3D printed homes for sale near me

FAQ | ICON

Media interested in writing a story about ICON, please visit our CONTACT page. To download assets for your story, visit our electronic press kit for media only.

What is ICON?

ICON develops advanced construction technologies that advance humanity. Using proprietary 3D printing robotics, software and advanced materials, ICON is shifting the paradigm of homebuilding on Earth and beyond. Follow @ICON3DTech on Instagram, Twitter, Facebook, LinkedIn and YouTube.

Tell us about the origins of ICON and the company’s mission.

ICON is an advanced construction technologies company dedicated to revolutionizing homebuilding. Through proprietary 3D printing technology and cutting-edge materials, ICON provides sustainable solutions to a number of our world’s most pressing issues, including the pandemic of homelessness in the developing world, the difficulty of constructing off-planet space habitats, and the exorbitant cost of customized housing.

ICON’s three co-founders were independently working on large-scale 3D printing for homebuilding in 2017. Jason Ballard, co-founder the CEO spent the last decade+ of his life focused on sustainability and health in the built environment. After working on literally thousands of homes, Jason began saying to himself, "Surely there is a better way to build homes that is more affordable, less wasteful, and more energy efficient than conventional building methods." Approaches to construction hadn't changed in so long it was like people had forgotten how to even imagine a different way. That began a months-long study and research project (including prefab, insulated concrete forms, SIP panels, advanced framing, robotic bricklaying, architectural fungus, etc.) that landed Jason on 3D printing as the most promising technology to create a true revolution that checked all the boxes he cared about. He re-connected with his TreeHouse co-founder and friend Evan Loomis and the two decided to start working on it and build a prototype in a warehouse in Austin on the weekends. Meanwhile, a fresh college-grad and engineer named Alex Le Roux was working on a similar project in Houston. His prototype was actually able to print a mortar-based tiny home. Eventually, after hearing rumors of each other for months, the three entrepreneurs met and decided to start working together.

Meanwhile, a fresh college-grad and engineer named Alex Le Roux was working on a similar project in Houston. His prototype was actually able to print a mortar-based tiny home. Eventually, after hearing rumors of each other for months, the three entrepreneurs met and decided to start working together.

Fast forward to today... ICON is a for-profit advanced construction technologies company using 3D robotics, software, and advanced materials to reinvent the homebuilding industry. The first 3D printer was ready to print in early 2018 and successfully printed a permitted, 3D printed home in Austin in March 2018 alongside nonprofit partner, New Story. In March 2019, ICON unveiled its next generation 3D printer for homes, the Vulcan, and began shipping the technology for projects in the U.S. and in Mexico. To date, ICON has delivered two dozen 3D-printed homes/structures across the U.S. and Mexico, the most completed by any construction tech company.

Tell us more about ICON’s printer?

ICON unveiled its next generation “Vulcan” 3D printer for homes on March 11, 2019 and a few months later began shipping the award-winning technology to begin its very important work of delivering affordable, resilient, dignified housing around the world. To date, the Vulcan construction system has delivered two dozen 3D-printed homes / structures across Mexico and the U.S.

To date, the Vulcan construction system has delivered two dozen 3D-printed homes / structures across Mexico and the U.S.

The Vulcan is the first printer of its kind in that it has the capability of printing homes in which people actually want to live. It can be operated by anyone with basic training thanks to the improvements in automation, mechatronics and a suite of specialized software.

Has ICON received any funding?

ICON has raised $451 million in funding to date.

February 2022: ICON raised $185 million in a series B-1 round of financing led by Tiger Global.

August 2021: ICON completed a $207 million series B round of financing led by Norwest Venture Partners. ICON welcomed Jeff Crowe, Managing Partner at Norwest Venture Partners, a leading multi-stage investment firm, to its Board of Directors. From world-renowned architects to the country’s largest homebuilders, ICON’s line-up of series B investors also included 8VC, BIG-Bjarke Ingels Group, BOND, Citi, Crosstimbers, Ensemble, Fifth Wall, LENx, Moderne Ventures and Oakhouse Partners.

August 2020: ICON announced its series A round of financing led by Moderne Ventures. The company welcomed Constance Freedman, Founder and Managing Partner of Moderne Ventures and Khan Tasinga, Director at Palantir Technologies, to its Board of Directors. Notably, the international architecture firm BIG-Bjarke Ingels Group joined the series A round of investors, which also includes CAZ Investments, Citi, Crosstimbers Ventures, Ironspring Ventures, Next Coast Ventures, Oakhouse Partners, Trust Ventures, Vulcan Capital and Wavemaker Partners.

October 2018: ICON announced $9 million in seed funding led by Oakhouse Partners. Jason Portnoy, Managing Partner, Oakhouse Partners, who led the seed round of funding, joined ICON's Board of Directors. Seed round investors included Cielo Property Group, D.R. Horton and Emaar among others. ICON’s round of funding accelerated the development of its printers, created a variety of home types and designs and enhanced its core technology stack to further its mission of using advanced construction technologies to advance humanity.

Is ICON a publicly traded company?

No, ICON is a privately held company.

How long was the next generation of the Vulcan 3D printer in development?

