Roboze 3d printing

Roboze launches PRO series 3D printers and two new filaments - technical specifications and pricing

0Shares

Industrial 3D printer manufacturer Roboze has announced the launch of two new 3D printers, as well as two additional printing filaments.

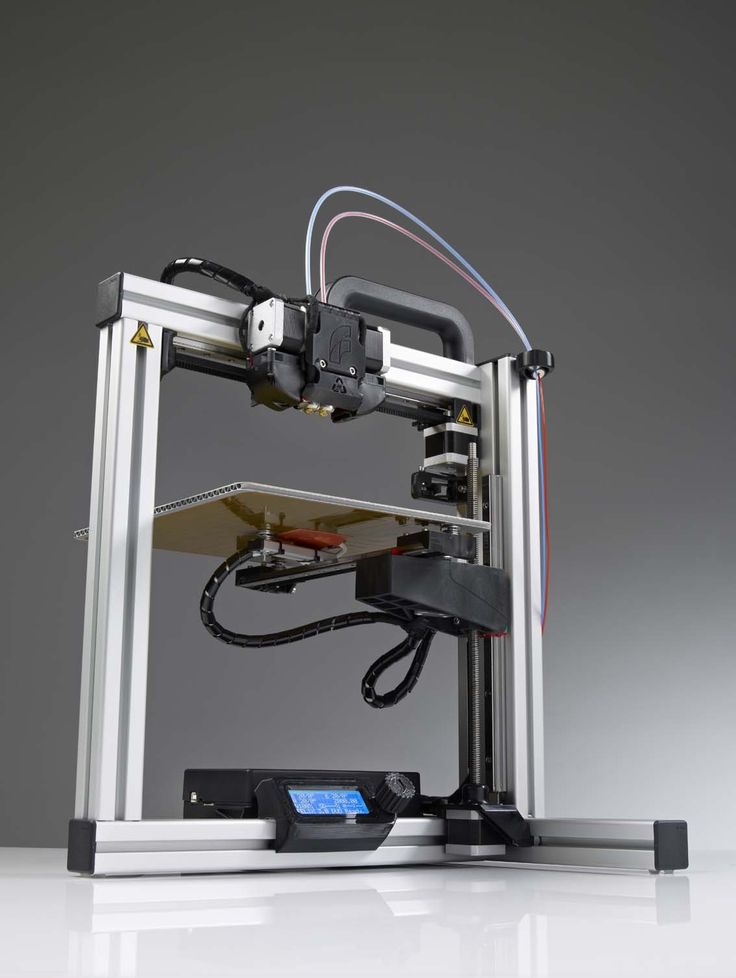

Replacing the older Roboze One product line, the new PRO series comprises the One PRO and Plus PRO machines, each operating on Roboze’s signature high-temperature FFF technology. The latest releases are designed primarily for functional prototyping and tooling applications with high-performance polymer and composite materials.

To complement the systems, the firm has also expanded its filament portfolio with the launch of Roboze PEKK and Roboze ToolingX CF.

“With the Roboze PRO series, production becomes stronger, faster and less expensive,” said Alessio Lorusso, founder and CEO of Roboze. “We have engineered the Professional solution with the sole aim of providing a performance-oriented solution for manufacturing companies, expanding application opportunities with accessible materials and industrial-grade hardware-software solutions. ”

The One PRO and Plus PRO

Both of the contenders in the PRO series aim to consolidate productivity, print quality, versatility, and cost-efficiency in one neat package. Starting with the Roboze One PRO, we have an enclosed 300 x 250 x 200mm build volume, a patented beltless movement system, and print precisions of down to just 15 microns. The system even leverages polymer films coating the build plate to improve part adhesion, and is compatible with Carbon PA, PP, ABS-ESD, Flex-TPU, and more.

On the other hand, we have the beefed-up Roboze Plus PRO, a true industrial-grade workhorse. Slightly larger with a build envelope of 300 x 250 x 220mm, the Plus PRO is designed to process the highest-performance engineering polymers on the market, including PEEK, Carbon PEEK, Carbon PA, and the firm’s new PEKK and ToolingX CF filaments.

