3D printing for charity

Enabling The Future – A Global Network Of Passionate Volunteers Using 3D Printing To Give The World A "Helping Hand."

What is e-NABLE?

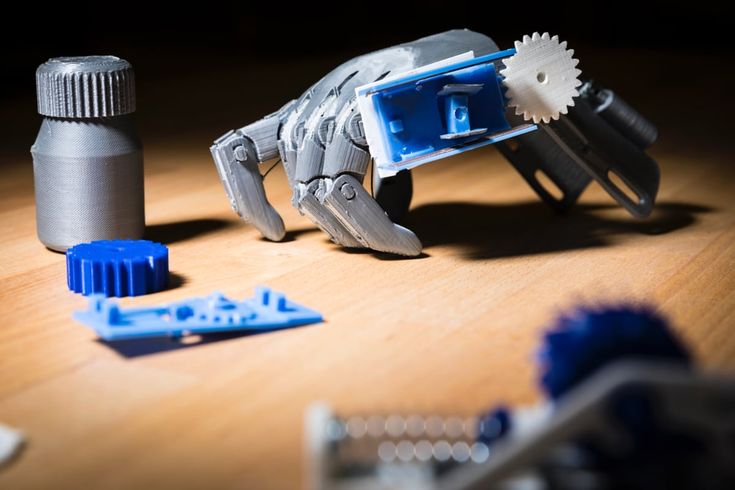

e-NABLE is an online global community of “Digital Humanitarian” volunteers from all over the world who are using their 3D printers to make free and low-cost prosthetic upper limb devices for children and adults in need. The open-source designs created by e-NABLE Volunteers help those who were born missing their fingers and hands or who have lost them due to war, natural disaster, illness or accidents.

There are approximately 40,000 e-NABLE volunteers in over 100 countries who have delivered free hands and arms to an estimated 10,000-15,000 recipients through collaboration and open-source design to help those in underserved communities who have little to no access to medical care. Our volunteers are working hard to “Give the World a Helping Hand” and would love to have you join us!

e-NABLE HUB

Welcome to e-NABLE!

Latest Stories

enablingthefuture. org / Favorite Stories / Featured stories / Feel Good Stories / Giving Back / Global Outreach / Hands Created / Informational / Personal stories / Stories From The Heart

It’s hard to believe that it has been nearly 10 years since the original metal prototype for the first 3D printed e-NABLE device was created for one child in need …

Announcements / Favorite Stories / Featured stories / Feel Good Stories / Giving Back / Global Outreach / Spreading the Word / Stories From The Heart

In the 9 years since its inception, e-NABLE volunteers all over the globe have 3D printed, assembled, and donated tens of thousands of hand and arm prostheses to people of …

Chapters / Design improvements / e-NABLE Chapter Spotlights / e-NABLE Chapters / Favorite Stories / Featured stories / Feel Good Stories / Giving Back / Global Outreach / Stories From The Heart / Volunteer Spotlight

A Tale of Two Chapters. In the shadows of his lab, Mažvydas Sverdiolas at first appears subdued. It is 2am in Lithuania, a time that has often marked the beginning …

It is 2am in Lithuania, a time that has often marked the beginning …

Chapters / e-NABLE Chapter Spotlights / e-NABLE Chapters / Events and Media / Favorite Stories / Featured stories / Feel Good Stories / Giving Back / Global Outreach / Personal stories / Stories From The Heart

The rapidly spreading COVID-19 pandemic has spurred makers across the globe to address an immediate concern for both health professionals as well as those diagnosed or experiencing symptoms: namely, the …

Design improvements / experimental devices / Global Outreach / Personal stories / Research and Development / Spreading the Word / Stories From The Heart / Volunteer Spotlight

A local amputee fulfills a dream, a rotary club guides a mission, an e-NABLE volunteer redesigns affordable prosthetics, a university adapts a new curriculum. Something remarkable is happening, and the …

Announcements / Design improvements / Favorite Stories / Featured stories / Feel Good Stories / Giving Back / Global Outreach / Hands Created / Research and Development / Stories From The Heart

This month, designer Mat Bowtell released his long-awaited Kinetic Hand, a new open-source design supported by an illustrated 99-page assembly manual. Initially modeled from a 3D scan of his own hand, the design …

Initially modeled from a 3D scan of his own hand, the design …

Announcements / Featured stories / Global Outreach / Informational / Spreading the Word

Many of our Hub members may have noticed that not all our members are human these days! To help share community metrics, Mažvydas Sverdiolas has created the e-NABLE bot to share post activity weekly …

Read More Stories

ABOUT US – Enabling The Future

Learn a little about the grassroots, open-source e-NABLE Community and our history!

