3D printer resin manufacturers

Who We Are - Photocentric

Who we are

Innovators in photopolymer

Since 2002 Photocentric has been at the cutting edge of innovation in photopolymer. We have reacted to create oligomers that make the building blocks of polyurethanes for nearly 20 years, primary in the process, expert in their formulation and dedicated to provide value by supplying them in bulk.

Our core expertise

3D printing

Applying our understanding of UV photopolymerisation to the visible part of the spectrum unlocked the power of the LCD screen in 3D printing. We have become the world leaders in LCD 3D printing.

Explore >

We are the world’s largest and most trusted manufacturer of crystal clear polymer craft stamps. We make millions of crystal clear beautifully detailed craft stamps, all made using imagepac.

Explore >

Office stamps

Where it all began. In 2002 we patented a unique concept, our imagepac photopolymer package. Since then we have continuously improved the printing process.

Explore >

Innovation

Over 30 scientists, engineers and chemists work to create new materials and hardware that will become the 3D printed applications of tomorrow.

Explore >

- We create the concept of autonomous digital manufacture using LCD screens.

- We move into our new 66,000 sqft 3D printing facility in Peterborough.

- We welcome HRH, The Princess Royal to our headquarters in recognition of our 3 Queen’s Awards.

- We move into a new 51,000 sqft building in Avondale, AZ.

- We launch the LC Opus, our first UV 3D Printer.

- Using just 45 Magna printers, we manufacture 1,000,000 face shields a month, or 50,000 a day, consuming an IBC of resin every 24 hours. We have finally demonstrated the true power of using LCD screens.

- We receive our 3rd Queen’s Award for Innovation for the invention of the LCD 3D printer.

- We are awarded a Faraday grant to develop novel 3D printed solid state batteries.

- We start construction of new 66,000 sqft 3D printing facility in Peterborough.

- We create Photocentric 3D Inc to serve the 3D printing market in USA.

- Liquid Crystal Magna, Dental and Pro are all listed in Aniwaa’s best large volume 3D resin printers.

- We partner with BASF to start the journey together to enable custom mass manufacture by offering functional materials with fully costed pricing models.

- The Liquid Crystal Precision 1.5 is listed in Aniwaa’s best resin 3D printers and wins ‘Best Personal Printer of the Year’ at the 3D Printing Industry Awards.

- We launch our largest printer to date, the Liquid Crystal Magna.

- We print dense alumina parts using our Liquid Crystal Ceramic printer.

- We employ our 30th research scientist working in 3D printing.

- We receive our 2nd Queen’s Award for International Trade in recognition of our growth in overseas sales.

- We launch the Liquid Crystal Precision 1.

5 and Liquid Crystal HR 2 3D printers.

5 and Liquid Crystal HR 2 3D printers.

- We launch Liquid Crystal Precision printer, our highest resolution printer driven by a 5.5” LCD screen

- We manufacture Colossus the largest LCD 3D printer ever, equipped with a 75” screen.

- We launch the Liquid Crystal HR 3D Printer.

- We win awards for Innovation, R&D and Best Overall Business at the SME Awards.

- We are awarded The Queen’s Award for Innovation for imagepac.

- We move into a new 24,000 sqft building in Phoenix, Arizona.

- We design Costa 2, the largest automatic stamp processing machine ever at 120ft long and it processes over 70,000 stamps in a single shift.

- We launch the Liquid Crystal 10, the world’s first LCD driven 3D printer.

- We move into a 35,000 sqft facility in Peterborough.

- We patent 3D printing using daylight polymer and LCD screens.

- Photocentric is awarded a UK Govt Innovate grant to develop a protype for a new type of 3D printer powered by LCD screens.

- Using knowledge from our first daylight activated Stampmaker resins we make a 3D printed object created on a LCD screen.

- We sell imagepac to users to make office stamps and use it ourselves to make millions of crystal-clear stamps.

- We make our 500 millionth stamp.

- Craft stamps become our core market and we become expert in handling custom designs automatically.

- We export 70% of our turnover.

- We expand and automate stamp production.

- We open Photocentric Inc in Phoenix, Arizona to better supply the largest craft market in the world with USA made product.

- We design and manufacture the first automatic inline stamp processing machine, Costa. It processes imagepac sachets on a large rotary process automating liquid polymer processing for the first time.

- Manufacture imagepac and processing stamps automatically in larger quantities than ever.

- Invent Stampmaker, the lowest cost and fastest stamp making machine ever sold.

Sales of Stampmaker have now exceeded 50,000 units.

Sales of Stampmaker have now exceeded 50,000 units.

- We use imagepac to make stamps and rapidly become the largest clear stamp manufacturer in Europe. We create our largest exposure unit, imagebox 10.

- Start selling photopolymer to make flexographic printing plates.

- We patent the digital exposure of daylight activated photopolymer using LCD screens.

- We make flexographic and lithographic plates using LCD screens.

- We patent the world’s first daylight activated photopolymer.

- We invent a home stamp making product, imagepac daylight, that uses the light from a desk lamp with a negative printed on a home printer to make a printing plate. It is the first application of daylight cured photopolymer outside dental in the world. Many years later this novel daylight chemistry becomes the inspiration for our 3D printing business.

