3D printer suppliers uk

Largest UK Supplier of Stratasys 3D Printers

Laser Lines is a Stratasys Platinum Partner. We are recognised for our knowledgeable advice, exceptional support and helpful customer service. We will take the time to understand your business and workflow to recommend the most effective additive manufacturing solution for your needs. With nearly 30 years in this industry, we are your trusted partner..

Browse our 3D printing technologies

Partner with us

We enable you to save time and money with the benefits of additive manufacturing

UK supplier and support

Our product specialists, support staff, demonstration suite and large 3D printing bureau are based in Oxfordshire.

Over 25 years of experience

We are the UK's most experienced reseller of Stratasys 3D printers, with nearly 30 years of history selling and supporting its portfolio.

Expert consultancy

We visit your premises to understand how you work and recommend the best additive manufacturing solution for your business.

Hot products

Create without limits and let ideas become reality.

Hot products

Create without limits and let ideas become reality.

Additive manufacturing advice

Browse our informative guides to help you take your next step on your 3D printing journey.

3D printing bureau with unrivalled choice

With direct access to one of the largest 3D printer ranges in Britain, our 3D printing bureau has 18 rapid manufacturing systems on-site.

Working with a comprehensive choice of engineering-grade, batch-traceable thermoplastic materials, our 3D printing service is perfect for producing low volume production parts, jigs, fixtures, cutting and drill guides.

With our 3D printing service, you can save up to 60% in costs in comparison to traditional methods of manufacture.

Case studies

Read some examples of the benefits of additive manufacturing in the real world.

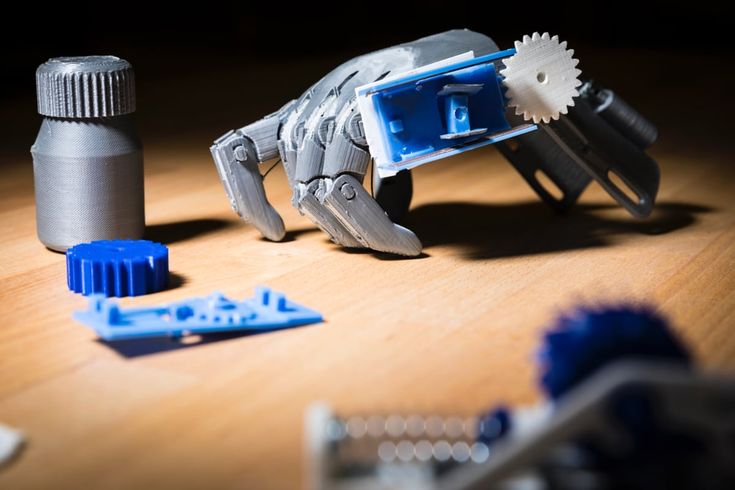

This robotics company relies on the Stratasys F370 3D printer to quickly and cost-effectively produce replacement end-of-arm tools for its network of robots.

Changing to additive manufacturing meant a 90% part reduction and a two minute repair time, rather than 50 minutes.

This digital production facility has a focus on engineering-led solutions and many customers in the automotive, aerospace and medical industries.

With the newest Stratasys machines from Laser Lines featuring SAF and Origin P3 technology, it is staying at the cutting edge.

Testimonials

"The advice we got from Laser Lines was invaluable. The team has a justifiably great reputation and its client confidentiality is second-to-none"

Dave Bennion, Sales and Marketing Director, Ogle Models and Prototypes

"The Laser Lines team was amazingly knowledgeable, helpful, responsive and came back to us ASAP – something that we really appreciated. It couldn’t have gone smoother, and we are so grateful for the support from Laser Lines."

James McInerny, Co-managing Director, Innovate-Design

"I have been impressed at how interested Laser Lines has been in the data and output of the machine and how committed the people there have been in supporting us. This was more than just a sale to them. They are a really nice bunch and a pleasure to work with.”."

