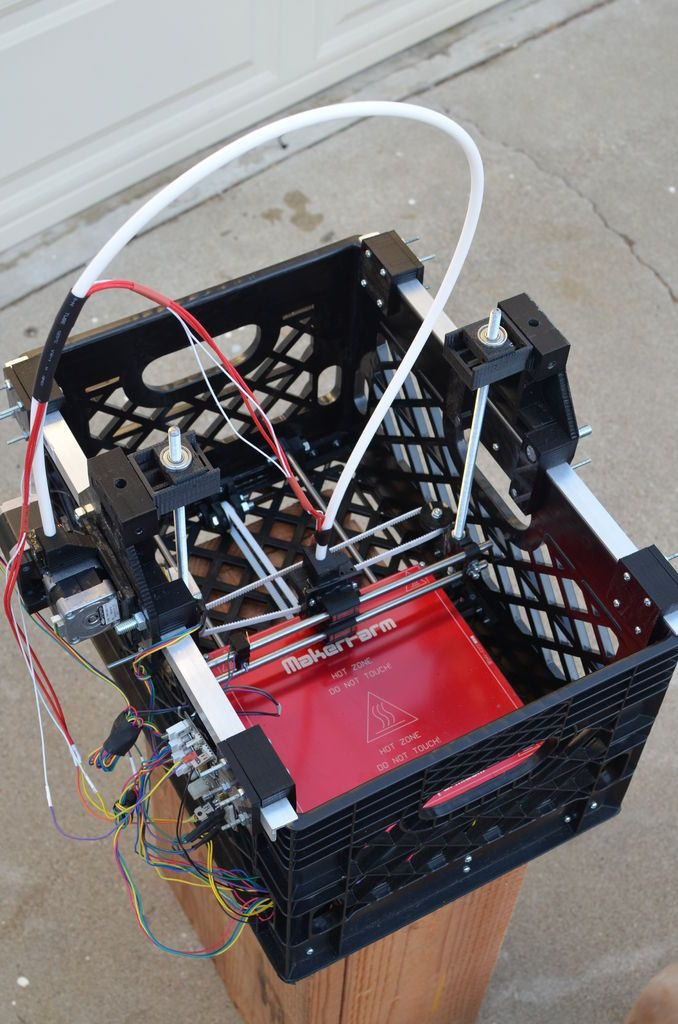

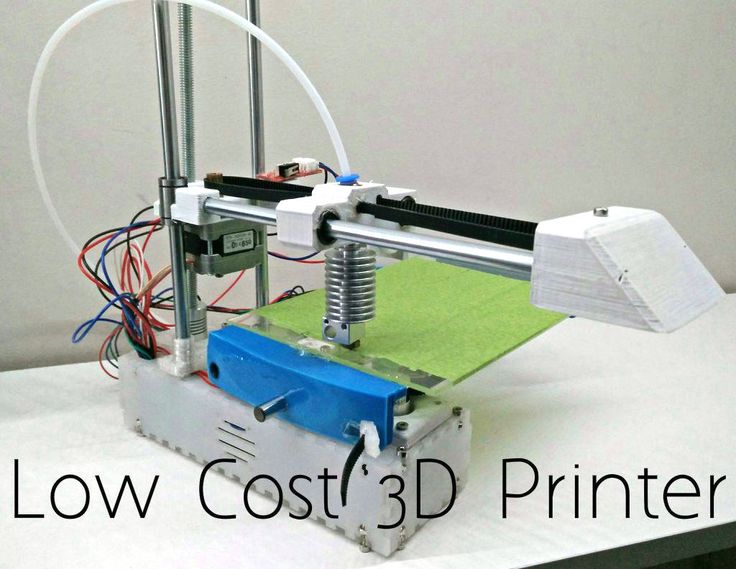

How to build a home 3D printer: recommendations from personal experience

3D printing and assembly of 3D printers is my hobby and passion. Here I will not share detailed diagrams and drawings, there are more than enough of them on specialized resources. The main goal of this material is to tell you where to start, where to dig and how to avoid mistakes in the process of assembling a home 3D printer. Perhaps one of the readers will be inspired by applied engineering achievements.

