3Mm filament 3d printer

3D Printer Filament 1.75mm vs 3mm – All You Need To Know – 3D Printerly

When searching through filament on Amazon, other websites and looking on YouTube, I came across filament sizes of 1.75mm and 3mm diameter. I didn’t know how much difference there was between the two and why people prefer one over the other.

I did some research and wanted to share what I found with you.

1.75mm filament is the most popular filament diameter, with 3D printers like the Ender 3, Prusa MK3S+, Anycubic Vyper & Voxelab Aquila using them. More filament brands create 1.75mm filament. 3mm is a more durable filament diameter and less likely to jam, used by printers like Ultimaker machines and the Lulzbot Taz 6.

I’ve gone into extra depth about the differences in filament diameter, listing the advantages of each, and answering whether you can convert one filament to the other so read on to find out.

What is the History Behind 3 mm Filament & 1.3D printers using filament have been around for over 20 years, but back in these times, they were extremely expensive and a very specialized piece of equipment.

One of the things that remained through the years in 3D printing was the standard of 3mm filament.

The history behind the presence of 3mm filament was merely a coincidental process by the supply chains, when 3D printer filaments were first being created by hobbyists.

A product called a plastic welding rod, which has a melting device and a source of filler material had a diameter of 3mm, which made it easier to manufacture. This was already being used in the plastic welding industry, so 3D printer manufacturers took advantage of existing suppliers of 3mm plastic filament to be used.

The product already had the technical requirements for 3D printing so it was a great fit. Another upside is how available the supply of the filament was, so it was adopted.

So several years ago, a majority of the 3D printers that were available to consumers would have exclusively only used 3mm filament.

Over time, techniques and equipment have seen vast amounts of research and improvement in the 3D printing industry. It got to a point where companies could manufacture filament specifically for the 3D printing industry.

The first thermoplastic extruders were designed specifically to be compatible with 3 mm filament, but this changed around 2011 with the introduction of 1.75 mm filament.

As 3D printing has become more refined, we’ve also increasingly used 1.75mm filaments because they are easier to manufacture and use.

RepRap was the company that brought 3D printers in the realm of the average home, but it did take a lot of research, development and hard work!

General Information About Filament DiameterThe size of filament that you’ll likely see in the 3D printing community is the 1.75mm filament.

The two standard filament sizes are 1.75mm and 3mm. Now, what is the difference between these filament sizes? The short answer is, there’s no significant difference between the two filaments. You simply should use the filament size that is advertised by your 3D printer.

You simply should use the filament size that is advertised by your 3D printer.

If you don’t have a 3D printer just yet, I’d definitely get one that uses the 1.75mm filament.

A few specialized filaments in the 3D printing industry aren’t actually available in the 3mm size, but in recent times the gap is certainly narrowing. It used to be the other way round.

You tend to hear different sides of the story on the benefits of bigger or smaller filament diameters. Realistically though, the true advantages of a 1.75mm filament vs a 3mm filament aren’t so significant, so it’s not something to worry too much about.

What Are the Advantages of 1.75mm Filament?- 1.75mm filament is much more popular and easier to buy than 3mm filament

- You have a wider range of materials that you can get access to, as well as many exclusive ranges of filaments made just for 1.75mm.

- It’s easier to use with a Bowden tube.

- You have more control and precision over the amount of filament extruded

- Faster print speed

- Less oozing because of smaller melt zone volume

- Faster potential flow rates

Some extruders use gears to push your filament through the hot nozzle. When using 1.75mm filament, the torque (force) that is required from the stepper motor is roughly a quarter of the amount needed with 3mm filament.

If you think about compressing 1.75mm filament down a 0.4mm nozzle, it will take a lot less work compared to compressing 3mm filament down the same nozzle.

This results in smaller, faster prints at lower layer heights because the system requires less torque and the smaller direct drive system lowers the axis resistance.

This permitted printers to move to direct-drive extrusion, with the drive pulley mounted straight on the motor shaft.

3mm filament extruders generally need to use a gear reduction between the drive motor and the pulley to generate enough force to push the thicker filament through the nozzle.

This not only makes the printer simpler and cheaper, but also gives better control over the filament flow rate due to not having slop from the gear reduction.

There is a difference in print speed. Using 1.75mm filament will require less time heating so you are able to feed the filament at a higher rate than with 3mm filament.

