3D printed rocket company

Relativity Space

Scroll

FACTORY OF

THE FUTURE

ROCKETS BUILT AND FLOWN IN DAYS

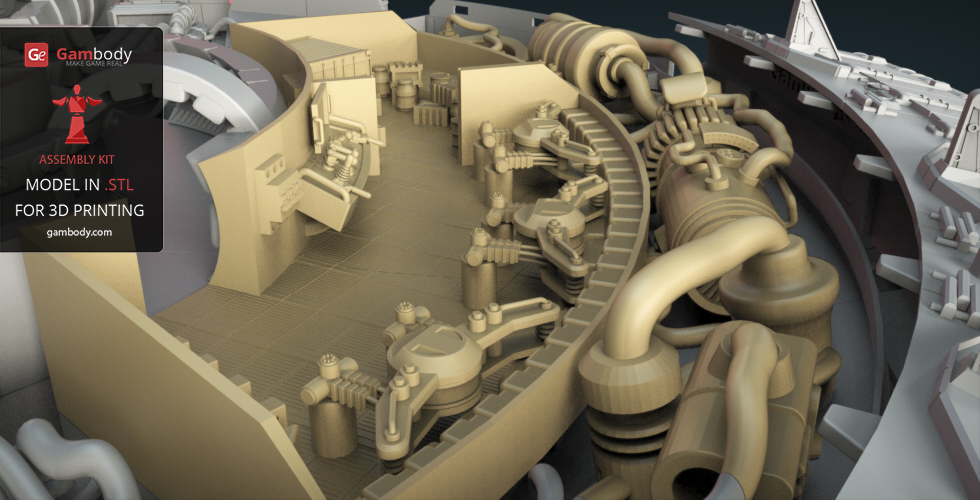

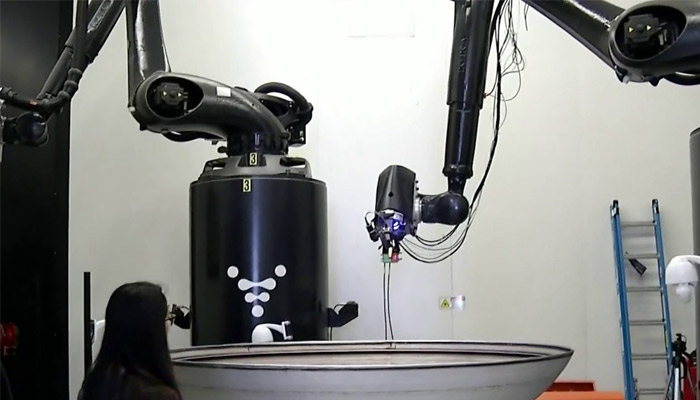

Relativity's proprietary Factory of the Future centers on Stargate, the world’s largest metal 3D printers, that create Terran 1, the world’s first 3D printed rocket, and the first fully reusable, entirely 3D printed rocket, Terran R, from raw material to flight in 60 days. Relativity’s Stargate printers’ patented technology enables an entirely new value chain and innovative structural designs that make Terran 1 and Terran R possible. By developing its Factory of the Future and rockets together, Relativity accelerates its ability to improve design, production, quality, and speed.

Zero fixed tooling and radical part count reduction

LEARN ABOUT TERRAN

POWERING THE STARGATE PRINTER

METALLURGY

Relativity developed multiple proprietary alloys custom designed for 3D printing to meet mission-critical performance.

UNIFORMITY

Parts are inspected during and after printing to ensure they meet the highest standards of uniformity and quality.

THE FUTURE IS 3D PRINTEDFor 60 years, aerospace manufacturing has relied on large factories, fixed tooling, complex supply chains, and extensive manual labor to build costly rockets comprised of 100,000+ parts in 2 years or longer.

To accelerate innovation in the industry, Relativity built its Factory of the Future, the first aerospace platform to automate rocket manufacturing, vertically integrating intelligent robotics, software, and data-driven 3D printing technology. Incorporating Stargate, the world’s largest metal 3D printer with AI-driven controls, our Factory of the Future continuously optimizes production, resulting in greatly compounded quality and time improvements, lower costs, and product designs previously not possible.

Relativity is an application-layer 3D printing company that is starting with rockets, and will extend its Factory of the Future to all of aerospace.

