3D scanner for cnc router

3D Scanning for CNC - CAD / CAM Services Inc. -

Scanning for Engineering and CNC

The world is a better place in the one-off part business. With new technologies, better scanners (both arms and 3D scanners), and smarter software – we now have an efficient and cost-effective way to scan items directly into CNC machines for engineering.

Consider this Scanning for CNC Issue:

Discontinued parts for 3D scanning and CNC

How do you take a discontinued part and create a duplicate of it?

Or, how do you create several copies of that same part?

Think of the first step in the Reverse Engineering process.

In the past, this has been an expensive, slow, and inaccurate process.

CAD / CAM Services Scans for CNC Engineering

Today’s Solution: Scanning for Engineering & CNC

Hexagon TIGO SF CMM 3D Scanning Station

Step 1: Generate a Point Cloud

of the Part or Object

There are two main approaches:

1) Arms with sensors attached, that can touch or scan any position on that part that you can see

2) 3D scanning.

Mitutoyo CMM machine 3D Scan Station

Types of CMM Machines

CMM machines start at $ 5-10,000 and can easily hit $ 130,000 or more depending upon the size and accuracy requirements.

Vendors like Mitutoyo, Hexagon and Zeiss are serious vendors in the CMM marketplace.

At best CMM machines can capture about 500mm per second.

Zeiss MMZ G CMM 3D Scanner

zCat Portable 3D Scanner

The zCAT 3D scanner is targeted at shop-floor measurement. it costs about $40,000.

Most significant shop-floor measurement innovations have been either portable, or probing systems built into CNC machine tools—also known as on-machine verification or OMV.

The zCAT advances the technology of portable measuring arms by automating repetitive part measurement with significantly better accuracy.

zCAT comes with a five-hour lithium-ion battery. It needs no electrical connection, therefor has no cables to stumble over. Another benefit is that zCAT doesn’t use air bearings, so there are no air hoses underfoot.

Another benefit is that zCAT doesn’t use air bearings, so there are no air hoses underfoot.

Arm Scanning with CMM

Arms with CMM have been the industry standard for years. They are mostly accurate and stable.

One advantage of arm scanners is that you can be very selective as to what section you wish to have tooled.

Think of a specific fitting / opening you need to mimic or fit to.

3D Scanning with Faro Scanner

With these types of scanners, you have the ability to capture specific sections.

Faro arm scanners are the industry standard and market leader here.

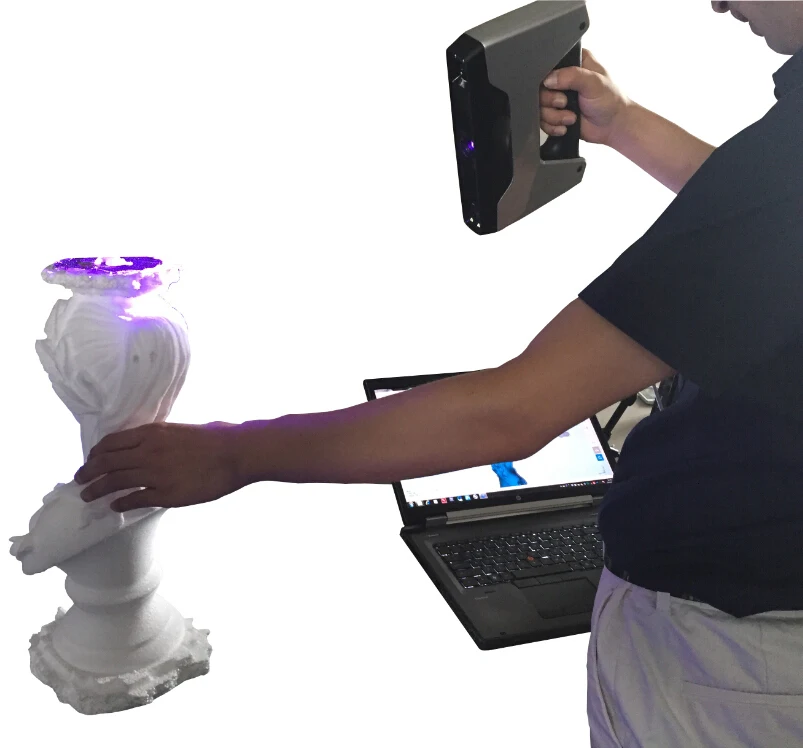

Handheld 3D Scanners

This category of scanners is much more affordable, quick and accurate.