This was more than just a sale to them. They are a really nice bunch and a pleasure to work with.”."

Robert Higham, Senior lecturer, NCME

Inspiration

Examples of parts you can produce quickly, accurately and at a low cost using additive manufacturing. Click an image to see a larger version.

- All

- Polyjet

- FDM

- SAF

- Metal

- Origin P3

- SLA

3D printing service | Try our industry leading service

01295 672599

01295 672599

KNOWLEDGE AND EXPERIENCE

As the leading supplier of 3D printers and related technologies, our expertise is unparalleled. This makes Laser Lines the perfect choice when buying a new printer and to use as a 3D printing service. From cutting-edge conceptual modelling to low volume production and the manufacture of jigs, fixtures and production tools, Laser Lines’ 3D printing bureau has been producing bespoke parts and tools for its clients since 2008.

From cutting-edge conceptual modelling to low volume production and the manufacture of jigs, fixtures and production tools, Laser Lines’ 3D printing bureau has been producing bespoke parts and tools for its clients since 2008.

CASE STUDY: AUTOMOTIVE

Holly Mason and Ten Tenths receive superb support from Laser Lines

Ten Tenths is dedicated to keeping Nick Mason’s collection of road and competition cars in peak operating condition. The collection, that numbers around 35-40 at any time, spans pre-war racers right up to today’s hybrid performance...

TRY BEFORE YOU BUY

Our 3D printing service is the ideal option if you are just starting to explore what 3D printing can do for your business. You can try before you commit to buying a 3D printer. We can produce samples and test models from your design files on our machines, using a huge variety of different materials. It is the perfect opportunity to audition a range of solutions. Outsourcing trial jobs to us will give you an indication of the time and money you could save with additive manufacturing.

CASE STUDY: DEFENCE

Lockheed Martin 3D Prints a Large Prototype Fuel Tank

Lockheed Martin Space Systems Company designs, develops & manufactures high-tech systems for civil, defence & commercial applications. In 2012 Lockheed Martin SSC were working on a new project to improve their satellite by...

PROVIDING SPARE CAPACITY

Our 3D printing service makes us the ideal partner to provide extra manufacturing capacity. If you already use rapid manufacturing on-site, but lack the capacity to accept larger projects, or find that you are running behind schedule, our 3D printing bureau allows you to outsource work and stay on top of demand. With multiple machines under one roof and a knowledgeable, experienced team to hand, we offer a fast turnaround time.

CASE STUDY: AEROSPACE

FDM Bureau Builds 3D Printed Parts for Recreational Aviation

Recreational aeroplane manufacturer ICON is working on their products becoming as popular as motorcycles & powerboats. ICON have used a FDM service bureau to not only save time & money but design end use parts for their latest A5...

ICON have used a FDM service bureau to not only save time & money but design end use parts for their latest A5...

SAVE MONEY BY OUTSOURCING

Having multiple machines to hand is useful, but not everyone has the space or the budget to accommodate them. You may not always require the use of multiple machines. Investing in a single printer allows most of our customers to meet 80% of their production requirements themselves. Many then take advantage of our bureau service to plug the gap. This is like having several devices they can call on whenever necessary, without the initial outlay or the ongoing maintenance costs.

CASE STUDY: AUTOMOTIVE

Using a bureau saves time for automotive jigs and fixtures

Roaring Forties specialise in manufacturing Ford GT40 replicas & have been using FDM parts sourced through a bureau service for years. Roaring Forties buy FDM jigs & fixtures as it decreases lead times & saves on expensive...

IMMEDIATE QUOTES, HELPFUL ADVICE

Use our online tool to get an immediate quote on the cost of any job or, if you have any questions, get in touch by calling 01295 672599 or emailing parts@laserlines. co.uk. Our dedicated team is on hand to answer any questions, offer advice on choosing a printer or material, and help with technical issues relating to the creation, conversion or editing of your 3D design files.

co.uk. Our dedicated team is on hand to answer any questions, offer advice on choosing a printer or material, and help with technical issues relating to the creation, conversion or editing of your 3D design files.