- We launch A8 imagepac size which becomes our most popular size, we now make sachets in all sizes from A8 up to A3.

- We automate the manufacture of imagepac by designing our first automatic filling and sealing machine.

- We create imagepac xtra which is designed for business stamps and has an integrated backing sheet.

- We automate the construction of this multi-layered package.

- We design our own exposure unit to make stamps using the imagepac sachets we make and call it imagebox. It’s our first experience of designing and engineering a machine.

- Photocentric Ltd is formed in the summer of 2002 by Paul Holt in a small room in Peterborough. The basis of the company is to commercialise Paul Holt’s patent of pre-packaging photopolymer to enable stamp making- small flexographic printing plates. It makes stamps easier and faster.

- Our first imagepac packages containing photopolymer are made, it is the world’s first pre-packaged photopolymer printing plate.

- At first, imagepac is made manually by folding plastic, sealing the edges, filling the photopolymer and rolling the air bubbles out with a rolling pin.

It’s a slow and variable process!

It’s a slow and variable process! - We improve the product and export it around the world.

- We create the concept of autonomous digital manufacture using LCD screens.

- We move into our new 66,000 sqft 3D printing facility in Peterborough.

- We welcome HRH, The Princess Royal to our headquarters in recognition of our 3 Queen’s Awards.

- We move into a new 51,000 sqft building in Avondale, AZ.

- We launch the LC Opus, our first UV 3D Printer.

- Using just 45 Magna printers, we manufacture 1,000,000 face shields a month, or 50,000 a day, consuming an IBC of resin every 24 hours. We have finally demonstrated the true power of using LCD screens.

- We receive our 3rd Queen’s Award for Innovation for the invention of the LCD 3D printer.

- We are awarded a Faraday grant to develop novel 3D printed solid state batteries.

- We start construction of new 66,000 sqft 3D printing facility in Peterborough.

- We create Photocentric 3D Inc to serve the 3D printing market in USA.

- Liquid Crystal Magna, Dental and Pro are all listed in Aniwaa’s best large volume 3D resin printers.

- We partner with BASF to start the journey together to enable custom mass manufacture by offering functional materials with fully costed pricing models.

- The Liquid Crystal Precision 1.5 is listed in Aniwaa’s best resin 3D printers and wins ‘Best Personal Printer of the Year’ at the 3D Printing Industry Awards.

- We launch our largest printer to date, the Liquid Crystal Magna.

- We print dense alumina parts using our Liquid Crystal Ceramic printer.

- We employ our 30th research scientist working in 3D printing.

- We receive our 2nd Queen’s Award for International Trade in recognition of our growth in overseas sales.

- We launch the Liquid Crystal Precision 1.5 and Liquid Crystal HR 2 3D printers.

- We launch Liquid Crystal Precision printer, our highest resolution printer driven by a 5.

5” LCD screen

5” LCD screen - We manufacture Colossus the largest LCD 3D printer ever, equipped with a 75” screen.

- We launch the Liquid Crystal HR 3D Printer.

- We win awards for Innovation, R&D and Best Overall Business at the SME Awards.

- We are awarded The Queen’s Award for Innovation for imagepac.

- We move into a new 24,000 sqft building in Phoenix, Arizona.

- We design Costa 2, the largest automatic stamp processing machine ever at 120ft long and it processes over 70,000 stamps in a single shift.

- We launch the Liquid Crystal 10, the world’s first LCD driven 3D printer.

- We move into a 35,000 sqft facility in Peterborough.

- We patent 3D printing using daylight polymer and LCD screens.

- Photocentric is awarded a UK Govt Innovate grant to develop a protype for a new type of 3D printer powered by LCD screens.

- Using knowledge from our first daylight activated Stampmaker resins we make a 3D printed object created on a LCD screen.

- We sell imagepac to users to make office stamps and use it ourselves to make millions of crystal-clear stamps.

- We make our 500 millionth stamp.

- Craft stamps become our core market and we become expert in handling custom designs automatically.

- We export 70% of our turnover.

- We expand and automate stamp production.

- We open Photocentric Inc in Phoenix, Arizona to better supply the largest craft market in the world with USA made product.

- We design and manufacture the first automatic inline stamp processing machine, Costa. It processes imagepac sachets on a large rotary process automating liquid polymer processing for the first time.

- Manufacture imagepac and processing stamps automatically in larger quantities than ever.

- Invent Stampmaker, the lowest cost and fastest stamp making machine ever sold. Sales of Stampmaker have now exceeded 50,000 units.

- We use imagepac to make stamps and rapidly become the largest clear stamp manufacturer in Europe.

We create our largest exposure unit, imagebox 10.

We create our largest exposure unit, imagebox 10.

- Start selling photopolymer to make flexographic printing plates.

- We patent the digital exposure of daylight activated photopolymer using LCD screens.

- We make flexographic and lithographic plates using LCD screens.

- We patent the world’s first daylight activated photopolymer.

