3D printer laboratory

Five innovative ways to use 3D printing in the laboratory

Valentine Ananikov, a chemist at the Zelinsky Institute of Organic Chemistry in Moscow, runs chemical reactions so delicate that just a trace of metal nanoparticles, smaller than a bacterium, could change his results. So when his laboratory finishes an experiment, rigorous cleaning is required. Or at least, it used to be. In 2016, Ananikov began creating disposable reaction vessels instead. To do that, he relies on a technology that has captured the imagination of do-it-yourself hackers, engineers and scientists alike: 3D printing.

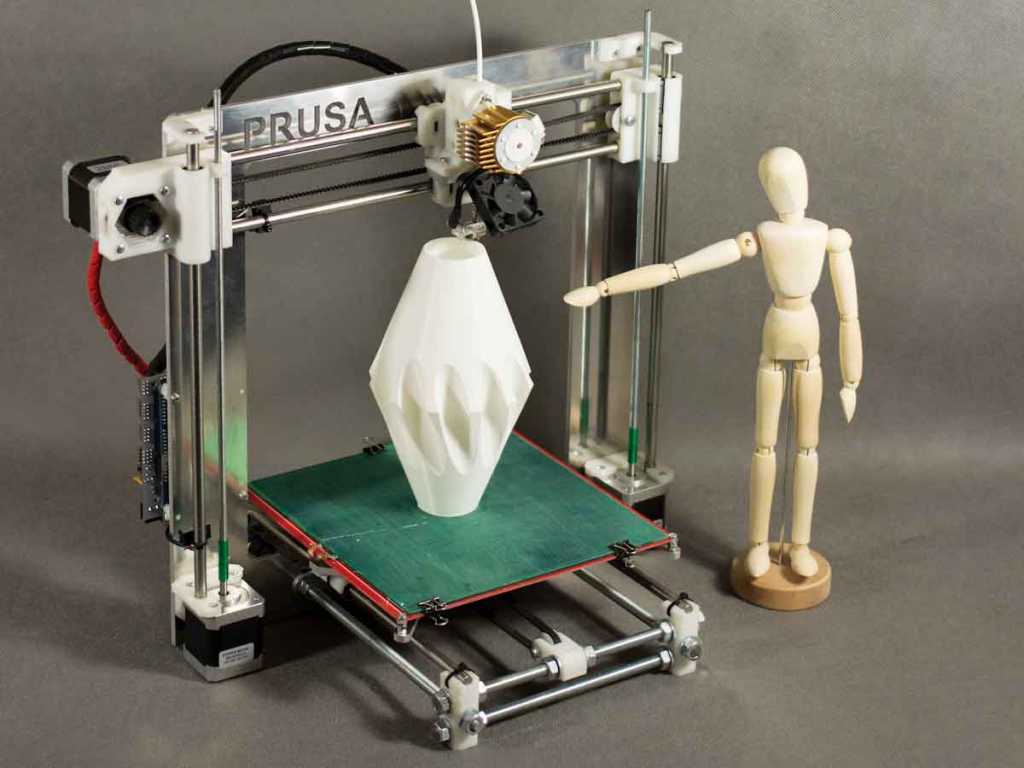

In 3D printing, also known as additive manufacturing, a 3D computer model is transformed into a physical object layer by layer, like icing a cake. Ananikov’s team uses the technology to create bespoke chemical reactors in days, rather than waiting weeks or more for them to be made and shipped by an outside vendor. More importantly, the cost of 3D printing plastic is so low that the group can afford to treat the equipment as consumables to be used once and then thrown away, with no clean-up required. “For research labs dealing with interdisciplinary projects,” Ananikov says, “3D printing is a kind of standard tool nowadays.”