With the passing of a laser scan, we can quickly and accurately capture the surface data of that part or object.

It might take several swipes/scans of that object to capture it in its entirety, but this scan will be worth its weight in gold.

artec-leo-2

Good industry handheld 3D scanners are are priced approximately $10-30,000.

We sell and use Artec hand helds, but Creoform are also excellent in this class.

The new Artec Leo can capture millions of points a second, which is rated at 80 frames per second.

Another huge benefit of the newer class of hand held scanners is portability. These hand held scanners can be run from a laptop.

Creoform White Light Hand Held 3D Scanner

Step 2- Point Cloud Data Assembly Required

3D Scanning with Point Cloud Generation and Assembly

What most suppliers tend to gloss over is the assembly of these new point clouds.

A point cloud is nothing more than a zillion 3D points in space that look like your part.

The wonderful news about this process is, software is now smart enough to greatly assist us in this automated assembly.

Point Cloud Density and Sub Density Map Piping

This results in a huge increase in productivity than the past.

In the past we had to use markers – targets, so a scanner knew when the next scan section starts and stops; along with knowing what to assemble to.

With small parts you can assemble the scan sections in just a few minutes, but on large buildings it can take 10-20 hours of computer processing.

Step 3- Turn Point Cloud into a Mesh

CAD Mesh of a Part

Now that we have an assembled and clean point cloud. It is almost ready to turn it over to the CNC machine.

But we must now turn that clean and assembled point cloud into a mesh – a surface.

Some 3D scanning vendors include this feature, but most production houses use a higher end version called GeoMagic Wrap for this task.

Here we can smooth out surfaces, define how tight we want the mesh to be, check for hot-spots and inconsistencies, and even provide quality control across multiple parts to make sure they are within the production specifications.

geomagic turbine design

Here we generally output to a generic *.stl file, but HOPS files are also suitable for most NC machines.

At this stage, these are not CAD Files yet, but clean, mesh point cloud files.

Except for cleaning up a mesh, you really don’t edit these mesh files very much.

Within reason, it is a WYSWIG type file.

the good the bad and the ugly

The Good, The Bad and The Ugly

Further down the page we will discuss building a full CAD model. CAD modeling is useful if you are going to modify or edit a part.

For a straight forward scan to print or CNC approach, you don’t need that. You just need to make a copy of something.

At this point we can now simply drop the *.stl file into https://www.cadcam.org/3d-cad-services/3d-printing-2/, get an instant quote, and directly print this for you in a day or two.

Or, you are now ready for your CNC machine and MasterCAM software.

Don’t underestimate the fact, that some assembly will be required for your part.

You would be amazed how often we see missing sections of your part / object that where missed during the actual scan.

How can your CNC machine, even try to machine something that is undefined?

On a recent project– we cleaned up a huge mesh file on a very large building. The point cloud contained ½ billion points.

The point cloud contained ½ billion points.

Taking all of this into account, you truly get what you pay for.

Don’t expect a $ 3,000 approach to create Aerospace accurate parts. It won’t happen.

Industrial quality 3D scanners with good quality software are a $ 30-50,000 investment.

The industry leader RX Solutions DeskTom/EasyTom/EasyTom XL and all the way up to the UltraTom range in price from $ 100,000 to $ 1m systems.

The better scanners give you a better product. We utilize two RX Solutions CT scanners for our 3D scanning.

The Solution

In our business, one size does not fit all. We have learned our lesson with cheaper, less production arms and scanners.

We have also developed a clean process to make sure we know how to scan all of your surfaces, without missing any data.

aluminum 3D scanning

On shinny parts like aluminum, we often have to spray them with an anti-glare (3D Scan Spray) to reduce the gloss.

Otherwise, the scanners laser light would reflect off the surface.

Don’t worry, it is temporary and only useful for about an hour!

Faro Focus 3D Measurement & Imaging

CAD/ CAM Services utilizes CMM, CMM arms, and high-end 3D laser scanners, including some with white or blue light.

Industrial CT Scanner

We also utilize two types of industrial CT scanners to capture your meteorology and surface data.

This even allows us to look inside of your objects for voids, and surfaces you cannot see from an outside appearance.

FARO-Focus-M70-Laser Scanner- Scanning Pipes

All of our software is current, with experienced staff who knows how to operate it for excellent results.

3D scanning can be a science. It is something you learn with practice.

Faro Focus Laser Scanner 1

Regardless of what the scanning sales people say, they are only as good as the operator.

That is why after 30 years in business, customers keep coming back to CAD/CAM Services.

