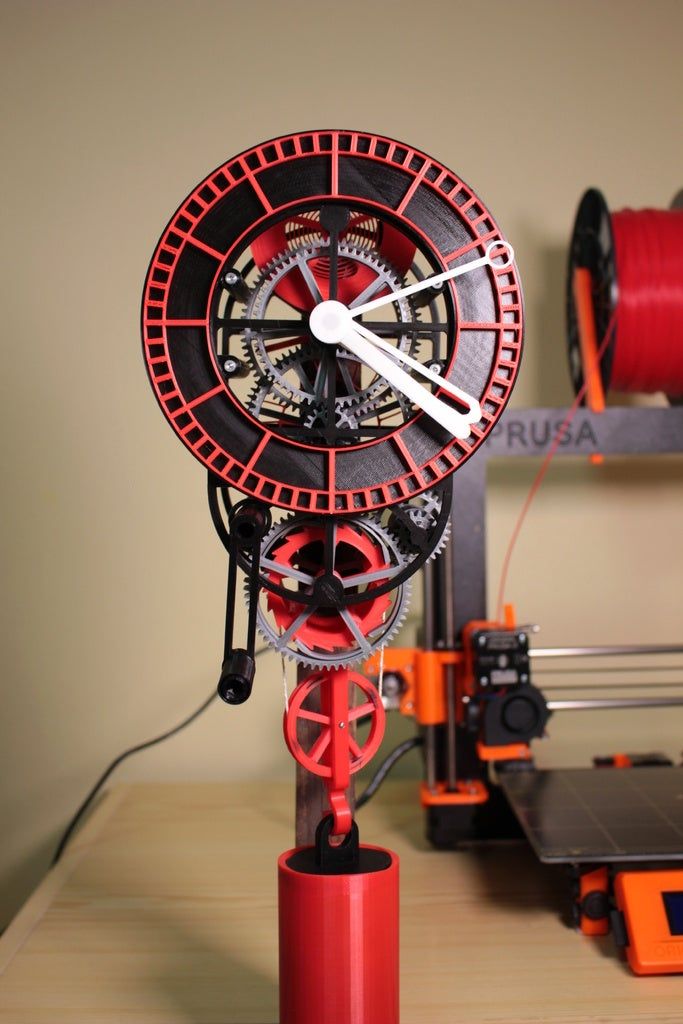

Sun clock 3d printed

3D printed digital sundial

Chris Fastie, August 7, 2016

Last year a clever guy named Julien Coyne posted his design for a digital sundial (Figure 1). As the sun moves across the sky, the digits representing 24-hour time are displayed in the shadow of the gnomon (the angled arm that traditional sundials have).

| Figure 1. The gnomon has intricate pathways for sunlight to pass through when the sun angle is just right. |