Rigid Factories, Fixed

tooling & HIGH Labor Costs

100,000+ Part Count

24 Month Build Time

48 Month Iteration Time

Complex Supply Chain

High Physical Complexity

ADAPTABLE, SCALABLE

AUTONOMOUS ROBOTICS

<1,000 Part Count

2 Month Build Time

6 Month Iteration Time

Simple Supply Chain

Software Defined Factory

CHANGING THE WAY ROCKETS ARE BUILT AND FLOWN

Custom designed

for printing

- High strength alloys specially designed for Stargate printers

- Physical properties designed to meet mission-critical structural requirements

- In-house material characterization lab for quickly iterating on new alloy development

- Relativity developed multiple proprietary alloys custom designed for 3D printing to meet mission-critical performance

- Parts are inspected during and after printing to ensure they meet the highest standards of uniformity and quality.

UNIFORMITY

REAL-TIME QUALITY CONTROL

AND PART INSPECTION

- Intelligent data-driven manufacturing

- Machine learning control algorithms

- Collaborative additive and subtractive process enables complex geometry

Collaborative robotics

and path planning

- Verification and validation data captured during manufacturing

- Flexible and highly scalable system architecture

- Cloud-based manufacturing simulation and training

Relativity Space

Scroll

CAREERS

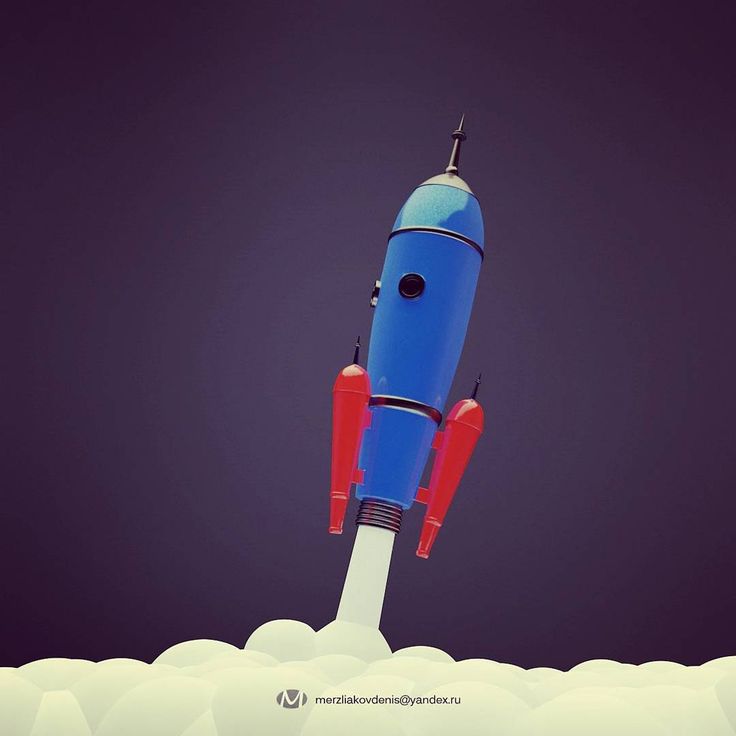

Relativity is disrupting 60 years of aerospace manufacturing by developing the first, and only aerospace platform to integrate machine learning, software, and robotics with metal 3D printing technology. Using Stargate, the world’s largest 3D metal printer, Relativity is producing the first entirely 3D- printed launch vehicle, Terran 1 and fully reusable, entirely 3D printed rocket, Terran R. With the ultimate goal of printing the first rocket on Mars, Relativity is expanding the possibilities of human experience by upgrading humanity’s industrial base on Earth and on Mars.

Using Stargate, the world’s largest 3D metal printer, Relativity is producing the first entirely 3D- printed launch vehicle, Terran 1 and fully reusable, entirely 3D printed rocket, Terran R. With the ultimate goal of printing the first rocket on Mars, Relativity is expanding the possibilities of human experience by upgrading humanity’s industrial base on Earth and on Mars.

Come build the future of humanity in space.

View Job Openings

View Internship Positions

Relativity is building the first autonomous rocket factory and launch services for satellite constellations. Our vision is to build the future of humanity in space -- starting with rockets. We are building the world’s first entirely 3D printed rocket, Terran 1. Terran 1 has 100x lower part count than traditional rockets, a radically simple supply chain, and will be built from raw material to flight in less than 60 days with unparalleled iteration speed.

Backed by leading investors including Baillie Gifford, BOND, Fidelity, General Catalyst, ICONIQ Capital, K5 Global, Mark Cuban, Playground Global, Social Capital, Tiger Global, Tribe Capital, Y Combinator, and 3L, Relativity deploys and resupplies satellite constellations with industry-defining lead time, flexibility, and cost, better connecting and securing our planet.

