Arcam 3d printers

Arcam EBM_Spectra H_Machine | GE Additive

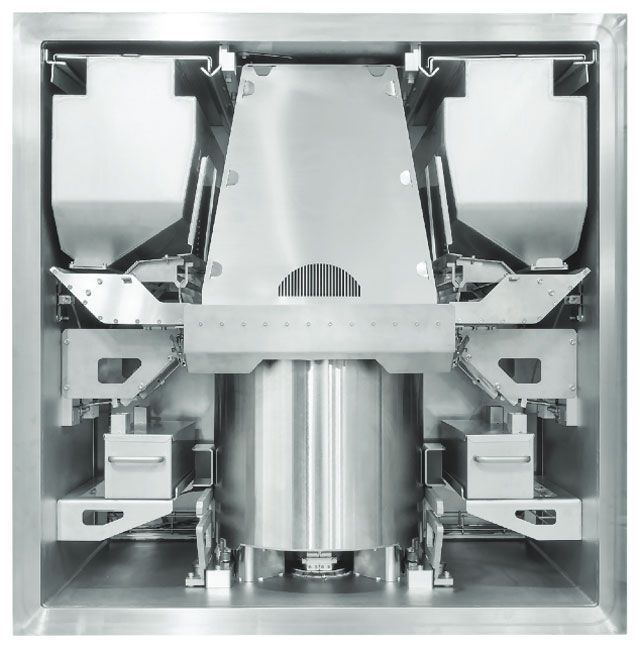

Arcam EBM Spectra H

Spectra H’s high-heat capability enables users to incorporate new alloys into production to expand their offerings, including high-temperature, crack-prone materials.

request a virtual demo

High heat for high-temperature alloys

With Spectra H’s high-heat capability, users can incorporate new alloys into production to expand their offerings, including high-temperature, crack-prone materials. The Spectra H has the capability to produce parts at temperatures exceeding 1,000 °C. The machine’s enhanced capacity is opening up new opportunities to produce high-integrity parts larger and faster than ever before. As part of a system that simplifies operation and maximizes output, Spectra H is the evolution that's helping the industry take the next step forward.

BUILD VOLUME: 250 x 430 mm (Ø/H)

ELECTRON BEAM POWER: 6kW

DOWNLOAD BROCHURE

AVAILABLE MATERIALS

- Arcam EBM Ti6Al4V Grade 5, P-Material datasheet

- Arcam EBM TiAl, D-Material

- Arcam EBM Nickel alloy 718, D-Material

- Arcam EBM Highly Alloyed Tool Steel, D-Material

Powder Recovery Station 30

GE Additive offers a comprehensive powder handling system to support EBM machines, including the Spectra H, both pre- and post-build. Learn about the PRS 30 for efficient, automated recovery of additive powder from builds on the Spectra H.

learn more

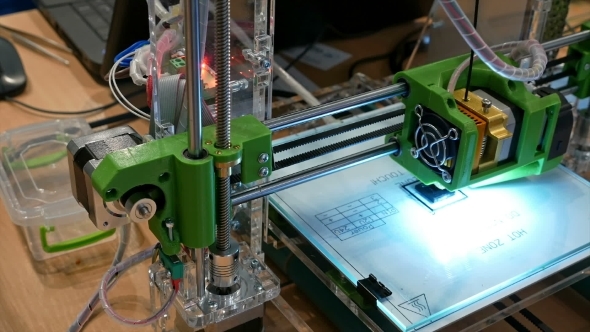

The EBM process at work

The EBM process utilizes a high-power electron beam that generates the energy needed for high melting capacity and high productivity. The hot process allows you to produce parts with no residual stress and the vacuum ensures a clean and controlled environment.

watch video

Arcam EBM Spectra L:

Largest EBM build envelope for high-volume production of quality parts

LEARN MORE

Arcam EBM Q10plus:

Optimized for serial production of orthopedic implants

LEARN MORE

Arcam EBM Q20plus:

For cost-efficient production of large, distortion-free aerospace components

LEARN MORE

Arcam EBM A2X:

Advanced process and material development in a clean and controlled environment

LEARN MORE

explore all machine solutions

Are you ready to create metal parts using

high-temperature, crack-prone alloys?

