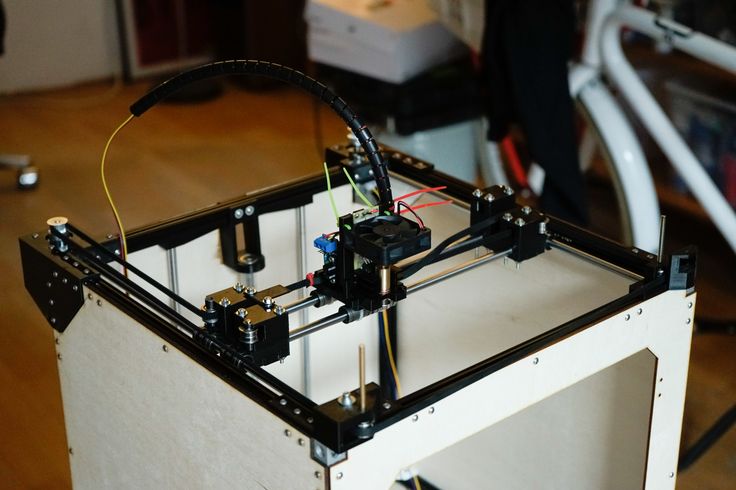

Hemp 3d printer

Entwined - Hemp Filament for 3D Printing

Sold out

$40.00

Combine quantities across all items on your order to get discount levels

12 Days of Filament - December 9-20

Just add items to your cart to SAVE 15% on everything and 30% off ReFuel.

No minimums and no discount code needed!

We offer discounts for Educational, Government Agencies, Veterans, Non-Profits, and 1st Responders

Entwined™ is hemp-infused 3D printer filament, the first and only commercially-available 3D printing filament produced from USA-grown and processed industrial hemp. Industrial hemp crops require no herbicides, no pesticides and grow more densely compared to corn. Entwined hemp filament uses only a small amount of colorant, allowing it to maintain a true natural brown. There's a large amount of visible bio-fill, something you don't get with standard PLA.

"Natural" color Entwined is also colored with a small amount of brown colorant that helps the product run well and stay in spec for our high-quality standards. It will now be a darker brown than the photos.

NOTE: This is not a product designed to make the filament stronger. The Hemp is there for color, texture, and to keep it out of the landfills. This is a novelty product that makes beautiful prints. Entwined Hemp-Filled PLA is made with a small percentage of Hemp byproducts, including hurd and fiber mixed with our Workday PLA.

| Are composites biodegradable? |

| Our composite materials made with Coffee, Beer, Hemp and others are made of over 90% sustainable PLA plastic and a smaller percentage of the recycled product from the material they contain. They have two primary purposes: 1) to utilize byproducts that would otherwise be placed in landfills, and 2) to create unique and interesting filaments with which to print beautiful items. Because there are not yet any truly 100% biodegradable plastics, they may be the closest you can get to a biodegradable plastic at this time. |

