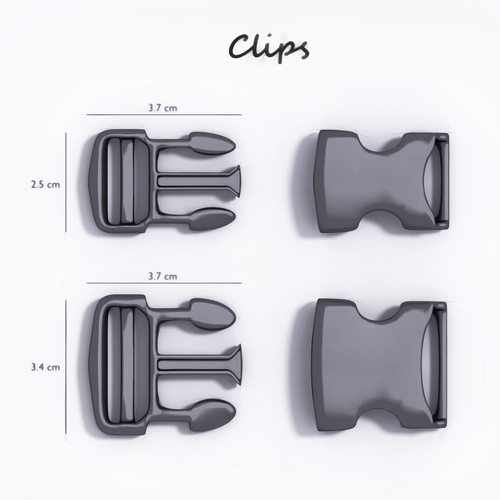

3D printing clips

How do you design snap-fit joints for 3D printing?

What are snap-fit joints and how do they work? This in-depth guide discusses the benefits of 3D printing snap-fit connectors and clips and gives design and material recommendations for designing custom parts with snap-fit joints.

Snap-fit joints are a quick and easy way to connect two 3D-printed components by using interlocking features. Not only are they a low-cost and time-saving connection method, but they can also reduce the number of parts needed in an assembly. Plus, they offer the possibility of rapid assembly and disassembly.

This article covers the basics of snap-fit joints (also called connectors and clips) for 3D printing , what to consider when designing snap-fits with plastics and thermoplastics and which 3D printing process is optimal for manufacturing the best snap-fits.

Does Hubs have a snap-fit tutorial?

Before (or after) diving into this comprehensive guide, check out this nifty tutorial on designing snap-fit joints for 3D printing.

What are snap-fit joints (or connectors/clips)?

A snap-fit joint is a cost-effective and relatively simple method of attaching two 3d-printed plastic components. Also known as a connector or clip, a snap-fit generally consists of a small and bendable protrusion, like a bead, stud, or hook, and a mating depression that deflects and catches the protruding feature. The two features clicking into place create a robust interlocking connection.

Once the features have clicked into place, an undercut holds the two components of the snap-fit together. Depending on the shape of this integral undercut, snap-fit assemblies can also be designed to make the interlocking connection permanent. A well-designed snap-fit joint with the right material can be used quite a number of times without any noticeable mechanical fatigue.

There are plenty of types of snap-fit types and geometries that follow the basic principles of two interlocking components.

Common types of snap-fits: cantilever and annular joints

The two most widely used and commonly effective types of snap-fit connectors are cantilever and annular joints. Let’s break these down.

Cantilever snap-fit joints

The most common snap-fit joint is the cantilever, consisting of a protrusion (some type of bead or hook) on one end of the component and a structural support feature at the other end. This protrusion is placed into an opening and bends back to lock the connection into place.

Cantilever snap-fits are easy to design and intuitive when it comes to assembly and disassembly. For many applications and cases, cantilevers are the most cost-effective way to connect to components.