We have the courage to challenge convention in pursuit of an expansive future

We are persistent, intentional, and focused on achieving meaningful results

We approach the world with awe and a deep curiosity to create

We seek to expand possibilities for human experience in this world and beyond

COMPREHENSIVE BENEFIT PACKAGEWe offer a top-quality health care package including health, dental, vision, paid parental support, as well as health and wellness resources including Carrot, Headspace, and more.

All team members are eligible to receive equity.

WORK / LIFE INTEGRATIONRelax and recharge when you need to, with our generous vacation policy.

TEAM CAMARADERIEWith monthly lunches, game nights, holiday celebrations, and offsites, our team plays together.

LEARNING AND DEVELOPMENT

With training opportunities, stipends for learning and development, company Lunch and Learns, and access to industry conferences, you’ll have opportunities to accelerate your career.

We believe investing in diversity and inclusion long-term, and the value of different backgrounds, identities, and perspectives will advance our mission and enable us to build the highest performing team possible. Our goal is to create, nurture, and sustain a culture where diversity, inclusion, and equity are integrated into our company’s DNA and drives how we make business decisions, attract, recruit, lead, hire, and retain high-performing talent.

Our goal is to create, nurture, and sustain a culture where diversity, inclusion, and equity are integrated into our company’s DNA and drives how we make business decisions, attract, recruit, lead, hire, and retain high-performing talent.

At Relativity:

Diversity is representation and seeking the missing perspectives.

Equity is having a diverse approach to how we set our employees up for success.

Inclusion is embracing, valuing, and celebrating diversity.

View Internship Positions

How Relativity Space prints rockets on a 3D printer

Relativity Space co-founder, CEO Tim Ellis / Relativity Space / AFP

Relativity Space is printing a metal space rocket on a 3D printer that it invented specifically for this purpose. Almost all: 95% is printed, and the remaining 5% falls on electronics, seals and some other elements. 3D printing has many advantages. She's cheaper. She's faster. It is made on the spot, no need to wait until the parts are brought from another factory. It is stronger: fewer places for fastening parts. “The Shuttle had 2.5 million parts,” says Relativity Space co-founder Tim Ellis. “According to our estimates, SpaceX and Blue Origin have reduced this number to 100,000 per rocket. We have a thousand - less than in your car.

Almost all: 95% is printed, and the remaining 5% falls on electronics, seals and some other elements. 3D printing has many advantages. She's cheaper. She's faster. It is made on the spot, no need to wait until the parts are brought from another factory. It is stronger: fewer places for fastening parts. “The Shuttle had 2.5 million parts,” says Relativity Space co-founder Tim Ellis. “According to our estimates, SpaceX and Blue Origin have reduced this number to 100,000 per rocket. We have a thousand - less than in your car.

Many space companies use 3D printing, but only for individual components. Skeptics insist that no one knows how the printed rocket will behave during takeoff and in space. So far, the startup's first rocket, Terran 1, has successfully passed all ground tests. The first copy for a real flight is collected slowly and carefully checked. Now it is ready for 85%. A test flight is scheduled for the end of this year. But investors believe in the idea. Last November, Relativity Space completed a series funding round and raised $500 million. After that, according to research company Pitchbook, with a business valuation of $2.3 billion, Relativity Space became the second most valuable venture capital-funded space company in the world. In 1st place, of course, SpaceX (however, Pitchbook does not include Blue Origin in the rating, which is fully funded by Jeff Bezos).

After that, according to research company Pitchbook, with a business valuation of $2.3 billion, Relativity Space became the second most valuable venture capital-funded space company in the world. In 1st place, of course, SpaceX (however, Pitchbook does not include Blue Origin in the rating, which is fully funded by Jeff Bezos).

Relativity Space has since raised another round, raising $650 million, based on a company-wide valuation of $4.2 billion. reusable. After all, competitors do not sleep. Relativity Space is just one of more than a dozen rocket companies created in the last 10 years.

Launch from Mojave

Ellis was born in 1990 in Texas. He is the eldest of three children of an architect father and a dentist mother. As a child, Ellis was fond of Lego and persuaded his parents to buy about 200 sets. He immediately threw away the instructions from them and collected the spaceships he invented himself. Until now, the thumb of his right hand, when at rest, arched back more than his left - Ellis assured the Los Angeles Times that this was the result of long hours when he assembled and disassembled the parts of the designer.