Tomas Kellner

19 September 2019

Arcam EBM to lead the future of AM » 3D Printing Media Network

Company VisitsDecision Makers

Inside the new GE Additive Arcam EBM Center of Excellence, we got to see why EBM is "on fire"

Davide SherFebruary 27, 2020

4 minutes read

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Sweden may be cold in Winter (actually not even that cold this time around) but Sweden’s own additive manufacturing technology, Electron Beam Melting or EBM, is really hot lately. Not just because process temperatures get up to 1200° but also because Arcam – now Arcam EBM – acquired by GE in 2017, is churning out some really impressive numbers. The company has been recording double-digit sales growth and – as Jason Oliver, GE Additive‘s CEO, explained [read 3dpbm’s interview with Mr. Oliver here], it is poised to grow by a factor of five over the next five to ten years.

But why is EBM technology so in demand? During our visit to the new GE Additive Arcam EBM Center of Excellence which was recently completed in Gothenburg, Sweden, Karl Lindblom, General Manager of Arcam, revealed in his opening remarks that GE invested over €18 million in the center, confident that Arcam’s business could grow by a factor of 5 over the next 5 to 10 years. Today Arcam is the only supplier of EBM additive technology however Mr. Lindblom conceded new competitors are likely to arise soon, adding that “we [Arcam] welcome the competition.”

Lindblom conceded new competitors are likely to arise soon, adding that “we [Arcam] welcome the competition.”

While some early EBM patents have now expired, Mr. Lindblom pointed out that “Arcam’s current patent portfolio consists of 200 patents and patent applications belonging to 56 different registered patent families.” Arcam developed and produces the electron beam gun powering the machines internally and works with dozens of academic institutions around the world, including North Carolina State University (Arcam’s first client), Oak Ridge National Lab and Milan’s Polytechnic Univerisity among others. In addition, companies like Volvo are based in the nearby region and can provide a significant talent pool for new engineers.

A titanium 3D printed moose… or is it an elk?Production-ready from the start

One of the reasons for its current success is that this technology represents the ideal mix between the reliability of powder bed fusion processes and the high-productivity of metal binder jetting systems. With the added advantage that while high-productivity metal binder jetting has just entered the market, EBM has been around for almost two decades.

With the added advantage that while high-productivity metal binder jetting has just entered the market, EBM has been around for almost two decades.

The history of EBM began in 1995 with a master thesis on TiG arc welding at Chalmers University of Gothenburg. The company was founded in 1997 and the first in-house machine, the R1, was completed in 2000. The very first commercial machine, the EBM S12 was launched in 2003 and titanium as the base material arrived in 2004.

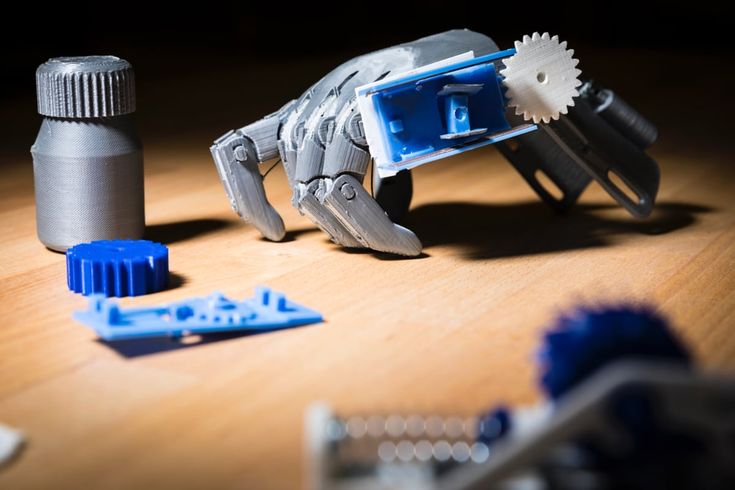

A “cake” containing several 3D printed elks in the Arcam EBM training facilityAs Annika Ölme, VP of Engineering explained in our interview [read the full interview here], one of the keys for Arcam’s early success was the decision to focus on two segments in particular: aerospace and medical applications. Regulatory approval of EMB 3D printed orthopedic implants in Europe dates back to 2007 (2010 in the US) and serial production of hip implants commenced shortly thereafter, with the impressive milestone of 100,000 of these parts produced as of 2018 (probably doubled by now). Today several major medical implant companies use Arcam technology for both serial and custom implant manufacturing.

