3D printer manufacturers canada

Canadian-made 3D printer to take on big name competitors

Who knew the 80/20 rule applies as much to 3D printer technology as it does to diet and exercise? Because that’s the precise ratio of aesthetic to performance enhancements Tinkerine Studios in Vancouver is offering in its latest 3D printer, the DittoPro – arguably giving a break from the relentless search for speed and power in return for an elegant, lower cost box in which to put it.

“[Our] previous models are [made from] laser cut wood and look like they’d [be suited for] a garage or a workshop,” says Tinkerine VP, Todd Blatt. “This machine, you’d be proud to have it on your desk.”

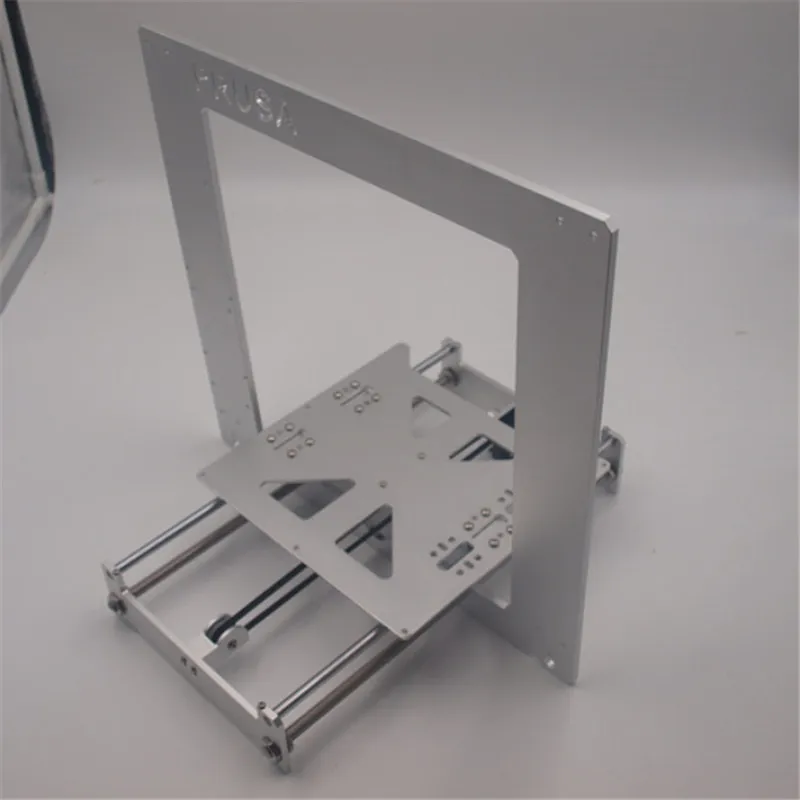

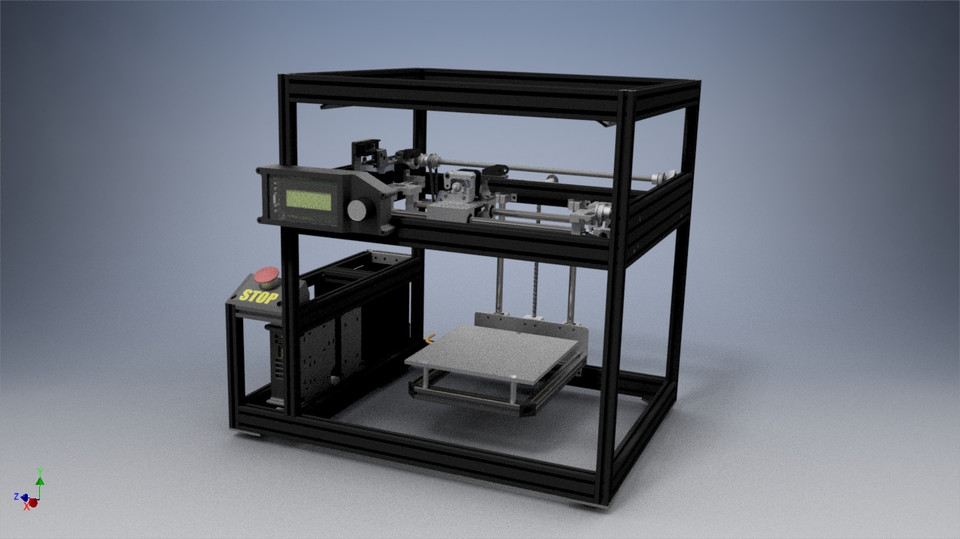

Blatt insists, however, that DittoPro is not just another pretty face. In development for just over a year, the new printer’s machined aluminum construction, over a 350 x 370 x 480mm footprint, also uses 43 percent less desktop than its competitors. The unit will have broad appeal says Tinkerine CEO Eugene Suyu, from prototype engineers and teachers to small business professionals.