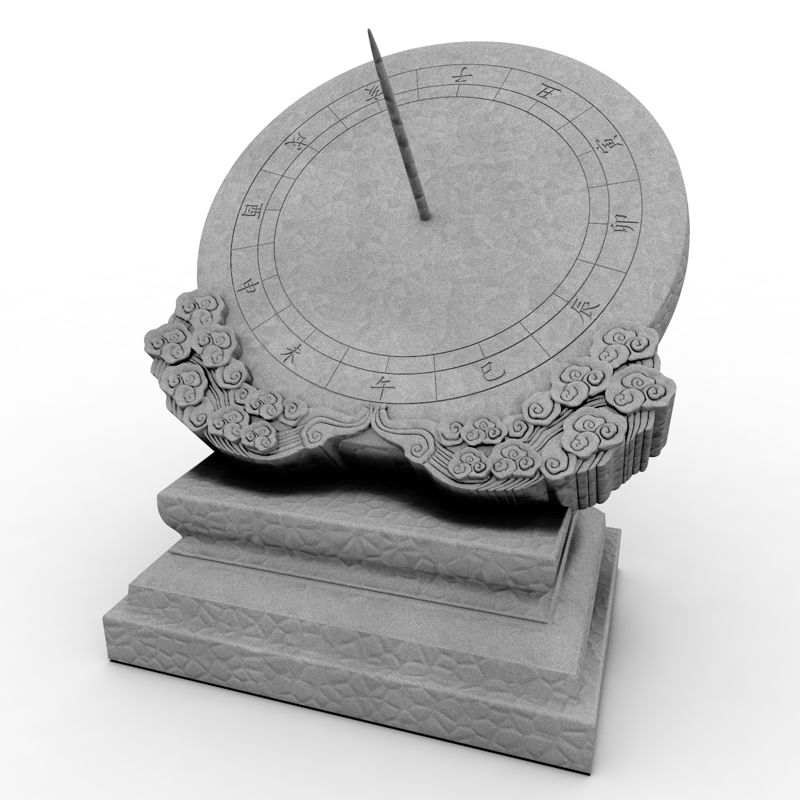

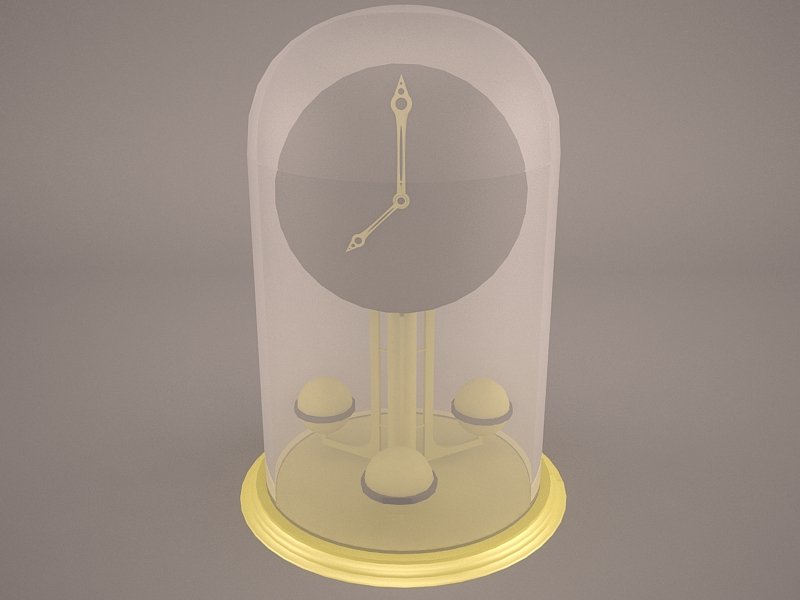

This was not the first digital sundial. The first one was a fiber optic device developed in 1984 by Steve Hines and patented in 1988 (Figure 2). In the following decade other designs were developed and patented in 1996 and 1997. These were simpler devices which directly blocked the sunlight except for the rays illuminating the digits in the time display. One of these is still offered for sale as an indoor (e.g., window mounted) time display (Figure 3). I have always wanted one of these, but they cost $129. 00, so I have been satisfied with an old fashioned gnomon stuck in the ground so it points at the north star and is surrounded by an arc of carefully placed rocks.

| Figure 2. Steve Hines patented this digital sundial in 1988. As the sun moves, light from an entrance slit enters fiber optic strands which guide the light to the proper plexiglas segment of a digit. |

| Figure 3. This beautifully made digital sundial was developed in the 1990s and is sold by one of the developers -- Daniel Scharstein of Middlebury College. |

The expense of the commercial digital sundial is due to the great precision required to manufacture it. Tiny masks block the sunlight except when the angle is just right, and these masks must be aligned perfectly.

