3D systems sugar printer

Exclusive: 3D Systems Sugar 3D Printing Brought to Market by Brill, Inc. - 3DPrint.com

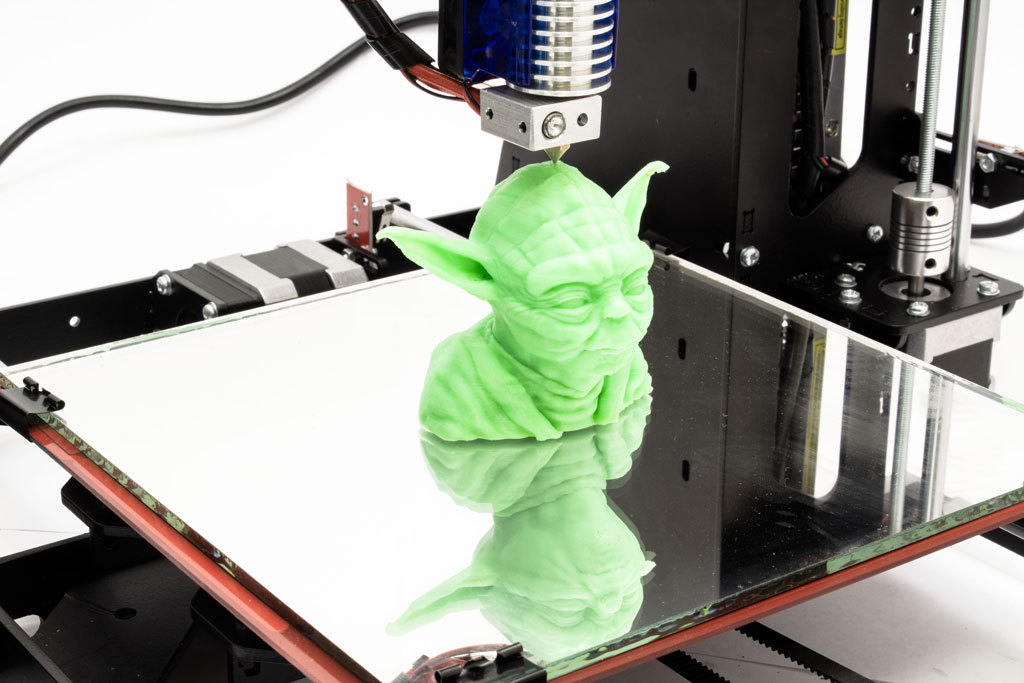

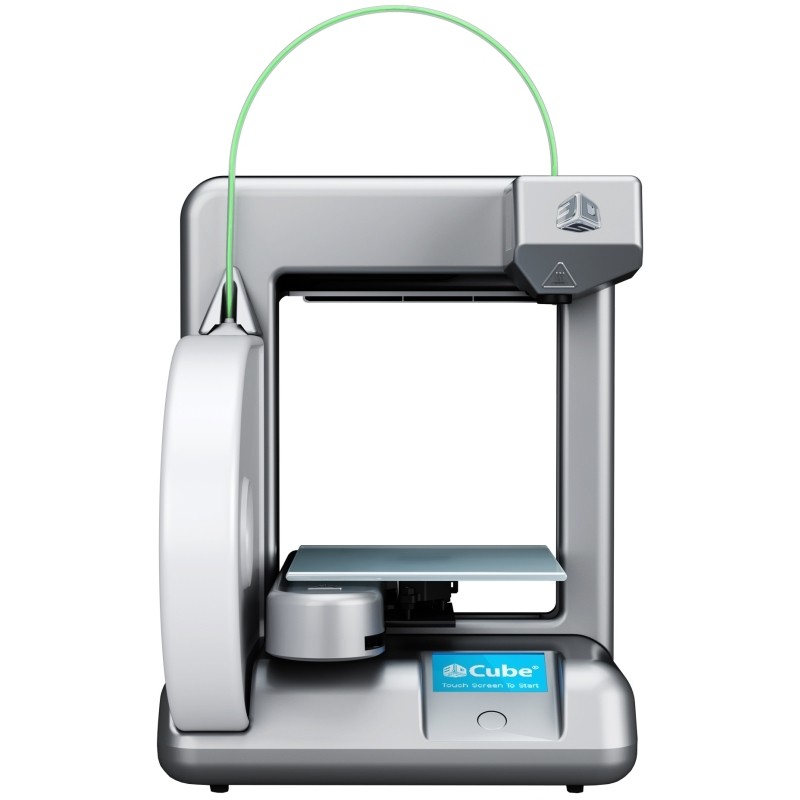

For any 3D printing fan with a sweet tooth, the unveiling of the ChefJet and ChefJet Pro 3D printers at CES 2014 was a major highlight. Displayed in brilliant colors and ornate shapes at the 3D Systems booth were immense cake toppers that were impossible to miss. The technology was brought into being by Kyle and Liz von Hasseln, founders of 3D Systems’ then-latest acquisition, The Sugar Lab.

Later that year, however, doubt began to surround the future of 3D Systems’ new sugar printing technology as former CEO Avi Reichental faced scrutiny from the board of directors and the stock market. Since then, we’ve heard tidbits here and there indicating that sugar printing was still under the company’s purview, despite the shelving of its consumer 3D printing unit.

It wasn’t until now that we had confirmation that the technology is alive and well and will be heading to market through a partnership with Brill, Inc. To learn more, we spoke to David Nies, Brill’s Vice President of Business Development.