“It really allows entrepreneurs to explore their ideas into real life and have access to something they didn’t have before: toys for the kids or to explore the robotics of industry that’s exploding in education; all those applications are now opening up,” he says.

Advertisement

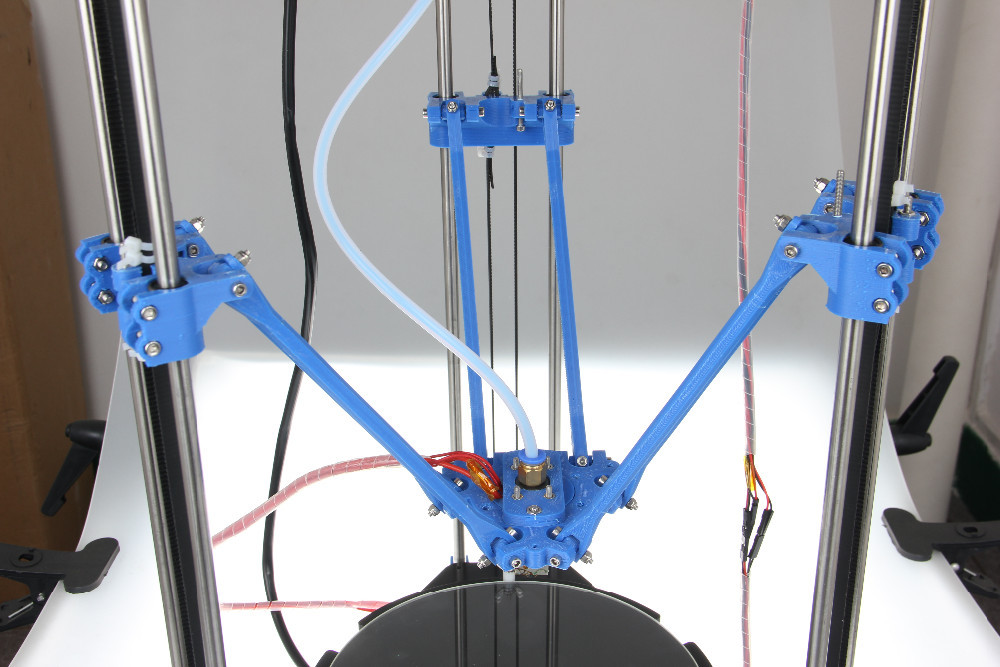

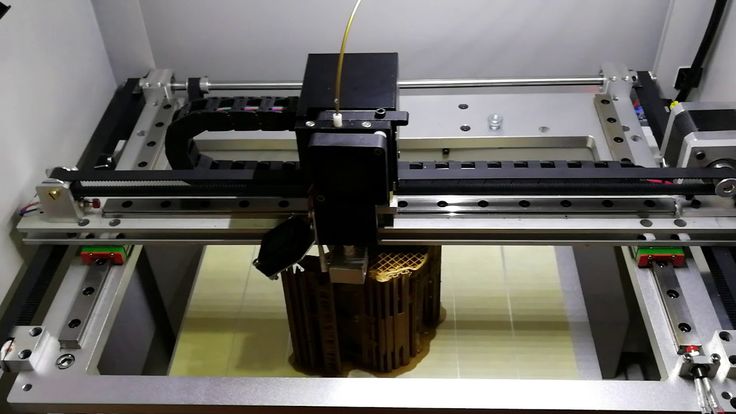

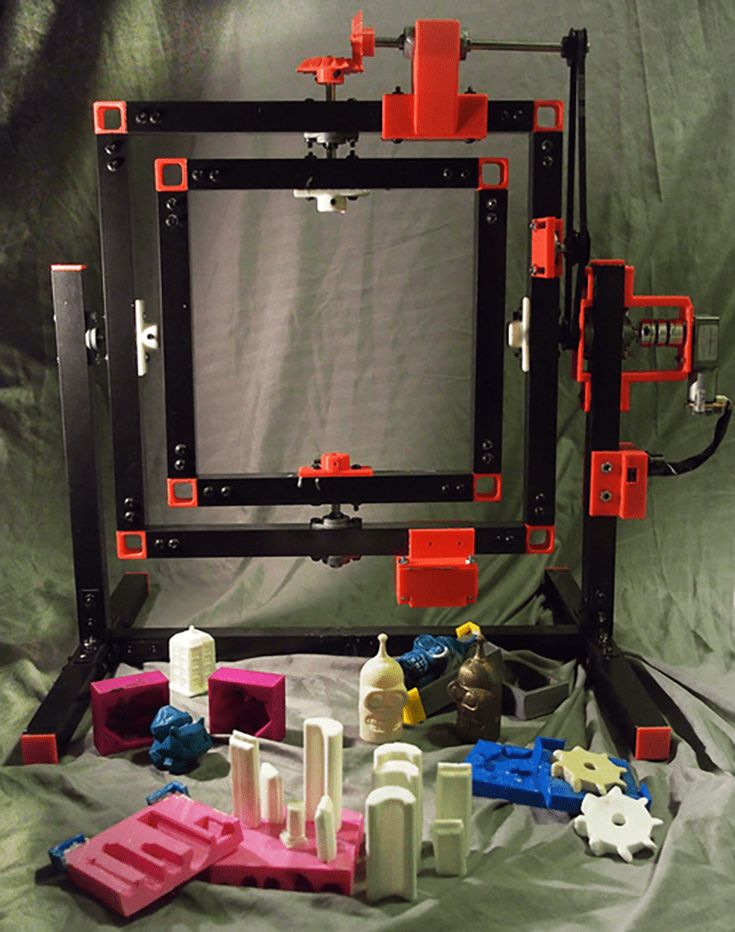

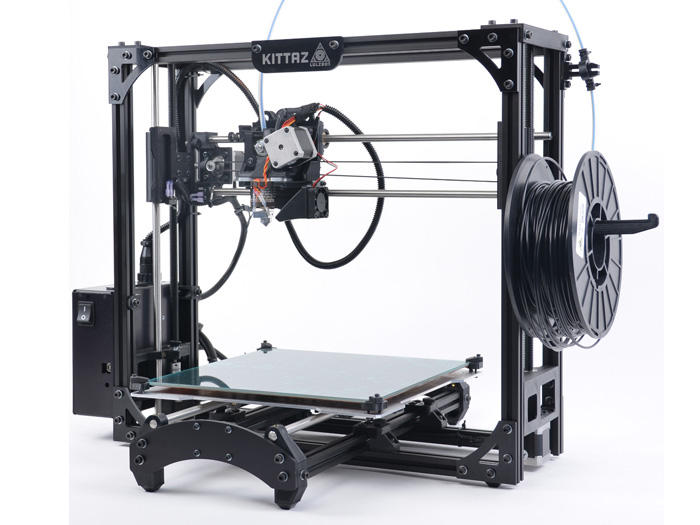

In fact, Tinkerine came into being as a result of Suyu’s own education. A graduate of Simon Fraser University in 2012, Suyu says he built his own 3D printing skills by tinkering with the “rods and bolts” of an open source RepRap printer. Suyu quickly decided that this technology wasn’t up to snuff. As prosumer models had yet to be introduced, he set out to rectify that by designing his own 3D printer.

“We found working on an open source platform was more tuning, tweaking, hacking and making as opposed to utilizing the tools of the machine for creating the actual product,” he says. “That was what I wanted to achieve.”

Scroll forward two years and Suyu’s newest 3D printer has increased speed over its predecessors, the Ditto+ and Litto, by 20 percent and doubled the resolution from 100 to 50 microns. Equally important, says Blatt, is Tinkerine’s open C frame design providing DittoPro with a build volume of 225mm x 165mm x 205mm for printing larger sizes—in other words, a little bit wider, deeper and taller than competitors’ 3D printers.

Equally important, says Blatt, is Tinkerine’s open C frame design providing DittoPro with a build volume of 225mm x 165mm x 205mm for printing larger sizes—in other words, a little bit wider, deeper and taller than competitors’ 3D printers.

“As a designer, I would find the height of those machines crippling,” says Blatt. “Using DittoPro, you get more detail when you’re printing on the Z axis. You’re able to print taller things because the machine is taller.”

Suyu agrees. “We just wanted to make one that you could utilize around what you want to build. So you’re not limited. You can open yourself up to long objects as well as small objects.”

