3D printer history

When Was 3D Printing Invented? The History of 3D Printing -

May 15, 2020

When you first heard the words “3D printing” did you imagine a super futuristic technology, like in the movies but, when was it really invented?

While the term 3D printing may sound like something you’d expect to hear in a science fiction novel, the history of 3D printing, also known as additive manufacturing, is longer than you might think.

Keep reading to learn about the history of 3D printing, and our BCN3D predictions on where we see this technology going in the future.

The History of 3D Printing in 3 PhasesThe 1980s: When Was 3D Printing Invented?The first documented iterations of 3D printing can be traced back to the early 1980s in Japan. In 1981, Hideo Kodama was trying to find a way to develop a rapid prototyping system. He came up with a layer-by-layer approach for manufacturing, using a photosensitive resin that was polymerized by UV light.

Although Kodama was unable to file the patent requirement of this technology, he is most often credited as being the first inventor of this manufacturing system, which is an early version of the modern SLA machine.

Across the world a few years later, a trio of French researchers was also seeking to create a rapid prototyping machine. Instead of resin, they sought to create a system that cured liquid monomers into solids by using a laser.

Similar to Kodama, they were unable to file a patent for this technology, but they are still credited with coming up with the system.

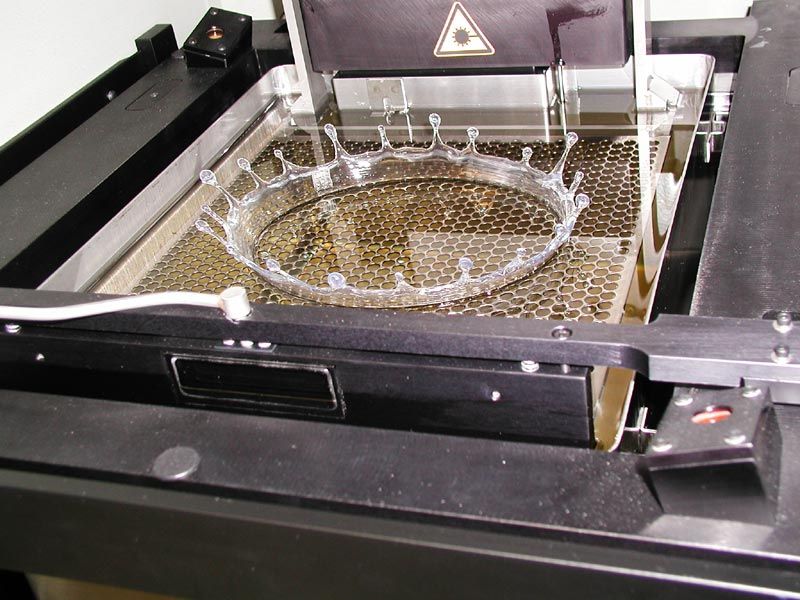

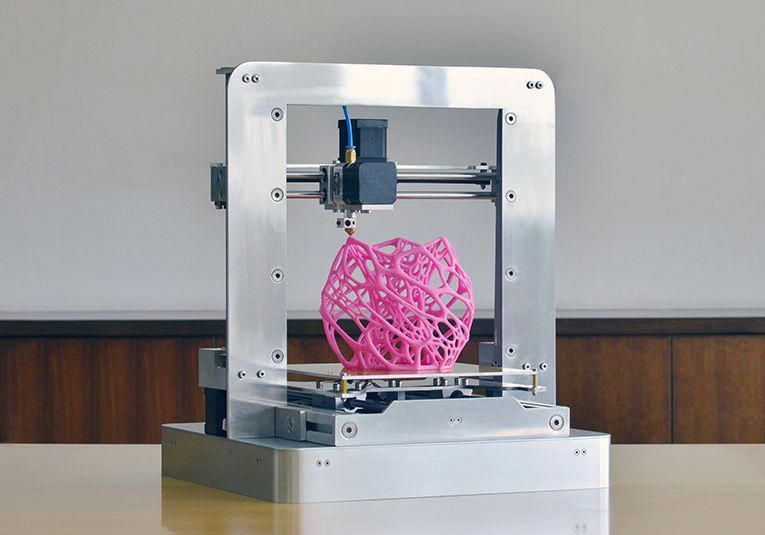

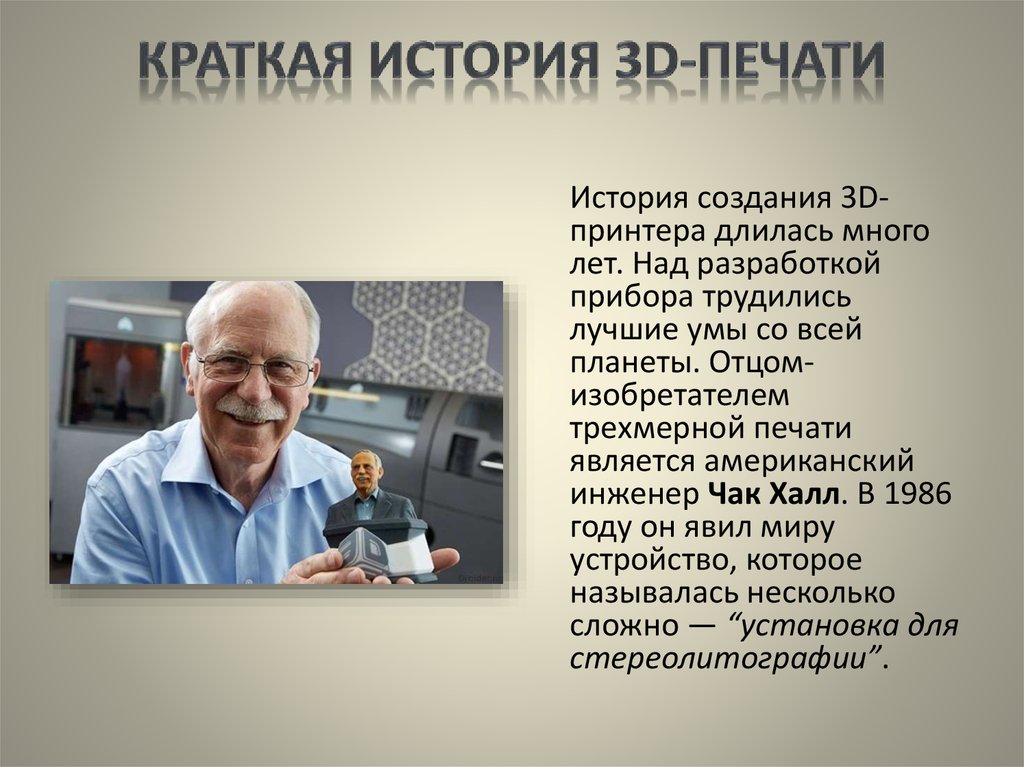

That same year, Charles Hull, filed the first patent for Stereolithography (SLA). An American furniture builder who was frustrated with not being able to easily create small custom parts, Hull developed a system for creating 3D models by curing photosensitive resin layer by layer.

In 1986 he submitted his patent application for the technology, and in 1988 he went on to found the 3D Systems Corporation. The first commercial SLA 3D printer, the SLA-1, was released by his company in 1988.

The first commercial SLA 3D printer, the SLA-1, was released by his company in 1988.

But SLA wasn’t the only additive manufacturing process being explored during this time.

In 1988, Carl Deckard at the University of Texas filed the patent for Selective Laser Sintering (SLS) technology. This system fused powders, instead of liquid, using a laser.