- We invent a home stamp making product, imagepac daylight, that uses the light from a desk lamp with a negative printed on a home printer to make a printing plate. It is the first application of daylight cured photopolymer outside dental in the world. Many years later this novel daylight chemistry becomes the inspiration for our 3D printing business.

- We launch A8 imagepac size which becomes our most popular size, we now make sachets in all sizes from A8 up to A3.

- We automate the manufacture of imagepac by designing our first automatic filling and sealing machine.

- We create imagepac xtra which is designed for business stamps and has an integrated backing sheet.

- We automate the construction of this multi-layered package.

- We design our own exposure unit to make stamps using the imagepac sachets we make and call it imagebox. It’s our first experience of designing and engineering a machine.

- Photocentric Ltd is formed in the summer of 2002 by Paul Holt in a small room in Peterborough. The basis of the company is to commercialise Paul Holt’s patent of pre-packaging photopolymer to enable stamp making- small flexographic printing plates. It makes stamps easier and faster.

- Our first imagepac packages containing photopolymer are made, it is the world’s first pre-packaged photopolymer printing plate.

- At first, imagepac is made manually by folding plastic, sealing the edges, filling the photopolymer and rolling the air bubbles out with a rolling pin. It’s a slow and variable process!

- We improve the product and export it around the world.

Our core values

Innovation

There is always a better way.

Integrity

Treat everyone; staff, customers and suppliers with respect and honesty.

Value

Provide value in our products & services.

Education

Educate and we all benefit.

We are proud members of

The best 3D printing resins for SLA, DLP, LCD & MSLA

The most reliable resins for 3D printing

Order now

Learn more

Order now

Learn more

3D-printing resins for endless applications

Liqcreate is a developing and manufacturing company of premium photopolymers for LCD, SLA and DLP technologies. Our high-end polymers are suitable for a wide range of industries including the prototyping, industrial, entertainment, consumer goods, healthcare and automotive.

Printer compatibility

Our resins are available for a wide variety of SLA, DLP and LCD 3D printers (385 – 420 nm). Do you want to know if your printer is compatible?

Check printer compatibility

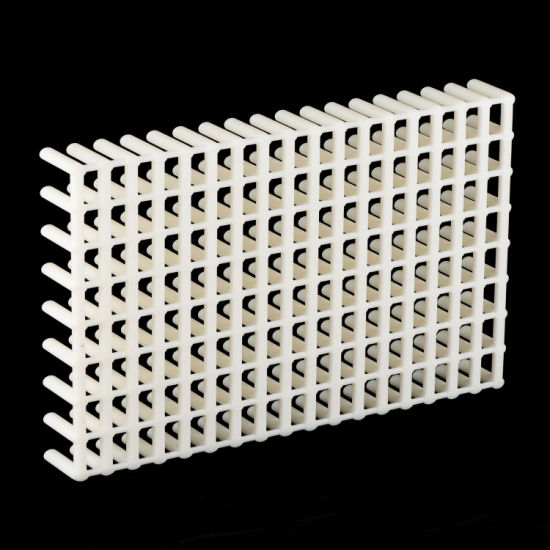

General purpose

Our range of general purpose resins are ideal for prototyping, entertainment and consumer applications. All resins are easy to use and have the best costs/quality performance in the market.

All resins are easy to use and have the best costs/quality performance in the market.

Choose these resins for:

| High | Low odor | Smooth surface |

Learn more

Learn more

Premium

High opacity, no discoloration and perfect quality on LCD 3D-printers: our range of Premium resins will give a premium result on all open source LCD and low power DLP 3D-printers. The Premium resin range includes a tough and flexible resin for functional objects. All our resins do not emit unpleasant odor, so in-office printing will be a piece of cake!

Choose these resins for:

| High | Low odor | Fast LCD printing |

Learn more

Learn more

Creative

Need a 4th dimension in your 3D-print? Our range of creative resins is ideal to create this extra dimension. Think about the endless options when you can add glow, scent, feel or sound to your 3D-print!

Think about the endless options when you can add glow, scent, feel or sound to your 3D-print!

Choose these resins for:

| Glow in | Rechargeable using light | Smooth surface |

Learn more

Learn more

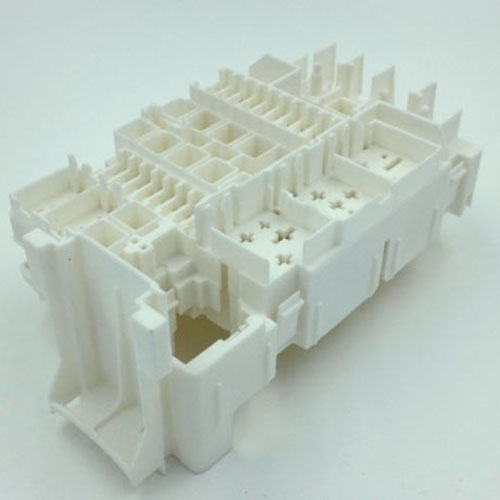

Engineering

Ideal for applications that require specific mechanical properties. This category contains our most advanced photopolymers for professional end results with flexible, tough, impact resistance or extremely strong properties.