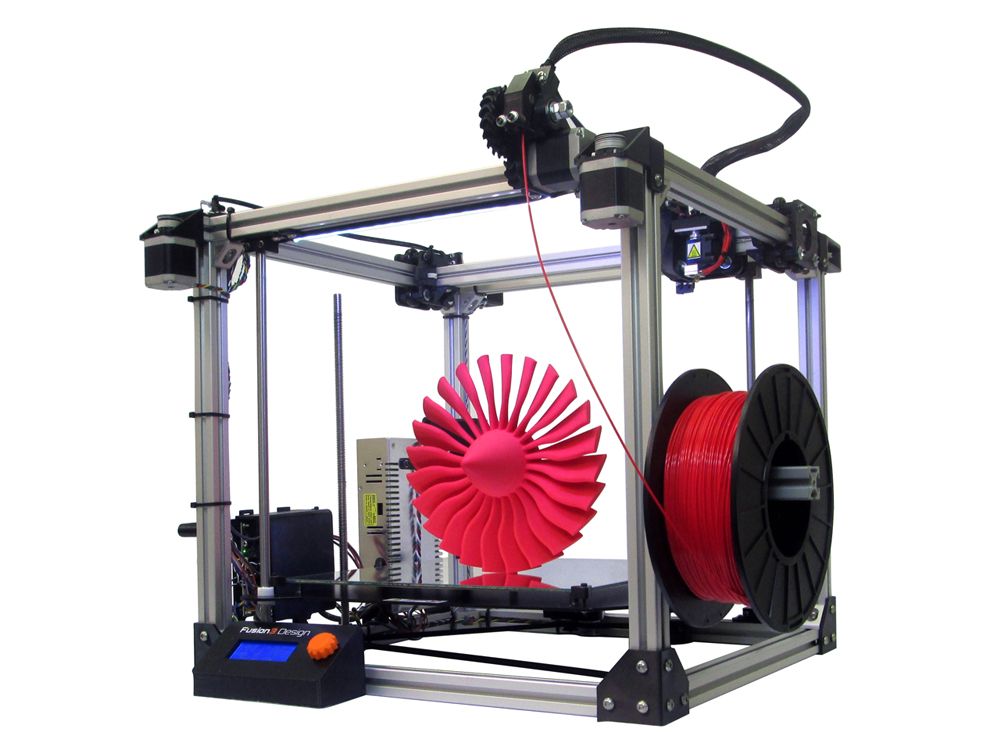

The aluminum construction and stable glass print bed allows precision printing of very small parts as well. In addition, DittoPro relies on an open spool filament system to avoid lock-in to a cartridge system, says Blatt. It’s a complaint aimed at CubePro and other cartridge-based 3D printer manufacturers. Blatt says that, far from being grateful that they can send back their empty cartridges in return for a discount on new cartridges, some customers view it as a money grab.

“They’re offering a discount on a very expensive product, so it’s deceptive,” he says. “You get much, much less plastic, like one third of the amount, and they charge more for the cartridge.” By contrast, he says, DittoPro’s filament system accommodates other manufacturers’ filament. “Not only do we manufacture high quality filament at an affordable cost, we’re not requiring you to use it.”

Beyond the printer’s larger build space, Tinkerine’s other objective is one-click operation and ease-of-use functionality with all settings available at the software level and automatic file generation. Available on Windows or Mac, Blatt says the printer’s software guides users through the printing process.

“You just push the import button,” he says, “[The software] brings in your model and puts it on the platform for you. There’s nothing imposing about it; the settings are preset and you’re ready to go.”

Suyu says Tinkerine prides itself on building high performance units at an affordable price. The price tag for its DittoPro seems to bear this out. At a retail price of US$1,899, it’s lower than MakerBot’s previous Replicator 2X (US$2,499), though that model’s build volume is comparable (246 x 152 x 155mm). By contrast, 3D Systems offers a single jet CubePro with comparable speed but a lower resolution of 100 microns and higher price tag of US$2,799.

The price tag for its DittoPro seems to bear this out. At a retail price of US$1,899, it’s lower than MakerBot’s previous Replicator 2X (US$2,499), though that model’s build volume is comparable (246 x 152 x 155mm). By contrast, 3D Systems offers a single jet CubePro with comparable speed but a lower resolution of 100 microns and higher price tag of US$2,799.

Has Tinkerine truly entered the big leagues in 3D printing? Perhaps not. MakerBot’s US$6,490 Replicator Z18 and 3D System’s US$5,000 CubePro, also unveiled this spring, justify their heftier price tags by providing higher build volumes (305mm x 305mm x 457mm; 275mm x 265mm x 240mm respectively) and connectivity that includes mobile and Wi-Fi. Neither is currently available with DittoPro.

www.tinkerine.com

Agile Manufacturing | 3D Printing Services | Manufacturing

Proven partner in Additive Manufacturing

- Canada's Largest 3D Printing Service Bureau

- New & Used Commercial 3D printer sales

- 3D printing materials

With 2 locations, Agile is well positioned to meet your Additive Manufacturing and Rapid Prototyping needs.

We produce parts in our ISO 9001:2015 certified facility. Additionally we provide New and Used Professional & Production 3D Printers across all technologies and stock materials in-house for immediate delivery.

