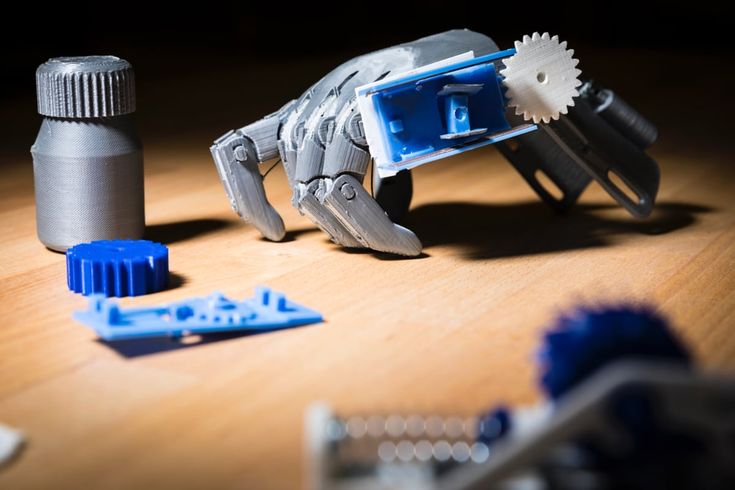

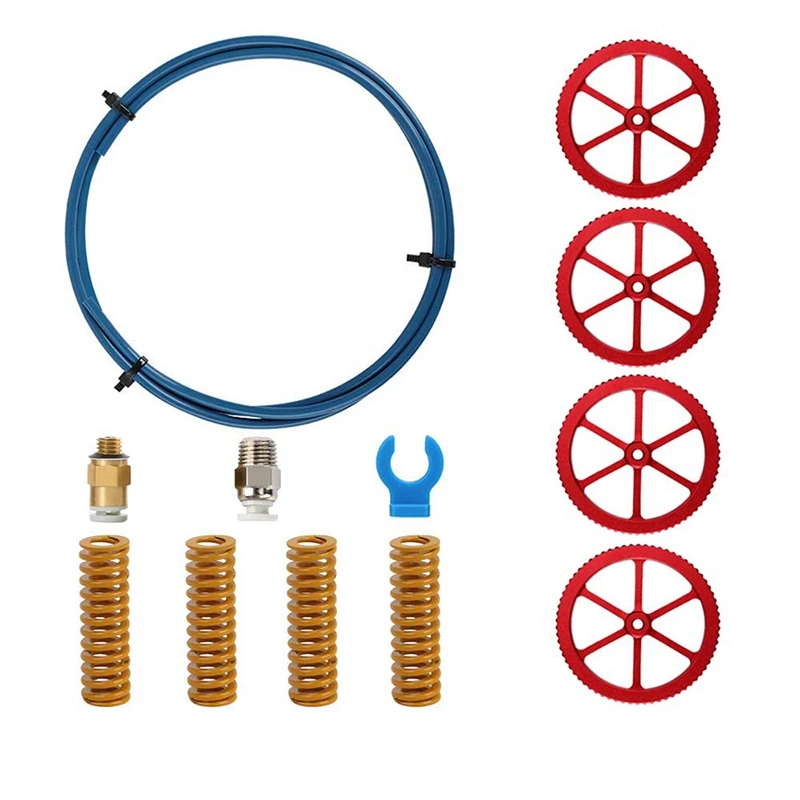

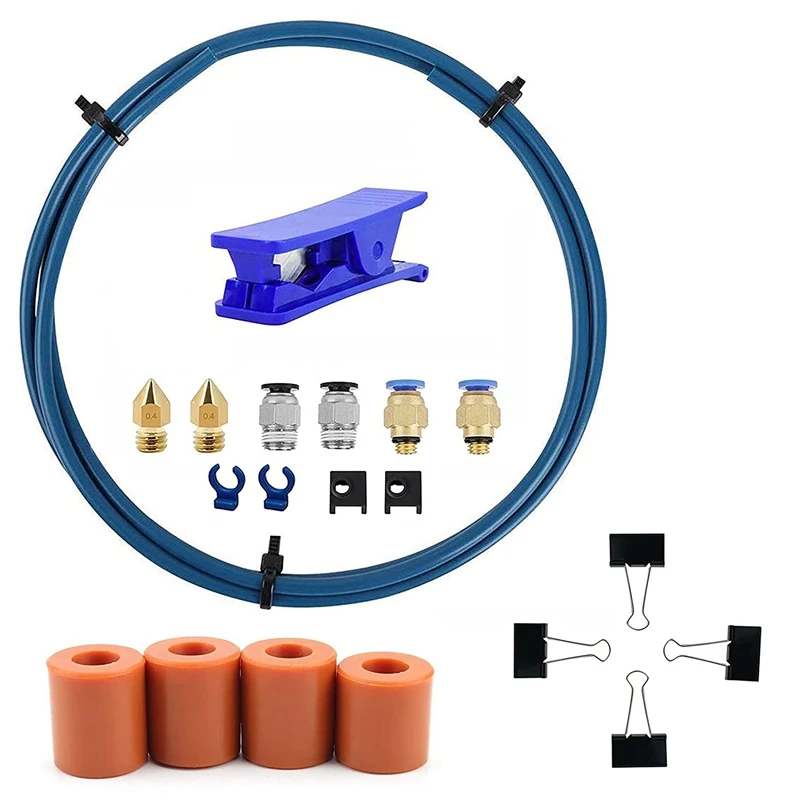

Capricorn 3d printer tubing

Technical Specifications

Technical SpecificationsWarning: Printing At High Temperatures May Create Harmful Off-Gassing

How To Install FAQ Safety Precautions Shop Now!

PTFE, or Polytetrafluoroethylene, is a synthetic polymer commonly used as a coating for non-stick pots and pans. It is the slipperiest substance known to man, and is said to be the only surface to which a gecko cannot stick. Although Bowden tubes can be made from several different polymers, PTFE is generally considered the best because of its high melting point and low coefficient of friction.

1.75mm Bowden tubing, because of its small diameter, is made with an expensive paste extrusion process. Very precise equipment is needed to