Elegoo Introduces World's First Large Scale 6K 3D Printer・Cults

Elegoo, a leading provider of 3D printing technologies, programming and accessories, is pleased to introduce Jupiter, its first large scale 6K 3D printer. This innovative 12.8" printer solution has been specifically designed to be affordable and high quality. The all new Jupiter will launch on Kickstarter at 14:00 UTC on September 11th with a limited discount of more than double starting at $600. nine0005

In recent years, 3D printing has taken over the world and helped change countless industries. From medicine and construction to education and prototyping, these powerful machines help increase productivity, reduce costs and change lives.

Established in 2015 in the heart of China's Silicon Valley, Elegoo is an award-winning technology brand dedicated to providing customers with the best 3D printing solutions on the market. From 3D printers and software to essential accessories such as resin, washing and curing machines, FEP film and Arduino software, Elegoo is committed to providing customers with high quality products and unrivaled service. nine0005

From 3D printers and software to essential accessories such as resin, washing and curing machines, FEP film and Arduino software, Elegoo is committed to providing customers with high quality products and unrivaled service. nine0005

Over the past six years, Elegoo has expanded worldwide, with products in use in the US, Canada, Mexico, Germany, France, Italy, Spain, Japan, India, Australia, the UK and the UAE. This global footprint has been developed through partnerships with global e-commerce platforms including Amazon, AliExpress and Alibaba, allowing shoppers to easily access their products.

Since its inception, Elegoo has also received significant media coverage, winning several awards and appearing in key publications such as Forbes, ZDNET and All3DP. The products are also regularly featured and covered by leading industry influencers, including prominent YouTube channels such as Uncle Jessy, Tested and Thomas Sanladerer. nine0005

This visionary brand has now unveiled its largest 3D printer to date. The Jupiter Mono LCD 12.8" printer is the company's first large-scale device and the first 6K 3D printer on the market built at a truly affordable price. Jupiter has been specifically designed to be as accessible as possible to professional designers and innovators, allowing them to create the highest quality 3D prints at home, in the office or in the studio. With high print volume, users can print models up to 27.78 cm x 15.60 cm x 30 cm.

The Jupiter Mono LCD 12.8" printer is the company's first large-scale device and the first 6K 3D printer on the market built at a truly affordable price. Jupiter has been specifically designed to be as accessible as possible to professional designers and innovators, allowing them to create the highest quality 3D prints at home, in the office or in the studio. With high print volume, users can print models up to 27.78 cm x 15.60 cm x 30 cm.

The revolutionary new monochrome LCD printer will be launched exclusively on Kickstarter in early September, and in honor of the launch, Elegoo will offer customers the opportunity to purchase the machine at an exclusive price. Until October 11, the Jupiter 6K 3D printer can be purchased for as little as $600-$850, up to a 55% discount. By comparison, similarly sized 3D printers typically sell for several thousand dollars.

The Kickstarter page will be open on Saturday, September 11 at 14:00 UTC, and interested parties can learn more on the site: ELEGOO Jupiter: 12. 8" 6K Mono MSLA 3D printer .

8" 6K Mono MSLA 3D printer .

We are very excited to introduce the new Jupiter 3D printer. Since launch, we have always strived to provide the best 3D printers, programming and accessories at the most affordable prices. This new addition confirms our commitment to providing the highest quality 3D printers, and Jupiter is our largest solution to date. With high volume printing, the device is the ideal solution for anyone looking for large scale 3D printing, regardless of industry or experience level. nine0005

More information about Elegoo can be found at elegoo.com. You can also stay up to date with the latest news by following them on Facebook, Instagram, Twitter, YouTube and TikTok.