Choose these resins for:

| High | Impact resistance | High temp | Extreme |

Learn more

Learn more

Dental

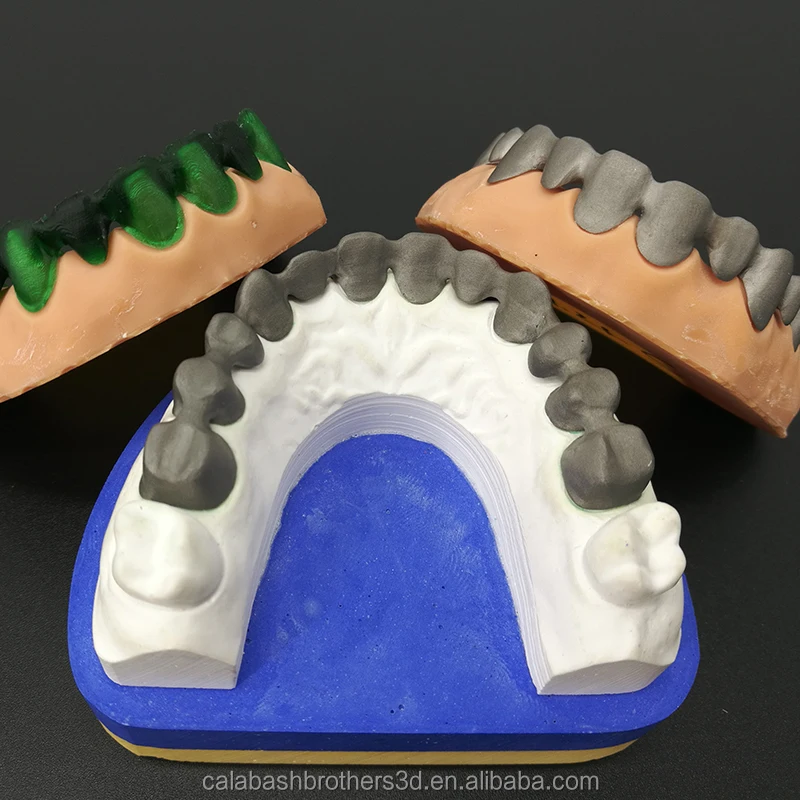

Liqcreate embraces dental 3D printing with a smile. Our range of dental resins are perfect for manufacturing a wide range of models like orthodontic, aligner, C&B and implant models and dental casting parts using the direct investment casting method.

Choose these resins for:

| Dental professionals | High XY accuracy | Low shrinkage |

Learn more

Learn more

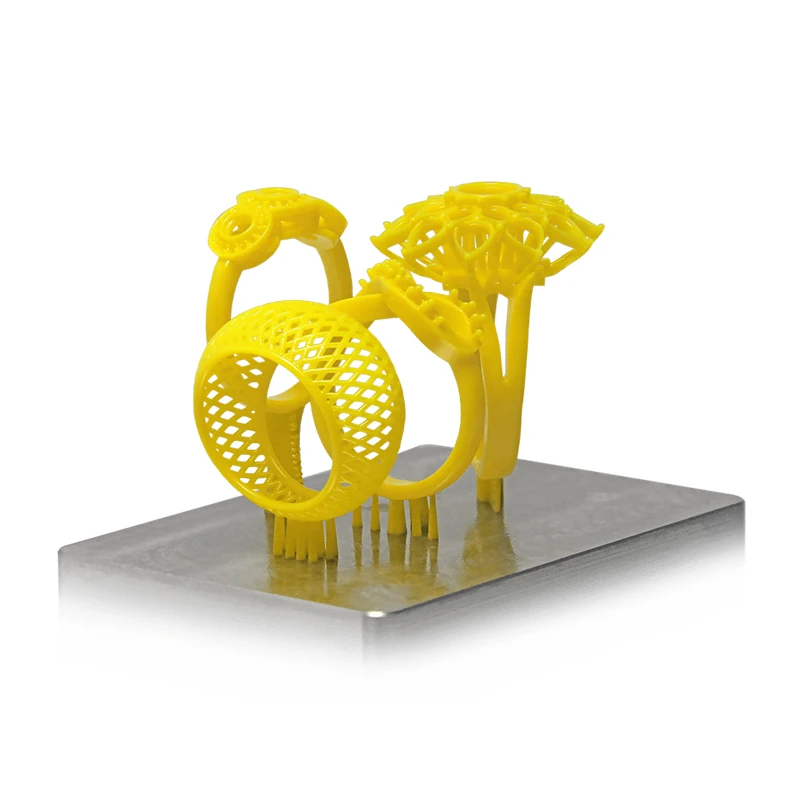

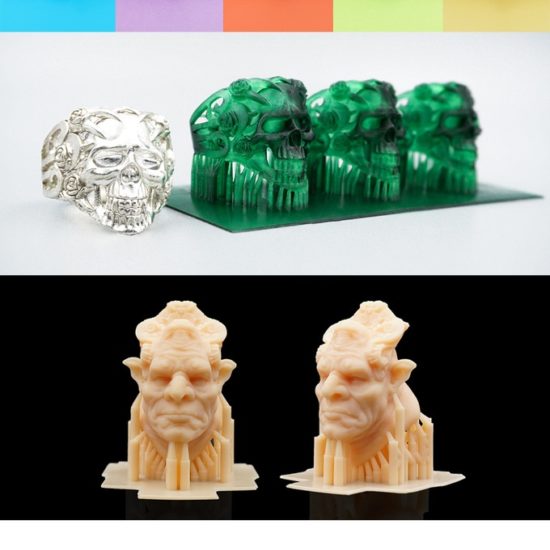

Castable

The perfect resin for manufacturing jewelry, dental and industrial parts. This wax-based material offers smooth Surfaces and crisp details with a clean burnout for a reliable casting process. Create custom made elegant organic geometries with this excellent castable resin.