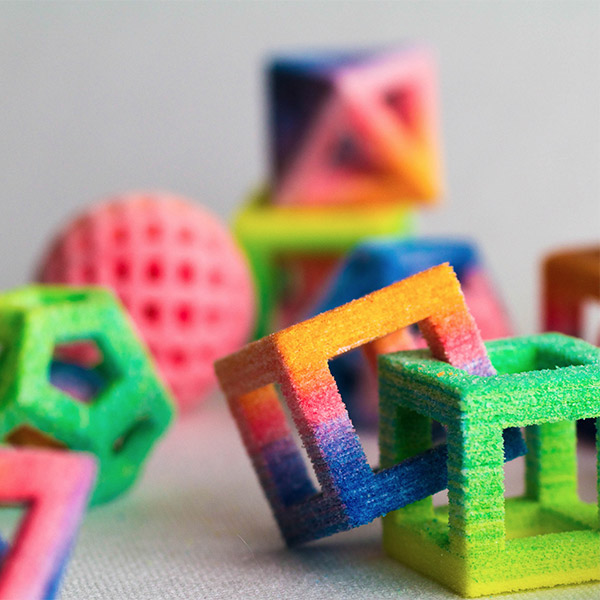

One of the reasons that The Sugar Lab made a great fit for 3D Systems was that the startup’s technology was based on 3D Systems’ own binder jetting process. Initially developed at MIT and licensed to Zcorp, binder jetting involves the deposition of a liquid binding agent into a bed of powder, building an object up layer by layer. Zcorp, acquired by 3D Systems in 2012, perfected the technology by incorporating a full color printhead that enabled the creation of vibrant, colorful 3D models.

Large, full-color 3D printed cake topper. Image courtesy of 3D Systems.

The Sugar Lab swapped out the gypsum used by Zcorp with powdered sugar and replaced the binder and coloring agent with food safe ingredients. Under 3D Systems, the result was a technology that could 3D print a rainbow of complex shapes with interesting flavors. However, that was just the beginning for what Brill and 3D Systems now have in store.

Established in 1928, Brill is a provider of bakery ingredients and products, ranging from icings and glazes to cookies and cakes. While consumers might be less familiar with the name, bakeries and food service operators across North America are sure to recognize it. They may also know the many other subsidiaries owned by Brill’s parent company, CSM Bakery Solutions.

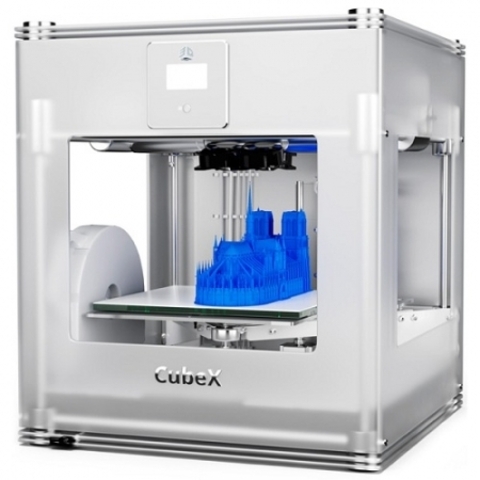

Now, Brill is taking the leap from pastries and fillings to food 3D printing via a partnership with 3D Systems that began in 2017. While 3D Systems has focused on the technological development of software and hardware, Brill has developed the flavored powders and liquid binding agents that work together to print objects. Together, the partners will be introducing the Brill 3D Culinary Studio powered by 3D Systems this summer.

Smaller, edible 3D printed sweets. Image courtesy of 3D Systems.

“When the Brill 3D Culinary Printer is launched this summer it will be the most advanced food 3D printer ever developed; capable of printing dozens or hundreds of objects simultaneously in full color and in amazing detail.

It has taken significant research and invention to get to where we are now and I’m really excited to see this technology finally land in the capable hands of chefs who will no doubt drive immediate advancements in the culinary arts,” said Kyle von Hasseln, director of Culinary Technology at 3D Systems.

Thanks to Brill’s existing customer relationships in the food industry, it will be able to get the 3D Culinary Studio to chefs and other culinary artists at high-end restaurants, casinos, hotels, theme parks, cruise ships and catering companies. Nies explained that his team envisions clients using the technology in one of two ways: to produce larger showpieces that won’t be consumed or smaller, edible pieces.

In addition to the liquid binding agents that will be jetted into a bed of powder to deliver the full spectrum of color in any printed piece, Brill is developing a wide variety of flavored powders to give chefs a range of choices. Flavors range from strawberry or watermelon, intended mostly for deserts, to cucumber, intended for drinks. Brill is even exploring savory options.

Brill is even exploring savory options.

“We have partnered with chefs who have investigated the use of 3D-printed savory-flavored objects in soups,” Nies told us. “That’s truly what we think is unique about this particular solution: not only will the system produce incredibly beautiful pieces, but it will also provide an amazing and complete sensory experience for our customers’ consumers — from the visual to the textural to the whole eating experience. What we’ve been able to develop in terms of flavor with powders is pretty remarkable in the sense of delivering trueness of flavor.”

A rendering of the Brill 3D Culinary Studio powered by 3D Systems. Image courtesy of 3D Systems.