obtain a consistent shape and internal diameter. Additives such as colorant are difficult, because the PTFE doesn't readily want to mix with anything. Plain white PTFE is the cheapest and most common.

Our tubing is manufactured using the most sophisticated equipment currently available. It always comes out perfectly round, and the diameter stays as consistent as possible.

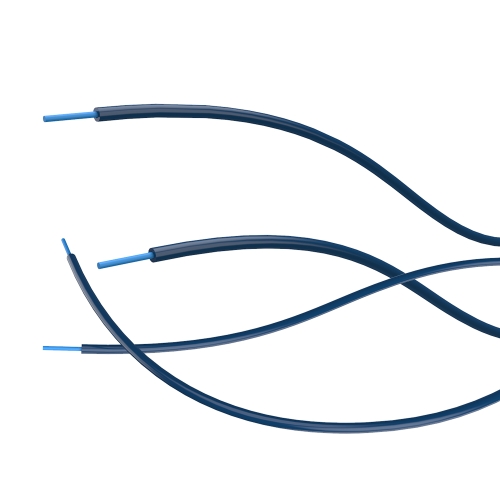

Our TL Bowden Tubing is made from pure virgin Japanese PTFE resin. This resin is not only translucent, it is also slightly softer and more flexible than average PTFE.

Our TL tubing features a 2.0mm nominal inner diameter. This makes it well suited for printing larger or uneven diameter filaments such as wood and metal flake filaments. Higher end wood filaments especially have a tendency to be "chunky," containing large bits of real wood.

