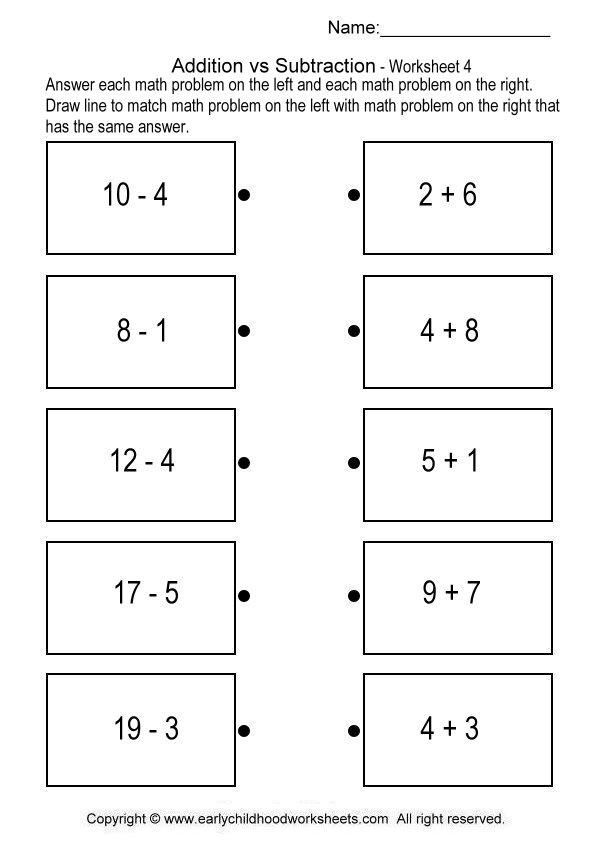

3D printer dental resin

Resin Library and 3D Printing Materials

Resin Library and 3D Printing MaterialsSkip to Main Content

Dental Resins

Bring production in-house or improve existing workflows with industry-leading Formlabs 3D printers. Our Dental Resins empower dental labs and practices to rapidly manufacture biocompatible surgical guides, splints, fixed patterns and models, clear aligner models, and full dentures.

Visit the Formlabs Store

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your lab or practice.

Request a Free Sample Part

The Form 3B+ and Form 3BL are compatible with the complete Formlabs resin library of more than 20 general purpose and speciality materials.

Explore All Formlabs Materials

Data Sheets

Download safety and technical data sheets for all Formlabs materials.

Handling & Safety

Handling & Safety

Resin should be handled with care. Proper handling will ensure safe printing and efficient use. Our resins have been designed to be similar or safer to handle as other household chemicals or adhesives. Formlabs materials do not contain volatile solvents so special ventilation is not required. Skin contact should be avoided.

The Safety Data Sheets (SDS) are up to date for every resin product and follow the latest government guidelines. Always consult the SDS as the primary source of information to understand safety and handling of Formlabs materials. For more information about handling resin, learn more tips for resin maintenance in our Help Center.

Technical Data

Technical Data

Plastics are complex materials, and finding the right one for your specific application requires balancing multiple attributes. Our library of resins is ideal for product development, rapid prototyping, and a variety of specialized applications. Download our Technical Data Sheets to explore the mechanical properties of each material.

Material

– Select –BioMed AmberBioMed BlackBioMed ClearBioMed WhiteBlackCastableCastable WaxCeramicClearColor BaseColor PigmentsCustom TrayDental LT ClearDental LT Clear V2Dental SGDigital DenturesDraftDurableESDElasticElastic 50AFlexibleFlexible 80AFull Materials LibraryGreyGrey ProHigh TempIBTModelModel V3Nylon 11Nylon 12Permanent CrownRigid 10KRigid 4000Soft TissueSurgical GuideTemporary CBToughTough 2000White

Language

– Select –BulgarianChineseCroatianCzechDanishDutchEnglishEstonianFinnishFrenchGermanGreekHungarianIrishItalianJapaneseKoreanLatvianLithuanianMalteseNorwegianPolishPortugueseRomanianRussianSlovakSlovenianSpanishSwedishTurkish

Technical Data Sheets

There is no technical data sheet available for the chosen material.

Safety Data Sheets

There is no safety data sheet available for the chosen material.

For more information, help choosing a material, or bulk orders, we're here to help.

Dental 3D Printing Materials by SprintRay

Resins designed for dental 3D printing.

See Open Certified Materials

Our large selection of dental 3D printing materials are designed to get the most out of SprintRay 3D printers. Developed and tested for market-leading performance in digital dentistry, SprintRay resins are built to achieve equivalent or superior results while providing better value for money. With a large selection of biocompatible materials, our resins are designed for dental 3D printing.

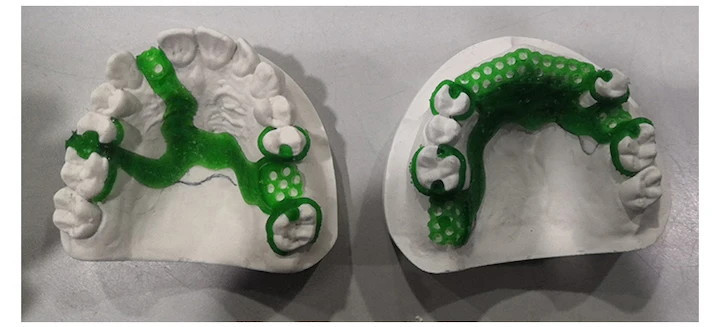

NightGuards

Surgical Guides

Crown

Castable

Try-In Dentures

Wax Up Models

Dental Models

Models for Aligners

Bonding Trays

Gingiva Mask

Denture Teeth

New

SprintRay Crown

TMStrong, accurate, long-lasting definitive restorationsApplications

Brochure

Read IFU

SprintRay Crown by BEGO® is a ceramic filled hybrid material for 3D printing single crowns, inlays, onlay, and veneers. This material is easy to finish and polish using traditional methods, and features excellent aesthetics to blend with existing teeth.

This material is easy to finish and polish using traditional methods, and features excellent aesthetics to blend with existing teeth.

High strength and resistance to wear make SprintRay Crown by BEGO® a go-to material for restorative 3D printing. And because SprintRay Crown by BEGO® is FDA 510(k) cleared and fulfills all the requirements for a Class II medical device, you can place with confidence.

Crown is available in seven shades: A1, A2, A3, B1, B3, C2, and D3. Available for sale in the US, EU, UK, and EFTA.