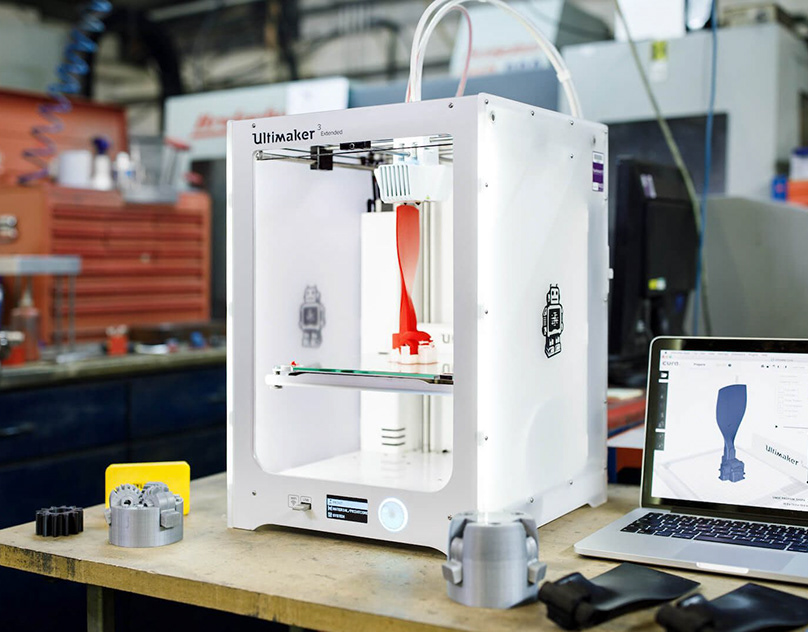

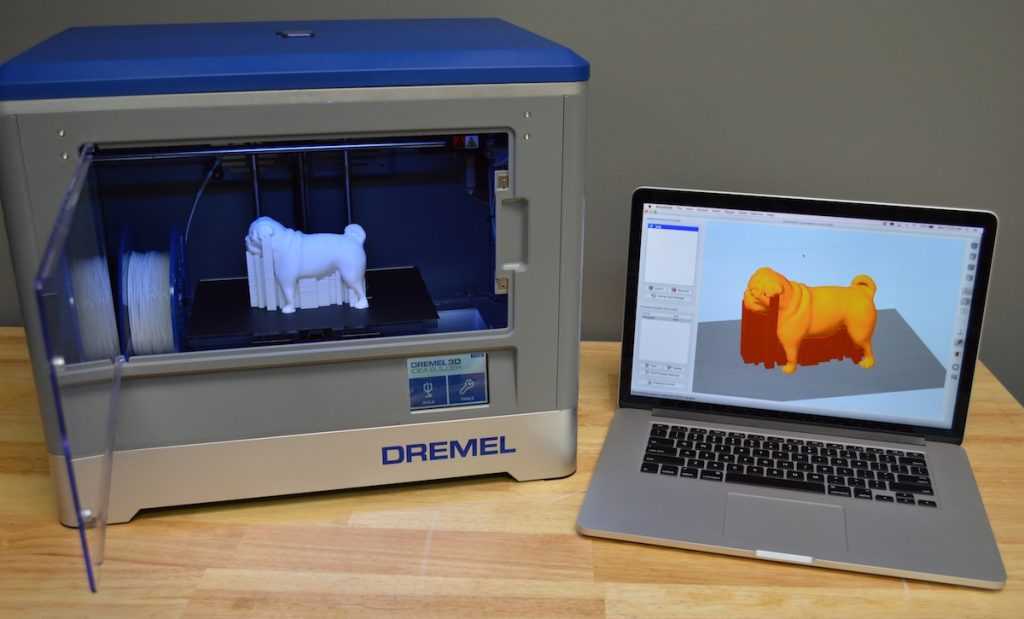

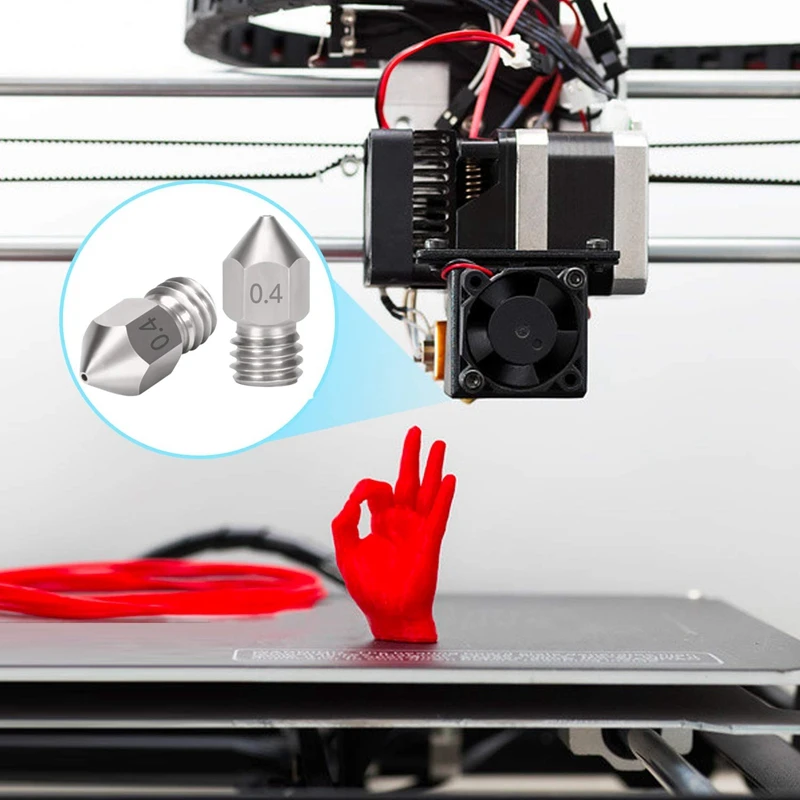

SLS fabrication machines in the Fundació CIM warehouseFused Deposition Modeling (FDM) was also patented around the same time by Scott Crump. FDM, also called Fused Filament Fabrication, differs from SLS and SLA in that rather than using light, the filament is directly extruded from a heated nozzle. FFF technology has gone on to become the most common form of 3D printing we see today.

These three technologies are not the only types of 3D printing methods that exist. But, they are the three that serve as the building blocks that would lay the groundwork for the technology to grow and for the industry to be disrupted.

In the 90s, many companies and startups began popping up and experimenting with the different additive manufacturing technologies. In 2006, the first commercially available SLS printer was released, changing the game in terms of creating on-demand manufacturing of industrial parts.

CAD tools also became more available at this time, allowing people to develop 3D models on their computers. This is one of the most important tools in the early stages of creating a 3D print.

During this time, the machines were very different from those that we use now. They were difficult to use, expensive, and many of the final prints required a lot of post-processing. But innovations were happening every day and discoveries, methods, and practices were being refined and invented.

Then, in 2005, Open Source changed the game for 3D printing, giving people more access to this technology. Dr. Adrian Bowyer created the RepRap Project, which was an open-source initiative to create a 3D printer that could build another 3D printer, along with other 3D printed objects.

In 2008, the first prosthetic leg was printed, propelling 3D printing into the spotlight and introducing the term to millions across the globe.

Then, in 2009, the FDM patents filed in the 80s fell into the public domain, altering the history of 3D printing and opening the door for innovation. Because the technology was now more available to new companies and competition, the prices of 3D printers began to decrease and 3D printing became more and more accessible.

3D Printing NowIn the 2010s, the prices of 3D printers started to decline, making them available to the general public. Along with the lowering prices, the quality and ease of printing also increased.

The materials that printers use have also evolved. Now there are a variety of plastics and filaments that are widely available. Materials like Carbon Fiber and Glass Fiber can also be 3D printed. Some creatives are even experimenting with printing materials like chocolate or pasta!

Some creatives are even experimenting with printing materials like chocolate or pasta!

In 2019, the world’s largest functional 3D printed building was completed. 3D printing is now consistently used in developing hearing aids and other healthcare applications, and many industries and sectors have adopted the technology into their everyday workflow.

It’s safe to say that the history of 3D printing is still being written.

Innovations and ideas are created every day. We’re very excited to see what’s next!

It's Older Than You Think [Updated]

Published Date

Author Drew Turney- 3D printing has existed in concept since 1945 and in practice—however primitive—since 1971, proposing a faster and more efficient method of making things.

- Concurrent development of 3D-printing technology down to consumer use and up to enterprise use has realized the benefits of 3D printing in construction, architecture, design, manufacturing, and other industries.

- Continuing advancements in additive manufacturing technology and 3D-printable materials, especially new metal alloys, will contribute to further growth.

- In the future, look for new 3D-printing applications in the aerospace, electronics, medical, energy, and automotive industries.

What technology is 80 years old in theory, 40 years old in practice, and looks brand new? Believe it or not, it’s 3D printing.

Although the craze for desktop 3D printers began around 2010, when companies like MakerBot made investors and the media salivate, those in manufacturing know that the process—applying material onto a substrate to build up an object from a digital 3D design—goes back much further.

The first patent for a process called a Liquid Metal Recorder dates to the 1970s, but the idea is much older. In 1945, a prescient short story by Murray Leinster called “Things Pass By” describes the process of feeding “magnetronic plastics—the stuff they make houses and ships of nowadays—into this moving arm. It makes drawings in the air following drawings it scans with photo-cells. But plastic comes out of the end of the drawing arm and hardens as it comes.” What in Leinster’s day was science fiction soon became a reality.