The amount of precise control you have with 1.75mm filaments against 3mm filament is higher. This is because when you feed the printer with thinner material, less plastic is extruded. You also have more choice in choosing a finer nozzle size.

What Are the Advantages of 3mm Filament?- Works great with larger nozzle sizes so can extrude faster

- More rigid so it’s easier to print when using flexible plastics

- Higher resistance to bending

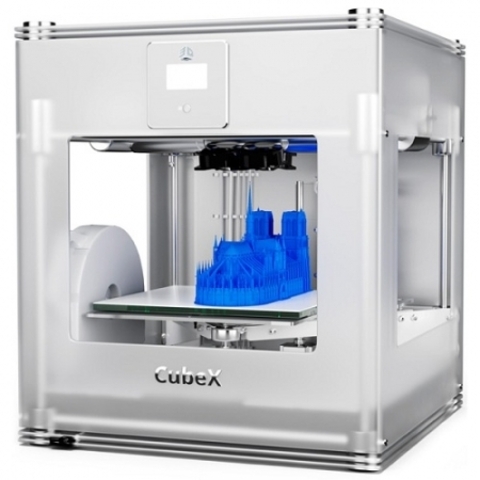

- Works best with professional or industrial 3D printers

- Less likely to jam as it’s harder to bend

With certain prints, you may opt to use a larger nozzle and want a high feed rate. In these cases, using 3mm filament should work to your benefit.

In these cases, using 3mm filament should work to your benefit.

If you try using a 1.75mm printer for certain flexible plastics such as NinjaFlex, it can give you trouble if you don’t take extra precautions, and have certain upgrades to make printing easier.

3mm filament are less flexible meaning it is easier to push through the hot end. This is especially true with Bowden-type setups.

Being the bigger size filament, it has the ability to extrude faster than the 1.75mm filament due to being able to make use of a bigger nozzle.

What Are the Main Differences Between 1.75mm & 3mm Filament?Flow Rates through the ExtruderWhen using a 1.75mm filament, you have a wider flexibility for flow rates because smaller filament has a higher surface area to volume ratio. This allows for quicker melting through the nozzle as heat can be pumped to it faster, and allows you to push your 3D printer to higher volume extrusion rates.

They will give you increased control as well as extrusion rates when using narrow nozzle sizes.

Getting to the end of a 3mm filament spool can be an issue due to the extra friction along the filament pathway. 3mm filament creates high tension when the spool is nearly finished. It can be a problem with the last couple of meters of the spool, making it unusable.

In terms of filament diameter and nozzle width, it’s not advised to be use 3mm filament with small nozzles (0.25mm-0.35mm) because the added pressure of being extruded through the smaller hole means you’ll have to use a low extrusion speed. In doing so, you may sacrifice print quality.

3mm filament is most effective when used with an accompanying larger nozzle size (0.8mm-1.2mm) and gives more control of the extrusion .

With these smaller nozzles, you’ll want to use 1.75mm filament.

Rate of ToleranceEven though 1. 75mm filament is more popular than the 3mm filament, the smaller diameter does mean that tolerances by manufacturers need to be tighter along the length of the filament.

75mm filament is more popular than the 3mm filament, the smaller diameter does mean that tolerances by manufacturers need to be tighter along the length of the filament.

For example, if you had a ±0.1mm difference in with along your filament, it would be ±3.5% for your 2.85mm filament and ±6.7% for 1.75mm filament.

Due to these differences, there will be a larger difference in the flow rates compared to the flow rates in your slicer, possibly ending up with lower quality prints.

To counteract this, going for higher quality, but more expensive 1.75mm filament should work well. These tend to have tighter levels of tolerance so they aren’t prone to causing jams.

3D printers with a Bowden-based hardware setup will give better results with the thicker filament because the thinner filament tends to compress more in the Bowden tube, creating a sturdy spring effect and leads to more pressure in the nozzle.

This can lead to stringing, over-extrusion and blobbing, which hinders the advantages from the retractions (filament pulled back into extruder when moving).

One of the main things you can do to negate most of the quality differences between the 1.75mm filament and 3mm filament is to adjust your printer and slicer settings accordingly.

Tangling Issues with 1.75mm FilamentWhen it comes to 1.75mm, they tend to entangle pretty easily, especially when it’s not on a spool. Many knots can be created accidentally and would be hard to untangle. If you keep your 1.75mm filament on the spool all the time, this shouldn’t affect you much.

