Action figure 3d print

Will Hasbro’s 3D Printed Action Figures Kick-Off Mass Customization?

Circa 2014, the world was being told by people like this author that 3D printing was ushering in an era of mass customization for consumers. That is, anyone would soon be able to purchase products tailored specifically to them… soon. While there were numerous attempts to realize this marketing vision, most didn’t really pan out. Nearly a decade later and the dream may finally be coming true as HasbroHAS and Formlabs have announced the launch of a new series of action figures featuring the faces of their owners, made possible with 3D printing.

3D Printed Hasbro Selfie Series

With the introduction of the Hasbro Selfie Series, consumers can now purchase six-inch action figures from their favorite franchises (e.g., Ghostbusters, G.I. Joe, Power Rangers, Star Wars, Marvel, etc.) in their own likenesses. According to Brian Chapman, Head of Global Design and Development at Hasbro, the technology for realizing the perfect personalized product wasn’t available until now.

“It wasn't until recently that two technologies came into play at once,” Chapman said in a promotional video for the product line. “One is a very simple way to scan someone's face and head, and then a very affordable way to print that head in a one-off way. And when those two things collided, we said, ‘Hey, I think the time is now to launch Hasbro's Selfie Series.’"

A G.I. Joe figure personalized with 3D printing.

Image courtesy of Formlabs.Using proprietary software, consumers are able to scan their faces with a simple smartphone app, Hasbro Pulse. The resulting model is then made on Formlabs 3D printers, which rely on custom resin developed specifically for the toy manufacturer to mimic a range of skin tones and hair colors. The heads then undergo a proprietary, ‘“state-of-the-art’ process for adding color and detail to ensure every Hasbro Selfie Series action figure is collector-grade. All of this is performed by Hasbro itself with each unit passing through standard product testing certification, which all Hasbro products receive.

MORE FROMFORBES ADVISOR

3D Printed Selfies of the Past

Hasbro has been toying with additive manufacturing (AM) for some time. In 2014, the company partnered with 3D printing service bureau Shapeways to allow users to sell their own printable fan art for My Little Pony, Transformers, Dungeons & Dragons, G.I. Joe., and more. It went a step further by partnering with a startup dedicated to essentially doing what it is doing now: 3D printing consumers heads and placing them onto mass produced figure bodies.

However, the consumer 3D printing bubble burst around the same time that the toy giant began publicly exploring the technology. The tides turned toward industrial manufacturing, leaving numerous AM businesses to go belly up. These included not only desktop 3D printer makers, but bespoke earbud startups, 3D printed shoe cobblers, and small firms dedicated to creating 3D printed selfies (or “shelfies,” as they were sometimes branded).

As cool as it was for consumers to see themselves 3D printed in full color, the business case didn’t make sense. To achieve the quality necessary for shelfies, expensive 3D scanners or even entire rigs were required. This, in turn, would necessitate renting a physical space—an actual brick-and-mortar shop in the high-rent-driven 21st century. Then, to bring shelfies into physical reality, an industrial, full-color 3D printer would be needed as well. To justify the cost, these stores would charge upwards of $50 for a full-color simulacrum that couldn’t even be played with because the only full-color 3D printers around used a very fragile medium.

To achieve the quality necessary for shelfies, expensive 3D scanners or even entire rigs were required. This, in turn, would necessitate renting a physical space—an actual brick-and-mortar shop in the high-rent-driven 21st century. Then, to bring shelfies into physical reality, an industrial, full-color 3D printer would be needed as well. To justify the cost, these stores would charge upwards of $50 for a full-color simulacrum that couldn’t even be played with because the only full-color 3D printers around used a very fragile medium.