Layers of Innovation: A 3D-Printing Timeline

1971–1999: The First 3D Printer Emerges

Inkjet technology was invented by the Teletype Corporation in the 1960s, a method of “pulling” a drop of material from a nozzle using electronics. It resulted in a device capable of printing up to 120 characters per second and ultimately paved the way for consumer desktop printing.

Teletype later experimented with melted wax as described in a 1971 patent belonging to Johannes F. Gottwald, whose idea was to output an object made of liquified metal that solidified into a shape predetermined by the inkjet’s movement upon each new layer. This device was the Liquid Metal Recorder, which is the basis of rapid prototyping and posited that “printing” could move beyond ink.

Gottwald, whose idea was to output an object made of liquified metal that solidified into a shape predetermined by the inkjet’s movement upon each new layer. This device was the Liquid Metal Recorder, which is the basis of rapid prototyping and posited that “printing” could move beyond ink.

Those were the baby steps into a territory called the material extrusion process, where thermoplastic is fed into a heated nozzle and laid upon an object one “slice” at a time in sequence—the same technique used in consumer desktop 3D printers. It’s speedy and cheap, but the materials (essentially rubbery plastic) aren’t good for much beyond model R2-D2s and racing cars.

Plans to print objects using liquified metal date to the 1970s, but practical metal additive manufacturing is much more recent—and will impact many more industries as new 3D-printable alloys become available.In 1980, Dr. Hideo Kodama, a lawyer working for a public research institute in the city of Nagoya, Japan, described two methods for Gottwald’s vision using thermoset polymer—a special plastic that hardens in response to light—instead of metal. His research was published in several papers and resulted in his own November 1981 patent, but a complete lack of interest meant the project went nowhere.

His research was published in several papers and resulted in his own November 1981 patent, but a complete lack of interest meant the project went nowhere.

Regardless, the seed was sown. Electronics and defense manufacturer Raytheon filed a patent in 1982 to use powdered metal to add layers to an object. In 1984, entrepreneur Bill Masters filed a patent for a process called Computer Automated Manufacturing Process and System, which mentioned the term 3D printing for the first time. Another 1984 patent in France described additive manufacturing using stereolithography, but like Kodama’s work, it was disregarded as having no commercial appeal.

3D Systems Corporation’s SLA-1After all these starts, inventor Chuck Hull was the first person to actually build a 3D printer. Based on his patent for curing photopolymers using radiation, particles, a chemical reaction, or lasers, his design sent the spatial data from a digital file to the extruder of a 3D printer to build up the object one layer at a time.

Hull’s company, 3D Systems Corporation, released the world’s first stereolithographic apparatus (SLA) machine, the SLA-1, in 1987. This machine made it possible to fabricate complex parts, layer by layer, in a fraction of the time it would normally take. Hull went on to file more than 60 patents around the technology, becoming the godfather of the rapid prototyping movement and inventing the STL file format that’s still in use today.

During this era, 3D printing was an emerging technology, and materials science wasn’t what it is today. If the product was made of popular polymers, they tended to warp as it set. At the time, the machines also cost hundreds of thousands of dollars, so 3D printing devices were installed only in heavy manufacturing plants—far out of the reach of consumers.

1999–2010: 3D Printing Shows Its PotentialAmid widespread worries that the Y2K bug would shut down computer systems and cause digital Armageddon, 3D printing showed great potential for many industries.

During this period, bioengineering was also making important advances. Scientists at Wake Forest Institute for Regenerative Medicine in Winston-Salem, NC, printed the building blocks of a human urinary bladder using additive manufacturing and coating the organ with cells from the patient so the body was unlikely to reject the 3D-printed bladder.

The next decade saw many advances in medical 3D printing as scientists, technologists and doctors built a miniature kidney, a complex prosthetic leg, and the first bioengineered blood vessels made using donated human cells.

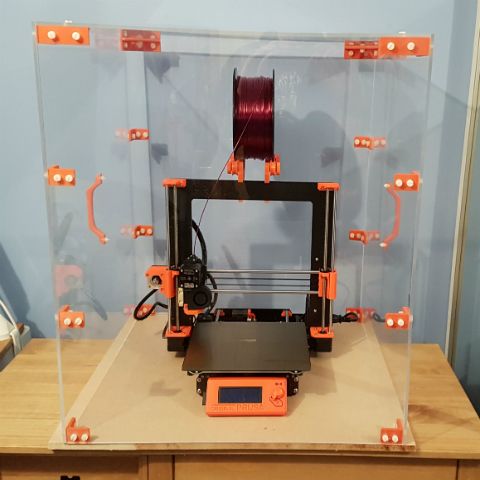

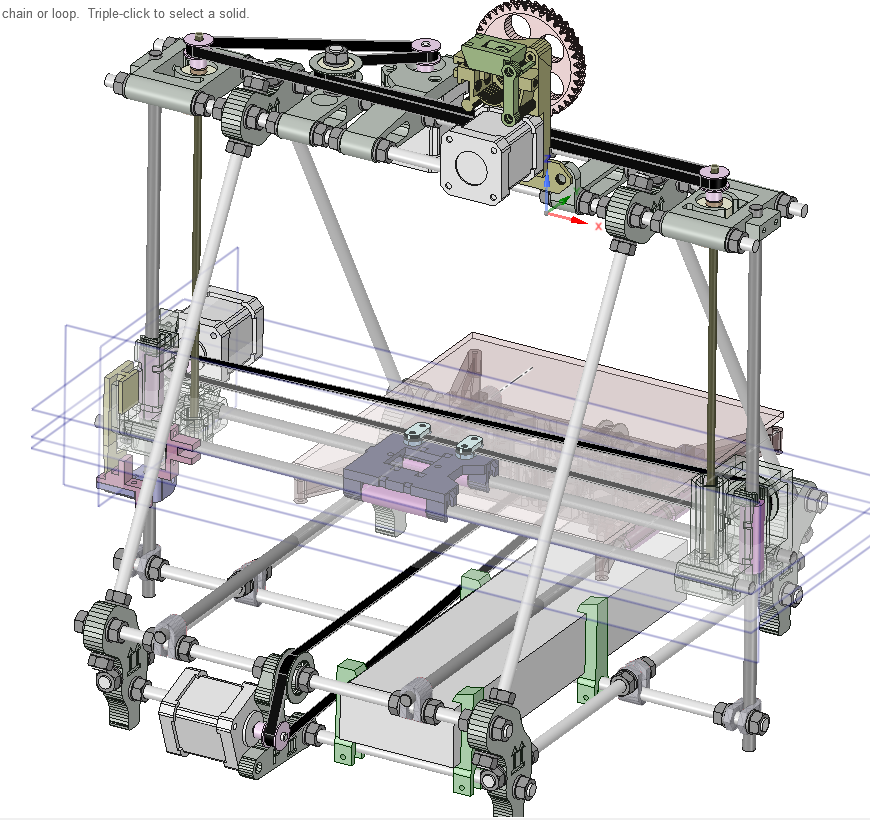

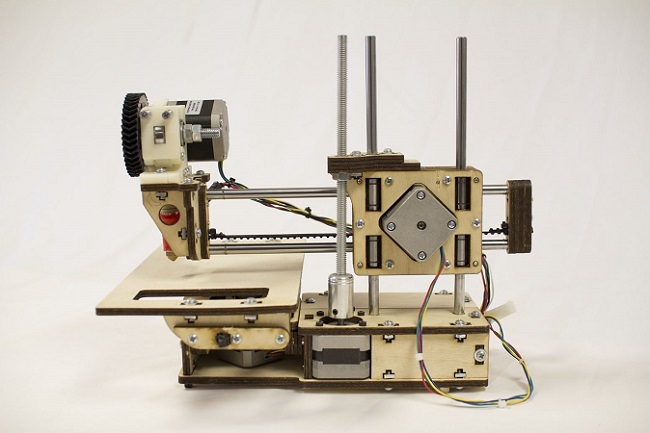

The 2005 open-source RepRap project produced the Darwin machine, a 3D printer that could print most of its own parts in order to self-replicate. Courtesy of RepRap.org.RepRap 3D PrinterBut the entire movement—especially the drive toward consumer use—received a big boost from the open-source paradigm sweeping the information and communications technology (ICT) sector. In 2005, Adrian Bowyer’s RepRap Project launched an open-source initiative to create a 3D printer that could build itself—or at least print most of its own parts.

The 1.0 Darwin machine was the first practical application of RepRap’s philosophy, and suddenly anyone had the power to create whatever they could dream up. Launched around the same time, Kickstarter gave home 3D printing another huge boost as crowdfunded projects sprung up everywhere. Manufacturing was democratizing fast.