The e-NABLE Community is an amazing group of individuals from all over the world who are using their 3D printers to create free 3D printed hands and arms for those in need of an upper limb assistive device.

They are people who have put aside their political, religious, cultural and personal differences – to come together and collaborate on ways to help improve the open-source 3D printable designs for hands and arms for those who were born missing fingers or who have lost them due to war, disease or natural disaster.

The e-NABLE Community is made up of teachers, students, engineers, scientists, medical professionals, tinkerers, designers, parents, children, scout troops, artists, philanthropists, dreamers, coders, makers and every day people who just want to make a difference and help to “Give The World A Helping Hand.”

April 2011 | It All Began with Cosplay Nerds!

In April of 2011, artist and designer Ivan Owen created a crazy metal functional puppet hand to wear to his first-ever steampunk convention with his fellow artist and friend, Jen Owen.

Ivan’s giant metal hand was a huge hit at the event and when they returned home from their adventure, he decided to post a short video of it on Youtube.

December 2011 | The Email

The video that Ivan shared was somewhat forgotten about until one evening, he opened his email to see a message from Richard, a carpenter in South Africa who had lost his fingers in a woodworking accident. Richard asked Ivan if he would be interested in helping him to create a functional finger replacement after he had searched online and discovered that a single prosthetic finger would cost him around $10,000 US Dollars.

Richard asked Ivan if he would be interested in helping him to create a functional finger replacement after he had searched online and discovered that a single prosthetic finger would cost him around $10,000 US Dollars.

He had been trying to design his own, but came upon the video that Ivan had uploaded and reached out for help.

January – October 2012 | Collaboration Across 10,000 Miles

Because Ivan and Richard were 10,000 miles apart, they had to work together through skype and email.

In early January of 2012, Richard sent a plastic mold of his hand to Ivan so that Ivan could design a device specifically for him.

Ivan started researching prosthetic devices and stumbled upon the story of Corporal Coles hand. It was created in the early 1800’s by an Australian dentist named Dr. Robert Norman who constructed it from whalebone, cables, and pulleys. This one hand, created over 100 years prior, inspired the design of what is now the building block for every e-NABLE Community 3D printed hand.

During the design process, they had to use objects they could both find around their homes and respective countries. Sometimes this involved items such as toilet paper tubes, leather scraps, zip ties, fishing line, rubber bands, surgical tubing, duct tape and various other items they could find.

March 2012 – First Blog is Created

As Ivan and Richard started making progress on the design for a single finger, Jen had started photographing the stages of development and sharing with her family and friends on social media channels. She decided it would be easier and more fun to create a blog, so that those that were interested in following their story, could visit and read about their adventures.

The Media started picking up their stories.

November 2012 – Time to Meet in Person

In early September, Ivan and Richard realized they had gone just about as far as they could go through online communication. They started a crowdfunding campaign to help get Ivan to South Africa so that he and Richard could work in person.

While they were raising money for airfare, a generous donor provided frequent flier miles so that Ivan could get to South Africa.

November 2012 – Along Came Liam

As more news articles and social media clips started circulating about Ivan and Richard’s work on a single finger design, people started reaching out to them personally to ask for help.

One of those people was Yolandi, the mother of a 5-year-old boy named Liam. Their family also lived in South Africa and she had read that Ivan was planning to fly down there to help Richard and had hoped he would be able to help her son too.

Liam was born missing his fingers on his right hand due to Amniotic Band Syndrome. He had never had fingers on his right hand before, so he had learned to do everything without them.

She had read the blog and had seen stories on Facebook. She messaged to ask if Ivan and Richard would be interested in creating a whole hand for her son, instead of just the single finger.