CAD/CAM Services Provides:

- Artec 3D scanner sales and rentals

- High-end 3D scanning services

- Point cloud to mesh creation

- And full CAD model and assembly

V6 Twin Turbo Engine 3D CAD Model Assembly

We now have an efficient & cost effective way to scan items directly into CNC machines for engineering.

Click now or call us at 800-938-SCAN (7226)

Request a Quote

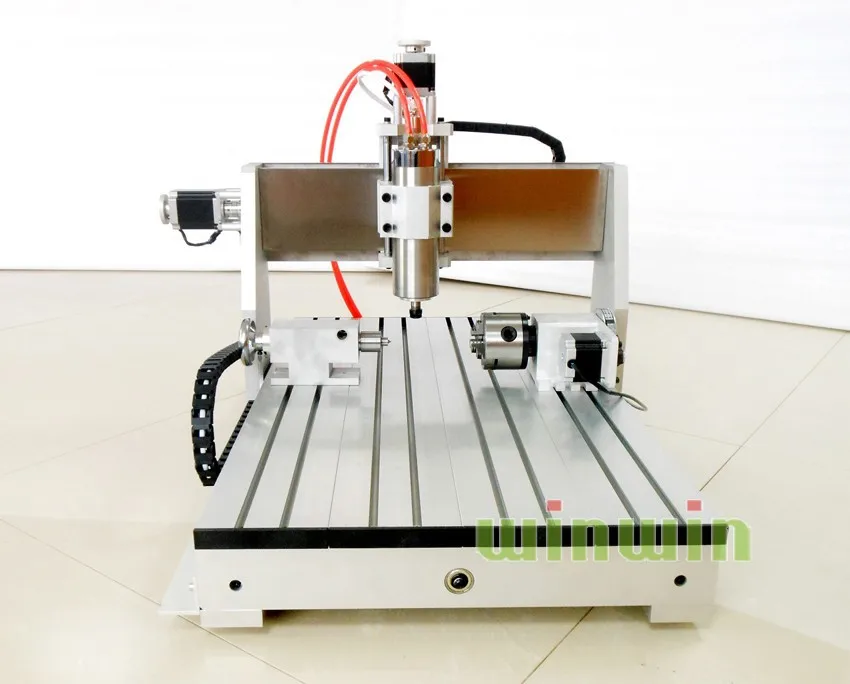

3d scanner for cnc wood router

High quality portable shining 3d body scanner , 3d scanner for cnc router

Features:

- 3D scanner with 2 Camera

- 1.

3 million Gemerny Camera technolog(can up to 2 millon work).

3 million Gemerny Camera technolog(can up to 2 millon work). - 12mm*2 Japan Lens.

- Japan light system.

- USA Tripod.

- USB cable.

- Softdog.

- Six Angle wrench 2 sets.

- Calibration target.

- Calibration point.

- Data CD.

- Scan software(3d-haohankeji).

- Edit software(Geomagic Studio 2012).

Parameters:

| Products Status | Stock |

| Type | Flatbed Scanner |

| Scan Element Type | CCD |

| Colour Depth | 48 Bit |

| Interface Type | COM, USB |

| Max Paper Size | 400mm- 1500mm |

| Optical Resolution | 0.015 |

| Scan Speed | 200 Scans/sec |

| Brand Name | BLUE ELEPHANT |

| Model Number | ELE-1M-12 |

| Place of Origin | Shandong, China |

| Product name | 3d scanner |

| Working area | 400*300mm |

| Object Size | 400mm-1500mm |

| Color | Black |

| Light Source | White light |

| Scanning time | 5s |

| Operation system | Windows98/NT/2000/XP |

| Data Output Format | *ASC; *PLY; S-TL; OBJ; IGES |

PS:All the working area and specifications can be customized according to your requests.

More about Price & Details? Inquiry Now!