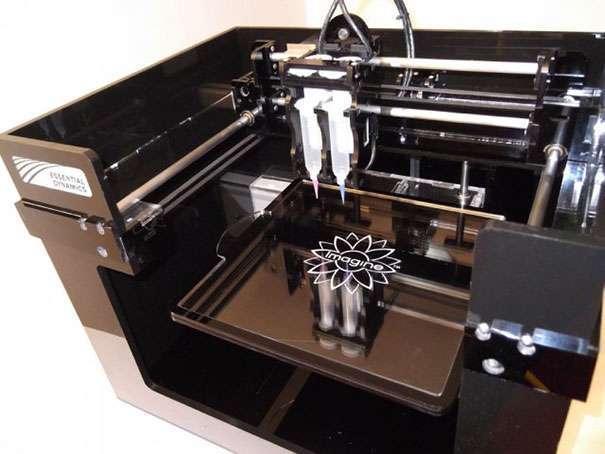

MakerBot 3D PrinterCommercial 3D printing finally came to the desktop in 2006 from Objet (now Stratasys), which let users send designs to its device in order to print them from multiple materials with different properties.

Marketplaces and virtual swap meets for trading, sharing, and acquiring designs sprung up everywhere, driving a huge groundswell of interest. When MakerBot arrived in 2009 with open-source DIY kits to design and print just about anything, it made co-founder Bre Pettis into a superstar and gave 3D printing the same cachet as past emerging technologies like social media, e-commerce, and even the Web itself.

Today, additive manufacturing is a mature technology. The consumer interest and robustness of industrial platforms grew throughout the 2010s, as the (often hysterical) MakerBot hype settled down and the industry found a groove. Some think additive will replace traditional CNC and milling manufacturing in the future, and a 2021 Lux Research report predicts that 3D printing will be worth $51 billion by 2030.

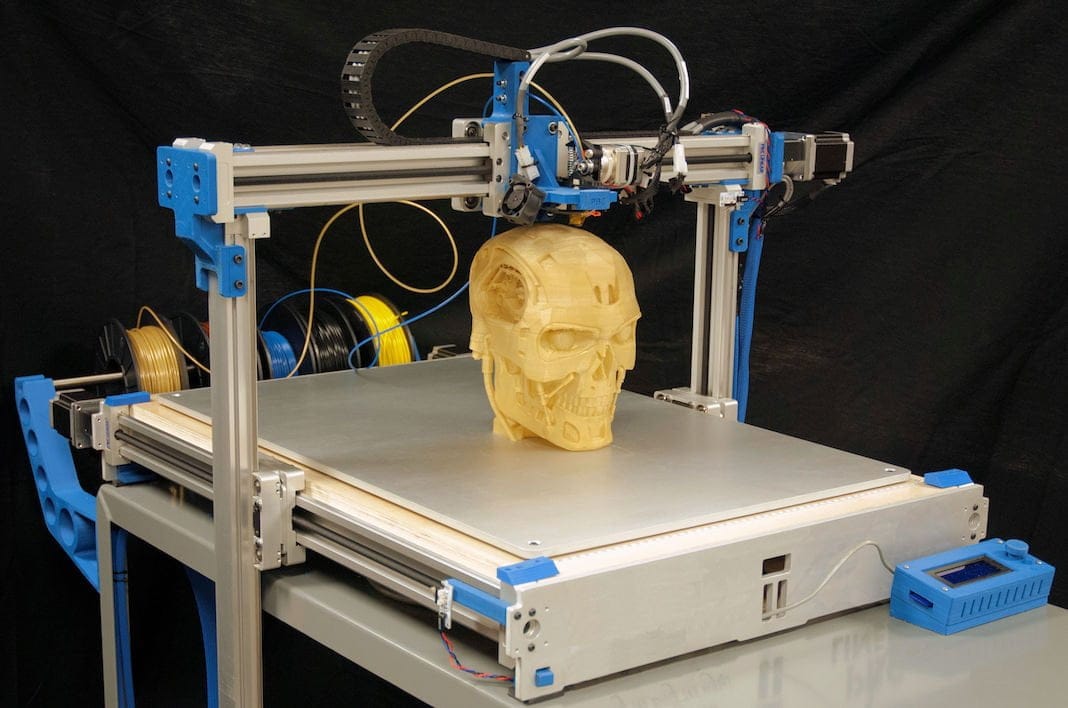

The plastic desk toys have been cleared away, leaving the real-world benefits 3D printing offers: everything from printing food to applying multiple materials in the same extrusion process, making the process faster and cheaper.

The range of materials available for 3D printing has also grown exponentially, from bioprinting human tissue and the beginnings of organs tailor-made to patients to crafting products from silver or gold.

The applications are also as varied as inventors’ and engineers’ imaginations. Scientists at the University of Southampton flew the world’s first 3D-printed unmanned aircraft; the makers of a 3D-printed car reached up to 200 mpg with a hybrid gas/electric engine; and a start-up specializing in building ecological living structures came up with a robot-made habitat suitable for living on Mars.

3D printing is being used to build emergency shelter in disaster areas and affordable housing in the developing world. And smart robotics, micromanufacturing, and articulated limb design were combined to to make self-powered prosthetics that give feedback to the brain.

A lot of high-end 3D printing in manufacturing for large structures is done using powder-bed fusion, where various materials can be used in powdered form and fused together using lasers or heat. This is the main process used for metal parts, but it’s expensive and needs very particular infrastructure, making it mainly been feasible for the heavy manufacturing sector.

Nevertheless, additive manufacturing has found a home in many industries. The amount of things from your daily life with some 3D-printed component may surprise you.

3D Printing in ConstructionConstruction is a massive, entrenched field with a legacy of wasteful and dangerous practices, responsible for almost 40% of greenhouse gas emissions. 3D printing could upend it with cleaner methods of creating cement-based products like walls and metal components like rebar—and climate change makes these changes even more crucial.

But speed is another compelling reason to adopt 3D printing. In 2016, a Chinese company 3D printed an entire two-story house in 45 days. That same year, Apis Cor 3D printed the structure of a 400-square-foot house in only 24 hours. Additive technologies can also be deployed in precarious places like mine sites or disaster areas quickly and cheaply; research is ongoing to use materials found onsite where printers are located instead of using more fuel and smoke-belching trucks to ship in materials.

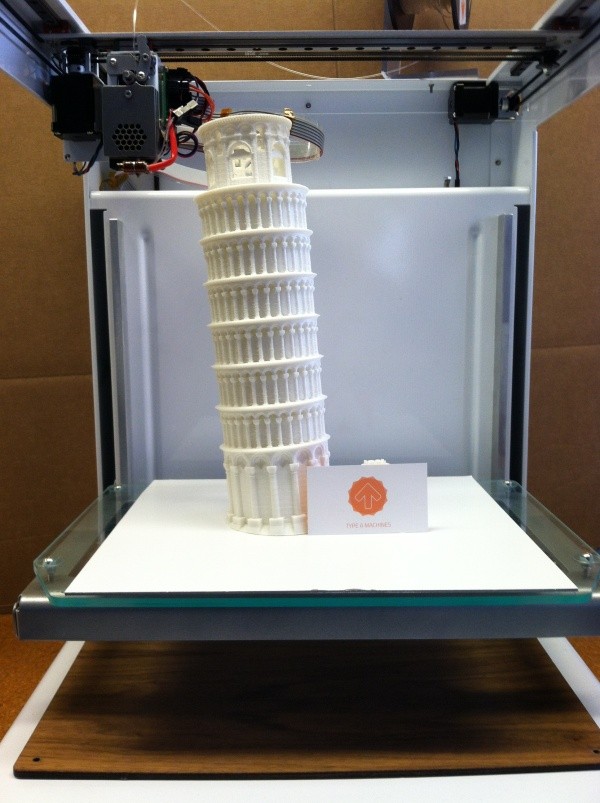

The biggest benefits of 3D printing to architecture seem obvious: designs already exist with every conceivable detail in digital form, so when you want to impress clients or investors, simply click a button and have a gorgeous model on your boardroom table just hours later. Want to change a beam, reorient a window, or add another story? Redo your drawings, rinse, and repeat.