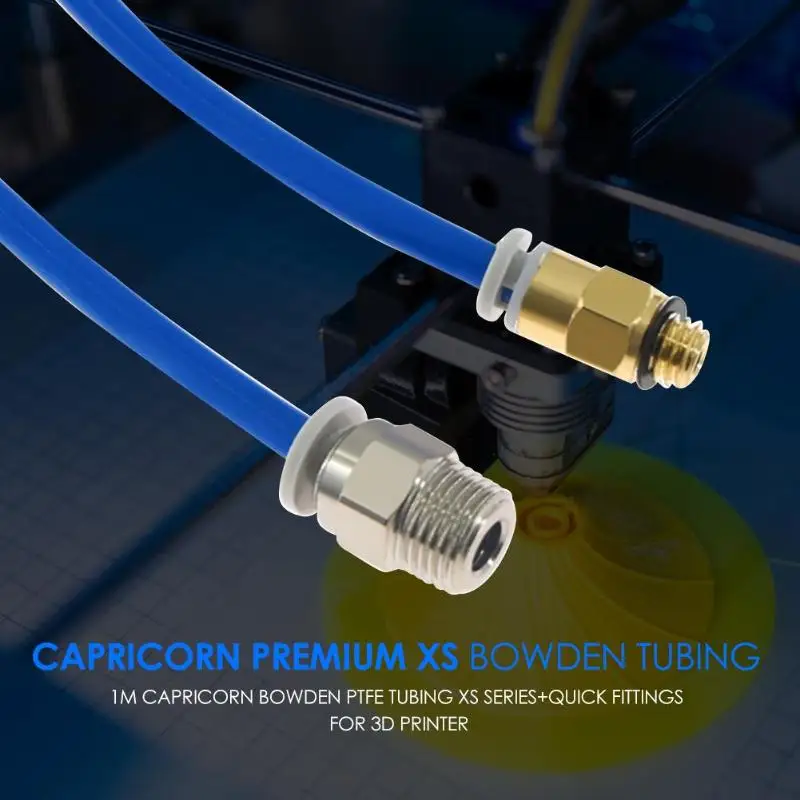

Our XS Bowden Tubing is also made from the highest quality pure virgin Japanese PTFE, and formed using the paste extrusion process. However, we have added a "Secret Sauce" which lowers the coefficient of friction. This additive also makes the tubing dark and opaque.

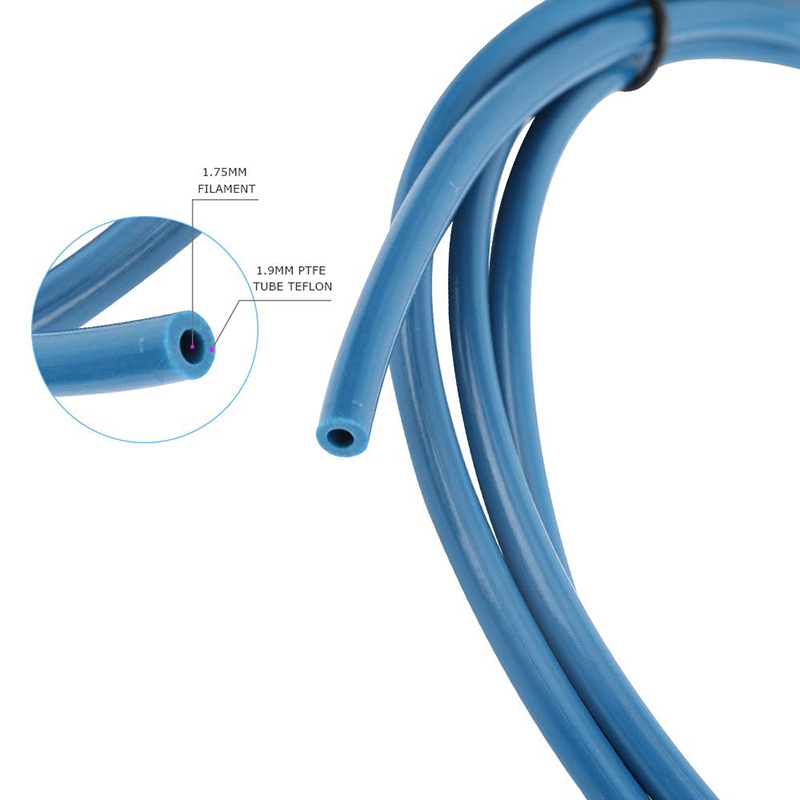

Our XS tubing has a nominal internal diameter of 1.9mm. This smaller diameter makes it ideal for printing flexible filaments, because there is no room for the filament to bind up inside the tube. The low friction coefficient allows any filament to glide through the tube with ease.