Choose these resins for:

| Clean & ash free burnout | Wax-based | High accuracy |

Learn more

Learn more

Medical

Every medical application brings its own set of requirements. Think of medical models, dental products and/or applications which are related to skin contact. Liqcreate offers custom resin development for these applications.

Choose these resins for:

| Dental applications | Healthcare applications | Medical models |

Best 3D printing resins for SLA, DLP, LCD and MSLA

Most Reliable 3D Printing Resins

Order

Learn More

Order

Learn More

Endless 3D Printing Resins

SLA and DLP. Our high quality resins are suitable for a wide range of industries, including prototyping, manufacturing, entertainment, consumer products, healthcare and automotive.

Printer compatible

Our resins are available for a wide range of SLA, DLP and LCD (385-420nm) 3D printers. Want to know if your printer is compatible?

Check Printer Compatibility

General Purpose

Our range of general purpose resins is ideal for prototyping, entertainment and consumer applications. All resins are easy to use and have the best value for money on the market.

Choose these resins for:

| High | Low smell | Smooth surface |

Learn more

Learn more

Premium

High opacity, no fading and excellent quality on LCD 3D printers: Our range of premium resins will deliver superior results on all open source LCD and DLP printers printers with low power consumption. The Premium resin range includes a durable and flexible resin for functional objects. All of our resins are odour-free, making office printing a breeze!

Choose these resins for:

| High | Low smell | Quick LCD |

Learn more

Learn more

creative

Do you need 4th dimension in your 3D printing? Our range of creative resins are perfect for creating that extra dimension. Think of the endless possibilities when you can add glow, smell, feel or sound to your 3D print!

Think of the endless possibilities when you can add glow, smell, feel or sound to your 3D print!

Choose these resins for:

| Glow | Rechargeable using light | Smooth surface |

Learn more

Learn more

Engineering

Ideal for applications requiring special mechanical properties. This category includes our most advanced photopolymers for professional end results with flexible, tough, impact resistant or extremely tough properties.

Choose these resins for:

| High | Influence Resistance | High temp | Extreme |

Learn More

Learn More

Dental

Liqcreate uses dental 3D printing with a smile. Our range of dental resins are ideal for producing a wide range of models such as orthodontic, alignment, C&B and implant models, as well as dental casting parts using direct investment casting.

Our range of dental resins are ideal for producing a wide range of models such as orthodontic, alignment, C&B and implant models, as well as dental casting parts using direct investment casting.

Choose these resins for:

| Dentists | High Precision XY | Low shrink |

Learn more

Learn more

Cast

Ideal resin for jewelry, dental and industrial parts. This wax based material offers smooth surfaces and sharp details with clean burnout for a reliable casting process. Create custom elegant organic shapes with this superior casting resin.

Choose these resins for:

| Clean and ash-free burnout | Based on wax | High Precision |

Learn more

Learn more

Medical

Every medical application has its own set of requirements. Think about medical models, dental products, and/or skin contact applications. Liqcreate offers custom resin development for these applications.

Think about medical models, dental products, and/or skin contact applications. Liqcreate offers custom resin development for these applications.

Choose these resins for:

| dental applications | Health Applications | Medical Models |

Consumables for SLA printing Photopolymers

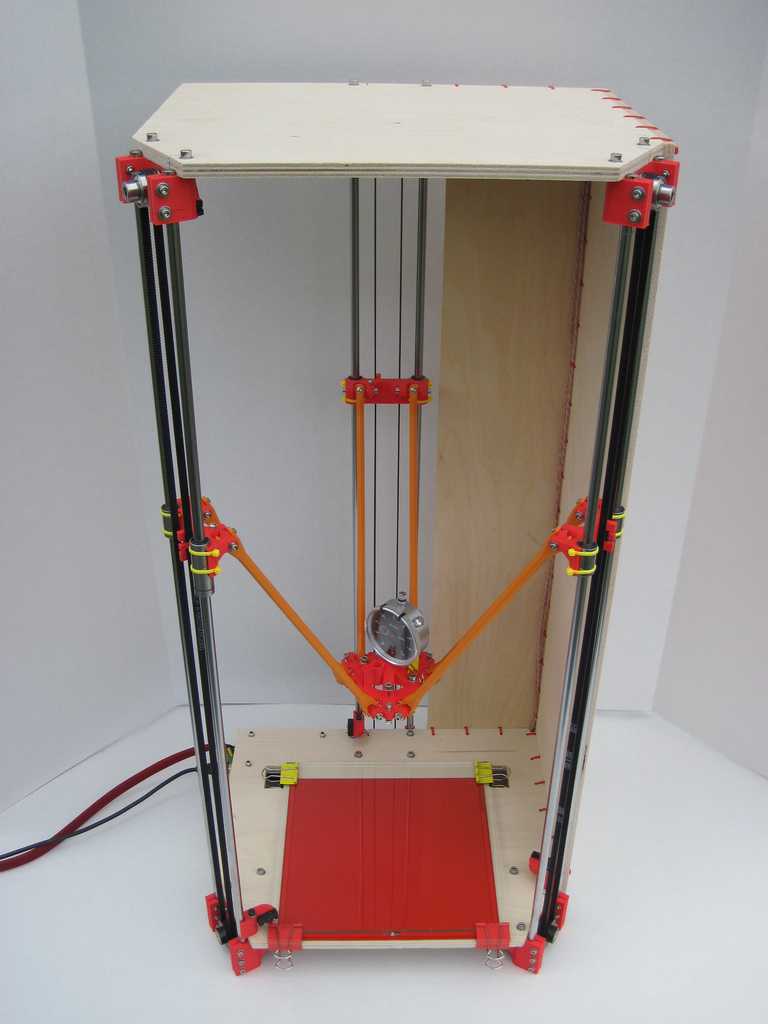

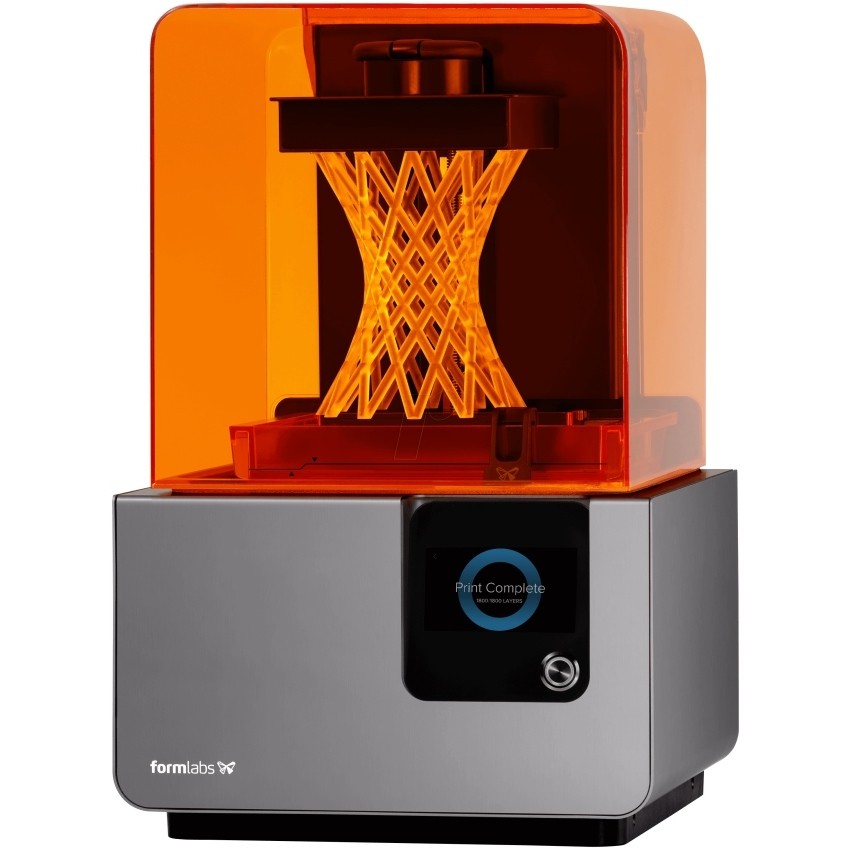

SLA printing is the second most popular 3D technology implemented not only in personal but also in professional 3D equipment. It is for her that compact personal 3D printers Form 1+ and Form 2 from Formlabs, the magnificent Nobel 1.0 from XYZPrinting, the DWS Lab equipment line, as well as professional 3DSLA installations from Starlight 3D, ProX 800 from 3D Systems and Minicube are created.

Each stereolithographic 3D printer uses photopolymer resin as a consumable, while each manufacturer of 3D equipment, as a rule, supplements its product line with photopolymer resins compatible with printers of its own production. ‘

‘

In our 3DMALL online store you can buy not only the best stereolithographic 3D printers for both personal and professional tasks, but also high-quality consumables for them. All purchases can be received at one of the many distribution centers, the largest of which is located in Moscow, or you can order a delivery service to anywhere in Russia.