When initially showcased at CES 2014, prices were listed at $5,000 and $10,000 for the ChefJet and ChefJet Pro, but the Culinary Studio may be different. Nies says that the exact cost will be discussed with customers directly and that it should fit within professional kitchen budgets. Included in the package will be the software, printer, finishing station (depowdering is necessary in sugar printing as well as traditional binder jetting), installation and training.

Included in the package will be the software, printer, finishing station (depowdering is necessary in sugar printing as well as traditional binder jetting), installation and training.

Regardless of the exact numbers, Nies believes that the 3D Culinary Studio can reduce cost and labor compared to methods for creating anything similar with traditional (manual) methods. Moreover, this technology can fabricate food objects impossible by any other means.

Chefs and culinary artists may be able to afford it, but will they be able to design for 3D printing? In addition to the package mentioned above, customers will also have access to a library of 150 to 200 3D models. If they want a custom design, they will be able to access a 3D design service developed exclusively for Brill 3D Culinary Studio to have their concept modeled for a small fee. The model is then theirs to keep and, through training provided by Brill, customers will be able to change the color, personalize, or add a company logo to the design within the software.

“One thing we’ve learned through user testing is that when someone has initially made an assumption that the 3D printer would be difficult to use or understand, they’ve been pleasantly surprised at how easy it is to use,” Nies said. “What we really want to try to do is let the culinary artists handle the art and let us handle the technical side of things and make it easy for you to produce anything you can imagine.”

Nies says that Brill’s waitlist for the Culinary Studio is already substantial, though customers cannot yet be revealed. The product will be officially on the market this summer. In the meantime, Brill will be opening a showroom at its offices in Atlanta, Georgia this spring, where potential clients can see the technology in person.

Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed food • 3D printed sugar • 3d systems • Binder Jetting • brill • Brill 3D Culinary Studio • brill inc. • partnership • the sugar lab

Please enable JavaScript to view the comments powered by Disqus.

the complete list of 3D printers and services -

For all sweet tooth lovers, today we will detail the existing solutions for sugar 3D printing or for ordering it. What forms of sugar are 3D printable? What technologies are used? Can we 3d print sugar at home?

After the article on chocolate 3D printing, we are tackling another pillar of baking: sugar!

Sugar is a great material, essential for making cakes. Sometimes called white gold, its use is often criticized.

The role of sugar in baking

Without wanting to get into controversy, it can however be said that sugar in itself is not dangerous, as long as it is consumed in reasonable quantities. Today, many pastry chefs devote themselves to de-sweetening traditional recipes, or else use less refined sugars.

This is what sugar is used for in baking, it:

- brings the sweet flavor.

- softens the acidity and bitterness.

- colors and brings a golden color to pastries during cooking.

- increases the crispness.

- feeds the yeast in yeast dough.

- is a texture agent in meringues, sponge cake and cookies.

- promotes the incorporation of air into battered dough.

- Adds water or alcohol, it turns into syrup and is used to soak, soak

- is used in the manufacture of sorbets (syrup)

- decorate (icing sugar, royal icing, pulled sugar, pastillage)

- is a preservative for fruits, jellies, jams, etc …

Mixed with other ingredients

Sugar is very often mixed with other ingredients. But it can be used on its own to make decorations using its ability to become viscous under heat. 3D printing enthusiasts therefore worked on the different forms of sugar: icing sugar, powdered sugar, caramel, royal icing…

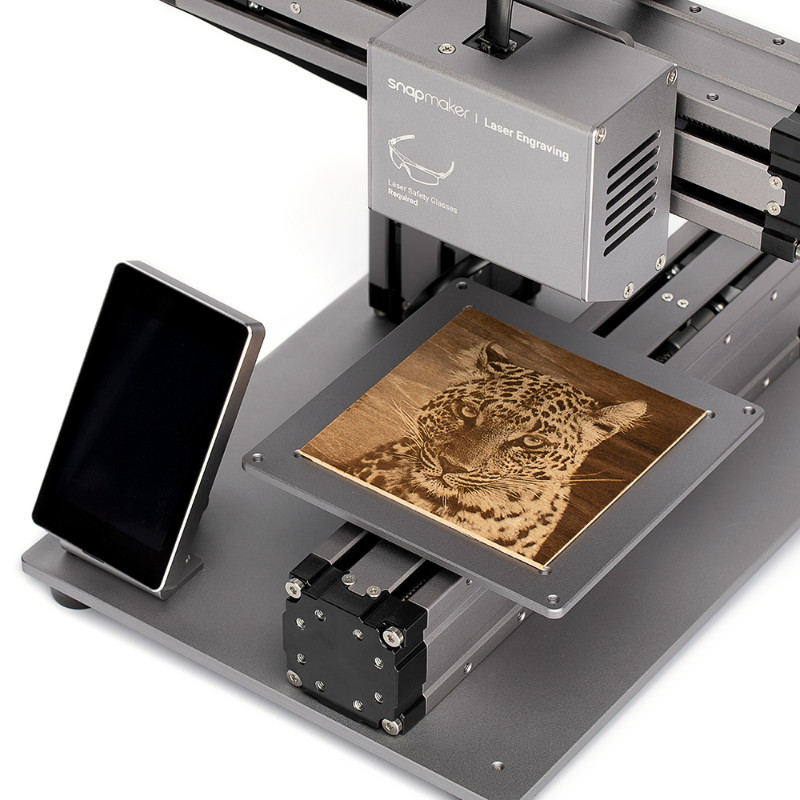

An example of 3D printed sugar by Culinary PrintworksThe full list of sugar 3d printers

Powder-based sugar 3d printers

How to solidify a powder of sugar? 2 techniques have been mainly used in 3D printing

- add a water-based liquid because sugar is soluble in water

- heat the sugar in a targeted manner so as to make it liquid

3D printing sugar by heating

Historically, 3D printing from powdered sugar has been a maker and designer business. Indeed, we cannot talk about 3D sugar printing without talking about Candyfab.