As Ellis got older, he began making amateur films with his friends, mostly action movies, where the characters were often confronted by zombies. He entered the University of Southern California to become a screenwriter. But already in his first year, he became interested in the profession of an aerospace engineer and joined the Rocket Propulsion Lab at the university, which was engaged in the development of rockets.

The University of Southern California is known for its space program. Its alumni include Apollo 11 commander Neil Armstrong, astronaut and former head of NASA Charles Bolden, and Dana Rohrabaker, chairman of the House Space and Aeronautics Subcommittee. There are several laboratories where students create real rockets and satellites. “I was amazed,” Ellis recalled in an interview with the university website about the first time he went to test the rocket engine he designed and built with his comrades in the Mojave Desert. – I always advise students: take part in practical classes. So you will understand why you need to study this or that differential equation, scheme or line of code.

So you will understand why you need to study this or that differential equation, scheme or line of code.

They wanted to be the first student group to launch a rocket into space. But, having carried out dozens of successful launches, they did not even achieve a suborbital flight - this was done by their successors in 2019, having developed more powerful engines.

Why leave Bezos and Musk

At Rocket Propulsion Lab, Ellis met and became friends with classmate Jordan Noone. Then their paths diverged for a while. Noon went to SpaceX, where he worked, among other things, on the Dragon 2 spacecraft. His emergency rescue system uses a 3D printed SuperDraco engine.

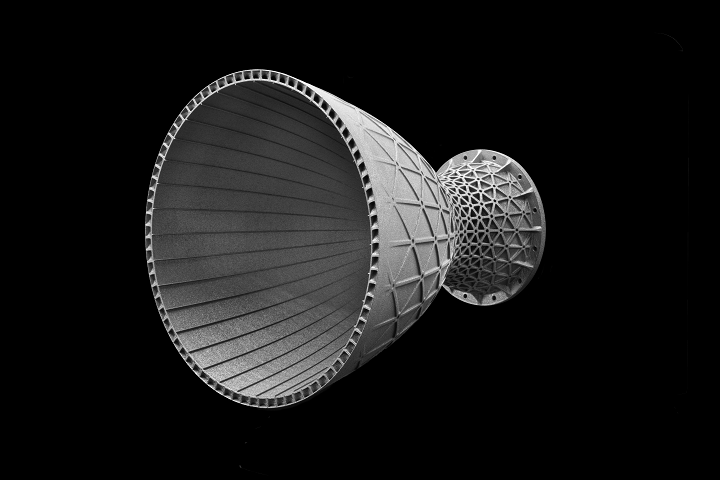

Ellis interned for three summers at Bezos' Blue Origin, and after graduation he was accepted full-time. He convinced Bezos to create a metal 3D printing division (by then many competitors, including Boeing, were doing it). He also created it from scratch. The traditional way of producing parts is turning on a lathe, stamping or casting with a mold. In 3D printing, robotic arms deposit layer upon layer of molten metal. A printed rocket has fewer parts, and therefore, places to connect them using welding, rivets, etc., and therefore fewer vulnerabilities. Skeptics object that if defects are found, the entire part has to be discarded and its manufacture must be started anew. But Ellis says that Relativity Space has developed a way to restart the printing process from the right place. “3D printed rockets are the future of rocketry and space exploration,” he told Inc. magazine.

In 3D printing, robotic arms deposit layer upon layer of molten metal. A printed rocket has fewer parts, and therefore, places to connect them using welding, rivets, etc., and therefore fewer vulnerabilities. Skeptics object that if defects are found, the entire part has to be discarded and its manufacture must be started anew. But Ellis says that Relativity Space has developed a way to restart the printing process from the right place. “3D printed rockets are the future of rocketry and space exploration,” he told Inc. magazine.

Ellis and Noon often called each other and talked about rockets, although they worked for different space companies. They put together a rough cost structure to understand why rockets are so expensive. “80 to 90% goes to wages,” Noon told Bloomberg. 3D printing can dramatically reduce these costs.

Ellis once mentioned that he was going to start a startup to 3D print entire rockets. He later admitted to Inc. that he tried to get Bezos to print more parts for the rocket, but his suggestions were never fully implemented. Then he decided to take up rocket science himself. Noon liked the idea. Both left in December 2015 to create startup Relativity Space.

Then he decided to take up rocket science himself. Noon liked the idea. Both left in December 2015 to create startup Relativity Space.