The ICON team began research and development immediately following the completion of their first prototype 3D-printed home in March 2018. The work shifted into high gear about fall 2018 following a seed round of financing.

What features does the next generation Vulcan have in comparison to its predecessor?

Tablet-based controls, advanced UI, 4x larger print area, 2.5x faster, automated material mixing, pumping, and delivery, safety features, remote monitoring, and on-board lighting for printing at night or in low-light conditions and more.

Where and when will you be 3D printing more homes?

ICON has delivered two dozen 3D-printed homes and structures to date across the U.S. and Mexico, the most completed by any construction tech company.

Numerous projects are underway to deliver social housing, disaster relief housing and mainstream housing developments in addition to the development of construction systems for further exploration of the Moon and eventually Mars.

What are the challenges of 3D printing in less than ideal conditions?

The Vulcan construction system has delivered projects in seismic zones, flood-prone areas and a variety of climates. The printer that was deployed to Nacajuca, Mexico in 2019 to deliver the world's first community of 3D-printed homes for housing nonprofit, New Story, was designed to work under the constraints common in places like Haiti and rural El Salvador where power can be unpredictable, potable water is not a guarantee, and technical assistance is sparse. Building the printer to not rely on these items was crucial to bet on the reliability of the printer in the field.

When will the first humans move into a 3D printed home by ICON?

In late summer 2020, the first humans to ever live in a 3D-printed home in the U. S. moved into their 400 square-foot homes at Community First! Village in Austin, TX. Learn more.

S. moved into their 400 square-foot homes at Community First! Village in Austin, TX. Learn more.

Additionally, the world's first community of 3D-printed homes were completed in Nacajuca, Mexico for housing nonprofit, New Story. The organization is working with families on the best dates to move into their new homes, but likely will occur once the neighborhood is complete, which includes ecoblock homes as well. Learn more.

The first, permitted 3D-printed home located in Austin, TX (also known as the Chicon House) is used as an office space for the owner.

Is the first printed home by ICON a permanent structure?

Yes. In March 2018, ICON built the first, permitted 3D-printed home in the U.S. Located in Austin, TX, the 350 square foot proof-of-concept home was 3D printed on-site and is a permitted, permanent structure that has received a full Certificate of Occupancy permit by the City of Austin.

How long are the 3D printed houses expected to last that ICON has printed?

The printed homes are expected to last as long or longer than standard Concrete Masonry Unit (CMU) built homes. The homes are built to the International Building Code (IBC) structural code standard.

The homes are built to the International Building Code (IBC) structural code standard.

Are the roof, windows and other finishes done conventionally or also 3D printed on ICON's past and current projects?

To date, each of ICON's delivered projects have included conventional construction methods for the finish out of the homes including the roof, windows and other finishes. To learn more about ICON's projects, visit the Updates page.

Are there challenges meeting housing codes?

Beyond torrential downpours in Austin over the printing time period of the first, permitted 3D printed home we delivered in March 2018, the challenges included mostly structural engineering and foundation adjustments as the city had never seen a building of its kind. The home received a full certificate of occupancy.

The homes at Community First! Village in Austin, TX are built to standard building codes according to IBC, City of Austin and ADA. The team is currently working with the City of Austin on its first mainstream housing development of 3D-printed homes for developer 3Strands.

Can you print two-story buildings?

The current technology is focused on single-story structures. We look forward to future advancements and delivering multi-story projects.

How long was ICON working on 3D printing before printing the first home in Austin, TX?

The team was tinkering for 2-3 years before forming the company, and then was actively in stealth mode for about a year creating the Vulcan construction system, which was unveiled during SXSW in March 2018. The next generation of the Vulcan construction system was unveiled in March 2019 and began printing homes summer 2019.

When was the first prototype home created and how long did it take?

In March 2018, the first permitted, 3D printed house was created in ~47 hours of total printing time spread across several days. The 350 square-foot home is located in Austin, TX. The home served as a proof-of-concept and was created in partnership with the housing non-profit, New Story. New Story and ICON broke ground on the first 3D printed community in the world in late summer 2019 in Tabasco, Mexico.

New Story and ICON broke ground on the first 3D printed community in the world in late summer 2019 in Tabasco, Mexico.

Is the Vulcan printer for sale?

We’re glad you’re interested in the future of homebuilding and considering a 3D-printed home. We are working hard to make more printers as fast as we can. We are working with strategic partners to deliver specific projects and continuing to further the advancements of the technology stack. We will keep everyone posted as there is new information to share.

When can we purchase 3D printed homes by ICON?

In March 2020, developer 3Strands, announced America's first 3D-printed homes for sale marking it the first multi-home mainstream housing development project leveraging ICON's proprietary 3D printing technology to construct the two to four bedrooms homes.

In the future, we hope to see ICON’s technology stack of robotics, software and advanced material in the hands of many developers, architects, builders and organizations. At this time, we are working with a handful of strategic partners to deliver big projects both domestically and internationally and continuing to iterate on the technology.

At this time, we are working with a handful of strategic partners to deliver big projects both domestically and internationally and continuing to iterate on the technology.

How long does it take to 3D print a home using ICON’s technology?