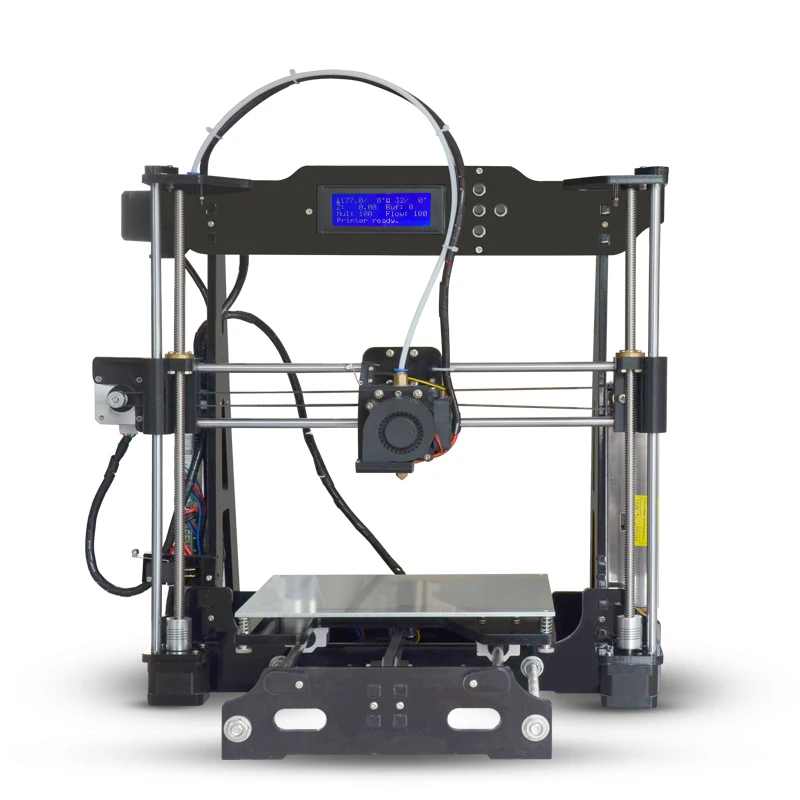

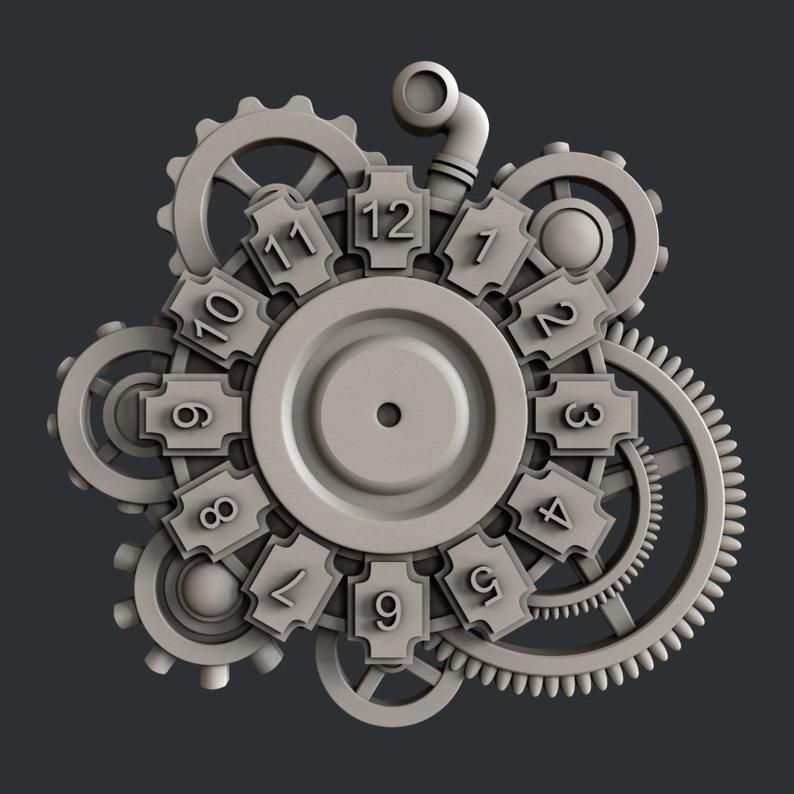

Julien Coyne understood that a parametric CAD (computer aided design) program could create the intricate 3D model of the gnomon with a few lines of code repeated for each desired sun angle and for each “pixel” defining the projected digits. The resulting object would be difficult to manufacture with traditional methods, but would be quite simple to make with a 3D printer. This sundial is one of the more elegant examples of a complex problem that has waited decades to be solved by 3D printing.