“I never saw him give up, give up, or fail to solve a problem, even a really difficult one,” Ellis told the Los Angeles Times of Noon. “I knew our startup was going to have a lot of problems, and he was the right person to make it all work.” And Noon noted: “I am strong in technical and practical aspects, and Ellis is strong in creative thinking and non-standard solutions.”

For 1 kg of satellite

Relativity Space received its first money from venture investor Mark Cuban. Ellis and Noon made about 20 attempts to guess Cuban's email address, as Cuban preferred texting to other forms of communication. Some of the letters were returned with a note that such an address does not exist, some got to other people. But one of the addresses turned out to be correct, and Cuban read the letter with the headline "Space Is Sexy: 3D Printing of an Entire Rocket. " Ellis and Noon asked for $100,000. Cuban, after five minutes of texting them, agreed to invest $500,000 (although they had to wait two months to check if they were fraudsters). “They are smart, resourceful, driven and always learning,” Cuban wrote in an email to The Times. “These are exactly the traits I look for in innovators.”

" Ellis and Noon asked for $100,000. Cuban, after five minutes of texting them, agreed to invest $500,000 (although they had to wait two months to check if they were fraudsters). “They are smart, resourceful, driven and always learning,” Cuban wrote in an email to The Times. “These are exactly the traits I look for in innovators.”

First, the startup needed to create a huge 3D printer - there were no models on the market suitable for their purposes. A lot of effort was put into this. But now the latest generation printer is able to print a part up to 32 feet (almost 10 m) high, while the height of the Terran 1 rocket is 115 feet (35 m). Ellis and Noon say that even if the rocket venture fails, they can always cash in on the sale of industrial 3D printers.

Terran 1 /Relativity Space

Created with Cuban's money, the first printer could print parts half the size of the last generation. But the working rocket engine printed on it made an impression on investors. First, they invested almost $10 million in the startup, then another $35 million, and in October 2019d. - another $ 140 million. Ellis and Noon planned to stop there. They did not want to dilute their share, and the funds raised should have been enough for the time before the first commercial launch, if they worked without haste. But in November 2020, another $500 million round of funding was raised. As Ellis explained to CNBC, “the development and scaling of the project needs to be accelerated.” That summer, the startup moved to a new 11,000-square-meter headquarters in Long Beach, California. m, where there will be a site for the production of rockets (the most important thing is that their new printer climbed there in height). Over the past year and a half, the company has more than doubled the number of employees. She now has 400+ people and plans to hire 200 more this year.

- another $ 140 million. Ellis and Noon planned to stop there. They did not want to dilute their share, and the funds raised should have been enough for the time before the first commercial launch, if they worked without haste. But in November 2020, another $500 million round of funding was raised. As Ellis explained to CNBC, “the development and scaling of the project needs to be accelerated.” That summer, the startup moved to a new 11,000-square-meter headquarters in Long Beach, California. m, where there will be a site for the production of rockets (the most important thing is that their new printer climbed there in height). Over the past year and a half, the company has more than doubled the number of employees. She now has 400+ people and plans to hire 200 more this year.

Ellis told Inc. that they already have $1 billion in launch contracts from government and commercial entities. Terran 1 can carry up to 1250 kg of payload. This is smaller than SpaceX's Falcon 9, but larger than Rocket Lab's Electron. Relativity Space is targeting a mid-sized satellite niche, much like a car, Ellis said. Its competitors are the Russian Soyuz-2-1V and the European Vega. Or the same Electron, if Terran 1 displays several small satellites at once.

Relativity Space is targeting a mid-sized satellite niche, much like a car, Ellis said. Its competitors are the Russian Soyuz-2-1V and the European Vega. Or the same Electron, if Terran 1 displays several small satellites at once.

The launch cost of Terran 1 is $12 million, i.e. slightly less than $10,000 per 1 kg. Last year, Roscosmos CEO Dmitry Rogozin announced a more than 30% reduction in the price of launch services for a number of satellites to the level of SpaceX: to $15,000–17,000 per 1 kg instead of $20,000–30,000.

Target Mars

The competitive advantage of Relativity Space is not only in cost, but also in the fact that it can print a rocket to customer requirements, changing both the diameter of the rocket and the shape of the fairing for the satellite - of course, within the limits allowed by aerodynamics, Forbes explained. And she can do it quickly. Once the technology has been proven in practice, Relativity Space is going to print the rocket in 30 days and take another 30 days for pre-launch tests, Ellis told Scientific American. According to him, even SpaceX takes 12 to 18 months to build a conventional rocket. But Musk claims that his reusable rocket is ready for a new flight 51 days after the previous launch.