Indeed, we cannot talk about 3D sugar printing without talking about Candyfab.

Candyfab is a hobby project carried out from 2006 to 2009 by Windell Oskay and Lenore Edman. The two researchers built a DIY powder printer with a head that blows hot air, which causes the sugar to melt in a targeted manner, in order to achieve each of the layers.

Demo image from the Candyfab’s websiteThis is an efficient process, but it does not allow perfect control of the shape of the 3D shape. Why ? If you take a good look at the photo above, you may notice that the sugar shrinks and forms a small ball rather than liquefying into a straight line.

Indeed, sugar has immense surface tension! We experienced this ourselves for a few weeks, when we wanted to make caramel with a laser cutting head.

Probably, you must have experienced it yourself when you cook dry sugar in the bottom of a saucepan, it forms little balls which then clump together. There, the same thing happens on the powder bed.

If we were to compare this technique with a pastry process, know that we learn to pour caramel in an inscription made in a bed of sugar in order to create personalized decorations in pastry schools. To my knowledge, no one has ever poured caramel into a bed of powdered sugar layer after layer to achieve a 3D shape. But it might be an idea!

Binder-jetting sugar 3D printing

The technique of binder projection is commonly used in the world of 3D printing with various materials: gypsum, metals. This consists in depositing drops of binder on a bed of powder layer after layer, with a view to their solidification.

And you can use glue, wax, water … it’s also possible to add colorants. Binder projection 3D printing is thus the oldest color 3D printing technique. Several projects have been set up to adapt this techno to the food world.

In 2012, Kyle and Liz von Hasseln created The Sugar Lab, a design studio dedicated to 3D sugar printing. Then in 2013, the studio was bought by 3D Systems which created a culinary division. During CES 2014, visitors (and me in particular!) were able to discover the chefjet and taste their first sweet printing. In September 2020, the project finally announces the launch of a 3D printing service for sugar parts and an upcoming commercialization of the machine.

Then in 2013, the studio was bought by 3D Systems which created a culinary division. During CES 2014, visitors (and me in particular!) were able to discover the chefjet and taste their first sweet printing. In September 2020, the project finally announces the launch of a 3D printing service for sugar parts and an upcoming commercialization of the machine.

At the same time, many fablabs and universities have adapted binder projection 3D printers to test other materials.

The University of West England, the University of Washington have done a lot of testing. In some cases, the results are even public. If you’re looking for recipes to test in your own powder printer, here are a few resources:

- recipes from the Open 3DP department of the University of Washington

- formulas tested and commented on the Reprap forum

After having reviewed the different 3D printing solutions based on powdered sugar (or icing sugar), I suggest that you take a look at cooked sugar!

liquid-based sugar 3D printers

Do you know which property of sugar interests researchers the most? This is because sugar is perfectly soluble in water. Therefore, it is a perfect backing material for making biological prints. In addition, living cells love sugar and can use the material to perform certain chemical reactions. It is therefore a good candidate for 3D printing of organic tissue.

Therefore, it is a perfect backing material for making biological prints. In addition, living cells love sugar and can use the material to perform certain chemical reactions. It is therefore a good candidate for 3D printing of organic tissue.

Also, when looking for liquid sugar 3D printing projects, we quickly come across applications related to living materials:

- in 2018, the University of Illinois developed a printer for printing isomalt ribbons, which serve as a three-dimensional support for cell culture

- since 2016, the Université de Laval has been working on structures printed in sugar for the construction of an artificial pancreas

And in video, what does it give? Here is a project carried out in 2012, (good news: open source plans are available through Thingiverse.)

Finally here is a video from the University of Illinois whose experiences we cited above. 3D printing takes around 40 minutes.

3D printing takes around 40 minutes.

Royal-icing (paste)-based 3D printers

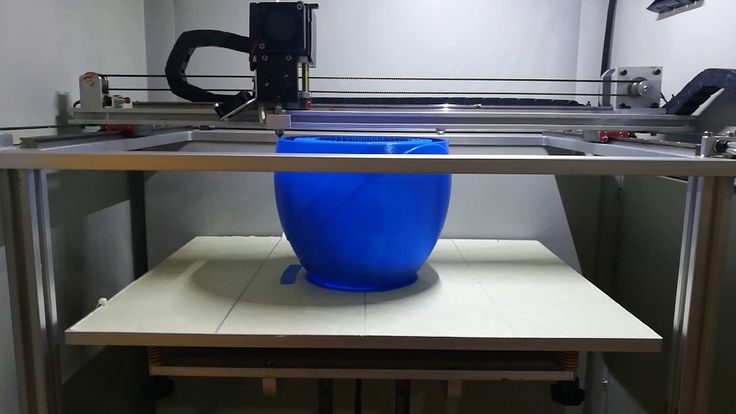

As in the case of chocolate, in this category, you can find “general” dough extrusion 3D food printers and FDM 3D printers which offer special versions for food.