Currently we have printed homes ranging from 400-500 square feet using the Vulcan 3D printer for homes, with each home taking around 24 hours spread across several days to complete the full wall system. We have printed three homes at a time, simultaneously, in Austin, TX and two at a time, simultaneously, in Mexico, which further increases the speed in which we can deliver homes.

What controls the Vulcan printer? How many people are needed to 3D print a house?

The ICON team communicates with the printer via an ICON developed app for mobile devices such as a tablet or smartphone.

Past and current projects require around 3-4 people for an average print job including 1-2 on the printer system and 1-2 on the Magma system.

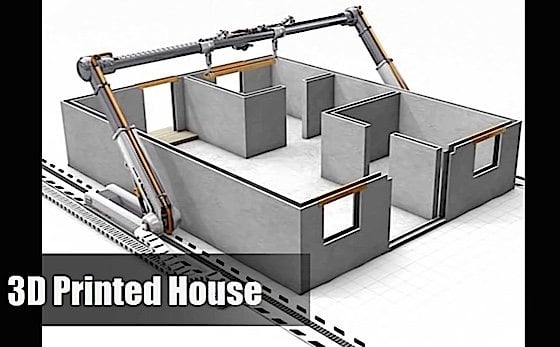

What is the process from start to finish of 3D printing a home?

Once the foundation has been poured and cured, the ICON team affixes two rails to the edge of the foundation. The Vulcan, a mobile, gantry-style 3D printer, arrives and rolls off the truck and onto the slab. The team completes a few software checks, gets the material ready via the Magma material delivery system and then begins to extrude layer by layer to deliver the full wall system of the home. The printer is operated with an ICON developed app for mobile devices such as a tablet or smartphone.

There are others who are working on 3D printing homes. What are the particular strengths of ICON?

ICON's proven 3D printing technology provides safer, more resilient homes that are designed to withstand fire, flood, wind, and other natural disasters better than conventionally built homes and that can be built in a matter of weeks.

Our technology works reliably enough for us to begin taking on numerous customers and projects across social housing, disaster relief housing and mainstream housing developments, in addition to developing construction systems to create infrastructure and habitats on the Moon and eventually Mars with NASA.

We have a conviction about the advantages of “site printing” a house as opposed to printing in a warehouse or printing pieces for assembly later.

We believe the gantry-style architecture of the printer is the fastest, most reliable, and easiest to control approach to 3D printing one and two story buildings.

Our proprietary, advanced material “Lavacrete” has been able to pass every structural test we have put it through so far. This means our homes will be safe for people to live in and resilient to the varieties of conditions where we may deploy this technology.

We have people living in 3D-printed homes by ICON since summer 2020.

What material is used in your 3D-printed homes and structures?

We developed a proprietary formula that is unique for our current and future printing projects that we’ve dubbed “Lavacrete.” Lavacrete is a combination of Portland cement, fillers, and supplementary cementitious materials (SCM’s) along with “advanced additives” intended to help it survive extreme weather.

Why is 3D printing the most appropriate technology for addressing affordability and building performance in construction?

Conventional construction is slow, fragmented, wasteful, and has poor thermal properties which increase energy use, increase operating costs, and decrease comfort. Also, conventional materials like drywall and particle board are some of the least resilient materials ever invented. By contrast, 3D printing offers the following:

Speed

Decrease in manual labor

Concrete is a well understood, affordable, resilient material

Concrete has a high thermal mass (comfort & energy efficiency)

3D printing produces a continuous, unbroken thermal envelope (comfort & energy efficiency)

Replaces multiple systems of the home in one technology (foundation, structure, insulation, interior & exterior sheathing, moisture barrier, finished surfaces, etc.)

Near zero waste

Tremendous design freedom (curves and slopes are no more challenging or expensive than straight, plumb lines).

What category of 3D printing are you using? Is this under ICON IP? Or is this a material innovation?

The Vulcan is a gantry-style printer on rails. We have several patents pending in hardware, software, process, and materials.

What distinguishes this printer from other 3D printers?

The ease of operation, the commitment to site-printing, it’s size and speed, the level and sophistication of the automations, and the safety features.

What are the technical specs of the Vulcan?

Total Height: 11.5 feet

Print Height: 8.5 feet

Total Width: 33 feet

Print Width: 28 feet

Length: effectively infinite

Weight: 3800 lbs

Operating Horizontal Speed: 5-7 linear inches per second

Nominal Power: 16 kW

Peak Power: 35kW

Voltage: 230/240 V single phase

Water Requirements: 2 GPM

Software: Tablet-based controls

Size of operating crew: 3-4 people

Printing Material Mixing & Pumping: ICON Magma System

Standard print bead: 1" tall, 2" wide

Required Concrete: ICON Lavacrete (proprietary mixture)

What accolades has ICON received?

TIME Magazine's 'Best Inventions of 2018' and TIME100 Next list featuring Jason Ballard, co-founder and CEO

Forbes '30 Under 30' featuring Alex Le Roux, co-founder and CTO

Fast Company ‘World’s Most Innovative Companies' for 2019, 2020, and 2021

Red Dot Design Award 2021

Fast Company 'World Changing Ideas' General Excellence 2020

Fast Company ‘Innovation By Design’ 2019, 2020, 2021

Popular Science 'Best of What's New/Best Innovations of 2018'

MIT's 'Innovators Under 35' featuring Alex Le Roux

Edison Awards finalist for 2019

SXSW Pitch Award - Social Good category 2018

What work is ICON doing for off-world construction?