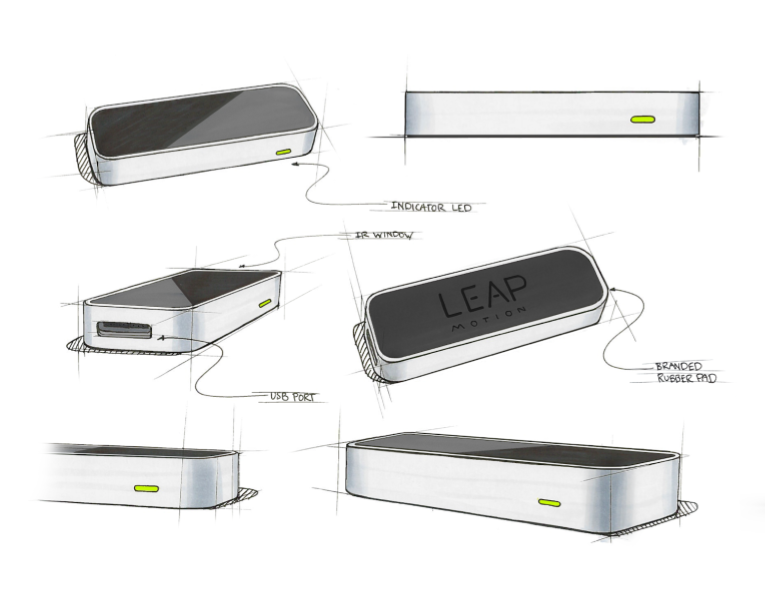

3D Printing in Product Design and ManufacturingWhen prototypes have to be made in or near the same factories where final production kicks into gear, it adds precious time to the design and review phase of product development if the designer and manufacturer are located far apart.

With access to 3D printing, it doesn’t matter how far-flung the factory is; a 3D printer in your office or garage can churn out as many prototypes as you need affordably and quickly, no matter how many design tweaks you have to make.

3D printing has the potential to make manufacturing viable in any region or economic climate, rather than only in the manufacturing hubs of the past 30–40 years.

A lot of manufacturing workflows already have the means to retool to additive processes. And as the product-design timeline is compressed further thanks to advances such as generative design and the easier transport and repurposing of design files, prototyping and production will happen faster, all at the speed of digital.

Early consumer 3D printing also promised to help reduce waste through a little less built-in obsolescence. If the broken part in an old vacuum cleaner isn’t in production anymore, but the design file for it still exists on the manufacturer’s website, you only have to send it to your desktop device and watch a quick YouTube video to learn how to install it.

What Is the Future of 3D Printing?According to Statista, the global additive manufacturing market is expected to grow 17% annually through 2023, as the applications for the technology increases and metal additive becomes more and more viable. And the market for additive manufacturing products and services is expected to almost triple between 2020 and 2026.

And the market for additive manufacturing products and services is expected to almost triple between 2020 and 2026.

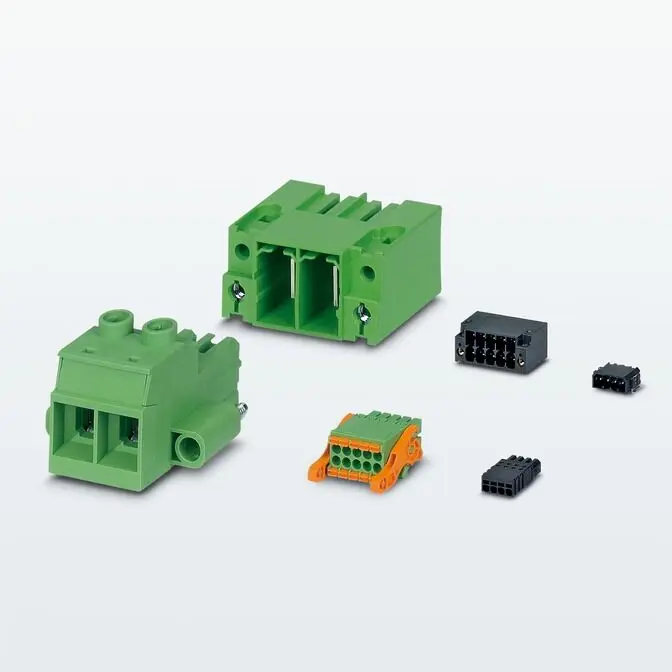

Industries such as manufacturing, architecture, and product design are surely reaping the benefits of 3D printing, but some of the greatest growth is expected in the electronics, aerospace, and medical industries. Todd Spurgeon, additive manufacturing project engineer for America Makes, says the electronics industry will see things like custom heat sinks for high-end products, and the aerospace industry will see a larger availability of 3D-printed components that will make their way from higher-end military applications to general aviation. In the medical industry, as more materials are evaluated for medical applications and insurance companies more broadly recognize additive manufacturing, personalized care will become the norm.

“Gone may be the days of the one-size-fits-most expensive prosthetic,” Spurgeon says. “Soon, personalized prosthetics, custom-fit to the user, are expected to be within the reach of the typical American household—even for growing children.”

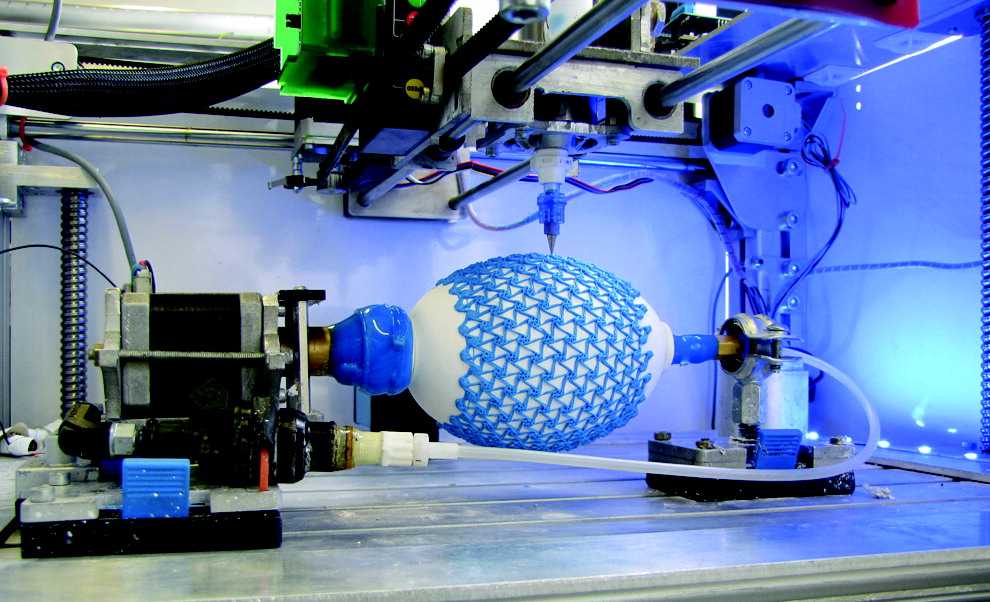

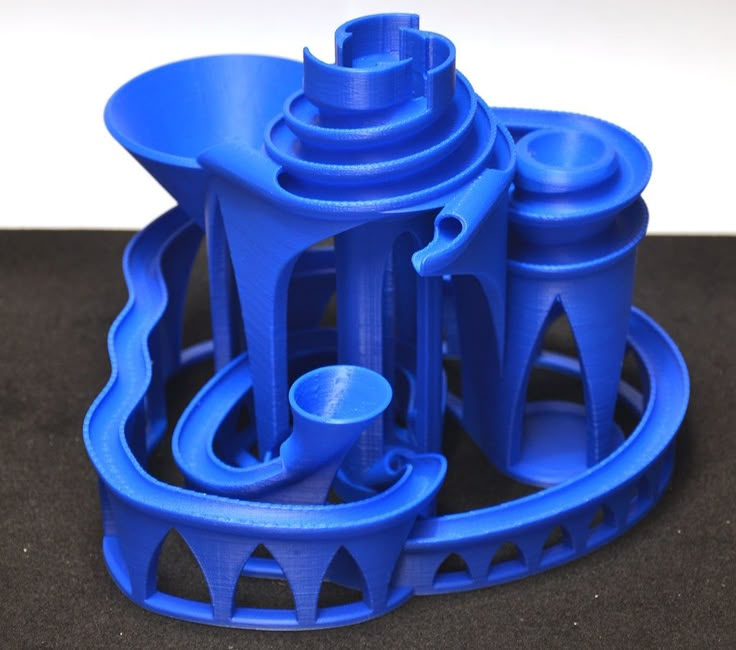

New Applications and New 3D-Printable MaterialsBeyond the existing technologies, there is much more on the horizon for additive manufacturing. According to Spurgeon, interesting work is being done in the direct-ink-writing and dense paste material extrusion communities. For example, research groups are exploring mixing cured photopolymers with advanced material systems such as ceramics and thermosets, which can ultimately be used for things like printed circuits, lower-cost heat exchangers, and nonbulk ceramics.