This is usually a problem if you unwind then rewind your filament incorrectly.

You should pay more attention to the orientation of your spool and the filament feed path. If you don’t properly store your reels of filament off-printer, filament can easily knot or get tangled when you attempt to print with it. This is less likely to be a issue with 3mm filament.

This is less likely to be a issue with 3mm filament.

A disadvantage that goes for 1.75mm filament is the presence of water absorption. It has a higher surface to volume ratio, meaning it is more likely to attract moisture. Though, it’s always important to keep any filament dry whether 1.75mm or 3mm.

Some people have made the mistake of buying 3mm filaments instead of 1.75mm filament. Even worse when it’s bought in bulk because they do tend to be the cheaper filament.

In most cases, the time and expense it will take you to modify and re-calibrate your 3D printer won’t be worth it. You are likely to be better off sending back your incorrect filament and reordering your normal filament size.

So if you don’t have a specific reason why you want to use 3mm filament then you should avoid the change.

Can 1.75mm Filament be Used in a 3D Printer That Takes 3mm Filament?Some people wonder whether they can use 1. 75mm filament in a 3D printer which takes 3mm filament.

75mm filament in a 3D printer which takes 3mm filament.

Now typically your extruder and hot end will be designed specially for either the 1.75mm filament or the 3mm filament. They won’t be able to support the other size unless some mechanical changes are implemented.

With the extruder designed for 3mm filament, it would have a hard time gripping the smaller 1.75mm diameter filament with enough force to feed and retract the materials evenly.

With the hot end, this is a little more complicated. The standard process of filament being pushed through the melting zone is something that requires a constant pressure pushing the filament down.

This happens easily when a 1.75mm filament is used in a designated 1.75mm 3D printer.

However, when you try to put a 1.75mm filament in a 3D printer using 3mm filament, there will be gaps throughout the walls of the hot end.

Due to the gaps and backwards pressure, it results in the softened filament travelling backwards, along the wall of the hot end.

The material will then cool in unwanted places, resulting in your hot end getting jammed, or at minimum, preventing an even flow of filament to be extruded.

There are hot ends out there that you can attach a small Teflon tube on which takes up the gaps between the filament and hot end walls so you can bypass the issue of backwards pressure.

The general practice if you want to use 1.75mm in a 3mm printer, is to upgrade your entire extruder and hot end parts to the correct size.

Using a 1.75mm filament in a 3mm extruder may work for a short time (emphasis on short), but you will most likely end up filling the melting chamber fairly quickly, causing an overflow to which the filament would cause a jam.

It will produce a lot of melted plastic which will flow backwards through the gaps of the extruder.

Another scenario could be the 1.75mm filament simply passing through and not getting heated enough to actually melt and get extruded.

Can I Convert 3mm (2.85mm) Filament to 1.75mm Filament?

It may seem simple at first. Simply taking a 3 mm hotend with a 1.75mm hole, then extruding the thicker filament through, letting it cool down then reeling it back up.

It would be very difficult to convert if you don’t have specialized equipment because there are many factors which would make the filament usable.

If you don’t have an even pressure or even temperature, you can end up with filament that has bubbles inside. The thickness of the filament has to be pretty accurate or you could get many ripples in the filament.

Basically, it’s not worth trying if you don’t already have the expertise beforehand.

There are too many possible issues that can arise with doing this, so it’s not worth the time and effort.

From what I’ve researched, there isn’t a simple 3mm to 1.75mm converter device available so for now, you’ll have to accept the difference.

How to Convert Your 3D Printer From 3mm to 1.75mm Filament

Below is a video by Thomas Sanladerer giving a step-by-step guide on converting your 3D printer to extrude 1.75mm filament rather than 3mm filament.

Doing this is a fairly long process and definitely takes some know-how and DIY experience to get working properly.

You’ll need to purchase a hotend that is suitable for 1.75mm filament and a few basic tools as well.

The basic tools you will need:

- 4mm drill

- 2.5mm & 3mm hex key

- 13mm wrench

- 4mm PTFE tubing (standard Bowden tubing for 1.75mm)

These tools will generally be used to disassemble your extruder and hotend assembly.

2.85mm Vs 3mm Filament – Is There a Difference?

Most good 3mm filament is actually 2.85mm filament because it’s the standard size known to manufacturers. 3mm is more so the general term.