Why do you need a 3D printer? Use cases for

I first came across the idea of 3D printing back in the 90s when I was watching the Star Trek series. I remember how impressed I was by the moment when the heroes of the cult series printed the things they needed during their journey right on board their starship. They printed anything: from shoes to tools. I thought it would be great someday to have such a thing too. Then it all seemed something incredible. Outside the window are the gloomy 90s, and the Nokia with a monochrome screen was the pinnacle of progress, accessible only to a select few.

Then it all seemed something incredible. Outside the window are the gloomy 90s, and the Nokia with a monochrome screen was the pinnacle of progress, accessible only to a select few.

Years passed, everything changed. Around 2010, the first working models of 3D printers began to appear on sale. Yesterday's fantasy has become a reality. However, the cost of such solutions, to put it mildly, discouraged. But the IT industry would not be itself without an inquisitive community, where there is an active exchange of knowledge and experience and who just let them dig into the brains and giblets of new hardware and software. So, drawings and diagrams of printers began to surface more and more often on the Web. Today, the most informative and voluminous resource on the topic of assembling 3D printers is RepRap - this is a huge knowledge base that contains detailed guides for creating a wide variety of models of these machines.

I built my first printer about five years ago. My personal motivation to build my own device is quite prosaic and based on several factors. Firstly, there was an opportunity to try to realize the old dream of having your own device, inspired by a fantasy series. The second factor is that sometimes it was necessary to repair some household items (for example, a baby stroller, car elements, household appliances and other small things), but the necessary parts could not be found. Well, the third aspect of the application is "near-working". On the printer, I make cases for various IoT devices that I assemble at home.

Firstly, there was an opportunity to try to realize the old dream of having your own device, inspired by a fantasy series. The second factor is that sometimes it was necessary to repair some household items (for example, a baby stroller, car elements, household appliances and other small things), but the necessary parts could not be found. Well, the third aspect of the application is "near-working". On the printer, I make cases for various IoT devices that I assemble at home.

Agree, it is better to place your device based on Raspberry Pi or Arduino in an aesthetically pleasing "body", which is not a shame to put in an apartment or take to the office, than to organize components, for example, in a plastic bowl for food. And yes, you can print parts to build other printers :)

There are a lot of scenarios for using 3D printers. I think everyone can find something of their own.

A complex part in terms of drawing that I printed on my printer. Yes, it's just a figurine, but it has many small elements

Ready solution vs custom assembly

When a technology has been tested, its value in the market drops markedly. The same thing happened in the world of 3D printers. If earlier a ready-made solution cost simply sky-high money, then today acquiring such a machine is more humane for the wallet, but nevertheless not the most affordable for an enthusiast. There are a number of solutions already assembled and ready for home use on the market, their price range ranges from $500-700 (not the best options) to infinity (adequate solutions start from a price tag of about $1000). Yes, there are options for $150, but we, for understandable, I hope, reasons, will not dwell on them.

In short, there are three cases to consider a finished assembly:

- when you plan to print not much and rarely;

- when print accuracy is critical;

- you need to print molds for mass production of parts.

There are several obvious advantages to self-assembly. The first and most important is cost. Buying all the necessary components will cost you a maximum of a couple of hundred dollars. In return, you will receive a complete 3D printing solution with the quality of manufactured products acceptable for domestic needs. The second advantage is that by assembling the printer yourself, you will understand the principles of its design and operation. Believe me, this knowledge will be useful to you during the operation of even an expensive ready-made solution - any 3D printer needs to be serviced regularly, and it can be difficult to do this without understanding the basics.

The main disadvantage of assembly is the need for a large amount of time. I spent about 150 hours on my first build.

What you need to assemble the printer yourself

The most important thing here is the presence of desire. As for any special skills, then, by and large, in order to assemble your first printer, the ability to solder or write code is not critical. Of course, understanding the basics of radio electronics and basic skills in the field of mechanics (that is, "straight hands") will greatly simplify the task and reduce the amount of time that needs to be spent on assembly.