Today several major medical implant companies use Arcam technology for both serial and custom implant manufacturing.

The key milestone for Aerospace applications came just recently, as Boeing’s new 777x aircraft completed its maiden voyage. The new plane features two GE9x engines, each of which has over 300 3D printed parts, including several dozen blades that are all 3D printed in titanium alumide using Arcam machines. Several blades (up to 10) can be printed at once in the newest Spectra H systems. Production of these blades can be expected to number in the thousands once the engines go into full production however their history goes back a long time, to when an Italian company called Avio Aero exploited an expired patent from GE to use titanium alumide in their fleet of Arcam A2X systems. Avio Aero and Arcam are now both part of GE Additive and that fleet has just grown to a lot more machines, with the target of producing up to 60,000 blades per year by 2023.

“For Larry Culp [CEO, General Electric], David Joyce [CEO, GE Aviation], and myself, additive represents a key aspect of GE’s future strategy”Jason Oliver, CEO, GE Additive

A new era for additive

With the acquisition by GE in 2017, Arcam and Concept Laser, together with AM powder manufacturer AP&C (which was already part of Arcam) and GE’s internal additive production capabilities within the facilities in Munich and Cincinnati form a powerful network that can cover all aspects of the AM production supply chain and workflow (even more so if we include GE’s CT Scanning capabilities).

Mr. Lindblom with the miniature reproduction of the new factory plant. On the right (closer to the viewer) are all the assembly stations, on the left is the testing facility with powder handling. The Center also includes a large area with dozens of Spectra and Q-series systems running continuously for QA.As Mr. Oliver explained during our interview, “GE Additive represents the clearest example of GE’s forward-looking strategy on technology. For Larry Culp [CEO of General Electric] to David Joyce and myself, additive represents a key aspect of GE’s future strategy and we know that companies are willing to bet their entire future on our technologies. We made a conscious decision that we are going to be playing and leading in this space and ultimately our goal is to make this a tier-one business for GE. It’s only a matter of time.”

For Larry Culp [CEO of General Electric] to David Joyce and myself, additive represents a key aspect of GE’s future strategy and we know that companies are willing to bet their entire future on our technologies. We made a conscious decision that we are going to be playing and leading in this space and ultimately our goal is to make this a tier-one business for GE. It’s only a matter of time.”

The new GE Additive Arcam EBM Center of Excellence is an integral part of this strategy. And it does represent the state of the art of modern workplaces. The new 15,000 square meter facility, triples the floor space of Arcam EBM’s previous site in Mölndal. It has capacity for up to 500 employees with production, R&D, training facilities and support functions now all housed under one roof, which allows GE Additive to put Lean manufacturing at the heart of its operations to increase production capacity. As more industrial additive users begin to make the shift to serial production, demand for Arcam EBM systems continues to grow and now the company is ready to begin focusing on other segments such as automotive and oil & gas.

Related Articles

Back to top button

Arcam 3D printers use metal for printing. Powder

When buying a 3D printer discount on plastic and polymers up to 10%

Presented 3 goods

Sort:- by default

- by default

- 9000

- Prices: cheaper

- prices: more than

- Show 24

- Show 24

- Show

Price on request

on order

Number

Number

In the favorites

Compare

Quick View

Arcam 9000 out of 5

(1 review)

On order

- Print technology - EBM

- Print material - Metal

- Print area - 350x350x380

Price on request

on order

Number

Number

In the favorites

Compare

Quick View

Arcam 9000 out of 5

(1 review)

On order

- Print technology - EBM

- Print material - Metal

- Print area - 350x350x380

Price on request

On order

Quantity

Quantity

Swedish company Arcam is today the world leader in providing cost-effective solutions for additive manufacturing - the metal components produced on industrial plants of this brand are unparalleled.