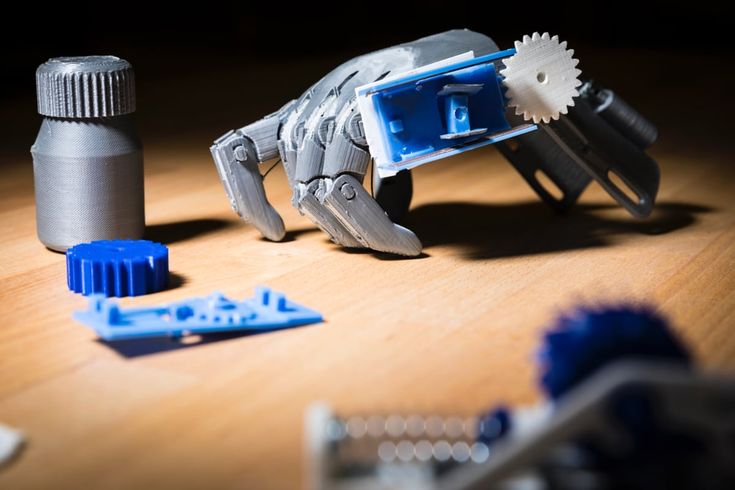

3D printers have been widely adopted by members of the ‘maker culture’ for education and creating innovative objects. But they are increasingly becoming standard equipment in scientific laboratories, as well. Researchers can use them to replace broken instrument parts, build custom sample holders and model everything from biological molecules to oil-bearing rocks. And clinicians can use them to create implants and teaching models.

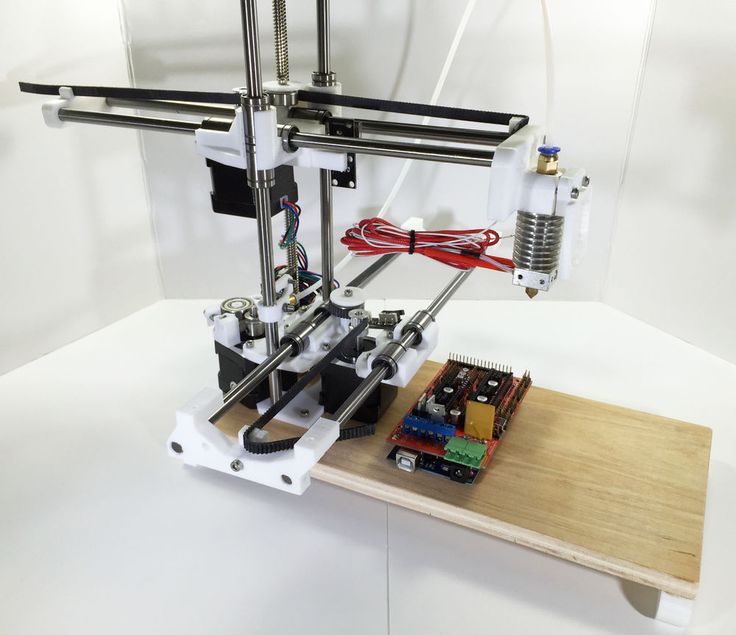

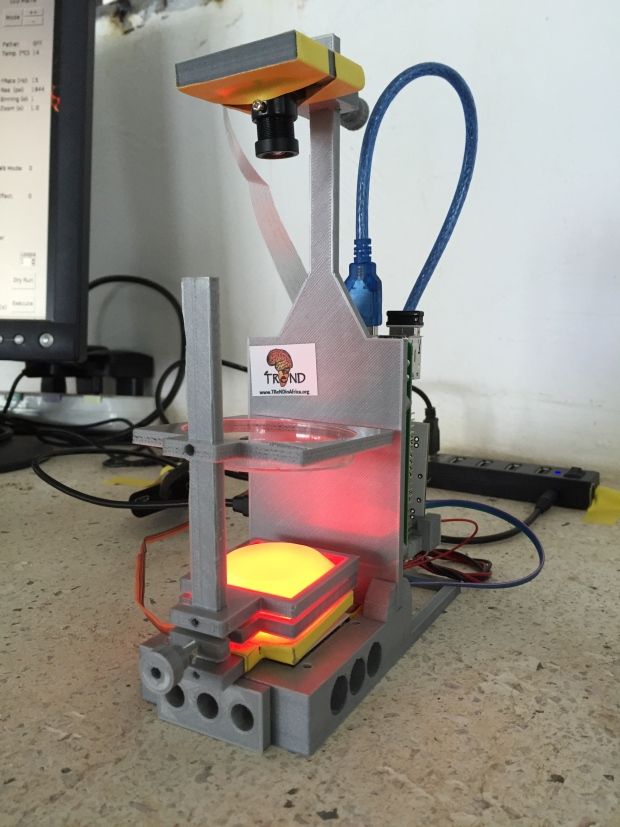

Objects can be 3D printed using several technologies, but one of the most widespread is fused-filament fabrication (FFF), also called fused-deposition modelling. In FFF printers, a narrow, coloured filament — typically plastic wire — is heated and extruded, forming a shape a layer at a time. By contrast, older stereolithography printers use a tank of liquid light-activated resin that is hardened into precise shapes with a laser. FFF printers tend to produce less detailed objects than stereolithography printers, but are easier and cheaper to use.