We produce parts in our ISO 9001:2015 certified facility. Additionally we provide New and Used Professional & Production 3D Printers across all technologies and stock materials in-house for immediate delivery. As an industry leader in additive manufacturing and rapid prototyping, clients look to Agile Manufacturing Inc.’s best-in-class services and materials to increase productivity, save time and reduce risk. How? By utilizing the latest 3D printing technologies and our expanded, state-of-the-art production facilities, Agile Manufacturing Inc. helps clients quickly pivot their business from planning and design to production and sales. Want to know more? Check out the videos below.

Life Sized Bronze Statues Using 3D Printed Masters

Industry NewsBy James Jack

See how Haddington Dynamics 3D Prints a Majority of it’s Dexter Arm, reducing number of parts from 800 to less than 70.

Read more

FabWeaver type A530 now available across Canada from Agile Manufacturing

Industry NewsBy James Jack

See how the new ProJet 5500X Multi-Material Printer combines the leading part quality and performance advantages of 3D System

Read more

Agile Sponsors the University of Waterloo’s Robotics Team

Industry NewsBy James Jack

“Thanks to Agile we were able to have some very precise parts, which greatly suited our needs especially for components like servos which required carefully fabricated components” To the team at Agile Manufacturing Inc: UW Robotics Team has been very grateful for the rapid prototyping services provided by your company over the past couple months. …

…

Read more

Jetcom-3D Blog about 3D printers, 3D scanning and 3D printing

Medical Applications of TPM3D SLS 3D Printers

Read more

How to choose a 3D printer?

Read more

How to choose a 3D scanner?

Read more

Series production and prototyping with 3ntr industrial 3D printers

Read more

Use of 3ntr 3D printers in the design and manufacture of bicycle seats

In this article, we will talk about the integration of 3D printing technologies into the technological process for the production of bicycle components.

Read more

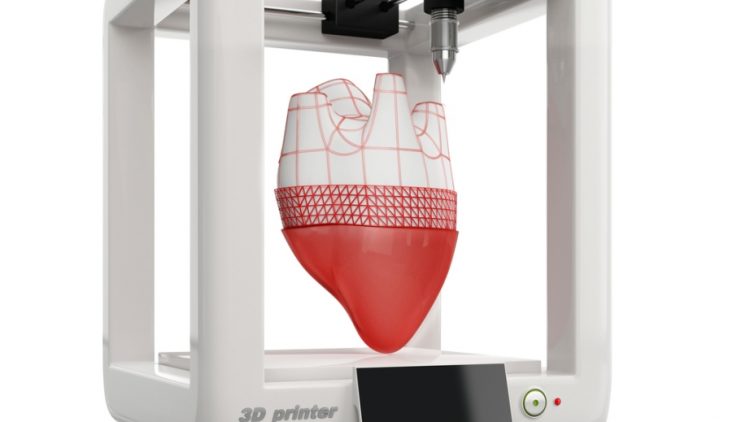

SLS 3D printers in medicine

Application of SLS 3D printers in medicine. 3D printing of ceramic bone substitutes. Production of demonstration models for surgery. Additive manufacturing of sterile and customized surgical instruments. Fast 3D printing of orthopedic products. High precision 3D printed surgical guides.

Read more

Prodways SLS 3D printers in automotive and robotics

3D printed BMW motorcycle prototype and e.DO robot gripper module.

More

The experience of using 3ntr 3D printers in the development of a motorcycle helmet by the Italian company Momodesign

The introduction of additive technologies into technological processes

Read more

Small batch production of unique tools using Prodways SLS 3D printers

Experience using SLS 3D printers for small batch production of plastic end products.

Read more

Prodways SLS and DLP 3D Printer Applications in the Automotive Industry

Industrial 3D printers are opening up more and more opportunities at every stage of vehicle manufacturing, from functional prototyping and visualization to final products and tools.