3mm filament does generally cover a range of filament sizes from 2.7mm to 3.2mm. Most manufacturers out there will aim for 2.85mm which should be compatible with 3mm 3D printers.

Suppliers and websites will usually explain this on their pages.

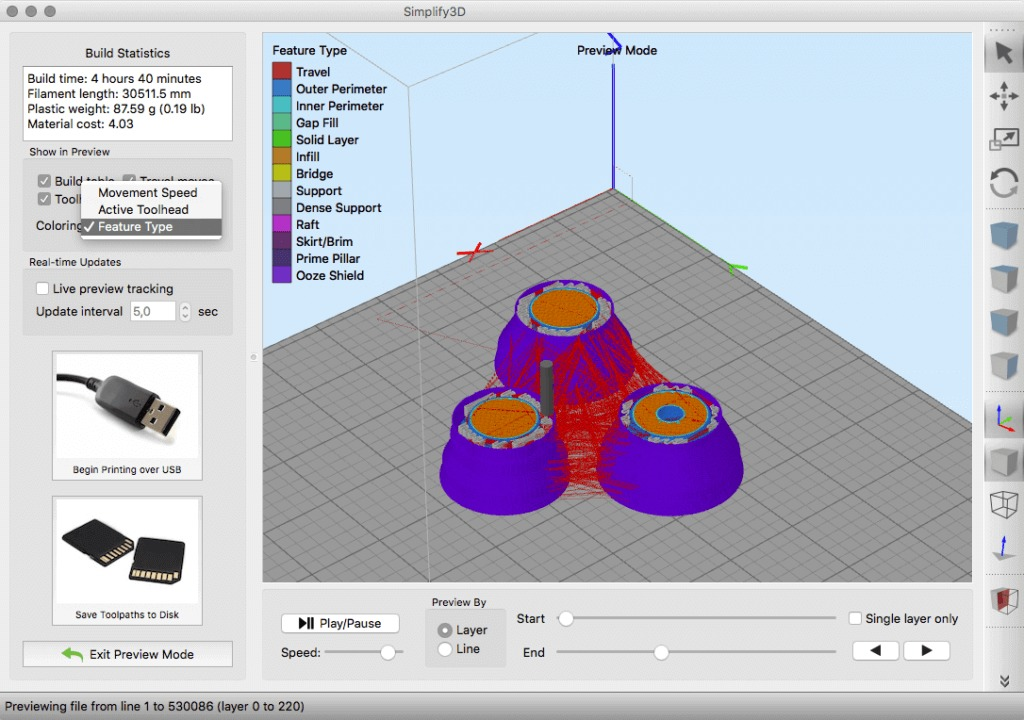

Up to a certain point, size doesn’t matter too much as long as it’s in a general range to work properly. When you put the measurements in your slicer software, it should be just fine.

For the most part, 2.85mm and 3mm filament should work the same. The default settings in many slicers are set to 2.85mm, so if you buy cheap, low quality filament it has higher variances in diameter so it can cause issues if it’s too different from what is set.

It is good practice to measure your filament diameter and adjust it accordingly in your settings, so your 3D printer can calculate the correct amount of filament to put through.

If you adjust your settings to better reflect the filament diameter you have, you are at less risk of under or over-extruding.

Depending on who your supplier is, some with bad quality control can sell you wrongly sized filament so keep aware of this. You are better off sticking to a reputable company that you know will give you consistent quality time after time.

3D printers with the Bowden System use PTFE tubes with an inner diameter of 3.175mm. There may be variation in the diameter of the Bowden tube and the 3mm filament.

1.75 mm or 3 mm?

The following article tries to clarify the differences between the filaments of diameter 1.75 mm and 3 mm (3mm filament is the same diameter and 2.85 mm), a question that many users of 3D printing tend to have before acquiring a 3D printer.