About

- Company Introduction

- Contact us

- Visit Factory

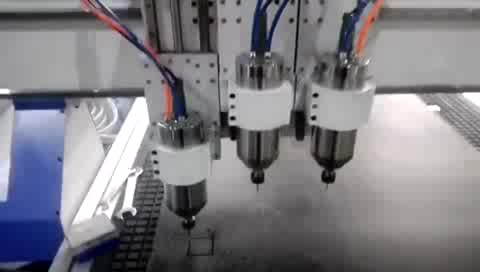

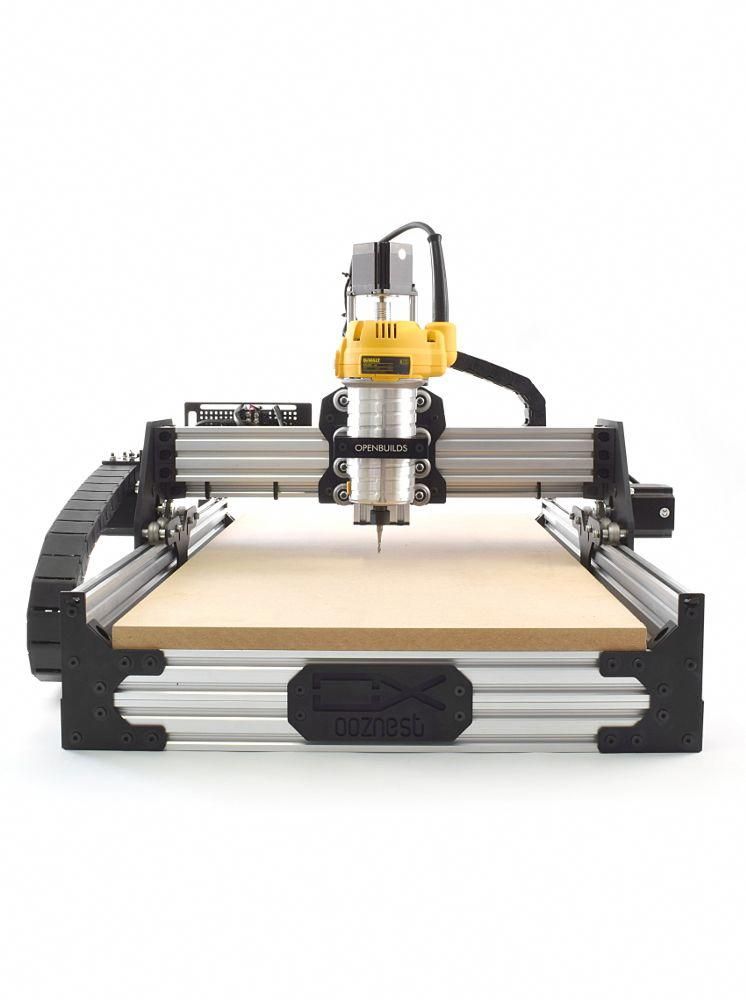

ELE1530 Linear ATC Wood Wook Cnc Router Machine ELE1530 Atc Wood Cnc Router Can be Costumised

how to install, characteristics, operation features

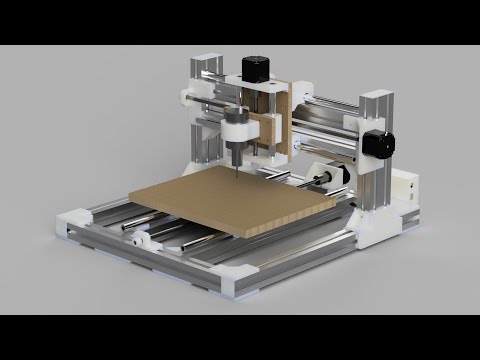

3D scanner for CNC provides a wide range of functions that are performed by numerical control. Used in many industries, from medicine to reverse engineering. With its help, you can build a three-dimensional model of a wide variety of parts as accurately as possible.

Contents:

- 1 What is a 3D CNC Scanner?

- 2 TTX

- 3 Construction

- 4 Applications

- 5 Step by step installation instructions

- 6 Pros and cons

What is a 3D CNC Scanner?

Scanners of this type allow you to recreate the correctness of the digitized part, which occurs by measuring the geometry of specific parts. It immediately provides an answer to the question: "Does the new component correspond to the original parameters of the product?". Such control of the manufactured goods reduces the risk of defective items. And also to minimize inaccuracies in the sizes.

It immediately provides an answer to the question: "Does the new component correspond to the original parameters of the product?". Such control of the manufactured goods reduces the risk of defective items. And also to minimize inaccuracies in the sizes.

The device helps to reproduce complex details. Even if they are sold manually from soft raw materials (plasticine is a good example). A similar method is actively used in the production of various decor. More responsible tasks lie ahead for industrial 3D scanners for CNC. Models of this configuration are distinguished by the accuracy and speed of their scanning.

performance characteristics

Sensors built into CNC scanners have the following performance characteristics:

- measurement from 5 to 1200 millimeters;

- maximum value measurement frequency 16150 Hz.