Advanced technology, combined with high-quality materials, also created by Arcam specialists, practically does not limit the possibilities in design and guarantees impressive performance. The main customers of the brand are medical institutions that use innovative developments for digital dentistry and orthodontics, as well as enterprises in the aerospace industry, the automotive industry, and mechanical engineering. nine0003

Advanced technology, combined with high-quality materials, also created by Arcam specialists, practically does not limit the possibilities in design and guarantees impressive performance. The main customers of the brand are medical institutions that use innovative developments for digital dentistry and orthodontics, as well as enterprises in the aerospace industry, the automotive industry, and mechanical engineering. nine0003 Read more…

The company was founded in 1997. Arcam is headquartered in Stockholm with offices in the US, Italy, UK and China. The brand's production sites are concentrated in the Swedish city of Mölndal. Arcam offers its customers a complete portfolio of EBM machines, accessories, software, metal powders.

Arcam 3D printers - a description of existing equipment models of this manufacturer

The Arcam company (Arcam) specializes in the production of 3D printers that produce metal parts. Additive manufacturing is based on the layer-by-layer fusion of metal powders using an electron beam gun.

3D modeling on the devices of this manufacturer is characterized by a high speed of creating a 3D object based on high-quality materials. nine0003

3D modeling on the devices of this manufacturer is characterized by a high speed of creating a 3D object based on high-quality materials. nine0003 3D printing on Arcam devices is different:

- The ability to produce 3D models of complex geometric shapes.

- Create 3D objects that are fully consistent with conventional materials.

3DMALL offers delivery in Moscow and Russia for products from this and other manufacturers. In stock and on order devices and consumables for 3D scanning and 3D prototyping from well-known domestic and foreign manufacturers: Asiga, Concept Laser, SLM and many others. All printers work on the basis of modern technologies: SML, Laser Cusing. Delivery within Moscow time is free, within the Russian Federation it depends on the value of the order. nine0003

The most popular models of 3D printers from Arcam:

- Arcam A2X. The model is designed for the production of metal parts and products. Layer-by-layer construction of an object in a vacuum makes it possible to create products with complex geometry and good physical and chemical properties.

- Arcam Q10. Despite the relatively small size of the camera for constructing a 3D object, the high accuracy and wide range of materials for production make this machine an ideal option for the manufacture of orthopedic implants. nine0010

- Arcam Q20 is suitable for industrial production of small and medium-sized parts for various industries. Compared with the previous model, this device has increased the size of the camera. This allows you to create custom objects.

All models use metal powder for printing and work with titanium and cobalt-chromium materials. All listed devices of this Swiss manufacturer are guaranteed for 1 year. Convenient intuitive interface will be understandable even for beginners. If necessary, 3DMALL specialists are always ready to answer all questions about installing and working with the printer. nine0003

Arcam AB 3D Printers

Assignment

Assignment

Professional

Industrial

Personal

Commercial

3D printer type

3D printer type

Tabletop

Food

Professional

For home

Chocolate

Jewelry

Russian

Reprap

Dental

Full color

Industrial

Not expensive

Medical

For training

Material type

Material type

Plastic

606

Metal

50

Photopolymer

245

Other

144

Manufacturer

Manufacturer

3D Systems

84

PICASO 3D

8

Stratasys Ltd

38

Leapfrog BV

6

EnvisionTEC

51

Myriwell

4

3D Experts

3

PrintBox3D

4

FELIXrobotics

11

Solidoodle

8

WANHAO

32

ROKIT

5

SeeMeCNC

4

mUVe 3D LLC

1

RepRapPro

5

Formlabs

9

Afinia

1

Airwolf 3D

6

Type A Machines

2

iRapid

1

RoBo 3D Printer

3

Mixshop Inc.

4

IonCoreLtd

1

Old World Laboratories

1

XYZprinting

13

Panowin Technologies Co., Ltd.