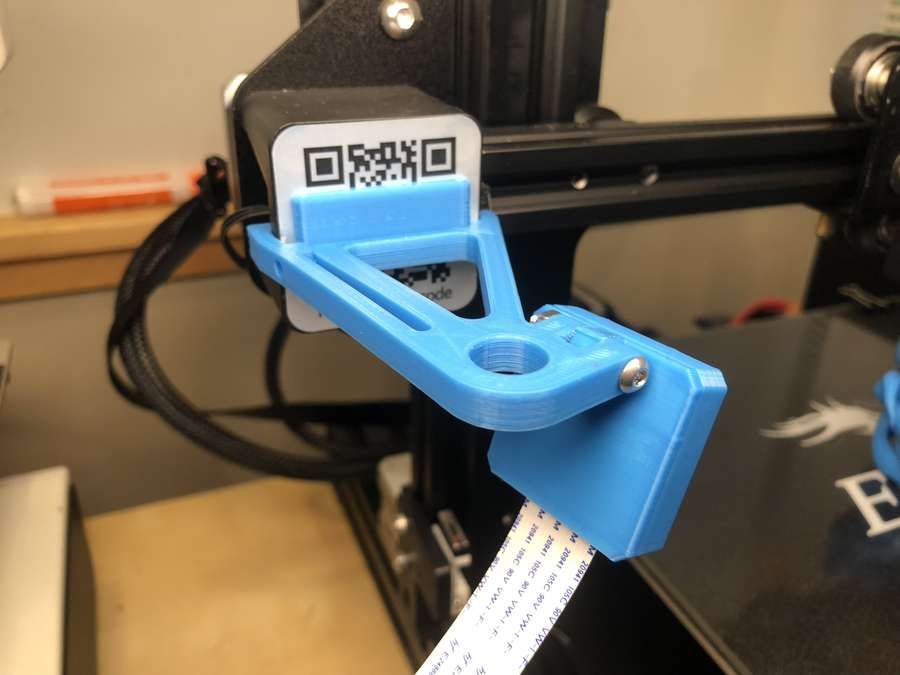

A cantilever snap-fit on a 3D-printed enclosureAnnular snap-fit joints

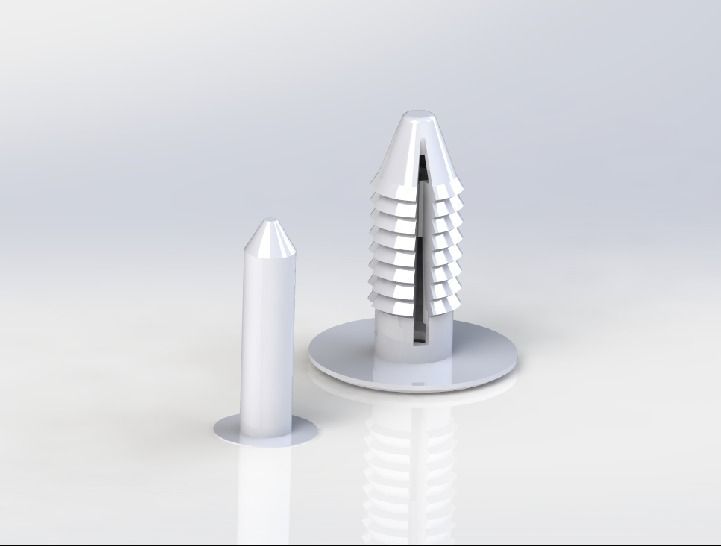

Annular snap-fit joints use a hoop strain to hold a pressed part in place. Common examples of annular snap-fits are bottle and pen caps. With annular snap-fits, it’s possible to create a waterproof seal around the joint.

Common examples of annular snap-fits are bottle and pen caps. With annular snap-fits, it’s possible to create a waterproof seal around the joint.

What are the advantages of snap-fitting with 3D printing?

While injection molding is often seen as the more robust way to produce snap-fit joints, 3D printing is a viable alternative (and even a go-to) with the right design and materials.

3D-printed snap-fits don’t have any of the design limitations associated with injection molding—for instance, draft angles, separation lines, wall thickness and undercuts—and can be designed and altered with ease. This makes them ideal for rapid prototyping, where clearance and fit are critical. This is why designers generally use 3D printing for snap-fits in enclosures .

Snap-fit construction for a DIY loudspeakerWhat materials are used for 3D printing snap-fit joints?

Every 3D printing process has its pluses and minuses when it comes to producing parts with snap-fit connectors. This is due in part to the materials used with each of the major additive manufacturing technologies.

This is due in part to the materials used with each of the major additive manufacturing technologies.