November 2012 | The First Prototype for an e-NABLE Hand Came to Life.

Yolandi had reached out just in time.

With just 3 days before he was set to leave on his journey, Ivan was able to take the design for that giant mechanical hand he had created for that first Steampunk convention, and shrink it down to a tiny 4 fingered version that he would be able to take with him to South Africa.

November 2012 | The World Was Waiting

After Ivan boarded his flight to head off on his long journey to meet Richard in South Africa, Jen asked people to send her videos and photos of themselves with words of encouragement for them.

Friends, family and even strangers showered them with images of inspirational quotes written on their hands, holding up posters and sending love to them from afar.

Thanksgiving 2012 | Liam’s New Hand

With a limited number of days available to work in person once he landed in South Africa 28 hours after leaving the USA, Ivan and Richard jumped right into finalizing the single finger prototype for Richard.

They then invited Liam’s family over for a full day of building what would ultimately become the original e-NABLE hand.

Liam was able to help build his very own hand.

It was made from aluminum bar stock, rivets, screws, copper tubing, fishing line and some thermoplastic. While it was bulky, awkward and still missing a thumb, Liam was able to strap it to his arm and pick up a ball and other objects for the first time in his life.

December 2012 | Liam’s Progress

Little Liam practiced daily with his new hand with the help of his mom and brother.

She created exercises for him to do at home and sent videos to Ivan to share.

Liam was determined to make his new hand work and learn how to use it, instead of getting frustrated and giving up. Because of this, Ivan and Richard were able to see how he was using the hand to get ideas for improvements for the next design.

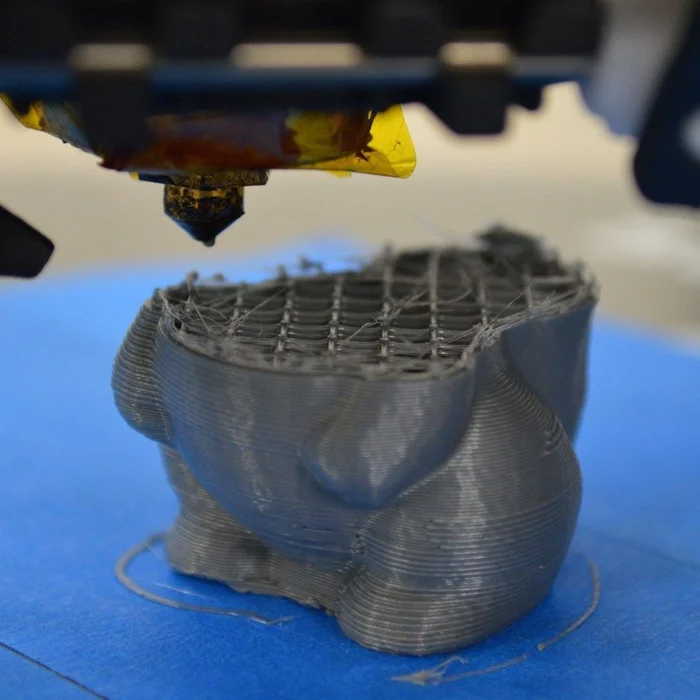

December 2012 | The First 3D Printed Prosthetic Hand for a Child

While creating that first hand prototype for Liam, Ivan and Richard realized that because of his age, Liam would quickly outgrow the device and it would be exhausting trying to keep remaking it out of the same materials.

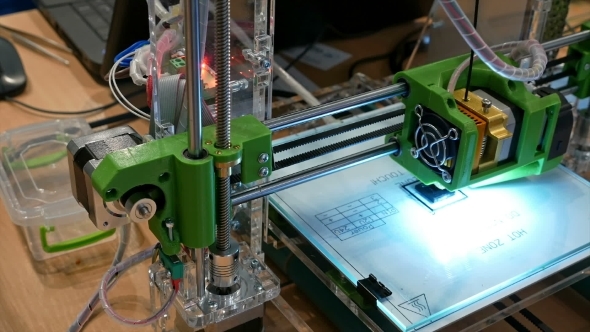

Ivan started researching the use of 3D printing to create the next version.