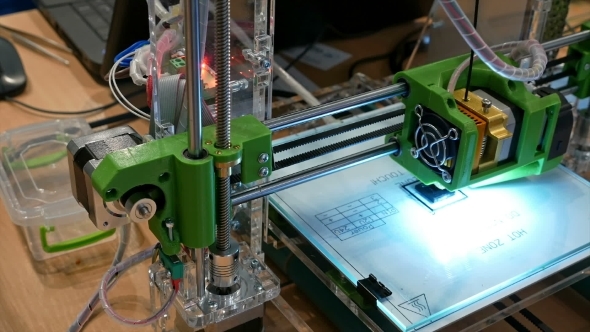

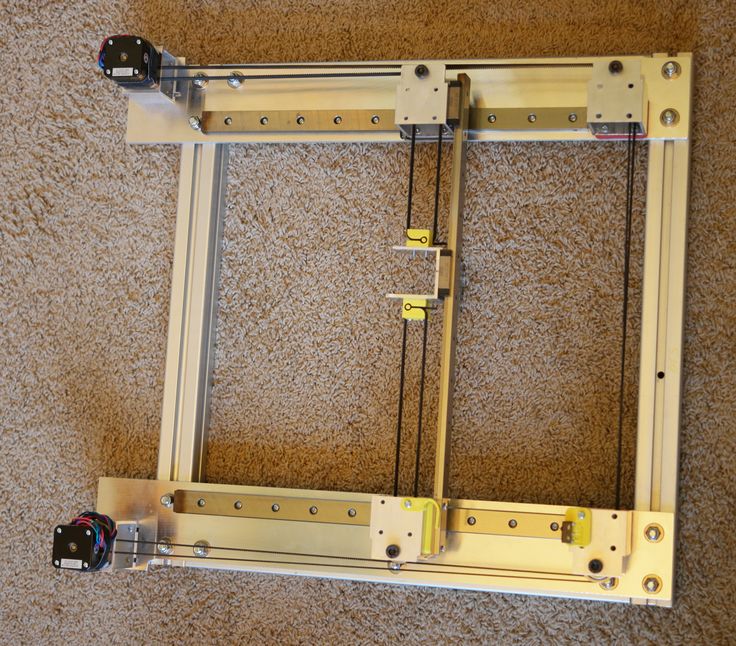

Entwined hemp filament can be printed on any machine capable of printing with PLA using standard PLA settings.

Entwined SDS

Entwined TDS

Print Settings

Entwined prints well at 180-210 C. In general, a good starting point is 10 degrees cooler than you typically print PLA. A heated bed is not necessary, though if you have one, set it to 45-60 C.

Filament Information Quality:

All 3D-Fuel 3D printer filament is manufactured in our own production facility located in Fargo, North Dakota. We have complete control over the manufacturing process and are able to ensure consistent quality for every spool. Learn more about 3D-Fuel USA filament quality.

We have complete control over the manufacturing process and are able to ensure consistent quality for every spool. Learn more about 3D-Fuel USA filament quality.

Diameter Tolerance:

Variable diameter can cause big problems in your 3D printer. We use a multi-axis laser measurement system to control our filament diameter and ovality in real time during production. Every spool has the diameter and ovality measurements listed right on the box.

Packing Information:

500g (1.1 lbs) or 1 kg (2.2 lbs) of Entwined Hemp Filament plastic filament arrives on an easy-to-use plastic reel and is vacuum sealed with a desiccant packet to keep out any moisture. Test Printing: The 3D-Fuel test lab features multiple brands of 3D printers including MakerBot, Raise3D, LulzBot, FlashForge, and more. We 3D print what we manufacture to ensure that our filament provides the absolute best quality possible. Download an Entwined™ brochure in PDF format

Hemp 3D printer filament: A sustainable alternative

Published on September 20, 2018 by Michelle J.

Cannabis has over recent time been a growing topic of debate. As it is discussed in various ways for its medical uses, environmental benefits and sustainable abilities, it is only natural that Hemp 3D printer filament would also come up at some point. While it is not the only alternative 3D printer filaments we covered on 3Dnatives, here is what you need to know about this 3D printing material.

The history

One material that historically has been a big part of the world culture in over 10.000 years is: hemp. It was one of the first plants domesticated by Humans and have been used in day-to-day life for its solid fibres, nourishing seeds and natural medicinal properties. It was even commonly used as paper and the growth of the plant encouraged by Kings. However around the 1950s a decline came about when cannabis was demonized for its euphoric properties. Since then the full plant has been looked down upon in big parts of the USA and Europe and the use of the material declined drastically.

Industrial hemp material

In recent years however, the focus have turned back into a positive spin for the versatile material. More and more places are changing legislation, such as in California, and opening up for implementing the plant into everyday life. So as Hemp is an environmental-friendly material, it could be the solution to a lot of environmental problems. The plant reduces water consumption, pesticide use, and much more. The versatility of the plant can be used for a ton of things, such as biofuel and textiles. This is where 3D printing comes into play, as a lesser-known usage of this plant is for 3D printer filament. Along with hemp filament being developed it brings a new aspect to the additive manufacturing industry.