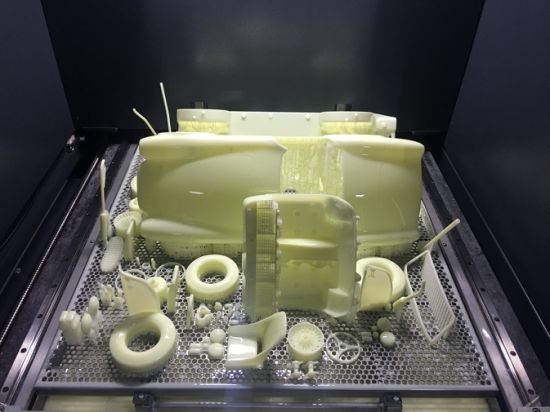

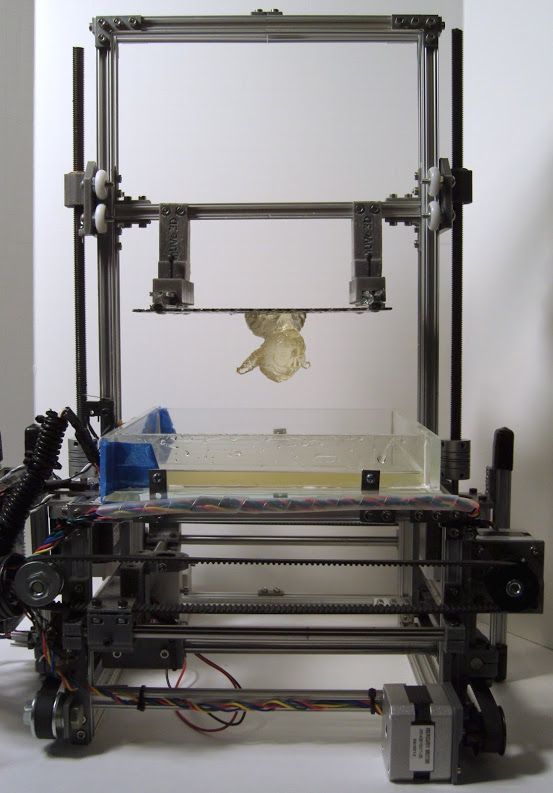

Features of working with photopolymer resins - consumables for SLA printing

Photopolymer resin is a liquid, predominantly pigmented filament, which, when layer-by-layer applied to the contour of a future 3D object, solidifies when exposed to ultraviolet radiation. The design of a stereolithographic printer implies the presence of a specialized tray in which the future model is grown from the bottom up. The formation of each layer is completed with a dosed supply of resin and a lightning-fast inclusion of a source of UV radiation. As soon as the layer has hardened, either the form falls to a distance equal to its thickness, or the print head rises to the same distance (depending on the design features), and the process of forming the next layer begins.

Liquid photopolymers can have different physico-chemical characteristics depending on what tasks they face. Some of the strength characteristics are not inferior to ABS plastic, some remain elastic when fully cured, like dense rubber.

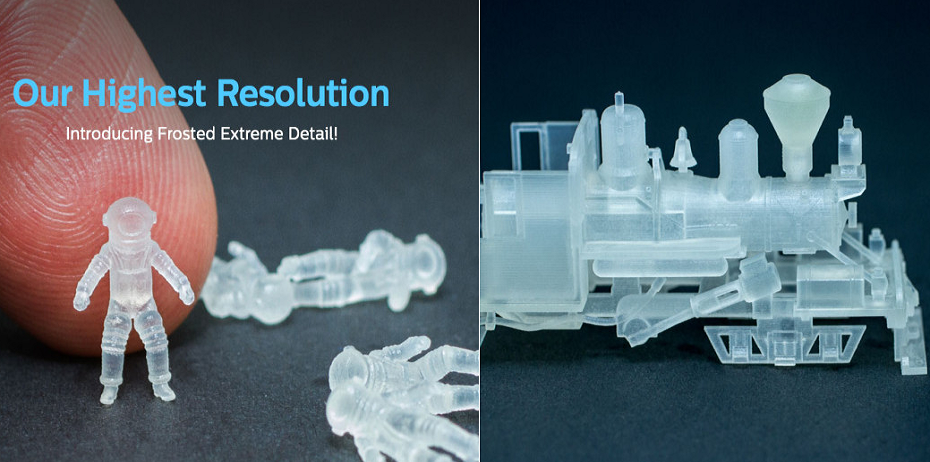

The key features of the resins include the highest accuracy of layer-by-layer building of the model, which can be easily explained by the consistency of the filament itself and its operational illumination, low waste (resin residues can be drained from the bath after printing is completed and reused), excellent surface quality of the finished product, large choice of colors and degree of transparency.

When printing in stereolithography technology, be aware that some resins can be toxic - be sure to follow the manufacturer's recommendations, use goggles and gloves. You should also be careful when storing them - the container should be hermetically sealed and placed in a dark and cool place, since daylight and elevated temperature can provoke their premature polymerization.