The resulting object would be difficult to manufacture with traditional methods, but would be quite simple to make with a 3D printer. This sundial is one of the more elegant examples of a complex problem that has waited decades to be solved by 3D printing.

| Figure 4. A cross section of Coyne's gnomon through one of the 16 slots that allow sunlight to form a column of "pixels" which make up the digits. Only four of the six possible pixels are needed for this column of pixels. |

In October, 2015 Coyne posted an elaborate and entertaining video about his sundial and also made the design files freely available. The video has been watched 426,000 times and the printing files have been downloaded 80,000 times from Thingiverse. The other patents from the 1990s have both lapsed (the owners stopped making fee payments) and might not have covered Coyne’s approach anyway. Coyne sells his sundials on Etsy (it takes him 30 hours to print each one), but the primary impact of his work is the thousands of people who can print their own. The great mystery of Coyne’s contribution is that the sundial video was his first real post at his Mojoptix website, and there has not been another one since. Maybe he’s just too busy printing gnomons.

The great mystery of Coyne’s contribution is that the sundial video was his first real post at his Mojoptix website, and there has not been another one since. Maybe he’s just too busy printing gnomons.

I made a timelapse video of the display of one of the sundials I printed. I used a Canon PowerShot the first time but the automatic focus made the video jerky. So I used a Canon EOS M with manual focus and that worked better. I took a photo every six seconds using the intervalometer feature in the firmware enhancement Magic Lantern. The silent video below also has the CAD model being manipulated in the slicing program Simplify 3D.

Video has no audio.

Digital sundials don’t change the digits every minute, and to make the printing manageable, Coyne limited the time increment to 20 minutes. He also limited the operating span to the six hours between 10:00 and 16:00 (10 AM to 4 PM). These were good decisions because the maze of light paths through his gnomon requires a structure about as intricate as home 3D printers can handle. When I printed mine I did not use the finer layer thickness that Coyne recommends and the printing took about half the time he reported. The projected time display of mine has some artifacts which might be due to my lower resolution printing.

These were good decisions because the maze of light paths through his gnomon requires a structure about as intricate as home 3D printers can handle. When I printed mine I did not use the finer layer thickness that Coyne recommends and the printing took about half the time he reported. The projected time display of mine has some artifacts which might be due to my lower resolution printing.

The sundial needs a supporting base, and Coyne’s sundial is designed to screw onto the top of a jelly jar which you can fill with rocks or coins so the whole thing won’t tip over. Unfortunately, Coyne is French, and his design requires a French jelly jar. This was discouraging until I found a box of dusty jars in the garage and was astounded to see French label on a few of them. The fact that in a few minutes, without leaving the house, I was holding French jelly jars prevented me from complaining about life for at least a day and a half. As it happens, Bonne Maman is a common brand of imported jelly distributed in the US, and I was soon buying new French jars filled with really wonderful French jelly.

| A fine French jelly jar full of stones makes a sturdy base for the gnomon. Coins are even better. |

| The best imported jelly jars make the best sundial bases. |

More Articles...

Digital Sundial - 3D Printed Sun Clock (Mojoptix Remake)

Pricing & History

- Sold for

Start Free Trial or Sign In to see what it's worth.

- Sold Date

- Source eBay

Digital Sundial - 3D Printed Sun Clock (Mojoptix Remake)So here it is, our final version and remake of the Digital Sundial3D printed in high quality ABS, PLA, Wood Compound and any color you like (default color is Black, let us know if you want a different color) Displays time as any digital clock but has no battery Worldwide free shipping Includes all parts plus a 3M double tape to find the optimum position Less than 120 grams and 20 cm longInside a SundialOur secret is simple. .. but not simple:Tiny little holes are designed and printed to let the sun go through only in a certain angle, allowing the Sundial to show the time in intervals of 20 minutes... not made for shiny moon nights.Sundials and KangaroosThere is a tiny subtlety if you want to use this sundial in the Southern hemisphere:Try to visualize an kangaroo in Australia. Just like everyone else, this 'roo has to orient the tip of its sundial toward the north pole. For him, that means having the tip of the sundial pointing toward the ground.... this doesn't seem very practical. Our hinge mechanism doesn't even allow to tilt the sundial below horizontal.The trick here is simply to build a subtly different magical black box (also called a gnomon) for kangaroos. This way, the 'roo can simply use this Southern-hemisphere sundial exactly the same way a cow or a penguin would use their Northern-hermisphere version the sundial, with just one difference: the 'roo will have to point the tip of his sundial toward the *South* Pole.