This page has been translated using machine translation. Suggest the best translation

An example of using an industrial 3D printer Omni Factory 2.0 in production

The terms 3D printers / 3D printing no longer raise questions or bewilderment. Any student will confidently answer: what is it, and “what is it eaten with”

Any student will confidently answer: what is it, and “what is it eaten with”

It is worth noting that over the past few years, 3D printers have entered our lives everywhere and are used to solve a variety of problems. With the rapid development of 3D printing technologies, the improvement of equipment, the emergence of new materials for 3D printers, new areas of application are opening up.

In this article we want to tell you about the experience of using the Omni Factory 2.0 3D printer in the development and production of new passenger seats in the train.

Briefly about the 3d printer itself. nine0005

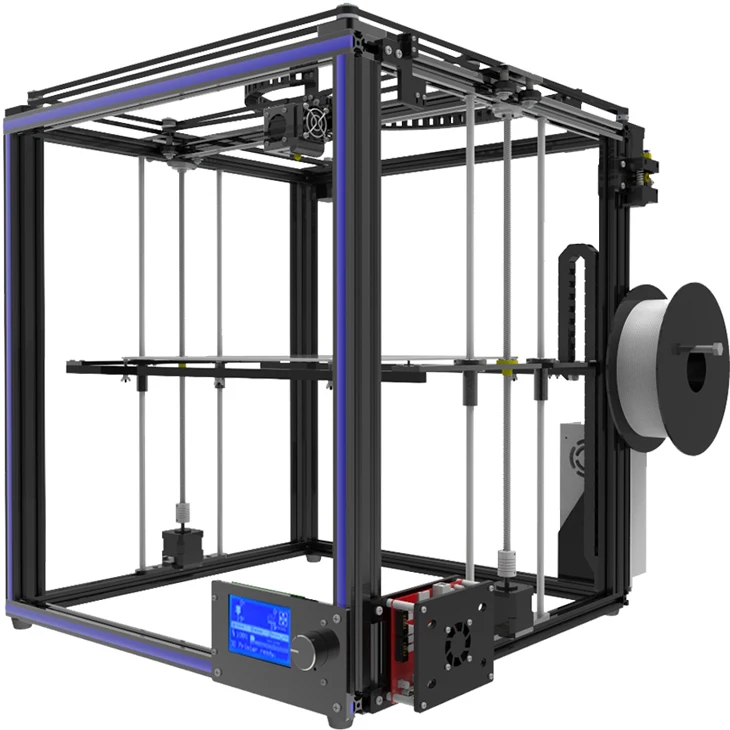

The industrial 3D printer Omni3d Factory 2.0 was announced at the end of 2015 and has already been awarded twice in Poland as

- the best product of 2016 in the 3D printing category. Additive manufacturing”,

- and also in March 2017 at the 9th international conference “3D Printing Days”, as the best industrial 3D printer.

The main distinguishing features of this 3D printer are the following:

1) Large construction chamber: 3D printer allows you to quickly grow products of any geometry up to 50*50*50 cm³. nine0005

nine0005

2) The 3D printer is equipped with two printing elements (extruders), which allows printing complex-shaped models where it is not easy to remove “support” automatically, and also where users place high demands on surface quality.

3) Omni Factory 2.0 has a liquid cooling system for extruders and air convectors inside the working chamber to maintain the optimal 3D printing temperature for the selected material. These options allow you to print dimensional products, with dimensions for the entire working space, made of ABS plastic and its derivatives, for example, ABS-PC, which are widely used in industry. nine0005

With low cost 3D printing and high speed, this 3D printer is becoming an increasingly attractive solution for various manufacturing companies.

Russia is no exception, several devices are already successfully operated in our country.

And now, how with the help of a 3D printer it was possible to reduce the production time by 80% and the development cost by 90%.