Manufacturing process

3D printing is improving the manufacturing processes in terms of reducing the environmental impact of manufacturing by reducing waste and speeding up the processes while often using less energy. Still, there are a way to go before a completely closed loop system and environmental-friendly filaments on the market. Mistakes and bad 3D prints happens from time to time. When using traditional plastics this can build up a lot of unwanted and unneeded waste. A way to counteract this is to print with biodegradable or recyclable material, such as PLA and Hemp. Because of hemps natural abilities it has no need for pesticides, it fertilises the soil it grows in and can grow more densely than other crops. Already these aspects make hemp a good material to work with as an eco-solution. PLA, which hemp is often combined with, is already biodegradable on its own. This based in PLA being sourced from materials such as sugar canes and cornstarch. Therefor combining PLA and Hemp in a hybrid material will bring new possibilities to the table.

Mistakes and bad 3D prints happens from time to time. When using traditional plastics this can build up a lot of unwanted and unneeded waste. A way to counteract this is to print with biodegradable or recyclable material, such as PLA and Hemp. Because of hemps natural abilities it has no need for pesticides, it fertilises the soil it grows in and can grow more densely than other crops. Already these aspects make hemp a good material to work with as an eco-solution. PLA, which hemp is often combined with, is already biodegradable on its own. This based in PLA being sourced from materials such as sugar canes and cornstarch. Therefor combining PLA and Hemp in a hybrid material will bring new possibilities to the table.

The process of making hemp filament is fairly simple. Most commonly you will see a material like PLA as a polymer base. The hemp fibre is grounded up into fine particles and mixed into it. This process is done in the same way a lot of other hybrid filaments are made. However, it is often made without added colour to keep the positive impact all the way through and has a special texture to add to the print. With this and as hemp is good for the environment, it is no wonder that there is a demand for it.

However, it is often made without added colour to keep the positive impact all the way through and has a special texture to add to the print. With this and as hemp is good for the environment, it is no wonder that there is a demand for it.

The debate on how legal the various filaments are, depends on the individual locations. In France the law is set to the filament having less than 0,2% Tetrahyrdocannabinol or THC for short. But the general laws are currently changing in various locations around the world. One place where legislation seems to be moving fast over recent years is the US. In 2014 then president Obama signed the agricultural act of 2014. This amongst other, allowed for universities and state departments of agriculture to start cultivating industrial hemp for limited purposes, opening up for the market to develop. This year alone at least 38 of the states considered legislation related to the hemp industry, covering everything from clarifying laws to establishing new licensing requirements and programs. Out of this at least 5 states have enacted legislation to establish hemp research and industrial pilot programs along with more states.

Out of this at least 5 states have enacted legislation to establish hemp research and industrial pilot programs along with more states.

Main producers

There are already a couple of companies out with their version of the hemp 3D printer filament. One such company is 3D4MAKER. They have developed their product for the market of biodegradable plastics with the ability to recycle or compost the filament afterwards.

Another company is 3Dfuel. The company have released a series of eco-friendly composite materials. Partnering with c2renew to produce the line, they came up with 4 materials so far. They consist of Wound Up: a coffee filament, Buzzed: a beer filament, Landfillament: a trash filament and Entwined: their hemp filament. All of which is produced using waste materials and Ingeo PLA to provide functional and sustainable 3D prints. 3Dfuel even released an improved version of their hemp filament. In the v2 version they basically reduced the particle size of the hemp material. The finer particles allows for an increase in the percentage used in the filament with the visible bio-fill creating a unique texture. Showing an interest in improving the possibilities.

The finer particles allows for an increase in the percentage used in the filament with the visible bio-fill creating a unique texture. Showing an interest in improving the possibilities.

A newer company, doing so as well and pushing the natural material is Kanèsis. Starting out slow with a campaign that didn’t take off, they still managed to fund their HempBioPlastic or HBP®. The company persisted, launched their website and have worked to develop solutions for a sustainable world ever since. On their site they sell the HBP filament as well as a Weed filament. The main difference between the two, being the THC levels. The Italian company is sole committed to natural materials designed for the manufacturing industry, bringing down the environmental impact and providing all-around benefits.

