Portable handheld 3d scanner

HandySCAN 3D, GoSCAN 3D & MetraSCAN 3D

Creaform develops highly accurate industrial 3D scanners.

Our handheld 3D scanners have been designed to accelerate the time-to-market with your product development workflows, all while helping you meet your quality control requirements in non-contact 3D measurements. Discover how our 3D scanners can help you gain a competitive edge, cut the time and costs associated with product development, and optimize production processes.

HandySCAN 3D | BLACK Series

Metrology-grade portable 3D scanners

View more

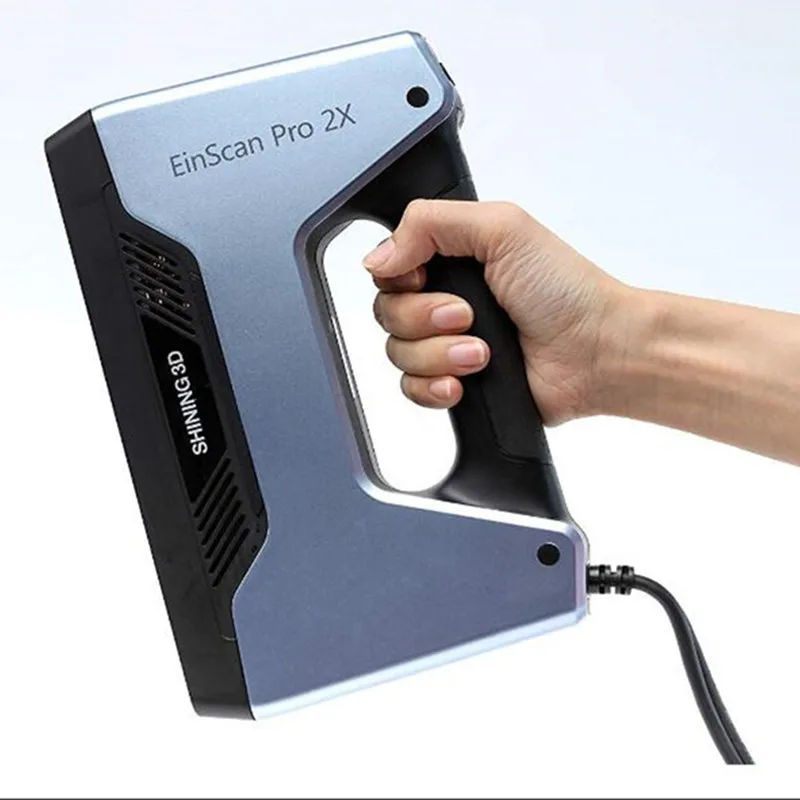

HandySCAN 3D | BLACK Series is the fastest portable metrology-grade 3D laser scanner on the market, offering the highest measurement rate and accuracy available. It’s ideal for product development and quality control.

Accuracy

0.025 mm

Resolution

0.025 mm

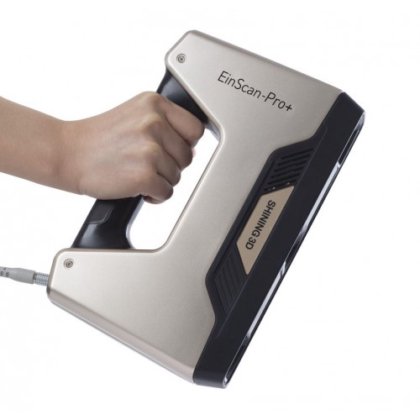

HandySCAN 3D | SILVER Series

Professional 3D laser scanners

View more

Made in North America, this professional-grade 3D scanner offers the perfect mix between unbeatable performance at a great price. Based on trusted and patented metrology-grade 3D scanning technology.

Accuracy

up to 0.030 mm

Resolution

0.050mm

Go!SCAN 3D

Professional portable 3D scanner

View more

Go!SCAN 3D enables easiest 3D scanning experience, generating fast and reliable measurements for all your design and prototyping needs. Effortlessly capture the 3D shape and color of any object.