He taught himself how to use 3D printer design software and contacted Makerbot, a 3D printer company to ask if they would be interested in donating a 3D printer so that he could make new hands for Liam as he grew.

Makerbot was excited to see what they were doing and donated 2 3D printers so that Ivan could design and send the files to Richard via email, who would then in turn print them out on his machine and assemble into a hand for Liam to test out.

They called the first device a “Robohand.”

Liam would then give them feedback on what was working and what didn’t feel good in each new design until they came up with the final prototype for him.

January 2013 | The first 3D Printed Open-Source Design is Shared with the World

After watching Liam with his new 3D printed hand they all realized that if this design could help one child, it could potentially help thousands.

They made the collective decision to forego any potential to make profits from this design and instead, published it to the internet as an open-source, public domain file so that anyone, anywhere in the world with access to a 3D printer – could make one for themselves or someone else in need.

The best chance for the design to help the most people, was to share it and hope those other designers would find it and improve it and reshare it back into the world.

July 2013 | The e-NABLE Google Plus Community is Born

In exchange for the donating two 3D printers, Makerbot asked that they get to create a video to share about the first 3D printed hand prosthesis for Liam.

Once the video was shared, fellow makers and 3D printing enthusiasts started leaving comments on the video to state that they would be interested in helping to make 3D printed hands for other people who may need them too.

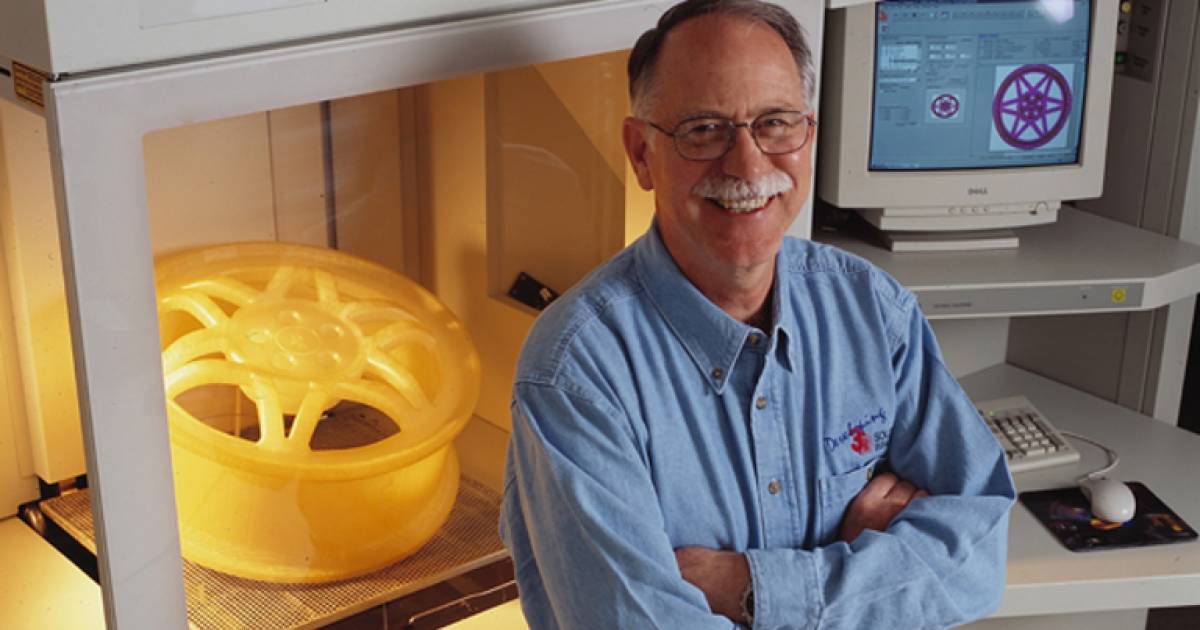

Jon Schull, then a professor at RIT, noticed that people were interested in helping and decided to start a Google Plus community where they could gather and communicate. He set up a Google Map where those who had 3D printers and wanted to help, could put a pin to show their location and let those who needed a 3D printed hand know how to find them.