Kanèsis’ HempBioPlastic or HBP®

How to use Hemp 3D printer filament

The general printing properties of most of the hemp 3D printer filament closely resembles PLA filament. However, it might be even easier to print with as it, depending on which producer you buy it from, can print at 10°C lower than PLA. The filament is also odorless, which helps for indoor use in smaller spaces. And it has low-warp, making a heated bed unnecessary when printing. Though if you have one an optimal heat setting seems to be around 45°C. Since hemp 3D printer filament is easy to print and works in the same manner as PLA, it can be used in a variety of ways. However, do to the ease of use, along with the biodegradable attributes it would be good for daily prototyping. Not to mention other projects of experimenting that wouldn’t have the need for colouring. Of course if you are searching for a specific look or texture to your print, it might be worth checking out as well. Although the hemp filament is a hybrid filament at this point, it seldom has the same texture as traditional PLA.

The filament is also odorless, which helps for indoor use in smaller spaces. And it has low-warp, making a heated bed unnecessary when printing. Though if you have one an optimal heat setting seems to be around 45°C. Since hemp 3D printer filament is easy to print and works in the same manner as PLA, it can be used in a variety of ways. However, do to the ease of use, along with the biodegradable attributes it would be good for daily prototyping. Not to mention other projects of experimenting that wouldn’t have the need for colouring. Of course if you are searching for a specific look or texture to your print, it might be worth checking out as well. Although the hemp filament is a hybrid filament at this point, it seldom has the same texture as traditional PLA.

The price varies quit a lot form one hemp printer filament to the next. Kanesis sells their HBP and Weed filament for around $37 for a 500g spool. 3D4MAKERS is around the same kg price with a 750g spool for ca. $48. In the more expensive corner you can look to 3Dfuel’s entwined that sells for $45,99 for 500g. Depending on the producer the prices varies, along with the actual plant material percentage in the filaments.

In the more expensive corner you can look to 3Dfuel’s entwined that sells for $45,99 for 500g. Depending on the producer the prices varies, along with the actual plant material percentage in the filaments.

3Dfuel created a short video to introduce you to the concept of hemp 3D printer filament:

So while there are bio-filaments on the market already, it is only the start. Both established and new companies will continue to develop and improve their products. What to you think of the hemp 3D printer filament? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news on progress, research and more entrepreneurs in 3D printing send straight to your inbox!

90,000 marijuana in the blood? No, hemp has now settled in the 3D printer Three-dimensional printing is becoming more and more firmly established in the life of mankind, today this innovative technology is actively used not only in the world of scientific developments, but also “by leaps and bounds” breaks into various fields of activity. You can even buy a 3D printer for your home, it has been on sale for a long time. However, such devices require "consumables" - raw materials from which various objects are printed; relatively recently, a natural base was developed to replace polymer components, which will be discussed in this article. nine0003

You can even buy a 3D printer for your home, it has been on sale for a long time. However, such devices require "consumables" - raw materials from which various objects are printed; relatively recently, a natural base was developed to replace polymer components, which will be discussed in this article. nine0003

How did it all begin?