Resin manufacturers, features and benefits of photopolymers

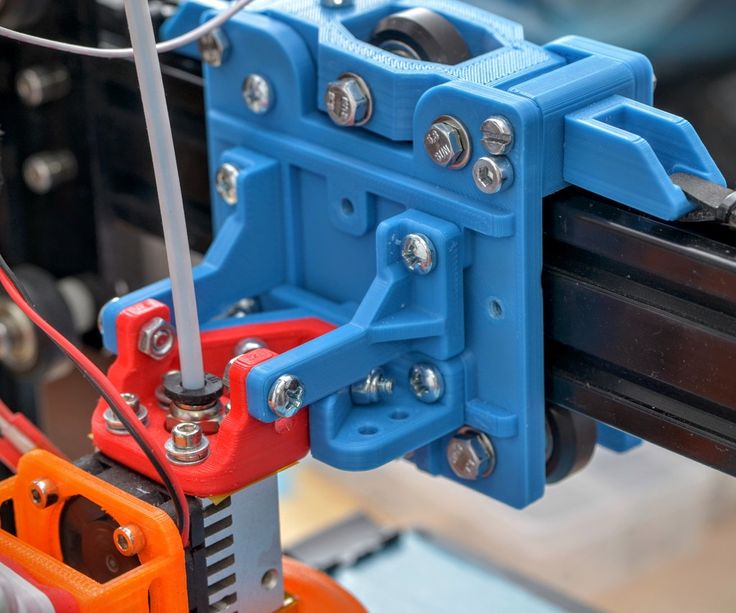

The need for careful selection of filament for a stereolithographic printer is due to its functional characteristics and features. These include printing speed, exposure time, and many other factors that affect the accuracy and quality of 3D modeling. Some resins are compatible with various models of 3D printers that also work in MJM or DLP technologies, and some are designed only for equipment manufactured by one brand.

Stratasys

Stratasys is one of the pioneers of 3D printing. This brand is known for innovative developments in technology, in particular, PolyJet photopolymer 3D printing. It combines the best features of classic stereolithography and satisfies today's requirements for additive manufacturing - the combination of different polymers that has become possible allows you to create fully functional composite materials.

Stratasys' top selling digital resins:

RGD525 is a pure white high temperature resin that can withstand temperatures up to 80 o C and used in the production of nozzles of various types and purposes for completing hot water and heated air circulation systems, in combination with rubber and its imitators, allows the manufacture of parts with different Shore hardness values;

- RGD720 - universal transparent material, imitation of classic transparent plastic;

- RGD-810, aka VeroClear - plexiglass simulant, almost 100% transparent;

- Vero Resins for Objet printers are high-strength color photopolymers that, when mixed together, create hundreds and thousands of new shades;

- RGD450/ Endur is a unique wear-resistant material designed for a perfect finish in bright white;

- RGD430/ Durus - Predecessor of RGD450/ Endur with similar performance but less wear resistance;

- Tango Resin Series are high quality rubber simulants available in a variety of colors that blend beautifully with Vero Resins;

- MED610, VeroDent MED670, VeroDent MED690 and VeroGlaze MED620 are biocompatible materials used in digital medicine such as dentistry and orthodontics.

3D Ink

This brand has excellent quality consumables for FDM and SLA printing with unique properties. As for stereolithography, the photopolymer line is represented by two main products so far:

- UV Resin is an acrylic monomeric photopolymer that cures under the influence of UV radiation, as well as white and blue sources, does not leave ash when burned, due to which it is in demand in the field of foundry production. master models;

- UV Resin Clear is the clear version of UV Resin except that the Clear version does not contain inhibitors.

Material characteristics are more than worthy - with a viscosity of 80-120 MPa at + 20 ° C, the exposure time of a 100 micron thick layer is only 2-4 s, according to the Shore D-scale, the hardness after complete polymerization is 70-75 points.

Asiga

Asiga specializes in the production of Plas Range photopolymers (clear, white, gray and pink), proven to be the best for fast and at the same time accurate prototyping, as well as SuperCAST wax, unique in its characteristics, intended mainly for for casting.

Both types of materials are designed specifically for Freeform Pico and Pro SLA-DLP 3D printers and are used in jewelry.

Digital Wax Systems

Like DWS 3D printers, photopolymers under this brand are sharpened in 3 main areas - jewelry production, digital dentistry and industrial design:

- DC series is used in the production of molds for jewelry and dentistry, products are distinguished by high surface quality and do not require post-processing;

- The DM/DL series is designed to work also with low-temperature materials and is considered ideal for prototyping thin-walled structures and objects with very complex geometries;

- IRIX series - natural stone simulants in a wide range of colors used for growing finished, full-featured products.

RapidShape

RapidShape is the current market leader in 3D printing resins. The assortment of this brand is rightfully considered one of the richest - it has resins for the implementation, without exaggeration, of any project in terms of complexity. Along with the improvement of 3D printers produced under this brand, consumables for printing in stereolithography technology are also being improved.

Along with the improvement of 3D printers produced under this brand, consumables for printing in stereolithography technology are also being improved.

RapidShape photopolymer resins are used in digital dentistry, jewelry, injection molding, hearing aids.

MadeSolid

This brand specializes in the production of experimental 3D printing consumables, its products are represented by three main series: complete set of a wide range of SLA and DLP printers, including those manufactured by FormLabs and FormLabs, and characterized by high surface quality of the prototyped object;

3D Systems

VisiJet FTI resins from 3D Systems are used exclusively for the ProJet 1000 and ProJet 1500 3D printers using MJM (Multi Jet Object Builder) technology.