Since its founding, ICON has been thinking about off-world construction and its natural progression around the ways additive construction and 3D printing can create a better future for humanity.

In October 2020, ICON announced it had been awarded a government Small Business Innovation Research (SBIR) contract including funding from NASA to begin research and development of a space-based construction system that could support future exploration of the Moon. ICON will also dedicated a division of the company to focus on space.

In fall 2020, ICON delivered the world’s first 3D-printed rocket pad designed by students from around the country. NASA and the student team conducted static fire with a rocket motor on the first 3D printed rocket launch pad outside of Austin, TX in March 2021.

Recently, ICON competed 3D printing the first simulated Mars surface habitat for NASA designed by renowned architecture firm BIG-Bjarke Ingels Group. Located at Johnson Space Center in Houston, Texas, Mars Dune Alpha will aid in long-duration science missions.

ICON + New Story + ECHALE Unveil First Homes in 3D-Printed Community

Located in Tabasco, Mexico, the homes will be granted to local families currently living in extreme poverty and makeshift, unsafe shelter. The resilient, 500 sq ft homes were each 3D-printed using ICON’s robotics, software and advanced material.

The resilient, 500 sq ft homes were each 3D-printed using ICON’s robotics, software and advanced material.

New Story, the nonprofit pioneering solutions to end global homelessness announced that the world’s first 3D-printed community is officially underway and they have revealed the first set of homes in Mexico. The resilient, 500 sq ft homes were each 3D printed in around 24 hours of print time across several days by ICON, a construction technologies company, and feature final construction build out by ÉCHALE, New Story’s nonprofit partner in Mexico.

The built-to-last homes located in Tabasco, Mexico will be granted to local families currently living in extreme poverty and makeshift, unsafe shelter. The community of 3D-printed homes will contain 50 homes in total.

After 18 months in planning, New Story and ICON have completed the first two printed homes in a remote part of Mexico. The 3D printer for homes, called the Vulcan II, is designed to work under the constraints that are common in rural locations, but the journey has not been easy. Power can be unpredictable and local rainfall has often flooded access roads to the construction site. This printer, designed to tackle housing shortages for vulnerable populations, is the first of its kind.

Power can be unpredictable and local rainfall has often flooded access roads to the construction site. This printer, designed to tackle housing shortages for vulnerable populations, is the first of its kind.

The 3D-printed homes feature two bedrooms, a living room, kitchen and bath. Co-designed with feedback from the families who will live in them, the homes have been created to meet the specific needs of the community. Resting within a seismic zone, the community and its homes were engineered above the standard safety requirements including robust foundations to ensure the homes will last for generations.

New Story is a nonprofit serving families in need of shelter. Since their founding just five years ago, the team has built more than 2,700 homes, serving over 15,000 people, using traditional construction methods across Haiti, El Salvador, Bolivia, and Mexico. In the last two years, they’ve spent thousands of hours and millions of dollars developing innovative solutions and R&D to help build homes better and faster for the global social housing sector.

The partnership with ICON and use of the 3D printing technology allows New Story to impact more families faster, while simultaneously improving quality and design flexibility. The hope is that this catalytic R&D project will influence the sector as a whole. Through the technology, software, and advanced material, the teams will learn, iterate, and then share the learnings with other nonprofits and governments to help everyone improve and reach families faster.

The families who will live in this community have been preselected and will move in upon community completion. Families are selected based on need; in this community, the median family income per month is $76.50, some of the lowest-income families in Mexico as a whole. When surveyed, 74% of families stated they do not feel safe in their current living conditions and that this greatly affects their quality of life. New Story has partnered with local government officials to survey over 500 families in the area. The families selected for this community are the 50 families with the greatest financial and physical need. The majority of the families in this area are from an indigenous population that has historically been left out of government programs.

The majority of the families in this area are from an indigenous population that has historically been left out of government programs.

Through partnership with the local government, the 3D-printed community is to be part of a larger community plan for the overall municipal area. The families will have access to green spaces, parks, community amenities, and basic utilities through this master plan provided by the local government. Through New Story’s partnership with the local government, families were invited to speak into the master plan for the area.

See the project in action: 3D Printed Homes - Mexico

Read an article about the first 3D printed houses?

3D printing has been used in construction for several years now. In this article, you will learn about the first real houses printed on 3D printers.

3D printing of houses is still quite new to the layman. While construction 3D printing technologies have been developed for many years, only a few "real" projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

There are many benefits to 3D printing. For example, the cost of a 3D printed house can be much lower. And it will take much less time to build.

In order to draw a line under what has already been achieved in this area and show some interesting projects, we have devoted an article to the "first" and the best. These projects will always remain milestones in the 3D construction printing industry as they set the stage for future advances in the field.

First 3D printed house in Germany

Germany is a country often associated with cutting edge engineering, so let's start our list with Germany's first ever 3D printed house.