It is possible to easily make a paste based mainly on sugar, which can be extruded. The most known :

- royal icing (a mixture of sugar and raw egg white)

- fondant and sugar paste (a mixture of sugar and glucose syrup)

- the meringue (a mixture of sugar and whipped egg whites)

- honey and agave syrup are also sweetening liquids (chemically they are not sucrose and therefore they cannot be called sugars)

It is probably possible to print sugar paste on the majority of general-purpose food 3D printers. However, I decided to name the ones for which I found a photo.

However, I decided to name the ones for which I found a photo.

- Byflow was developed by Nina Hoff and Jacek. This versatile food 3D printer is well designed to make different 3D prints from extruded pasta. The site offers recipes and an online studio to support you.

- Bocusini by Print2Taste offers marzipan prints (sugar + almond powder)

- Zmorph offers a thick paste extruder to be mounted on its general machine. In 2017, they released this sample use to achieve sweet personalization.

Sugar 3D printing at the Digital Patisserie

After having reviewed the printers available on the market, I suggest that you tell you in a few lines about the experiences that we have carried out at the Digital Pastry Shop.

In the summer of 2019, we did quite a bit of 3D printing using a “syringe pump” system. And we restarted it to make the Rosette of Notre-Dame on the chocolate pie you can see in this video.

But to be honest, we weren’t happy with the results with a syringe plunger. This is what prompted us to imagine Cakewalk 3d and we have made dozens of 3D prints of meringue and royal icing with this simple device that mounts to any Cartesian FDM printer. It was much more satisfying!

It is necessary to deploy a high speed of extrusion to obtain satisfactory results but there is no longer the problem of having to manage the retraction / pressurization after having made a non-printing move.

Royal Icing 3D printing with Cakewalk 3DFinally, this sharing would not be exhaustive our tests with a laser cutting laser on icing sugar. Because of the surface tension we told you about above, we had great difficulty in obtaining interesting results. Here is a photo of my attempts to produce a surface by changing the parameters and as you can see, I had not found the solution yet!

Here is a photo of my attempts to produce a surface by changing the parameters and as you can see, I had not found the solution yet!

We have summarized the technologies and 3D printers available for 3D printing sugar. Now let’s move on to the second part of this article: where to order 3D printed sugar?

Sugar 3d printing services

So, curious about tasting 3D printed sugar? Several services have opened in recent years and offer their creation.

As discussed earlier in this article, Culinaryprintworks is the 3D printing service set up by the 3D Systems culinary studio. Based in Los Angeles, it primarily targets chefs and professionals and offers them applications in pastry and mixology.

3D prints of cocktails made by the company Devoray using the binder jetting techniqueIf you like cocktails, we suggest you check out the Canada-based devoray website. They have developed an innovation that allows them to 3d print cocktails ready to be infused into your glasses!

Do you live in Europe? 3Dchef. nl is a Dutch site that offers you to make designer cake in colored sugar.

nl is a Dutch site that offers you to make designer cake in colored sugar.

In France, you can contact the company Tridifoodies which has developed its own binder projection printing process and offers different textures of sugar.

An example of sugar 3D printing by TridifoodiesSugar 3D printing at home

So, has this article made you want to try 3D printing of sweet products at home? In this part, we share with you some tips based on our own experience.

Let’s talk of royal icing again…

Already, it should be noted that we are a bit addicted to royal ice cream. If you are not familiar, it is a mixture of icing sugar, egg white and a little acid (citric acid or cream of tartar) in the following proportions:

- 1% cream of tartar (or lemon juice)

- 16% raw egg white

- 83% icing sugar

Depending on the amounts you are preparing, you can mix all the ingredients in a bowl with a fork, or use your food processor fitted with a leaf.

You get a viscous paste that can be perfumed or colored. It is often used to decorate flat shortbread. Warning: it air dries quickly, so you better cover it with a film if you are not using it immediately.

The 3D printer is a mechanization of the classic pastry cone. Here are some constraints to take into account:

- As the material is viscous, it is important to apply some pressure before starting

- Not all 3D files can be printed. Because royal icing solidifies when it dries, but not quickly enough to build layers in most cases.

- Also avoid 3D models that require supports, as you will never be able to remove them cleanly.

- As with all food materials, there is no dedicated slicer. Allow time to play around with the settings.

- A big cleanup of your favorite 3D printer is MANDATORY! Fat from engines doesn’t taste very good… and is sure to give you a VERY stomach ache.

- Take your time to print very slowly. You must allow time for the viscous material to settle (think of honey drips on your toast).

Our reference value is 15 mm / s.

Our reference value is 15 mm / s. - Always allow space around your printer, an area that you can easily clean. Finding royal icing on your raspberry PI is surely not your goal …

If you’re more fan of caster sugar

Do you want to print powdered sugar using the binder projection technique, but you do not have a suitable 3D printer? No problem, we have the solution. This is a maker project that will occupy you for many weeks!

We recommend that you watch the Oasis project on Hackaday which is really well detailed.

For those tempted by the impression of cooked sugar or caramel, there are instructions for the Baricuda Extruder Project on Thingiverse. We haven’t tried to do it ourselves, but there are detailed explanations.

In conclusion, there are quite a few possibilities to taste 3d printed sugar, even if it is less common than chocolate! Let us know your comments and your tests, we will be happy to add them in this article!