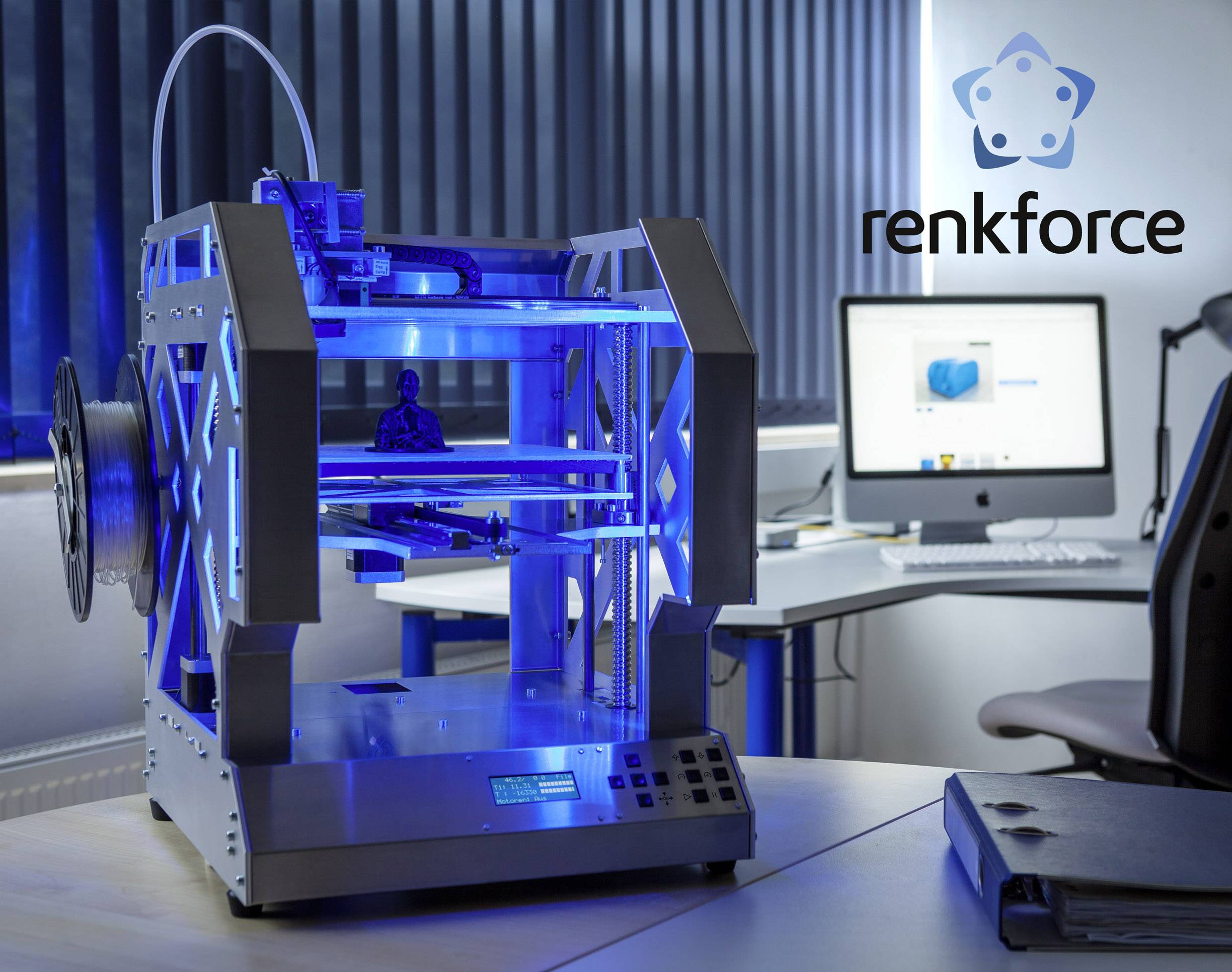

Many professional and industrial 3D printers most use a Bowde System to reduce the moment of inertia, generated by the weight of the motors, on the axis of the HotEnd and thus have more printing precision) use 3 mm diameter filament.

One of the things that uses 3 mm and not 1.75 mm in this type of machines, is because the extruder motor has to work much less. Next we explain why:

If it is assumed that under theoretical conditions a 3D printer with pinion moves a filament with a radius R=10 mm, turning 10 turns with a filament of 1.75 mm (for example PLA 1.75 mm) would displace 1511.29 mm³ of plastic volume. In order to move the same volume with a 3 mm filament (for example PLA 3 mm), the extruder pinion would only need 3.4 turns.

Now we do the previous operations in reverse order to obtain the turns that the same pinion of the motor of the extruder with a filament of 3mm must turn:

This reduction favors when making long-lasting 3D prints, since with the filament of 1.75mm the motors can get overheated by the rapid movements you need to do to push and retract the material, lose steps and ruin the entire piece that was to be printed. Another advantage of having less filament feed is that the pinion marks less amount of filament at the time of making the retractions.