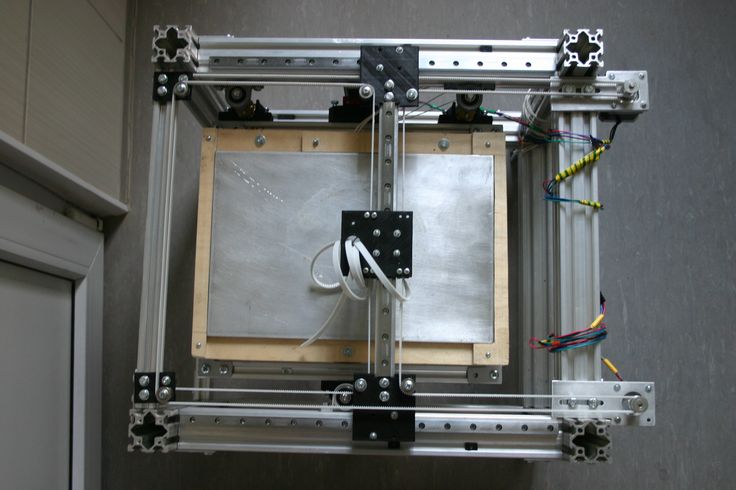

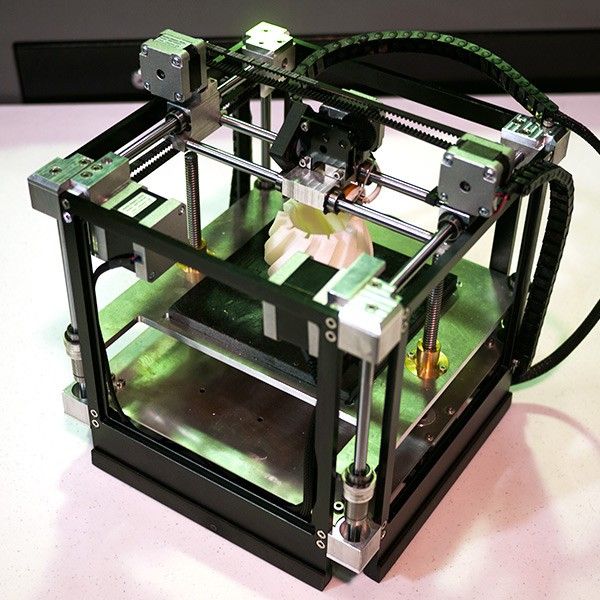

In 1986, the American scientist-engineer Chuck Hull invented a stereo lithography machine, which is recognized as the forefather of the modern 3D printer. And in 1988. developer Scott Crump introduced the 3D modeling method. After 8 years, 3D Systems released the first prototype in history (Actua 2100), which performs the design of three-dimensional objects.

Yes, it required serious improvements, and therefore decades were spent on its improvement. Scientists have invested a lot of effort to ensure that the modernized models produce high quality prints, since 2008 the raw material platform has also expanded significantly. The standard used earlier ABS plastic began to be replaced by other materials, and sometimes quite unexpected ones, for example, chocolate, biocomposites, sandstone and even hemp. nine0003

The standard used earlier ABS plastic began to be replaced by other materials, and sometimes quite unexpected ones, for example, chocolate, biocomposites, sandstone and even hemp. nine0003

Advanced 3D Designs

Today, 3D design finds its application in many areas, some of which, frankly, surprise and amaze the inexperienced layman.

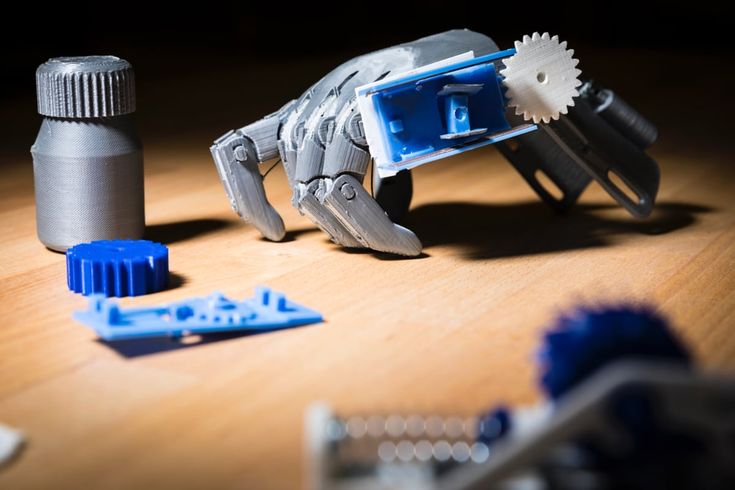

1. Human organ transplantation and prosthetics.

This direction has been developing vigorously since 2013, as the need for bioimplants - analogues of human organs that can save a lot of lives, or at least alleviate them, is only growing. Unfortunately, the short lifespan of the analog organ remains a pressing issue here, so researchers still have work to do. nine0003

2. Manufacture of technical accessories and components.

Based on the elastic, non-deformable NinjaFlex material and the 3D engineering system in England, the Fenner Drives plant has launched the production of polymer components for various kinds of equipment and electronics: buttons, covers, etc.