Accuracy

up to 0.050 mm

Resolution

0.100 mm

MetraSCAN 3D

Optical CMM 3D scanners and probe

View more

The most complete 3D scanners for metrology-grade measurements on all materials, MetraSCAN 3D is a powerful inspection solution that is insensitive to instabilities and harsh environments.

Accuracy

0.025 mm

Resolution

0.025 mm

Which portable 3D scanner is right for you?

No matter what type of industrial 3D scanner you are looking for, Creaform has the widest breadth of 3D measurement technologies for any workflow or project. Easy to use, they deliver unmatched performance.

Easy to use, they deliver unmatched performance.

| Accuracy | Up to 0.030 mm(0.0012 in) | Up to 0.050 mm(0.0020 in) | 0.025 mm(0.0009 in) | 0.025 mm (0.0009 in) | ||||

|---|---|---|---|---|---|---|---|---|

| Probing | X | |||||||

| Color Acquisition | X | |||||||

| Light Source | 7 red laser crosses(+ 1 extra line) | White light (99 stripes) | 11 blue laser crosses(+ 1 extra line) | 15 blue laser crosses(+ 1 extra line) | ||||

| Accreditation | ISO 17025 | ISO 17025 | ||||||

| Price | + | + + | + + + | + + + + | ||||

| View the full specs | View the full specs | View the full specs | View the full specs |

Find the best portable 3D scanner on the market

Talk to one of our metrology experts to determine which Creaform 3D scanner meets your unique needs.

Contact us today

VXelements software platform

Discover a fully integrated 3D software platform and application suite that powers Creaform’s entire fleet of 3D scanners and 3D measurement technologies. It offers all the essential tools in a user-friendly environment for real-time visualization and complete 3D scanning experience.

VXinspect™

Dimensional inspection software module for first article inspections or quality control

Get the details

VXmodel™

Scan-to-CAD software module to finalize and prepare 3D scan data for use in any 3D printing or CAD solution

Get the details

Pipecheck™

NDT pipeline integrity assessment software

Get the details

SmartDENT 3D™

3D scanning solution for aircraft quality control

Get the details

3D Measurement solutions designed for manufacturers’ unique needs

Creaform’s 3D scanners address the 3D measurement requirements for each stage of the manufacturing process.

Product development and design

Creaform’s portable 3D scanners help engineers and designers to develop innovative new products and push product development further—all while minimizing design iterations and accelerating manufacturers’ time to market.

Read more application cases

Quality assurance and quality control

Thanks to our portable 3D scanning technologies, quality assurance and quality control teams can minimize the risk of delivering defective and non-compliant products to customers. Our 3D scanners enable manufacturers to reduce their total costs of quality.

Read more application cases

Maintenance, repair and overhaul

Maintenance, repair and overhaul (MRO) companies around the world benefit from Creaform’s industrial 3D scanners for accurate, repeatable and reliable 3D measurements to cater to the demanding needs and regulations of OEM and airline customers.

Read more application cases

Non-destructive testing for oil and gas

Robust, easy to use and featuring lightning-fast speed, Creaform’s 3D scanners and pipeline assessment software help non-destructive testing (NDT) service companies and inspectors safeguard pipelines’ state of health—and the security of local communities.

Read more application cases

Reverse engineering

Creaform’s handheld 3D scanners and scan-to-CAD software are the tools engineers and industrial designers need to quickly and accurately generate 3D models of existing parts, assemblies and their surrounding environments for a wide range of reverse engineering workflows.

Read more application cases

Explore all of our 3D measurement applications

See more

Portable 3D scanners for the healthcare and educational sectors

Explore our 3D scanning solutions for healthcare, with our Healthcare Partner 3D scanner, and for education, with Creaform ACADEMIA.

3D scanning in healthcare

Creaform’s Healthcare Partner 3D scanner is the ideal device for healthcare and 3D scanning for body measurement, including orthotics, prosthetics, cranial scanning, podiatrics, plastic survey and more. Contrary to traditional measurement methods, such as plaster casts, our 3D scanner enables fast and highly accurate data acquisition.