For mor information about the differences between our two lines of tubing, please see our How to Choose page.

Data Sheet

| Additives | None | None | Blue Color | Blue Color and Secret High Lubricity Additive Mixture | |

| Best For Chunky Filaments | NO | NO | YES | YES | |

| Best For Flexible Filaments | NO | NO | NO | YES | |

| Can See Through | NO | YES | YES | NO | |

| Pulling Friction♠ | 1. 0 0 | 0.9 | 0.8 | 0.8 | |

| Color | White | White, Clear, or Translucent | Blue, Translucent | Dark Blue | |

| Density (kg/m3) | 2100-2200 | 2100-2200 | 2100 +/-100 | 2300 +/-100 | |

| Hardness | 50-70 | 50-70 | 55 | 60-65 | |

| Inner Diameter (mm) | Typically 2.0 to 2.1 | Typically 2.0 to 2.1 | 2.05 +/- 0.05 | 1.90 +/- 0.05 | |

| Linear Thermal Expansion at 250 °C | No data | No data | 3.4-3.6% | 2.2-3.3% | |

| Material | Cheapest PTFE, FEP, or Other Polymers | Better PTFE, PFA, or Other Polymers | Highest Quality Pure Virgin PTFE | Highest Quality Pure Virgin PTFE | |

| Melting Point (°C)♥ | Variable, as low as 220 | Variable, as low as 220 | around 300 | up to 340 | |

| Outer Diameter (mm) | Typically 3. 9 to 4.1 9 to 4.1 | Typically 3.9 to 4.1 | 3.95 +/- 0.05 | 3.95 +/- 0.05 | |

| Roundness (ϵ) | Variable | Variable | < 0.1 | < 0.1 | |

| Stiffness§ | High | High | Medium | Medium High | |

| Thermal Conductivity (W/m-k) | no data | no data | 0.25 | 0.25 | |

| Wear Rate (gm/s) | No data | No data | 0.01 | 0.01 | |

| Young's Modulus (GPa)¥ | Variable | Variable | 0.5 | 0.53 |

♠Pulling Friction is calculated as the average force required to pull 1.2 meters of 1.75mm PLA filament through 1 meter of tubing at a constant speed, relative to 1 meter of cheap white reference tubing. Note that although we observed the friction of the TL series to be about the same or even slightly lower than our XS series, it also has a larger internal diameter. |

| §Other Bowden tubes may vary significantly in stiffness, depending on the material from which they're made. Our tubing generally tends to be more flexible than most, with the TL being more flexible than XS, partly because of the difference in additives, and partly because the XS has a greater cross-sectional area (XSA) due to the smaller internal diameter. |

| ¥Young's Modulus (YM) is the measure of elasticity of the material. Our XS Series additives give the PTFE a slightly greater YM than the TL Series. |

| ♥Temperatures were approximated by heating samples of all tubing simultaneously, observing how quickly each one began to deform. Printer failures may happen at significantly lower temperatures. |

| Printing high temperature materials may create dangerous off-gassing. Please refer to the Safety Page. |

How To Install FAQ Safety Precautions Shop Now!

How To Install Your New Capricorn Bowden Tube

Choose Tubing Choose Fittings Measure Filament Safety Precautions Shop Now!