When using flexible materials (Filaflex or TPU) or fragile (Lay-Woo3D) the 3mm filament has the advantage of being more resistant to bending than the same filament in 1.75 mm. In addition, thanks to this resistance, the material remains more tense when winding it, which helps manufacturers to get coils with an almost perfect alignment and free of overlaps.

In the beginning, the filament was 3mm because of the ease of manufacturing it to that extent with an acceptable tolerance, but as technology has evolved, the large manufacturers of 3D printers have demanded the change to 2.85 mm (nº 4 inch) for being a standard measure in the world of industrial manufacturing, in which there are tools of this diameter and very accurate.

This change also favors the 3D printers with Bowden System, since these systems use PTFE tubes of 1/8" (3.175 mm) of inner diameter, so if a 3 mm filament with a tolerance of ± 0.05 is used (Beware of low quality filaments that may have areas of 3.2 mm) the material may slide very just through the PTFE tube, causing a high friction that will cause jumps in the extruder or even a total clog with low quality filaments that do not comply with the tolerance indicated by the manufacturer.

With the Direct System the filament is introduced in the HotEnd immediately and therefore this problem does not occur, regardless of the use of 2.85 mm or 3 mm. This measure of 3 mm is also favorable to use it with nozzle diameters larger than normal (0.8 mm, 1 mm, 1.2 mm or more) to be able to have a good control of material between the entrance and exit of the nozzle. As it is evident, with a nozzle of smaller diameter than usual (0. 35 mm, 0.3 mm, 0.25 mm or less) the use of a 3 mm filament is an inconvenience to be forced to use a low extrusion speed, which can result in traces of material in the piece. In the previous case, the best option is to use a 1.75 mm filament that, in combination with small nozzle diameters, is possible to obtain very small and detailed models.

35 mm, 0.3 mm, 0.25 mm or less) the use of a 3 mm filament is an inconvenience to be forced to use a low extrusion speed, which can result in traces of material in the piece. In the previous case, the best option is to use a 1.75 mm filament that, in combination with small nozzle diameters, is possible to obtain very small and detailed models.

This diameter of 1.75 mm, having less resistance to bending, needs less pressure to be displaced by the extruder, which implies a simpler extruder design than for the 3 mm filament, simpler electronic components and can be used in any 3D printer with any type of extruder without great difficulty (not to be confused with any type of drive system).

As a final conclusion to this article and taking into account that it is not a trivial matter, we can say that the 1. 75 mm filament is more suitable for non-professional use, with desktop 3D printes where 3D prints are often made for many hours or days. And on the other hand, the 3 mm filament is more suitable for professional o industrial 3D printers where 3D prints of even days are usually made, with large output diameters.

75 mm filament is more suitable for non-professional use, with desktop 3D printes where 3D prints are often made for many hours or days. And on the other hand, the 3 mm filament is more suitable for professional o industrial 3D printers where 3D prints of even days are usually made, with large output diameters.

Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing.

* By registering you accept our privacy policy.

Esun3D Fiber Printer Red 3mm ABS 0.5KG Spool

JavaScript seems to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.

Proceed to Checkout

Total price

$0.00

Basket 0

{{/findAutocomplete}}

{{/isPromoted}} {{/isFlashDealEnabled}} {{#isPromoted}} {{/isPromoted}}SKU: {{sku}} {{#isFreeshippingEnabled}} Free shipping on eligible orders {{/isFreeshippingEnabled}}

{{#rating_summary}}

{{/rating_summary}}

{{#isDiscountFlag1Enabled}}

{{/isDiscountFlag1Enabled}} {{#isDiscountFlag2Enabled}}

{{/isDiscountFlag2Enabled}} {{#isDiscountFlag3Enabled}}

{{/isDiscountFlag3Enabled}} {{#isDiscountFlag4Enabled}}

{{/isDiscountFlag4Enabled}} {{#isDiscountFlag5Enabled}}

{{/isDiscountFlag5Enabled}} {{#isDiscountFlag6Enabled}}

{{/isDiscountFlag6Enabled}} {{#isDiscountFlag7Enabled}}

{{/isDiscountFlag7Enabled}} {{#isDiscountFlag8Enabled}} 9isProhibited}} More {{/isProhibited}} {{/is_combo_product}} {{#isProhibited}}

We are sorry, this product is not available in your country

{{/isProhibited}}

{{#hbk_price. stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with.