Learn more

3D scanning in education

Teachers and researchers can help educate the engineers and designers of tomorrow thanks to Creaform ACADEMIA. Whether you need to teach students about metrology or conduct advanced research, our professional-grade 3D scanners are designed with educational purposes in mind.

Learn more

Creaform’s customer success stories

Find out about some of our latest customer satisfaction testimonials and learn how our clients are taking advantage of our 3D measurement technologies.

« Not only in the sport industry but in any kind of industry, when designing new products, we have to give the designers a base to work with. The HandySCAN 3D allows us go from the handmade prototype to the 3D models much faster. »

Bertrand Didier, Chief Engineer Sports division, SCOTT Sports

« After benchmarking all available measurement systems, we felt that Creaform’s products and solutions fitted best with our demanding requirements and environment, as they are less sensitive to movements during scanning. »

»

Jon Gunner, Technical Director, Koenigsegg Automotive AB

« With the MetraSCAN 3D scanner, we have a dynamic production development process with a common work basis for QC and design/construction. We can now make adjustments to components where we had not previously thought was possible before. »

Sebastian Witt, Quality control motorsport, KTM

« The automotive industry benefit highly from the MetraSCAN 3D optical CMM scanner line-up in the ability to scan in real time, get a precise image of what is going on with our parts and solve those critical quality issues. It ensures we provide good parts for our customer. »

Aaron Boyer, Global director – CAD/CAE, Flex-N-Gate

Effective and efficient 3D scanning is at your fingertips

Creaform’s continuous innovations in 3D measurement technologies gives you peace of mind knowing you are relying on proven 3D scanning solutions that get the job done.

Find out how

Handheld 3D scanners | Portable 3D scanning solutions

Artec 3D is a global leader in 3D scanning technology, providing the best and most comprehensive 3D scanners and processing software applicable in a wide range of industries

Compare 3D scanners' specs

| Leo | Space Spider | Micro | Eva / Eva Lite | Ray | Metrology Kit |

|---|---|---|---|---|---|

| Scanner type | |||||

| Handheld, tetherless | Handheld | Desktop | Handheld | Long-range | Photogrammetry kit |

| Size of scanning object/area | |||||

| Medium to large | Small | Very small | Medium | Large to very large | Medium to very large |

| Accuracy, up to | |||||

| 0.1 mm | 0.05 mm | 0.01 mm | 0.1 mm | 0. 7 mm @15 m 7 mm @15 m | 0.002 mm |

| Resolution, up to | |||||

| 0.5 mm | 0.1 mm | 0.029 mm | 0.2 / 0.5 mm | 0.0125° | N/A |

| Target-free technology | |||||

| Yes | Yes | Yes | Yes | Yes | No |

| Color + geometry tracking | |||||

| Yes | Yes | Yes | Yes / No | Yes | N/A |

| Scanning software | |||||

| On-board software | Artec Studio | Artec Studio | Artec Studio | Artec Studio or Artec Remote App | Artec Metrology Kit Plugin for Artec Studio |

| 3D mesh export formats | |||||

| OBJ, PLY, WRL, STL, AOP, ASC, Disney PTX (PTEX), E57, XYZRBG OBC | |||||

An easy way to get to know our range of 3D scanners

How to choose the right 3D scanner for your specific needs. View our product overview brochure.

Download PDF

Need help choosing the right 3D scanner?

Chat to us today! One of our experts will give you all the info you need for choosing the right 3D scanner for your workflow.

Got a question about 3D scanners?

How can I choose the best 3D scanner for my tasks?

There are many aspects to consider when choosing a scanner for your task, such as the type of object/s that you need to scan, the required technical specifications (accuracy, resolution, texture, etc.), the price of the equipment, and many other factors. For this reason, we have created a guide that can help you better understand which 3D scanner is most suitable for what you need. Consult the guide.

Do you need to be a professional to use Artec 3D scanners?

No. We design our scanners so that any person, even with little to no 3D scanning experience, is capable of using them.

What software can I use with Artec 3D scanners?

When you buy an Artec scanner, you also need to purchase an Artec Studio software license, which allows you to process the data captured with a scanner into a final 3D model. The software is a single application which, once purchased, can be used across the entire spectrum of Artec scanners that you may be purchasing later.