The house itself is located in Beckum, a city that is partly located in North Rhine-Westphalia, next to Holland and Belgium. This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

The project is the result of a collaboration between German construction company Peri and Danish construction 3D printing firm COBOD. Peri is a large corporation that operates not only in Germany, but throughout the EU. Its portfolio includes many products, including scaffolding and formwork solutions that every construction site needs.

Peri followed the construction 3D printing segment for years before acquiring a stake in COBOD in 2018. Now they are pushing the technology together and further. The construction of the house in Beckum began two years after the acquisition of the share.

For 3D printing at home, a BOD2 modular 3D printer from COBOD was used. The printing itself took just over 100 hours.

• Built: (started) September 17, 2020

• Commissioned: summer 2021

• Where: Beckum, North Rhine-Westphalia, Germany

• By: Peri, COBOD

First occupied 3D printed home in the US

Several homes have been printed in the US, but this home is the first officially occupied home, according to CNN. Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

From a distance, you might think that this is an ordinary house. However, when approaching it, the layered structure of the concrete walls becomes noticeable. After all, 3D printing creates an object in layers.

Surprisingly, the 111.5 square meter concrete structure of the house (was printed in about 12 hours, significantly faster than traditional construction methods would allow.

The house was reportedly purchased by April Springfield, who lives there with her son and dog She bought the house through Habitat for Humanity's housing program, and given that the nonprofit's goal is to help solve the global housing crisis, it makes sense to use 3D printing to create affordable homes that will make many people's dreams of home ownership come true.0005

• Built: 2021

• Commissioned: December 22, 2021

• Where: Williamsburg, Virginia, USA

• By: Alquist 3D, Habitat for Humanity Peninsula, Greater Williamsburg

The first five-story 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

The house is located in Suzhou Industrial Park in Jiangsu province in eastern China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at the WinSun designs, you can't help but notice that they don't look like they've been 3D printed. Usually 3D printed structures are gray in color, the layer lines are clearly visible. But WinSun adds color and makes walls smoother. Nowhere is it stated how the company achieves the smoothness of the walls, but we assume that the workers smooth them by hand. WinSun projects are not like the ones we're used to.

• Built: Winter 2014

• Commissioned: Not specified

• Where: Suzhou, Jiangsu, China

• By: WinSun

First 3D printed biodegradable house

Can you guess that there is rice in the walls of this house?

Most 3D printed buildings are made from concrete mix. But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

WASP developed the sustainable blend in collaboration with Ricehouse, a company that specializes in using natural and agricultural materials such as clay and rice in construction.

The house is named Gaia in honor of the ancient Greek goddess of the earth. In fact, 25% of the mixture contains local soil, 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

An innovative solution not only in terms of material, but also in the design of the walls themselves. The specific corrugated structure was used to provide ventilation on warm days as well as insulation on cold periods, virtually eliminating the need for air conditioning.

Gay's house is small - about 20 square meters. The wall printing took only 10 days, while the estimated materials cost is just under $1,000.

• Built: not specified

• Commissioned: October 7, 2018

• Where: Massa Lombarda, Ravenna, Italy

• By: WASP, Ricehouse

AirBnB's first 3D printed house

The perfect weekend getaway.

You can find many different types of accommodation on AirBnB, but what about a 3D printed home?

The so-called Fibonacci house is the first 3D printed house to be offered for booking through AirBnB. Considering that it is located in rural British Columbia, it will be a wonderful place to stay.

Although the Fibonacci house looks small, it has a lot to offer vacationers. About 35 square meters is enough to accommodate up to four people.

The concrete walls of the house were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced offsite in just 11 days. The material was produced by Laticrete. The parts were later transported and assembled at their current location.

• Built: 2020

• Commissioned: Not specified

• Where: Kootenays, British Columbia, Canada

• By: Twente Additive Manufacturing

First 3D printed houseboat

Prvok is not only the first 3D printed house in the Czech Republic, but the world's first floating 3D printed house on a pontoon.

The project was implemented by the start-up company Scoolpt. The concrete structure of the houseboat took only 22 hours to print.

Approximately 43 square meters of living space divided into bathroom, bedroom and living room with kitchen. Weight isn't usually discussed in the context of houses, but given that this one is on water, it's interesting to note that Prvok weighs 43 tons.

The house is equipped with a built-in recirculating shower and tanks for drinking and municipal water and has a service life of at least 100 years.

• Built: June 2020

• Commissioned: August 18, 2020

• Where: Prague, Czech Republic

• By: Scoolpt

Europe's first 3D printed residential house

Not every 3D printed house has visible line layers.

More often than not, 3D printed houses are demos made to show what the technology can do. For most of them there is no information about the actual residents. But in 2017, the couple did move to live in a 3D printed house located in Nantes, France. Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

The house is a project of the University and the Laboratory of Digital Sciences of Nantes. An interesting aspect of the project is the special technique used in its construction by BatiPrint3D. Instead of 3D printing a concrete structure, the robotic arm created wall shells using polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

It took a total of 54 hours to print. It took a little over 4 months to complete the construction. Mainly due to the fact that the rest of the components were created using conventional means. House area - 95 square meters.