“Improvements in this domain could result in a larger insertion of additive manufacturing into high-end applications such as aerospace and automotive, as well as large production processes such as the desalinization of water,” Spurgeon says. Even more opportunities surface when you consider this technology in conjunction with other additive-manufacturing modalities, such as printed circuits integrated into the structure of prosthetics or new form factors for batteries.

Even more opportunities surface when you consider this technology in conjunction with other additive-manufacturing modalities, such as printed circuits integrated into the structure of prosthetics or new form factors for batteries.

The list of 3D-printable materials is growing, as well. “Refractory super alloys will enable innovations in the energy, aerospace, and defence sectors,” Spurgeon says. “More durable polymers are being developed today that are likely to meet flame, smoke, and toxicity testing required by the FAA, which will result in sustainment costs reduction for relevant sectors.”

With new research and developments in additive manufacturing on the rise, the future remains bright for 3D printing—so bright that it’s time to don your new 3D-printed shades.

This article has been updated. It was originally published in September 2014. Dana Goldberg contributed to this article.

About the Author

After growing up knowing he wanted to change the world, Drew Turney realized it was easier to write about other people changing it instead. He writes about technology, cinema, science, books, and more.

He writes about technology, cinema, science, books, and more.

More Content by Drew Turney

History of 3D printing

In this section, we wanted to trace the history of 3D printing from its inception to the present day, as well as give a forecast regarding the future development of technology.

The first 3d printer was invented by the American Charles Hull, he worked on the technology of stereolithography (SLA), a patent for the technology was issued in 1986. The printer was a fairly large industrial installation. The installation "grew" a three-dimensional model by applying a photopolymerizable material to a moving platform. The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers.

Charles Hull was not the only one to experiment with 3D printing technology, as in 1986 Carl Deckard invented Selective Laser Sintering (SLS). You can learn more about the method in another article, briefly: a laser beam sinters a powder (plastic, metal, etc.), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0.1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied.

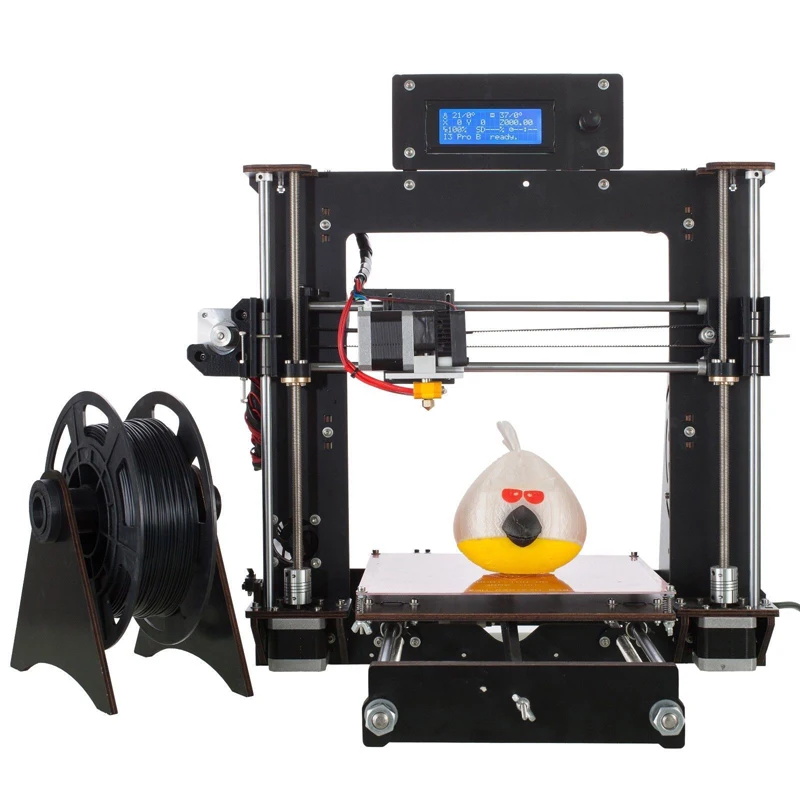

However, the most famous and widespread 3D printing method today is layer-by-layer direction (FDM). The idea of technology belongs to Scott Crump (Scott Crump), the patent dates back to 1988. You can learn more about the method in another article, in short: material (usually plastic) is fed from the heated nozzle of the print head using a stepper motor, the print head moves on linear guides along 1 or two axes, and the platform moves along 1 or 2 axes . The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers.

The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers.

All the devices described above belonged to the class of industrial devices and were quite expensive, so one of the first 3d Dimension printers from Stratasys in 1991 cost from 50 to 220 thousand US dollars (depending on the model and configuration). Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

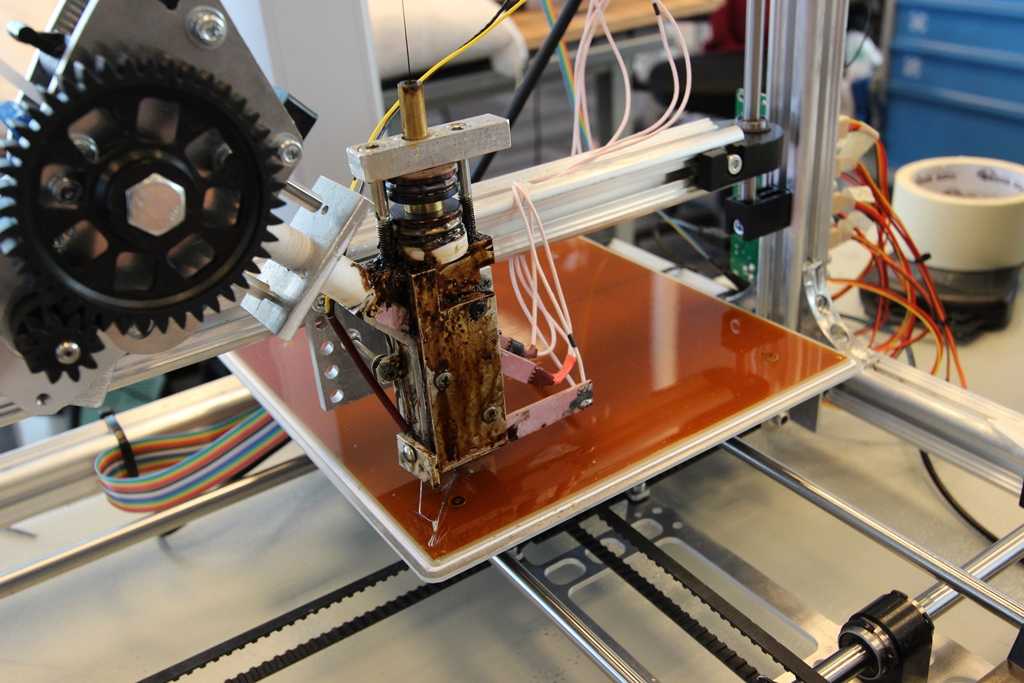

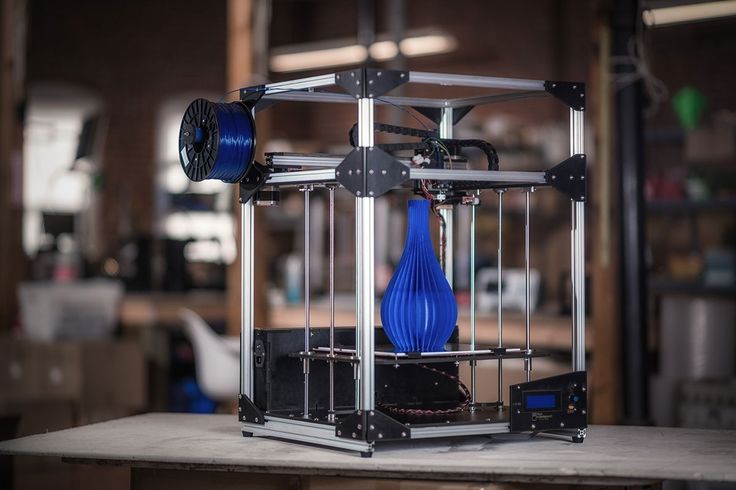

Everything began to change since 2006, when the RepRap project (from the English Replicating Rapid Prototyper - a self-replicating mechanism for rapid prototyping) was founded, with the goal of creating a self-copying device, which was a 3D printer working on technology FDM (layer by layer deposition). Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain.

Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain.