The software is a single application which, once purchased, can be used across the entire spectrum of Artec scanners that you may be purchasing later.

Besides working in Artec Studio, the final model can be exported directly into Geomagic Design X and SOLIDWORKS, as well as uploaded to other reverse engineering and 3D modeling software such as Geomagic Control X, Autodesk, Blender, ZBrush, and many others.

Find more information on the compatible software and available export formats here.

Artec 3D scanners: essential tools for every phase of product lifecycle management

Originate

Dream. Delineate. Innovate.

Synergize the technical requirements of what must be, together with what could be.

From the many, focus on one: decide upon a design and move ahead.

Work up preliminary design and measurement via paper and ultimately CAD software.

Implement portable 3D scanner for creating 3D models quickly.

Review and analyze design until ready for prototyping.

Design

where it all takes shape.

First prototypes created and iteratively tested.

Enhance CAD designs with greater complexity, improved structures.

3D scanning device for accelerated capture-and-refine sequencing using 3D images.

Simulation & analyses including CAE, FEA, CFD, etc.

Detailed master design achieved, rapid prototype with precise measurement created with handheld 3D scanner.

Manufacture

Faster. Stronger. Better.

Components, tools, and materials gathered and/or sourced, quantities determined.

Creation of first run production units for in-house use.

First article inspection with handheld 3D scanners to reveal contrasts with CAD model.

Pre-production (QA) testing and accurate measurement prior to full product launch.

Employ 3D scanning to devise damage-free packaging solutions.

Support & Service

focused inquiry leading to refinement & excellence

First day of use to completion of product lifecycle.

Comprehensive reviews of manufacturing, product performance, longevity, recurring issues, failures.

Integrate feedback to evolve design, manufacturing, and development of more effective marketing and sales.

Optimize long-term support via portable 3D scanning for reverse engineering legacy and out-of-stock parts.

Bringing you the best in handheld 3D solutions since 2008

See why Artec 3D scanners are the global leader in 3D scanning technology. Used in a wide range of professional applications, our scanners are the perfect complement for your important measurement needs.

Reverse engineering

Industrial design

and manufacturing

Healthcare

Science and education

Art and design

Speed and accuracy Get the most accurate 3D images with Artec’s cutting-edge capturing and processing technology. Achieve professional results with high-speed capturing of objects and their measurements.

Portability and compatibility

Discover the limitless possibilities of 3D scanning with our portable 3D devices. Lightweight, mobile and compatible with several popular tablets, Artec scanners can be used absolutely anywhere to ensure a smooth capturing process without having to relocate objects to a particular place for measurement.

Lightweight, mobile and compatible with several popular tablets, Artec scanners can be used absolutely anywhere to ensure a smooth capturing process without having to relocate objects to a particular place for measurement.

Ease of use, no need for targets Our portable 3D scanners are engineered to easily be used by both experienced and first-time users, with expert guidance available during every stage of capture and processing. Advanced tracking ensures the best data capture possible and eliminates the need for using targets, which is a great time saver.

4 Advantages of Portable 3D Scanners for Inspection of Cast and Forged Workpieces

You are here

Home

Problem: How can manufacturers ensure that cast and forged blanks contain enough material for further processing?

Many manufacturers face a number of problems when machining cast and forged blanks. For example, the lack of material on some surfaces of the parts leads to the fact that after processing they do not meet the requirements of the customer. The supply of such products can have serious consequences and lead to financial and legal problems. To avoid such situations, customers require a detailed quality control report on all parts. Geometry control allows not only to correctly position the raw part on the machine, but also to ensure that there is enough material for machining.

The supply of such products can have serious consequences and lead to financial and legal problems. To avoid such situations, customers require a detailed quality control report on all parts. Geometry control allows not only to correctly position the raw part on the machine, but also to ensure that there is enough material for machining.

How to identify cast and forged blanks with a potential shortage of material for processing?