One of the most noteworthy features of the PRO series is the previously unseen integration with the firm’s Prometheus slicing software. The comprehensive yet easy-to-use print preparation has now been graced with a new set of ‘UltraFAST’ printing profiles, enabling PRO 3D printer builds to run faster than ever before when using Carbon PA and ULTRA-PLA filaments. Roboze also intends to release high-speed print profiles for some of its other materials.

The comprehensive yet easy-to-use print preparation has now been graced with a new set of ‘UltraFAST’ printing profiles, enabling PRO 3D printer builds to run faster than ever before when using Carbon PA and ULTRA-PLA filaments. Roboze also intends to release high-speed print profiles for some of its other materials.

Additionally, Prometheus also now supports UltraQuality profiles for PEEK, Carbon PEEK, and ToolingX CF filaments, with a focus on part quality.

Roboze PEKK and ToolingX CF

Looking at the new materials, Roboze PEKK is a polyetherketonketone formulation defined by its thermal, mechanical, and chemical resistance, as well as its flame retardant properties. Suitable for applications such as custom aerospace test benches, the filament is tough, lends itself to isotropic parts, and is great for both high-stress and high-temperature conditions.

Similarly, Roboze ToolingX CF is a carbon-fiber reinforced composite combining lightweight, rigidity, excellent thermal stability, and self-extinguishing properties. The material also features chemical resistance, making it ideal for tooling components surrounded by organic acids, gasoline, oils, brake fluids, and coolants.

The material also features chemical resistance, making it ideal for tooling components surrounded by organic acids, gasoline, oils, brake fluids, and coolants.