90,000 characteristics, pros and cons of each model 07. 04.2021

04.2021

Content

-

- What is a food 3D printer

- Field of use

- used raw materials

- 9000 9000 9000 9000

- Top 10 Best Food Printers: A List of the Most Current Models

- 1. PancakeBot 2.0

- 2. Wiiboox Sweetin

- 3. Choc Creator V2.0 Plus

- 4. Choc Creator V2.0 Plus Food 3D Printer with Cooling Chamber

- 5. byFlow Focus

- 6. Chefjet Pro

- 7. Foodini

- 8. Mmuse – Chocolate 3D Printer Commercial ArtcakesOT7 .90BOT Printer F5

- 10. ZMorph VX

- What is a food 3D printer

- Selection guide

- Output

A food printer is a high-tech device that is used to create culinary masterpieces. The decorative design of food products has reached a new level thanks to the use of modern technologies: high-quality and large-format printing is carried out on cakes, waffles, pancakes and even coffee. Here are the top best 3D food printers in different price categories for people who are fond of cooking.

What is a 3D food printer

The main feature of a food 3D printer is the raw materials used: instead of printing ink, the device is filled with edible ingredients. The database stores a large number of different recipes, and in order to print a dish, you just need to select one of them and activate the printing process. The final product is layered on a work surface or on a plate: it can be baked in the oven or sent to the freezer.

Application

Futuristic 3D Printed Sugar Candy

Cookies printed with icing

Chocolate logos of famous companies

Cream Photo Print

Buying a food 3D printer is worth the owners of coffee houses, author's bakeries and private workshops. The finished product has a unique shape and bright appearance. Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products.

The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products.

Raw materials used

The following ingredients are used as raw materials:

-

Chocolate without additives and impurities;

-

Mastic;

-

Sugar;

-

Whipped cottage cheese;

-

Vegetable and fruit pastes;

-

Fish and meat pates;

-

Flour;

-

Cheese, etc.

The confectionery pattern is applied to sugar, wafer or shock transfer paper. The first type has a sweetish aftertaste and aroma of vanilla. Due to the snow-white surface, no additional coating is required: the drawings look bright and clear. The wafer paper is made from rice flour and does not have a special taste, due to the light shade, the final drawings look less clear. Shock transfer paper is completely transparent and is suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used.

For the packaging of finished products, food-grade plastic for a 3D printer is used.

Interesting! Food printers are involved in waste reduction. Unattractive fruit and confectionery leftovers are used in the preparation of printing mixes. This makes it possible to use the means of production more efficiently.

Types of 3D food printers

Cooking enthusiasts can take advantage of the following food printing devices:

-

Food 3D printers are devices that print dishes whose recipes are listed in a database. The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges;

-

Confectionery printers are used to transfer images onto specialty paper or to design small confectionery products such as candies. Such printers print an image on pre-prepared paper: rice, wafer or shock transfer;

-

Food plotters transfer the image not to paper, but directly to the finished product.

For example, a plotter is used to transfer an image directly onto a cake.

For example, a plotter is used to transfer an image directly onto a cake.

There are several types of food 3D printers:

-

Extrusion - paint is applied to the surface before the dish is created. The process is controlled by the computer with the loaded image. The system has an extruder that heats the food mixture, and the distribution of raw materials depends on the print head. The raw material is loaded into a syringe placed in the head. This means that in order to combine different shades, you have to periodically stop printing and change the syringe;

-

A carousel-type food 3D printer also has an extruder, but its main feature is the method of feeding raw materials: the containers rotate around the working surface, the supply and dosage of the material used depends on the recipe specified in the program. The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

Popular brands

Eminent manufacturers offer the best value for money food 3D printer. Quality devices provide accurate printing, high speed, durability, simplicity and ease of use.

Wiibox

This company manufactures 3D printers with high build quality and high productivity. These are universal mechanisms that fill both chocolate paste and mashed potatoes. Numerous positive reviews confirm the high quality of Wiibox products.

byFlow

The Dutch company byFlow specializes in food printing technology. The pursuit of excellence helps the company open up new horizons: the technique prints products from spinach, meat emulsion and other materials. High build quality, ease of use and durability - all these characteristics are applicable to the products of this company.

Choc Edge

Choc Edge is committed to revolutionizing the world of chocolate making. Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Attention! Printing dishes helps save time on cooking: instead of culinary worries, the user can simply activate the printing process and get on with other things.

Free shipping

Add to compare

Item added to compare Go

| Manufacturer | Choc Edge |

Available on credit. To checkout, add the product to the cart and follow the instructions Go

| Manufacturer | Wiiboox |

Free Shipping

Add to compare

Item added to compare Go

| Manufacturer | Choc Edge |

Top 10 Best Food Printers: List of the Most Current Models

Before you buy a food 3D printer, you need to familiarize yourself with the most popular devices on the world market. The top is based on ratings and customer reviews.

1. PancakeBot 2.0

PancakeBot 2. 0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

Pros:

-

Ease of operation;

-

A wide range of proposed projects;

-

High speed.

Cons:

2. Wiiboox Sweetin

Buying a food printer from Wiiboox is worth not only for confectionery lovers, but also for ordinary chefs: the device prints cakes, cookies and even mashed potatoes. The main raw materials can be meat, cheese, chocolate, jam, mashed potatoes, dough and much more. A convenient touch panel helps to set the desired mode of operation, and a stylish appearance complements the interior of any establishment.

Pros:

-

Versatility: the ability to print not only sweet dishes, but also side dishes;

-

Attractive appearance;

-

High build quality;

-

Convenient control by touch panel.