To control the quality of raw castings and forgings, the manufacturing industry uses the method of intermediate checks - before and after processing. Before machining, a geometry control is performed and it is checked whether there is enough material on certain surfaces. After processing, the product undergoes a general inspection, as well as quality control of the treated surfaces. The goal, of course, is to produce parts that fully comply with the required tolerances.

Is it possible to immediately check for tolerances the entire surface of the part, and not just its individual points?

The quality control process requires accurate dimensional analysis of parts of all shapes and sizes in a wide variety of environments. Optical technology allows operators to take detailed measurements of more workpieces without prior surface preparation. Indeed, unlike contact measurements, 3D scanning provides control of the entire part, and not just its individual points. Surface analysis with 3D scanners helps determine if a workpiece contains enough material to process.

Optical technology allows operators to take detailed measurements of more workpieces without prior surface preparation. Indeed, unlike contact measurements, 3D scanning provides control of the entire part, and not just its individual points. Surface analysis with 3D scanners helps determine if a workpiece contains enough material to process.

The Creaform HandySCAN BLACK 3D scanner is one of the most flexible and reliable solutions for 3D measurement in manufacturing. Creafrom devices are equipped with VXelements software for processing scan data.

How to speed up quality control and at the same time reduce production costs associated with scrap?

3D scanning allows operators to measure the dimensions of parts and easily identify parts that are out of tolerance. In this way, it is possible to reject parts early in production before investing time and money in their further processing. These quick checks save the company time and money, as the production of substandard parts is drastically reduced, and sometimes stopped altogether.

Solution: portable, easy-to-use, fast and versatile 3D quality inspection scanners

Optical metrology provides the manufacturing industry with a portable, easy-to-use, fast and efficient tool for measuring, inspecting and inspecting the quality of cast and forged workpieces before and after processing .

-

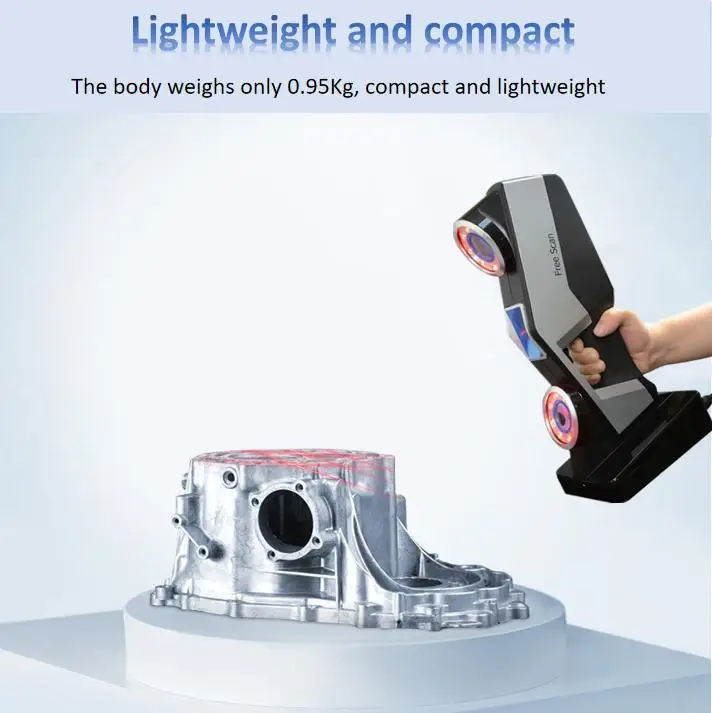

Portable because the measuring tools can be used directly in the shop where the parts are made. Thanks to portable 3D scanners, cast and forged blanks and products no longer need to be sent for analysis to a coordinate measuring machine (CMM). This saves time and allows you to increase the number of inspections.

-

Easy to use as handheld 3D scanners operate on a pass/fail basis. In this way, workpieces with a shortage of material can be easily identified, as well as those that do not meet the required tolerances after processing. Inspectors can skip or reject parts right away so they don't have to invest in a further production process.

-

Fast as optical technology significantly reduces test time. With instant meshing, inspectors will see the capture of the surface on their laptop or tablet screen. Geometry control is much faster than with traditional measuring instruments. This saves time, makes it easier to measure complex parts, and ultimately eliminates the need to buy another CMM.