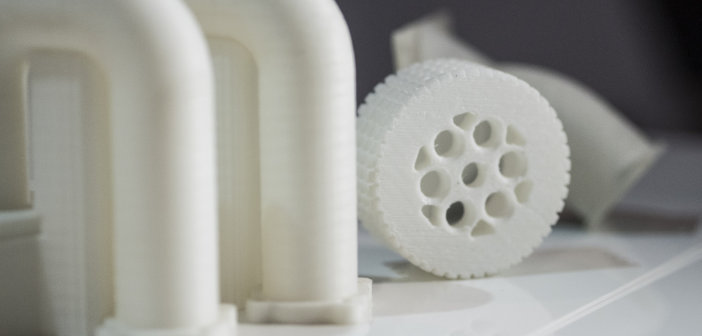

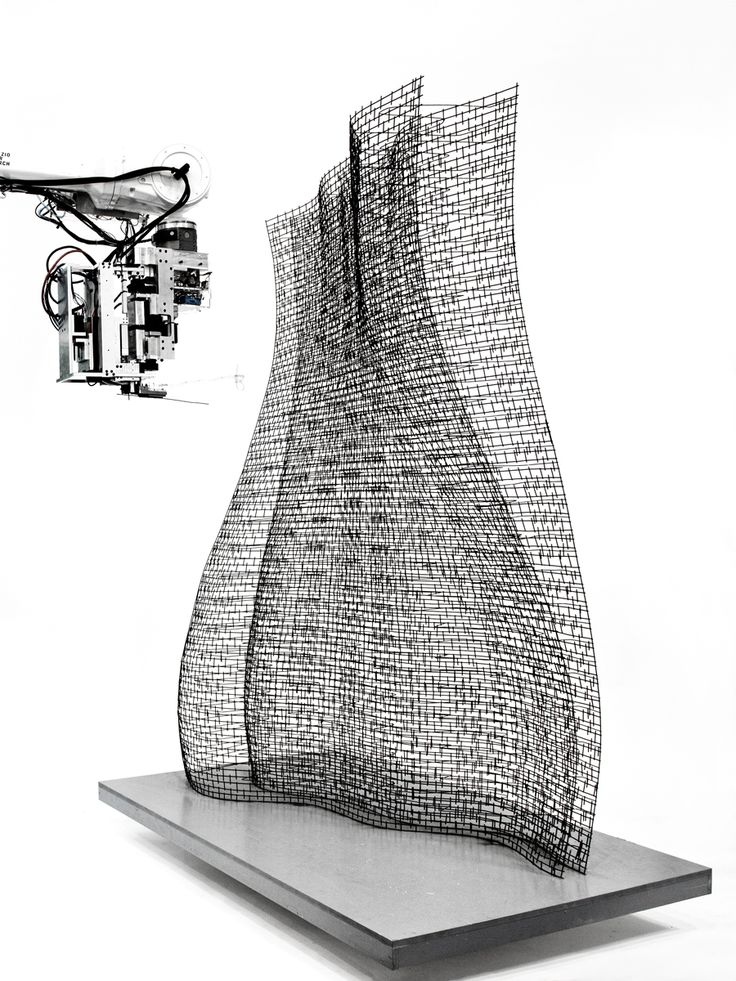

According to Roboze, a prime use case of ToolingX CF is the 3D printing of molds for paper pulp products. A printed mold would replace a part that would usually be manufactured out of aluminum, cutting costs by over 60% while enabling optimized geometries that would otherwise be impossible to fabricate.

Part 3D printed with ToolingX CF filament. Photo via Roboze.Technical specifications and pricing

Below are the technical specifications for the Roboze One PRO and Plus PRO 3D printers. Contact Roboze to receive a quote.

| One PRO | Plus PRO | |

| Build volume | 300 x 250 x 200mm | 300 x 250 x 220mm |

| Precision | 15 microns | 15 microns |

| System dimensions | 790 x 690 x 1660mm | 790 x 690 x 1910mm |

| Weight | 280kg | 300kg |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Roboze Plus PRO (left) and One PRO (right). Image via Roboze.

Tags Alessio Lorusso Prometheus Roboze Roboze One PRO Roboze Plus PRO ToolingX CF

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Siemens Partners with Roboze to Automate 3D Printing - 3DPrint.com

Siemens and Roboze have announced that they are collaborating to develop workflows dedicated to the industrialization of 3D printing. This includes an emphasis on expanding the use of the technology in energy, mobility, and aerospace. Though the exact nature of the agreement isn’t fully elucidated, it marks a significant shift for both firms.

Though the exact nature of the agreement isn’t fully elucidated, it marks a significant shift for both firms.

Siemens is the largest industrial manufacturer in Europe, with a storied history spanning nearly two centuries and annual revenues totaling €62.3 billion, as of 2021. In contrast, Roboze is a comparatively new firm, established in Italy in 2013. The company has since built itself up into a leader in industrial-grade material extrusion 3D printers, earning such customers as Ducati, GE, and the U.S. Army.

The partners do not exactly clarify their intent except to say that they will work together to “increase the productivity, competitiveness and efficiency of manufacturers that have embarked on the path to the future of industry.” They do mention focusing on “digitalization and automation projects”.

The Roboze Argo 500 3D printer. Image courtesy of Roboze.

“We have embarked on a path that sees us leading the way with Roboze to increase the production capacities of manufacturing companies around the world,” explains Tim Bell, Additive Manufacturing Business Manager at Siemens.

“We have experienced the potential of Roboze’s 3D printing firsthand, so much so that we have chosen to implement their ARGO 500 into our processes. I’m excited to be part of this project as I see ample strategic opportunities for the future of manufacturing.”

“We are excited to announce our new partnership with Siemens, which actually represents another step in our strategy to be closer to the industries we have served for years such as energy, mobility and aerospace.” says Francesco Pantaleone, VP of Business Development of Roboze. “For us, Siemens is an ideal partner to be even more present in these innovative sectors that want to start strategic digital transformation paths.”