- Biocompatible, FDA 510(k) cleared and fulfills all the requirements for a Class II medical device

- Versatile: use as a single crown on natural tooth or abutment, as an inlay, onlay or veneer

- Very low water absorption reduces the tendency to age while a smooth surface means low plaque accumulation

Breaking Load

Breaking loads for crowns made of VarseoSmile Crown Plus (SprintRay CrownTM) and the competitor resin before and after a 10-year chewing simulation.

Initial

SprintRay Crown

1936 N

COMPETITOR RESIN

1740 N

After 10 Year Simulation

SprintRay Crown

1936 N

COMPETITOR RESIN

1337 N

New

SprintRay OnX Tough

The first hybrid ceramic resin created with NanoFusion™Applications

Brochure

Read IFU

Workflow Guide

SprintRay OnX Tough is a next generation hybrid ceramic, class II resin designed for the fabrication of dental prosthetics. Created using proprietary NanoFusion™ technology, OnX Tough delivers unparalleled durability and a smooth surface finish that mimics natural enamel with optimal translucency.

The resin allows for a highly efficient in-office workflow with easy post-processing and characterization and can now be cleaned with ProWash. Simple-tear supports separate with the flick of a wrist. With no extra mixing (or rolling) required, OnX Tough delivers extraordinary strength and lab-quality aesthetics. OnX Tough (1Kg) is currently available in the shade Hollywood Bleach.

Simple-tear supports separate with the flick of a wrist. With no extra mixing (or rolling) required, OnX Tough delivers extraordinary strength and lab-quality aesthetics. OnX Tough (1Kg) is currently available in the shade Hollywood Bleach.

- 5X tougher than first generation technology

- Easy to post-process and characterize

- A smooth surface finish and optimal translucency that mimics natural enamel

X-Ray of Restorative Materials

Images for demonstrative purposes only

WORK OF FRACTURE

Higher work of fracture means greater fracture resistance.

SprintRay ONX Tough

> 900 J/m²

first generation technology

150 J/m²

FRACTURE TOUGHNESS

Describes the ability of a dental material containing a crack to resist fracture.

SprintRay OnX Tough

2. 9 K1C

9 K1C

first generation technology

1.8 K1C

SprintRay OnX

The first radiopaque nanoceramic restorative resin.Applications

Brochure

Read IFU

SprintRay OnX is a nanoceramic hybrid class II 3D printing resin for the production of denture teeth. SprintRay OnX features an optimal combination of translucency and opacity to mimic natural dentition. Industry-leading ceramic content provides superior aesthetics, giving your patients something to smile about.

In-house production of 3D printed denture teeth reduces patient visits and chair time. SprintRay OnX features a clinically advanced formula that requires minimal resin prep and effortless finishing -- up to 7x faster time to teeth than the leading competitor.

- 1st fully radiopaque restorative 3D printed resin

- High condensed ceramic content

- Exceptionally aesthetic and easy to characterize

X-Ray of Restorative Materials

FLEXURAL STRENGTH

Higher flexural strength allows for greater resistance to fracture

SprintRay OnX

147MPa

COMPETITOR RESIN

125/136MPa

FLEXURAL MODULUS

Higher flexural modulus prevents distortion, which can impact placement accuracy during the procedure

SprintRay ONX

7986MPa

COMPETITOR RESIN

3360MPa

IMPACT STRENGTH

High impact strength reduces the chance of breakage under load

SprintRay ONX

COMPETITOR RESIN

New

SprintRay Surgical Guide 3

Fast and Accurate Implant GuidesApplications

Brochure

Read IFU

Surgical Guide 3 is the fastest, most durable implant guide material that SprintRay has ever made. Featuring improvements to flexural strength and modulus vs Surgical Guide 2, you can confidently place implants with this FDA-compliant, biocompatible resin. Plus, improved printing speeds further reduce time to surgery, improving flexibility and offering a superior patient experience.

Featuring improvements to flexural strength and modulus vs Surgical Guide 2, you can confidently place implants with this FDA-compliant, biocompatible resin. Plus, improved printing speeds further reduce time to surgery, improving flexibility and offering a superior patient experience.

By taking advantage of SprintRay Cloud Design and the Pro-Line of 3D printers, you can fabricate surgical guides of all kinds varying from single unit quadrants to full-arch multi-unit implant guides.

- Fastest-ever SprintRay Surgical Guide resin

- Clear and aesthetic appearance after autoclaving

- Improved flexural modulus and strength

FLEXURAL STRENGTH

Higher flexural strength ensures that the guide does not break during use.

SprintRay Surgical Guide 3

105 MPa

SprintRay Surgical Guide 2

88 MPa

FLEXURAL MODULUS

Higher flexural modulus prevents the guide from distorting, which can impact placement accuracy during the procedure.

SprintRay Surgical Guide 3

2579 MPa

SprintRay Surgical Guide 2

2418 MPa

VISCOSITY

Lower viscosity values indicate that the resin is easier to mix.

SprintRay Surgical Guide 3

343 Centipoise

SprintRay Surgical Guide 2

700 Centipoise

SprintRay NightGuard Flex

Clinically formulated for maximum speed, patient comfort, and durability.Applications

Brochure

Read IFU

Longevity Study

- Simple chairside experience with heat-set delivery

- >2X faster print speeds vs competitive products

- Comfortable, easy to clean, and flavorless

- High impact strength and flexibility

- Designed for patient comfort

NightGuard Flex was formulated from the ground-up to create the fastest, most comfortable 3D printed occlusal guard in dentistry. Featuring high impact strength and flexure at body temperature, your patients will love the comfort and longevity. Achieve superior fit and finish with a guard that is easy to polish and clean. Plus, NightGuard Flex is flavorless, ensuring smooth delivery.

Featuring high impact strength and flexure at body temperature, your patients will love the comfort and longevity. Achieve superior fit and finish with a guard that is easy to polish and clean. Plus, NightGuard Flex is flavorless, ensuring smooth delivery.

Designed to work in tandem with SprintRay Cloud Design and Pro 3D printing systems, this biocompatible* material creates efficiencies across your fabrication ecosystem. Faster printing speeds and improved dimensional stability while printing mean you save time and resin.

With NightGuard Flex, SprintRay is delivering on the frictionless occlusal guard workflow - from scan, to design, to printing and placement, protecting more smiles and delighting more patients.

Available for sale in the US only.

510(k) cleared

IMPACT STRENGTH

High impact strength reduces the chance of breakage under load.

SprintRay NightGuard Flex

118 J/m

COMPETITOR RESIN

46 J/m

FULL-ARCH PRINT TIME

Print speeds measured on SprintRay Pro95 at 170µm layer thickness vs competitor resin at 100µm.