POLGAR KFT has been on the market for more than 20 years among manufacturers of parts for the automotive industry. This Hungarian corporation specializes in the production of products made of plastic, rubber, polyurethane and other similar materials for cars (bushings, anthers, mudguards, protective trays, mats, etc.), truck seats, including pneumatic equipment, as well as products for the locksmith industry. nine0005

Local company METRIS3D received an order from POLGAR KFT to develop new passenger train seats. For the production of a functional seat prototype, METRIS3D turned directly to the 3D printer manufacturers at OMNI3D. The project was made using FFF technology on an OMNI Factory 2.0 industrial printer.

Traditional prototyping has never been faster and more economical than 3D printing! The result is the following picture:

| Traditional production method | Now with 3D printing | Economy | |

| Production time | 16 weeks | 3 weeks | 80% (13 weeks) |

| Price | 400 thousand euros | 30 thousand euros | 90% (€370,000) |

“It now costs around 30,000 euros to produce a functional prototype, while it used to cost around 400,000 euros. This is just a small part of the project budget. nine0005

This is just a small part of the project budget. nine0005

In terms of time, it now takes only 3 weeks to build the first prototype, compared to about 4 months before,” says Miki Fukzo, Chief Engineer of METRIS3D.

POLGAR KFT wanted to change the look of the passenger seats on the train. In functional design, there are always some important points in the design that should be at least double checked and, preferably, in real scale.

“It's very convenient to have a functional prototype that you can actually try out. Previously, it was almost impossible to obtain a life-size sample of a product due to the very long period of its production. Now, with the help of 3D printing, we can quickly change the design, after we have grown the first sample on a 3D printer. nine0005

For example, after we made the first seat, it turned out that some moving parts (such as holders and waste containers) could not move, which was missed when designing in the CAD file,” adds a METRIS3D representative.

OMNI3D provided technical specification for parts grown on industrial 3D printer OMNI Factory 2.0

Model: 2 passenger seats and platform

Number of items: 37

Printing time: 500 hours

Largest element size: 480 x 210 x 370 mm³

Smallest element size: 70 x 70 x 20 mm³

3D printing media type - ABS-42 plastic, support - HIPS-20 (These are original filaments offered by OMNI. In Russia, there are complete analogues of materials for a 3D printer at a lower price)

Material weight: 10 kg (70% ABS-42 main material)

Due to the fact that the Factory 2.0 3D printer has a large working space and has a heated closed chamber, OMNI3D specialists were able to print from durable ABS plastic and minimize the number of printed parts, which is very important and affects the strength of the final model. nine0005

“In 3D printing, the most difficult task is to produce large elements, reproduce accurate dimensions, and reduce production time. Factory 2.0 allows you to print large products with linear dimensions up to 500 mm (along the XYZ axes) and very high accuracy. The whole 3D printing process took about 2 weeks,” adds Krzysztof Kardasz, Head of Technology at OMNI3D, who was in charge of the order.

Factory 2.0 allows you to print large products with linear dimensions up to 500 mm (along the XYZ axes) and very high accuracy. The whole 3D printing process took about 2 weeks,” adds Krzysztof Kardasz, Head of Technology at OMNI3D, who was in charge of the order.

The printed parts were then scanned with a professional 3D scanner to evaluate the accuracy of the 3D printed models. (For detailed information on recommended 3D scanners for such tasks, see sections: Artec 3D scanners, RangeVision 3D scanners, Volume Technologies 3D scanners.)

3D scanning is the best way to check the quality control and accuracy of production, in this case 3d printing.

“We scanned the largest element (480 x 210 x 370 mm³) with a professional 3D scanner and checked the dimensions against the CAD file. The result was impressive! The part was printed with such precision that it fits perfectly on the metal seat frame prepared earlier,” Miki explains.

Factory 2.0 is now sold in 13 countries: Ireland, UK, France, Switzerland, Spain, Czech Republic, Slovakia, Poland, Hungary, Russia, India, Australia and New Zealand.