Of course, understanding the basics of radio electronics and basic skills in the field of mechanics (that is, "straight hands") will greatly simplify the task and reduce the amount of time that needs to be spent on assembly.

Also, to start we need a mandatory set of parts:

- Extruder is the element that is directly responsible for printing, the print head. There are many options on the market, but for a budget build, I recommend the MK8. Of the minuses: it will not be possible to print with plastics that require high temperatures, there is noticeable overheating during intensive work, which can damage the element. If the budget allows, then you can look at MK10 - all the minuses are taken into account there.

- Processor board. Well known to many Arduino Mega. I didn't notice any downsides to this solution, but you can spend a couple of dollars more and get something more powerful, with a reserve for the future.

- Control board.

I'm using RAMPS 1.4 which works great with the Arduino Mega. A more expensive but more reliable board is Shield, which already combines a processor board and a control board. In modern realities, I recommend paying attention to it. In addition to it, you need to purchase at least 5 microstep stepper motor controllers, for example - A4988. And it's better to have a couple of these in stock for replacement.

I'm using RAMPS 1.4 which works great with the Arduino Mega. A more expensive but more reliable board is Shield, which already combines a processor board and a control board. In modern realities, I recommend paying attention to it. In addition to it, you need to purchase at least 5 microstep stepper motor controllers, for example - A4988. And it's better to have a couple of these in stock for replacement. - Heated table. This is the part where the printed element will be located. Heating is necessary due to the fact that most plastics will not adhere to a cold surface. For example, for printing with PLA plastic, the required surface temperature of the table is 60-80°C, for ABS - 110-130°C, and for polycarbonate it will be even higher

There are also two options for choosing a table - cheaper and more expensive. Cheaper options are essentially printed circuit boards with preheated wiring. To operate on this type of table, you will need to put borosilicate glass, which will scratch and crack during operation. Therefore, the best solution is an aluminum table.

Therefore, the best solution is an aluminum table. - Stepper motors. Most models, including the i2 and i3, use NEMA 17 size motors, two for the Z axis and one each for the X and Y axes. Finished extruders usually come with their own stepper motor. It is better to take powerful motors with a current in the motor winding of 1A or more, so that there is enough power to lift the extruder and print without skipping steps at high speed.

- Basic set of plastic fasteners.

- Belt and gears to drive it.

Examples of elements appearance: 1) MK8 extruder; 2) Arduino processor board; 3) RAMPS control board; 4) motor controllers; 5) aluminum heated table; 6) NEMA 17 stepper motor; 7) a set of plastic fasteners; 8) drive gears; 9) drive belt

This is a list of items you need to purchase. Hardcore users can assemble some of them themselves, but for beginners, I strongly recommend purchasing ready-made solutions.

Yes, you will also need various small things (studs, bearings, nuts, bolts, washers ...) to assemble the case. In practice, it turned out that using a standard m8 stud leads to low printing accuracy on the Z axis. I would recommend immediately replacing it with a trapezoid of the same size.

M8 trapezoid stud for the Z axis, the use of which will save you a lot of time and nerves. Available for order on all major online platforms

Customized plastic parts for the X axis must also be purchased, such as these from the MendelMax retrofit kit.

Most parts available at your local hardware store. On RepRap you can find a complete list of necessary little things with all sizes and patterns. The kit you need will depend on the choice of platform (we'll talk about platforms later).

What's the price

Before delving into some aspects of the assembly, let's figure out how much such entertainment will cost for your wallet. Below is a list of parts required for purchase with an average price.

Below is a list of parts required for purchase with an average price.

Platform selection

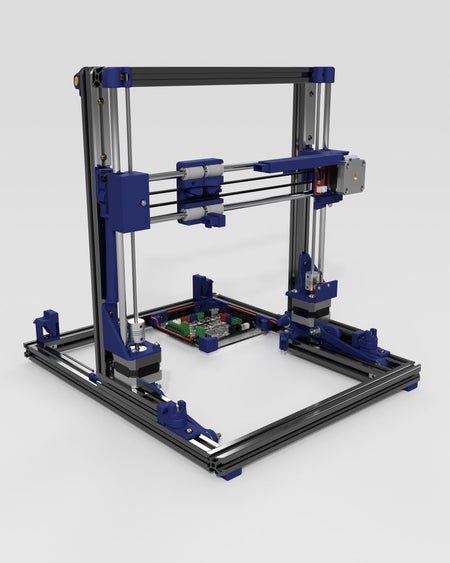

The community has already developed a number of different platforms for assembling printers - the most optimal case designs and the location of the main elements, so you do not have to reinvent the wheel.