3D Printing in the 2020s

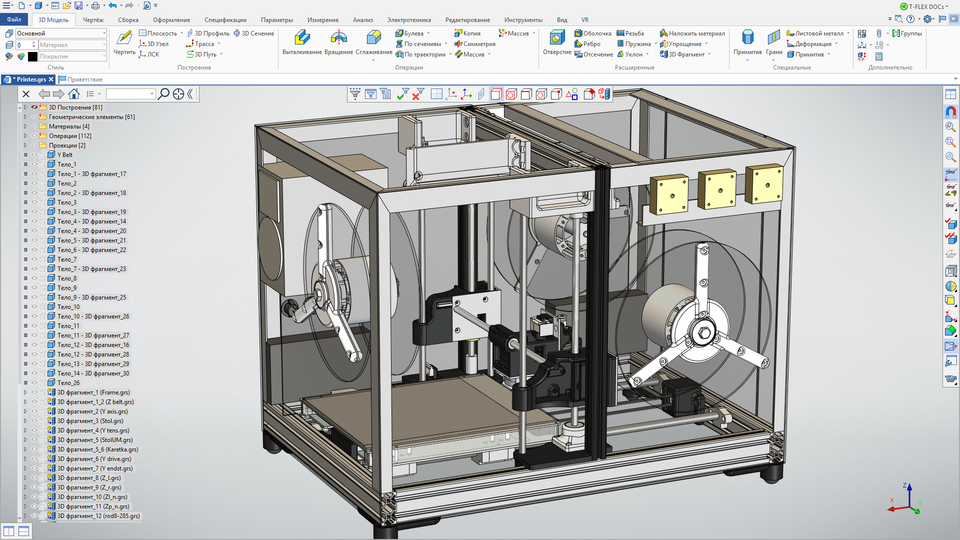

Though the consumer 3D printing bubble burst around 2014, AM continued developing more or less apace. Formlabs was one of the strongest desktop startups to come out of that period. This was largely due to the high quality and low cost of its technology, which allowed Formlabs to straddle the consumer and industrial sectors. One industrial client was Hasbro, which teamed with the 3D printer manufacturer in 2014, first using its machines for in-house prototyping and, now, for end part production. For the Hasbro Selfie Series, the toy giant operates a fleet of 30 Form 3 printers and runs specialized versions of Formlabs’ PreForm and Dashboard software to integrate Formlabs’ API into Hasbro’s other manufacturing processes.

For the Hasbro Selfie Series, the toy giant operates a fleet of 30 Form 3 printers and runs specialized versions of Formlabs’ PreForm and Dashboard software to integrate Formlabs’ API into Hasbro’s other manufacturing processes.

A build tray from a Formlabs 3D printer full of 3D printed heads for the Hasbro Selfie Series.

Image courtesy of Formlabs.Meanwhile, related technologies, such as augmented reality (AR), became more refined. For instance, the introduction of depth sensors to smartphones has made 3D scanning much more accessible. While originally meant to visualize IKEA furniture in living rooms and medical information onto surgical patients, depth sensing has had the added benefit of enabling a number of new consumer applications, like scanning oneself into the metaverse or 3D printing a custom action figure.

Mass CustomizationAttendees of the upcoming San Diego Comic-Con, July 21-24, will be able to get a preview of the Hasbro Selfie Series. A select number will even get to make and buy their own figures, which will ship this fall. The release of Hasbro’s newest product could be a step toward full mass customization, often considered the holy grail of 3D printing. Such a world would mean that products would be tailored exactly to the needs of the consumer. Size, fit, shape, weight, material, texture—everything could be custom.

A select number will even get to make and buy their own figures, which will ship this fall. The release of Hasbro’s newest product could be a step toward full mass customization, often considered the holy grail of 3D printing. Such a world would mean that products would be tailored exactly to the needs of the consumer. Size, fit, shape, weight, material, texture—everything could be custom.

We’re already inching toward such possibilities. In addition to the latest news from Hasbro, Arevo is selling 3D printed e-bikes and scooters that can be matched to a rider’s height and riding style. Orthotics companies are adopting AM for the production of patient-specific insoles. Hearing aids and dental aligners have long been made in the millions through the use of 3D printing.

If we are reaching a level in which such ordinary goods as action figures can be personalized for the consumer, then that may be just the beginning for a whole slew of products: shoes, eyewear, golf clubs, and more. And, once everything is designed perfectly for the consumer, we may be left wondering why and whether or not more consumption was really worth it in the end.

And, once everything is designed perfectly for the consumer, we may be left wondering why and whether or not more consumption was really worth it in the end.

3d Printed Figures - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

Related to 3d printed figures

- 3d printed jewelry

- 3d printing

3D printer printing figurines, printing 3D models to order.

Cheap. 3d studio Skill

Cheap. 3d studio Skill Printing 3D models to order is becoming an increasingly popular service, as it allows you to turn a virtual model into a real product in a short time.

One of the world's most popular applications - 3D printer printing figures - in the future is quite capable of replacing the usual photographs.

You can make a unique and unforgettable gift for friends and family by choosing to print 3D models on order and choosing one of the many options:

- your own miniature;

- figurines of loved ones;

- 3 d sculptures of newlyweds;

- picture of friends and colleagues;

- images of idols;

- figurines of favorite characters;

- ultrasound baby;

- 3D printed children's drawing;

- pet figurine;

- miniature vehicle;

- 3d copy of a work of art, etc.