Though the details are sparse, the development is a significant one for a number of reasons. To begin, we can see Siemens applying its motion control to Roboze equipment, as we’ve seen with other Siemens partnerships. Or it could be more geared to automation, for which Siemens has many solutions. It may be as simple as integrating Siemens PLM software into a Roboze 3D printing workflow, as occurred between Siemens and Nexa3D. Or it could mean automating various steps in the production chain, such as post-processing or conveyance of parts.

It may be as simple as integrating Siemens PLM software into a Roboze 3D printing workflow, as occurred between Siemens and Nexa3D. Or it could mean automating various steps in the production chain, such as post-processing or conveyance of parts.

For Roboze, having a partner in one of the world’s largest manufacturers obviously carries a lot of weight. The company has been steadily advancing its way in the industrial material extrusion space, of which Stratasys is the market leader. However, with Siemens as a customer and collaborator, it could begin to overtake the extrusion stalwart.

Roboze 3D printed parts for space applications.

This is especially true because Siemens is, or was previously, a Stratasys customer. Siemens Mobility has so far used Stratasys machines to 3D print spare parts for its growing rail repair program. If the multinational decides to play favorites and choose Roboze, it could indicate an important loss for Stratasys. However, because Siemens Mobility is a separately managed company, it’s possible that the different divisions have their own agendas.

Additionally, Siemens Energy, which was recently spun out into its own company, has its own additive agenda. The company just launched a 3D printing network called MakerVerse. This could significantly expand its impact in the service bureau space, previously limited to its Materials Solutions 3D printing service. Again, this business operates separately from the larger Siemens conglomerate, but we can imagine some crossover in terms of shareholders.

So, could Siemens help build Roboze up to the point that it competes successfully with Stratasys and then acquire it, like it did with Materials Solutions? Or is it simply content to making Roboze technology more suited to its own production needs? As the partnership advances, hopefully we’ll have a better idea of what the future holds.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: automation • partnerships • plastic 3d printing • polymer 3D printing • roboze • Siemens

Please enable JavaScript to view the comments powered by Disqus.

3D Roboze Printers - Printing high -temperature matheirans

When buying a 3D printer Discount on plastic and polymers up to 10%

Presented 3 goods

Sort:-

- in terms of popularity

- prices: cheaper 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 Prices: more expensive

- Show 24

- Show 24

- Show

Price on request

on order

Number

Number

In the favorites

Compare

Quick View

Roboze

3D Roboze One Printer +400

9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 2 4 out of 5

(1 review)

On order

- Print technology - FDM

- Print material - Plastic

- Print area - 200x200x200

Price on request

on order

Number

Number

In the favorites

Compare

Quick View

Roboze

3D 3D 3D 3D 3D 500

9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9 out of 5

(1 review)

On order

- Print technology - FDM

- Print material - Plastic

- Print area - 500x500x500

Price on request

On order

Quantity

Quantity

The Italian company Roboze (Roboze) offers three models of 3D printers to the international market: Argo 500, Roboze One and One +400.

All devices are designed and manufactured in a factory in Europe, where every step of production is closely monitored. This and the use of our own design developments make Roboze printers reliable and high-quality devices for volumetric printing.

All devices are designed and manufactured in a factory in Europe, where every step of production is closely monitored. This and the use of our own design developments make Roboze printers reliable and high-quality devices for volumetric printing. Read more…

Benefits of Roboze equipment

- The company has completely abandoned the use of drive belts. The mechanism works on a rack and pinion, which breaks much less often and lasts much longer.

- This mechanism allows frequent repetition of movements, which improves the quality of the final products.

- Low noise and vibration.

- A wide range of plastics that can be used for 3D modeling. For example, lightweight CARBON PA has good strength characteristics and is suitable for printing durable 3D objects with light weight. Polyetherimide is used to make products for the dental, medical and food industries, while ASA technopolymer makes ideal 3D models for the automotive industry.

Roboze One provides versatile 3D printing.