He set up a Google Map where those who had 3D printers and wanted to help, could put a pin to show their location and let those who needed a 3D printed hand know how to find them.

He left a comment on the video and invited people to join.

By the end of July, the first 70 e-NABLE Volunteers had joined the Google plus community and were actively working on cleaning up the designs and trying to locate recipients.

January 2014 | The enablingthefuture.org Website is Created

Jen suggested that this new community allow her to start sharing their stories and create a blog. With their permission and the permission of the recipient families, she created enablingthefuture.org – the home of the e-NABLE Community’s history and stories of inspiration and hope.

The media started picking up the stories and families with limb different children started finding the e-NABLE Community and asking for help.

January – September 2014 – e-NABLE Superheroes

Famlies starting finding the Google Plus Community and volunteers began creating devices for recipients and connecting with these families. Parents of limb different children were joining and becoming designers and makers of these hands themselves.

Parents of limb different children were joining and becoming designers and makers of these hands themselves.

Designers started getting creative with and the recipients were eager to get their own “Super Hero” hands.

Many of the children who have upper limb differences, tend to be bullied or feel very self-conscious and tend to hide their hands and arms.

Now, with superhero themed hands, they were suddenly the envy of everyone in the class.

Volunteers started teaching families and recipients how to assemble their own devices. Children were building their own 3D printed hands and learning how to teach others to do the same.

September 2014 | e-NABLE’s First Conference

In September of 2014, Dr. Albert Chi, a leading trauma surgeon learned about e-NABLE and invited the community to hold a conference at Johns Hopkins Medical Center.

They called it “Prosthetists Meets Printers.”

Over 400 people attended. The participants were made up of medical professionals, hand therapists, medical students, e-NABLE volunteers and 25 recipients and their families.

In just 72 hours, the global e-NABLE Community had been given a call to action to send as many 3D printed hand parts as possible to the conference so that volunteers could teach not only medical professionals how to assemble the devices, but also the families and recipients.

December 2014 | The First Hand-A-Thon is Born

After attending the e-NABLE Conference and joining the e-NABLE Community, volunteer Maria Esquela put together an event with local scout troops in Baltimore. She created the first-ever e-NABLE “Hand-a-thon” where over 100 boy and girl scouts, their parents and mentors spent their entire Saturday, working in teams to assemble 3D printed hands.

The hands were boxed up and sent to a clinic on the Syrian border where children and adults who had lost their hands due to war, were waiting for them.

January 2014-December 2015 | Design Boom

Throughout 2014, the e-NABLE Community exploded with new designs. Designers were joining by the thousands.

By the end of 2015, the first 3D printed, low cost, myo-electric version had been developed.

Teachers starting using e-NABLE as an example of how 3D printing could be used as STEM based learning projects in their classrooms. Thousands of students all over the world started participating in the project.

e-NABLE Today

The e-NABLE Google Plus Community started with around 100 people who were simply offering to print the files that were already in existence. A handful of devices had been made for children in various parts of the world.

Within that first year – the e-NABLE community grew from 100 members to over 3000. They created over 750 hands for people around the world and numerous new designs had been developed. The designers reshared those files into the public domain as open-source designs.

Within another year – they had more than doubled to nearly 7000 members with approximately 2000 devices created and gifted to individuals in over 45 countries.

All of these 3D printed hands and arms were free to the end user thanks to the incredible volunteers in our community.

By the end of 2018, the e-NABLE Community had over 10,000 members.

As of November 2019, nearly 7 years after the first device was created for Liam out of metal and scrap materials, there have been approximately 7,000 3D printed hands and arms created and gifted to children and adults in need in over 100 countries around the world. There are an estimated 30,000 e-NABLE Volunteers (Including students and teachers) who are helping to make a difference in their local communities, clinics and schools all across the globe.

There are over a dozen new designs and more being shared every day.

The e-NABLE Community has over 140 e-NABLE Chapters and hundreds of schools participating in helping to make free 3D printed hands for those in need.

You never know where your ideas and imagination will take you!

Will you join us?

Together, we can change the world.