SprintRay NightGuard Flex

44 Minutes

COMPETITOR RESIN

92 Minutes

SprintRay NightGuard Firm

The industry’s strongest, most aesthetic 3D printed occlusal guards.Applications

Brochure

Read IFU

- Outstanding wear resistance

- Great aesthetics with blue tint

- Up to 20% faster than competitive materials

- 10% stronger than previous Splint formulations

- No chemical flavor

Outstanding longevity, strength, and aesthetics come to 3D printed occlusal guards with SprintRay NightGuard Firm. This biocompatible material is easy to keep clean, resists wear, and is easy to polish. Designed for SprintRay clinicians, it helps create efficiencies across your workflow from design to print to placement.

Designed for SprintRay clinicians, it helps create efficiencies across your workflow from design to print to placement.

Featuring class-leading strength, NightGuard Firm is a high strength formulation, meaning it can take dropping, biting, and grinding in stride. Plus it prints fast - 20% faster than hard splint materials from other brands, empowering same- and next-day workflows that will delight your patients.

With NightGuard Firm and the SprintRay 3D printing ecosystem, you can rapidly produce beautiful occlusal guards to protect more smiles.

Available for sale in the US only

FLEXURAL STRENGTH

Higher flexural strength ensures that the model doesn't break during normal use.

SprintRay NightGuard Firm

119 MPa

Competitive resin

60 MPa

FLEXURAL MODULUS

Higher flexural modulus prevents the model from distorting, which can impact accuracy.

SprintRay NightGuard Firm

2452 MPa

competitive resin

1510 MPa

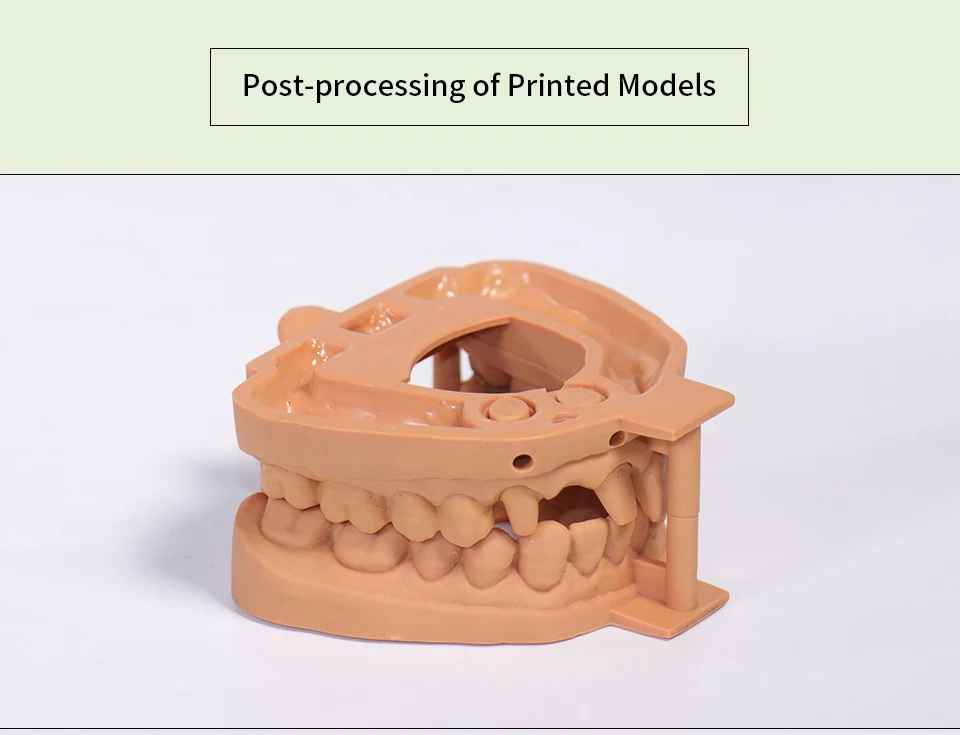

SprintRay Die and Model 2

Rapidly 3D Print High-contrast Dental ModelsApplications

Brochure

Read IFU

- Improved flexural modulus and strength

- Up to 10% faster print speeds

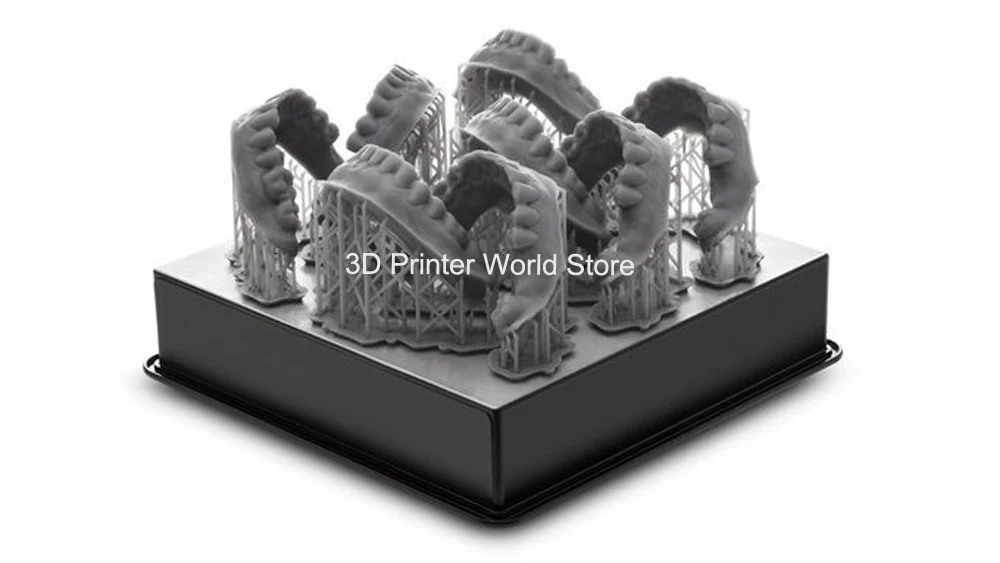

- Print up to eight full arch models in just 15 minutes*

- Fantastic color and finish that mimics dental stone

- Easy to separate from thermoforming materials

- Biocompatible, FDA-compliant material

SprintRay Die & Model 2 represents a big step forward in dental modelling materials. Our new colors mimic classic dental stone and feature almost no pigment settling, which means you can spend more time printing and less time mixing. Improved adhesion to the build plate is matched by an increase in flexural modulus and strength, providing higher success rates and a reduced chance of breakage.