.. but not simple:Tiny little holes are designed and printed to let the sun go through only in a certain angle, allowing the Sundial to show the time in intervals of 20 minutes... not made for shiny moon nights.Sundials and KangaroosThere is a tiny subtlety if you want to use this sundial in the Southern hemisphere:Try to visualize an kangaroo in Australia. Just like everyone else, this 'roo has to orient the tip of its sundial toward the north pole. For him, that means having the tip of the sundial pointing toward the ground.... this doesn't seem very practical. Our hinge mechanism doesn't even allow to tilt the sundial below horizontal.The trick here is simply to build a subtly different magical black box (also called a gnomon) for kangaroos. This way, the 'roo can simply use this Southern-hemisphere sundial exactly the same way a cow or a penguin would use their Northern-hermisphere version the sundial, with just one difference: the 'roo will have to point the tip of his sundial toward the *South* Pole. Please let us know your hemisphere!!!Fun fact about this sundialYou will most likely never see it in a supermarket or a department store. The swiss cheese inside the sundial is so intricate, that you can't realistically use injection molding, or some other mass-production method. 3D printing seems actually to be the only practical way to build this digital sundial ! We will ship the item from our closest and available 3D printer (USA, Spain or Netherlands) read more

Please let us know your hemisphere!!!Fun fact about this sundialYou will most likely never see it in a supermarket or a department store. The swiss cheese inside the sundial is so intricate, that you can't realistically use injection molding, or some other mass-production method. 3D printing seems actually to be the only practical way to build this digital sundial ! We will ship the item from our closest and available 3D printer (USA, Spain or Netherlands) read more

Relevant Toys, Dolls, Games & Puzzles Articles

Click below to begin your paid subscription.

Your credit card or PayPal account will be charged.

What the first 3D printed steel bridge looks like

Trends

TV channel

Newspaper

Pro

Investments

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Conferences

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Mashable / YouTube

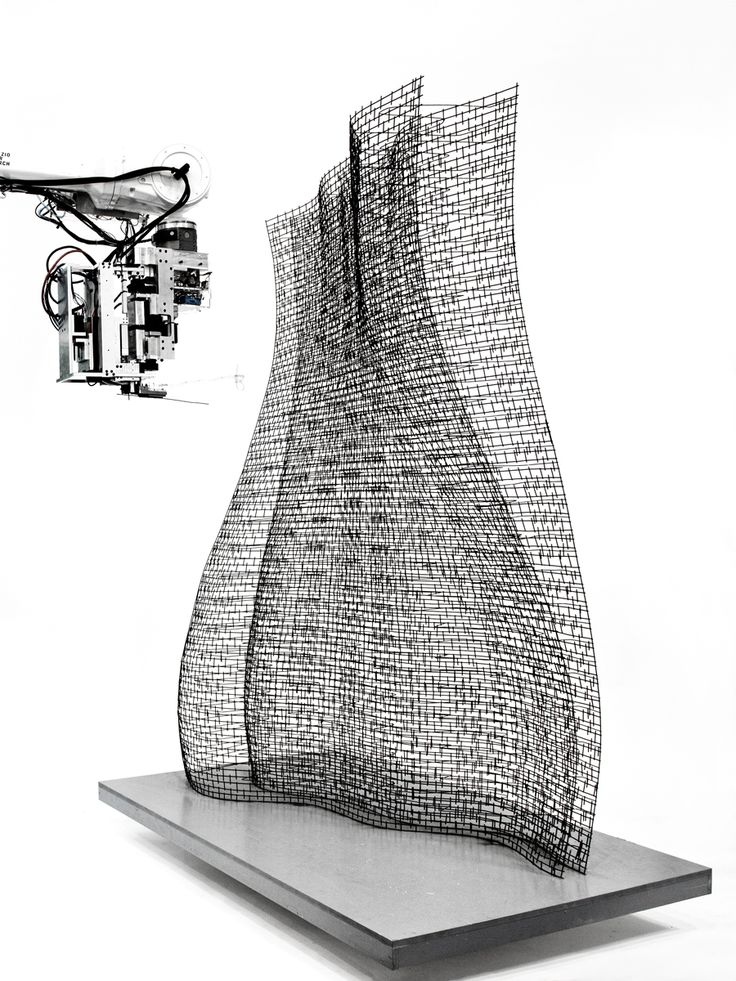

The world's first 3D printed steel bridge has been installed in Amsterdam. The project was ready three years ago, but the installation of the bridge was constantly delayed

What's happening

- On July 15, the world's first 3D printed steel bridge was opened in Amsterdam.