3. Making clothes.

Many designers were also inspired by the idea of creating clothing and decor elements using 3D modeling after the successful project of the Victoria's Secret brand. In 2013, he presented the Snow Queen costume to the general public, the main elements of which were made using innovative technology. Designers emphasize the exclusivity of this method, which allows 3D scanning to fit, for example, a dress, to the individual shape of the figure. nine0003

4. Construction of buildings.

In the United Arab Emirates, a project was launched to create a one-story office center with a total area of about 180 sq.m. using a six-meter 3D printer. This technology, according to experts, will reduce time costs by 75% and labor costs by 2 times. By the way, the internal interior filling is also planned to be produced according to the above scheme.

And the European Space Agency ("European Space Agency") proposed to build a base on the moon, erecting buildings using the 3D design method. According to their calculations, the “construction” of 1 complex will take an average of 7 days. nine0003

According to their calculations, the “construction” of 1 complex will take an average of 7 days. nine0003

5. Auto simulation.

The first printed car was released in 2010, and in 2013. on its basis, the concern "Korecologic" released a new improved model "Urbee 2". And this unique car of its kind can go. Its maximum speed is 112 km/h.

6. Making weapons.

Defense Distributed holding in the United States of America in 2013. The first printed pistol with the loud name "Liberator" ("Liberator") was released, only one part of which out of all sixteen was made of metal. nine0003

Hemp as raw material for 3D printing

The possibilities of using the innovative 3D printing method, as time has shown, are almost limitless. Every year new sources of raw materials appear in this area, which not only expand the boundaries of what is permissible, but also allow us to improve existing developments. Cannabis is one of the most recent bio-resources. What has changed with its appearance in the 3D industry?

Cannabis is one of the most recent bio-resources. What has changed with its appearance in the 3D industry?

nine0003

3D technology to help canna farmers

Slovenia has developed a 3D printer capable of revolutionizing traditional crop production. It “prints” with a specially prepared mixture of soil and seeds, distributing the latter within strictly specified parameters. This innovation will greatly simplify the process of breeding new varieties of marijuana.

In addition, in the USA, with the assistance of 3Dponics, a leader in the hydroponic agricultural industry, a 3D printing machine was made that allows you to create unique pots for growing cannabis. These pots, consisting of three elements - the tub itself, the stand and the lid, are an artificial soilless environment enriched with essential minerals. So the consumer (amateur gardener or farmer) can only ensure regular watering of the plant. nine0003

nine0003

"Miracle of technology" in medicine

Medicinal marijuana has already been legalized in many countries around the world, it is prescribed for the treatment of a number of diseases, and for pharmacists the issue of the correct dosing of drugs is acute.

Two developers from America, Ashley Herr and Paige Colin, solved this problem, based on the achievements of the 3D industry. Hemp oil, which has become the main ingredient, they dry and mix with a water-soluble biopolymer and other inert pharmacological substances. Then the resulting mass is forced through the forming tool, turning into edible fibers. This allows you to achieve the necessary and precise ratio of the active substances of cannabis - cannabinoids and terpenoids. And also to resolve the issue of their dosage. nine0003

Ashley Herr and Paige Colin patented their invention under the name "Potent Rope", which literally translates as "powerful, potent or effective rope. " Talking name, whatever one may say!

" Talking name, whatever one may say!

"Potent Rope" cannot be classified as food products, such as hemp cookies, sweets, marmalade, etc., as it contains a pharmacological polymer. It is clearly a drug, which means that it can be freely sold throughout the United States, while in many of them the usual use of cannabis products is prohibited by law. However, athletes are afraid to take it, as the discovery of marijuana in the blood may lead to disqualification. nine0003