According to him, even SpaceX takes 12 to 18 months to build a conventional rocket. But Musk claims that his reusable rocket is ready for a new flight 51 days after the previous launch.

So in June, Relativity Space raised another $650 million from investors to accelerate the development of its own reusable Terran R rocket (of course, also almost completely printed on a printer). Its first launch is scheduled for 2024. It will be larger than the first one - 216 feet (66 m) high and designed for 20 tons of payload.

For Ellis and Noon, the main thing is that this project is another step towards interplanetary flights. Musk is looking for a way to get colonists to Mars, and Ellis and Noon are hoping to help them settle on the Red Planet. "If you believe - and I believe - that Elon [Musk] and NASA will send people to Mars, then <...> they will need a whole bunch of things," Ellis told CNBC. “Our printers are reducing the amount of infrastructure that would need to be transported from Earth to Mars in order to establish a colony there,” explained Noon Inc. – Traditionally, you need to send tons of equipment for a factory that will be able to produce factories that, in turn, will produce cars, houses, warehouses ... In our vision of the future, you simply send a 3D printer to Mars that prints everything using Martian raw materials this is". In a speech to the students of his alma mater, Ellis added: “We are going to 3D print the first rocket made in Mars <...> I don’t see a future in 50 years in which rockets will not be 3D printed. It just doesn't make sense otherwise, because printing is much easier and cheaper."

– Traditionally, you need to send tons of equipment for a factory that will be able to produce factories that, in turn, will produce cars, houses, warehouses ... In our vision of the future, you simply send a 3D printer to Mars that prints everything using Martian raw materials this is". In a speech to the students of his alma mater, Ellis added: “We are going to 3D print the first rocket made in Mars <...> I don’t see a future in 50 years in which rockets will not be 3D printed. It just doesn't make sense otherwise, because printing is much easier and cheaper."

what the Relativity Space startup does - The future on vc.ru

The company received $185.7 million in investments and signed contracts with NASA and large companies before launching rockets.

7154

views On October 1, 2019, 3D printing and space launch startup Relativity Space raised $140 million in funding from venture capital firms Bond and Tribe Capital and announced plans for its first commercial launch in February 2021.

Also in 2019Relativity Space received NASA approval to build the first fully autonomous rocket factory and awarded commercial launch contracts to four major satellite operators.

While the company has yet to launch a single rocket, the partners believe in 3D printing and the possibilities of Relativity Space.

The startup plans to produce rockets using 3D printing, machine learning and automation. Relativity Space will reduce the number of parts in a rocket from 100,000 to less than a thousand, helping to build rockets in days or weeks rather than years.

Relativity's next task is to 3D print a launch vehicle on Mars and deliver it to Earth. “We have some pretty ambitious plans,” CEO Tim Ellis admitted to Ars Technica.