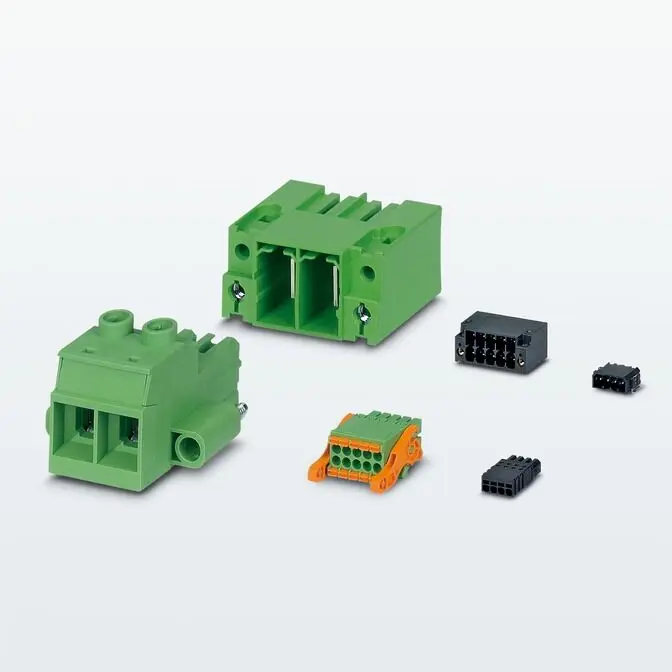

Digital interfaces are:

- Virtual COM port.

- Ethernet 100 Mb.

- RS232 and RS485.

- CAN 2.0A, 2.0B.

Analog inputs for programming:

- .5mA (load ≤ 2800Ω)

- .10mA (Load ≤ 1400Ω)

- .20mA (Load ≤ 700Ω)

- .20mA (Load ≤ 700Ω)

And the following characteristics are also provided:

- several modes of data buffering, namely by synchronizing signal or time;

- built-in buffer for storing up to 40 thousand measurements;

- it is possible to connect positioning signals for up to two axes;

- has four galvanic inputs and two outputs;

- many models are IP67 rated;

- supply voltage is five volts;

- stepper motor signal buffering is present.

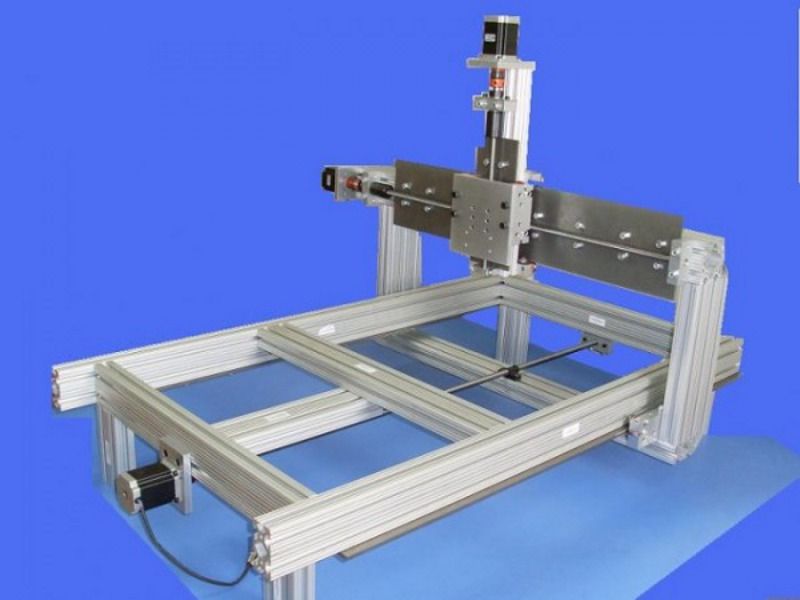

Construction

With regard to construction, this device is divided into three subsections. They differ in the specifics of the mechanism and are expressed in the following forms:

- System with fixed components.

And also with high precision angle type sensor. The measuring arm is positioned at the end, providing mathematical calculations that are directly related to the rotation of the wrist. Suitable for probing interior or recessed spaces with several small inlets.

And also with high precision angle type sensor. The measuring arm is positioned at the end, providing mathematical calculations that are directly related to the rotation of the wrist. Suitable for probing interior or recessed spaces with several small inlets. - Inside the carriage is a perpendicular measuring arm. During the sliding of the hand on the carriage, axial displacement occurs. The optimal system is used for convex curves or flat surfaces.