FFF printers tend to produce less detailed objects than stereolithography printers, but are easier and cheaper to use.

Commercial FFF printers can be acquired for anything from hundreds to thousands of dollars. Or researchers can build the hardware themselves with kits or designs from the open-source RepRap project for just a few hundred dollars.

3D printing isn’t new: stereolithography printers have existed since the 1980s. But falling prices have made the technology widely available. Below are four ways in which researchers have taken advantage of 3D printing.

Equipment on the go

Julian Stirling, a physicist at the University of Bath, UK, is part of a team that designed light microscopes that can be made with 3D-printed plastic components. The idea is to build them in the field in Tanzania and use them to diagnose malaria by searching for parasites in blood. Tanzania has a shortage of knowledgeable mechanics and local components for repairing scientific equipment, he says, and importing components can be expensive and time-consuming. By 3D printing parts, local doctors and scientists can repair their microscopes more quickly and cheaply. A local firm in Tanzania has even created FFF printers from electronic waste and other local materials, he adds.

By 3D printing parts, local doctors and scientists can repair their microscopes more quickly and cheaply. A local firm in Tanzania has even created FFF printers from electronic waste and other local materials, he adds.

Several websites, including Thingiverse and MyMiniFactory, provide forums for scientists to share computer models of printable components. But in Stirling’s experience, models on these sites are often incomplete, lacking either documentation for a particular project or key files for modifying the designs. As a result, his team creates its builds from scratch, using an open-source programming language called OpenSCAD. Their microscopes can be entirely 3D printed except for the camera, motors and lenses.

When it comes to 3D printing, it’s easy to make mistakes, Stirling says. But because the technology is fast and inexpensive, it’s simple to iterate on designs. “This experience can only be built up by trial and error,” he notes.

Practice has taught Stirling that there’s a big difference between using a 3D printer in the laboratory and doing so in the field. 3D printing plastic filament in Tanzania’s humid climate is typically harder than in a climate-controlled laboratory because the humidity affects the plastic filament, leading to more failed prints. Furthermore, power cuts are not uncommon, and only some printers can resume printing a half-finished object after power is restored. There’s not much that Stirling and his team can do about the climate, but they do use uninterruptable power supplies to ensure their print jobs run to completion, he says.

3D printing plastic filament in Tanzania’s humid climate is typically harder than in a climate-controlled laboratory because the humidity affects the plastic filament, leading to more failed prints. Furthermore, power cuts are not uncommon, and only some printers can resume printing a half-finished object after power is restored. There’s not much that Stirling and his team can do about the climate, but they do use uninterruptable power supplies to ensure their print jobs run to completion, he says.