The maximum printing temperature reaches 300 degrees, which significantly expands the list of materials used (up to 10 different plastics and composites). Thanks to the advanced ventilation system, printing is completely safe. Tasks for additive manufacturing are set using the touch screen.

The maximum printing temperature reaches 300 degrees, which significantly expands the list of materials used (up to 10 different plastics and composites). Thanks to the advanced ventilation system, printing is completely safe. Tasks for additive manufacturing are set using the touch screen. Roboze One +400 is the professional version for 3D prototyping. In it, the maximum printing temperature already reaches 400 degrees, which allows the use of more plastics. Due to this, this device is actively used in various industries. A metal extruder prints two different materials at the same time.

3DMALL offers a wide range of 3D scanning and printing products. In stock and on order there are printers, scanners, pens, manipulators, consumables and spare parts from manufacturers from Russia and Europe: Imprinta, Shining 3D, Wuhan CTS, Zenit, Photocentric and many others. Printers work on modern technologies FDM, FFF, SLA, DLP and PolyJet. All products are certified and delivered in Moscow (Moscow time) and the Russian Federation.

Overview of Roboze 3D printers

What is it?

Roboze is a company that makes and sells 3D printers. The company's lineup now includes two printers - Roboze One and Roboze One + 400.

Another Chinese printer?

Roboze is an Italian company that designs and manufactures its printers in Europe. The company's headquarters is located in Bari, a beautiful seaside town on the Adriatic Sea.

What is the difference between Roboze One and Roboze One + 400?

Roboze One

Roboze One is a personal printer with improved printing accuracy. High accuracy and repeatability of movements is achieved due to the rejection of belt drives, which are not in the printer (all drives are on a rack and pinion gear).

The printer's extruder maintains temperatures up to 300 degrees Celsius, heating the printing table up to 100 degrees, which ensures a large number of materials used. The printing accuracy is 25 microns (0.025 mm) and the print area size is 280 x 220 x 200 mm.

Galvanized steel chassis, 6082 and AISI 303 stainless steel internals.

The extruder is constructed entirely from stainless steel, which increases its life by two and a half times.

Roboze One + 400Roboze One + 400 is the industrial version of Roboze One. Its main difference from the “younger brother” is the extruder temperature increased to 400 degrees and the printing table up to 150 degrees, in connection with this, the ability to print with high-viscosity industrial materials that require high temperatures and create working prototypes of products from them.

The model can be equipped with two extruders, for printing two different materials at the same time.

Main control - 3.

5” touch screen.

5” touch screen. Printing accuracy is ensured by the same concept as in the junior model - beltless rack and pinion.

The resolution of an industrial printer, however, is two times less than that of its personal counterpart - only 50 microns. And the size of the print area is slightly smaller - 200x200x200 mm. But even with such characteristics, the print quality does not disappoint.

What do they print with?

Roboze printers print with any synthetic material used for FDM printing, including highly abrasive and high temperature extrusions.

Below are the materials normally used for printing on Roboze.

Carbon PA

CARBON PA consists of polyamide with 20% carbon fibers. The material has a high tensile modulus, low flammability, resistance to moisture, low specific gravity and high strength, which makes it possible to print parts from it to replace metal ones, reducing the weight of the final products.

Material melting point - 178°C, pour point - 149, nozzle temperature when printing - 260, platforms - 85-98.

Both Roboze printers print with this material.

PEI

Polyetherimide is a functional engineering polymer due to its physical and chemical properties such as resistance to hydrolysis and acid solutions. Products made from it can be used at elevated temperatures and retain their mechanical properties, for example, after repeated processing in an autoclave, which allows them to be used in the food and medical industries.

Nozzle operating temperature when printing with this material - 400 degrees Celsius, table temperature - 180.

Printed on Roboze One + 400.

PEEK

such a range of conditions that allows it to be used in the food, aerospace, automotive, defense, electronics and semiconductor industries, the oil and gas industry, nuclear and hydropower, as well as in the creation of space technology, medical and cable products.

Melting point 340°C, solidifies at 145°C.