Leaving aside the ideological component, the community (which exists and develops to this day) managed to create a 3d printer accessible to the "ordinary person". So a set of unprinted parts can cost around a couple of hundred US dollars and a finished device from $500. And even though these devices looked unsightly and were significantly inferior in quality to their industrial counterparts, all this was an incredible impetus for the development of 3D printing technology.

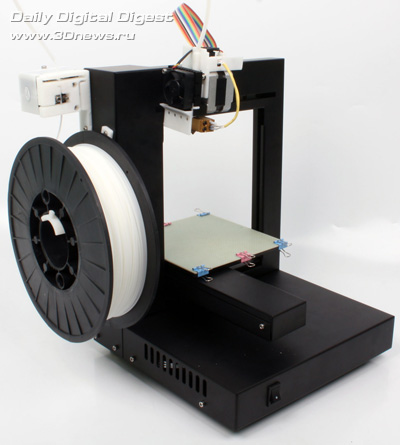

As the RepRap project developed, 3D printers began to appear, taking as a basis the base laid down by the movement in technical and, sometimes, ideological terms (for example, commitment to the concept of open source - OpenSource). The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible.

First of all, it is worth mentioning the MakerBot company, which started as a startup, took RepRap ideas as a basis and gradually turned them into a product of a new quality.

Their flagship product (and in our opinion the best to this day) remains the MakerBot Replicator 2 3D printer. The model was released in 2012 and later discontinued, but remains one of the most popular 3D printer models to this day " personal" segment (according to 3dhubs). The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes.

The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes.

In parallel with the release of equipment, the company actively developed the Thingiverse resource, which contains many models for 3d printing, available for download for free. During the development of the first printer and beyond, the community has helped the company a lot, testing the product and offering various upgrades. After the release of the Replicator 2 (and the closure of development), the situation has changed. You can learn more about the history of MakerBot and other companies and people associated with 3d printing by watching the film Print the legend.

This film also highlights the history of Formlabs, one of the first companies to launch an affordable 3D printer based on SLA (Strereolithography) technology. The company raised funds for the first FORM 1 model through crowdfunding, encountered production difficulties, but eventually released an affordable and productive 3D printer, closing the quality gap described above.

The company raised funds for the first FORM 1 model through crowdfunding, encountered production difficulties, but eventually released an affordable and productive 3D printer, closing the quality gap described above.

And although the 3D printers described above were far from perfect, they laid the foundation for the development of affordable 3D printing technology, which continues to this day. At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials.

Personal 3d printers of today are very close to professional devices, the development of which also does not stop. In addition to the "founders" of the technology (Stratasys, 3dsystems), many small companies specializing in industrial 3D printing technologies (metal in particular) have emerged. 3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal).

However, 3D printing technologies are developing not only in breadth, but also in depth. One of the main disadvantages of 3D printing, compared to other production methods, is the low speed of creating models. A significant advance in terms of accelerating 3D printing was the invention of CLIP technology by CARBON, printers operating on this technology can produce models 100 times faster than classic SLA technology.

There is also a constant expansion of the range, properties and quality of materials and post-processing of products. All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) .

In addition to the "classic" scope of 3D printing, today more and more often you can see news about how a house or some organ (or rather, a small part of it) was printed on a 3D printer from bio-material. And this is true, several companies around the world are testing or already partially using 3D printing in the construction of buildings and structures. This mainly concerns the contour pouring of walls (similar to the FDM method) with a special composite concrete mixture. And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages.

And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages.

With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells.

Looking to the future, it is safe to say that 3D printing technology will expand both in breadth and depth, improving technology, speeding up processes, improving quality and improving material properties. 3D printers will increasingly replace old methods in production chains of various scales, and world production, due to this, will move towards the “on demand” scheme of work, increasing the degree of product customization. Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten).

Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten).

3d printing of houses (and other structures) will no doubt also develop, reducing costs and production time, which, together with the development of new approaches in architecture and urban planning (such as modular construction and the prefabricated method), will give a tangible impetus to development the industry as a whole.

Biological 3D printers will be an important tool in scientific research. However, before they appear in hospitals and clinics, where they will print new organs, it is still very, very far away (in fact, this is science fiction).

Alcom | History of 3D printers

May 13, 2018

Since the beginning of the new millennium, the concept of "3D" has firmly entered our daily lives. First of all, we associate it with cinema, photography or animation. But there is hardly a person now who has not heard about such a novelty as 3D printing at least once in his life.

First of all, we associate it with cinema, photography or animation. But there is hardly a person now who has not heard about such a novelty as 3D printing at least once in his life.

What is it and what new opportunities in creativity, science, technology and everyday life bring us 3D printing technologies, we will try to figure it out in the article below.

But first, a little history. Although there has been a lot of talk about 3D printing in the last few years, in fact, this technology has been around for a long time. In 1984, Charles Hull developed a 3D printing technology for reproducing objects using digital data, and two years later named and patented the stereolithography technique.

At the same time, this company developed and created the first industrial 3D printer. Subsequently, the baton was taken over by 3D Systems, which developed in 1988 printer model for 3D printing at home SLA - 250.

In the same year, fused deposition modeling was invented by Scott Grump. After several years of relative calm, in 1991 Helisys develops and markets a technology for the production of multilayer objects, and a year later, in 1992, the first selective laser soldering system is released at DTM.

After several years of relative calm, in 1991 Helisys develops and markets a technology for the production of multilayer objects, and a year later, in 1992, the first selective laser soldering system is released at DTM.

Then, in 1993, Solidscape was founded, which began mass production of inkjet-based printers that are capable of producing small parts with an ideal surface, and at a relatively low cost.

At the same time, the University of Massachusetts patents a 3D printing technology similar to conventional 2D inkjet technology. But, perhaps, the peak of development and popularity of 3D printing still fell on the new, 21st century.

In 2005, the first 3D printer capable of printing in color appeared, this is the brainchild of Z Corp called the Spectrum Z510, and literally two years later the first printer appeared that could reproduce 50% of its own components.

Currently, the scope and scope of 3D printing is constantly growing. Everything turned out to be subject to these technologies - from blood vessels to coral reefs and furniture. However, we will talk about the areas of application of these technologies a little later.

However, we will talk about the areas of application of these technologies a little later.

So, what is printing on a 3d printer?

In short, this is the construction of a real object according to a 3D model created on a computer. Then the digital three-dimensional model is saved in the STL file format, after which the 3D printer, to which the file is output for printing, forms a real product.

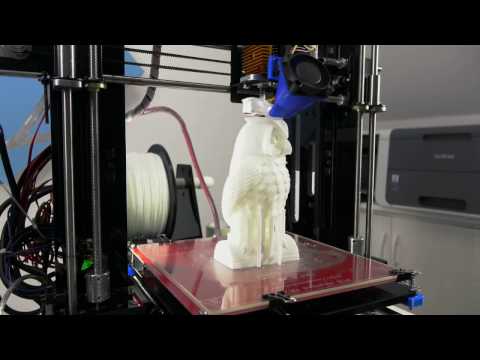

The printing process itself is a series of repetitive cycles associated with the creation of three-dimensional models, applying a layer of consumables to the desktop (elevator) of the printer, moving the desktop down to the level of the finished layer and removing waste from the surface of the table.

The cycles follow one after another continuously: the next layer of material is applied on the first layer, the elevator is lowered again and so on until the finished product is on the working table.

How does a 3D printer work?

The application of 3D printing is a serious alternative to traditional methods of prototyping and small-scale production. A three-dimensional or 3D printer, unlike a conventional one that prints two-dimensional drawings, photographs, etc. on paper, makes it possible to output three-dimensional information, that is, to create three-dimensional physical objects.

A three-dimensional or 3D printer, unlike a conventional one that prints two-dimensional drawings, photographs, etc. on paper, makes it possible to output three-dimensional information, that is, to create three-dimensional physical objects.

At the moment, this class of equipment can work with photopolymer resins, various types of plastic filament, ceramic powder and metal clay.

What is a 3d printer?

The principle of operation of a 3d printer is based on the principle of gradual (layered) creation of a solid model, which, as it were, is “grown” from a certain material, which will be discussed a little later. The advantages of 3D printing over the usual, manual methods of building models are high speed, simplicity and relatively low cost.

For example, to create a 3D model or any part manually, it can take quite a long time - from several days to months. After all, this includes not only the manufacturing process itself, but also preliminary work - drawings and diagrams of the future product, which still do not give a complete vision of the final result.

As a result, development costs increase significantly, the period from product development to its mass production increases.