Our new colors mimic classic dental stone and feature almost no pigment settling, which means you can spend more time printing and less time mixing. Improved adhesion to the build plate is matched by an increase in flexural modulus and strength, providing higher success rates and a reduced chance of breakage.

A reduced odor improves the quality of life for 3D printing models for an overall experience that your practice staff will love. Plus, Die & Model 2 resins are easier to separate from thermoforming materials, saving time and labor for more efficient in-office fabrication workflows. With rapid, repeatable results that are easier than ever to use, Die & Model 2 is helping to bring dental 3D printing into dental practices everywhere.

* When printed on SprintRay Pro with Ludicrous Speed profile. Learn More

FLEXURAL MODULUS

Higher flexural modulus prevents the model from distorting, which can impact accuracy.

Die and Model 2

2650 MPa

Die and Model

1700 MPa

FLEXURAL STRENGTH

Higher flexural strength ensures that the model doesn't break during normal use.

Die and Model 2

91.5 MPa

Die and Model

66.7 MPa

SprintRay Gingiva Mask

3D Print Accurate Soft Tissue ReplicasRead IFU

Gingiva Mask is a flexible yet durable material intended for use with SprintRay model materials to mimic the look and feel of natural gum tissue. Gingiva Mask has a high tear resistance and is easy to trim for optimal restorative planning.

- Excellent Tear Resistance

- Flexible & easy to trim

- Biocompatible, FDA-compliant

SprintRay Study Model White 2

Rapid, pure-white models for patient presentationApplications

Read IFU

SprintRay Study Model White 2 is a special material formulation that provides outstanding color, clarity, and production speed, making it perfect for patient presentation. With a 20% increase in curing efficiency, you can offer same-day mockups and waxups. Plus, get pure white prints every time thanks to an improved color formulation that doesn’t discolor during post-processing.

With a 20% increase in curing efficiency, you can offer same-day mockups and waxups. Plus, get pure white prints every time thanks to an improved color formulation that doesn’t discolor during post-processing.

- Wow patients with same-visit mockups and waxups

- 20% faster; print full-arch models in just 18 minutes

- Pure white color, even after post-curing

PRODUCTION TIME

Higher speed means faster model production, allowing for same-day waxup and diagnostic models.

Study Model White 2

17 Minutes

Die & Model 2 Gray

24 Minutes

SprintRay IDB 2

Bond a full arch of braces in just a few minutesView Application

Read IFU

SprintRay Indirect Bonding 2 resin features exemplary tear resistance and translucence, making it perfect for rapid bracket placement. Improved mechanical properties allow orthodontists to design thinner trays with greater accuracy, making the indirect bonding process rapid and cost-effective.

Improved mechanical properties allow orthodontists to design thinner trays with greater accuracy, making the indirect bonding process rapid and cost-effective.

- High tear resistance, flexibility, and translucence

- Improved formula for accurate placement

- Biocompatible, FDA-compliant material

ELONGATION

A higher elongation value means that the material can flex and stretch before it loses its shape or tears. High elongation is critical for indirect bonding appliances.

SprintRay IDB 2

Formlabs IBT

SprintRay Try-In 2

Rapidly print monolithic try-in denturesView Application

Read IFU

Digital dentures can reduce the number of appointments required for denture placement. SprintRay’s biocompatible try-in material can be rapidly printed to check bite registration and occlusion of dentures. This material can be printed monolithic or as a baseplate combined with individual tooth setup for maximum flexibility.

This material can be printed monolithic or as a baseplate combined with individual tooth setup for maximum flexibility.

- Biocompatible FDA-compliant material

- Allows rapid, cost-effective iteration of try-in denture

- Can be characterized and worn as short-term temporary

SprintRay Splint

Splints with high flexural strengthView Application

Read IFU

Biocompatible resin for splints and occlusal guards features superior flexural strength compared to other leading splint 3D printing materials. High flexural strength allows for long-lasting parts with a reduced chance of breakage during normal use.

- Biocompatible, FDA-compliant material

- Category-leading flexural strength

- Superior mechanical properties

FLEXURAL STRENGTH

Higher flexural strength ensures that the splint doesn't break during normal use.

SprintRay Splint

105 MPa

NextDent Ortho Clear

85 MPa

Cutting-edge Digital Dentistry Powered by SprintRay

The SprintRay 3D printing ecosystem is designed for the unique needs of dental professionals. With SprintRay as your partner, pushing the boundaries of what’s possible in dentistry has never been easier.

Schedule Consultation

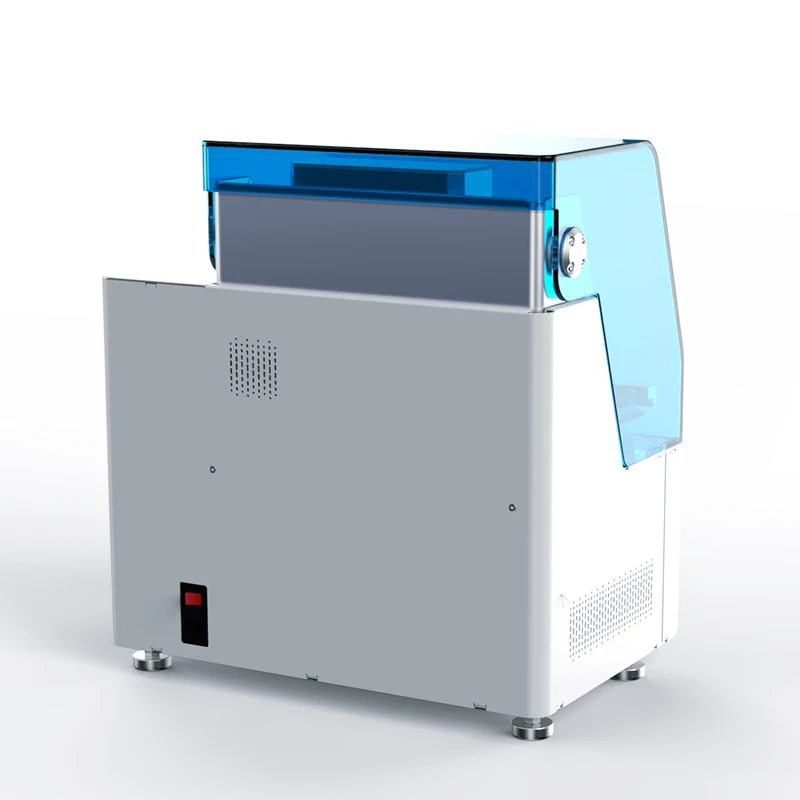

Desktop 3D Printer

Automated Wash/Dry

Automated Post-processing

3D Printing Materials

3D Printing Software

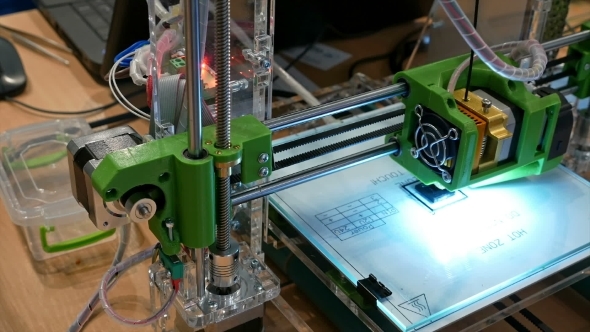

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries: nine0053

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning. nine0053

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface. nine0053

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using a Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable. nine0053