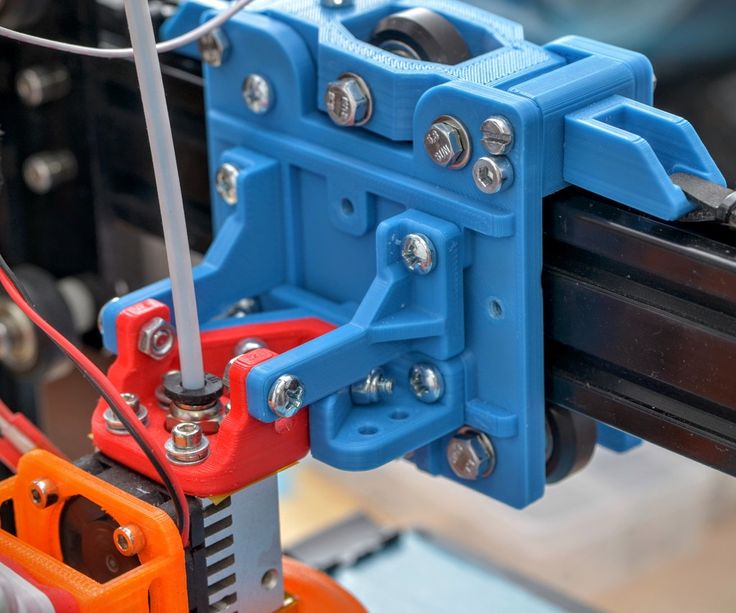

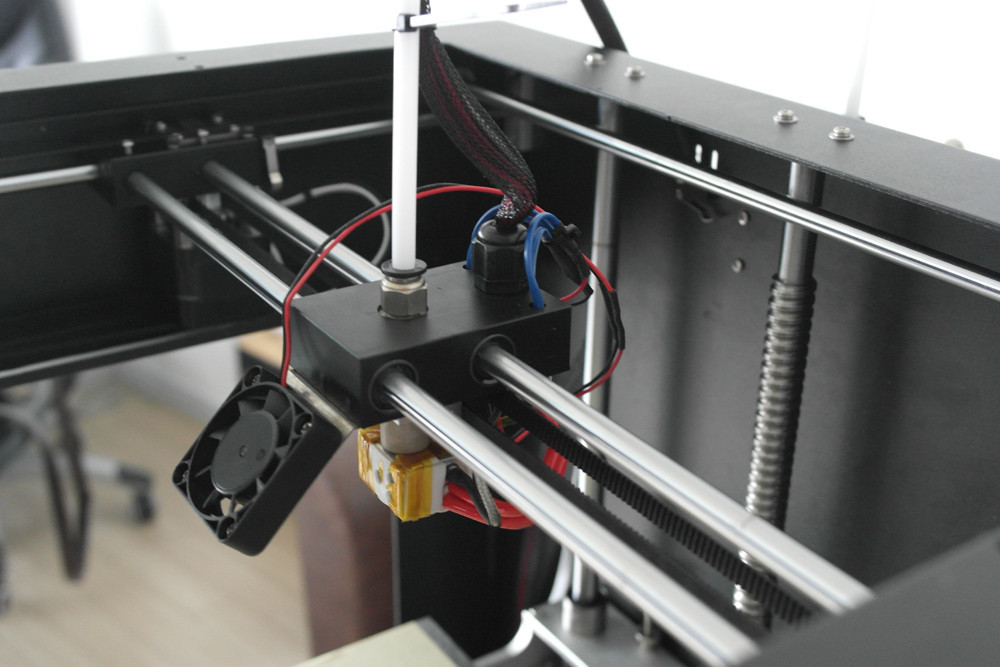

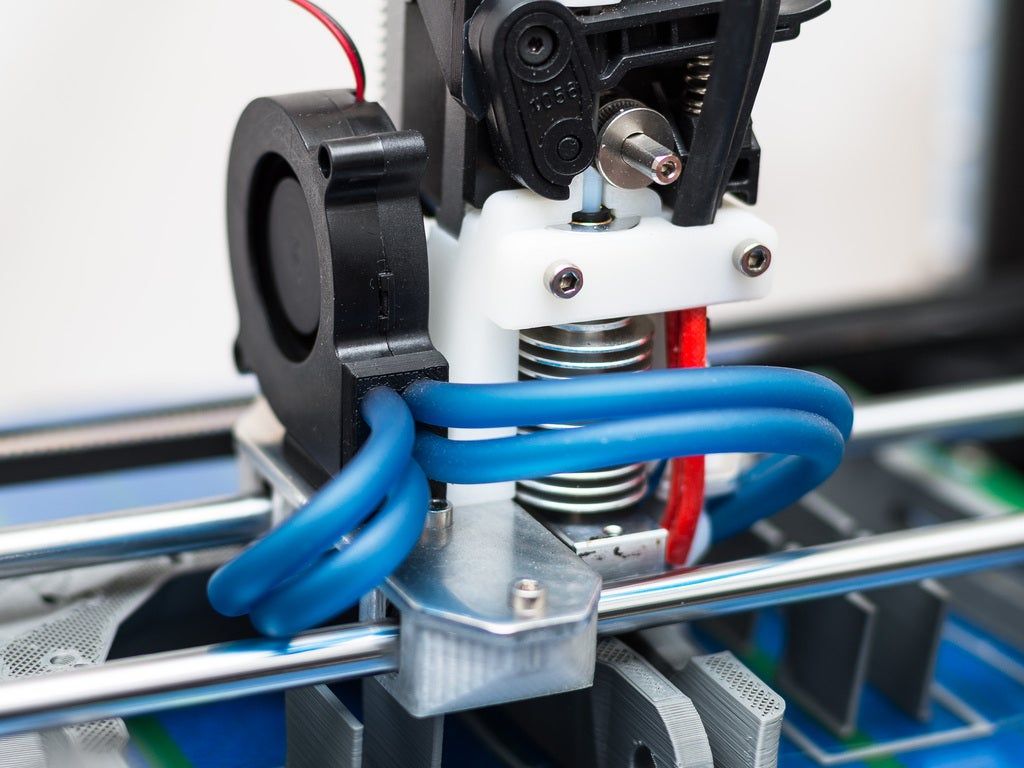

FDM is the most cost-efficient way to manufacture snap-fit connectors. While it’s definitely effective, the process has lower accuracy than other printing methods. If you choose FDM, we recommend using strain-resistant materials, such as ABS, Nylon and TPU.