It connects the embankments of the Oudesijds Achterburgwal canal. The grand opening was attended by Queen Maxima of the Netherlands.

It connects the embankments of the Oudesijds Achterburgwal canal. The grand opening was attended by Queen Maxima of the Netherlands. - The structure weighs 6 tons and is 12 meters long.

- The bridge was printed by four robots by welding layers of stainless steel wire, it took them 4.5 tons of steel and six months to make a span of 12 meters. Then coastal supports and decorative elements were made.

- This project was developed by the laboratory of Joris Laarmann and ABB, Air Liquide, ArcelorMittal, Autodesk, AMS Institute and Lenovo, while the Amsterdam-based company MX3D was fabricating and installing the structure.

- More than ten sensors are built into the bridge, with the help of which it will be possible to monitor its condition and deformation. Thus, he will himself indicate the need for repair. The sensors will also count the number of pedestrians crossing the bridge each day.

- The structure was installed for two years as a replacement for the conventional bridge, which will be under reconstruction at that time.

- This bridge was first presented at Dutch Design Week Eindhoven 2018, where the project won the Dutch Design Award and the Audience Award. After that, the finished bridge lay in storage for another three years: first, in anticipation of the reconstruction of the canal, then due to the coronavirus pandemic and lockdown.

What does it mean

In recent years, there has been an active development of 3D printing technology in construction. The Netherlands seems to be on a roll with this trend, with the first fully 3D-printed residential building in the EU populated in the suburbs of Eindhoven in early May, followed by the opening of the world's first 3D-printed steel bridge.

We have already said that 3D printing is the future of construction and design. Compared to classic buildings, 3D printing has a number of undeniable advantages, such as short construction times, reduced economic and environmental costs, and ease of execution of complex shapes.

“This is not just about reducing and optimizing construction costs, but about giving architects and designers a new tool, a very cool new tool, with which they can rethink the design of their architecture and their projects,” notes Tim Görtjens, co-founder of MX3D, a bridge builder.

Mika Mos, member of the council of the municipality of Amsterdam, expressed the hope that this construction will also help the city attract quality new tourists:

“This could attract a new type of visitor, those more interested in architecture and design, which will change the perception of the area (famous for nightclubs and noisy parties. — RBC Trends ).”

Updated on 10/18/2022

Text

Ksenia Yanushkevich

Top of the trend

Related materials

3D printers and 3D printing

3D printers have appeared in our lives not so long ago, but are already very popular in the field of high technology. In the future, instead of buying various items in the store, will we simply download a file from the Internet and print them on a home 3D printer? Will there be a 3D printer on the International Space Station that will print the parts and spare parts necessary for space exploration? You can find answers to these and other questions in this section.

In the future, instead of buying various items in the store, will we simply download a file from the Internet and print them on a home 3D printer? Will there be a 3D printer on the International Space Station that will print the parts and spare parts necessary for space exploration? You can find answers to these and other questions in this section.

3D production

one Technology

Specialists of the Perm Research and Production Institute have developed and proposed for application a technology for 3D printing of graphene parts of complex shapes for use in aviation, which will significantly reduce the cost of their production while improving the quality of products.

0 Weapons

A radio station in Utica (USA) released an interview with a man under the pseudonym "Kem", who told how he managed to take advantage of a hole in the state program for buying weapons from the population. Due to the extremely criminal situation in the state of New York, the authorities began to give out $ 500 gift certificates to those who . ..

..

4 Science

Engineers at the University of Washington conducted a series of experiments that proved the fundamental possibility of creating strong and reliable cermets from regolith. In this case, "regolith" is a conditional substance, an imitation of lunar soil and Martian dust. During the exploration of the Moon and Mars, this ...

four Kosmos

According to TASS special correspondent and cosmonaut Oleg Artemiev, the latest Russian-designed 3D printer, created by RRK Energia specialists from the Roskosmos structure, has already arrived at the ISS and is fully prepared for printing.