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes. nine0053

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance. nine0053

nine0053

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips. nine0053

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber nine0053

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping. nine0053

nine0053

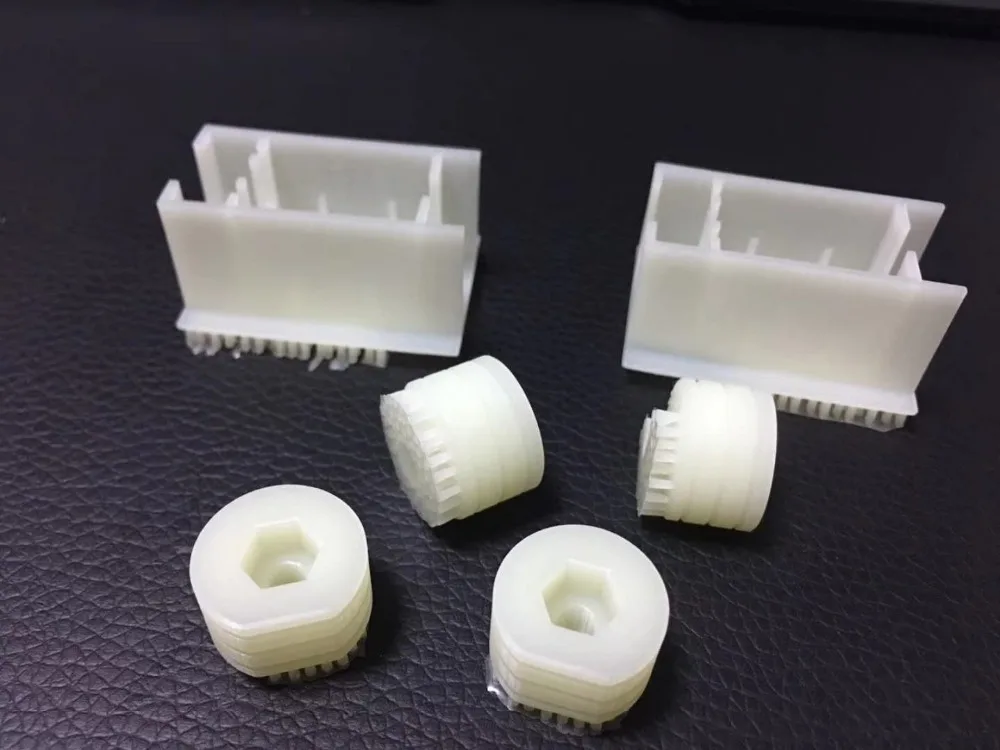

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is great for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

nine0053

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models. nine0053

nine0053

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness. nine0053

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity. nine0053

nine0053

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs nine0053

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A Biocompatible)

114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price nine0053

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin nine0053

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds nine0053

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Molding resin allows you to take the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

nine0113 Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you! nine0053

To order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

INSTAGRAM nine0053

In contact with

Types of resins for photopolymer 3D printer, characteristics, application

In recent years, the introduction of photopolymer printers in various areas of production is gaining more and more popularity. In order for the printer to reach its full potential, it is necessary to choose the right material - photopolymer resin.

In order for the printer to reach its full potential, it is necessary to choose the right material - photopolymer resin.

Now there is a wide variety of resins designed to solve a wide range of problems. Sometimes it can be difficult not to get confused in such a variety of materials. It is conditionally possible to divide photopolymer resins into several types - standard, engineering, dental, jewelry (burned). nine0053

Standard resins

Standard resins are well suited for making decorative models. They are strong and hard enough for making miniatures, master models, paintable figures or mock-ups, but their strength is usually not strong enough for functional products.

But standard resins are different from each other. Some of them can be washed not with alcohol, but with plain water, there are transparent types of resins or, for example, with a wide color palette. nine0053

Standard

Compared to other types of photopolymers, standard resins have a richer color palette. The main advantages are an inexpensive price, good detail and fast curing time.

The main advantages are an inexpensive price, good detail and fast curing time.

ESUN Standard

A good resin for professionals and beginners who are just getting acquainted with photopolymer printing. The advantages of ESUN Standard are a large palette of colors, no smell and fast printing speed.

ESUN Standard is suitable for printing decorative models or any other product that will not be subjected to heavy physical exertion. nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm (transparent 395-410nm)

Shore hardness: 80-82 D

Impact strength according to Izod: 18 - 40 J/m

Bending strength: 46-72 Mpa

Modulus of elasticity: 1000 - 1400 MPa

Elongation at break: 28-35%

Exposure time per layer (recommended): 5-10 sec. nine0053

Color palette: white, black, gray, red, blue, yellow, green, light green, flesh, orange, transparent.

Volume: 0. 5 kg, 1 liter.

5 kg, 1 liter.

Deadpool figurine

Bust of a military man

Moving castle, miniature

Users note good detailing, a good balance of strength and light elasticity, and excellent adhesion to the platform. The print time of the layer corresponds to the one declared by the manufacturer (5-10s) even on 3D printers with a weak UV source. nine0053

Of the minuses - sometimes the resin can be difficult to stir and a fine suspension comes across. This does not reduce print quality, but it does make me nervous. The gray color is slightly transparent, many users would like the color to be more “dense”.

ESUN eResin-PLA

eResin-PLA is based on PLA monomer, familiar to many from FDM printing. This makes the resin environmentally friendly and the finished product very tough and scratch resistant. nine0053

Resin is well suited for decorative items, master models or functional models without load.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 75-80 D

Elongation at break: 20-50%

Modulus of elasticity: 600 - 800 MPa

Impact strength according to Izod: 15 - 32 J/m nine0053

Tensile strength: 35-50 Mpa

Exposure time per layer (recommended): 15-20 sec.