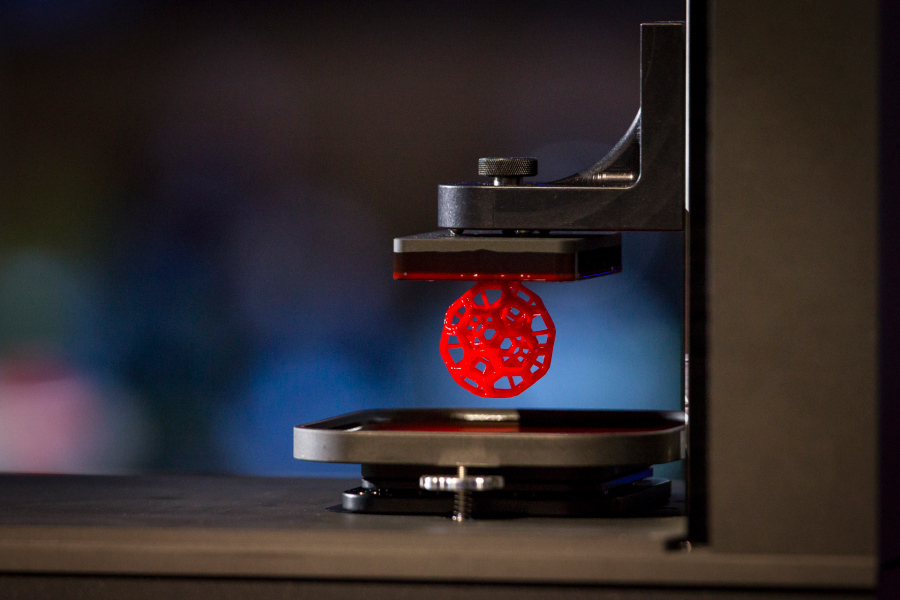

SLA resins are also a viable option for making snap-fit joints, but they are relatively brittle. Using resins may increase the chances of the snap-fit breaking after repeated use. We recommend durable SLA resin if you print snap-fits with this technology.

SLS is more suitable than FDM and SLA for printing functional snap-fit prototypes and end-use parts that will be opened and closed many times. The best material for maximum tear resistance is SLS Nylon.

Similar to SLS, MJF is optimal for manufacturing snap-fit connectors. MJF produces robust parts from Nylon PA 12 and a few other nylon and polypropylene options. What’s important to remember with MJF is that there are several design guidelines to follow to achieve the best results. For instance, we recommend a minimum thickness of 1 mm at the base of the cantilever and a minimum common overhang depth of at least 1 mm.

MJF produces robust parts from Nylon PA 12 and a few other nylon and polypropylene options. What’s important to remember with MJF is that there are several design guidelines to follow to achieve the best results. For instance, we recommend a minimum thickness of 1 mm at the base of the cantilever and a minimum common overhang depth of at least 1 mm.

Explore pricing options for every 3D printing process

FDM SLS MJF SLA

Designing snap-fit clips isn’t the same for all technologies, materials and applications. Engineers faced with snap-fit design for 3D printing often encounter a few key challenges. Here we cover the main ones.

-

Sharp corners in the design may add stress to a cantilever, which may raise the probability of the joint breaking off.

-

Constant stress on plastics and thermoplastics tends to cause creeping (deformation). Creep will eventually weaken the snap-fit or even compromise it entirely.

-

Misplaced gaps on parts will cause tolerance issues, in turn making it harder for components to fit together.

-

The more you assemble and disassemble snap-fit joints, the more likely you are to come across fatigue failure.

In general, snap-fits will encounter the most stress during attachment and should return to their neutral position once the joining process is completed. Depending on the shape of the undercut, snap-fit assemblies can also be designed to make them permanent. A well-designed snap-fit with suitable material can be used many times without any noticeable fatigue.

What are the right tolerances for snap-fit joints?

3D printing properties can vary quite a bit, from printer calibration and materials to the printer technology itself. Because of these varying factors, there are no strict tolerancing rules for printing snap-fit joints and connectors.

While there are no set rules, we do recommend the following optimal tolerances for different types of 3D printers.

-

For FDM (fused deposition modeling): 0.5mm

-

For SLA (stereolithography), SLS (selective laser sintering) and MJF (Multi Jet Fusion): 0.3mm

When designing snap-fit joints for 3D printed parts, it is important to consider features that will reduce stress and strain on the snap-fit assembly. Here are some of our best practices for designing snap-fit joints for 3D printing.

Taper the design

A snap-fit cantilever with a constant cross-section has an uneven distribution of strain. We recommend reducing the cross-section of the cantilever beam over its length. This uses less material and results in more even distribution of strain across the entire cantilever.

This uses less material and results in more even distribution of strain across the entire cantilever.

Fillet the base of the cantilever:

Adding a fillet at the base of a cantilever will help distribute stress over a broader area, resulting in a stronger connection between snap-fit components. The radius of the fillet should be at least 0.5 times the thickness of the cantilever’s base.

Increase the width:

Increasing the width of the clip, if it’s feasible given any design constraints, makes the design stronger. You may need to iterate several times to get the right part stiffness, and remember that the clip should be at least 5mm wide.

Deflect during assembly:

To help reduce stress and improve the strength of the connection, make sure that the snap-fit cantilever is only deflected during assembly rather than when the components are connected.

Consider build direction:

If possible, avoid designing snap-fit cantilevers that are built up vertically (in the z-direction). These are inherently weaker due to the anisotropic nature of 3D printing.

These are inherently weaker due to the anisotropic nature of 3D printing.

Add lugs:

Consider adding lugs to your assembly to assist with the alignment of components and to transfer some of the shear load your snap-fit clips may be subjected to.

-

Sound design principles can make or break your snap-fit joints. Remember to implement good design practices that reduce stress (fillets, build direction and locating lugs) and strain (tapered profiles and cantilever width).

-

Choose the right tolerances for different 3D printers. Use 0.5mm tolerances for FDM snap-fit connectors and 0.3mm for all other 3D printing processes.

-

Do your materials homework beforehand. Prototyping plastics are ideal for design confirmation, but they are typically weaker than SLS or material jetting materials.

Think about functional or end-use materials for applications where the connector will be opened and closed repeatedly.

Think about functional or end-use materials for applications where the connector will be opened and closed repeatedly.