Read more

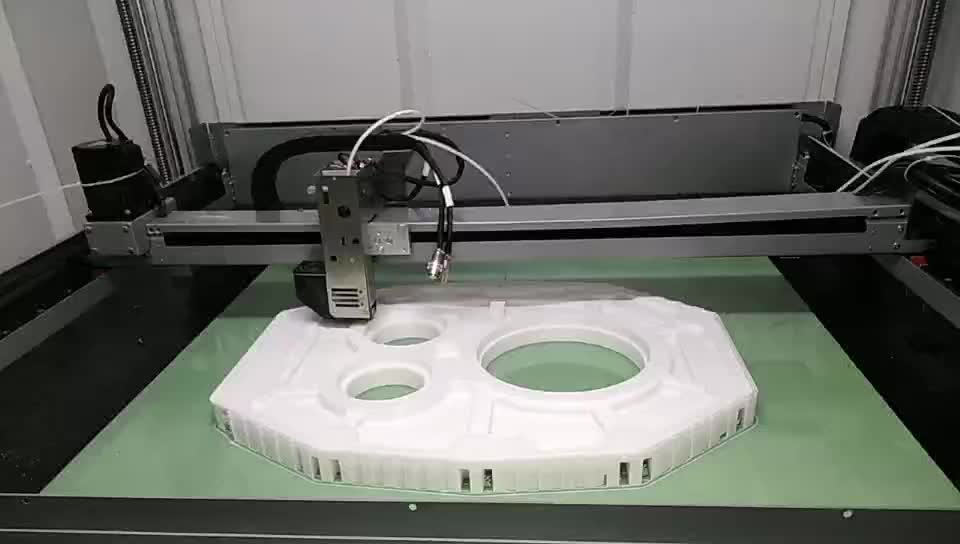

3D Printing of Prototyping Agricultural Machinery with 3ntr 3D Printers

Experience with 3ntr 3D Printers by International Industrial Design and Prototyping Studio XForm

Read More

Prodways SLS 3D printers used in robotics demo production

Experience with ECO Group SLS Prodways 3D printers for production of robot models

Read more

Benefits of Triple Extruder 3D Printing

Successful experience with 3ntr A2v4 3D printer in industrial prototyping. Advantages of triple extruder 3D printing over traditional production methods.

Advantages of triple extruder 3D printing over traditional production methods.

Read more

Industrial SLS 3D Printing in the Automotive Industry

Continental Experience in Additive Manufacturing

Read More

Application of 3D printing in the production of household appliances

Individual alternative solutions in a short time and without unnecessary costs - the experience of using the universal three-extruder 3D printer 3ntr A2v4 by the world famous Italian company Unitekno.

Read more

3ntr A4 Triple Extruder 3D Printer - experience in the development of an innovative medical device Lumen

Experience in using the 3ntr A4 Triple Extruder 3D printer by the world famous design studio Frog.

Read more

3D printing of a small series of final products on an industrial SLS printer ProMaker P1000

Selective Laser Sintering (SLS) technology is currently the most productive in terms of printing speed and the least expensive in terms of material cost in the production of small series of final products. The high accuracy and smoothness of the surface of the resulting products, the absence of restrictions on the complexity of the model geometry and a wide range of materials were the key points when choosing 3D printing equipment for McLloyd.

Read more

Carbon fiber 3D printing of racing yacht components

The American Magic team, one of the contenders for victory in the 36th America's Cup, the most famous international sailing yacht competition, uses 3D printing to make components for their racing boats.

Read more

Experience with THULE 9 Fortus 450mc 3D printer0004

Read more

Fortus 900mc 3D Printer - Bombardier Transportation's Additive Technology Experience

André Bialoscek, Head of Engine Implementation: usually takes a lot of time. And while speeding up the production process, we still need to ensure full functionality, safety and reproducibility of parts. With our Fortus 9 system00mc, we are capable of all of this – which means that additive technologies are changing the rules of the game for us.”

More

Application of 3D printing for restoration and repair of vintage cars

The use of 3D printing technologies in the automotive industry can significantly accelerate its development. The ability to recreate any part, regardless of its rarity or complexity of geometry, makes it easy to carry out repairs of any complexity.

The ability to recreate any part, regardless of its rarity or complexity of geometry, makes it easy to carry out repairs of any complexity.

Read more

Stratasys Additive Manufacturing - Traditional Production Limits No Longer

Speeding up production is one of the benefits of the booming 3D printing market. The ability to start production without delays and machining costs, as well as the ability to create any geometrically complex product without traditional restrictions.

More

3D printing in high fashion

At New York Fashion Week, fashion designer Travis Fitch collaborated with designers from ThreeASFOUR and Stratasys to present the Chro-Morpho clothing collection with innovative use of 3D printing