Color palette: white, black, gray, red, blue, yellow, green, light green, flesh, orange, transparent.

Volume: 1 liter

Shoe model

Figurine cartoon girl nine0053

Play miniature

Non-standard focusing rings for lens

Phrozen Aqua 4K

The Phrozen Aqua 4K is specifically designed to unlock the full potential of 4K photopolymer printers. A pleasant bonus is the almost complete absence of shrinkage.

Resin is well suited for precision printing of decorative patterns. The manufacturer specifies that all properties of the resin are revealed when using printers with high resolution, such as Sonic Mini 4K / Sonic Mighty 4K. nine0053

The manufacturer specifies that all properties of the resin are revealed when using printers with high resolution, such as Sonic Mini 4K / Sonic Mighty 4K. nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 77 D

Color palette: gray, ivory.

Volume: 1 kg

Armor printed in gray resin Phrozen Aqua 4K

Bust Predator

Figurine war with a bear, to demonstrate the capabilities of Phrozen Aqua 4K

Phrozen Beige Low Irritation

This resin is hypoallergenic. Phrozen Beige Low-Irritation has passed the ISO-10993 10 test, which means that the resin does not contain heavy metals and the finished models can directly contact the human body.

The resin can be used in dentistry or for products that will come into contact with the skin. nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Color palette: beige

Volume: 0. 5 kg

5 kg

Decorative figurine

Jaw

ESUN Precession Model

Resin is designed for fast printing of high-precision models. In addition, finished products are tough and can withstand heat up to 80 degrees. nine0053

ESUN Precession Model is a good choice for models that need high detail.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 85 D

Elongation at break: 12.1%

Bending strength: 77 Mpa

Tensile strength: 335-410 Mpa

Color palette: red. nine0053

Volume: 1 liter

DC Universe Riddler Head

Miniature model of ICE

Clear resins

Clear resins are present in other photopolymer ranges, but may become yellow or cloudy over time. If optical transparency without yellowness is important in the finished model, then you should pay attention to special polymers. nine0053

nine0053

Phrozen SC-801 Clear

The main advantage of Phrozen SC-801 Clear is its optical transparency. Models made from Phrozen SC-801 Clear do not become cloudy or yellow during post-curing and during use.

This photopolymer is suitable for the manufacture of durable and accurate models for which optical transparency is important.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm nine0053

Shore hardness: 70 D

Color palette: transparent

Volume: 1 liter

Material transparency model

Left product made of Phrozen SC-801 Clear, right RESINMAGIC3D High-Grade Clear

Figure printed with Phrozen SC-801 Clear

Miniature bottles printed for a articulated doll. Left made from Phrozen SC-801 Clear, right made from another polymer.

Washable

Finished models made on a photopolymer printer are recommended to be washed from photopolymer residues with alcohol. There are situations where this is not acceptable, such as when the printer is being used in schools. For such cases, manufacturers have created the Washable line. Washable are resins that can be washed with plain water. nine0053

There are situations where this is not acceptable, such as when the printer is being used in schools. For such cases, manufacturers have created the Washable line. Washable are resins that can be washed with plain water. nine0053

ESUN Water Washable

ESUN Water Washable is as strong and precise as ESUN Standard resins. The only difference is that the finished product can be washed not with alcohol, but with plain water.

ESUN Water Washable is well suited for printing at home or in educational institutions due to its low toxicity and odorlessness.

Print Technology: DLP/LCD/LED

UV wavelength: 395-410 nm

Shore hardness: 76 D

Tensile strength: 68 MPa

Elongation at break: 5-10%

Bending strength: 45-70 MPa

Modulus of elasticity in bending: 900-1400 MPa

Izod impact strength: 18-39 J/m

Color palette: white, transparent, flesh, gray, black.

Volume: 0. 5 kg

5 kg

Rings and pendant printed in clear ESUN Water Washable

Fox figurine

Phrozen Water Washable

Phrozen Water Washable compares favorably with other water-washable resins in terms of strength, durability, and short flash-over time.

The resin is suitable for making prototypes and other models at home and in educational institutions where it is undesirable to use strong-smelling alcohols for washing. nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80 D

Color palette: gray, black.

Volume: 1 kg

Bust made from Phrozen Water Washable

Alien printed from Phrozen Water Washable

Bust of Spiderman

Wanhao Water washable

It is a resin with high resolution and good hardness. Wanhao Water washable has very little shrinkage and a wide range of colors.

Wanhao Water washable has very little shrinkage and a wide range of colors.

Resin is well suited for printing master models and decorative models when it is not possible to use alcohol to wash the final product.

nine0152

Print Technology: DLP/LCD/LED

UV wavelength: 395~420nm

Shore hardness: 75D

Color palette: white, transparent, black, gray

Volume: 0.5 kg, 1 kg

Han Solo in transparent Wanhao Water washable

Test model of transparent Wanhao Water washable

Test patterns in different colors Wanhao Water washable

Engineering

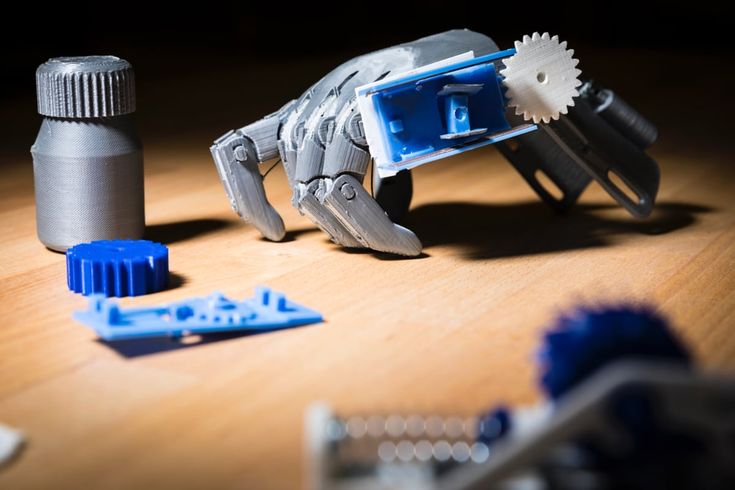

Previously, photopolymer printers were mainly used for making master models and products with high accuracy. Now they face a wider range of tasks. It is much more convenient to make a ready-made, functional model right away. For this, engineering photopolymer resins with improved characteristics have been developed. Depending on the application required, they can be harder, heat resistant and durable than standard resins. nine0053

Depending on the application required, they can be harder, heat resistant and durable than standard resins. nine0053

Reinforced

These are polymers with improved characteristics - for example, high heat resistance or impact strength. They can be used to produce functional prototypes, engineering models, etc.