-

Versatile because 3D scanners can perform analysis not only in the foundry, but also at customer premises, production sites or supplier sites. In addition, they can measure a wide variety of products without surface preparation, regardless of their size, shape, geometry and complexity.

An alternative to traditional CMMs is the new handheld Creaform MetraSCAN BLACK 3D scanner. It is the fastest device in its class, delivering up to 1.8 million measurements per second

Benefits: 3D scanners help improve quality, reduce time and reduce costs

The use of optical measurement technology in the manufacturing industry helps to reduce scrap costs and improve product quality with minimal time spent on quality control.

-

Part quality enhancement: Performing intermediate checks (before and after processing) can quickly detect both parts lacking material in critical areas and inconsistencies with CAD files. This results in an overall improvement in product quality and compliance with customer specifications and required tolerances.

-

Reduced production costs: Pre- and post-processing inspection with a handheld 3D scanner helps identify parts with material shortages early in the process. This greatly reduces production costs, since such parts can still be corrected and will not be rejected after processing.

-

Reduced Inspection Time: With an acquisition rate of 0.5 million points per second, the entire surface of a part can be inspected in a matter of seconds. In addition, there is no longer a need to send it to the metrology laboratory. Thus, inspection with portable 3D scanners helps to analyze more details quickly and in detail compared to CMM.

The freed up time can be used for more important and valuable tasks, such as the control of finished products.

The freed up time can be used for more important and valuable tasks, such as the control of finished products.

Optical gauges can be used to produce cast and forged blanks with enough workpiece material to meet customer requirements.

3D scanners in the manufacturing industry give you the ability to get detailed information on more parts in less time. Thus, valuable time that used to be spent on CMM analysis can be used to prepare final reports for customers.

3D scanning helps reduce CMM workload, makes it easier to measure complex parts, and eliminates the costly purchase of another coordinate measuring machine. 3D scanners not only help save valuable CMM runtime, but also minimize inspection time and manufacturing costs associated with scrap, resulting in overall improved product quality.

Author Ilya Krupennikov

Source

Tags:

3D Scanner, 3D Scanners, Handheld 3D Scanners for Inspection of Cast and Forged Workpieces, Creaform HandySCAN BLACK 3D Scanner, Geometry Inspection

Other materials:

- 3D printer for champions: Sharebot optimizes the design of racing motorcycles

- Gutenberg never dreamed: Russian 3D printers summed up the five-year plan

- Where to start and how to avoid mistakes when introducing additive manufacturing

- Auto-calibration of the table in 3D printers

- 8 steps for quick and easy work with a stationary 3D scanner

Attention!

We accept news, articles or press releases

with links and images. [email protected]

[email protected]

Top Ten 3D Scanners from $100 to $100,000 / Habr

Do you need a 3D model for 3D printing? There are several ways for you: you can of course create your 3D model from scratch in a 3D modeling program or find a suitable one on the Internet, but you can also scan an existing object! The purpose of this review is to help you understand the variety of 3D scanners available and offer the best in every price segment from a photogrammetric smartphone app to professional 3D scanners.

Scanners are listed in ascending price order so you can choose the one that suits your budget and use the resulting 3D models for both 3D printing and animation.

If you are not satisfied with the suggested solutions, there is an extended overview at this link.

3D scanner in hand:

1. Best smartphone app: Autodesk 123D Catch (free)

Autodesk 123D Catch is a free photogrammetric application. It allows you to create a 3D model from photographs of an object taken from different angles. You can use it to scan objects, people, and even the landscape. For some applications, if you don't need perfect accuracy, you don't need special equipment. This application actually provides quite good detail and is easy to use. However, it will take you at least 30 minutes for the app to process your photos as the processing takes place on the server and it takes time to send them.

It allows you to create a 3D model from photographs of an object taken from different angles. You can use it to scan objects, people, and even the landscape. For some applications, if you don't need perfect accuracy, you don't need special equipment. This application actually provides quite good detail and is easy to use. However, it will take you at least 30 minutes for the app to process your photos as the processing takes place on the server and it takes time to send them.