Any 3d model is made by professional designers based on photographs taken from different angles, or based on 3d scanning using computer technology. In both cases, the work consists of two stages. At the first stage the designer creates a virtual 3D model, which can then be repeatedly printed. The second stage is the manufacture of the figurine itself.

When planning to print 3D models to order, you can choose the size that is convenient for you, stylish monochrome or realistic colorful option. Printing of 3D models is carried out on special equipment using modern high-quality environmentally friendly materials. Colored gypsum resin will provide photographic accuracy, monochrome photopolymer will convey the smallest details, and one-color or two-color plastic printing will be the most advantageous in price. In addition to the choice of material, the cost of a 3d portrait is also affected by its scale and degree of detail. Depending on the technology, size and complexity of the 3D printer, printing figurines takes from several hours to several days.

Depending on the technology, size and complexity of the 3D printer, printing figurines takes from several hours to several days.

Made according to your order in the singular in the form of a toy, figurine, keychain or magnet, any model will be made quickly, efficiently and in an original way. A practical and durable 3D figurine printed on a 3D printer will become an exclusive decoration for any interior, desktop or Christmas tree for a long time.

You can estimate the expected quality of the 3D printing service, taking into account the selected material and settings, by requesting photos of finished works or by visiting our office.

90,000 manufacturing miniatures 28mm, dioram, gaming locations using 3D printer09.03.2022

Content

-

- How to choose a 3D printer for miniatures

- Printing 3D printing

- FDM LCD/ DLP

- Printing 3D printing

- Printing Examples

- Best Printer Rankings

- FDM

- LCD

- Totals

- How to choose a 3D printer for miniatures

3D printing finds its application in various fields, not only as a production machine, but also as a reliable hobby assistant.

Miniature figurines with amazing detail attract the eye. A little grotesqueness and slightly wrong proportions (otherwise it would be inconvenient to play or transport such a “little one”) are more than compensated by detailed elaboration and an abundance of small, at first glance, insignificant details. These are no longer just small table soldiers, but heroes with their own unique history.

Warhammer 40k miniature soldier

Miniatures come in different sizes: from 6mm and more. The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

A 3D printer will help not only in the production of miniatures, but also in related areas, such as the creation of figurines, details of game locations, or, for example, elements of dioramas. To understand the advantages of 3D printing over classical manufacturing methods, it is worth remembering how such models are usually made at home.

Advantage of 3D printing for miniatures

Not everyone was ready to shell out a substantial amount for the purchase of a set of table soldiers, and sometimes the necessary heroes simply were not on sale. Then baked and self-hardening plastics for modeling were used.

Then baked and self-hardening plastics for modeling were used.

First you need to make a wire frame, so the finished figure will turn out to be more durable, and it will be much easier to keep all the proportions. The wire frame can be attached to the stand, which will make the miniature statue more stable, and it can be easily fixed in any position without fear of smearing small parts with your fingers.

Wire frame for miniature

Gradually, layer by layer, the volume of plastic increases on the frame. Each layer must be baked or dried well, depending on which plastic is used - self-hardening or baked.

Gradually, we begin to add small details and work out the details. In fact, this is a very painstaking process that requires perseverance and some sculpting abilities. For a convenient study of small details, you may need special stacks for modeling, but they can be successfully replaced with improvised tools.

Sculpting tool kit

The result is such a miniature statue.

Miniature 28mm baked plastic

By the same principle, large table figures, or some elements of dioramas, can be made.

Sometimes a sculptor is more accustomed to working with plasticine. Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army.

But it is necessary to properly prepare the figurine for casting. The finished "warrior", most likely, will have to be divided into several parts, so that it would be more convenient for the caster to remove the molds and make castings. During the cutting process, it is worth adding a few locks so that the finished castings can be easily assembled, like pieces of a puzzle.

Molded figurine against silicone mold

Some craftsmen have learned to cast metal copies. Such soldiers are usually made of low-melting metals (for example, lead) and cast in plaster molds. Sometimes a special silicone is used, but it is a little more difficult to achieve good shedding of a small product in a silicone mold.

Such soldiers are usually made of low-melting metals (for example, lead) and cast in plaster molds. Sometimes a special silicone is used, but it is a little more difficult to achieve good shedding of a small product in a silicone mold.

Metal soldier casting

In addition to making figurines from scratch, some craftsmen remake ready-made miniatures. This is called conversion.