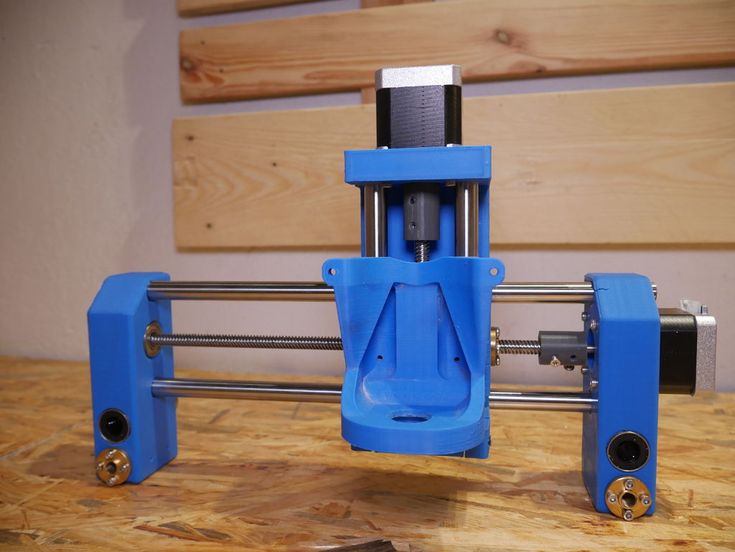

i2 and i3 are key platforms for self-assembly printer enclosures. There are also many modifications of them with various improvements, but for beginners, these two classic platforms should be considered, since they do not require special skills and fine-tuning.

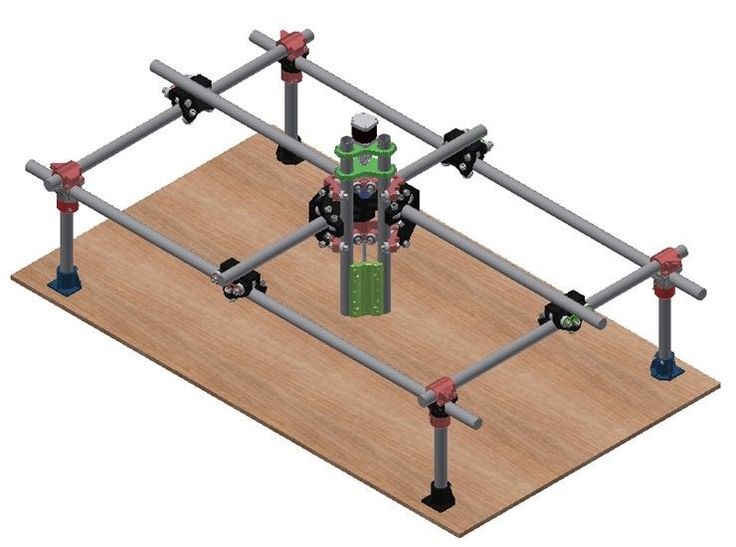

Actually, illustration of platforms: 1) i2 platform; 2) i3 platform

On the plus side of i2: it has a more reliable and stable design, although it is a little more difficult to assemble; more opportunities for further customization.

The i3 variant requires more special plastic parts to be purchased separately and has a slow print speed. However, it is easier to assemble and maintain, and has a more aesthetically pleasing appearance. You will have to pay for simplicity with the quality of printed parts - the body has less stability than i2, which can affect print accuracy.

You will have to pay for simplicity with the quality of printed parts - the body has less stability than i2, which can affect print accuracy.

Personally, I started my experiments in assembling printers from the i2 platform. She will be discussed further.

Assembly steps, challenges and improvements

In this block, I will only touch on the key assembly steps using the i2 platform as an example. Full step by step instructions can be found here.