0 Technologies

For the first time, the possibilities of 3D printing technology in space were tested in December 2018 by Russian cosmonauts Alexei Ovchinin and Oleg Kononenko - then they launched the Organ. Avt”, developed by the staff of the laboratory 3D Bioprinting Solutions (Russia).

one Technology

The use of 3D printing technology in construction has already shown its effectiveness in many countries of the world, so it is not surprising that the US Army plans to build three 530 sq. meters each. For comparison, the area of one of the administrative buildings in Dubai, erected on…

0 Technology

One of the world leaders in 3D printing, the American company ICON, together with the homebuilder Lennar, are embarking on an ambitious project to build a residential area of 100 family homes in Austin, Texas, designed by the design firm Bjarke Ingels Group (BIG). The settlement will become…

one Technology

Scientists at the Massachusetts Institute have created a new tool that replaces tactile sensors, pressure gauges and displacement sensors at the same time. It is a flexible structure built from metamaterials that responds to the user's touch and transmits commands depending on their strength and direction. One more…

One more…

0 Technology

Developers from the American startup Lore have found a way to improve the efficiency of the legs of cyclists during races. They decided to eliminate such a factor as the displacement of the foot inside the shoe - this consumes a certain amount of energy that could be used to pedal. As a solution, they offer…

3 Technologies

The world's first 3D-printed stainless steel bridge connecting the banks of one of the city's canals was opened in Amsterdam with the participation of the Queen of the Netherlands Maxima.

one Technique

The rocket industry is actively developing advanced 3D printing technologies. In the production of their spacecraft, it has already been adopted by Rocket Lab, NASA and Space X. The next may be the startup Relativity Space, whose members are going to print the world's first launch vehicle Terran R on a 3D printer . ..

..

3 Technology

Construction of houses using 3D printing is no longer the lot of individual experiments and is gradually reaching the industrial level. One such project is nearing completion in Austin, Texas, where construction firm Icon has begun building the first $450,000 "printed" homes.

one Technology

Over the past few years, 3D printed home building has gone from being a hobbyist to building full-fledged offices and affordable housing. The next step seems to be the creation of the world's first printed school in Madagascar.

ten DIY

For quite a long time, 3D printed weapons were unreliable and often disposable crafts that were only enough for one shot. But technology does not stand still, and today the weapons printed on the printer are becoming more and more formidable.

0 Technology

The construction industry is rapidly embracing 3D printing. There are already enough examples of this: this is the creation of an entire village in Mexico, consisting of printed houses, and the construction of two-story houses in Germany using the 3D printing method. Next in line is a three-story house.

There are already enough examples of this: this is the creation of an entire village in Mexico, consisting of printed houses, and the construction of two-story houses in Germany using the 3D printing method. Next in line is a three-story house.

0 Technology

MIT Media Lab graduate student Jack Foreman has figured out how to take advantage of a flaw in FDM printers that creates specific gaps in an object during printing. Formally, they are considered a lack of technology, a consequence of insufficient extrusion, and the product turns out to be defective. However, Foreman noticed that…

0 Gadgets

3Doodler has updated its lineup with the new Pro Plus pen. The main goal of the developers is to get rid of associations with toys, entertainment, change the image of a 3D printing pen and present it as a professional tool. At the same time, the essence and purpose have not changed - with the help of a pen . ..

..

0 Technology

For many years, coral reefs have been under the threat of extinction. The solution to this problem was proposed by scientists from the University of Hong Kong. Using 3D printing technology, they created special mosaic tiles that are supposed to be placed on the bottom of shallow water areas.

3 Technology

KFC has announced that it intends to make chicken nuggets using 3D printed fake meat technology.

0 Technologies

Engineers from the Max Planck Society in Düsseldorf and the Fraunhofer Institute for Laser Technology in Aachen (Germany) have developed a new technology for creating heterogeneous microstructures using 3D printing. To visualize their work, they printed an analogue of the famous Damascus steel. This is not a blank for weapons, oh ...

0 Technologies

Today, the size of objects that can be printed on a 3D printer is limited by the size of the 3D printer itself (unless you design complex prefabricated structures). Therefore, when it becomes necessary to print a large object - for example, for the needs of the aerospace industry - the manufacturer is forced to ...