Conversion in miniatures is a refinement, stylization or alteration of a finished figure. Unfortunately, not every hobbyist has good sculpting skills, and this alteration helps to achieve good results regardless of artistic skills. The main thing is to act very carefully.

Conversion helps enthusiasts achieve amazing figurine detail, add some detail, change the pose, or create a new character that is not yet on sale.

Lord of the Astral Claws turned to Chaos

In addition to making the figures themselves, modelers create colorful locations to immerse themselves in the world of their favorite game. This is true not only for 28mm miniatures, but for example for DND games. Such voluminous locations allow you to immerse yourself in the world of your favorite game much better and make the game more exciting.

This is true not only for 28mm miniatures, but for example for DND games. Such voluminous locations allow you to immerse yourself in the world of your favorite game much better and make the game more exciting.

Game location for board game Warhammer40k

The creation of such locations is painstaking work, and both improvised and special equipment are used as material.

Role play location

A 3D printer allows you to produce miniature figures and game locations much faster. On the Internet you can find many paid and free models of 28mm figures from different universes or various elements of locations - houses, fences, mechanisms, etc. Adapting or slightly changing the finished 3D model for yourself is much easier than cutting and gluing a finished figure. And creative people with modeling skills are unlikely to have difficulties with the transition to “digital clay”.

Warhammer40k universe 3D model

And of course, dioramas are worth noting. This is a separate art form with a scene or location frozen in time. Dioramas come in different sizes, but each of them impresses with its detail and careful study.

This is a separate art form with a scene or location frozen in time. Dioramas come in different sizes, but each of them impresses with its detail and careful study.

Diorama based on the game STALKER

Each diorama is unique, so the craftsmen use improvised materials to make it. Everything is limited only by the imagination and ingenuity of the artist.

Diorama “Desert Hero”

The main advantage of 3D printing is high detail and repeatability. If you need to make a small batch of miniatures, it will be much easier to print them than to cast, for example. Casting small items is a painstaking process that requires some skill and equipment. It is very difficult to achieve good pourability of small products the first time.

From model to finished figure

And for the manufacture of piece products, such as a diorama element, a 3D printer can replace many materials and tools for modeling. In addition, by using and combining different materials, it is possible to create models that are difficult or almost impossible to create manually. For example, using a special polymer, you can print optically transparent products that can imitate glass.

In addition, by using and combining different materials, it is possible to create models that are difficult or almost impossible to create manually. For example, using a special polymer, you can print optically transparent products that can imitate glass.

Which technology to choose

To begin with, it is important to determine the requirements for the printer - will it be used only for the manufacture of 28mm personal army or should it be a universal printing machine? It is important to understand what size the finished model will be, how detailed it should be, and how much time can be spent on post-processing.

Depending on this, it is worth deciding on the technology by which the 3D printer will work. You can choose one of two technologies - FDM or photopolymer printing (there are several technologies, but DLP and LCD printers are currently popular).