Phrozen TR250-LV

The Phrozen TR250-LV has been specifically designed to meet engineering challenges. In addition to high strength and hardness, the resin has increased heat resistance and can withstand heating up to 150 degrees.

The Phrozen TR250-LV is suitable for the production of models for subsequent thermoforming or products that require increased heat resistance. nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 79D

Tensile strength 25 MPa

Izod impact strength: 6.31 kJ/m2

Color palette: gray

Volume: 1 kg

Jaw Layout

nine0053

Orc Bust

Phrozen ABS-like

This resin is similar in characteristics to ABS plastic, familiar to many from FDM printing. There is a white color in the palette, this allows, if necessary, to easily paint the finished product.

There is a white color in the palette, this allows, if necessary, to easily paint the finished product.

Phrozen ABS-like is suitable for printing functional models and prototypes.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm nine0053

Shore hardness: 79D

Izod Impact Strength: 2.32 kJ/m2

Color palette: gray, white

Volume: 1 kg

Skull Model

Weapons for miniature figures

1/4 mask

Phrozen Rock-Black Stiff

When creating Rock-Black Stiff, emphasis was placed on strength, wear resistance and heat resistance (up to 97 degrees). Models are strong and slightly flexible to withstand shock loads.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 81D

Elongation at break: 4%

Izod impact strength: 2. 68 kJ/m2 nine0053

68 kJ/m2 nine0053

Color palette: black

Volume: 1 kg

Elf bust

Bust printed in Phrozen Rock-Black Stiff

Phrozen Nylon Green Tough

Photopolymer is an analogue of nylon. Nylon is a very strong and wear-resistant material, familiar to many from FDM printing. Products are very durable and resistant to stress. Finished models printed in Nylon Green Tough can be folded. nine0053

Suitable for the manufacture of finished products or functional prototypes.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 68D

Elongation at break: 130%

Tensile strength: 19 MPa

Izod impact strength: 23.79 kJ/m2

Color palette: green nine0053

Volume: 1 kg

Phrozen Nylon Green Tough Vase

Test model

Spectacle frame

Phrozen TR300 Ultra-High Temp

TR300 Ultra-High Temp allows you to quickly produce durable, shock and heat resistant products (up to 160 degrees). The photopolymer compares favorably with its competitors with a short exposure time (on 3D printers of the Phrozen Sonic series, 1.3 seconds per layer). nine0053

The photopolymer compares favorably with its competitors with a short exposure time (on 3D printers of the Phrozen Sonic series, 1.3 seconds per layer). nine0053

Phrozen TR300 is suitable for the manufacture of heat-resistant and durable products. For example, it can be a model for subsequent thermoforming or manufacturing an industrial layout.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80D

Tensile strength: 32 MPa

Izod impact strength: 8 kJ/m2 nine0053

Elongation at break: 2%

Color palette: gray

Volume: 1 kg

Phrozen Onyx Rigid Pro410

The main properties of models made from Onyx Rigid Pro410 are amazing detailing and durability. The resin was developed in partnership with Henkel and is intended primarily for home workshops.

The photopolymer is perfect for models with an abundance of small details that need high detail. Or for engineering/functional models where high accuracy and strength are important. nine0053

Or for engineering/functional models where high accuracy and strength are important. nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Color Palette: Black

Volume: 1 kg

Tablet stand

Fruit vase

Wall mounted spice holder

Wall hanger

Flexible

Products made from such resins will look like silicone or rubber. Such photopolymers make it possible to obtain flexible and durable functional products resistant to tearing.

Phrozen Biege Flex

This is a resin designed for products that need to be strong and slightly flexible. Phrozen Biege Flex is suitable for functional models that need some flexibility. nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 65D

Tensile strength: 40 MPa

Modulus of elasticity: 192 MPa

Color palette: beige

Volume: 0. 5 kg

5 kg

Bust of Harley Quinn

Miniature from Phrozen Biege Flex

Functional carabiner

HARZ Labs Industrial Flex

By its properties, finished products from HARZ Labs Industrial Flex resemble polyurethane. Products from it are elastic and very durable.

HARZ Labs Industrial Flex is suitable for the manufacture of gaskets or any other model where softness and tensile strength are important. nine0053

Industrial Flex can be used as an additive for other HARZ Labs resins. This allows you to increase the flexibility and strength of the finished model. Depending on the resin ratio, different degrees of flexibility can be achieved in the finished product.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 63D

Shrinkage: 0.5%

Elongation at break: 103% nine0053

Tensile strength: 13 N/mm2

Color palette: transparent

Volume: 0. 5kg 1kg

5kg 1kg

Various gaskets printed from HARZ Labs Industrial Flex

ESUN Flex

Flexible and durable material with good wear resistance. Good tear resistance and accuracy allow ESUN Flex to be used in engineering models. nine0053

For example, products that must be strong and flexible at the same time. These can be engineering prototypes or functional models.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 85-90 A

Shrinkage: 6.9%

Elongation at break: 100-150%

Bending strength: 77 Mpa nine0053

Tensile strength: 390-320 kN-m

Color palette: transparent yellow

Volume: 0.5 kg

Test model from ESUN Flex

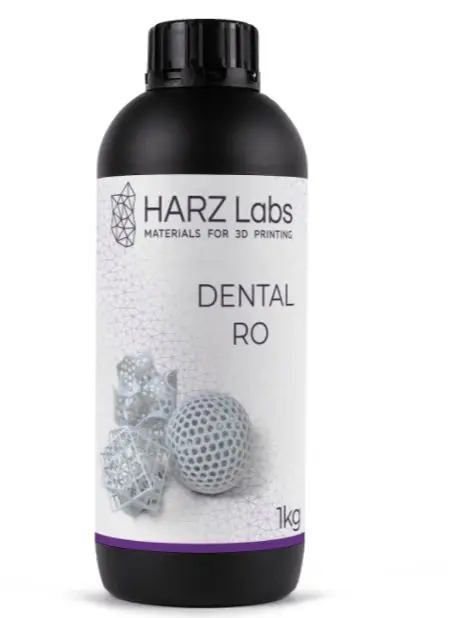

Dental resins

From the very beginning of its existence, photopolymer printers have taken the place of indispensable assistants in the dental industry, therefore, in the assortment of many companies that manufacture photopolymer resins, there are materials intended for use by dentists. nine0053

nine0053

Special photopolymers

These are special polymers that are focused on solving specific problems. No one forbids using them for other than their intended purpose, but they fully reveal their potential precisely in the task for which they were created.