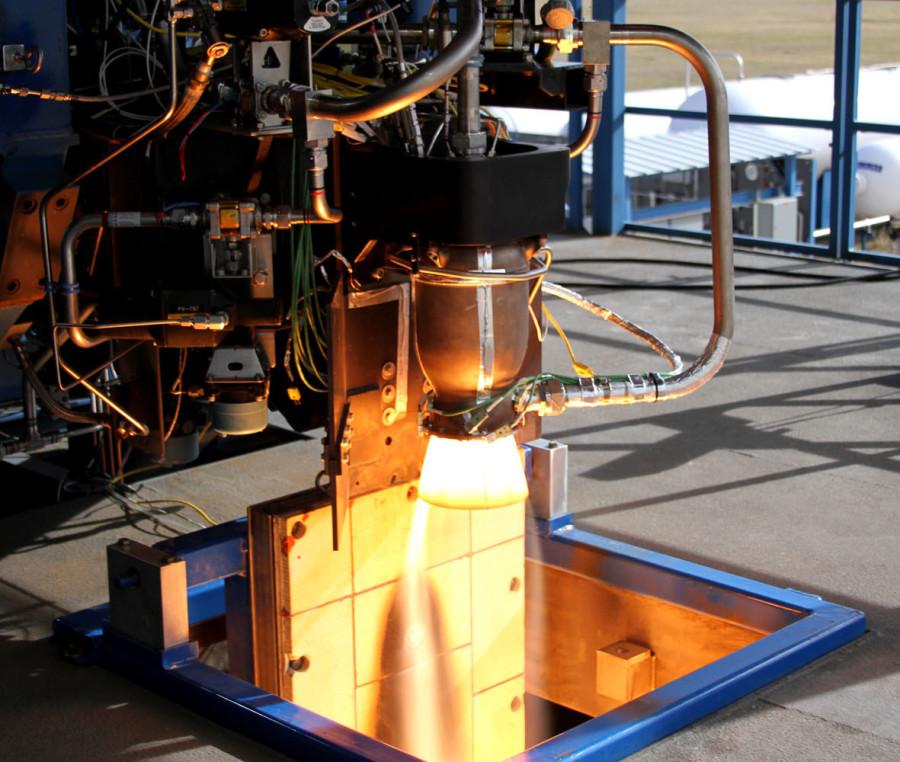

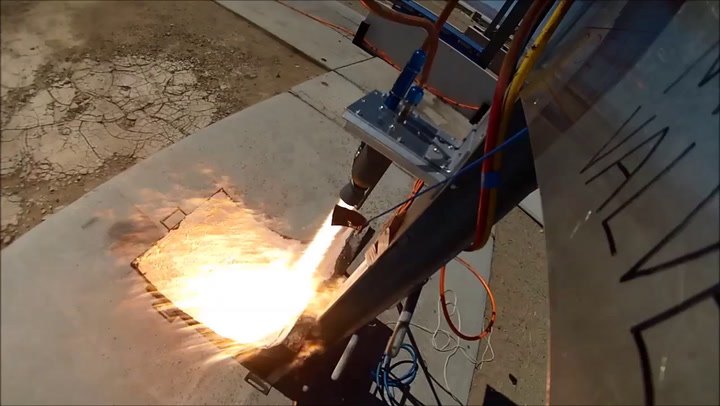

By August 7, 2019, the company has successfully tested the Aeon 1 engine, which consists of three parts printed on a 3D printer, 200 times. The first tests of the assembled Terran 1 rocket will take place in 2020.

Creation of Relativity Space

Before launching Relativity Space, Ellis worked for Blue Origin. He helped develop the BE-4 rocket engine. Ellis made an economic case for introducing metal 3D printing into the manufacturing process.

He helped develop the BE-4 rocket engine. Ellis made an economic case for introducing metal 3D printing into the manufacturing process.

Startup co-founder Jordan Noon worked for SpaceX on the SuperDraco engine program used in the Crew Dragon spacecraft.

Tim Ellis on the left and Jordan Noon on the right

The founders felt that SpaceX and Blue Origin, two of the most advanced companies in the aerospace industry, were not developing enough 3D printing technology, so they decided to create their own project.

They believe that 3D printing will significantly reduce production costs and allow faster creation and modification of new 3D models.

As of October 2019, Relativity Space has raised $185.7 million in four investment rounds. Dot-com billionaire Mark Cuban was the first to invest in Y Combinator startup. He was inspired by the project after receiving a letter from Ellis with an offer to invest in a startup.

In the second round of investments, the company received $10 million, led by Social Capital, and in the third, $35 million from Playground Global, American talent agency Creative Artists Agency, actor Jared Leto and other investors.

What are the ambitions of Relativity Space

Relativity Space is not the first company to use 3D printing to produce space rockets, according to 3DPrint. Startup Rocket Lab, for example, is printing a battery-powered engine, and in 2016 NASA tested 3D printing of a combustion chamber. But the goal of Relativity Space is to completely change the space rocket manufacturing industry.

According to Tim Ellis, rocket development hasn't really changed in the last 60 years - it's still a complex production line of machines and people that produces small parts and then assembles a large rocket.

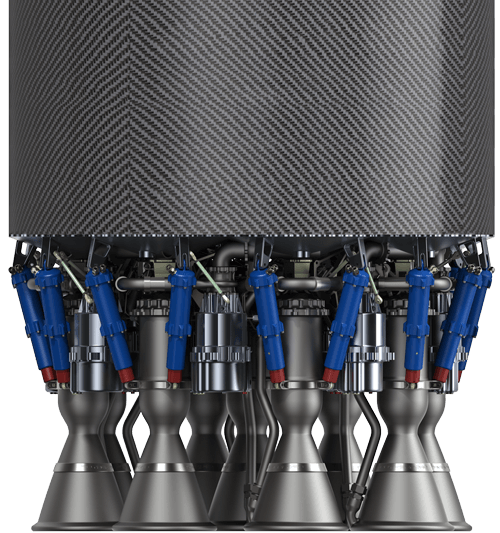

A startup wants to reduce the number of people in production - thus speeding up and reducing the cost of it. To do this, the company is developing its own Stargate 3D printers, which can create all the parts needed to assemble a rocket, from engines to fuel tanks and skins.