FDM

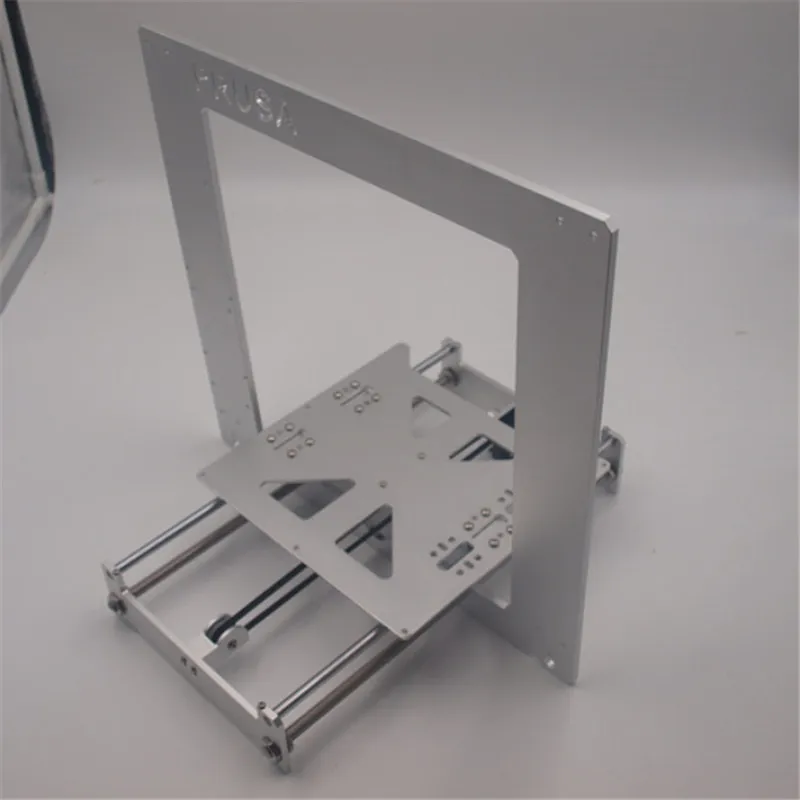

FDM 3D printers use a plastic filament as a material. In a heated extruder, the filament is melted and extruded through a thin nozzle, so layer by layer, a three-dimensional model is grown.

Working principle of FDM 3D printer

Layer thickness and nozzle diameter can be changed in some printer models. The minimum layer is usually 0.1 mm. In some models of 3D printers, a layer of 0.05 is available, but for printing with such a layer, it is important to choose the right many settings and the print speed will be quite slow.

Pros:

-

Large print area

-

Many different materials are available for every “taste and budget”

-

Inexpensive Consumables

Cons:

Of course, FDM printers are hardly suitable for making miniature figures, but they can be successfully used to print large souvenir figures, create game locations and some parts of dioramas.

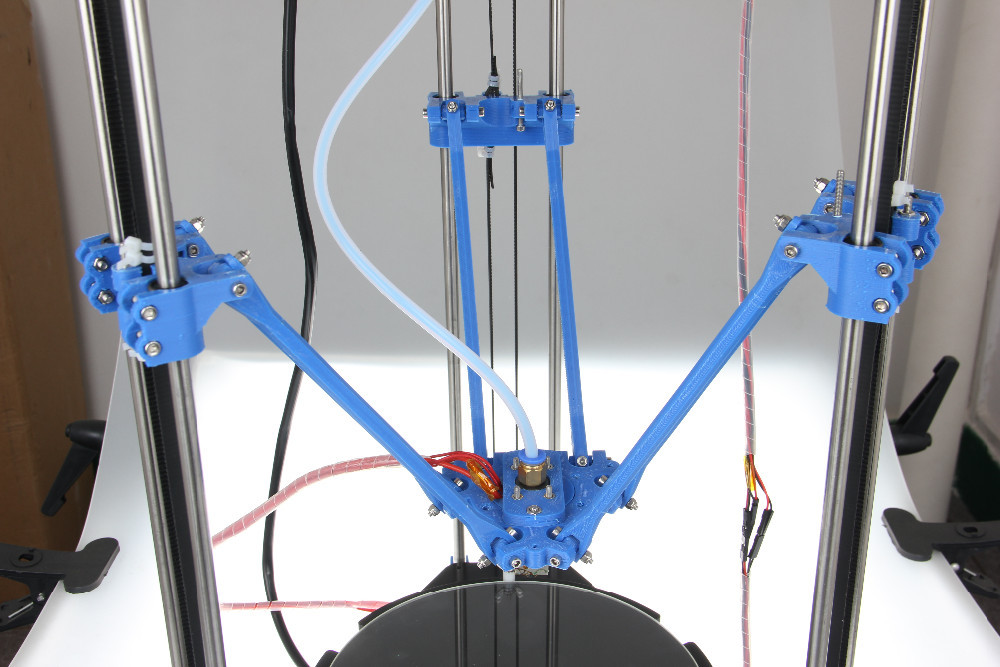

LCD/DLP

The principles of operation of LCD and DLP printers are very similar. The material used is polymers that harden under the action of UV light. The only difference is that an LCD printer uses an LED matrix in conjunction with an LCD screen as a source of UV radiation, while a DLP uses a projector.

The material used is polymers that harden under the action of UV light. The only difference is that an LCD printer uses an LED matrix in conjunction with an LCD screen as a source of UV radiation, while a DLP uses a projector.