• Built: 2017

• Commissioned: March 2018

• Where: Nantes, France

• By: University of Nantes, Nantes Digital Science Lab

India's first 3D printed house

This building was built in a couple of days.

India's first ever 3D printed house was completed back in 2020. The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The significance of this project lies in its possible impact on the solution of the housing crisis worldwide and in India in particular. The ability to build such a house within a few days and at a low cost cannot be underestimated.

House 55.7 sq.m. with a spacious layout, one bedroom, combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the parts were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground.

• Built: 2020

• Commissioned: Not specified

• Where: Chennai, India

• By: Tvasta Construction

Africa's first 3D printed house

Back in 2019, in the Moroccan city of Ben Guerir, Spanish firm Be More 3D created Africa's first 3D printed house. The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

Be More 3D printed house 32 sq.m. in about 12 hours, took first place and received the title of the most innovative startup.

Be More 3D didn't stop building in Africa and later created the first 3D printed house in Spain and developed its own concrete 3D printer in partnership with several corporations from the automation and materials industries.

• Built: 2019

• Commissioned: Not specified

• Where: Ben Guerir, Morocco

• By: Be More 3D

First 3D printed home for sale in the US

Last on our list is the first 3D printed home for sale in the US.

This house was printed in the same place by SQ4D, a company specializing in the development of robotic building systems. The building was printed with SQ4D's Arcs concrete extrusion system and has a 50-year warranty on the printed structure.

Living area of 130.7 sq.m. with three bedrooms and two bathrooms. There is also a garage for 2 cars.

The house was listed for sale in January 2021 for $299,999. Considering the size of the house and the fact that it is priced 50% below the cost of comparable newly built houses in the same area, the deal is pretty good.

• Built: 2020

• Commissioned: 2021

• Where: Riverhead, New York, USA

• By whom: SQ4D

Translation source: https://m.all3dp.com/2/first-3d-printed-house/

On our website you can choose and order a construction 3D printer for both building construction and small building forms. To do this, go to the catalog of construction 3D printers. "Tsvetnoy Mir" is a reliable supplier of 3D printers with many years of experience, supplying directly from manufacturers and guaranteeing their quality.

house building printers, the most important technology news

World's largest 3D printed housing development to be built in Texas

After completing four buildings in collaboration with Lake|Flato Architects in Texas, the company has teamed up with real estate developer Lennar for an even more ambitious project of 100 3D-printed residential buildings designed in conjunction with Bjarke Ingels Group (BIG).

Project described by

...3D technology Diamond Age will increase the speed of building houses nine times

Tech startup Diamond Age has received its first $8 million in venture capital investment to bring its construction robots to industrial scale production. A California-based company has developed the system for printing residential buildings on massive 3D printers and promises to show it in action in the near future on the construction of a private house with an area of 335 square meters. meters.

...Founder and

3D printed Fibonacci house for rent

The Fibonacci sequence found in nature has already been used in the creation of cars, yachts and buildings. Now this row, each number of which is the result of adding the previous two, has been used by Twente Additive Manufacturing (TAM) to design "Canada's first 3D printed house. " The project is a stationary concrete building,

" The project is a stationary concrete building,

Mighty Buildings received $22 million to create cheap 3D-printed eco-houses

US startup Mighty Buildings, which developed the unique 3D printed building method , has raised $22 million in Series B funding. With this amount, the amount of capital raised since the company was founded in 2017 has reached 100 million.

Mighty Building declares its mission to create "beautiful, sustainable and

...The world's first 3D printed steel bridge goes into operation

MX3D has completed its ambitious plan to install a 3D printed metal footbridge across a canal in Amsterdam. The official opening of the facility took place with the personal participation of the Queen of the Netherlands .

Designed by Joris Laarman Lab, engineered by Arup with ABB, Lenovo,

...Icon launches next generation 3D printing at home

While 3D printed construction is in its infancy, Icon has already printed both budget housing in Mexico and luxury cottages in the US . Now she has teamed up with the prestigious design studio

Now she has teamed up with the prestigious design studio

TECLA's first 3D-printed clay house is ready

Italian 3D printing company WASP and its partner Mario Cucinella Architects have successfully completed the first building of the TECLA project, which was unveiled last year. Innovative hornet's nest home built close to

...3D-printed house can already be bought in the US

Kirk Andersen, CEO of New York-based SQ4D, has announced the creation of a home that will be the first 3D-printed building in the US to go public. Andersen's company has already proved the capabilities of its 3D construction printing technologies by erecting a demonstration

...The largest construction 3D printer printed a two-story concrete house (video)

Belgium-based Kamp C, a provincial center for sustainable development and building innovation, recently used Europe's largest concrete 3D printer to create the world's first two-story house 3D printed in one piece.

The building took three weeks to complete. In the future, the company hopes to reduce this period to just under two days. The finished building has an area of 90 square

...Lunar base buildings to be 3D printed - Project Olympus

NASA has teamed up with architecture firm Bjarke Ingels Group, developer of advanced building technologies ICON, and SEArch+, an innovative design firm for human life beyond Earth, to create Project Olympus, a system of space-based buildings that will be needed to explore the moon.