“Now all the fingers of this tree (darling) have hands, and all the hands have people; and more each particular person is (my love) alive than every world can understand…” – E.E. Cummings

Liam with one of his 3D printed e-NABLE hands.

Like this:

Like Loading...

A bit about marketplaces, prices and 3D printing

Personal diaries

Subscribe to the author

Subscribe

Don't want

12

Good afternoon, colleagues!

Do you like shopping on marketplaces? I personally love it - great selection. Fast delivery, low prices.

For example, isopropanol on OZONE is almost two times cheaper than in retail ... It is cheaper to take it only in some Russian chemical store, etc. But if you take into account the delivery, then OZONE can come out cheaper if you live in some territory remote from Moscow. nine0003

Are you interested in isopropanol? Then how do you like filament with free ozone delivery?

As for prices - I won't say, I don't know the prices for filament - not my profile . ..

..

And then, during one of the discussions under Picasso's article about salvation, it came up:

What kind of nonsense? No, I understand that OZON is not a charitable organization and takes something for its services... But the prices are usually the same. We check.

We go to the site of the Savior,

going to OZONE.

The prices are the same, but on OZONE there are balls, gifts and free delivery. The author of the sketch about "want it cheaper" skillfully merged and did not become responsible for his market - traditionally for scribblers.

Okay… Saved has nothing to do with 3D printing, let's look at photopolymers:

How do you like the choice and prices? Are you saying it's expensive? I saw cheaper only on Ali and only on Chinese photopolymers. And that is not always the case.

Check prices. Top3Dshop website,

Prices for bitter liquid like the manufacturer for both.

Esun, OZONE

dealer site:

As you can see, the price on OZONE will be even lower. ..

..

Anikubik, seller Leader-3D

And, by the way, on other marketplaces - wherever the seller is the Leader, the price of the Leader is the same as on the site! But you can't prove anything to scammers and haters...

And by the way, Esun and Anycubic on Ali can be bought even cheaper, but this does not negate the truth that when you buy on marketplaces you DO NOT overpay for ANYTHING. NO THIS! Prices are basically the same as on the seller’s website, only buns from the marketplace and free shipping! nine0003

Are you saying that this doesn't happen????

But pick out for yourself what happens… How does it happen? Don't know. Ask the Leader - how the price on his website and the purchase price through OZONE can coincide and how much he gives for each sale to OZONE - I will not ask. Because I would not answer - finance is not a public topic. But the prices for the photopolymer are the same ... What is on the Leader's website, what is on OZONE, what is on Waldberry, what is on Yandex Market, what is in Sbermegamarket.

That's all for now! nine0003

Where to buy is up to you, and before each purchase you should monitor prices, but I just reminded you that prices on usual marketplaces are not higher than those of sellers/suppliers/manufacturers. Though it wouldn't hurt to check.

And one more thing – OZON is not the only marketplace with goods for 3D printing… And if Top-3D-shop, Leader and other sellers are represented on OZONE, Yanderks-Market, Walberry, Sbermegamarket with prices “like on the seller’s website”, then they this cooperation is beneficial. And it may be beneficial for us to buy on the marketplace with a free deposit, and not on the seller’s website with a paid one. nine0003

Happy shopping!

Subscribe to the author

Subscribe

Don’t want

12

95% cheaper: what is the effectiveness of 3D printing for modern business

Unfortunately, even industry experts do not fully understand the potential of using additive technologies work. Because of the high-profile headlines that a car or even a house was printed on a 3D printer, the whole essence of the technology and its advantages over traditional working methods are lost. After all, for the most part, it is needed to replace routine processes and make the final product cheaper than when working with traditional means. nine0003

Because of the high-profile headlines that a car or even a house was printed on a 3D printer, the whole essence of the technology and its advantages over traditional working methods are lost. After all, for the most part, it is needed to replace routine processes and make the final product cheaper than when working with traditional means. nine0003

From stone carving to additive manufacturing – why do businesses need 3D printing?

For any business that produces a physical product, a prototype is essential. Previously, the processes were labor-intensive - prototypes had to be sculpted from clay or carved from stone, which took a lot of time, and if you made a mistake somewhere or something needs to be changed, you had to redo the whole form again.