Learn more

From prototypes to production with the Fortus 9 3D printer00mc

Ricoh (Ricoh Company, Ltd. ) experience with Fortus 900mc 3D printer

) experience with Fortus 900mc 3D printer

Read more

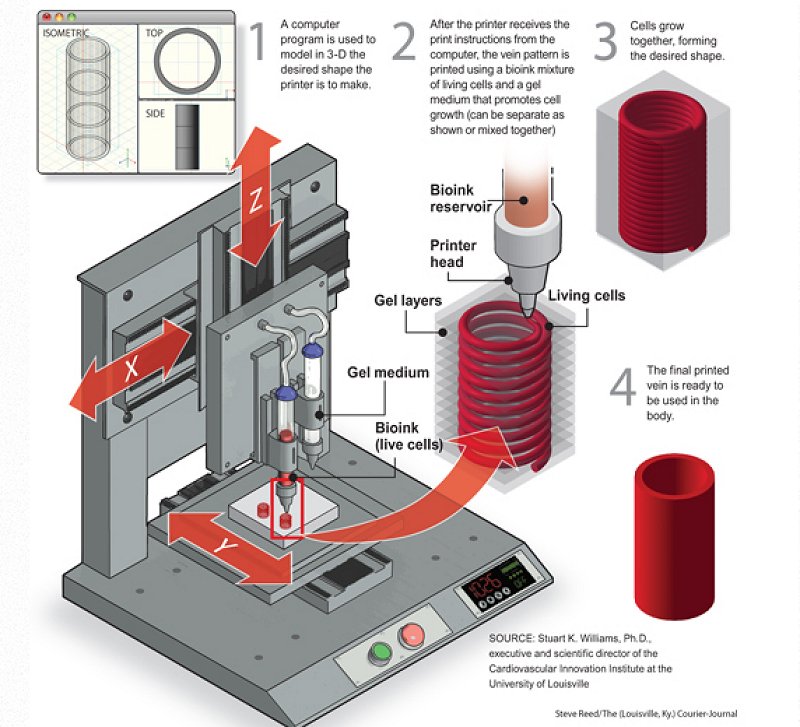

Biorobotics. Prototypes that can help many.

Scientists can now prototype almost anything from robotic exoskeletons to cancer diagnostic tools and MRI scanners

Learn more

Application of the Fotus 450mc 3D printer in the design and manufacture of bicycles

Santa Cruz Bicycles 3D printing experience

Read more

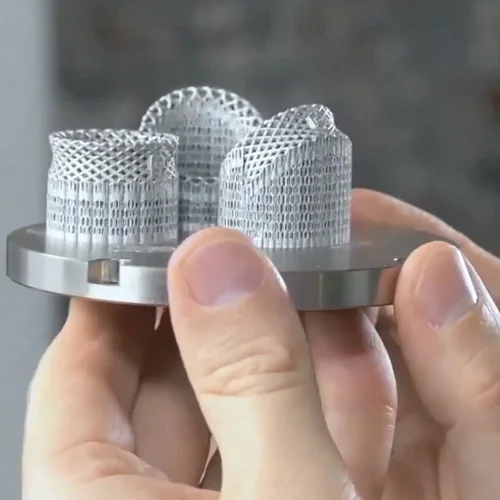

Dental 3D printers (Dental Series)

Dental 3D printers (Dental Series). How and where 3D printers are used in dentistry. What can a dentist print on a 3D printer. A few examples of how 3D printing is used by dentists, orthodontists and prosthetists.

Read more

Using the Stratasys J750 3D Printer to Plan Complex Surgery

How 3D printing of realistic patient anatomy models is a huge help in achieving accurate and successful surgery and improving patient outcomes.

Read more

3D printing in education, business and Formula 1 racing

Partnership of industrial enterprises and education, integration of additive manufacturing into internal production processes.

Read more

Additive technologies as an integral part of the educational process

Integrating additive technologies into training courses demonstrates the growing need of large companies for graduates with knowledge and experience in the field of 3D printing technologies.

Read more

Volvo Trucks Stratasys 3D Printer Experience

To reduce production time for truck assembly tools by 94%, Volvo Trucks prints many of them on Stratasys Fortus Series 3D printers

Read more

Automotive tooling 3D printing

Experience with Fortus 3D printers by Solaxis Ingenious Manufacturing, Bromont, Canada

Read more

Eckhart's experience with Stratasys 3D printers

3D printing technology has already established itself in the industry as a worthy alternative to traditional production methods

Read more

Production of flight-ready parts and ground equipment on the Stratasys Fortus 450mc 3D printer

Marshall Aerospace and Defense Group uses the Stratasys Fortus 450mc 3D printer to produce flight-ready parts and ground equipment for a number of its aircraft.

Read more

Stratasys 3D Printer Applications in the Aviation Industry

Examples of Manufacturing Optimization Using Additive Manufacturing in the Aviation and Aerospace Industries

Read more

Stratasys Aerospace 3D Printer Applications

Fortus Industrial 3D Printer Applications for Aerospace Parts

Read More

3D Printing Sand Casting Tooling

Stratasys 3D Printer Application: Making Sand Casting Tooling Using Additive Manufacturing Methods

Read more

Composite Molding Tooling

Print a mandrel for molding resin composite parts.

Read more

Production tooling

Optimize your production and quickly adapt the yoke to the current tasks.

Read more

3D printing of molds for injection molding

3D printing of molds and master models for injection molding on Stratasys 3D printers.

Read more

Prototyping for visualization and design

With 3D printing, you can turn all your ideas into reality in just hours.

Read more

3D print functional parts

Print prototypes for mechanical testing, functional testing and more.

Read more

Medical 3D printers

No matter how good the 3D graphics are, they still can't compare to the model in your hands. Operations planning. Education.