Life-like organs

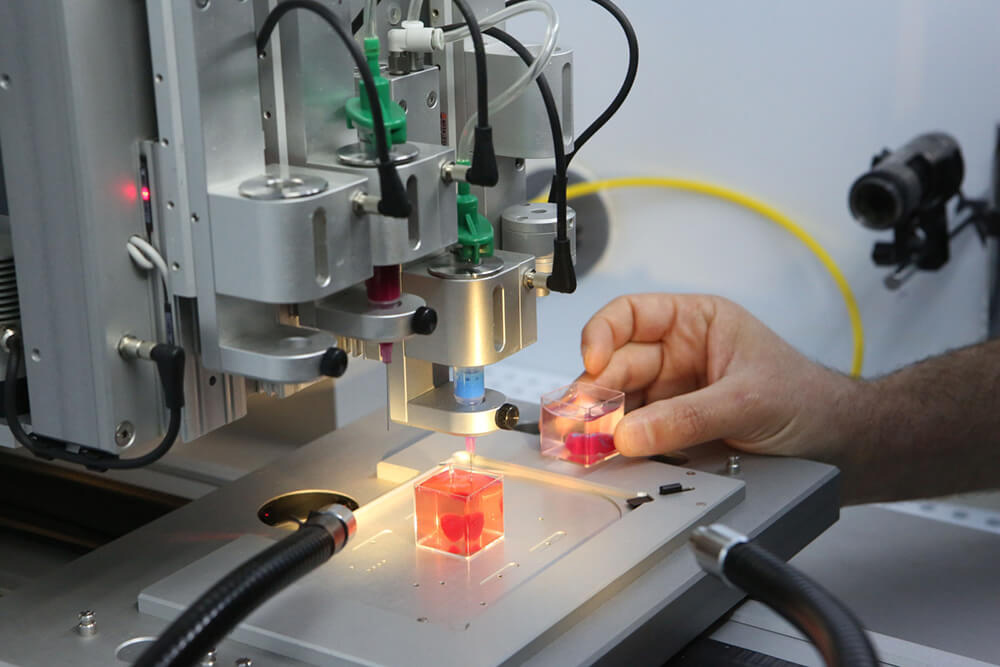

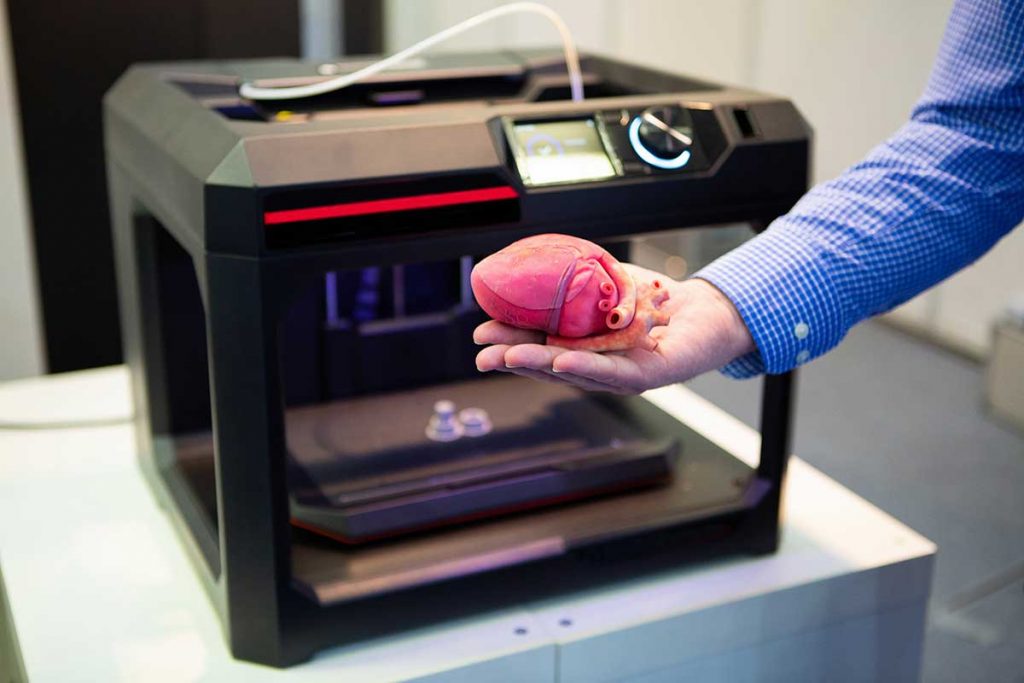

Ahmed Ghazi, a urological surgeon at the University of Rochester Medical Center in New York, uses 3D printing to create non-functional human organs, which surgeons can use to practice robot-assisted surgery. For relatively simple procedures, such as removing a spleen, there is little need for such practice. But more complex procedures, such as excising a tumour, can vary wildly from patient to patient. As Ghazi notes, “Tumours are not in textbooks.”

Ghazi starts with 3D computer-assisted tomography scans of the patient’s tissue, then feeds the data into the commercial medical modelling software Mimics, from Materialise in Leuven, Belgium, and Meshmixer, a free tool from Autodesk in San Rafael, California, to create 3D models. He then prints those models as hollow plastic moulds using an FFF printer, inserts blood-vessel replicas that will connect to a fake-blood pump, and injects the mould with a hydrogel that will solidify into an object with organ-like stiffness. The resulting structures are realistic enough for surgeons to practice their procedures with real-world consequences, including bleeding.

He then prints those models as hollow plastic moulds using an FFF printer, inserts blood-vessel replicas that will connect to a fake-blood pump, and injects the mould with a hydrogel that will solidify into an object with organ-like stiffness. The resulting structures are realistic enough for surgeons to practice their procedures with real-world consequences, including bleeding.

Ghazi says that he and his team use these models for up to four surgery cases a week. In each case, they create two copies of the models and pick the most accurate representation. And they’re training other doctors to apply the technology in fields such as heart and liver surgery. “This is definitely something that’s catching on a lot more,” Ghazi says.

But imperfections remain. The moulds produced by FFF printers often feature tiny ridges and pits, says Ghazi. Such defects are often too small to see with the naked eye, but are plainly visible to the robotic camera, which could affect the surgeon’s experience. Ghazi’s solution is to spread a layer of room-temperature wax over the inside of the mould, which fills in the ridges and pits, thus smoothing out the final product. “Those little things make a difference,” he says.