2. Best DIY 3D scanner: Kinect ($99.99)

The Xbox Kinect is designed to expand your gaming experience. It is not designed for 3D scanning, but you can easily find manuals and third party software (like ReconstructMe) to turn it into a 3D scanner. If your arms are growing out of your shoulders, this is an interesting and inexpensive solution for 3D scanning.

Price: $99.99

Resolution: 0.051 mm

)

This scanner can be attached to your tablet or phone (generally designed for iPad, but can be adapted to other devices). Lightweight and easy to use, with a very good resolution. Suitable for large items (can scan a full-length person) and outdoor scanning. You will be able to use it with software running on Occipital's SDK. This will increase the resolution and give you access to special features like room scanning. It probably won't be something you'll use for 3D printing, but it's interesting for game development, for example.

Lightweight and easy to use, with a very good resolution. Suitable for large items (can scan a full-length person) and outdoor scanning. You will be able to use it with software running on Occipital's SDK. This will increase the resolution and give you access to special features like room scanning. It probably won't be something you'll use for 3D printing, but it's interesting for game development, for example.

Price: $ 379

Resolution up to: 0.5 mm

Poom accuracy to: 4 mm

4. The best of cheap manual 3D scanners: Cubify ($ 399)

9000 3D 3D-SKANERS. quite affordable and easy to use if you choose from inexpensive portable models. Cubify fits these criteria very well and has a relatively good resolution. But still, its capabilities are not enough for texture scanning and it is better to use it for subsequent 3D printing of one-color models.

Price: $ 399

Resolution: 0. 9 mm

9 mm

Resolution at a distance of 0.5 m: 1 mm

3D-scanner on the table:

5. The best and cheapest thing 3D 3D- scanner: Matter and Form ($519)

If you're looking to take your quality to the next level, you can purchase a desktop 3D scanner. This model is compact, easy to use, and delivers good resolution, especially considering the price (not your go-to option if you're looking for perfection, but great for educational and demo purposes). The scanning process takes place with the help of a laser and a rotating platform. The scan takes about five minutes and simultaneously reads the texture of the object.

Price: $ 519

Resolution: 0.43 mm

accuracy: ± 0.25 mm

6. The best device "two in one": XYZPRINTING DA VINCI 1.0 ($ 600) 9000 ($ 600) 9000 ($ 600) combines a 3D scanner and a 3D printer. The quality of the models is not too high, but the price is very low for such a combined device. This makes the XYZprinting Da Vinci the easiest solution for beginners who want to get into the world of 3D scanning-printing.

This makes the XYZprinting Da Vinci the easiest solution for beginners who want to get into the world of 3D scanning-printing.

Professional 3D scanners:

7. Best value for money portable 3D scanner: Fuel3D Scanify ($1490)

Very easy to use, intuitive, and feels good in the hand, this scanner delivers good accuracy and texture quality. The only limitation is that the size of the scanned area is limited, which is great for small objects, but for scanning a full-length person, for example, it will not work.

Price: $ 1490

Resolution: 0.35 mm

accuracy: to 0.3 mm

8. Best price The scanner uses a different scanning technology than others. Instead of a dual laser scanning system, it uses a structured light source and cameras for fast scanning with very fine detail down to 0.06mm! The scanner comes with DAVID Pro Edition 3 software that works with OBJ, STL and PLY 3D file formats that can be exported to other programs for further editing.

Price: $ 3995

Resolution: 0.06 mm

accuracy: 0.5% of the size of the object

9. Best professional 3D scanner: SolutionIX REL The 3D scanner and its price provides much better scanning quality. Solutionix Rexcan is equipped with two cameras for greater accuracy. It uses optical phase shift triangulation technology and two high-resolution CCD cameras to provide high-precision data. The scanner can be used to scan larger objects by increasing productivity with a photogrammetric system. As an option, it can be equipped with an automatically rotating platform capable of supporting up to 50 kg of weight.