3D technologies, on the other hand, allow you to completely eliminate manual labor and the need to make drawings and calculations on paper - after all, the program allows you to see the model from all angles already on the screen, and eliminate the identified shortcomings not in the process of creation, as is the case with manual production, but directly during development and create a model in a few hours.

This virtually eliminates the possibility of manual errors.

What is a 3d printer: video

There are various 3D printing technologies. The difference between them lies in the way the product layers are applied. Let's consider the main ones.

The most common are SLS (selective laser plexus), HPM (molten material overlay) and SLA (stereolithiography).

The most widely used technology due to the high speed of building objects is stereolithography or SLA.

SLA Technology

The technology works like this: a laser beam is directed onto a photopolymer, after which the material hardens.

The photopolymer is a translucent material that deforms when exposed to atmospheric moisture.

Once cured, it can be easily glued, machined and painted. The working table (elevator) is in a container with a photopolymer. After the laser beam passes through the polymer and the layer hardens, the working surface of the table moves down.

SLS Technology

Sintering powder reagents under the action of a laser beam - it is also SLS - the only 3D printing technology that is used in the manufacture of molds for both metal and plastic casting.

Plastic models have excellent mechanical properties, which make them suitable for making full-featured items. SLS technology uses materials that are similar in properties to the brands of the final product: ceramics, powdered plastic, metal.

The 3D printer device looks like this: powder substances are applied to the surface of the elevator and sintered under the action of a laser beam into a solid layer that corresponds to the parameters of the model and determines its shape.

DLP technology

DLP technology is new to the 3D printing market. Stereolithographic printers are positioned today as the main alternative to FDM equipment. This type of printer uses digital light processing technology. Many people wonder what the 3d printer of this sample prints with?

Instead of a plastic filament and a heating head, photopolymer resins and a DLP projector are used to create three-dimensional figures.

Below you can see how the 3d printer works video:

Having heard about a DLP 3d printer for the first time, what it is is a completely reasonable question. Despite the intricate name, the device is almost no different from other desktop printers. By the way, its developers, represented by

QSQM Technology Corporation, have already launched the first samples of high-tech equipment into a series. It looks like this:

It looks like this:

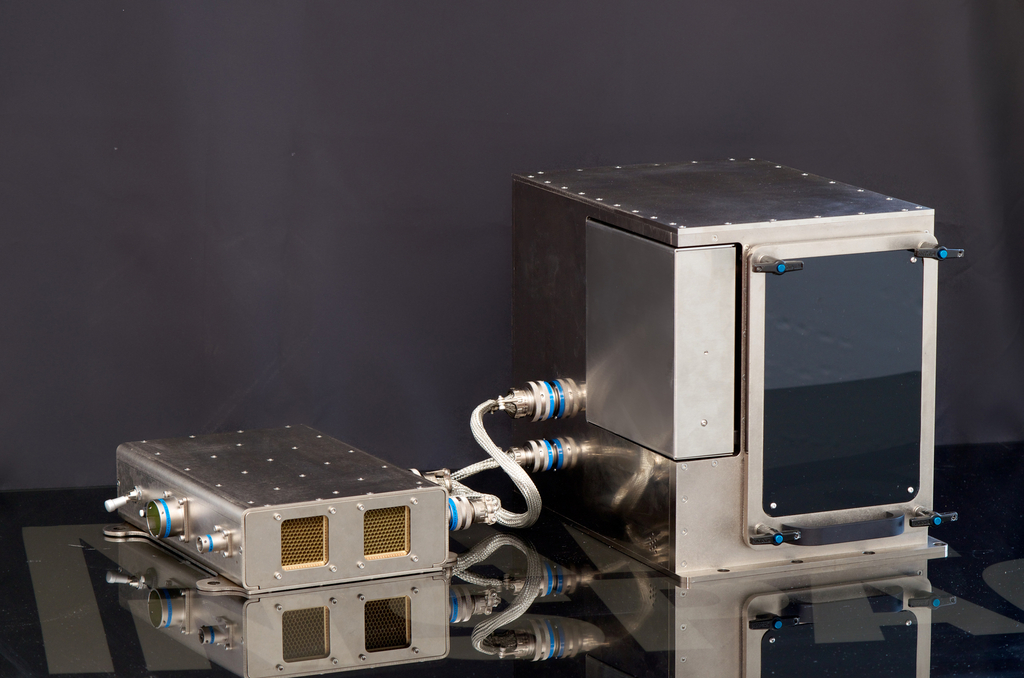

EBM Technology

It should be noted that SLS/DMLS technologies are far from the only ones in the field of metal printing. Currently, electron beam melting is widely used to create metal three-dimensional objects. Laboratory studies have shown that the use of metal wire for layer-by-layer deposition in the manufacture of high-precision parts is ineffective, so engineers have developed a special material - metal clay.

The metal clay used as ink during electron beam melting is made from a mixture of organic glue, metal shavings and a certain amount of water. In order to turn the ink into a solid object, it must be heated to a temperature at which the glue and water will burn out, and the chips will fuse together into a monolith.

EBM 3d printer: how

works It is noteworthy that this principle is also used when working with SLS printers. But unlike them, EBM machines generate directed electron pulses instead of a laser beam to melt metal clay. I must say that this method provides high print quality and excellent drawing of small details.

I must say that this method provides high print quality and excellent drawing of small details.

Today, only industrial printers using EBM technology are sold. Here is what one of them looks like:

The video below demonstrates the capabilities of a 3d printer adapted for electron beam melting:

HPM Technology (FDM) HPM

Allows you to create not only models, but also final parts from standard, structural and high-performance thermoplastics. It is the only technology that uses production grade thermoplastics to provide unparalleled mechanical, thermal and chemical strength to parts.

HPM Printing stands out for its cleanliness, ease of use and suitability for office use. Thermoplastic parts are resistant to high temperatures, mechanical stress, various chemicals, wet or dry environments.

Soluble auxiliary materials allow the creation of complex multi-level shapes, cavities and holes that would be problematic to obtain with conventional methods. HPM 3D printers create parts layer by layer by heating the material to a semi-liquid state and extruding it according to computer-generated paths.

HPM 3D printers create parts layer by layer by heating the material to a semi-liquid state and extruding it according to computer-generated paths.

HPM printing uses two different materials - one (main) will consist of the finished part, and an auxiliary, which is used for support. The filaments of both materials are fed from the 3D printer bays into the print head, which moves based on changes in the X and Y coordinates and fuses the material, creating the current layer, until the base moves down and the next layer begins.

When the 3D printer has finished creating the part, it remains to separate the auxiliary material mechanically, or dissolve it with detergent, after which the product is ready for use.

Interestingly, not only automatic desktop HPM printers are popular these days, but also manual printing devices. Moreover, it would be correct to call them not printing devices, but pens for drawing three-dimensional objects.

Pens are made in the same way as printers using fusing technology. The plastic thread is fed into the pen, where it melts to the desired consistency and is immediately squeezed out through a miniature nozzle! With proper skill, these original decorative figures are obtained:

The plastic thread is fed into the pen, where it melts to the desired consistency and is immediately squeezed out through a miniature nozzle! With proper skill, these original decorative figures are obtained:

And of course, just like technologies, printers themselves differ from each other. If you have a printer that works according to SLA, then it will be impossible to apply SLS technology on it, i.e., each printer was created only for a certain printing technology.

3D printing applications

3D printing has opened up great opportunities for experimentation in areas such as architecture, construction, medicine, education, clothing design, small-scale production, jewelry, and even in the food industry.

In architecture, for example, 3D printing allows you to create three-dimensional models of buildings, or even entire neighborhoods with all the infrastructure - squares, parks, roads and street lighting.

Thanks to the cheap gypsum composite used, the cost of finished models is low. And more than 390 thousand CMYK shades make it possible to embody any, even the most daring, imagination of an architect in color.

And more than 390 thousand CMYK shades make it possible to embody any, even the most daring, imagination of an architect in color.

3d printer: construction application

In construction, there is every reason to believe that in the near future the process of erecting buildings will be much faster and easier. Californian engineers have created a 3D printing system for large objects. It works on the principle of a construction crane, erecting walls from layers of concrete.

This printer can build a two-story house in just 20 hours.

After that, the workers will only have to carry out finishing work. 3D House 3D printers are gradually gaining a strong position in small-scale production.

These technologies are mainly used for the production of exclusive products, such as art, role-playing game characters, prototype models of future products or any structural parts.

In medicine, thanks to 3D printing technologies, doctors have been able to recreate copies of the human skeleton, which allows them to more accurately practice techniques that increase the guarantee of successful operations.