Hemp Biofilament

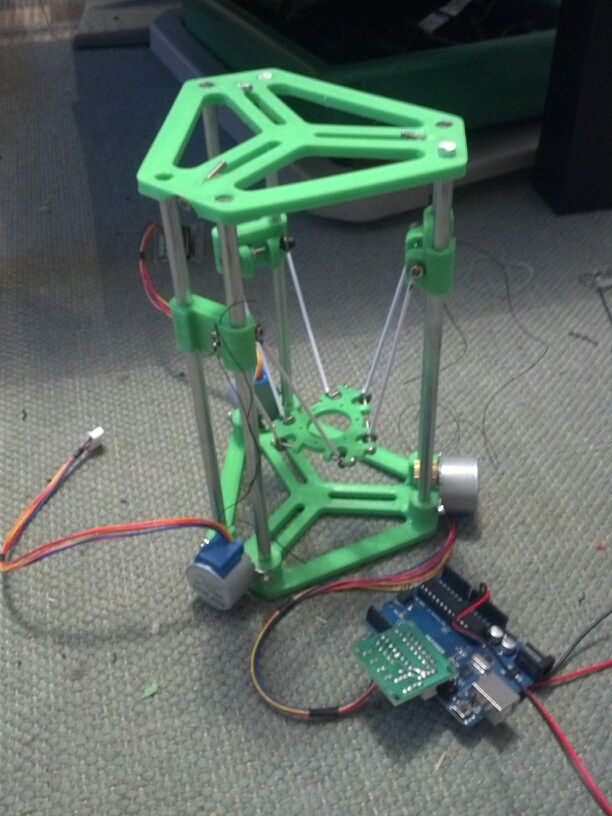

The main raw material for FDM printing, layer-by-layer fusing modeling, is a thermoplastic eco-friendly bio-resource - polylactide. However, the developers of the Brooklyn-based design studio MatterLab announced the creation of new natural and biodegradable sources. These are composite biofilaments (filamentous formations) made of marijuana and tagua nuts, capable of competing for the "palm" with the reigning leader. According to the data provided, only 20% of this material will consist of traditional polylactide, the remaining 80% will be derivatives of technical cannabis and tagua palm fruits. nine0003

According to the data provided, only 20% of this material will consist of traditional polylactide, the remaining 80% will be derivatives of technical cannabis and tagua palm fruits. nine0003

In parallel with American engineers, the Italian company Kanèsis announced a similar know-how to the world. The leaders of Kanèsis, Giovanni Milazzo and Antonio Caruso, have already patented the composition of a 100% biodegradable 3D modeling raw material, the fundamental component of which is industrial hemp. The development was given a name - "HempBioPlastic".

Giovanni Milazzo and Antonio Caruso note the special thermoplasticity of plant fibers, similar to propylene. But unlike the latter, biocomposite cannabis is 20% lighter and 30% stronger, as well as more environmentally friendly and cheaper than its counterpart. Contracts have already been concluded, according to which HempBioPlastica will be used to produce bottles, disposable tableware and other products. nine0003

nine0003

3D printing:

The wave of legalization of medicinal cannabis stirred up not only the raw material segment of the market, but also made many entrepreneurs and researchers puzzled by the invention of new products in the field of direct use of the product itself.

Design smoking pipes

American brothers Al and Saul Jacobs founded the company "Printabowl" and set up the production of exclusive designer pipes for smoking cannabis, which are created on their own, once home, 3D Printer. Any model is rather a work of art, they are least of all similar to classic smoking devices - actually traditional pipes, bongs or pipes. nine0003

The brothers are engaged in the development of each model range independently. After the design work, blanks are directly printed on a 3D printer, into which ceramics are poured. The hardened product is baked, after cooling it is polished and baked again. The result is a durable, glossy and authentic smoking ceramic product.

The result is a durable, glossy and authentic smoking ceramic product.

Medical marijuana inhaler

The Israeli holding "Syge Medical Ltd" has released two samples of a medical compact inhaler on a 3D technology platform. The development of these devices was carried out over a long four years, and yet engineers and doctors managed to achieve the necessary balance of required parameters, such as reliability, accuracy, thermal stability and biocompatibility of the components. nine0003

Inhalers allow you to use a medicinal product based on medicinal cannabis, correctly calculating the dosage of inhalation. This makes it possible for patients to avoid the intoxicating side effect and not to think about how long cannabis stays in the blood and urine, and how this will affect their health later.