The general scheme of all the main components looks something like this. There is nothing particularly complicated here:

I also recommend adding a display to your design. Yes, you can easily do without this element when performing operations on a PC, but it will be much more convenient to work with the printer this way.

Understanding how all components will be connected, let's move on to the mechanical part, where we have two main elements - a frame and a coordinate machine.

Assembling the frame

Detailed frame assembly instructions are available on RepRap. Of the important nuances - you will need a set of plastic parts (I already talked about this above, but I'd better repeat it), which you can either purchase separately or ask your comrades who already have a 3D printer to print.

Of the important nuances - you will need a set of plastic parts (I already talked about this above, but I'd better repeat it), which you can either purchase separately or ask your comrades who already have a 3D printer to print.

The frame of the i2 is quite stable thanks to its trapezoid shape.

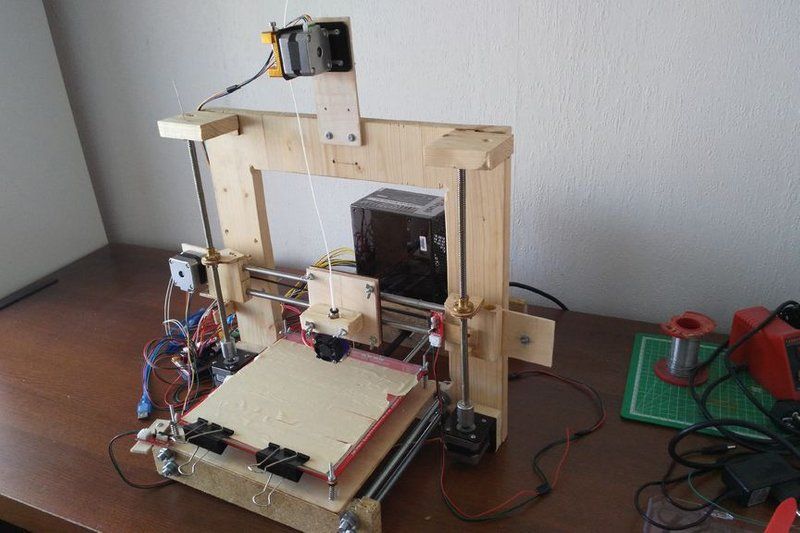

This is how the frame looks like with parts already partially installed. For greater rigidity, I reinforced the structure with plywood sheets