Ghazi’s solution is to spread a layer of room-temperature wax over the inside of the mould, which fills in the ridges and pits, thus smoothing out the final product. “Those little things make a difference,” he says.

Replica rocks

For Mehdi Ostadhassan, a petroleum engineer at the University of North Dakota in Grand Forks, 3D printing provides a tool for optimizing the extraction of oil and gas from rock.

Ostadhassan prints ‘rocks’ using programs such as OpenSCAD and the commercial 3D computer-aided design software AutoCAD (from Autodesk) in combination with various 3D printers and materials. These rock models have realistic physical properties, including tiny, detailed pores, and Ostadhassan puts them under physical stress to better understand how liquid flows through their real-life equivalents.

To create the most realistic rocks, Ostadhassan uses a range of printing approaches, including binder-jet technology, in which a liquid binding agent is applied layer by layer to gypsum powder or silica sand. The process produces objects with mechanical properties that closely mimic those of real rocks. But unbound powder can also get stuck in the pores, Ostadhassan says, diminishing the quality of the final product. And for some experiments, he needs to apply a water-repelling treatment to get the ‘wettability’ right. Stereolithography printers are better at printing rocks with detailed pores to enable the study of liquid-flow properties, but the models they produce are not as strong as binder-jet-printed rocks.

The process produces objects with mechanical properties that closely mimic those of real rocks. But unbound powder can also get stuck in the pores, Ostadhassan says, diminishing the quality of the final product. And for some experiments, he needs to apply a water-repelling treatment to get the ‘wettability’ right. Stereolithography printers are better at printing rocks with detailed pores to enable the study of liquid-flow properties, but the models they produce are not as strong as binder-jet-printed rocks.

As such, Ostadhassan is collaborating with other researchers to develop a custom printer that can mimic those pores and cracks but still produce models with the same mechanical strength as real rocks.

Heavy metal

Today’s 3D printers can output a range of materials — but not all of them. “The material for 3D printing is very, very limited,” says Yang Yang, chief executive of UniMaker in Shenzhen, China, which makes 3D printers for scientific use. But research in the space is intense, and change is coming. One hot growth area is bioprinting, for use in creating structured biological materials. Jin-Ye Wang, a biomedical scientist at Shanghai Jiao Tong University in China, says that her institution has acquired one such device for use in the classroom. These bioprinters blend cells and hydrogels to create structures such as bones and tumour models.

One hot growth area is bioprinting, for use in creating structured biological materials. Jin-Ye Wang, a biomedical scientist at Shanghai Jiao Tong University in China, says that her institution has acquired one such device for use in the classroom. These bioprinters blend cells and hydrogels to create structures such as bones and tumour models.

Another growth area, Yang says, is metals. Metal-capable printers use a beam of electrons or a laser to melt metal powders in defined patterns. Jeremy Bourhill, a physicist at the University of Western Australia in Perth who researches dark matter, is studying the use of laser-based 3D metal printers to build a mesh of superconducting niobium. This could be used to block strong magnetic fields that would interfere with dark-matter detection, Bourhill says.

Using conventional machining to create the mesh would require toxic lubricants and waste a substantial amount of niobium, which is expensive. So Bourhill’s team is using high-powered lasers to melt and fuse cross-sections of metal powder together. But because the melting point of niobium is about 2,500 °C, the process requires considerable amounts of power. “Niobium’s a really tough material,” Bourhill says.

But because the melting point of niobium is about 2,500 °C, the process requires considerable amounts of power. “Niobium’s a really tough material,” Bourhill says.

Once upon a time, researchers such as Bourhill would have been limited in their options. But with the increased availability of 3D printers, a fundamental shift has occurred, says Yusheng Shi, a materials engineer at the Huazhong University of Science and Technology in Wuhan, China: 3D printing is enabling personalized manufacturing, supplanting centralized manufacturing. As these examples show, researchers have just scratched the surface of what they can do with that power.

3D Labs HTX High Temperature 3D Printer

Cost-effective high-temperature additive manufacturing with next-gen materials such as PEEK, PEI, PC and more.

Developed, assembled, and shipped from USA, the 3D Labs HTX is available to meet your additive manufacturing needs today.