Conclusion

In modern realities, it is difficult to make an unambiguous decision on the controversial issue of attitudes towards marijuana. Of course, its recreational use causes negative emotions and fear in the majority of the world's population. But the realization of its practical undeniable benefits both in industry and in the treatment of many diseases does not give the right to deny its exorbitant merits and our need for it. nine0003

Of course, its recreational use causes negative emotions and fear in the majority of the world's population. But the realization of its practical undeniable benefits both in industry and in the treatment of many diseases does not give the right to deny its exorbitant merits and our need for it. nine0003

Rather, society should be guided not by a reputation that was "tarnished" in its time, but by the foundations of its expediency and beneficence for civilization as a whole. Scientists and engineers continue their research in a given direction, and humanity has yet to appreciate their work with gratitude.

Discuss on the forum

Will a hemp 3D printer see the light of day?

- home nine0140

- Blog

- Will a hemp 3D printer see the light of day?

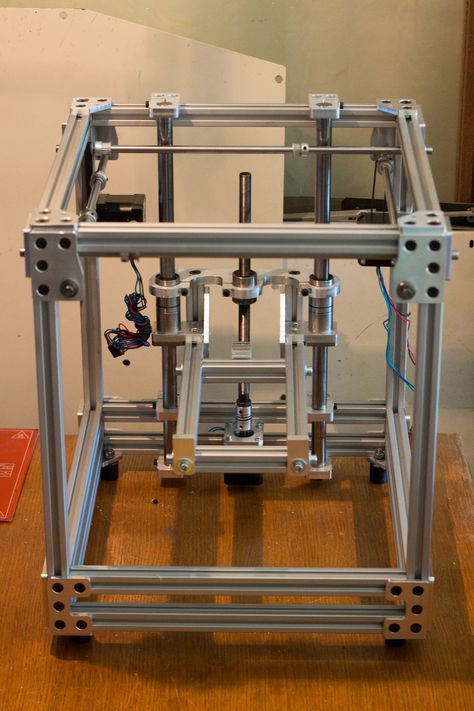

More than three decades have passed since the introduction of the first 3D printer (1986). During this time, experts have made a lot of efforts to improve it. They worked:

- over image fidelity;

- print speed;

- strength;

- size reduction.

Over the years, the search has been on for sustainable printing materials that could expand the range of 3D products. What do modern 3D printers print?

The materials are quite diverse: various types of plastic, metal, food substances, building materials and even living cells. nine0003

nine0003

Every day, scientists try to discover more and more new materials with which to create three-dimensional images. There are also quite strange ideas.

How about cannabis?

Yes, just imagine! Sometimes the ideas of specialists are simply striking in their originality. The authors of this unusual idea were the employees of the Australian company Mirreco. According to experts, quite a variety of products can be obtained from hemp. And all thanks to the outstanding properties of the plant, such as:

- cheap;

- intensive growth;

- environmental friendliness;

- excellent performance;

- resistance to the greenhouse effect;

- destruction of carbon dioxide.

In fact, they started talking about cannabis for a reason. The fact is that Mirreco is engaged in the production of mobile plants that help in the processing of technical hemp, as well as its separation into seeds, fibers and fire. Why do they do it? It's simple - these components serve as raw materials for the manufacture of various goods and materials. The bonfire is used in the manufacture of paper, the fibers for fabrics, and the seeds for paints and lubricants. But what were the Mirreco employees up to? nine0003

The bonfire is used in the manufacture of paper, the fibers for fabrics, and the seeds for paints and lubricants. But what were the Mirreco employees up to? nine0003

You won't believe your ears! They decided to grind the stems and leaves of the plant into biomass in order to build real hemp houses from the resulting material!

Why choose hemp

As Mirreco assured, hemp material has many advantages:

- excellent thermal insulation properties;

- easy to manufacture.

Products made from hemp have such qualities as:

- durability; nine0140

- anti-allergenic;

- antiseptic;

- ability to breathe;

- comfort temperature maintenance.

Experts say that a hemp house can be erected in just a couple of weeks! And it will already be equipped with communications and modern technologies for generating electricity from sunlight.

How good are those who try to invent something, to somehow make life easier and diversify! Everyone should follow their example.

As they are mostly PLA, they are compostable in an industrial compost, will eventually biodegrade (won't last forever like petrol-based plastics), and are made from plants.

As they are mostly PLA, they are compostable in an industrial compost, will eventually biodegrade (won't last forever like petrol-based plastics), and are made from plants.