The joint work is carried out within the framework of the plan for the study of the natural satellite of the Earth, adopted by NASA in 2020

...TECLA - clay house created on a 3D printer based on the principle of a hornet's nest

3D printing will soon become the most important tool in the construction industry around the world, so architects and designers are creating new housing projects that can be simply reproduced on a printer.

...

DFAB House is a robot-built house that is revolutionizing the industry (video)

Construction is one of the most harmful to nature and inefficient areas of human activity. According to a UN study, the construction industry is responsible for 40% of the world's carbon dioxide emissions. In Switzerland, robotics and digital technologies were proposed to solve this problem, and a house called

...3D Printed 'Sun Palm Concrete Forest' Could Be Dubai Pavilion at Expo 2020

MEAN (Middle East Architecture Network) from the UAE proposed an original design solution for the Dubai Pavilion (Boulevard Roundabout Pavilion) at the international exhibition Expo-2020.

Imprinted from concrete on

...The first 3D-printed houses in Mexico are inhabited (video)

We previously wrote about New Story, a non-profit organization that has developed 3D housing technology for the homeless and underprivileged in Latin America. Recently, an ambitious plan has been successfully implemented.

Recently, an ambitious plan has been successfully implemented.

The first stage of the project, in which

...World's largest 3D printed building opens in Dubai (video)

A new building 9.5 meters high with an area of 640 square meters has been opened in Dubai's Warsan district. It became a record in size among structures created using the 3D printer. The house serves as a clear illustration of the advantages of using such technologies in construction. The authorities are confident that with their help it will be possible to make a revolution in

...3D printer will build a whole village of houses for the homeless

3D printing technology has great potential in many areas - from space to medicine , but the benefits of its practical

...New construction 3D printer can print a house in 12 hours

The widespread use of 3D printers in the construction industry is a matter of the near future, and the creators of advanced equipment demonstrate not only houses and military barracks, but even entire microdistricts ,

. ..

.. ICON construction 3D printers will build low-income low-income housing in Latin America

The housing problem can be solved with the help of three-dimensional printing, engineers are sure. Modern technologies 3D construction allow you to build budget houses, which is especially important for Latin American countries, where many families live on less than $200 a month. In the future, such an experience of cheap and fast construction of buildings may become the world's

...3D printing of budget housing has accelerated by 2 times with the new ICON Vulcun II printer

An Austin tech company has unveiled the Vulcan II 3D printer, which can print a house up to 180 square meters. m. with the cost of production is two times lower than the traditional method of construction.

"Vulcan II is four times bigger and twice as fast as the previous version, and we are ready to start delivering it to customers in the near future," said ICON CEO and co-founder Jason

. ..

.. India plans to launch mass 3D house construction

Indian company Tvasta Manufacturing Solutions announced its intention to build houses from foundation to finish using 3D printed .

Entirely 3D printed houses could appear in India within a year. The basis for such optimistic forecasts is the success of the Indian Institute of Technology Madras (ITT Madras) team, state

...Construction robot creates pavilion from gravel and rope (video)

In front of the museum in the historic center of the Swiss city of Winterthur stands one of the strangest buildings ever built - the Rock Print Pavilion. At first glance it seems that its columns are made of rough reinforced concrete or gabions, so popular among architects today. However, neither cement nor iron fittings were involved in its creation - in fact, it is made of small loose stones,

...Crane Wasp construction 3D printer can print eco-house for $1000 (video)

Soil construction is one of the oldest techniques that blends well with modern digital technologies. A few years ago, Italian engineers decided to use it in conjunction with 3D printed to build a low-budget sustainable

A few years ago, Italian engineers decided to use it in conjunction with 3D printed to build a low-budget sustainable

New cement mortar for 3D printing will be stronger under load (video)

Engineers figured out how to turn cement mortar's vulnerabilities into strengths in the extreme conditions of fires and earthquakes.

Purdue University researchers have developed a cement paste for 3D printers that could be a key ingredient in concrete or other mixtures used in the construction of complex architectural structures. The new material has an innovative

...Mobile building printing robots will make 3D construction more efficient

3D printers are capable of printing very large things, but the amount of work they have to do is often limited. There are manipulators that print anywhere they can get, and portal building printers that create structures such as buildings, as long as the structures are a bit smaller than they are.

To avoid such restrictions, it is necessary to ...

Video: what will be 3D-printed houses on Mars - versions of NASA and participants in the 3D Printed Habitat Challenge

Although it may be a long time before colonization of Mars , back in 2015 NASA announced a competition for the design of housing for astronauts on the Red Planet - maybe temporary, or maybe permanent. The contest is called...