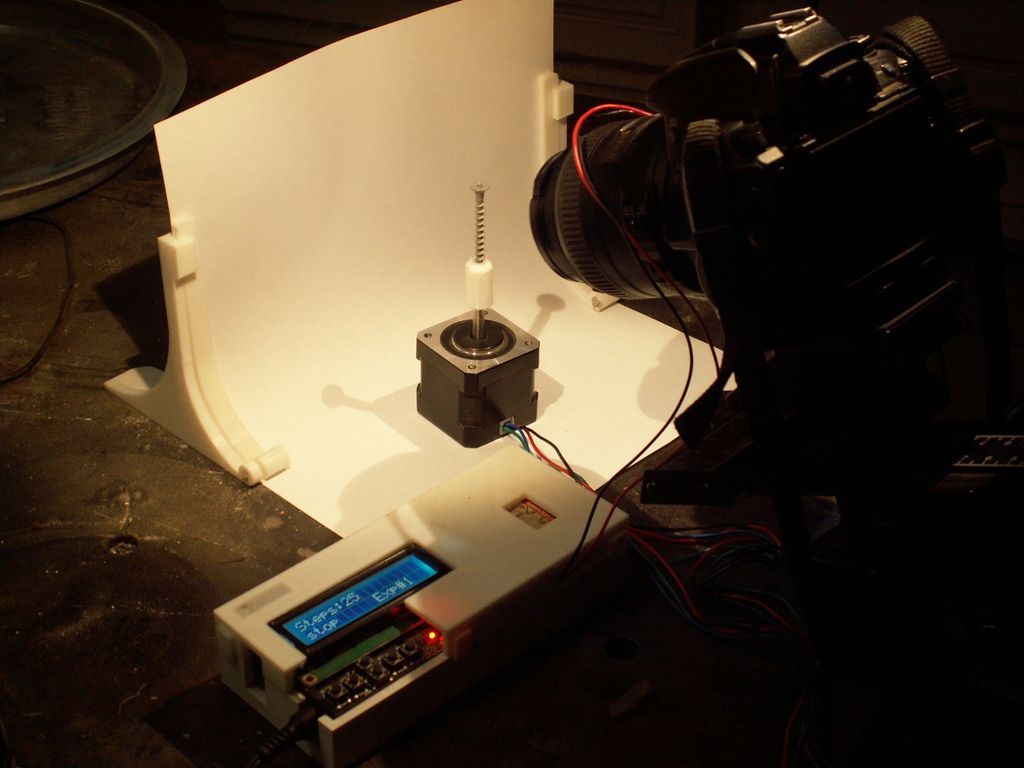

Coordinate machine

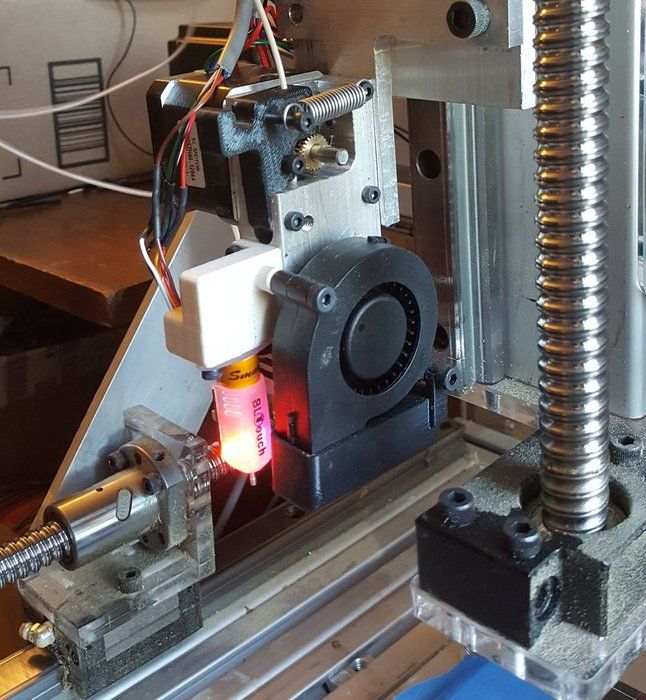

An extruder is attached to this part. The stepper motors shown in the diagram above are responsible for its movement. After installation, calibration is required along all major axes.

Important - you will need to purchase (or make your own) a carriage for moving the extruder and a mount for the drive belt. Drive belt I recommend GT2.

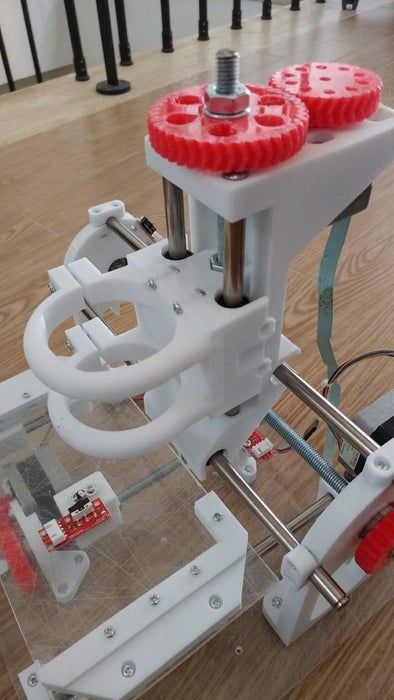

Carriage printed by the printer from the previous picture after it has been assembled. The part already has LM8UU bearings for guides and belt mount (top)

The part already has LM8UU bearings for guides and belt mount (top)

Calibration and adjustment

So, we completed the assembly process (as I said, it took me 150 hours) - the frame was assembled, the machine was installed. Now another important step is the calibration of this very machine and extruder. Here, too, there are small subtleties.