"Measure Twice,

Cut Once. "

"

Getting Started

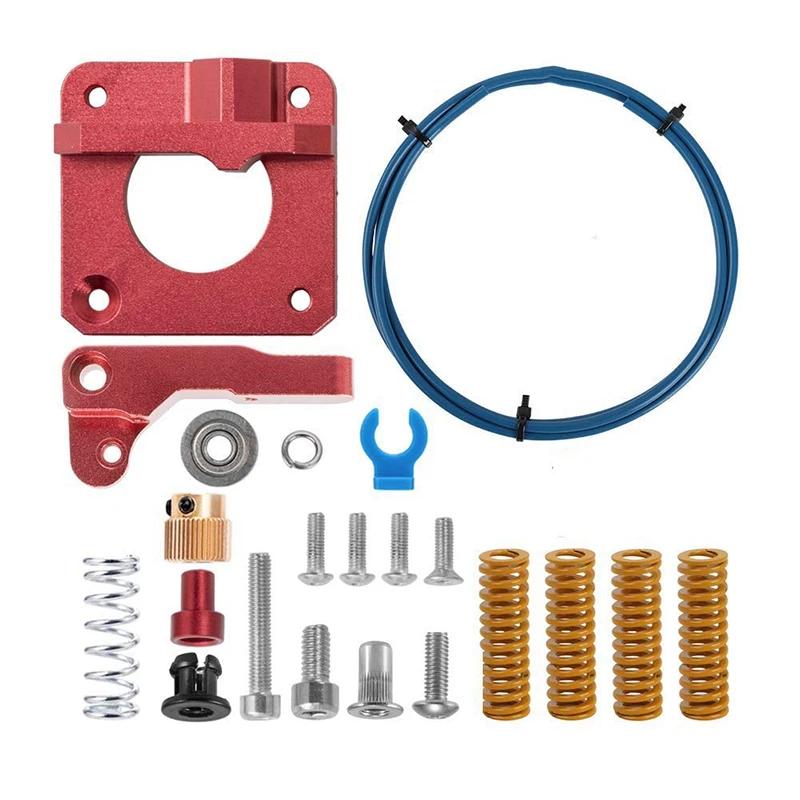

The first step is to remove the old Bowden tube. Look inside your printer for a plain white or translucent tube running from the extruder to the hot end. It will be attached by a fitting at both ends.

In some cases it may be beneficial to remove one or both of the fittings from the machine, but this is usually not necessary. If needed, simply turn the fitting with a crescent wrench to loosen it.

Some printers have a Bowden tube that goes all the way through the fitting down into the hot end. Before removing the tube from the hot end, mark it with a piece of tape so you will know how deep the tube needs to go. This can also be the case with the extruder, although it is less common. If you have a paint marker, that's even better, because even the stickiest tape doesn't want to stick to PTFE.

The Fittings

There are two types of fittings you may have to deal with. Most all fittings have an inner collar that physically bites into and locks onto the tube as it is pulled outward away from the fitting. Some of these are spring loaded, and some are held in place by a plastic C clip. On the C clip kind, simply remove the clip by pulling it to the side. Push down on the collar if you need to, and the tube will come loose.

Most all fittings have an inner collar that physically bites into and locks onto the tube as it is pulled outward away from the fitting. Some of these are spring loaded, and some are held in place by a plastic C clip. On the C clip kind, simply remove the clip by pulling it to the side. Push down on the collar if you need to, and the tube will come loose.

On the spring loaded kind, you will need to simultaneously pull on the tube and push down on the collar. Apply pressure evenly to all sides. Grip the tube as close as you can to the fitting, to avoid damaging it. Pull straight so as not to kink the tube. As a last resort, you can use pliers to grab the tube instead of bare hands, but this will almost certainly damage it. (Doesn't matter if you're about to throw it away, but a good habit to get into in case you have to re-install your Capricorn tube at some point.)

Sometimes a tube just won't come loose from a fitting. This is usually because of some internal damage to the tube or fitting, so we recommend replacing it at that point.