Price: $ 79 900

accuracy: from 0.03 to 0.71 mm

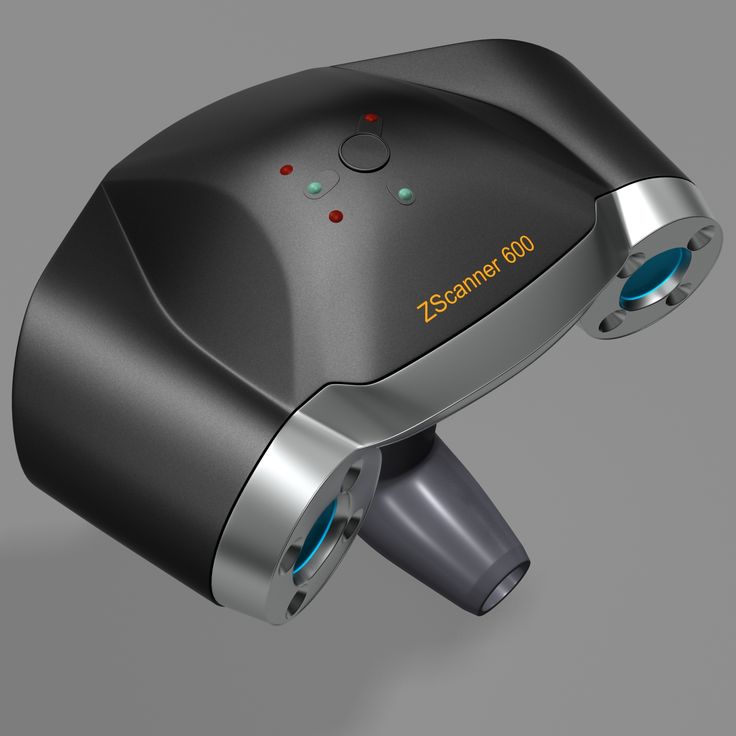

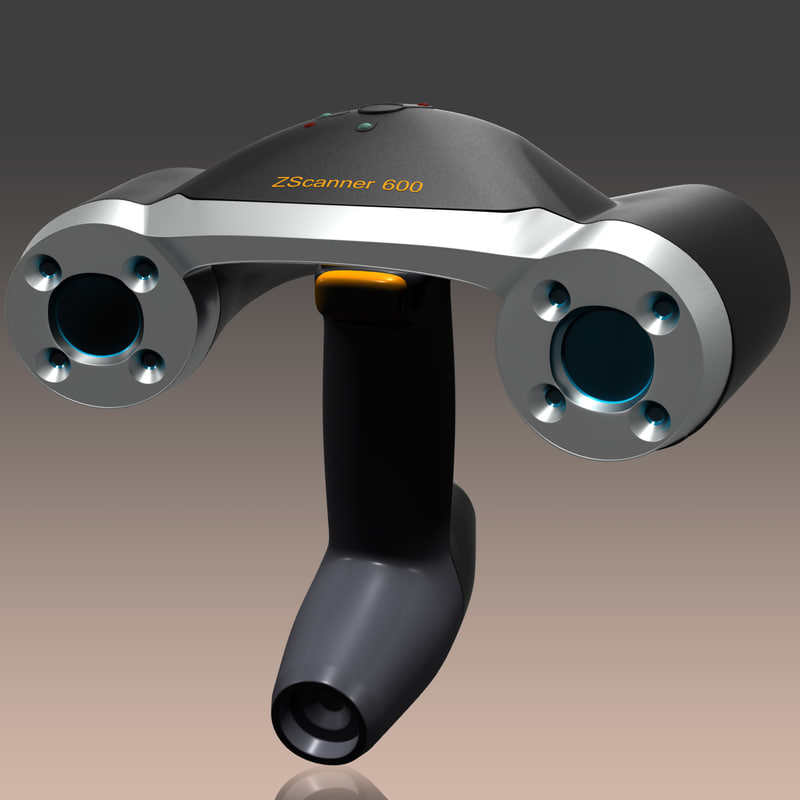

10. Best professional manual 3D scanner: Metrascan 750 ($ 50,000 - $ 100,000)

CreaForm MetraScan 750 is a complete professional, production solution for accurate 3D scanning.