Read more

3D printers in dentistry

3D printing with biocompatible materials in dentistry and dental technology.

Read more

Additive manufacturing

Direct manufacturing of single end parts or small batches from metals and plastics

Read more

3D printing for jewelry

Bring your wildest ideas to life with Staratasys 3D printers. There are combustible materials.

More

3D printing tooling for vacuum forming

Read more

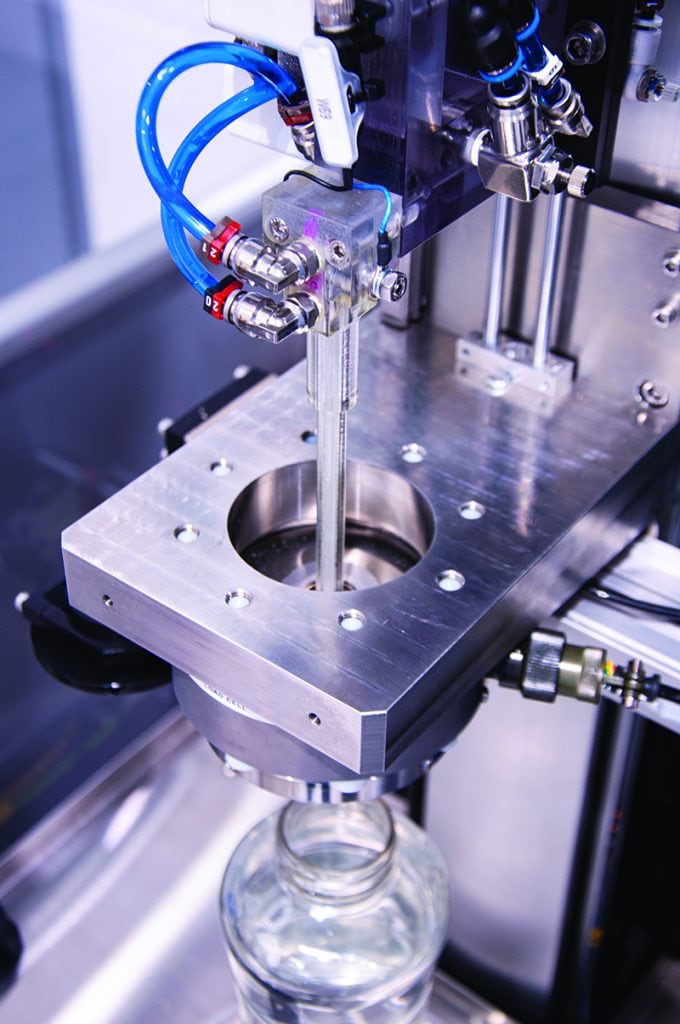

The impact of 3D printing and FrameCAD technologies on home construction in Canada

In 2014, a breakthrough began in the field of building construction. Buildings are built from concrete using a 3D printer. Many people already know what a 3D printer is - it is a numerically controlled machine that uses the layer-by-layer method of creating a part.

Vancouver's high home prices make buying a home an impossible dream for most residents. Therefore, fortunately for many who want to buy a house for themselves, an affordable alternative will appear on the market - houses built by 3D printers.

New construction solution based on laser 3D printing of custom modular and steel beams and panels. The technology allows you to quickly create completely new tasks for printing. These steel parts are created with the design of the building under construction in mind, and then sent to the construction site and assembled in a short time.

Construction company LifeTec Construction Group uses a 3D printer to print metal structures to speed up the building process. The company is based in Vancouver.

Traditionally, large wooden trusses are used in the construction of small residential buildings. Their production noticeably slows down the construction process.

The new technology involves the replacement of wooden trusses with metal ones. At the same time, there is an important feature - they are printed on a special 3D printer using Framecad technology. It was developed in New Zealand and has since been tested around the world. Builders say building is faster and more efficient when trusses can simply be printed.

At the same time, there is an important feature - they are printed on a special 3D printer using Framecad technology. It was developed in New Zealand and has since been tested around the world. Builders say building is faster and more efficient when trusses can simply be printed.

In addition to speed, builders note the increased durability of such structures. Printing also allows for less construction labor, which is especially true in Vancouver.

It is impossible to distinguish a 3D printed house from a traditional house. A 3D printer is laying the foundation of a house by pouring cement in layers. Then roofing, electricity and plumbing are added. For a small fee, customers can customize the settings for their future homes and thus design their own home the way they want. A four-bedroom house will only cost $20,000. The foundation of the house with an area of 2500 sq.m. can be built in 24 hours.

Benefits of 3D printed houses

- Uses lightweight metal parts that are stronger and more durable than regular construction wood.

Learn more