Cutting The Tube

The second step is to measure the old Bowden tube. Be sure to hold it straight while measuring. In most cases, you will want the new one to be the exact same length. You might be able to go shorter, but be careful because once you cut the tube you can't make it longer again. If designing a new printer, bear in mind that you want the tube as short as possible, so measure the distance from the extruder to the farthest point the hotend can reach.

Next cut the tube. Its very important to get a good clean and square cut. By square, I mean it should be perpendicular to the tube itself. This will allow it to fully seat within the fitting without any gaps where the filament can get snagged.

There are a number of tools available to make a good square cut. It is not recommended to use scissors or wire cutters because they will smush the end. If this is all you've got, then use a pair of needle nose pliers to carefully un-smush the end and make sure the hole is open and round before moving on. A good sharp razor blade will get you a perfect cut, but it takes some practice.

A good sharp razor blade will get you a perfect cut, but it takes some practice.

If you want the easiest way to get a perfect cut every time, we recommend our Capricorn Premium Tubing Cutters.

Using Capricorn Tubing Cutters

To use the cutters, simply squeeze to open, and place the tubing in the groove, aligning the path of the blade with where you want to make the cut.

Release the pressure on the blade, and allow it to come to rest on the tubing, so you can make sure it is in exactly the right spot.

Now make sure the tubing aligned in the cutter, and squeeze it between your fingers and thumb.

PTFE is very slippery, and it will want to slide out during the cut, resulting in an end that isn't square. You will be tempted to press slowly and carefully on the cutter, but the trick to getting a good cut is actually to squeeze fast, like using a stapler.

Putting It All Back Together

Now that the tube is cut to length, simply install it into the fittings. If you marked your old tube with tape, use it as a reference to make sure you've got the tube all the way in and fully seated.

If you marked your old tube with tape, use it as a reference to make sure you've got the tube all the way in and fully seated.

To install the tube in spring loaded fittings, push down on the collar and push the end of the tube into it. To install the tube in C clip fittings, insert the tube and then pull the collar out by either holding the fitting upside down, grabbing it with needle nose pliers, or prying it with a screwdriver. Insert the C clip to keep it in place. Tug gently on each end of the Bowden tube to make sure it is secure.

Some Hot-ends, such as the SeeMeCNC HE280, require a special procedure to propertly seat the Bowden tube. Consult your documentation! Failure to Completely seat the tube will result in a puck of melted plastic forming between the opening of the tube and the entrance of the nozzle, which will cause severe under-extrusion and worst case completely jam.

Finishing Up

At this point in the install, apply the included Capricorn sticker to the front side of your printer, so everyone will know you're printing with genuine Capricorn technology.

Make sure you're Bowden tube is clear of any moving parts, and you're now ready to go. You're prints will look great, and your printer will look great too!

The final, and most important step, is to take some pictures and video of your printer in action, and share them on social media with hashtag #captubes. Share your prints with #capprints.

Choose Tubing Choose Fittings Measure Filament Safety Precautions Shop Now!

>

(There is a solution) What causes my Bowden tube to melt on the side?

If the tubing is PTFE, it will most likely not melt unless the hotend gets out of control. You would probably pay attention to PLA cooking.

So maybe they're not PTFE, or maybe it's wear.

If it wasn't PTFE, you should be able to tell from texture, slipperiness and bending strength.

The four thinned faces look like they match the four spikes in the connector. The thinned ring under the four thinned edges looks like a wear line where the tubing is pressed against the connector exit. It seems to me that the tube is moving or bending in the connector. The barbs act like little chisels that cut into the pipe, which is how they hold back slippery material like PTFE. nine0003

The thinned ring under the four thinned edges looks like a wear line where the tubing is pressed against the connector exit. It seems to me that the tube is moving or bending in the connector. The barbs act like little chisels that cut into the pipe, which is how they hold back slippery material like PTFE. nine0003

This could work better if the tube were a little longer. This can reduce the forces at the movement boundaries that can stress the pipes. If you can, you can also create a warp relief for the tube so it doesn't bend straight out like it does from the connector. If you can shorten the movement, you will help with external wear.