To explore 3D printing further, check out our full guide for a comprehensive overview and detailed design and manufacturing tips.

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quote3d design - Designing clips that won't break

Ask Question

Asked

Modified 6 years, 4 months ago

Viewed 7k times

$\begingroup$

As my first project, I'm trying to design a holder for glass vials, for a scientific application. The photo below shows the latest design iteration, and also shows the problem with it:

As you can see, one of the clips that's meant to hold the vial in place has broken off. This happened after inserting the vial once or twice.

This happened after inserting the vial once or twice.

I think I understand the reason for this. It's because I'm printing in the orientation shown below, in order to avoid the need for supports. (This will be more important later, when I scale it up to an array of many holders.) This means that it's relying on the strength in the z dimension, which is much weaker than in the other two directions, because it relies on the cohesion between the layers.

My question is whether I can do anything about this by changing the design of the clips, without abandoning my hope of support-free printing. I don't care at all what the design looks like, except that as much of the vial as possible needs to be visible from the front. I'm printing in ABS.

I have tried varying the thickness of the clips. Thinner ones don't break as easily, but they are a bit floppy and aren't very good at keeping the vial vertical. The ones shown are the thickest I've tried - I'm afraid that if they're too thick they won't bend at all. (The vial is supposed to be inserted from the front rather than the top.)

(The vial is supposed to be inserted from the front rather than the top.)

Edit just as an update, here's what it looks like using John Biddle's suggestion, which works perfectly:

- 3d-design

- print-strength

$\endgroup$

2

$\begingroup$

It looks like those clips are thin and need to bend pretty far to let the vial out. Try to make the clips thicker, but with a smaller clip to retain the vial so that it doesn't have to bend as much.

This is what I'm thinking, in beautiful MS-PAINT form:

$\endgroup$

2

$\begingroup$

I agree with the previous assessments -- printing vertically for that part of the clip will definitely alleviate the layer adhesion being your weak point.

You might also consider splitting that clip as a separate modular piece (which will clip/socket/bolt into the stand). Depending on implementation, this would give you the ability to

- Print that part vertically without supports

- Swap the part if it breaks, without having to print the whole assembly again

- Preattach the clip to vials, which may be good or bad depending on your usage

$\endgroup$

1

$\begingroup$

Considering that you wish to print the clip in the vertical orientation but without supports, I would suggest that you create a suitable taper of the clip from the bottom. The taper would provide necessary support-free support but may reduce the amount of bottle access one has to remove it from the clips.

As such, you could also reduce the amount of the straight vertical segment of the clip at the front, which would allow the support-free support to start at a higher level from the bottom.

If the bottle bottom encirclement is raised, you'd receive additional retention. You could then reduce more the upper encirclement and taper for easier release.

I too prefer to design models that require no support, but have run into the same circumstance, where the weaker axis takes a disproportionate load.

$\endgroup$

$\begingroup$

Come on. Wider clips will just survive a bit longer. The real cause is the orientation (plane) of printing.

Continues filament layer will always be more durable than few layers sticked together.

So the question is why not to change printing plane? You can use better design which utilizes support without using "support material"

$\endgroup$

$\begingroup$

The Short

- Just print vertically

- Reduce the clip size to bring them closer to the centerline

- Try a vapor treatment or epoxy to increase strength

The Long

Ultimately, printing the object vertically (so the clips are printed horizontally) would be the strongest solution.

Alternatively, you could adjust your model to bring down the size of the clips to reduce the strain. Consider making more of a cup or cone on the bottom for the vial to slide into center. Then reduce the length of the clips to bring the closer to where the center of the vial will be. Make sure, however, that your clips still curve slightly around the center (and maybe a mm or two beyond). From a design point, the bottom clip is probably unnecessary.

Another option might also be to use a small vapor treatment on the ABS. Depending on how deep the alcohol penetrates, it could diminish some of the issues with the part cracking along the grain. This is just a fairly labor intensive process compared to some of the others posted here.

Side note, those are great looking prints! I like how smooth ABS can look. Its hard to tell, but it looks like your part has a bit of warping on the bottom. Definitely look into some of the warping questions here on Stack.

$\endgroup$

2

$\begingroup$

Printing the model vertically should certainly be considered, as that will alleviate your issue by a whole lot. If altering the design by adding a taper to your model isn't what you are looking for, placing a manual, removable support structure at the outer edge og the overhang could also be an option. This way, you could print the overhang as a bridge, making it much easier to print vertically.

If altering the design by adding a taper to your model isn't what you are looking for, placing a manual, removable support structure at the outer edge og the overhang could also be an option. This way, you could print the overhang as a bridge, making it much easier to print vertically.

Also, have you considered using another material than ABS? There are a large variety of filament types available that have better semi-flexible properties than ABS, without sacrificing overall strength. For instance, PETG and Taulman's Alloy 910 filaments are both very strong, and surprisingly flexible.