2

MiiCraft

7

Portabee 3D Printer

2

Zeepro

1

Pirate 3D

1

Qualup SAS

2

BEETHEFIRST

3

Heacent

2

Robot Factory

2

Kuhling&Kuhling

1

3Dfactories

3

Tangible Engineering USA Corporation

1

DWS Lab

1

Sedgwick

2

3DJoy

4

Futura Elettronica

1

Makible Ltd

2

ALT Design

1

Active 3D

2

Trinitylabs

1

Sumpod Ltd.

4

Brahma3

1

Hyrel 3D

5

Omni3D

4

BCN3D Technologies

7

Boots Industries

2

ORD Solutions

2

Ironvault

1

2PrintBeta

3

Unique Design

3

Hot Proceed

1

3DD Plus

2

York3dPrinters

1

Code-P

4

Deezmaker

3

Ruian Maitian Network Technology Co

2

CB Printer

1

Print Technologies Pty Ltd.

5

MaukCC

1

Choc Edge Ltd

2

Shenzhen WeisTek Co.,Ltd

5

Delta Tower

2

Tegelbeckers Ltd

1

Deltaprinter

1

MindKits

1

Robot Co, Ltd

1

Romscraj

2

Fabmaker

1

Peerbhai Robotic

1

Sintermask GmbH

1

KL Services Group Inc

1

Fochif Mechatronics Technology Co.

, Ltd

, Ltd 4

Teil3

1

Maker's Tool Works, LLC.

2

Gaminu

1

re:3D

1

inDimension3

4

Acuity Design

1

Essential Dynamics

1

Isis3D

1

Velleman

1

Kentstrapper

4

Blue Eagle Labs

1

Gubbels Engineering

2

Zortrax

8

3dBotic

1

MakerGear LLC

1

Jelwek

1

it is 3D

2

Cablysa Systems, S.

L.

L. 3

Ac123Dc

1

E3D Online

1

Hydraraptor

1

MakerBot Industries, LLC

8

Delta Micro Factory Corporation

3

Ultimaker B.V.

11

Solidscape Inc. nine0003

8

MBot3D

4

B9 Creations

4

Jinhua Flashforge Technology Co., Ltd

26

Tinkerine Studio Ltd

3

Aleph Objects Inc.

nine0003

nine0003 4

DeltaMaker

1

Reprap Austria

3

IC3D LLC.

1

Ultibots, LLC.

2

Intelligent Machine Inc. nine0003

1

Metamaquina

1

Shenzhen Mootooh Engineering Co., Ltd.

1

Multitec GmbH

3

German RepRap GmbH

3

Sharebot

17

Nova 3D

1

QU-BD Inc.

4

RDMCU

1

Full Spectrum Laser LLC

1

Piece Maker Technologies

1

Printbot, Inc.

7

Terawatt Industries

1

botObjects

1

Lunavast

2

Maker Farm

3

NWRepRap

1

eMotion Tech

1

Printed Worlds

1

Reprapsource

1

Twelvepro Co

1

Replicator Warehouse

1

Stellamove Inc.

1

Make Mendel

6

Rapide 3D

2

Makealo

1

Crew Ltd.

1

Open cube

1

3D Kits

1

Coombes Solutions Ltd.

1

SHARK Limited Partnership

1

Smartfriendz

1

3DMonstr

1

Kikai Labs

2

THY3D

1

Tantillus

1

RepRap Diffusion

1

QSQM International Co.

1

Tumaker

1

Makism 3D Corp.

3

3dBotZ

1

ZMorph 3d

1

Eckertech Inc.

1

Imec Proto

6

miniFactory Oy Ltd

1

printMATE 3D

1

CMET Inc.

5

Arcam AB

6

3Geometry Manufacturing Systems Pvt Ltd

8

Electro Optical Systems

15

Trump Precision Machinery Co.

, Ltd.

, Ltd. 4

Wuhan Binhu Mechanical & Electrical Co., Ltd.

11

Optomec Inc.

1

Shaanxi Hengtong Intelligent Machine Co., Ltd.

9

Matsuura Machinery Corporation

1

ExOne Company, LLC

6

Concept Laser GmbH

9

Instrument Tech Co, Ltd

7

UnionTech

8

Renishaw plc

2

D-MEC Ltd.