It is also possible that the tubing is stressed by the high filament pressure. The entire drive for pushing the filament into the hot end is matched to the equivalent back pressure from the tube to the connector. If you can handle the higher printing temperature, the life of the tube can be extended. nine0003

@towe added comment:

I don't think these are air clutch teeth.

The questions say "where it pushes the nozzle" and the Ender 3 Pro seems to have a hotend where the Bowden tube reaches all the way through the cold end and thermal break to the nozzle.

The mechanical drawing of what could be an MK-10 hot end, as used on the Ender 3 Pro, also suggests that the Ender 3 Pro has a PTFE lined hot end. Let's take this picture as proof that @towe is right. However, the marks you show in the photo are similar to the types of cuts I've seen from an air clutch. How to reconcile this contradiction? nine0003

The most direct answer would be that the tube does not reach the nozzle. You don't show enough of the blue tube in the photo to show the muff scars, which should be a little further down the tube. Assume that the tube is not actually pressed against the nozzle. This may not be true if any of these are true:

- There is a separate piece of PTFE that is constantly hot. Creality Ender 3 Pro looks like he is not set for Bowden.

Hot end with PTFE lining for straight extruder will have a piece of PTFE cut to length in hot end. A simple mod to make Bowden leave this sculpted PTFE tube in place. nine0026

Hot end with PTFE lining for straight extruder will have a piece of PTFE cut to length in hot end. A simple mod to make Bowden leave this sculpted PTFE tube in place. nine0026 - Pneumatic couplings have been replaced. Many couplings are allow the pipe to pass through them, although the hole at the end can be drilled up to a diameter of 4 mm. In fact, preventing the passage of the tube through the pneumatic clutch is a feature in the intended applying the coupling to air pipes at moderate pressure .

- There is a bump on the way that catches the tube and does not allow her to reach out to the cold end and beyond.

Best 3D Printable Capricorne・Cults

Zodiac emblems - Capricorn pendant

4,99 €

NoZipp clip - environmentally friendly

0.55 €

Gift box Star Sign Capricorn

1,50 €

Medabots / Medarot - (CPC00) Capricorn

1,50 €

nine0034 Ring of Capricorn 2. 82 €

82 €

zodiac symbols

3 €

Smoking pipe 3D model 3D printed model

2,99 €

Key rings "Zodiac signs"

1,50 €

Aquarium cutter

0.99 €

nine0034 Carver Maiden0.99 €

Libra Shearer

0,99 €

Cutter "Scorpion"

0,99 €

Leo Cutter

0.99 €

Capricorn

0.99 €

Archer cutter

0,99 €

nine0034 Cutting cancer0.99 €

Cutter "Aries"

0,99 €

Fish Shearer

0. 99 €

99 €

Tilcer cutter

0,99 €

Twin cutter

0.99 €

Pisces silhouette cutter

0,99 €

nine0034 Silhouette cutter for aquariums0,99 €

Capricorn silhouette cutter

0,99 €

Silhouette cutter for Sagittarius

0,99 €

Silhouette cutter "Scorpion"

0,99 €

Silhouette Cutter Scale

0,99 €

nine0034 Virgo silhouette chisel0,99 €

Leo silhouette cutter

0,99 €

Cutting cancer

0,99 €

Twin cutter

0. 99 €

99 €

Tilcer cutter

0,99 €

Cutter "Aries"

0.99 €

SHURA OF CAPRICORN - GOLDEN KNIGHTS

3,50 €

zodiac charms

3,60 €

REMOVE CLUTCH SProckets RC CAR

Free

PISTON DISMANTLER NOVAROSSI RC CAR ENGINES

0,80 €

nine0034 VENTURI DUCT, for NOVAROSSI CARBURETTOR RC CAR0,80 €

Capricorn on stone - SLA print - Zodiac

11.49 €

Zodiac Charm Set

Free

All 12 main symbols of the Zodiac, astrology, signs of the horoscope

2.