$\endgroup$

1

$\begingroup$

If you don't want your clip to break, you'll have to engineer in some form of flexibility in a strong part of your design. For example, right now it looks like the bases of the clips are sitting rather solidly on the underlying surface such that it can't move. I'd suggest that instead it might be better to have two clips attach separately to the bottom using a "post", and have each post attached to the solid part of the base with a piece of plastic whose horizontal cross-section is a somewhat-rounded accordion-style double zig-zag.

I'd suggest that instead it might be better to have two clips attach separately to the bottom using a "post", and have each post attached to the solid part of the base with a piece of plastic whose horizontal cross-section is a somewhat-rounded accordion-style double zig-zag.

From the top:

Having multiple "pleats" will mean that each degree that the clips flex outward will only require each pleat to flex a fraction of a degree. You'd have to play around to find out what number of pleats would give a suitable degree of stiffness and flexibility, but if the printer renders the design by drawing the zig zags, stresses should be concentrated in the directions where the material is strongest.

$\endgroup$

reviews, photos and characteristics on Aredi.ru

Our website displays products that are automatically imported from allegro.pl and translated into Russian.

Since we are not the seller of the product displayed on our site, we cannot have all the information about a particular product. Additional information about the goods can be found in several ways:

Additional information about the goods can be found in several ways:

1. Read the description in detail. Usually all the necessary information is in the official description on the lot page.

2. If the information you are interested in is not in the description, you can ask the question directly to the seller. He will respond to you within one business day.

3. If you have a rich experience of surfing the Internet, you may be able to find information about this product in various forums and other Internet resources using global Internet search services.

4. If you do not speak the language or do not want to clarify the information for any other reason, please contact us - we will be happy to help you. In order for us to ask the seller a question, place an order and write down your questions in the comments to the product. During the day we will make a request to the seller, comments will appear in your personal account.

1.Search by keywords, check the catalog on the left

Suppose you want to find a headlight for AUDI, but the search engine returns a lot of results, then you will need to enter the exact make of the car in the search box, then in the list of categories that is on the left, select a new category (Auto Parts - Car Parts - Lighting - Headlights headlights). After, from the presented list, you need to select the desired lot.

After, from the presented list, you need to select the desired lot.

2. Shorten the query

For example, you need to find the front right fender for KIA Sportage 2015, do not write the full name in the search box, but write the fender KIA Sportage 15 . The search engine will say "thank you" for a short, clear question that can be edited based on the search engine's results.

3. Use similar combinations of words and synonyms

The system may not understand any combination of words and translate it incorrectly. For example, the query "computer desk" has over 700 lots, while the query "computer desk" has only 10 lots.

for example, looking for glass on your smartphone, you need to score "glass on xiaomi redmi 4 pro" and not "glass on xiaomi redmi 4 pro".

5. Write abbreviations and abbreviations in English

If you give an example, the phrase “bmw e65 hub” will give no results due to the fact that in e65 the letter e is Russian. The system does not understand this. In order for the automation to recognize your request, you need to enter the same thing, but in English - “BMW e65 hub”.

In order for the automation to recognize your request, you need to enter the same thing, but in English - “BMW e65 hub”.

6. Few results? Look not only in the title of the ad, but also in the description!

Not all sellers write the necessary search parameters in the ad title, so use the search function in the ad description! For example, you are looking for a turbine and you know its number "711006-9004S”, insert the number into the search box, select the “search in description” checkbox - the system will return much more results!

7. Feel free to search in Polish if you know the name of the thing you need in this language

You can also try using Yandex or Google translators for these purposes. Remember that if you have unresolvable problems with the search, you can always contact us for help.

50 3D Printing Ideas

It looks like we'll soon be drowning in unnecessary things made for 3D printing projects. But you can do something that will really be useful! If you're running out of ideas, here's a list of 50 3D printable items you're unlikely to throw away.

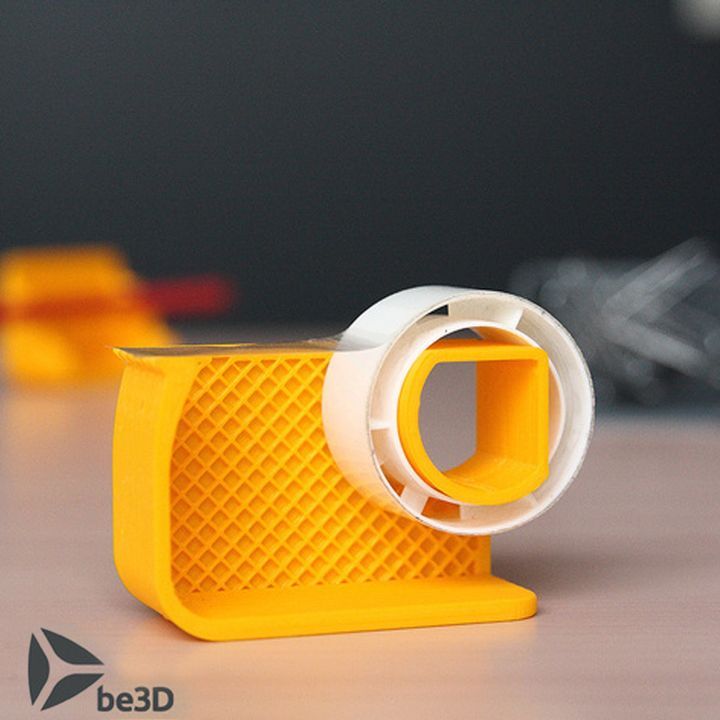

Bag clip with screw cap

Now the bag clip will have a new feature - a hole with a lid for quick access, as in the photo. This clip is easy to print and convenient to use. Strange that no one thought of this before.