Stargate 3D printers print about 95% of the rocket. The remaining 5% is manual assembly, testing and delivery of finished missiles. According to Relativity Space, their developments will save two to four years of preparation for a rocket launch.

“The most expensive part of development is human labor. By automating the printing of 90-95% of the components, we made the production of the rocket the cheapest.”

Relativity Space products: Stargate printer and Terran 1 rocket

Stargate: 3D printer for

rocketsAccording to Ellis, the developed printer can create various shapes and print complex components as a single piece that does not need to be assembled.

In this way, Relativity can produce rockets with 100 times fewer parts than a conventional rocket. For example, an injector and an engine chamber consist of three parts, while usually about 3000 parts are needed to assemble them.

Relativity Space founders at Factory

"It's all in the software, because you have to work out the details of the object and its CAD model," says Ellis. But also thanks to sophisticated printing, Relativity Space can quickly correct small parts of the engine and print it right there.

Terran 1:

Fully Printed Space LauncherRelativity Space's second product, the 30m Terran 1 small to medium payload launch vehicle with a payload of 1250kg (6% of SpaceX Falcon 9 capacity)). It consists of 730 components, while competitors have about 60,000, says Relativity Space. Terran 1 production cost - about $10 million

Render Terran 1

Due to ease and speed of printing, Relativity Space plans to produce the Terran 1 rocket in 60 days. The startup believes that it can be redesigned to meet the requirements of customers, such as satellite operators.

NASA partnership and autonomous rocket factory

NASA

In March 2018, Relativity Space signed a twenty-year partnership with NASA's Stennis Space Center to exclusively lease the E4 test facility in South Mississippi.

Four test benches will test enough engines to build 36 rockets a year. The partnership is valued at $30 million.

Ellis said this is the first Stennis Space Center agreement that allows private companies to use NASA's rocket-launch facilities. A similar agreement is used by SpaceX - the company entered into a partnership with the Kennedy Space Center to use the Launch Complex-39 site.A.

The partnership avoids additional infrastructure costs and does not require permission for each test - the test facility is available to the company around the clock.

Autonomous Rocket Plant

In June 2019, Relativity Space signed an agreement with NASA to convert a factory building in Mississippi into "the world's first automated rocket factory." It will be located three kilometers from the engine test area and the Relativity Space Terran 1 rocket stage.0003

At the factory, the company plans to use a new version of the Stargate printer, which is smaller than the original and can be placed on a building-high moving platform to print rocket parts.

Also over the next five years, Relativity Space will spend $60 million on its infrastructure and increase its staff to 200 people.

First customers

Telesat

In April 2019, Canadian satellite manufacturer and satellite communications operator Telesat became Relativity Space's first customer, with its Terran 1 rocket delivering small satellites to lower Earth orbit from 2021.

Mu Space

On April 23, 2019, Relativity Space announced a partnership with Thai startup Mu Space. Relativity will send a startup satellite into orbit in 2022. The terms of the deal were not disclosed.

Spaceflight

On May 6, 2019, Relativity Space's third partner, Spaceflight, was launched, which will use Terran 1 to launch microsatellites into orbit in the third quarter of 2021, with the possibility of additional launches later.

Momentus

On September 11, 2019, the company signed a contract with Momentus, Mikhail Kokorich's space transportation startup. The launch of the Terran 1 rocket is scheduled for 2021, which will carry a payload of small and medium-sized Momentus satellites for placement in orbit. Further plans include five more additional launches.

The launch of the Terran 1 rocket is scheduled for 2021, which will carry a payload of small and medium-sized Momentus satellites for placement in orbit. Further plans include five more additional launches.

Seal on Mars

If Relativity Space can succeed on Earth, the startup will move production to Mars and start printing rockets there. According to Ellis, the company has two full-fledged products - both rockets and an automated factory.

The CEO of Relativity Space was inspired by Elon Musk and SpaceX's main mission to colonize Mars. But for their mission to be successful, they need dozens or hundreds of companies working on technologies for life on Mars, including assembling rockets.

“Imagine a spaceship landing on Mars. The doors open, the astronauts come out, and there is emptiness. There must be someone who will work on manufacturing technologies, ”Ellis believes.

Now the potential flight to Mars is largely "one-way" - you can fly there, but you can not leave or somehow return the equipment.