In Holland, a whole microdistrict will be created from 3D-printed houses (video)

In the Dutch city of Eindhoven, the first of five designed 3D printed concrete houses will appear this year; It will be put into operation at the beginning of 2019. The partners of Project Milestone are Eindhoven City Hall, the local university of technology, contractor Van Wijnen, building materials supplier Saint Gobain-Weber Beamix and engineering firm Witteveen+Bos. All five

...Span of a metal bridge printed on a 3D printer (video)

The Dutch company MX3D has printed a complete span of the steel pedestrian bridge to be installed over the Oudesijs Achterburgwal in Amsterdam. According to post on the company's website, from the beginning of the design of the bridge to the creation of

According to post on the company's website, from the beginning of the design of the bridge to the creation of

"The first 3D printed house in Europe" will be built by Arup and CLS Architetti

Looks like 3D building is going mainstream. This is facilitated by engineering companies Arup and CLS Architetti, who are working together on the "first 3D printed house in the EU". The project is named 3D Housing 05 and its goal is to demonstrate the effectiveness of new additive technologies in

...3D house building with polyurethane foam: French experience (video)

Over the past couple of weeks, the 3D building industry has been aware of several exciting new projects, including a $4,000 printable house from New Story startup and "the first European

...A new house printed on a 3D printer will cost $4,000

About a billion people on the planet still do not have any housing similar to a normal house. American companies ICON and New Story hope to correct this situation. They learned how to create houses on a 3D printer from local building materials. A printed house with an area of 55 to 75 square meters. m costs about 4 thousand dollars, and its construction takes only one day.

American companies ICON and New Story hope to correct this situation. They learned how to create houses on a 3D printer from local building materials. A printed house with an area of 55 to 75 square meters. m costs about 4 thousand dollars, and its construction takes only one day.

...

3D-printed hanging pods designed for New York's homeless

Creative agency Framlab has unveiled a new type of parasitic architecture to accommodate the growing number of homeless people in New York City. The concept is called Homed and is a temporary housing consisting of printed on ...

The world's first 3D printed reinforced concrete bridge is being built in Holland

Engineers from the Faculty of Civil Engineering of the Technical University of Eindhoven (TU/e) have begun to build a concrete bridge on a 3D printer using a new technology. The bike crossing will be part of a new section of the ring road around Gemert, where the construction company BAM Infra will also apply its innovative technologies. It is worth noting that 3D printed bridges have been created before

It is worth noting that 3D printed bridges have been created before

Standalone construction 3D printer to quickly print buildings on other planets created by MIT scientists

Researchers at the Massachusetts Institute of Technology have created a robot that can print an entire building. An innovative 3D construction printer could herald entirely new methods of building structures, significantly reducing the cost and speed of the process.

Using new technology, builders

...For the first time in the world, Cazza will print a skyscraper on a 3D printer

Dubai-based construction firm Cazza has announced plans to build the world's first 3D printed skyscraper. The high-rise building will be built using a technology the company calls "crane printing." For this

...PassiveDom: "smart" eco-house, printed on a 3D printer, developed in Ukraine

Ukrainian startup PassivDom intends to revolutionize the construction industry by offering its 3D printing technology that creates completely ready-to-live . ..

..

Apis Cor: how to print a house on a 3D printer for $10,000 in a day (video)

It usually takes months or even years to build a residential building. These deadlines exacerbate the housing crisis that is constantly inherent in large cities. Apis Cor decided to overcome this problem with by creating

...At the InnoTech Ukraine forum Maksim Gerbut rozpovist, how to encourage the booths for help from a 3D printer

7–9 April at InnoTech Ukraine 2017 speak at the conference as CEO of the project PassivDom Maxim Gerbut.

Topic of the yoga update: “Energy-efficient technologies and mobile life: how 3D-technologies improve efficiency”.

...

World's first 3D printed bridge opened for public use in Spain

In Alcobendas, south of Madrid, the world's first 3D printed footbridge is open for public use. The length of the structure is more than 12 meters.

The length of the structure is more than 12 meters.

The grand opening of the printed bridge took place on December 14 in the Castilla-La Mancha Park in Alcobendas. It consists of 8 parts and is made of

...Arconic created the concept of an eco-skyscraper 5 km high (video)

American engineering company Arconic has developed a concept for the city of the future, including 3D-printed kilometer-high skyscrapers, unmanned aerial vehicles, teleportation, and ubiquitous augmented reality. The developers drew inspiration not only from modern achievements and trends in science and technology, but also from

...Cazza will open a way to quickly 3D print houses and entire cities

American startup Cazza plans to automate the entire process of building houses. At the same time, the new method will be environmentally friendly due to 3D printing of buildings using a special technology and proprietary materials developed by the company itself. According to its creator, you can build a house with an area of 100 square meters in

According to its creator, you can build a house with an area of 100 square meters in

A house that will 3D print itself and grow food for its residents

British researchers at the University of Sheffield have come up with a concept for houses of the future that will build themselves using 3D printing and produce food for their owners. The development was called Aquaponic Future Housing (Aquaponic houses of the future).

These are two or three story buildings printed with ...

Australians built a robot mason (video)

Australian startup Fastbrick Robotics has developed a technology for automatic bricklaying. Created by the company's engineers, the robot named Hadrian 105 is absolutely capable of laying 225 bricks per hour, which is 4 times faster than

...The warmest non-volatile house in the world will be shown in Ukraine

August 16, 2016 in the shopping center "Domosfera" (Kyiv, Stolichnoe shosse, 101) will host a conference-presentation dedicated to the latest achievements in the field of energy-saving technologies and energy efficiency.