- The third form implies a combination of the two above. So the manipulator is combined with the carriage. Allows you to get more voluminous and large-scale objects that have internal planes. Or overlap one another with a surface.

Applications

The use of the 3D CNC scanner is spreading across multiple industries at the same time. Professional equipment belongs to different fields of activity: science, business, medicine, production and design. The following usage solutions are common:

- Automotive.

Designing cars or motorcycles. Their repair and tuning.

Designing cars or motorcycles. Their repair and tuning. - Architecture. Scanning entire buildings, facades or individual rooms.

- Media sphere, advertising and design. Allows you to produce the kind of material. Develop graphics for advertising or design.

- Dentistry, medicine. Precise scanning of various parts of the body. Preparation of prostheses and dental implants.

- Oil and gas industry. Monitoring the wear of a pipe system or scanning areas for their laying.

- Science and education. Solving various problems for educational purposes. Scientific measurements, preparation of constructors and designers to work with large design tasks.

- Industry. production tasks. Design development. Quality control of manufactured products. Precise control over the dimensions of components. More simplified assembly of overall equipment and mechanisms.

- Engineering. Accurate marking for further design and preparation of design documentation for production work.

Step by step installation instructions

- Sensor installation. On the machine, you need to install the sensor so that it has the ability to move simultaneously on two axes. They must be mutually perpendicular. More often this is the situation with the X and Y axes.

- Connecting the sensor to the machine. There are two options for this step. The first involves working with signals on the CNC controller. The second works with quadrature axes A and B.

- Power connection. Cheaper modifications are powered exclusively from the USB port. Industrial sensors can be provided not only by this. But also the power supply. Moreover, power sensors have a voltage of up to five volts. It is also possible to consider the option of a galvanically isolated sensor power supply (9–36 volts).

- Connect the sensor to the computer.

To scan qualitatively, connect the sensor together with the USB virtual COM port. You can also use the Ethernet port. The latter option has the advantage of a higher exchange rate. For USB, the advantage is that there is no need for an external power supply. But the cable length will need at least five meters, according to the USB specification.

To scan qualitatively, connect the sensor together with the USB virtual COM port. You can also use the Ethernet port. The latter option has the advantage of a higher exchange rate. For USB, the advantage is that there is no need for an external power supply. But the cable length will need at least five meters, according to the USB specification. - Establish communication with the encoder. Run the installed program and confirm the connection with the "Connect" button. After that, you can go to the connection settings by selecting the "RS232/RS485/USB" tab. This is important for those wishing to work via aorta COM or USB. You can also select "Ethernet" if you plan to operate via Ethernet.

Pros and Cons

| Pros | Drawbacks |

|---|---|

| Good value for money. The price depends on the performance characteristics. | Difficulty setting. |

| High precision. In the production of parts, every millimeter is controlled. Allows you to work with complex geometry. | Regular inspection required. |

| Fully autonomous operation can be configured. | |

| Easy to use once you understand the settings. Instructions are included with the models. |

There are many more key benefits. This can guarantee the popularity of application in all industries. From medicine to engineering.

Share on social networks

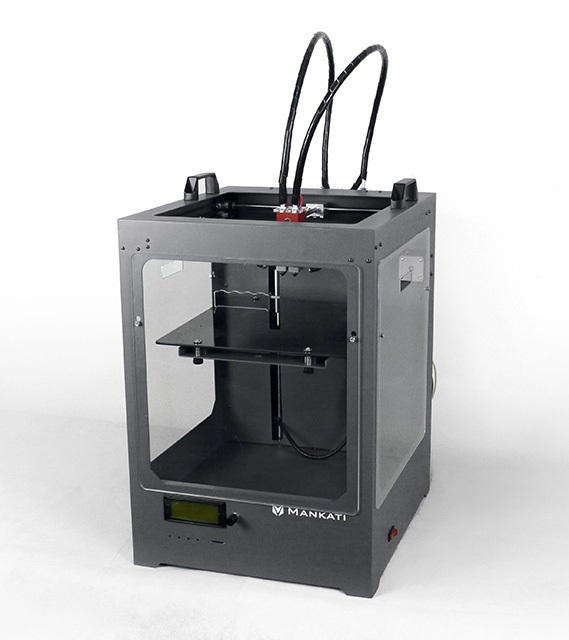

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment.

There are cheaper models, and there are professional options. The second option is used in the industrial sector. Cheaper options are a solution for advertising and non-standard small tasks.

There are cheaper models, and there are professional options. The second option is used in the industrial sector. Cheaper options are a solution for advertising and non-standard small tasks.