Harz Labs Dental Soft

Dental Soft was created as a material to simulate gums in demonstration models. The finished print is pink in color and has high strength and chemical resistance. Despite its flexibility, the finished model will be resistant to deformation. Harz Labs Dental Soft is certified for medical use. nine0053

The material is suitable for gum printing or other medical applications.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 87-90D

Shrinkage: <0.5%

Elongation at break: 68%

Tensile strength: 1.2 N/mm2

Color palette: pink nine0053

Volume: 0.5 kg, 1 kg

Gums from Harz Labs Dental Soft

Gums from Harz Labs Dental Soft

NextDent Gingiva Mask

Another gum simulation resin from NextDent. Gingiva Mask is a flexible and durable resin that blends beautifully with model material.

Gingiva Mask is a flexible and durable resin that blends beautifully with model material.

The resin is suitable for various models in the dental industry. nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 60 - 75 A

Elongation at break: 40 - 60%

Color palette: pink

Volume: 1 kg

Gingiva made from NextDent Gingiva Mask

nine0055 Part of the gum made from NextDent Gingiva Mask

Jaw Demo with NextDent Gingiva Mask Inserts

Harz Labs Dental Clear

Products from this resin are durable and hard. The main feature is the resin is transparent, without turbidity and yellowness. Harz Labs Dental Clear is certified for medical use.

This photopolymer is suitable for the manufacture of surgical templates, demonstration models and even aligners. nine0053

nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 90-92D

Elongation at break: 4-6%

Shrinkage: less than 0.5%

Color palette: transparent

Volume: 0.5 kg, 1 kg

Jaw Demo Model

nine0055

Piece of jaw printed from Harz Labs Dental Clear

Dental Yellow Clear

Very similar in its properties to Harz Labs Dental Clear - just as strong and hard. The only difference is that the color of the resin is not crystal clear, but yellow. The resin is certified for use in medicine.

Dental Yellow Clear is suitable for making aligners or demonstration models. nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 90-92D

Elongation at break: 4-6%

Shrinkage: less than 0.5%

Color palette: transparent yellow

Volume: 0. 5 kg, 1 kg

5 kg, 1 kg

Gingiva pad made of Dental Yellow Clear

Jaw models

Dental Yellow Clear Demonstration Product

Burnout

In addition to specialized resins, dentistry needs low-ash burnable or smelted materials for direct casting.

Before casting, be sure to read the instructions from the manufacturer. Each resin has its own burnout cycle in order to obtain a good casting quality. nine0053

ESUN Castable Dental

ESUN Castable is designed for direct casting in dentistry. Finished products are smooth and hard. When burning, the ash content is practically absent.

High precision allows ESUN Castable to be used for crowns, bridges and other castings.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm nine0053

Shore hardness: 80D

Elongation at break: 11-20%

Bending strength: 49-58 Mpa

Impact strength according to Izod: 44 - 49 J/m

Color palette: green

Volume: 1 kg

Crowns printed from ES

ESUN Castable jaw

Example of printed and molded model

Phrozen Wax-like Dental Green

Wax-like Dental Green is a waxy resin with low shrinkage and zero ash content. Due to the low shrinkage, the finished products are very accurate, and the matte surface will help to see even small imperfections.

Due to the low shrinkage, the finished products are very accurate, and the matte surface will help to see even small imperfections.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm nine0053

Color palette: green

Volume: 0.5 kg

Ring made from Phrozen Wax-like Dental Green

HARZ Labs Dental Cast Cherry

HARZ Labs Dental Cast Cherry was developed for direct casting of dental products. With the correct burnout cycle, it is possible to achieve almost zero ash content. The photopolymer is certified for medical use. nine0053

Dental Cast Cherry is suitable for casting metal or ceramic crowns and bridges.

The manufacturer recommends the use of phosphate-based phytomass, because they can be used at high temperatures, which are required for high-quality burning of the model.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 40-50D

Shrinkage: less than 1%

Color palette: red

Volume: 1 kg

Crown models printed with Dental Cast Cherry

Cast crowns

NextDent Cast

It is an easy-to-burn-out resin with zero ash content. Designed for the manufacture of burn-out dental models. nine0053

Designed for the manufacture of burn-out dental models. nine0053

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80-90D:

Color palette: red

Volume: 1 kg

Crowns made from NextDent Cast

Demo model

DETAX Freeprint cast UV

High precision resin designed for fast manufacturing of dental products. Finished products can be used for direct casting. DETAX Freeprint cast UV burns out ashless even with large casting volumes. For molding, it is recommended to use phosphate-based masses.

Print Technology: DLP/LCD/LED

UV wavelength: 378-388 nm

Color palette: red nine0053

Volume: 1 kg

Overlay made of DETAX Freeprint cast UV

Crowns made from DETAX Freeprint cast UV

Burnout resins

In addition to dentistry, 3D printers have firmly established themselves in the jewelry industry. 3D printing allows you to create complex products much faster than classical methods (manual wax cutting, CNC machine). Burnt-out resins were created especially for jewelers. nine0053

3D printing allows you to create complex products much faster than classical methods (manual wax cutting, CNC machine). Burnt-out resins were created especially for jewelers. nine0053

ESUN Castable for jewelers

Photopolymer specially designed for printing and casting small models with high detail. Products from ESUN Castable are smooth, and almost zero ash content makes it easy to get the desired product in the metal.

The resin is suitable for printing jewelry - rings, pendants, earrings and for other burn-out models, in which precision and perfect surface quality are important.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 60 D

Color palette: yellow, green

Volume: 1 kg

Ring printed from ESUN Castable

Ring from ESUN Castable nine0053

Phrozen Wax-like Castable Violet

Waxy polymer with low shrinkage and zero ash content. Products made of Phrozen Wax-like Castable Violet have a nice matte surface, which will show the slightest imperfections.

Products made of Phrozen Wax-like Castable Violet have a nice matte surface, which will show the slightest imperfections.

Wax-like Castable is suitable for making any castable models.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Color palette: purple

Volume: 0.5 kg

Ring printed in Wax-like Castable and finished casting

Wax-like Castable Openwork Rings and Precast Castings

Wax-like Castable pendant and finished product

HARZ Labs Jewelry J-Cast

This is a photopolymer designed for the manufacture of burn-out models for subsequent casting in metal. High precision, low shrinkage (less than 1%) and low ash content (less than 0.1%) make it possible to print even very small products without distortion.

HARZ Labs Jewelry J-Cast is suitable for printing jewelry. Due to its high thermoplasticity, the photopolymer can be burned out over a wide temperature range.