Therefore, when it becomes necessary to print a large object - for example, for the needs of the aerospace industry - the manufacturer is forced to ...

one Technologies

Professor Jonathan P. Singer of Rutgers University in New Jersey (USA) has developed a technology for coating complex three-dimensional structures throughout their area. It can be used both for simple coloring of products (including those printed on a 3D printer), and for treating them with special substances. Working…

0 Technologies

The new application of 3D printers has nothing to do with stamping complex engineering parts. Food printed with such a printer changes the structure of products in such a way that a person feels more full, while consuming less food.

0 Technology

The Laboratory of Applied Photonic Devices at the Federal Polytechnic School of Lausanne (Switzerland) has developed a technology for ultra-high-speed three-dimensional printing of objects. Its main advantage and difference from the usual additive printing in the absence of layers is that the entire object is created at once. True, there are fundamental ...

Its main advantage and difference from the usual additive printing in the absence of layers is that the entire object is created at once. True, there are fundamental ...

0 Gadgets

At CES 2020, Taiwanese company XYZ Printing unveiled the da Vinci Color 5D desktop FDM 3D printer. Developers define 5D in its name as "3D + 2D".

0 Technologies

The possibilities of aluminum 3D printing are a dream come true for car manufacturers and reenactors when it comes to small-scale or custom production. Brands such as Koenigsegg and Bugatti officially use printed parts when assembling cars to order. Wheel manufacturer HRE with…

1 Technologies

The main goal of the non-profit organization New Story is to help the most socially vulnerable groups of the population find affordable housing. According to experts, by 2050, 3 billion people will be deprived of the opportunity to live in normal conditions. One of the directions in solving this problem is the construction of economical houses with…

One of the directions in solving this problem is the construction of economical houses with…

2 Technology

Researchers from the ETH Zurich (Switzerland) conducted an experiment in which they tried to create DNA for inanimate objects. The goal is to learn how to convey information about the structure of synthetic structures in each of their particles, so that with the help of any fragment it is possible to reproduce the entire object ...

0 Gadgets

On the eve of the New Year holidays, the Chinese company Tronxy has launched what is probably the most affordable 3D printer in the world. The Tronxy X1 model with a regular price tag of 13600r with a holiday coupon is on sale for only 6500 (if you want to try your hand at 3D printing and start with Tronxy, use when buying ...

0 Technology

A unique retaining wall has been completed in the Chinese city of Suzhou to strengthen the shoreline of one of the water channels. What makes it special is that the wall was built using construction 3D printing technology. With a length of 500 m and a height of several meters, this is by far the largest structure ...

What makes it special is that the wall was built using construction 3D printing technology. With a length of 500 m and a height of several meters, this is by far the largest structure ...

0 Technology

Of all the "inks" used in 3D printing, "glass" is still one of the most problematic. Scientists at the Swiss research center ETH Zurich Research are working on a technology that will make these problems a thing of the past.

one Technologies

A team of engineers from Northwestern University (Illinois, USA) introduced HARP (high-area rapid printing) 3D printing technology. This printer with a substrate area of 2322 sq. cm. and a maximum height of 4 m can print at a speed of almost 50 cm / h, which allows for 2-3 hours ...

HIGHLIGHTS

Aeromine wind turbines proved to be 1.5 times more efficient than solar panels

F-35's long-suffering engine found a part made in China

Random article

His curious fact

the road can create very low pressure, enough to lift the manhole cover. This happened, for example, in Montreal in 1990 at the race of sport prototypes - the cover, raised by one of the cars, hit the car following it, which started a fire.

This happened, for example, in Montreal in 1990 at the race of sport prototypes - the cover, raised by one of the cars, hit the car following it, which started a fire.

Refresh

Latest Comments

Valery → Construction of a "gigafactory" for the production of batteries has begun in Russia

Let's hope that Rosatom is not Rosnano

Valery → In December, the first prototype of the future orbital power plant

Vwill go into space times more efficient? Author, are you out of your mind?

Gesha → Maximum submersion depth of submarines

It is better to make bulkheads stronger. And the pressure will withstand everything.

Al → An infrared implant in the skull showed effectiveness in fighting brain cancer

I read about this method about 15 years ago, it was aimed at adenoma, but so far nothing more has been heard, although it seems to be very promising.