Accelerate your business with advanced AM capabilities with packages starting at $13,900

GET A QUOTE

- Dual 500C Nozzles

- Lifting Nozzles for Dual Material Prints

- High-temperature Stepper Motors

- Fully Hot-Swappable Hotends

We made traditional hotends obsolete.

Have a clog? Need to change to a lower temp material?

No problem, just swap and go.

Focus on production, not fiddling.

The first of it's kind in the industry - our patent-pending cast-tooling plate magbed can surpass operating temperatures of 200C+.

3/8" thickness, large build volume of 350 x 300 x 300mm. Extremely flat for that perfect first layer.

Our specially developed magnets with curie temperatures of 350C+ won't de-magnetize at high-temperatures like the competition.

Clunky bed clamps are a thing of the past.

Slap on your plate and go.

Actively heated build chamber providing a constant 100C heated environment. Dense foil backed insulation keeps the heat inside.

Print parts in ultra performance materials such as PEEK, PEI, PEKK and engineering grade materials like ABS, ASA, PC.

Parts printed in an actively heated chamber have superior layer bonding and strength when compared to passively heated chambers.

American made high-temperature carbon fiber sheets bonded to 430 stainless steel for the ultimate in removable build surfaces.

Accelerate your workflow with swappable plates saving time and money.

Build plates also available in Garolite, PEI and Polypropylene for tough to adhere exotic materials.

TBI high-temperature linear rails provide precise and accurate motion. This means superior dimensional accuracy in your printed parts.

Achieve greater consistency and repeatability in your workflow.

High-quality dual TBI ball screws provide rock-solid support for our bed platform and superior Z accuracy while printing high-temperature parts.

Patent-pending high-temperature bed probe rated to 204C developed at 3D Labs.

Extreme accuracy and repeatability at high-temperatures.

Don't be fooled by claims of "industrial" or "high-temperature" machines using off the shelf hobbyist probes such as the BLTouch.

Reliability of the bed probe in high-temperature scenarios is paramount. Ensuring proper mesh and physical bed leveling will increase your throughput in production cutting both frustration and cost.

Operate your machine directly at the touch screen without the need for network connectivity.

Network down? No problem, you'll have immediate and complete control over the machine while in operation. Pause your print, change filament, or change speed and feeds.

Other competing systems rely on network connectivity to control the printer, and have no way to control the machine while offline, presenting an operational safety hazard.

The 3D Labs HTX is able to work in high-security airgapped environments without the need for network connectivity.

Polished professional touch screen interface on a vibrant 7" large touch screen.

Automated wizards for platform calibration, mesh bed leveling, z-offset, input shaper, and more.

Use your phone, workstation, tablet, or any other device to control HTX.

Access advanced features:

- Online Project Management

- A robust multi user authentication system

- PDF print reports per user, including per-print cost analysis

- Camera view and timelapse support

- MQTT integration, integrate into your automation workflow

- Thumbnail preview for gcode sliced with ANY slicer

- GCODE area avoidance

- Real-time 2D and 3D print progress display

- Much more!

Commercial slicing software developed at 3D Labs , tailored for the HTX and materials across the engineering spectrum.

Access to our curated profiles for quick-start printing with popular and exotic high-temperature materials.

Two CPU processors monitor each other for failure in real time. If either fails, a thermal runaway event can be triggered at the host or subordinate layer.

90% of our components that touch high voltage are UL listed, with full parts traceability from the manufacturers.

This means SSR's, fuses, fuse relays, terminal blocks, and relays are from trusted, genuine manufacturers. All UL listed components are sourced from the USA or within NAFTA.

Don't risk efficiency or safety by using substandard components found in competitors' machines.

The heated bed is equipped with a high-temperature thermal fuse. If the bed exceeds the maximum rated temperature for too long, the fuse will kill electrical power to the bed.

Mains power to the heated bed and chamber can be killed during a thermal runaway event by the firmware via an electromagnetic relay. Not only will the system stop heating the bed with normal thermal runaway protections, it will also kill electrical power ensuring a complete shutdown.

Not only will the system stop heating the bed with normal thermal runaway protections, it will also kill electrical power ensuring a complete shutdown.

Request Quote

First Name*

Last Name*

Company Name* Number of Employees 1-1010-5050-500500+Email* Phone Number* Message*3D printing in Moscow at the 3D printing laboratory

Application of 3d printing

Gaining popularity and being in great demand, 3D printing on order is becoming an integral and indispensable part of life in our time.

The manufacture of cases and volumetric products is a very profitable solution when small-scale production is spreading.