Cons:

-

High price.

3. Choc Creator V2.0 Plus

When talking about which chocolate 3D printer to buy, it is worth mentioning the numerous advantages of Choc Creator V2.0 Plus. The new model has become more perfect: the developers have worked hard to eliminate the shortcomings of the previous version. The modern model has small dimensions, thanks to which it can be used in any kitchen, and the uniform heating of the syringe ensures high-quality and uninterrupted operation. In practice, the chocolate printer has shown tremendous potential: it prints complex figures from chocolate.

Pros of :

-

Attractive appearance;

-

Uninterrupted work;

-

Durability;

-

The ability to create durable and beautiful chocolate figures.

Cons :

4.

Choc Creator V2.0 Plus 3D food printer with cold chamber

Choc Creator V2.0 Plus 3D food printer with cold chamber

The new version of the Choc Creator V2.0 Plus printer is equipped with cooling chambers by popular demand. Users say that maintaining the optimal temperature in the room to preserve the integrity of chocolate figures is too problematic: therefore, the new device cools the raw materials. The price of a food 3D printer with a cooling system is slightly higher than a classic one, but the high performance of the final product justifies any costs.

Pros of :

-

Availability of a cooling system for finished products;

-

High printing precision;

-

Long service life;

-

Ease of use: You can turn the fans on and off with the side buttons.

Cons :

-

High price.

Attention! Confectionery food 3D printers are often used by artists to create edible masterpieces.

This is a unique technology that helps to unleash the creative potential of the chef.

5. byFlow Focus

Food printer from the Dutch company byFlow, which specializes in 3D printing of food. The compact high-tech device is used for the bakery industry, and the cartridges are suitable for the application of any pasty ingredients.

Pros:

Cons:

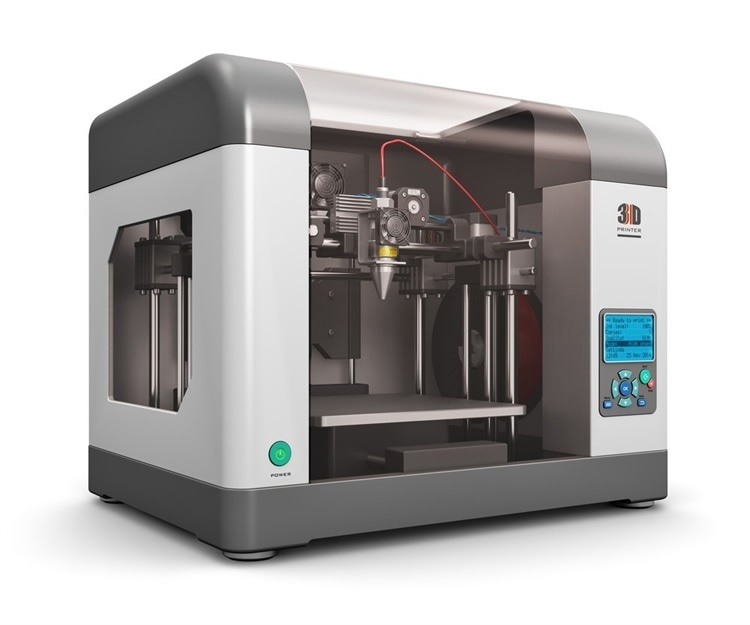

6. Chefjet Pro

Buying a ChefJet Pro food printer is a must for people who dream of making bright and stylish sweets. The device is created on the principle of inkjet printing: sugar-containing powder materials are used instead of paints. The final product is made by powder layering. The printer is suitable for combining different shades and creating gradients.

Pros:

-

The ability to create unique flavors;

-

Neat and bright printing;

-

Aesthetic appearance of the device.

Cons:

-

High price.

7. Foodini

The 3D food printer from Foodini works on the principle of a stationary printer, but instead of printing inks, layer-by-layer imposition of edible raw materials is used: dough, cream, chocolate, cream, etc. The device is versatile: the user himself can choose the material, or use ready-made cartridges with products.

Pros:

-

Practicality;

-

High build quality;

-

Attractive appearance;

-

Availability of an online platform with unique recipes.

Cons:

8. Mmuse – Chocolate 3D Printer

The closed MMuse 3D printer is suitable for chocolate printing. Chocolate beans are used as raw materials: they are heated in an extruder and fed to the work surface through the print head.

Pros:

Cons:

9. ZBOT Commercial Art Pancakes Printer F5

ZBOT Commercial Art Pancakes Printer F5 3D Printer

A food printer from Chinese manufacturers is used in the process of making pancakes of various shapes. Ease of operation allows the device to be used by children under adult supervision.

Pros:

-

Ease of operation;

-

High build quality;

-

Affordable cost.

Cons:

10. ZMorph VX

A multifunctional 3D printer capable of printing not only food, but also rubber, ABS plastic, polylactide, PVA, nylon, elastic and metal materials. The product is able to print with chocolate, butter, cookies, icing and other ingredients. In addition, there is a function of engraving and CNC milling.

Pros:

Cons:

-

High price.