PEEK products can be used temporarily at 300°C, permanently in the range from -60°C to 240°C.

Printed on Roboze One + 400.

ABS-ESD

ABS-ESD is an ABS-based material whose main feature is electrostatic safety. Products made from this material do not accumulate static charge on the surface and have a very high resistance, which makes them suitable for use in the electronics industry and laboratories.

Produced on the basis of ABS plastic, which is processed according to a certain technology and supplemented with special additives.

Glass transition occurs at 105°C.

Can be used in both printers.

PMMA

PMMA is a transparent filament made of polymethyl methacrylate, also known as plexiglass. It is used in many areas, including the optical industry and the medical industry.

Print head temperature - 260, bed - 100°C, layer thickness - 0.

2-0.1 mm.

2-0.1 mm. Printed on Roboze One + 400.

Functional

Functional is a durable Nylon 12 print filament. It is recommended for printing components that are subject to increased stress and wear.

Print head heating - 250°C, platforms - 98°C.

Can be used in both printers.

Strong

Strong is another ABS-based plastic that has improved mechanical properties and is certified after practical strength tests. Natural color - black, with the addition of dye - any.

Nozzle temperature - 250°C, platforms - 85-90°C.

Can be used in both printers.

Flex

Flex is a flexible synthetic material based on thermoplastic polyurethane. It has high resistance to abrasion, wear and tear. It is mainly used in cases where it is necessary to make a soft part - seals, gaskets, decorative products.

Print media heating - 240°C, platforms - 66°C.

Can be used in both printers.

Ultra

Material designed to print objects to precise dimensions. Consists of PLA and other additives that set its properties. It is used for printing prototypes and small batches of finished products in cases where exact observance of the form is necessary.

Print media heating - 220°C, platforms - 60°C.

Can be used in both printers.

PC

Polycarbonate is a well-known material that needs no introduction. High resistance to temperature extremes and shock loads made it very popular in the industry long before the advent of 3D printing.

Nozzle temperature - 310°C, table temperature - 100°C.

Printable on Roboze One + 400.

PC-ABS

Polycarbonate/ABS blend filament. Combines the mechanical properties of ABS and the thermal properties of PC. When printed, it gives a beautiful glossy surface, it is used in the repair and tuning of cars.

Nozzle temperature - 270°C, table temperature - 100°C.

Can be used in both printers.

ASA

ASA - plastic with high hardness and rigidity. It tolerates ultraviolet light, is stable at elevated temperatures. It is used in car repair and the creation of products resistant to weather influences. With the new Roboze One, it is able to surprise with high quality printouts without post-processing, as its properties are optimal for use with a small nozzle diameter.

For printing on Roboze One.

Nylon-6

Nylon-6 is a polyamide with high resistance to continuous mechanical stress. Compared to nylon-12 (Roboze Functional), it has more compressive strength but less stretch, and slightly more impact strength.

For printing on Roboze One.

ABS-HD

ABS plastic with powder additives that improve the appearance of the surface while maintaining the high mechanical properties of ABS.

Recommended for obtaining prints with an optimal balance of strength and appearance.

Recommended for obtaining prints with an optimal balance of strength and appearance. For printing on Roboze One.

Why are Roboze printers interesting?

Both printers are interesting primarily for their print quality - the mechanical rigidity and accuracy of the rack and pinion ensures high repeatability of movements, and a thorough approach to the manufacture of printers and the quality of materials available for their production complete the picture.

It is indicative that the quality of the Italian printer has already been appreciated by such giants as GE and the Israeli defense company Cyclone Ltd.

General Electric purchased a Roboze One + 400 printer for the Knoll Atomic Energy Laboratory in Niskeyoon, New York, and Cyclone, a subsidiary of the defense concern Elbit Systems, bought the same machine with two extruders to work on their projects.

In both cases, the decisive criterion for choosing a supplier was that Roboze printers are one of the very few 3D printers that can successfully print with tough, refractory engineering polymers.

Learn more