Setting up the machine

I recommend calibrating the machine with an electronic caliper. Do not be stingy with its purchase - you will save a lot of time and nerves in the process.

The screenshot below shows the correct constants for the Marlin firmware, which must be selected in order to set the correct number of steps per unit of measure. We calculate the coefficient, multiply it, substitute it into the firmware, and then upload it to the board.

Marlin 9 firmware constants0382

For high-quality calibration, I recommend relying on larger numbers in measurements - take not 1-1. 5 cm, but about 10. So the error will be more noticeable, and it will become easier to correct it.

5 cm, but about 10. So the error will be more noticeable, and it will become easier to correct it.

Calibrating the extruder

When the frame is assembled, the machine is calibrated, we start setting up the extruder. Here, too, everything is not so simple. The main task of this operation is to correctly adjust the supply of plastic.

If underfeeding, the printed test item will have noticeable gaps, like test die 1. Conversely, the result will look bloated if plastic is overfed (dice 2)

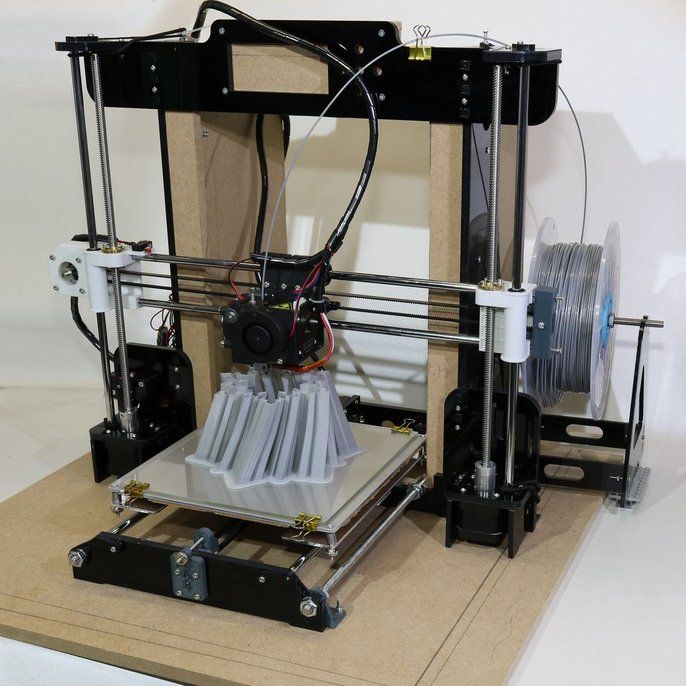

Getting Started Printing

It remains for us to run some CAD or download ready-made .stl, which describe the structure of the printed material. Next, this structure needs to be converted into a set of commands understandable to our printer. For this I use the Slicer program. It also needs to be set up correctly - specify the temperature, the size of the extruder nozzle. After that, the data can be sent to the printer.

Slicer interface

As a raw material for printing, I recommend starting with regular ABS plastic - it is quite strong, its products are durable, and it does not require high temperatures to work with. For comfortable printing with ABS plastic, the table must be heated to a temperature of 110-130 ° C, and the extruder nozzle - within 230-260 ° C.

For comfortable printing with ABS plastic, the table must be heated to a temperature of 110-130 ° C, and the extruder nozzle - within 230-260 ° C.

Some important details. Before printing, calibrate the machine along the Z axis. The extruder nozzle should be approximately half a millimeter from the table and ride along it without distortion. For this calibration, a regular sheet of A4 paper inserted between the nozzle and the surface of the heated table is best suited. If the sheet can be moved with little effort, the calibration is correct.

Another thing to keep in mind is the surface treatment of the heated table. Usually, before printing, the surface of the table is covered with something that hot plastic sticks to well. For ABS plastic, this can be, for example, Kapton tape. The disadvantage of adhesive tape is the need to re-glue it after several printing cycles. In addition, you will have to literally tear off the adhering part from it. All this, believe me, takes a lot of time. Therefore, if it is possible to avoid this fuss, it is better to avoid it.

Therefore, if it is possible to avoid this fuss, it is better to avoid it.