3

Realizer GmbH

5

SLM Solutions GmbH

5

Fabriconic LLC

3

Mark Forged

8

Keyence Corporation

2

SYS+ENG

1

Lithoz GmbH

1

DWS s.r.l.

12

Beijing TierTime Technology Co. Ltd

17

Carima

3

Mcor Technologies Ltd.

3

Asiga

11

Rapid Shape GmbH

14

solido ltd. nine0003

1

Blueprinter ApS

1

Kevvox Pte Ltd.

2

JER Education Technology Co., Ltd

1

Azuma Engineering Machinery Inc.

2

Space Monkey

1

Trimaker

1

Most Fun

1

Iniciativas 3D

1

IdeaLab 3d

1

MendBot Labs

Bonsai Lab

2

MakerDreams

1

i3Dbot Co.

, Ltd

, Ltd 2

Natural Machines

1

Cyrus3D

ITALYmaker

Something3D

Cagelli Distribution

E Crew Vis

BigRep GmbH

2

Voxeljet Technology GmbH

5

Sciaky Inc.

Mankati

4

F&B rapid production

3

3DQuality

17

Workshop Churyumov

2

Unimix

2

Center for Additive Technologies

3

ENNOVA

1

Exclusive Solutions

2

Magnum

5

SHEKLA

1

D-Force

3

BigRep

4

Roland

1

ABC 3D

2

MAKEX

1

3D Master Kit

7

Shining 3D

25

3NOVATICA

3

AVS Robotics

1

IMPRINTA

11

Createbot

5

AIO Robotics

1

RK-3D

1

SPETSAVIA

3

3DiY

14

Wonwall

1

Apium Additive Technologies

3

3DSUN

1

Cheap3D

1

3rd

1

EGL3D

1

Creality 3D

42

UNIMATECH

2

VolgoBot

3

ZVER 3D

3

Zenith

2

MicroFactory

1

Hewlett Packard

2

Shenzhen Anet Technology Co Ltd

15

MASS PORTAL SIA

11

Cyberon

2

PHOTOCENTRIC

2

TotalZ

11

3dcon

2

Raise3D

6

OOO RUSSIAN ENGINEER

1

Vortex-3D

5

Flying bear

11

Print3D

5

ROBOINO

1

SoloPrint

1

Fun Distribution

1

Alekmaker

2

Cronos

2

TEVO 3D

9

3D printers from China

2

ZAV 3D printer

4

Epo3d

1

FLSUN 3D

3

WINBO

19

PROTOTYPE

1

UNIZ TECHNOLOGY

2

W2P Engineering GmbH

4

MAESTRO

1

Pi 9 3D printer0003

1

Shenzhen Tronxy Technology Co

23

Kelandi

1

Geeetech

21

3DCeram

2

Omaker

1

Builder 3D Printers

6

Creatable Labs

1

ROBOZE

3

Desktop Metal

1

Sintratec

2

CreatBot

10

ANYCUBIC

29

3dlaboratorio

2

OOO SPC "Lasers and Equipment"

2

Prusa Research

6

Prismlab

3

ivilol

2

Geralkom-3D

7

EqMex

1

Tsar3D

2

Zhuhai CTC Electronic Co.

, Ltd

, Ltd 3

Shenzhen Aurora Technology Co., Ltd

6

Monoprice

1

Shenzhen Salon Technologies Co., Ltd.

1

Shenzhen Sundystar Technology Co., Ltd

2

Shenzhen Easythreed Technology Co., Ltd

1

WOW Innovation Technology Co., Ltd.

2

Jinhua Xingzhe 3D Technology Co., Ltd

1

Shenzhen Zhongxin Microscience Software Co., Ltd. nine0003

1

Shenzhen Yaying Trading Co.

, Ltd

, Ltd 5

Z Bolt Co.

2

Anisoprint

1

Shanghai 3D ARTEL Science and Technology Co.

3

FABERANT 3D printers

1

Self-assembly 3D printers

4

ZRapid Tech

21

Zonestar

13

3DGence

3

BLB Industries

1

Hard Light

1

Stereotech

2

TPM3D

7

Artillery

4

Phrozen Tech Co.

Learn more