Author: Minkix

Where to download: Thingiverse

Modular Furniture Connector

This connector allows you to quickly assemble modular furniture. The default model is designed for 17×17 mm wood, but the size and material can be changed to suit your needs using a parametric file for customization.

Creator: LeFabShop

Where to download: Cults

Sealant cap

No more throwing open sealant tubes away. The screw cap for the nozzle presses the o-ring tightly against the body of the tube and closes the access of air to the solvents inside.

Author: The-Mechanic

Where to download: Thingiverse

Laptop niche

Now the laptop will always be at hand, but hidden from prying eyes in a special niche that is attached to the bottom of any coffee table.

Author: Too Snide

Download: Thingiverse

Phone holder - Candice

Elegant and simple, perhaps the easiest thing you can print on a 3D printer.

Author: Clem.C2

Where to download: Cults

Polypanel

The idea of Polypanels came from Devin Montes. A polypanel is a series of three-dimensional building blocks. The individual elements of a Polypanel look simple, but if you print a lot of them and different types, you can create all sorts of complex designs. Something like LEGO where you can design each brick.

Creator: MakeAnything

Where to download: MyMiniFactory

Clothes Hook

This clothes hook is designed as an E3D nozzle and can be printed as many times as you need for all your clothes.

Author: Filar3D

Where to download: Cults

Plant Pot

This anatomical brain flower pot is easier to print than it looks, creator DrFemPop says. For assembly, it is only necessary to glue the parts after printing. It turns out an original house for plants.

For assembly, it is only necessary to glue the parts after printing. It turns out an original house for plants.

Author: DrFemPop

Where to download: Cults

Door Holder

This is a simple solution for holding a door. Double-sided adhesive tape is sufficient for surface mounting.

Author: Akiraraiser

Where to download: Thingiverse

Piggy bank

A simple piggy bank for beginners, no complicated settings.

Author: lecaramel

Where to download: Thingiverse

Cable Ties

This tie is perhaps the simplest and most ingenious of all devices. Clips are printed as a whole sheet at once, and then the required amount can be cut off from it.

Author: Sunshine

Where to download: Cults

Roller ruler

An indispensable device if you need to measure the length of something non-linear: a piece of rope, a curved line, a perimeter with bends, etc. The ruler is called Geneva and has step 5 mm.

The ruler is called Geneva and has step 5 mm.

Author: MechEngineerMike

Where to download: Thingiverse

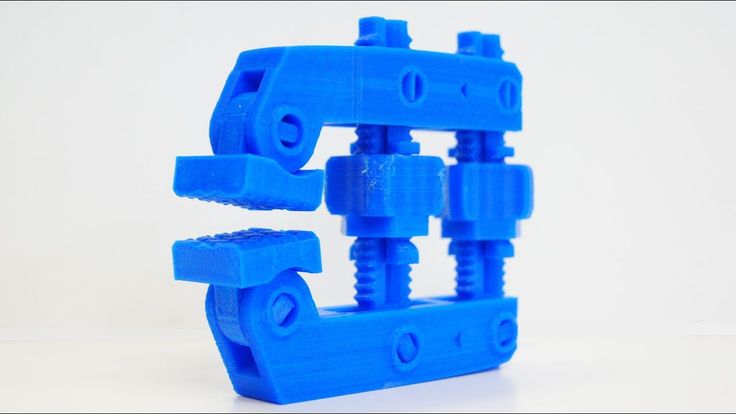

Pliers

This small solid piece of plastic can replace your pliers/pliers. These forceps take the force to the handles and redistribute it at the end of the grip. It's definitely pliers. Just smarter.

Author: BYU CMR

Where to download: Thingiverse

Cylindrical textured box

Beautiful tube from Syboulette decorated with hexagons. Well suited as a kitchen utensil for storing oatmeal, rice and other crumbly substances.

Author: Syboulette

Where to download: Cults

Door Stop

This stop is modeled after the Guyer Anderson cat statue in the British Museum. The design is hollow, which allows you to fill the limiter with something for additional weight.

Author: Duaneindeed

Where to download: Cults

Plague Doctor Mask

Not exactly the most useful item on the list since bubonic plague is a thing of the past. But a mask can come in handy, for example, when you need to clean up after your pet. And you can also go to the carnival in it.

But a mask can come in handy, for example, when you need to clean up after your pet. And you can also go to the carnival in it.

Author: Odrivious

Download: Cults

Universal Spool Holder

This adjustable spool holder uses a spring and an adjustable rewind clutch. It's the perfect place to store those pesky wires.

Who made it: Vincent Goenhuis

Where to download: Thingiverse

Sturdy waterproof box

This tight-fitting box will keep things from getting wet. Print it in PLA or PETG, add a flexible TPU seal and M3 screws for the spring hinge, and you're done.