An alternative option that I use instead of scotch tape is applying several layers of ordinary light beer, followed by heating the table to 80-100 ° C until the surface is completely dry and re-applying 7-12 layers. It is necessary to apply the liquid with a cloth moistened with a drink. Among the advantages of this solution: ABS plastic separates from the table on its own when it cools down to about 50 ° C and is removed without effort, the table does not have to be peeled off, and one bottle of beer will last you for several months (if you use the drink only for technical purposes :)).

After we have collected and configured everything, we can start printing. If you have an LCD screen, then the file can be transferred for printing using a regular SD card.

The first results may have bumps and other artifacts - do not worry, this is a normal process of "grinding" the printer elements, which will end after a few print cycles.

Tips to make life easier (and sometimes save money)

In addition to the small recommendations given in the text above, in this section I will also give a short list of tips that will greatly simplify the operation of a 3D printer and the life of its owner.

- Do not experiment with nozzles. If you plan to immediately print from materials that require high temperatures, then it is better to immediately take the MK10 extruder. On MK8, you can "hang" special nozzles that support high-temperature conditions. But such modifications often cause difficulties and require special experience. It is better to avoid this fuss on the shore by simply installing the right extruder for you.

- Add starter relay for heated table. Improving the power supply system of this important part for printing with a starter relay will help solve the known problem of RAMP 1.4 - overheating of the transistors that control the power of the table, which can lead to failure of the board.

I made this upgrade after having to throw away a few RAMPS 1.4s.

I made this upgrade after having to throw away a few RAMPS 1.4s. - Select the correct filament diameter for printing. I recommend using 1.75mm plastic for MK8 and MK10. If we take plastic, for example, 3 mm, then the extruder simply does not have enough strength to push it at an acceptable speed - everything will be printed much longer, and the quality will drop. ABS plastic is ideal for MK8, MK10 will be able to produce products from polycarbonate.

- Use only new and precise X and Y guides. Print quality will be affected. It is difficult to count on good quality with bent or deformed guides along the axes.

- Take care of cooling. In the course of my experiments with various extruders, the MK10 showed the best results - it prints quite accurately and quickly. The MK10 can also print plastics that require a higher print temperature than ABS, such as polycarbonate. Although it is not as prone to overheating as its younger brother MK8, I still recommend taking care of its cooling by adding a cooler to your design.

It must be permanently enabled, this option can be configured in Slicer. You can also add coolers to keep the stepper motors at an acceptable temperature, however, make sure that their air flows do not fall on the printed part, as this can lead to its deformation due to too rapid cooling.

It must be permanently enabled, this option can be configured in Slicer. You can also add coolers to keep the stepper motors at an acceptable temperature, however, make sure that their air flows do not fall on the printed part, as this can lead to its deformation due to too rapid cooling. - Consider heat retention. Yes, on the one hand, we are struggling with overheating of the elements. On the other hand, a uniform temperature around the printer will contribute to high-quality printing (the plastic will be more pliable). To achieve a uniform temperature, you can put our printer, for example, in a cardboard box. The main thing is to connect and configure the coolers before that, as described above.

- Consider insulating your desk. Heated table heats up to high temperatures. And if part of this heat leaves properly, heating the printed part, then the second part (from below) just goes down. To concentrate the heat from the table onto the part, you can perform an operation to insulate it.

To do this, I simply attach a cork mouse pad to its bottom using stationery clips.

To do this, I simply attach a cork mouse pad to its bottom using stationery clips.

Pins

I am sure that during the build process you will encounter a number of difficulties specific to your project. Neither this text nor even the most detailed guides will insure against this.

As I wrote in the introductory part, the above does not claim the status of a detailed assembly manual. It is almost impossible to describe all the stages and their subtleties within the framework of one such text. First of all, this is an overview material that will help you prepare for the assembly process (both mentally and financially), understand whether you personally need to bother with self-assembly - or give up on everything and buy a ready-made solution.

For me, assembling printers has become an exciting hobby that helps me solve some issues in home and work affairs, take my mind off programming and do something interesting with my own hands. For my children - entertainment and the opportunity to get unusual and unique toys.