Layer-by-layer material growth technologies (or fabber technologies) for creating physical objects came to Russia not so long ago, but their popularity is growing rapidly. Performing 3D printing - in Moscow or in any other city - is not a problem today. Products for various purposes - from prostheses to parts for cars and aircraft - can be made on the basis of the fabber method. nine0005

nine0005

The term “additive manufacturing” is accepted in industry guides, however, this technology has become commonly referred to as “3d printing” and it is in this version that it is used in the startup environment, between entrepreneurs and journalists.

Layer-by-layer build-up is applicable both for creating prototypes, prototypes of a future product, and for direct manufacturing of parts and solid objects.

Where is a 3d printer used

In what case may 3D printing be required? At the stage of product development, when it is required to visualize it and determine the likelihood of defects or unsatisfactory quality during production. It is also in demand for creating prototypes of architectural objects, as well as for prototyping. nine0005

Prototyping of parts, production of tooling - for example, molds for casting; assembly tools - this is not a complete list of cases when they decide to use 3D printing on order. Moscow in this regard is in a much more advantageous position compared to other Russian regions, since ideas and technologies, for the most part, are concentrated here.

We use additive technologies and high-quality materials to make your models, which will then be presented in many industries after printing: medicine, science and education, architecture and construction, energy and oil and gas industry, automotive and mechanical engineering, aerospace industry, jewelry manufacturing . nine0005

3D printing, ordering the release of a single item or a series is possible only on the basis of three-dimensional modeling based on special software products - this is where work on a separate project begins. If you want to create a copy or form of an existing object, you will need to apply three-dimensional scanning.

The principle of operation of a 3d printer

Ordering 3d printing means placing an order for the reproduction of a digital three-dimensional model of an object in physical form by horizontal layering of a substance. Layering is carried out using additive installations or three-dimensional printers, the variety of which is quite large today. nine0005

nine0005

For each of the layering methods, including lamination, fusion, sintering, extrusion, jet spraying, UV curing, there is a separate category of devices. To create an accurate three-dimensional geometric product (3d model) that can perform any function, "3D printer" is used - this is the general name for a whole family of equipment capable of performing 3d printing on order (Moscow). At its core, each device is a numerically controlled machine that performs layering operations. nine0005

To reproduce the desired objects, it is necessary to use different 3D printing technologies that differ from each other.

Here are the main 3D printing technologies:

- Fused deposition modeling (FDM). ABS and PLA printing with this technology is the most popular of all 3D printing technologies. It is used in most desktop 3D printers and represents an ideal price / quality ratio, which allows printing by layer-by-layer supply of a filament of molten plastic; nine0038

- Laser stereolithography (SLA).

Photopolymer printing using SLA technology allows you to form an object by layer-by-layer laser exposure of a liquid photopolymer resin, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage; nine0038

Photopolymer printing using SLA technology allows you to form an object by layer-by-layer laser exposure of a liquid photopolymer resin, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage; nine0038 - Selective laser sintering (SLS). Reproduction is performed by layer-by-layer melting of a special powder under the action of laser radiation. This 3D printing method is widely used in the industry for the manufacture of durable metal elements.

To order printing on a 3d printer using any of the above methods, you must select the material in which the product will be made. What will be the composition of the product, such will be the cost of the work. nine0005

Printing on a 3D printer is possible using powder forms of gypsum, polystyrene, polyamides, metal alloys; liquid photopolymers, wax and other materials. The specific task and requirements for the final product depend on which consumables are selected. Importantly, with this production method, whatever you choose, there is little to no mechanical post-processing required.

The specific task and requirements for the final product depend on which consumables are selected. Importantly, with this production method, whatever you choose, there is little to no mechanical post-processing required.

In order to understand the principle of 3D printing, it is necessary to reproduce the step-by-step process of creating models. nine0005

Let's describe some stages of 3D printing:

- 3D modeling of the required object according to the specified parameters;

- loading a file with a digital model into a slicer program that generates a control code for a 3D printer;

- setting the required 3D printing parameters;

- writing a code to a removable memory that connects to a 3D printer;

- 3D model reproduction.

Objects are reproduced progressively in the desired shape, the selected material is applied layer by layer, forming the finished product. nine0005

The possibilities of 3D printing are almost limitless, that is, you can make anything you want and this is a huge advantage of this type of printing. In some technologies, for very thin overhanging elements, supports are provided, thanks to which, sagging can be avoided.

In some technologies, for very thin overhanging elements, supports are provided, thanks to which, sagging can be avoided.