Author: ZX82

Where to download: Cults

Dice

This dice is suitable for flat 3D printing and has a face size of 16mm.

Author: Devin Montes (MakeAnything)

Where to download: MyMiniFactory

Collapsible Coat Rack

Really cool coat rack. That's all there is to say about her.

Author: Komaru

Where to download: Thingiverse

Business Card Holder

Perfect for showing off your new business cards to your Wall Street friends. What could be more delightful than this Zippo card holder with flip-top lid.

Author: PentlandDesigns

Where to download: Cults

Pencil and pen holder

Iceberg or melting beehive? Be that as it may, this is a handy pen and pencil holder that is cheaper to print than to buy.

Author: BeeVeryCreative

Where to download: Cults

Groovi Monster Audio Amplifier

This is a passive smartphone audio amplifier that looks stylish and does the job well. It's called Groovi Monster for a reason.

Author: 3DShook

Where to download: Cults

Cup holder

Can be used not only as a cup holder, but also as a coaster for hot dishes. The dimensions of the template are easily adjusted to suit any size cookware.

Author: jmdbcool

Where to download: Thingiverse

Clamp

Designed to hold different materials, including the ends of the wire in the coil. Also great as a clothespin replacement.

Author: Med

Where to download: Cults

Pencil Box

Suitable for storing all your desk trivia and trinkets (memory cards, rubber bands, pencils, paper clips, etc.).

Author: Monkey3D

Where to download: Cults

Headphone holder

This is a duck. Yes, you can hang headphones on it.

Author: Toshi_TNE

Download: Thingiverse

Polyhedral Succulent Pot

Unusual geometric pots for your growing succulent collection. These small pots can be configured to be connected together.

Author: PrintFutura

Download: Cults

Survival Whistle

This is a survival whistle with original design. It is durable, easy to make and very loud (118 dB is more than enough to be heard in an emergency).

Author: Joe Zisa

Where to download: Thingiverse

Measuring cube

A simple and original measuring cube for the kitchen. On each side there are recesses for measuring the volume of ingredients (in cups - according to the American system, and in metric units for everyone else). It is best to print with PETG material, it is the safest for products.

Author: iomaa

Where to download: Thingiverse

Hinge

This is a parametric hinge that can be sized to suit specific needs.

Written by Rohin Gosling

Where to download: Thingiverse

Car Eyewear Holder

Attaches to your car's sun visor. Glasses will always be at hand.

Author: Trevor Long

Download: Thingiverse

Opener

The simplest things are usually the most useful. Convenient and easy to print opener. Covers the sharp edges of the cork as much as possible, protecting you from injury.

Author: Jeremy Peterson

Download: Thingiverse

Superhero Keychains

Sometimes you need to remind yourself of your hidden superpowers. Stylish and cool keyrings are well suited as a small gift.

Author: Formbyte

Where to download: Cults

Headphone stand

Will be useful for music lovers and gamers who use headphones a lot and often. After all, now they will no longer roll around anywhere.

Author: MakerBot

Where to download: Thingiverse

Bag Clip

The model consists of two printed parts. Allows you to keep packages closed and keep food fresh longer.

Author: Walter Hsiao

Download: Thingiverse

Plastic wrench

Handy wrench, but don't choose soft plastic to make it.

Author: Daniel Noree

Where to download: Cults

Sliding Decal

No more worrying about whether cups are clean or dirty right now in the dishwasher! With the help of a special mechanism, the slider easily changes the inscription on the plate.

Who made it: MiddleFingerBoss

Where to download: Thingiverse

Folding basket

Cool picnic item. A folding square basket with five sections is printed from several parts and then glued together. For product safety, it is recommended to use PETG plastic.

Author: PatternToPrint

Where to download: Cults

Self-watering plant pot

Houseplants are dying from your forgetfulness? This will not happen again! This pot will water them by itself, and your conscience will be clear.

Author: Parallel Goods

Where to download: Cults

Maze Gift Box

Cash is not the most original gift. But if you present them in such a gift box, your friend will surely like it. The lucky recipient will have to work hard to get to the prize, because there is only one right way.

Author: Robert

Where to download: Thingiverse

Wired headphone holder

The headphones will now be protected from tangles and breakage.

Author: Robert

Where to download: Thingiverse

Tube Squeezer

Will help squeeze out the contents of the tube to the last drop. Wide enough to fit most tubes on the market. Printed in three separate parts.

Author: Justin Otten

Where to download: Thingiverse

Webcam Shutter

The best thing for the paranoid and just for those who are uncomfortable being under the gun of a webcam. Instead of sticking tape or sticky tape over the lens, attach a slider shutter to the body and open it when you need a video call.

Author: Horizon Lab

Where to download: Cults

Prefabricated Hexagonal Crates

Useful to free the table from the noodles of cables, wires and just every little thing. The design can be easily expanded if necessary.

Author: Dan O'Connell

Where to download: Cults

Wall Mounted Phone Shelf

Attach the shelf to a power outlet and place your phone on it while charging.