Selection guide

The modern market offers a wide range of food printers. Before making a purchase, you need to carefully study the characteristics of each model and build on your own preferences. Experts have created several recommendations for choosing:

-

In case you want to create realistic images for confectionery 3D printing, pay attention to the diameter of the nozzle: the narrower it is, the more accurate the image will be;

-

It is better for people living in regions with a warm climate to purchase chocolate 3D printers with a cooling system: such devices ensure that the figurines are kept at the optimum temperature;

-

The possibility of self-refilling the cartridge is the most practical and economical way to operate the printer;

-

Print speed is an important consideration for restaurant owners. Large batches of dishes must be produced quickly, and for home use this is not a very strict selection criterion.

Output

In the catalog of our online store, you can choose the best food printers from famous brands to create culinary masterpieces. Explore our range, learn about the characteristics of each printer and make great purchases.

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

How PLA is made for 3d printers. Report from the shop / Sudo Null IT News

A pistol shot was the signal to create a business.

To dispel the myths that plastic spools for 3d printers grow on trees can only be bought and resold, as well as that it is enough to buy an all-in-one extruder and start a business, I went on reconnaissance to the Moscow manufacturers of ABS and PLA (and HIPS). Indeed, I ended up in a professional workshop with industrial equipment, with high-precision measuring and control devices, high standards of cleanliness (because the production process is very responsible) and sociable founders (ready to share knowledge with an inquisitive and thinking audience), who have a lot of techno-creative ideas and takeover plans world market. (+5 National Pride Level)

(+5 National Pride Level)

As the co-founder of the company told me: "First we saw a fruit knife open and an orange peeled with it, then the video of Cody Wilson's gun came as a shock and away we go..."

At the time when I wrote the first 2 articles about 3d printers on Habré (spring 2013), these guys had already started creating a plastic production business. It is interesting that both I and they came up with a similar idea, how to supplement the saying, they say, a person can endlessly look at fire, water, how another person works and how a 3d printer prints.

Polylactide (PLA, PLA) is a biodegradable, biocompatible, thermoplastic, aliphatic polyester whose monomer is lactic acid. The raw materials for production are annually renewable resources such as corn and sugar cane. It is used for the production of products with a short service life (food packaging, disposable tableware, bags, various containers), as well as in medicine, for the production of surgical sutures and pins.

Under the cut - the main stages of turning raw materials into coils with PLA for 3d printers

Shop view

Right to left

There was a corn, then it is processed into such balls and put in such boxes

About 900 kg of plastic is obtained from a ton of raw materials

Since this is a natural product, it is afraid of light and moisture, so it is protected with such a bag and a piece of silica gel

And this is a "vacuum cleaner" with which 100 kg of "corn balls" are scooped up and sent to container

Here the raw materials are dried, while the smell is like in a confectionery

Add a “pinch” of dye (also completely natural, Austrian quality)

Here the raw material is heated and turns into a viscous mass.

Under the pressure of the shaft, we pass through the heating elements.

The diameter of the “furnace” outlet is about 3 mm, the plastic acquires the desired diameter (1.75 mm) due to the fact that it is immediately pulled, and the draft is very precisely adjusted

Bosh. For ABS and PLA different temperatures

The diameter of the cooled plastic is measured by a laser device. Thread diameter tolerance set to ±0.03 mm

Remote monitoring of plastic diameter

Laser threading speed 55 meters per minute

Traction control. It is the thrust that creates the desired diameter. Using this unit, you can very accurately select the thrust of the motors and thereby adjust the diameter of the plastic.

"Spindle" - controls the speed of winding on the coil. No on COIL.

Here is the COIL.

Without plastic

It is important to note the uniformity of filling the spool

After the large spool is full, it is removed and the thread is rewound onto small (usual for everyone) spools.

Ordinary coils fall into the caring hands of the girl who completes the box

Dust-proof bag, moisture-proof silica gel, strong box to protect from direct sunlight and stickers. The stickers indicate the recommended melting temperature (they are different for ABS and PLA), filament diameter, weight and material.

From here they will go all over Moscow and the CIS countries

Purity

What I noticed is that the workshop is very clean, all measures have been taken to keep dust as low as possible: windows are sealed with adhesive tape, cleaning is often done, antistatic liquid is used, especially important places are covered with polyethylene.

soluble plastic

high-strength polystyrene (HIPS), which in its characteristics is very similar to conventional ABS (for which Rep 2X is “optimized”). HIPS dissolves in limonene, a citrus-based substance. Complex objects can be printed with standard ABS or PLA, and HIPS can be used as support material. The final product is immersed in a limonene bath where the HIPS dissolves in a few hours. In addition, HIPS has a close operating temperature, adheres well to ABS and the platform. The consumption of limonene is small, since most of the support is usually removed by hand. A lemon bath is a slightly more complicated procedure than if it were ordinary water, but it has its own plus: after bathing, the item smells like lemon.

Complex objects can be printed with standard ABS or PLA, and HIPS can be used as support material. The final product is immersed in a limonene bath where the HIPS dissolves in a few hours. In addition, HIPS has a close operating temperature, adheres well to ABS and the platform. The consumption of limonene is small, since most of the support is usually removed by hand. A lemon bath is a slightly more complicated procedure than if it were ordinary water, but it has its own plus: after bathing, the item smells like lemon.

A couple of tips on how to choose good plastic.

PLA is very sensitive to storage conditions (dark, dry and dust-free). The twig should be clean, without inclusions, smooth, without delamination, on the surface - a slight sheen.

The presence of foreign bodies is checked at the rupture site. If you pull up and break a piece of plastic (it breaks where it is “thin”), then the place of the gap should be uniform - this is a sign of good quality.