Today, thanks to additive technologies, businesses have the opportunity to automate these processes and reduce not only the time spent on a project from several days to hours, but also the funds invested in the product. nine0003

nine0003

Thus, different departments in companies benefit from the introduction of technology:

- R&D employees begin to do their work faster, as the production of a prototype is automated and takes less time;

- Designers can quickly prepare new iterations, since all work is completely digital;

- Everyone who demonstrates their products - from sales to top management - can convince customers and business partners with the help of visual prototypes; nine0108

- Marketing departments can demonstrate prototypes to focus groups to prepare a final product that meets the needs of the client, and additionally make small souvenirs for promotional purposes.

In-house and outsourcing - 3D printing methods

There are three main methods of prototyping in terms of additive technologies: outsourcing work to a 3D printing company, printing with your own industrial printers, or working with your own desktop printers. The choice of method depends more on the volume of work in the company and its financial capabilities. nine0003

The choice of method depends more on the volume of work in the company and its financial capabilities. nine0003

Consider the advantages and disadvantages of each method.

3D Printing Bureau are best suited for small complex jobs. It is worth contacting the bureau when you have less than five orders per month, but they require non-standard materials. Bureaus are also useful when different materials are needed to make each item. In other cases, this is the slowest and most expensive option.

Advantages:

- Bureaus work with several 3D printing technologies at once, such as SLA, FDM and SLS; nine0108

- The bureau has more materials in stock, including rare or very expensive ones;

- The Bureau will advise on materials and their limitations;

- If contractors do not work well, then you can quickly terminate the contract and find new ones.

Drawbacks:

- The cost of a prototype will be ten times higher than when working with our own desktop and industrial 3D printers;

- Much slower than native 3D printing (may take weeks instead of one day). nine0108

In-house industrial 3D printers are a reliable option for large productions (200 items per week or more). Products are made of one material, and their size is more than 30 cm³. This option may suit the R&D centers of the largest companies. However, businesses often do not use industrial printers in affordable volumes, which is why the cost of equipment will take a long time to “fight back”.

Advantages:

- Allows deep immersion in technology; nine0108

- Work faster than in cooperation with the bureau;

- The production of a product at high throughput will be cheaper compared to a bureau.

Drawbacks:

- Installation costs about $30,000 for an entry-level system, $300,000 for a full-fledged production system;

- Complete production systems require separate specialists to work with them, as well as more than 30 m² of production areas, industrial HVAC systems, finishing stations, cleaning stations, etc.; nine0108

- At low throughput, this will cost more than service bureaus and desktop 3D printers;

- Higher cost per part and total cost of ownership compared to desktop 3D printers, even in large scale production

- Limited range of materials compared to service bureaus;

- The cost of materials per kilogram is higher than for desktop printers.

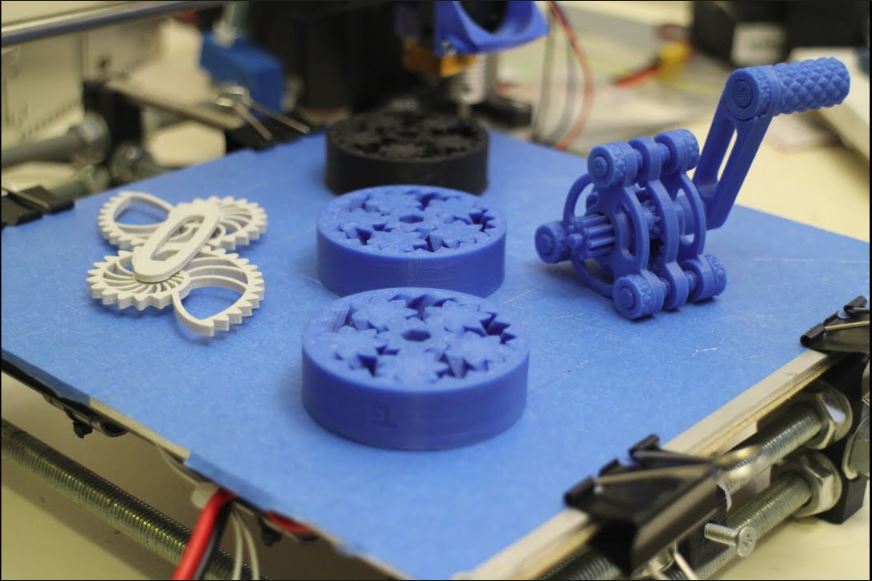

Desktop 3D printers are great for businesses when they have a lot of projects and speed is important. For small companies, you can get one desktop printer to get a newly developed prototype within a few hours.