Such a brief description of the stages, where there is no ready and detailed analysis of the complete picture of the 3D printing process, gives only an idea of the essence of the technique.

What equipment does LAB3DPrint 9 have0003

Due to the fact that 3D printers are quite expensive equipment, and not everyone can use 3D technologies, but there is a need, our company provides printing services quickly, efficiently and in accordance with your wishes, will complete your task.

The high speed and accuracy of printing, as well as the maximum reliability of our 3D printers, reduce the cost of all types of 3D printing.

We can order a full range of preparatory work and the actual printing on a 3D printer (Moscow) using various methods and materials. We have all the necessary equipment and software. nine0081 Our company works with professional equipment, so the quality of the finished product is guaranteed and the result exceeds all expectations.

In the case of infrequent 3D printing, there is simply no point in purchasing expensive equipment, and the only thing you can do is entrust the creation of any object to us. When you need to print various products, for example, a part made of photopolymer or Abs plastic, you can safely use the services of our company by contacting the site where delivery and payment are processed. nine0005

Benefits of Lab3DPrint

Our company provides 3d printing services, creating industrial design items, product prototypes, functional models, layouts, souvenirs and many other objects from sketches and drawings.

Depending on what device and what printing material is used, these will be the cost and turnaround time.

Our staff will help you navigate and make the right choice, as well as take care of the calculations after receiving a file with information about your model. nine0005

You only need to describe your task in detail, and we will select the best technology and materials for its implementation.

To do this - when placing your order, you must fill out a special form on our website. Here you can also ask questions regarding the production of 3D models.

Write to us and we will be glad to cooperate!

3D printing of teeth and other products

Home

Dental laboratory Top 3D Shop

Top 3D Shop Dental Laboratory

Top 3D Shop Laboratory manufactures a full range of dental products using additive and classical methods, using materials and equipment from leading manufacturers: crowns and implants, bridges and caps, abutments, inlays, frameworks and bars, clasp, veneers, caps, surgical templates, models.

Designs:

Abutments

We accept STL files from any intraoral scanners:

- iTero

- Sirona

- ЗM

- Zshape

- MHT

- Planmeca

Workpiece materials:

- Wax

- Titanium

- Ceramic

- Cobalt Chrome

- Zirconia nine0035 Polyetheretherketone

- Polymethyl methacrylate

- Composites and specialty materials from leading manufacturers

Implant systems:

- ABDental

- Adin

- AlphaBio

- Ankylos

- Antogyr

- Astra

- Bego Semados

- BioHorizons

- Biomet 3i nine0035 Biotech

- Conmet

- CSM

- C-Tech

- Dio

- Impla Conical

- ImplaSchutz

- Implantium

- Impro

- LIKO-M

- Medentix

- Megagen

- Mis

- NeoBiotech

- NIKO

- Nobile Active

- Nobel Branemark nine0035 Nobel Conical Connection

- Nobel_Replace

- Osstem

- OT Medical

- Radix

- Renova

- Sic

- Sin

- Sky Bredent

- TBR

- Xive

- Zimmer

3D dentistry - new in the world of prosthetic technologies

Denture on a 3D printer is no longer a fantasy, but a completely familiar and ordinary solution to many issues related to prosthetics. Now, many modern advances are used in dental clinics, thanks to which it is possible to solve problems as simply as possible and much cheaper than it was before. Unfortunately, not everyone has access to 3D dentistry, since such equipment requires additional costs and the ability to work with special equipment. But our services can be considered a way out of the situation, because we represent the whole range of work that a dental laboratory can perform. Our only difference is the 3D technologies used, thanks to which it is possible to print almost any products and designs. nine0005

Now, many modern advances are used in dental clinics, thanks to which it is possible to solve problems as simply as possible and much cheaper than it was before. Unfortunately, not everyone has access to 3D dentistry, since such equipment requires additional costs and the ability to work with special equipment. But our services can be considered a way out of the situation, because we represent the whole range of work that a dental laboratory can perform. Our only difference is the 3D technologies used, thanks to which it is possible to print almost any products and designs. nine0005

The production of abutments, crowns or bridges can be quite time consuming using classical methods. The manufacture of dentures and other products in a modern laboratory equipped with appropriate equipment is a completely different direction, which allows you to reduce the cost of the process as much as possible, but not reduce the quality of the products obtained. Even an artificial gum, thanks to printing in a private clinic, is not a problem - all activities in our dental laboratory are carried out quickly and professionally.