Working principle of photopolymer 3D printer

Pros:

-

The ideal surface of the finished figure

-

Many different materials available

-

High print accuracy even for the smallest items

Cons:

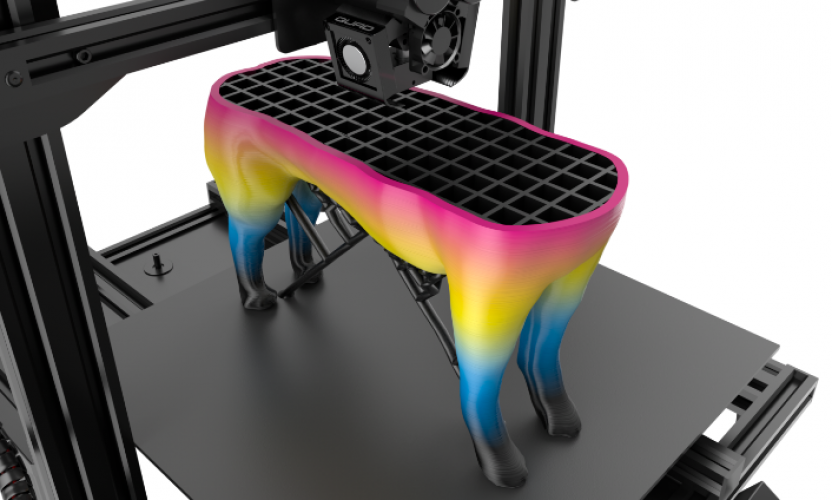

Photopolymer 3D printers are able to create miniature products that cannot be made using FDM technology. This technology will be an ideal choice for creating miniatures, small poster models, etc.

Print examples

Robot printed on Asiga Pro 4k

Figurine made with Phrozen Sonic Mini 4k

28mm miniatures printed on photoresin 3D printer

3D Printed Halloween Miniature

3D Printed Game Models

FDM Cube Thrower

Figure making process from 3D model to painting

Best Printer Ranking

FDM

Creality3D Ender 3 (Build Kit)

Features:

Print technology: FDM/FFF

Working area size: 220x220x250 mm

Number of extruders: 1

Max. extruder temperature: max. 255℃

extruder temperature: max. 255℃

Closed Camera: No

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

A popular and unpretentious 3D printer that many makers liked. Creality3D Ender 3 is sold as a kit (assembly kit), but thanks to the detailed instructions, there should be no problems with assembly.

Wanhao Duplicator 6 Plus

Features:

Print technology: FDM/FFF

Working area size: 200*200*180mm

Number of extruders: 1

Max. extruder temperature: max. 260°C

Closed Camera: Optional

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

Wanhao Duplicator 6 Plus is an updated version of the Duplicator 6. The new modification adds automatic calibration, printing resume after a power outage, and others. You can immediately purchase a printer with a closed case, this will allow you to easily print with composites. Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers.

Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers.

FlashForge Creator Pro 2

Features:

Print technology: FDM/FFF

Working area size: 200x148x150 mm

Number of extruders: 2

Max. extruder temperature: max. 240°C

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

FlashForge Creator Pro 2 is an almost professional dual extruder 3D printer. Thanks to the closed body, Creator Pro 2 has no problem even with composite materials, and two extruders allow the use of soluble support for complex models. Moreover, FlashForge extruders are independent, this allows you to print 2 mirror or identical models at the same time. This allows you to speed up the production of the same type of models. FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production.

FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production.

LCD

Anycubic Photon Mono 4K

Features:

LCD display resolution: 3840x2400 (4K)

UV wavelength: 405 nm

Working area size: 132x80x165 mm

Layer thickness: 0.01-0.15mm

Inexpensive, but fairly modern 3D printer with a 4K monochrome display. Anycubic Photon Mono 4K will be a good tool for printing miniature models.

Phrozen Sonic Mini 4K

Features:

LCD resolution: 6.1" 4K Mono LCD

XY positioning accuracy: 35 microns

UV wavelength: 405 nm

Working area size: 134x75x130 mm

Layer thickness: 0.01-0.30mm

The Phrozen Sonic Mini 4K is a compact high resolution 3D printer. It allows you to get accurate models even with an abundance of small details. Sonic Mini 4K is a good choice for those who need to print quickly and accurately.

Phrozen Sonic Mighty 4K

Features:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0.01-0.3mm

With a larger work area, the Phrozen Sonic Mighty 4K allows you to quickly produce large models or small batches of small items. Such a 3D printer will be a good help for a small workshop or a hobby circle.

Phrozen Sonic Mini 8K

Features:

LCD resolution: 7.1" 8K Mono LCD

XY Positioning Accuracy: 22 µm

UV wavelength: 405 nm

Working area size: 165x72x180 mm

Layer thickness: 0.01-0.3mm

Phrozen Sonic Mini 8K is one of the representatives of 8K photopolymer printers, which can still be counted on the fingers of one hand. The high resolution LCD-matrix allows you to print figures with amazing surface quality and amazing detail.