For small companies, you can get one desktop printer to get a newly developed prototype within a few hours.

A larger business that manufactures more than 200 items a week assembles a farm of several printers - for them it is cheaper than installing industrial ones. Such farms will also give more flexibility and provide access to several materials at the same time. Sometimes companies can use the services of a 3D printing bureau when larger parts or rare materials are needed for work. nine0003

Advantages:

- The cost of a printer to get started is 10 times less than a commercial one;

- Cost per part and total cost of ownership is the most affordable of the in-house manufacturing options;

- Allows deep immersion in technology;

- Compact, resulting in less space requirements.

Drawbacks:

- Low reproducibility compared to industrial machines; nine0108

- There will not be many manufactured products in one batch;

- Not all desktop 3D printer manufacturers provide long-term warranties and support.

How Lush saves on 3D printing

Lush is one example of how the company is using 3D printing with its own desktop printers. The company has located its farm in an R&D center in the south of England, where employees come up with ideas for new forms of cosmetics.

The R&D center itself also offers support to Lush's global manufacturing sites in the UK, Japan, Australia, Croatia and Germany. They can order the right molds and special tools to give cosmetics their whimsical look. nine0003

3D printing on its own printers opened up opportunities for Lush employees to creatively solve problems and quickly respond to customer requests.

The team now designs a product and launches production in less than a day, with 4.5 hours spent printing a new mold. This was also the case with Lush, a charity project to help wildlife in Australia during last year's wildfires, which brought the new product to market within a week. nine0003

nine0003

With access to the full range of digital manufacturing tools, the R&D center completed 580 projects in the first half of 2020. This saved a significant amount of time and labor. In doing so, they were able to respond more quickly to the pandemic and prioritize projects that clients needed in a volatile year.

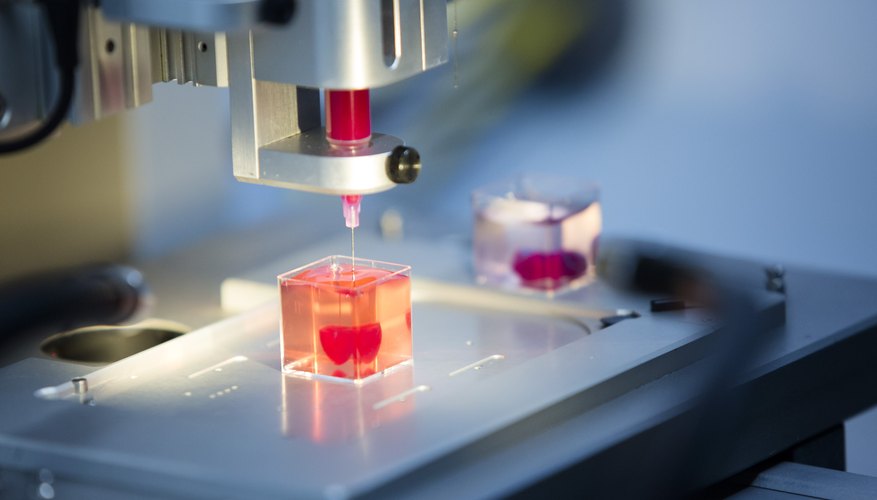

The 3D printing process itself turned out to be several times cheaper than traditional methods of work when delegating them to outsourcing - an average of 9five%.

Comparison of in-house and outsourced 3D printing costs Source - Lush and Formlabs calculations

| Product | The cost of outsourced work | Cost of printing on a 3D printer (including labor) | Saving |

| Thank You Coin Mold | £114 | £6 | 95% |

| Architectural model of the R&D center | nine0250 £15,000£900 | 94% | |

| Special tooling for production | £99 | £4. |